Microchannel

REMOTE AIR-COOLED CONDENSER

Technical Bulletin: MXCC_001_071015

Products that provide lasting solutions.

Microchannel Remote Air-Cooled Condenser

Krack’s new Microchannel Remote Air-Cooled Condenser incorporates

a new patented modular assembly.

n Smaller size and less weight reduces cost in the building construction.

n The new coil has less internal volume resulting in a significant reduction

in refrigerant charge. Less refrigerant is environmentally friendly.

n Coil slabs are easily replaced from the rear of the unit.

Environmentally Friendly Benefits

Krack, a Hussmann

Corporation brand,

has a long tradition

of leadership and

product innovation

in the refrigeration

n Reduced Coil Internal Volume - Resulting in a significant reduction

in condenser operating and flooding charge.

n Quiet Fans - “Swept-wing” blade design offers lower noise levels at

the same speed. Quiet multi-bladed direct driven propeller fans provide

uniform air distribution through the coil. Venturi fan orifices optimize

efficiency. Lower noise condensers can translate into savings by

minimizing the need for costly noise barriers.

n California Energy Commission - All Microchannel condensers are

compliant with CEC Title 24 condenser efficiency requirements.

industry.

Table of Contents

Benefit and Features 1

System Selections 2

Model Key 2

Applications 3

Performance Data 4

Dimensional Data

- Standard Model 5

- Receiver Model 6

Receiver Data 6

Control System 7

Electrical Motor AMP Data 7

Electrical Motor Watts Data 8

Control Panel Nomenclature 8

Condenser Control Panel 9

MICROCHANNEL REMOTE AIR-COOLED CONDENSER

Specifications subject to change without notice.

Microchannel Remote Air-Cooled Condenser

US

Benefits and Features

REMOTE AIR-COOLED CONDENSER

Patented Microchannel Condenser Modular

Assembly Design (Patent #6988538)

n Arranged for vertical air discharge.

n Multi-fan sections compartmented to allow

individual fan cycling while preventing off-fan

“windmilling.”

n Removable end panel for clean out and service

access.

Corrosion Resistant

n All models employ mill galvanized steel fan

sections and coil side baffles.

n Legs are heavy mill gauge galvanized steel.

n Corrosion resistance is improved with an all aluminum

microchannel coil, reducing the chance for galvanic

corrosion that exists on traditional copper tube and

aluminum fin coils. Additionally, the microchannel

tubes are coated with a sacrificial metallic layer that

is less noble than the tube, fin, and braze material.

PROTECTIVE COVER PANELS

Weather Resistant Fan Motors

n Outdoor condenser motors designed with ball

bearings inherent overheat protection in each phase;

shaft slingers; enclosure, hardware, and lubrication

for all weather conditions.

n Each motor lead is wired to terminals in an electrical

enclosure.

n Inverter duty suitable fan motors are standard.

COMPACT DESIGN

n Lighter weight.

- Up to 35% weight reduction compared to

traditional condenser design.

n Modular construction and fewer parts.

- Available in 2 to 14 fan models.

OPTIONAL FEATURES

n Electro-Fin coated coils.

n Mounted receiver.

n Reusable air filter.

n Winter reduction control solenoids.

n Modular isolation ball valves.

Modular Winter Reduction Solenoid

n Maintains condenser pressure by isolating coil sections

in conjunction with fan cycling.

n Reduction in coil volume results in reduced refrigerant

operating and flooding charge.

Versatile Fan Cycling Control Methods

n Electronic relay boards.

n Pressure fan cycling.

n Temperature fan cycling.

Replaceable High Efficiency Coil

n Extruded aluminum microchannel coil construction

increases coil efficiency, while reducing refrigerant

operating charge, unit weight and footprint.

n Unit design allows for coil replacement from rear

of unit.

MICROCHANNEL REMOTE AIR-COOLED CONDENSER

1

Specifications subject to change without notice.

