Kraft Power KCM-CKCM-CCKCM, KRBP-CKRB-CCKRB, KCG-CKCG-CCKCG, KDM-CKDM-CCKDM, KDMB-CKDMB-CCKDMB Operation And Maintenance Manual

...

N

n

T

L

A

C

0

–

M

J

d

S

S

2

FI

AL OPERA

ION AND M

ORDEN D

FM

INTENANC

E COMPRA

TECHNOL

E MANUAL

H336073-P

OGIES PRO

MINA MINI

031/A 45011

ECT B6042

TRO HALE

90525

PROJECT

FMCTech

ologiesChile

tda.Callao#2

970Oficina7

4EdificioStu

ioLasCondes

Fono:56‐2‐2

320825

INDEX

1

CONTENTS PAGE

DESCRIPTION 2

OPERATION 2 to 4

ADVANTAGES 4

CHARACTERISTIC CURVES 5

VERSIONS 6

LAYOUTS 6

SELECTION 7 to 10

DIMENSIONS 11 to 23

OIL FILL 24

SAFETY DEVICES 24 to 27

STANDARD AND REVERSE MOUNTING 28

APPLICATIONS 29

OTHER TRANSFLUID PRODUCTS 30

DESCRIPTION & OPERATING CONDITIONS

2

DESCRIPTION

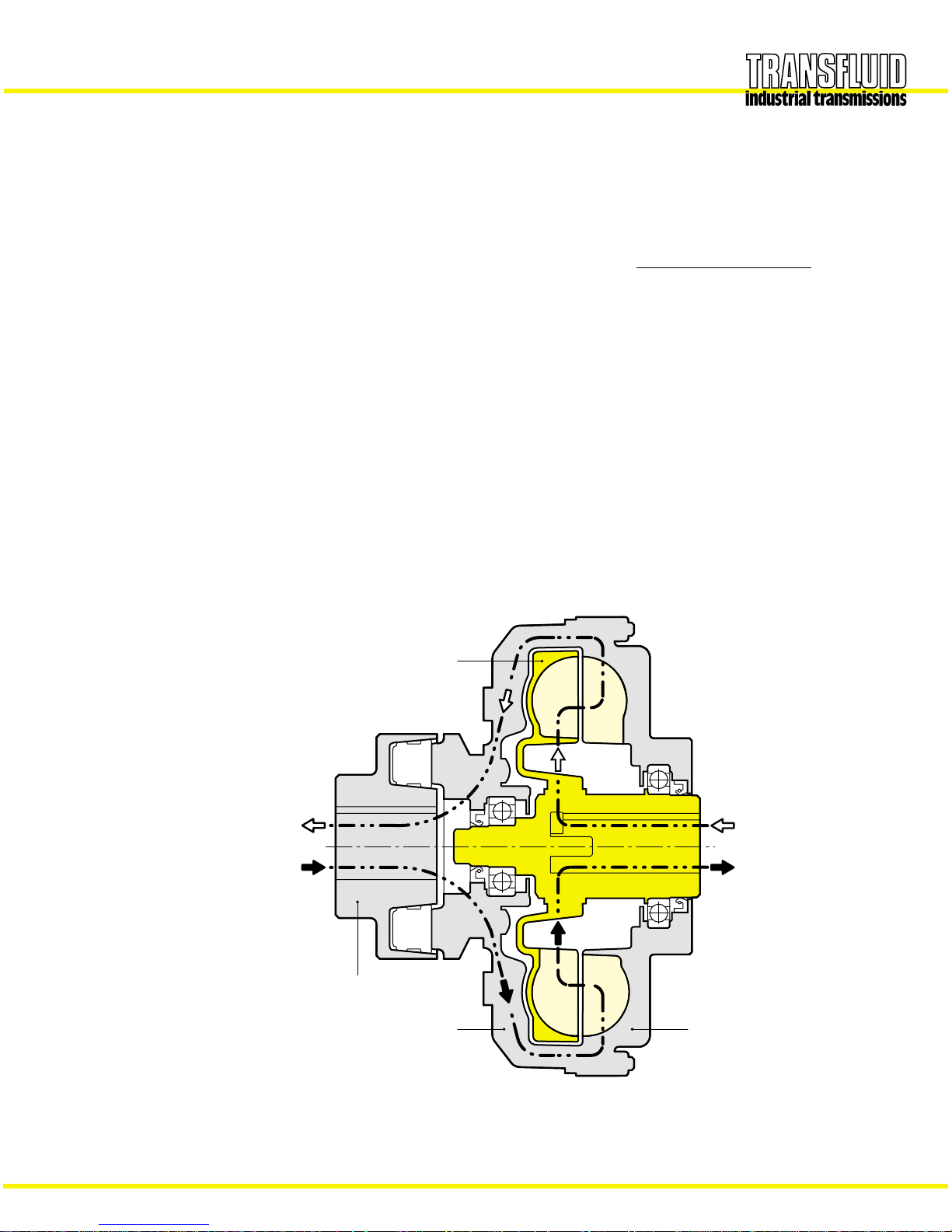

The TRANSFLUID coupling (K series) is a constant filling type

comprising three main elements:

1 Driving impeller (pump) mounted on the input shaft.

2 Driven impeller (turbine) mounted on the output shaft.

3 Cover, flanged to the output impeller, with an oil-tight seal.

The first two elements can work both as pump and/or turbine.

OPERATING CONDITIONS

The TRANSFLUID coupling is a hydrokinetic transmission. The

impellers perform like a centrifugal pump and a hydraulic turbine.

With an input drive to the pump (i.e. electric motor or Diesel

engine) kinetic energy is imparted to the oil in the coupling. The oil

moves by centrifugal force across the blades of the turbine towards

the outside of the coupling.

This absorbs the kinetic energy and develops a torque which is

always equal to input torque thus causing rotation of the output

shaft. The wear is practically zero since there are no mechanical

connections.

The efficiency is influenced only by the speed difference (slip)

between pump and turbine.

The slip is essential to the functioning of the coupling: there could

not be torque transmission without slip! The for mula for slip, from

which the power loss can be deduced is as follows:

slip % = x 100

In normal conditions (standard duty), slip can vary from 1.5%

(large power) to 6% (small power).

TRANSFLUID couplings follow the laws of all centrifugal machines:

1 Transmitted torque is proportional to the square of input speed;

2 Transmitted power is proportional to the cube of input speed;

3 Transmitted power is proportional to the fifth power of circuit

outside diameter.

