Levitor II

AIR-COOLED CONDENSER

(Available for Fluid Cooler Applications)

Technical Bulletin: LEVC_001_083115

Products that provide lasting solutions.

Levitor II Air-Cooled Condenser

Table of Contents

Benefits and Features 1

System Selection 2

Levitor Application 3

Model Key 4

LAVE Performance Data, One and Two Fans Wide 5

LAVA Performance Data, One and Two Fans Wide 7

LAVC Performance Data, One and Two Fans Wide 9

LAVF Performance Data, One and Two Fans Wide 1 1

Electrical Motor AMP Data 13

Electrical Motor Watts Data 14

Dimensional Drawings 14

LAVB Performance Data, One and Two Fans Wide 15

Dimensional Drawings (for B Fan Models) 17

Mounted Receiver Diagrams 1 8

Low Ambient Controls 20

Mounted Receivers 20

Control Panel Nomenclature 2 1

Standard Fan Cycling/Control Arrangements 22

Fan Cycling Sequence 22

Wiring Diagrams 23

LEVITOR II AIR-COOLED CONDENSER

Specifications subject to change without notice.

Rooftop condensers have to operate in some of the toughest

US

conditions imaginable. Temperature extremes result in

constant expansion and contraction of refrigerant tubes as

fans cycle and loads vary.

The consequences are costly: rapid tube wear results inleaks,

system breakdown and loss of costly refrigerant.

Levitor II Air-Cooled Condenser

Benefits and Features

The LEVITOR system addresses refrigerant coil wear

and leaks due to vibration and thermal stress.

LEVITOR Coil Design Eliminates Refrigerant Tube Wear

Environmental concerns and spiraling cost of refrigerants have led to the

development of direct drive remote air-cooled condensers with the LEVITOR

coil support system. This innovative design uses dedicated stainless steel tubes

and a unique coil support system to isolate refrigerant tubes from the unit. Coil

support is transferred from the fins to the stainless tubes and truncated tube

plates which ride freely in “C” channels. Tubes expand and contract without

interference. The result, contact and friction wear are eliminated.

Quiet by Design

LEVITOR coil design does more than just eliminate tube wear.

Sound reduction is an added benefit. Unlike traditional air-cooled condensers,

fan and coil vibration are isolated from the cabinet, so it is not transmitted to

the unit frame and building supports.

Low Sound Quietor Fan

n The “swept-wing” blade design offers lower noise

levels at the same fan speed. For example, the

QUIETOR fan blade on a 575-rpm motor will be

much quieter (8 dBA) than the old 575-rpm fan.

n Lower noise condensers can translate into savings

for your customer by minimizing the need of costly

noise barriers.

n Quietor fan not available on 24” models.

Computerized Circuiting

n Our computerized coil circuiting program is

designed to minimize the condenser refrigerant

charge and maximize sub-cooling. Every condenser

will be custom circuited to precisely meet your

application needs.

Modular Design

n Arranged for vertical or horizontal air discharge.

Multi-fan sections compartmented to allow

individual fan cycling while preventing off-fan

“windmilling”. Large clean-out access doors

standard.

Corrosion Resistant

n All models employ mill galvanized steel fan sections

and coil side baffles. Legs are heavy gauge mill

galvanized steel.

High Efficiency Coil

n Copper tubes are mechanically expanded into

corrugated full collared aluminum fins spaced 8,

10, or 12 per inch. Coils are helium leak and pressure

tested with 400 psig dry air, shipped pressurized

with dry nitrogen.

n Optional fin materials are copper or polyester

coated aluminum.

n Optional electrofin or heresite coil coatings.

n Multi-circuiting available.

Direct Driven Propeller Fans

n Quiet multi-bladed propeller fans provide uniform

air distribution through the coil. Venturi fan orifices

optimize efficiency.

Weather Resistant Fan Motors

n Outdoor condenser motors designed with ball

bearings inherent overheat protection in each

phase; shaft slingers; enclosure, hardware, and

lubrication for all weather conditions. Each motor

lead is wired to terminals in an electrical enclosure.

n Inverter duty suitable motors are standard.

Versatile Fan Cycling Control Methods

n Temperature fan cycling.

n Pressure fan cycling.

n Temperature and pressure fan cycling.

n Electronic relay boards.

n Variable speed header end fans.

LEVITOR II AIR-COOLED CONDENSER

Specifications subject to change without notice.