Microchannel Remote Air-Cooled Condenser

EVAPORATOR

TEMP (˚F)

-40

-30

-20

-10

0

5

10

15

20

25

30

40

50

90

1.66

1.57

1.49

1.42

1.36

1.33

1.31

1.28

1.26

1.24

1.22

1.18

1.14

100

1.73

1.62

1.53

1.46

1.40

1.37

1.34

1.32

1.29

1.27

1.25

1.21

1.17

110

1.80

1.68

1.58

1.50

1.44

1.41

1.38

1.35

1.33

1.31

1.28

1.24

1.20

120

2.00

1.80

1.65

1.57

1.50

1.46

1.43

1.40

1.37

1.35

1.32

1.27

1.23

130

*

*

*

1.64

1.56

1.52

1.49

1.46

1.43

1.40

1.37

1.31

1.26

140

*

*

*

*

1.62

1.59

1.55

1.52

1.49

1.45

1.42

1.35

1.29

CONDENSING TEMPERATURE (˚F)

HERMETIC COMPRESSOR

EVAPORATOR

TEMP (˚F)

-30

-20

-10

0

10

20

30

40

50

90

1.37

1.33

1.28

1.24

1.21

1.17

1.14

1.12

1.09

100

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.15

1.12

110

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.14

120

*

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

130

*

*

1.47

1.41

1.36

1.32

1.27

1.23

1.20

140

*

*

*

1.47

1.42

1.37

1.32

1.28

1.24

CONDENSING TEMPERATURE (˚F)

OPEN COMPRESSOR

TABLE 1

TABLE 2

* Beyond the normal limits for single-stage compressor application.

* Beyond the normal limits for single-stage compressor application.

EVAPORATOR

TEMP (˚F)

-40

-30

-20

-10

0

5

10

15

20

25

30

40

50

90

1.66

1.57

1.49

1.42

1.36

1.33

1.31

1.28

1.26

1.24

1.22

1.18

1.14

100

1.73

1.62

1.53

1.46

1.40

1.37

1.34

1.32

1.29

1.27

1.25

1.21

1.17

110

1.80

1.68

1.58

1.50

1.44

1.41

1.38

1.35

1.33

1.31

1.28

1.24

1.20

120

2.00

1.80

1.65

1.57

1.50

1.46

1.43

1.40

1.37

1.35

1.32

1.27

1.23

130

*

*

*

1.64

1.56

1.52

1.49

1.46

1.43

1.40

1.37

1.31

1.26

140

*

*

*

*

1.62

1.59

1.55

1.52

1.49

1.45

1.42

1.35

1.29

CONDENSING TEMPERATURE (˚F)

HERMETIC COMPRESS

OR

TABLE 1

* Beyond the normal limits for single-stage compressor application.