input speed – output speed

input speed

1 INTERNAL IMPELLER

2 EXTERNAL IMPELLER

3 COVER

4 FLEX COUPLING

1

2

3

4

OUTPUT

INPUT

OUTPUT

INPUT

FLUID COUPLING FITTED ON ELECTRIC MOTORS

3

TRANSFLUID COUPLING FITTED ON ELECTRIC MOT ORS

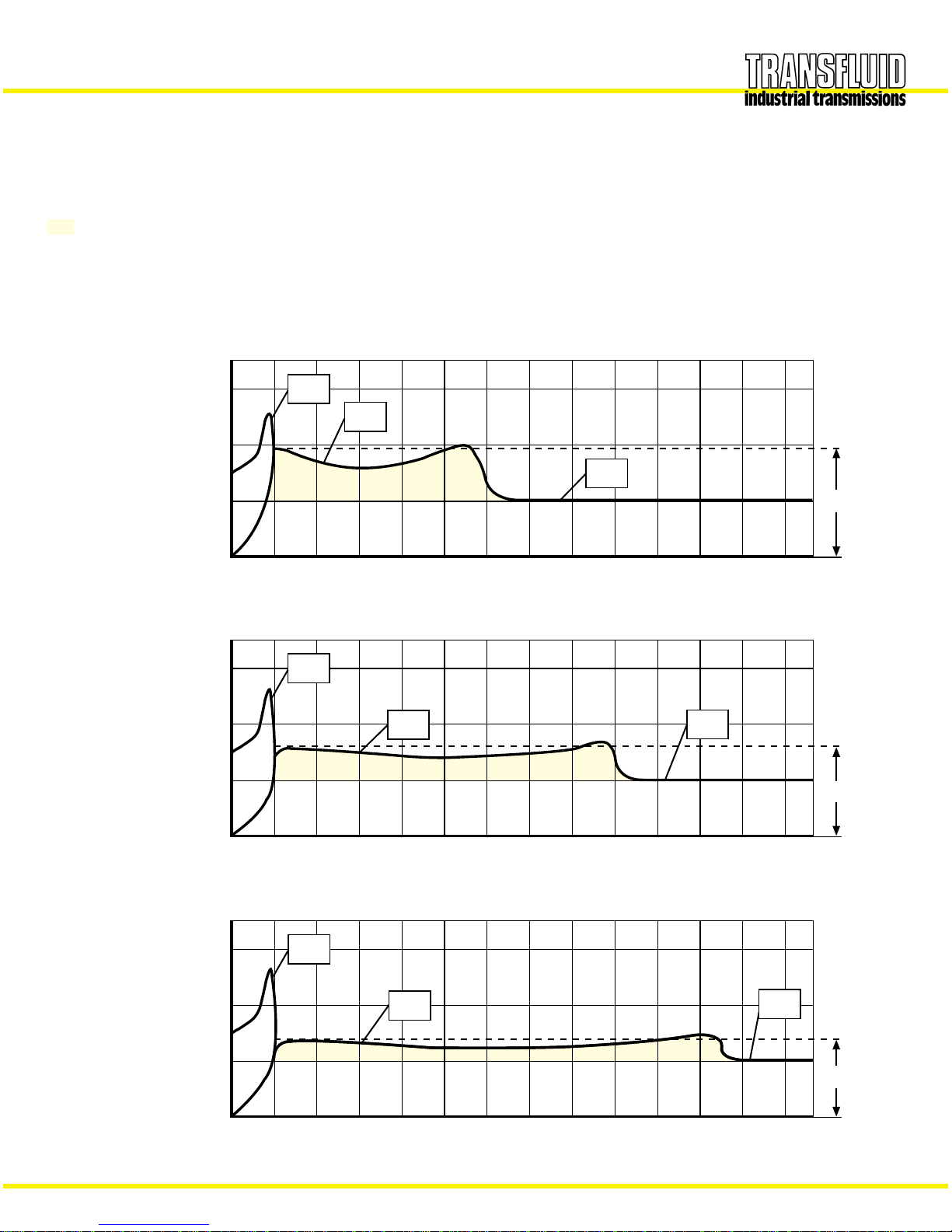

Three phase synchronous squirrel cage motors are able to supply

maximum torque only near 100% synchronous speed. Direct

starting the system utilized the most current. Figure 1 illustrates the

relationship between torque and current. It can be seen that the

absorbed current is proportional to the torque only between 85%

and 100% of the synchronous speed. With a motor connected

directly to the load, there are the following disadvantages:

– The difference between available torque and the torque required

by the load is very low until the rotor has accelerated to between

80-85% of the synchronous speed

– The absorbed current is high (up to 6 times the nominal current)

throughout the starting phase causing overheating of the

windings, overloads in the electrical lines and, in cases of

frequent starts, major production costs.

– Oversized motors are required by the limitations indicated abo ve.

To limit the absorbed current of the motor during the acceleration

of the load, a Y-D (wye – delta) star ting system is frequently used

which reduces the absorbed current by about 1/3 during starting.

Unfortunately, dur ing operation of the motor under the delta

configuration, the available torque is also reduced by 1/3 and for

machines with high inertias to accelerate, oversizing of the motor is

still required. Finally, this system does not eliminate current peaks

originating from the insertion or the commutation of the device.

Any drive system using a Transfluid fluid coupling has the

advantage of the motor starting without load. Figure 2 compares

the current demands of an electric motor when the load is directly

attached verses the demand when a fluid coupling is mounted

between the motor and load. The colored area shows the energy

that is lost, as heat, during start-up when a fluid coupling is not

used. A Transfluid fluid coupling reduces the motor’s current draw

during start-up thus reducing peak current demands. This not only

reduces power costs but also reduces brown outs in the power grid

and extends the life of the motor. Also at star t-up, a fluid coupling

allows more torque to pass to the load for acceleration than in drive

systems without a fluid coupling.

Figure 3 shows two curves for a single fluid coupling and a

characteristic curve of an electric motor. It is obvious from the stall

curve of the fluid coupling (s=100%) and the available motor

torque, how much torque is available to accelerate the rotor of the

motor (colored area). In about 1 second, the rotor of the motor

accelerates passing from point A to point B.The acceleration of the

load, however, is made gradually by the fluid coupling, utilizing the

motor in optimal conditions, along the part of the curve between

point B, 100% and point C, 2-5%. Point C is the typical point of

operation during normal running.