1

Levitor II Air-Cooled Condenser

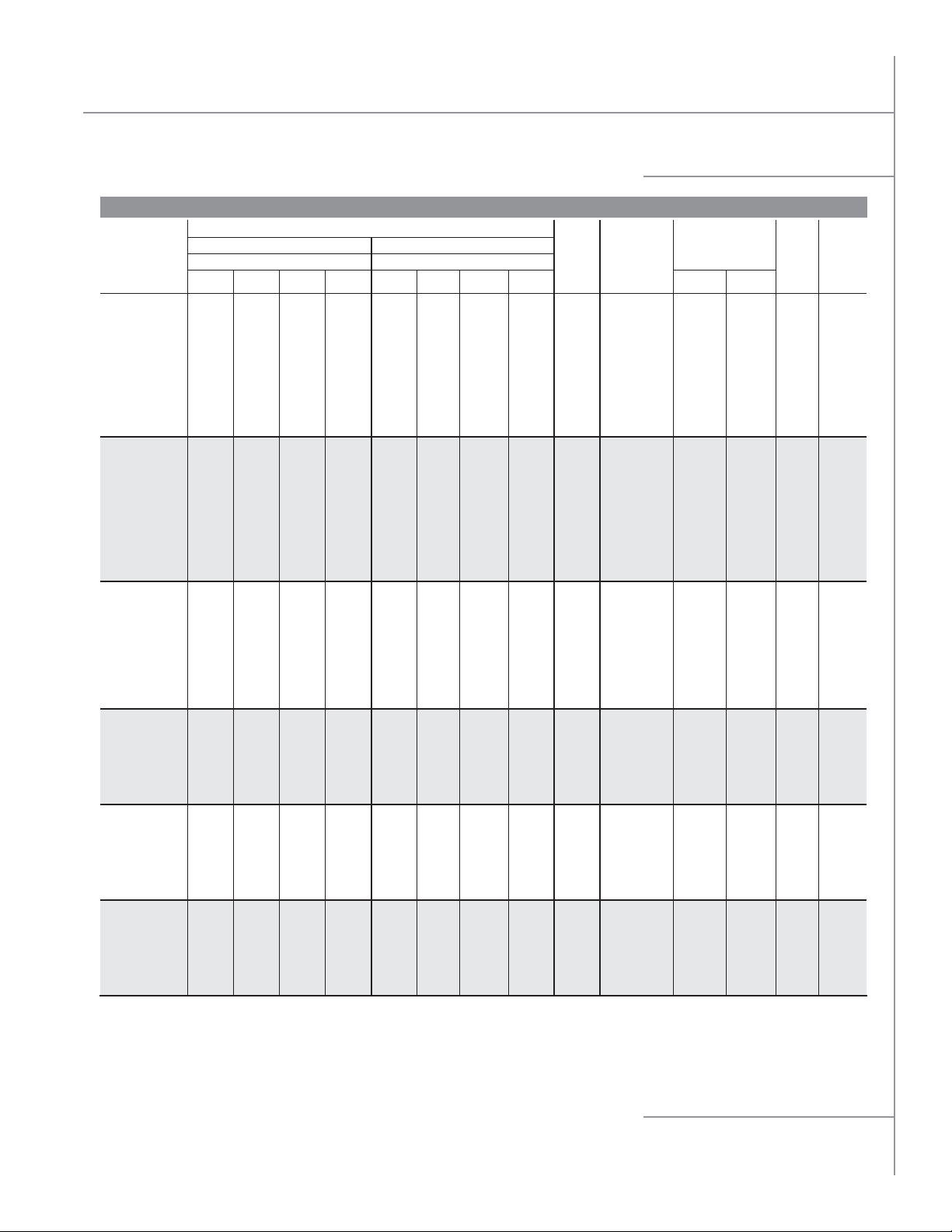

EVAPORATOR

TEMP (˚F)

-40

-30

-20

-10

0

5

10

15

20

25

30

40

50

90

1.66

1.57

1.49

1.42

1.36

1.33

1.31

1.28

1.26

1.24

1.22

1.18

1.14

100

1.73

1.62

1.53

1.46

1.40

1.37

1.34

1.32

1.29

1.27

1.25

1.21

1.17

110

1.80

1.68

1.58

1.50

1.44

1.41

1.38

1.35

1.33

1.31

1.28

1.24

1.20

120

2.00

1.80

1.65

1.57

1.50

1.46

1.43

1.40

1.37

1.35

1.32

1.27

1.23

130

*

*

*

1.64

1.56

1.52

1.49

1.46

1.43

1.40

1.37

1.31

1.26

140

*

*

*

*

1.62

1.59

1.55

1.52

1.49

1.45

1.42

1.35

1.29

CONDENSING TEMPERATURE (˚F)

HERMETIC COMPRESSOR

FEET

1,000

2,000

3,000

4,000

FACTOR

1.02

1.05

1.07

1.10

FEET

5,000

6,000

7,000

8,000

FACTOR

1.12

1.15

1.17

1.24

ALTITUDE

EVAPORATOR

TEMP (˚F)

-30

-20

-10

0

10

20

30

40

50

90

1.37

1.33

1.28

1.24

1.21

1.17

1.14

1.12

1.09

100

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.15

1.12

110

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.14

120

*

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

130

*

*

1.47

1.41

1.36

1.32

1.27

1.23

1.20

140

*

*

*

1.47

1.42

1.37

1.32

1.28

1.24

CONDENSING TEMPERATURE (˚F)

OPEN COMPRESSOR

TABLE 1

TABLE 2

TABLE 3

* Beyond the normal limits for single-stage compressor application.

* Beyond the normal limits for single-stage compressor application.

EVAPORATOR

TEMP (˚F)

-40

-30

-20

-10

0

5

10

15

20

25

30

40

50

90

1.66

1.57

1.49

1.42

1.36

1.33

1.31

1.28

1.26

1.24

1.22

1.18

1.14

100

1.73

1.62

1.53

1.46

1.40

1.37

1.34

1.32

1.29

1.27

1.25

1.21

1.17

110

1.80

1.68

1.58

1.50

1.44

1.41

1.38

1.35

1.33

1.31

1.28

1.24

1.20

120

2.00

1.80

1.65

1.57

1.50

1.46

1.43

1.40

1.37

1.35

1.32

1.27

1.23

130

*

*

*

1.64

1.56

1.52

1.49

1.46

1.43

1.40

1.37

1.31

1.26

140

*

*

*

*

1.62

1.59

1.55

1.52

1.49

1.45

1.42

1.35

1.29

CONDENSING TEMPERATURE (˚F)

HERMETIC COMPRESSOR

TABLE 1

* Beyond the normal limits for single-stage compressor application.