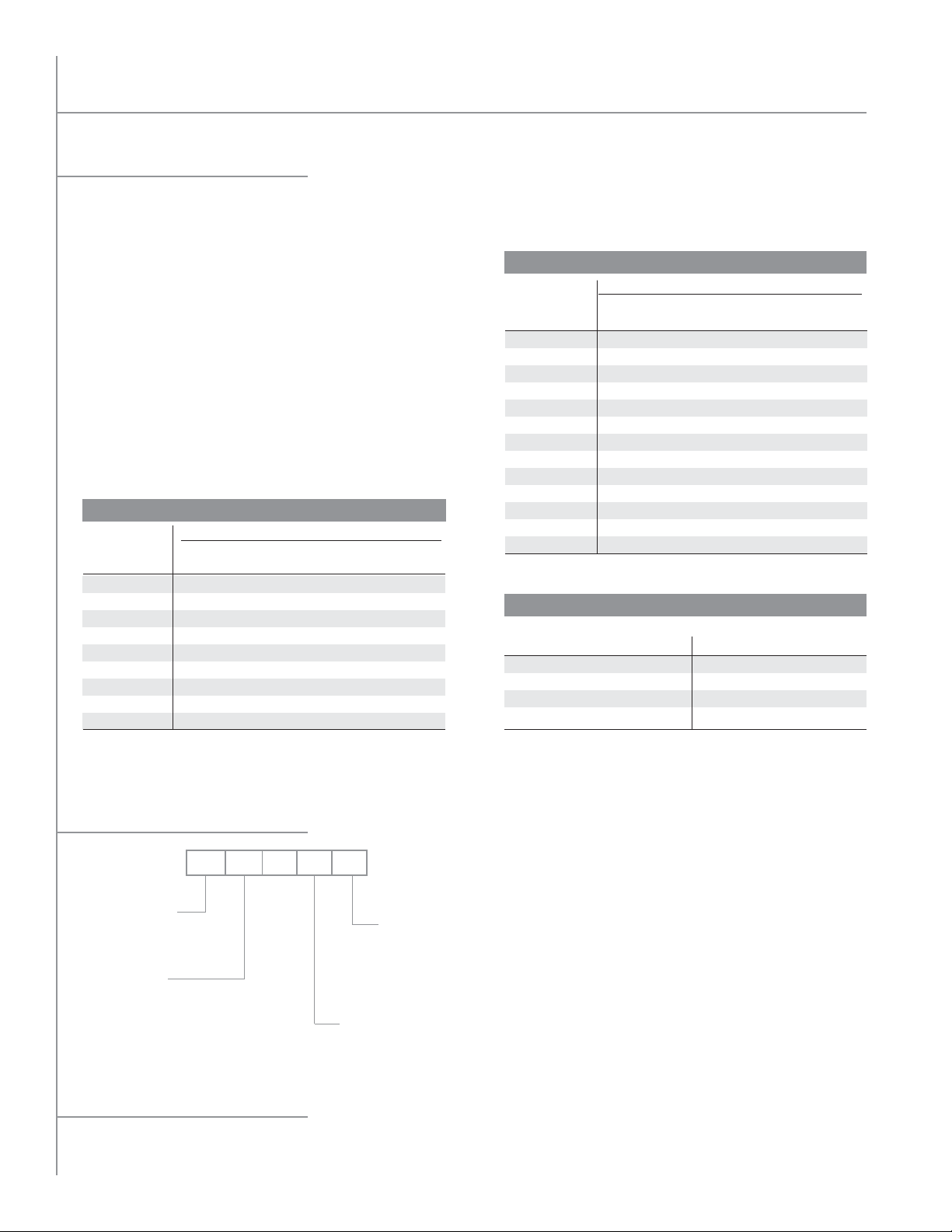

System Selections

THR - Total Heat of Rejection

n Condenser total heat of rejection (BTU/h) is the sum of the

evaporator refrigeration effect and the heat of compression

which varies with compressor type and operating conditions.

THR Calculation Method

n THR = Open Reciprocating Compressor Capacity

(BTU/h) + (2545 x BHP)

n THR = Suction Gas Cooled Hermetic Reciprocating

Compressor Capacity (BTU/h) + (3413 x kW)

THR Estimated Method

n THR may be estimated by multiplying the rated

compressor BTU/h capacity by the compressor operating

condition factor shown in Table 1 or 2.

Multiply result by altitude factor when applicable.

EVAPORATOR

TEMP (˚F)

-30

-20

-10

10

20

30

40

50

* Beyond the normal limits for single-stage compressor application.

Model Key

UNIT TYPE:

MX = Microchannel

FAN/MOTOR

COMBINATION:

A=1 HP 850 RPM 30"

C=1-1/2 HP 850 RPM 30"

E=1/2 HP 575 RPM 30"

F=1-1/2 HP 1140 RPM 30"

0

CONDENSING TEMPERATURE (˚F)

90

1.37

1.33

1.28

1.24

1.21

1.17

1.14

1.12

1.09

MX F-06 M

TABLE 2

OPEN COMPRESSOR

100

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.15

1.12

110

120

1.47

1.42

1.47

1.37

1.42

1.32

1.37

1.28

1.32

1.24

1.28

1.20

1.24

1.17

1.20

1.14

1.17

130

*

TOTAL NUMBER OF FANS:

02 10

04 12

06 14

08

140

*

*

*

*

1.47

1.41

1.36

1.32

1.27

1.23

1.20

*

1.47

1.42

1.37

1.32

1.28

1.24

MOTOR VOLTAGE:

K= 208-230/3/60

M= 460/3/60

P= 575/3/60

U= 380/3/50 (Capacity Derate of Around 10%)

TABLE 1

HERMETIC COMPRESSO

EVAPORATOR

TEMP (˚F)

-40

-30

-20

-10

0

5

10

15

20

25

30

40

50

* Beyond the normal limits for single-stage compressor application.