Fig. 1

Fig. 2

Fig. 3

% motor speed

% start-up time

% motor current

% torque

% motor speed

without fluid coupling

with fluid coupling

FLUID COUPLING WITH DELAYED-FILL CHAMBER

ADVANTAGES

4

TRANSFLUID FLUID COUPLINGS WITH A DELAYED FILL

CHAMBER

With the standard circuit in a maximum oil fill condition, fluid

couplings may transmit over

200% of the nominal motor torque. It

is possible to decrease the starting torque

down to 160% of the

nominal torque, by decreasing oil fill.This, however, leads to higher

slip and working temperature in the fluid coupling, during the

steady running conditions.

The most convenient solution to provide lower starting torque while

maintaining low slip at steady running is to provide a delayed fill

chamber mounted on the main circuit. This chamber holds a

percentage of the oil which at start-up is gradually released into the

main circuit through

calibrated bleed orifices as the coupling

spins.For couplings sized

15CK and above these orifices are set in

externally mounted valves.

The external mounting provides easy adjustment of the orifice size

which controls starting time and the maximum transmitted torque.

When the coupling is at rest, the

delay fill chamber contains a

percentage of oil quantity in the main circuit (Fig.

4a).This reduces

the torque

the coupling transmits and allows the motor to quickly

reach its steady running speed,

as if it was started without load.

As the coupling accelerates, the oil flows from the

delay fill

chamber

to the main circuit (Fig. 4b) at a rate proportional to the

coupling’s rotational speed.

The oil continues to transfer from the delay fill chamber the to the

main circuit emptying the delay fill chamber. Once all the oil is in

the main circuit (Fig.

4c) the coupling is then transmitting 100% of

the motor torque and the

minimum slip value is reached.

With a

single delay fill chamber, the ratio between starting and

nominal torque may reach

150 %.This ratio can be reduced to 120 %

with a double delay fill chamber

. This lower start-up torque

results from a smaller amount of oil in the main circuit due to more

oil in the bigger delay fill chamber.

Fluid couplings with single or double delay fill chamber provide

very smooth start-ups with low start-up torque transmission, and

this makes them excellent for applications with high inertia loads

and for use on belt conv eyors.

The single size chamber is available from size 11CK and above.

The double size chamber is available from size 15CCK and above

SUMMARY OF THE ADVANTAGES GIVEN BY FLUID

COUPLINGS:

– Very smooth start-ups

– Reduction of absorbed current during the starting phase: the

motor starts with very low load

–

Protection of the motor and the driven machine from jams and

overloads

– Utilization of asynchronous squirrel cage motors instead of

special motors with soft start devices

–

Longer life and up time of the whole drive train, thanks to the

protection provided by the fluid coupling

–

Energy saving, due to current peak reduction

–

Limits starting torque to 120% with a double delayed fill

chamber

–

Same torque at input and output: the motor can supply the

maximum torque even when load is jammed

– Torsional

vibration absorption for internal combustion engines,

thanks to the presence of a fluid as a power transmission

element

– Possibility to achieve a high number of

start-ups, or reversal of

the rotational direction.

–

Load balancing with dual motor drive: fluid couplings

automatically adjust load speed to the individual motor’s speed

–

High efficiency and minimum maintenance

– Viton rotating seals and O-rings

–

High resistance to corrosion by using cast aluminum for the

major coupling parts and providing

anticorrosion treatment on

smaller

cast iron and steel parts

ACCELERATION

valve

calibrated plug

All oil in circuit

into main circuit

Oil drains from chamber

for initial start

Oil available

use after start

Oil in reserve for

Fig. 4 c

RUNNING

Fig. 4 bFig. 4 a

AT REST

Fig. 4 a

AT REST

Fig. 4 b

ACCELERATION

Fig. 4 c

RUNNING

STARTING TORQUE CHARACTERISTICS

5

CHARACTERISTIC CURVES

MI : transmitted torque from fluid coupling

Mm : starting torque of the electric motor

Mn : nominal torque at full load

...... : accelerating torque

K type

(standard circuit)

CK type

(circuit with a

delayed chamber)

CCK type

(circuit with a double

delayed chamber)

Mm

MI

Mn

200%

100%

0510

Time [s]

180÷200%

Torque

Mm

Mn

200%

100%

0510

Time [s]

150÷180%

Torque

MI

Mm

200%

100%

0510

Time [s]