EVAPORATOR

TEMP (˚F)

-40

-30

-20

-10

0

5

10

15

20

25

30

40

50

90

1.66

1.57

1.49

1.42

1.36

1.33

1.31

1.28

1.26

1.24

1.22

1.18

1.14

100

1.73

1.62

1.53

1.46

1.40

1.37

1.34

1.32

1.29

1.27

1.25

1.21

1.17

110

1.80

1.68

1.58

1.50

1.44

1.41

1.38

1.35

1.33

1.31

1.28

1.24

1.20

120

2.00

1.80

1.65

1.57

1.50

1.46

1.43

1.40

1.37

1.35

1.32

1.27

1.23

130

*

*

*

1.64

1.56

1.52

1.49

1.46

1.43

1.40

1.37

1.31

1.26

140

*

*

*

*

1.62

1.59

1.55

1.52

1.49

1.45

1.42

1.35

1.29

CONDENSING TEMPERATURE (˚F)

HERMETIC COMPRESS

OR

EVAPORATOR

TEMP (˚F)

-30

-20

-10

0

10

20

30

40

50

90

1.37

1.33

1.28

1.24

1.21

1.17

1.14

1.12

1.09

100

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.15

1.12

110

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.14

120

*

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

130

*

*

1.47

1.41

1.36

1.32

1.27

1.23

1.20

140

*

*

*

1.47

1.42

1.37

1.32

1.28

1.24

CONDENSING TEMPERATURE (˚F)

OPEN COMPRESSOR

TABLE 1

TABLE 2

* Beyond the normal limits for single-stage compressor application.

* Beyond the normal limits for single-stage compressor application.

