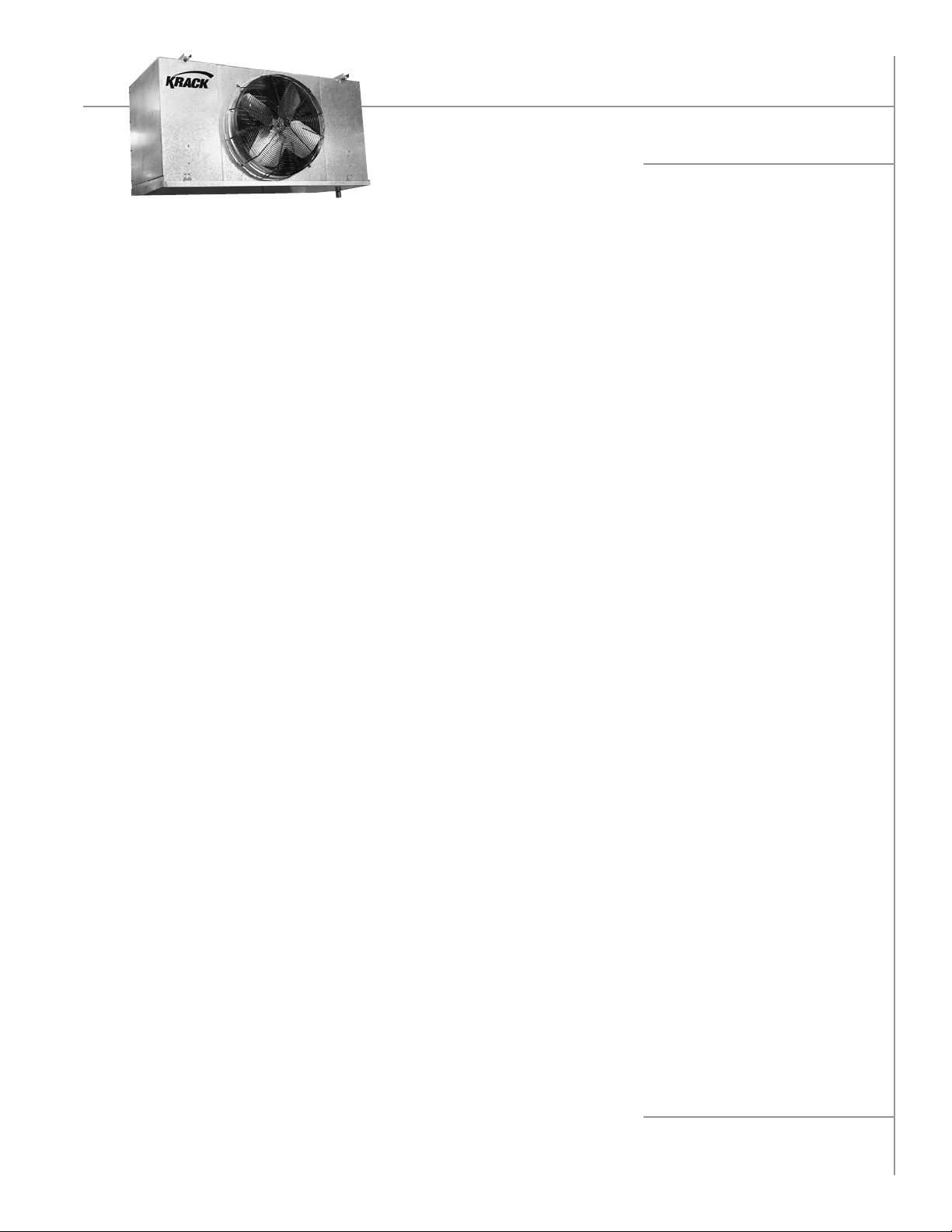

SM/SV Series

PRODUCT COOLERS

Technical Bulletin: SMSV_001_083115

Products that provide lasting solutions.

SM/SV SERIES UNIT COOLERS

Specifications subject to change without notice.