120÷150%

Torque

MI

Mn

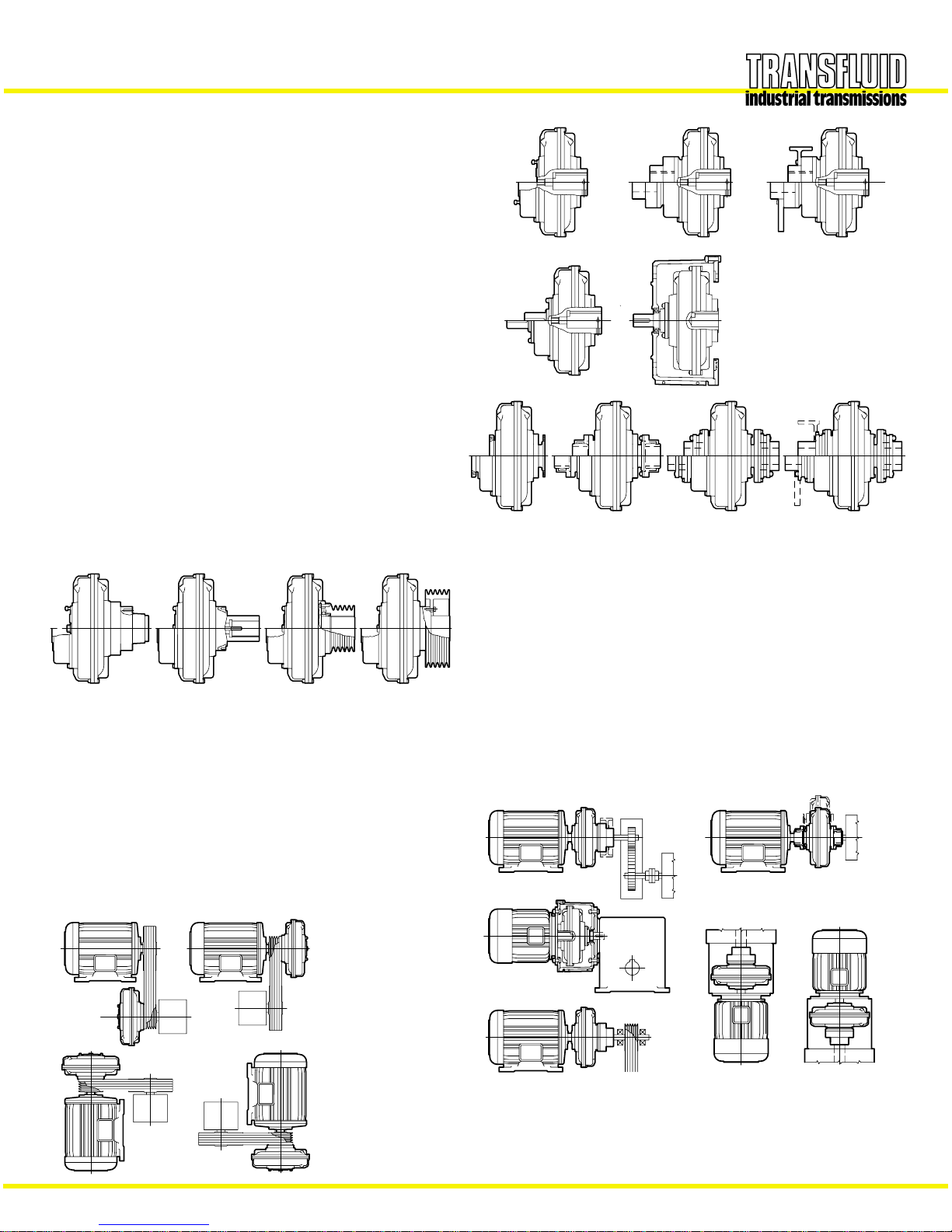

PRODUCTION PROGRAM

Fig. F

Fig. G

21

STANDARD MODELS

6

KRB

CKRBP - CCKRBPCKR - CCKR

KR

CKRG - CCKRG

KRG

KDMB

KDM

CKDMBP- CCKDMBPCKDM - CCKDM

KRD EK

KCG

KCM

CKRD - CCKRD

CKCG - CCKCGCKCM - CCKCM

Fig. B

Fig. D

21

Fig. A

Fig. C

Fig. E

PULLEY

KSD-QD–CKSD-QD

: fluid coupling that will use a QD style pulley

CCKSD-QD

KSD–CKSD–CCKSD

: basic coupling that accepts a flanged pulley,

with single (CK..) or double (CCK..) delayed fill

chamber

KSI-CKSI-CCKSI : fluid coupling with an incorporated pulley,

which is fitted from inside.