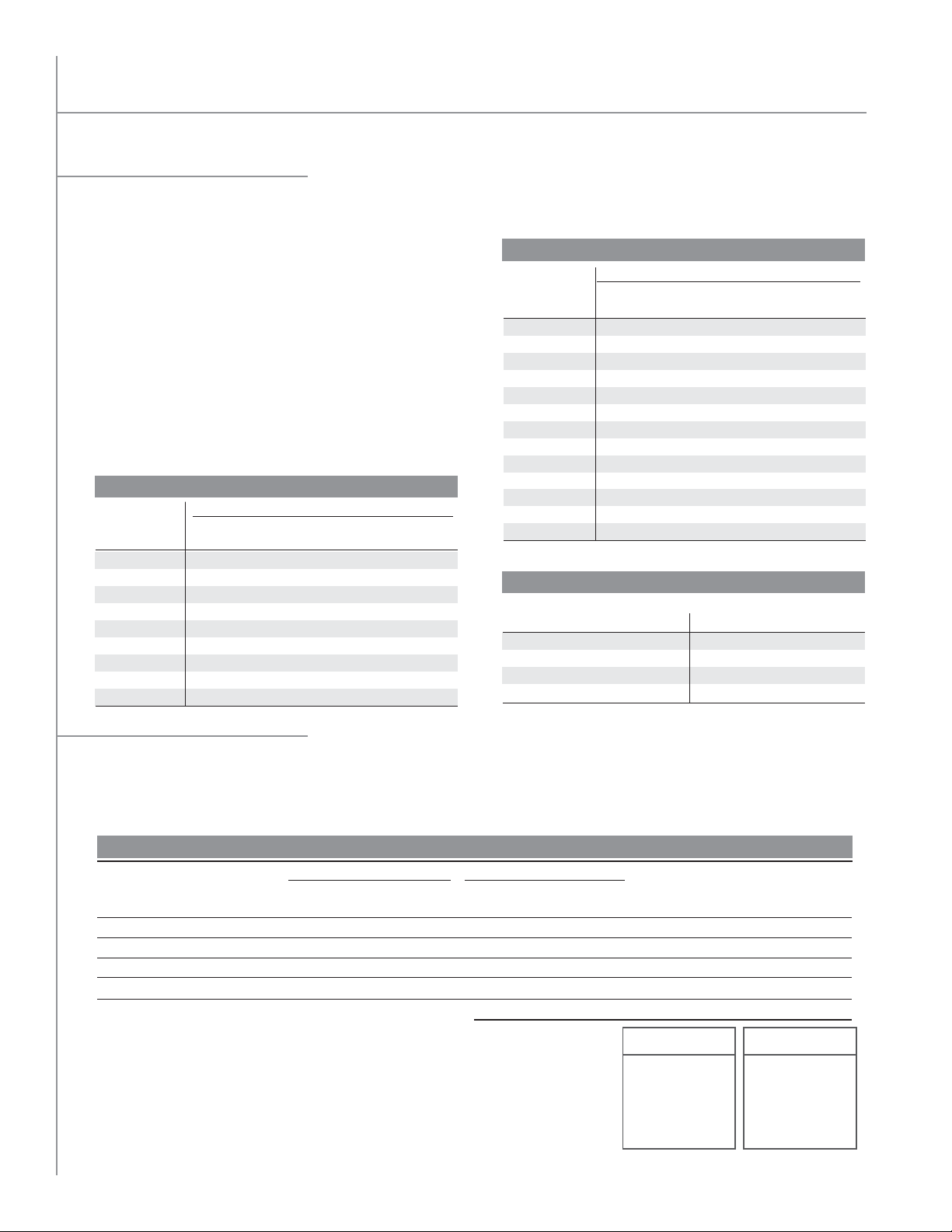

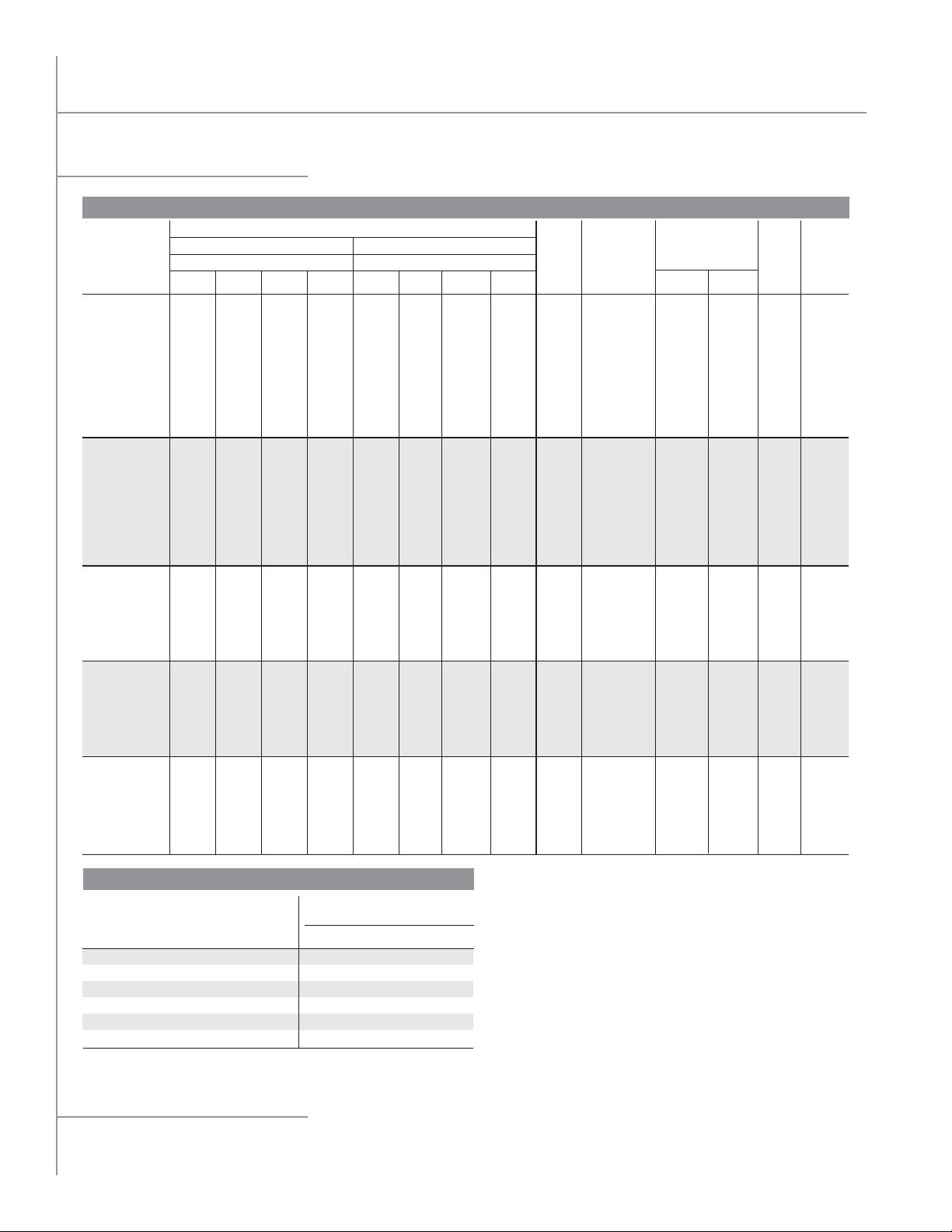

System Selection

THR Total Heat of Rejection

n Condenser total heat of rejection (BTU/h) is the sum of the evaporator refrigeration effect and the heat of compression

which varies with compressor type and operating conditions.

THR Calculation Method

n THR = Open Reciprocating Compressor Capacity

(BTU/h) + (2545 x BHP)

n THR = Suction Gas Cooled Hermetic Reciprocating

Compressor Capacity (BTU/h) + (3413 x kW)

THR Estimated Method

n THR may be estimated by multiplying the rated

compressor BTU/h capacity by the compressor

operating condition factor shown in Table 1 or 2.

Multiply result by altitude factor when applicable.

EVAPORATOR

TEMP (˚F)

* Beyond the normal limits for single-stage compressor application.

Multi-Circuit Selection

n Condenser coils may be divided into several individual refrigeration circuits or systems; each sized for a specific refrigerant,

THR capacity and TD. Systems are tagged for identification from left to right; facing the connection end. Avoid 3 row

condensers. Add excess circuits to low TD sections next to high TD sections. Add excess circuits to outboard sections.

Temperature fan cycling is recommended with multi-circuited condensers.