CONDENSING TEMPERATURE (˚F)

90

100

110

1.66

1.73

1.80

1.57

1.62

1.68

1.49

1.53

1.58

1.42

1.46

1.50

1.36

1.40

1.44

1.33

1.37

1.41

1.31

1.34

1.38

1.28

1.32

1.35

1.26

1.29

1.33

1.24

1.27

1.31

1.22

1.25

1.28

1.18

1.21

1.24

1.14

1.17

1.20

TABLE 3

ALTITUDE

FEET

1,000

2,000

3,000

4,000

FACTOR

1.02

1.05

1.07

1.10

FEET

5,000

6,000

7,000

8,000

120

2.00

1.80

1.65

1.57

1.50

1.46

1.43

1.40

1.37

1.35

1.32

1.27

1.23

R

130

*

*

*

1.64

1.56

1.52

1.49

1.46

1.43

1.40

1.37

1.31

1.26

FACTOR

1.12

1.15

1.17

1.24

140

*

*

*

*

1.62

1.59

1.55

1.52

1.49

1.45

1.42

1.35

1.29

MICROCHANNEL REMOTE AIR-COOLED CONDENSER

2

Specifications subject to change without notice.

Microchannel Remote Air-Cooled Condenser

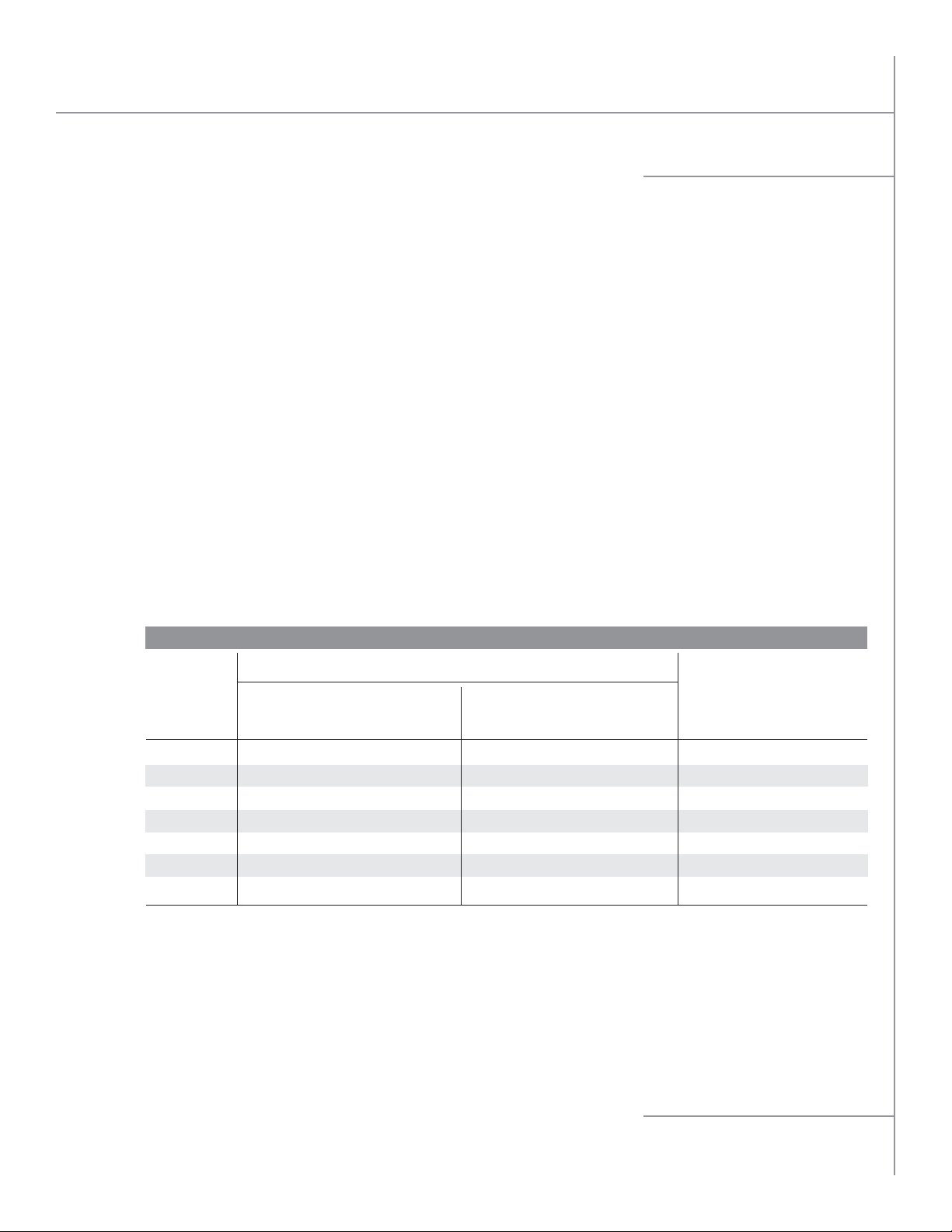

Applications

n Locate Condensers no closer than their width from walls

or other condensers. Avoid locations near exhaust fans,

plumbing vents, flues or chimneys.

n Parallel Condensers should be the same model resulting

in the same refrigerant side pressure drops. Compressor

discharge lines should have equal pressure drops to each

condenser.

n Condenser Refrigerant Charge for Summer conditions

are listed on the Performance Data Table. The additional

Winter Flooding charge required is difficult to predict

with fan cycling and is maximized with holdback; however,

the maximum additional refrigerant charge is also listed

on the Performance Data Table for Winter conditions

at -20˚F. The Summer operating and Winter maximum

flooding charge is substantially less than that required for

traditional tube and fin condensers due to the reduced

internal volume of the microchannel coils. Further

reduction in flooding charge can be obtained with the

“Modular Winter Reduction” option, by “shutting down”

the associated refrigerant circuit in combination with

fan cycling.

REFRIGERANT LINE CAPACITY DATA