KSDF-CKSDF

: basic ..KSD coupling with flanged pulley,

CCKSDF

externally mounted and therefore to be easily

disassembled.

IN LINE

KR-CKR-CCKR

: Basic coupling (KR), with a single

(CKR) or double (CCKR) delayed fill

chamber.

KRG-CKRG-CCKRG :

Basic coupling with elastic coupling

KRM-CKRM-CCKRM

(clamp type), or superelastic.

KRB-CKRB-CCKRB

: like ..KRG, but with brake drum or

…KRBP brake disc.

KRD-CKRD-CCKRD

: basic coupling ..KR with output shaft. It

allows the utilization of other flex

couplings; it is possible to place it (with

a convenient housing) between the

motor and a hollow shaft gearbox.

EK : fluid coupling fitted with a bell housing, to

be placed between a flanged electric

motor and a hollow shaft gearbox.

KCM-CKCM-CCKCM

: basic coupling for half gear couplings.

KCG-CKCG-CCKCG

: basic ..KCM with half gear couplings. On

request, is available with brake dr um or

brake disc.

KDM-CKDM-CCKDM

: fluid coupling with disc couplings.

…KDMB : like ..KDM, but with brake drum or

…KDMBP brake disc.

IN LINE VERSIONS MOUNTING EXAMPLES

Fig. A Horizontal axis between the motor and the driven

machine (KR-CKR-CCKR and similar).

Fig.

B It allows a radial disassembly without moving the motor

and the driven machine (KCG-KDM and similar).

Fig.

C Between a flanged electric motor and a hollow shaft

gearbox by means of a bell housing (..KRD and EK).

Fig.

D Vertical axis mounting between the electric motor and

a gearbox or driven machine.

When ordering, please

specify mounting type 1 or 2.

Fig. E Between the motor and a supported pulley for high

powers and heavy radial loads.

PULLEY VERSIONS MOUNTING EXAMPLES

Fig. F Horizontal axis.

Fig. G Vertical axis. When ordering, please specify motor shaft

pointing up (type 1) or motor shaft pointing down (type 2).

Note: The ..KCG - ..KDM versions allow a radial disassembly without moving the motor or the driven machine.