COMP

NOM

HP

6

9

10

12

Selection

n LAVA-14410 Rated at THR of 457.3 MBH with R-404A at 15°F TD.

LAVA-14410 Unit lists 34 Circuits.

n Sample Calculation: THR Req’d./Circuit = 426304 ÷ 34 = 12538.

LAVA-14410 = 457300 ÷ 34 = 13450 (Available THR/Circuit).

n Circuits Req’d. = Select THR ÷ THR/Circuit. Example: 56460 ÷ 13450 = 4.2 Circuits.

n Assign Number of Circuits System and System Number Left to Right.

Actual TD = (Circuits Req’d ÷ Assign Circuits) x Design TD.

Example: 4.2 ÷ 4 x 15 = 15.7.

-30

-20

-10

0

10

20

30

40

50

REF

134a

404A

404A

22

90

1.37

1.33

1.28

1.24

1.21

1.17

1.14

1.12

1.09

SAMPLE CALCULATION:

DESIGN

TD

°F

15

10

10

15

SAT

SUCT

°F

+20

-20

-20

+20

TABLE 2

CONDENSING TEMPERATURE (˚F)

100

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.15

1.12

SAT

COND

110

105

105

110

OPEN COMPRESSOR

110

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

1.14

NET

BTU/h

°F

40090

45900

50640

104000

120

*

1.47

1.42

1.37

1.32

1.28

1.24

1.20

1.17

95°F AMBIENT-SUCTION COOLED SEMI-HERMETIC RECIPROCATING COMPRESSORS

COMPRESS

MOTOR

kW

4.3

8.1

9.6

9.7

130

*

*

1.47

1.41

1.36

1.32

1.27

1.23

1.20

OR RATING

BTU

14676

27645

32765

33106

140

*

*

*

1.47

1.42

1.37

1.32

1.28

1.24

TOTAL

BTU/h

54,766

73,545

83,405

137,106

EVAPORATOR

TEMP (˚F)

-40

-30

-20

-10

0

5

10

15

20

25

30

40

50

* Beyond the normal limits for single-stage compressor application.

FEET

1,000

2,000

3,000

4,000

90

1.66

1.57

1.49

1.42

1.36

1.33

1.31

1.28

1.26

1.24

1.22

1.18

1.14

FACTOR

1.02

1.05

1.07

1.10

BASED ON R-404A AT 15°FTD

SELECT

REF

FACTOR

÷

0.97

÷

1.00

÷

1.00

÷

1.02

UNIT THR REQ’D

FACTOR

x

x

x

x

TD

1.0

1.5

1.5

1.0

=

=

=

=

THR

56460

110318

125108

134418

426304

R-404A - 1.00

R-22 - 1.02

R-134a - 0.97

TABLE 1

HERMETIC COMPRESSO

CONDENSING TEMPERATURE (˚F)