SM/SV Series Unit Coolers

Photo on front cover shown

with optional Long Throw Air

Boosters

SM SERIES –

Ideal for Warehouse Coolers or Freezers to Fit

a Wide Range of Capacities

n Ruggedly constructed fan cabinet hung by hanger

rods from the ceiling.

n Efficient air draw-thru design with 30” diameter

aluminum fans for uniform air distribution; air throw

is approximately 50 to 60 feet.

n High efficiency three phase, 850 RPM fan motors are

permanently lubricated.

n Air defrost for medium temperature rooms.

n Electric or hot gas defrost for medium and low

temperature rooms.

n Adjustable defrost termination and fan delay

thermostat installed with electric defrost.

n By-pass tee installed with hot gas defrost. Check

valve provided shipped loose.

n Mill galvanized drain pan and fan cabinet.

n Drain pan is insulated for electric or hot gas defrost

applications.

n Drain pan and fan cabinet end panels are hinged for

easy access and cleaning.

n 4, 5, 6, and 7 fins per inch spacing.

n Coated, corrosion-resistant wire fan guards.

n Compartmental fan sections.

n 3-phase, ball bearing motors 230/460V or 575V.

n Suction Schrader valve for easy suction pressure/

temperature measurement.

Optional Features

n Cooler can be used with fluid and CO

n Brine and heat reclaim circuiting.

n Stainless steel housing and drain pan.

n Insulated drain pan cover for air defrost models.

n Electro-Fin/Heresite coated coil for air defrost models.

n Painted housing.

Optional Accessories

n Long throw air boosters (air throw approx. 100 feet).

n Room thermostat.

n Thermostatic expansion valve.

n Defrost time clock.

n Liquid line solenoid valve.

n Suction liquid heat exchanger.

n Remote located electrical control panel.

applications.

2

Standard Features

SV SERIES –

Designed to Deliver Low Temperature Air

at Extra-High Velocity in Freezers

n Ruggedly constructed fan cabinet hung by hanger

rods from the ceiling.

n Wide capacity range.

n Efficient air draw-thru design with 30” diameter

aluminum fans for uniform air distribution; air throw

is approximately 60 to 80 feet.

n High efficiency three phase, 1140 RPM fan motors are

permanently lubricated.

n Electric or hot gas defrost for low temperature rooms.

n Adjustable defrost termination and fan delay

thermostat installed.

n Mill galvanized drain pan and fan cabinet.

n Insulated drain pan.

n Drain pan and fan cabinet end panels are hinged

for easy access and cleaning.

n 4, 5, and 6 fins per inch spacing.

n Coated, corrosion-resistant wire fan guards.

n Compartmental fan sections.

n 3-phase, ball bearing motors 230/460V or 575V.

n Suction Schrader valve for easy suction pressure/

temperature measurement.

Optional Features

n Cooler can be used with fluid and CO

n Stainless steel housing and drain pan.

n Electro-Fin/Heresite coated coil for hot gas defrost

models.

n Painted housing.

Optional Accessories

n Long throw air boosters (air throw approx. 120 feet).

n Room thermostat.

n Thermostatic expansion valve.

n Defrost time clock.

n Liquid line solenoid valve.

n Suction liquid heat exchanger.

n Remote located electrical control panel.

n Copper tins.

SM/SV SERIES UNIT COOLERS

Specifications subject to change without notice.

applications.