Fig. A

Fig. B

Fig. C

Fig. E

Fig. F

Fig. G

Fig. D

KSDF

KSI

PRODUCTION PROGRAM

KSD-QD KSD

CKSDF - CCKSDFCKSD-QD CCKSD-QD

CKSD- CCKSD

CKSI - CCKSI

FLUID COUPLING SELECTION

7

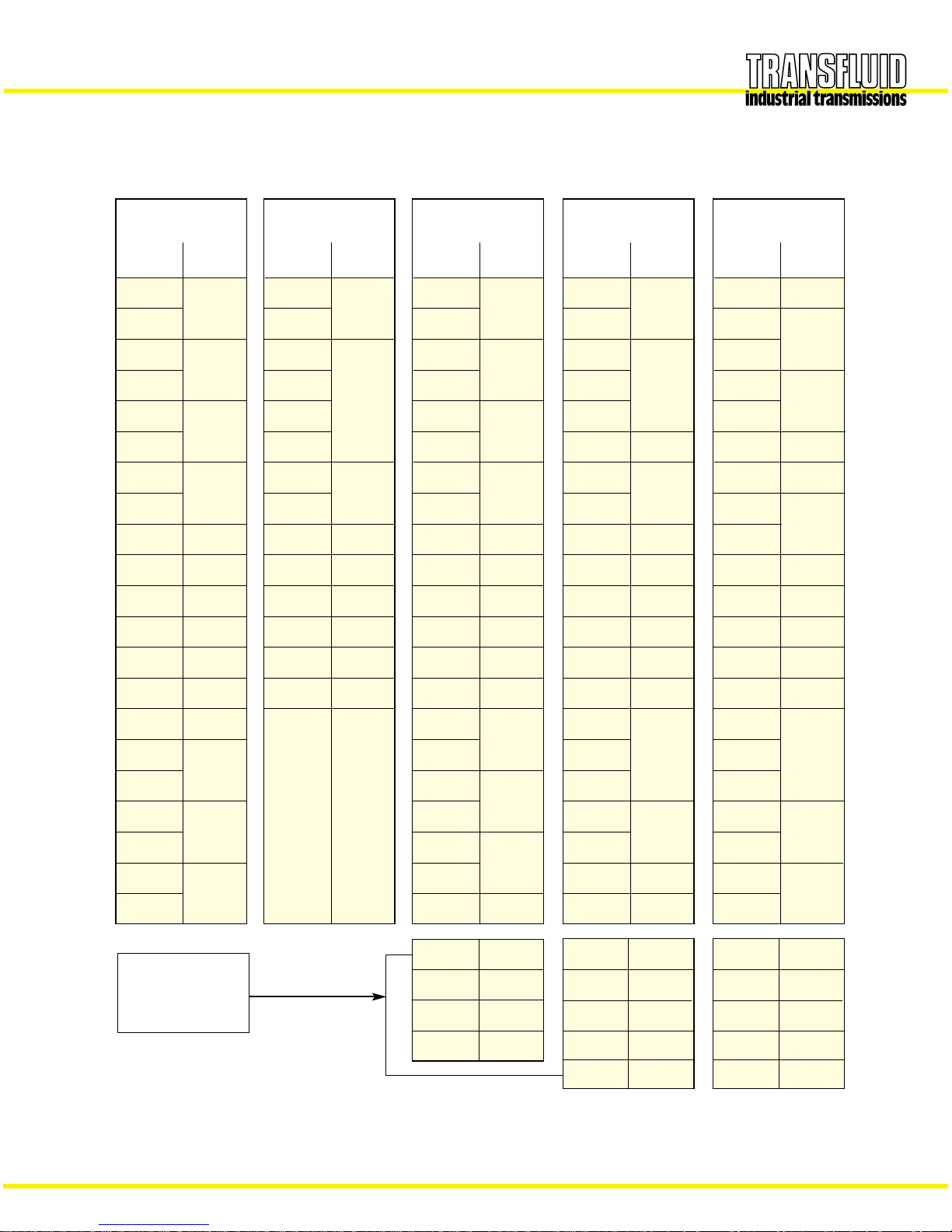

SELECTION

SELECTION CHART

The chart below may be used to select a unit size from the

horsepower and input speed.If the selection point falls on the line

dividing one size from the other, select the larger size with a

proportionally reduced oil fill.

GENERAL REFERENCE HORSEPOWER CHART

HP

kW

HORSEPOWER

INPUT SPEED RPM

THE CURVES SHOW THE POWER CAPACITY OF COUPLING IN REFERENCE TO INPUT SPEED

FLUID COUPLING SELECTION

8

MOTOR

FRAME

143T

22.275

(0.875)

145T

182T

28.575

(1.125)

184T

213T

34.925

(1.375)

215T

254

41.275

(1.625)

256T

284T

47.625

(1.875)

284TS

41.275

(1.625)

286T

47.625

(1.825)

286TS

41.275

(1.625)

324T

53.975

(2.125)

324TS

47.625

(1.875)

53.975

(2.125

60.325

(2.375)

73.025

(2.875)

85.725

(3.375)

326T

364T

365T

404T

405T

444T

445T

SHAFT DIA.