100

110

120

1.73

1.80

2.00

1.62

1.68

1.80

1.53

1.58

1.65

1.46

1.50

1.57

1.40

1.44

1.50

1.37

1.41

1.46

1.34

1.38

1.43

1.32

1.35

1.40

1.29

1.33

1.37

1.27

1.31

1.35

1.25

1.28

1.32

1.21

1.24

1.27

1.17

1.20

1.23

R

130

*

*

*

1.64

1.56

1.52

1.49

1.46

1.43

1.40

1.37

1.31

1.26

TABLE 3

ALTITUDE

CAP

PER

CIRCUIT

13450

13450

13450

13450

REF FACTOR

CIRCUIT

REQ’D

4.2

8.2

9.3

10.0

FEET

5,000

6,000

7,000

8,000

#

CIR

4

10

10

10

34

SYSTEM

NUMBER

L TO R

1

2

3

4

TD FACTOR

10°F - 1.50

15°F - 1.00

20°F - 0.75

25°F - 0.60

FACTOR

ACTUAL

1.12

1.15

1.17

1.24

15.7

15.0

140

*

*

*

*

1.62

1.59

1.55

1.52

1.49

1.45

1.42

1.35

1.29

TD

°F

8.2

9.3

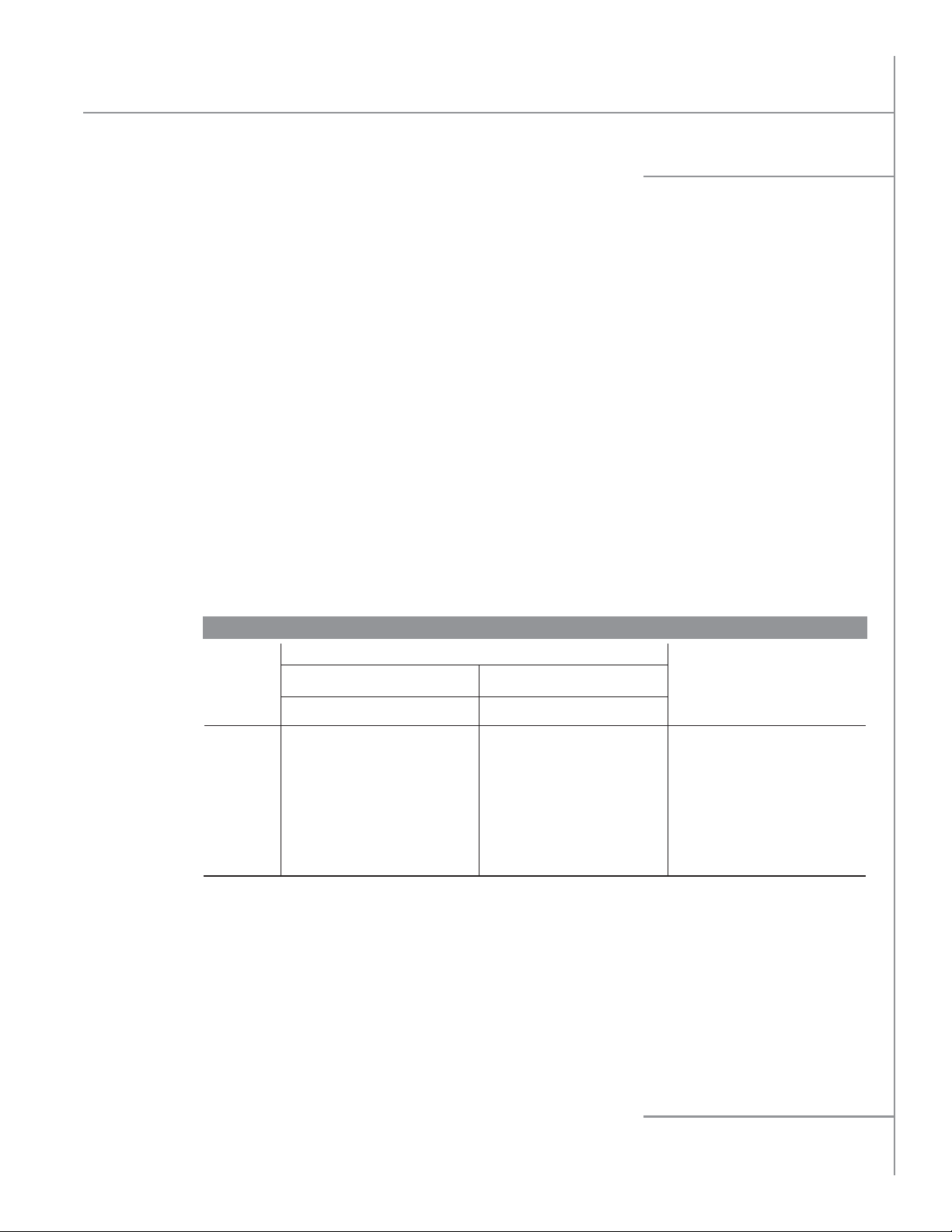

Levitor II Air-Cooled Condenser

Levitor Application

Locate Condensers no closer than their width from

walls or other condensers. Avoid locations near

exhaust fans, plumbing vents, flues or chimneys.

Parallel Condensers should be the same models

resulting in the same refrigerant side pressure drops.

Compressor discharge lines should have equal

pressure drops to each condenser.

Summer Charge based on 25% of condenser volume

with 90˚F liquid. Multiply by 1.1 for R-407A.

Winter Charge based on 90% of condenser volume

with -20˚F liquid. Multiply by 1.08 for R-407A.

Receiver Capacity should be sized to store condenser

summer charge, plus the condenser low ambient

allowance, plus the evaporator charge, plus an

allowance for piping and heat reclaim coil charges.

REFRIGERANT LINE CAPACITY DATA

COPPER

LINE

SIZE

O.D.

5/8

7/8

1-1/8

1-3/8

1-5/8

2-1/8

2-5/8

COMPRESSOR DISCHARGE LINE

R-404A

R-407A

0.5

2.0

4.5

7.0

15.0

30.0

45.0

LINE CAPACITY IN TONS

R-134A

1.0

3.0

6.5

15.0

20.0

45.0

75.0

0.5

2.0

4.5

7.0

11.0

28.0

43.0

Compressor Discharge lines should be sized to

minimize pressure drops and maintain oil return gas

velocities. Each connection should be looped to the

top of the condenser.

Gravity Liquid Drain Lines should drop from each

outlet as low as possible before headering or running

horizontally. Pitch downhill to receiver.

Off-Line Coil Sections will have refrigerant pressures

corresponding to the ambient. Check valves or

isolating valves should be installed in the liquid line

drains to prevent refrigerant migration and receiver

pressure loss.

See Installation and Operating instructions for piping, holdback and fan cycling details.

LBS. OF REFRIGERANT

CONDENSER TO RECEIVER

LIQUID LINE 100'

R-404A

3.0

6.0

10.4

16.0

23.0

40.0

62.0

R-407A

3.6

7.4

12.7

19.2

29.0

47.0

73.0

R-134A

3.7

7.7

13.0

20.0

28.5

46.0

72.0

LIQUID PER 100'

R-404A

11.0

22.0

36.0

55.0

78.0

138.0

212.0

OF LENGTH

R-407A

13.0

25.0

42.0

64.0

90.0

160.0

245.0

R-134A

13.0

26.0

43.0

65.0

92.0

163.0

250.0

n Capacity is compressor suction tons for application between -40°F and +40°F suction at condensing

temperatures between 80°F and 120°F sat.

n For multiple or unloading compressor applications, the vertical discharge riser from the compressor

may need to be one size smaller.

n This table data is only to be used as a guide. For exact values, please calculate to your specific job line

lengths and design pressure/temp values using ASHRAE handbook or ARI refrigerant tables.