2

1

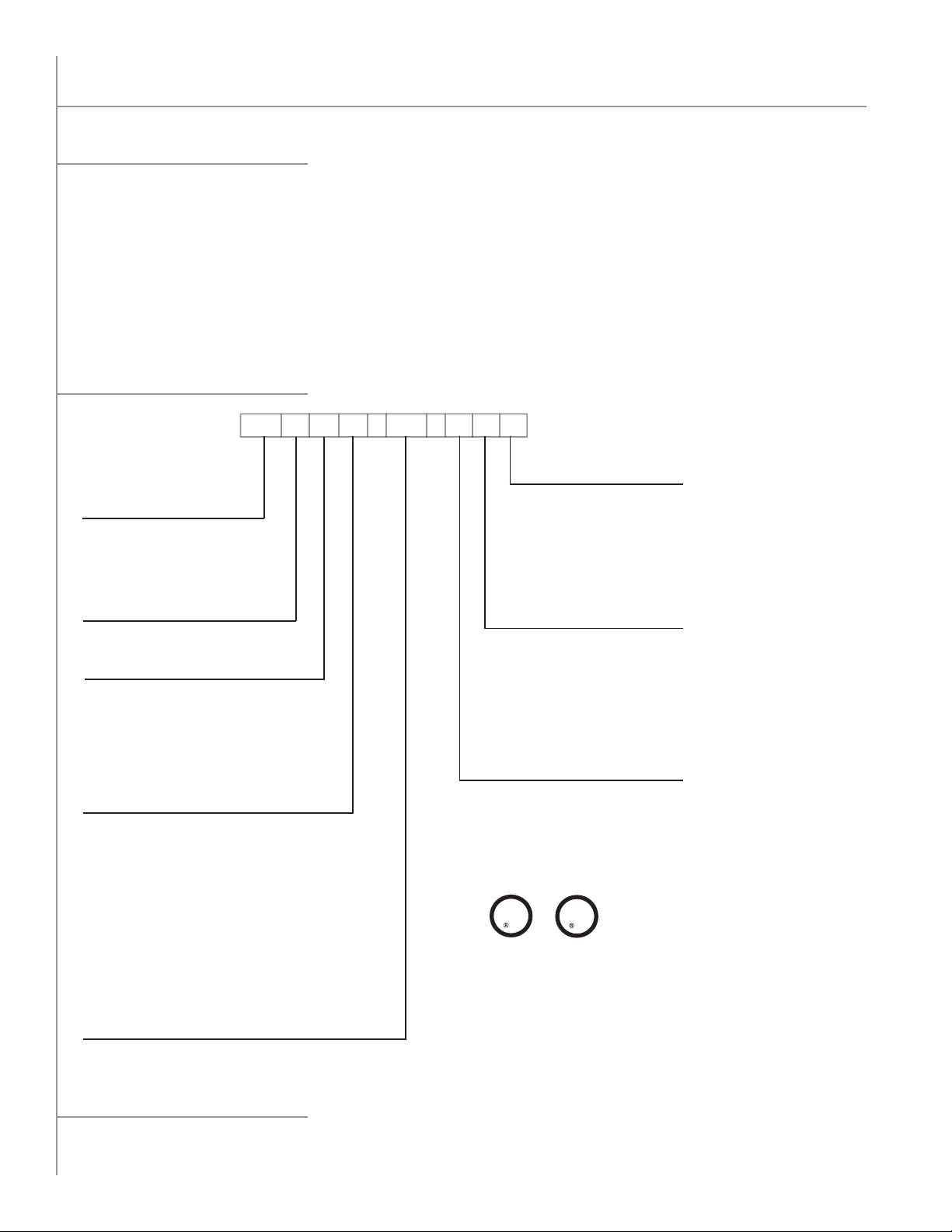

SM/SV Series Unit Coolers

Ordering Information

Specify When Ordering All Models

n Complete model number. n Liquid refrigerant temperature.

n Refrigerant R22, R404A, or R507. n 230/3, 460/3 or 575/3 motor and heater voltage.

n Room temperature. n Optional features.

n Saturated suction temperature. n Optional accessories.

Model Key

SM 25E-842 -C KK

Heater Voltage

Unit Type

SM = Space Master

SV = High Velocity SM

Number of Fans

Fin Spacing

4 FPI

5 FPI

6 FPI

7 FPI

Type of Defrost

A = Air

B = Brine

D = Electric with No Pan Heat

E = Electric with Electric Pan

G = 3 Pipe Hot Gas with Hot Gas Drain Pan

H = 3 Pipe Hot Gas with Electric Drain Pan

K = 2 Pipe Kool Gas with Kool Gas Drain Pan

P = 2 Pipe Kool Gas with Electric Drain Pan

R = Heat Reclaim

U

Motor Voltage

Motor Type

L

C

K=208-203/3/60

M= 460/3/60

P=575/3/60

U= 380/3/60

K=208-203/3/60

M= 460/3/60

P=575/3/60

U= 380/3/60

C=3 Phase Motors,

Inverter Duty Suitable Motor (Standard)

U

L

BTU/h in Hundreds (00)

SM/SV SERIES UNIT COOLERS

2

Specifications subject to change without notice.

Loading...

Loading...