mm (inch)

1800 rpm

HP

1

6K

1.5 - 2

3

7 K

5

7.5

8K

10

15

9K

20

25 11 K

--

30 12 K

--

40 12 K

--

13 K

15 K

17 K

19 K

50

60

75

100

125

150

200-250

COUPLING

1200 rpm

HP

0.75

7 K

1

1.5

8 K

2

3

9K

5

7.5

11 K

10

15 12 K

--

20 13 K

--

25 13 K

--

15 K

17 K

19 K

21 K

30

40

50

60

75

100

125

COUPLING

900 rpm

HP

0.5

7 K

8 K

0.75

1

9 K

1.5

2

11 K

3

5

12 K

7.5

10

13 K

--

15 15 K

--

20 17 K

--

17 K

19 K

21 K

25

30

40

50

60

75

100

COUPLING

3600 rpm

HP

1.5

6 K

2

3

5

7.5

7 K

10 - 15

15 - 20

8K

20 - 25

--

30 9K

--

40 9K

--

50 9K

--

COUPLING

NON - STANDARD

MOTOR

400

600

21 K

24 K

958

27 K

1360

29 K

270 24 K

400

598

27 K

29 K

1088

34 K

1350

D 34 K

150 24 K

220

350

27 K

29 K

600

34 K

1000

D 34 K

SELECTION T ABLE

Fluid couplings for standard electric motor

max max

max

General note: The fluid coupling size is tied to the motor shaft dimensions

(1) Special version, 24 hours/day service

(1)

Loading...

Loading...