LEVITOR II AIR-COOLED CONDENSER

Specifications subject to change without notice.

3

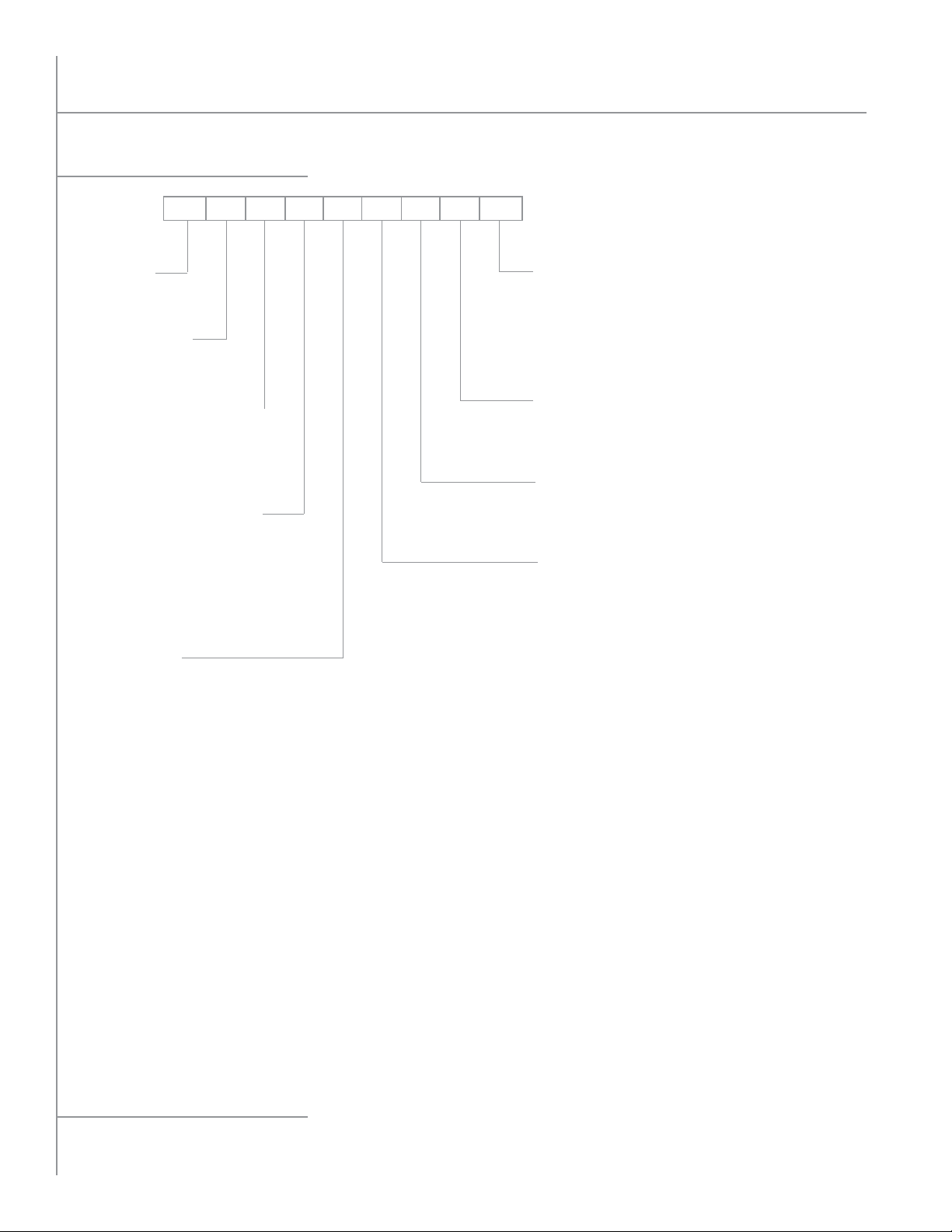

Levitor II Air-Cooled Condenser

Model Key

LAVA12410 M

UNIT TYPE:

L=Levitor Condenser

TUBE DIAMETER:

A=3/8 O.D.

E=1/2 O.D.

FAN DISCHARGE DIRECTIONS:

H=Horizontal

V= Vertical

X=Hinged Vertical

E=Hinged Horizontal

FAN/MOTOR COMBINATION:

A=1 HP 850 RPM 30"

B=1/2 HP 1140 RPM 24"

C=1-1/2 HP 850 RPM 30"

E=1/2 HP 575 RPM 30"

F=1-1/2 HP 1140 RPM 30"

FANS WIDE: 1, 2

VOLTAGE:

A=230/1/60 (24” Fan B Model Only)

K=208-230/3/60

M=460/3/60

P=575/3/60

U=380/3/50 (Capacity Derate of Around 10%)

FIN SPACING:

08 =8 FPI

10 =10 FPI

12 =12 FPI

ROWS DEEP:

2

3

4

FANS IN LINE:

1

2

3

4

5

6

7=24" Fan Only (B Motor)

LEVITOR II AIR-COOLED CONDENSER

4

Specifications subject to change without notice.