n Receiver Capacity should be sized to store condenser

summer charge, plus the condenser low ambient

allowance, plus the evaporator charge, plus an allowance

for piping and heat reclaim coil charges.

n Compressor Discharge lines should be sized to minimize

pressure drops and maintain oil return gas velocities. Each

connection should be looped to the top of the condenser.

n Gravity Liquid Drain Lines should drop from each outlet as

low as possible before headering or running horizontally.

Pitch downhill to receiver.

n Off-Line Coil Sections will have refrigerant pressures

corresponding to the ambient. Check valves or isolating

valves should be installed in the liquid line drains to

prevent refrigerant migration and receiver pressure loss.

COPPER

LINE

SIZE

O.D.

5/8

7/8

1-1/8

1-3/8

1-5/8

2-1/8

2-5/8

LINE CAPACITY IN TONS

CONDENSER TO RECEIVERCOMPRESSOR

DISCHARGE LINE

R-404A R-407A R-134a

0.5 1.0 0.5 3.0 3.6 3.7 11.0 13.0 13.0

2.0 3.0 2.0 6.0 7.4 7.7 22.0 25.0 26.0

4.5 6.5 4.5 10.4 12.7 13.0 36.0 42.0 43.0

7.0 15.0 7.0 16.0 19.2 20.0 55.0 64.0 65.0

15.0 20.0 11.0 23.0 29.0 28.5 78.0 90.0 92.0

30.0 45.0 28.0 40.0 47.0 46.0 138.0 160.0 163.0

45.0 75.0 43.0 62.0 73.0 72.0 212.0 245.0 250.0

Capacity is compressor suction tons for application between -40ºF and +40ºF suction at condensing temperatures between 80ºF and 120ºF sat.

For multiple or unloading compressor application, the vertical discharge riser from the compressor may need to be one size smaller.

This table data is only to be used as a guide. For exact values, please calculate to your specific job line lengths and design pressure/temp values

LIQUID LINE 100’

R-404A R-407A R-134a

LBS. OF REFRIGERANT

LIQUID PER 100’

OF LENGTH

R-404A R-407A R-134a

using ASHRAE handbook or ARI refrigerant tables.

MICROCHANNEL REMOTE AIR-COOLED CONDENSER

Specifications subject to change without notice.

3

Loading...

Loading...