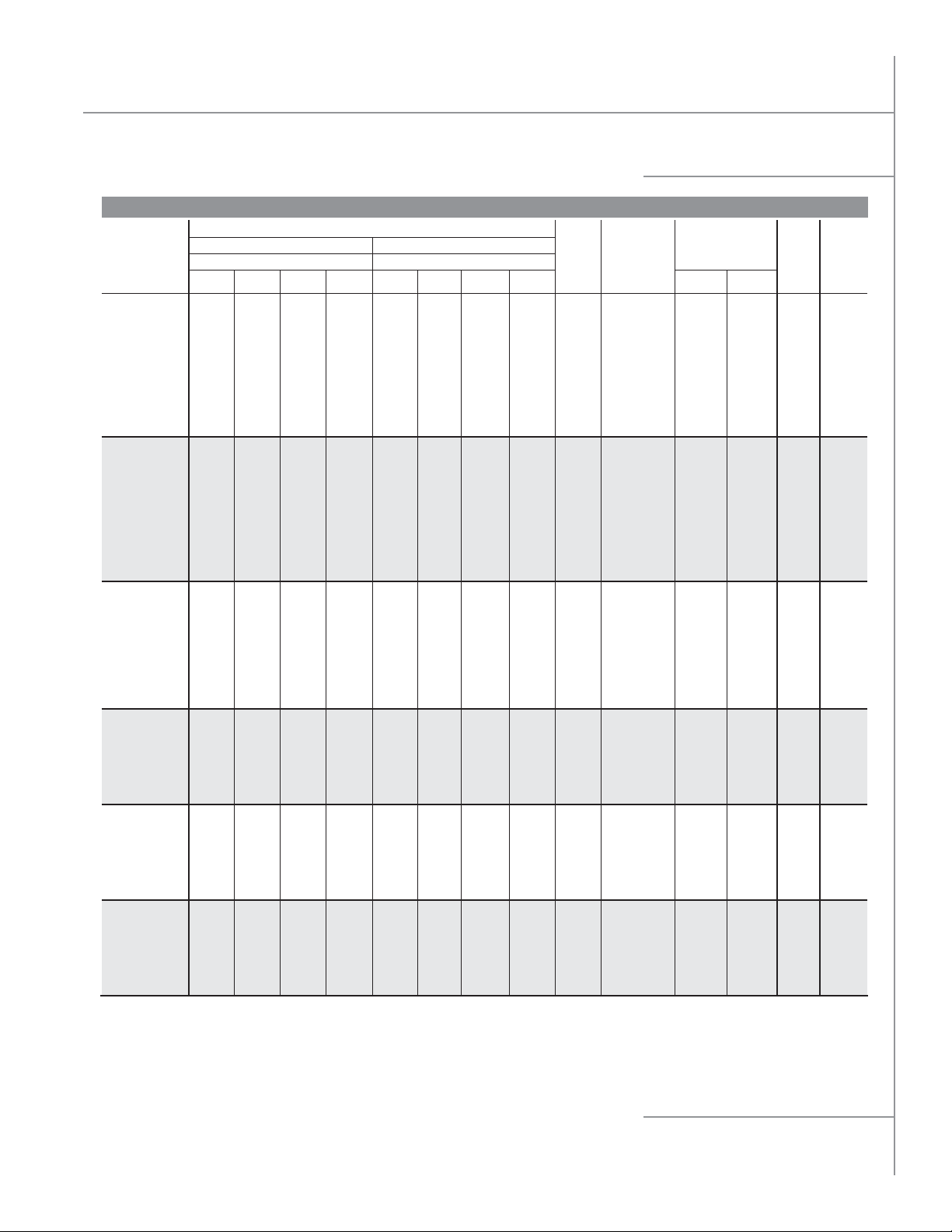

Levitor II Air-Cooled Condenser

LAVE/LEVE Performance Data

LAVE Performance Data

ONE FAN WIDE

TOTAL HEAT OF REJECTION (MBH)

R-407AR-404A, R-507

TEMPERATURE DIFFERENCE TEMPERATURE DIFFERENCE

MODEL

LAVE11208 35.2 52.8 70.3 87.9 34.4 51.6 68.8 86.0 6480 Compliant 4 17 52 437

LAVE11210 41.3 61.9 82.5 103.1 40.5 60.7 81.0 101.2 6420 Compliant 4 17 52 439

LAVE11212 45.9 68.9 91.9 114.8 45.7 68.6 91.4 114.3 6360 No 4 17 52 444

LAVE11308 47.1 70.6 94.1 117.7 46.4 69.6 92.8 116.0 6300 Compliant 6 25 52 466

LAVE11310 53.0 79.4 105.9 132.4 53.0 79.5 106.0 132.5 6200 Compliant 6 25 52 469

LAVE11312 57.1 85.6 114.2 142.7 58.3 87.5 116.6 145.8 6100 No 6 25 52 478

LAVE11408 55.9 83.9 111.9 139.8 56.6 84.8 113.1 141.4 6105 Compliant 8 33 52 495

LAVE11410 61.1 91.7 122.2 152.8 63.5 95.3 127.1 158.8 5975 Compliant 8 33 52 499

LAVE11412 64.7 97.1 129.5 161.8 68.3 102.5 136.6 170.8 5835 No 8 33 52 508

LAVE12208 70.3 105.5 140.7 175.9 68.8 103.2 137.6 172.0 12960 Compliant 9 32 55 718

LAVE12210 82.5 123.8 165.0 206.3 81.0 121.5 162.0 202.5 12840 Compliant 9 32 55 721

LAVE12212 91.9 137.8 183.7 229.6 91.4 137.1 182.9 228.6 12720 No 9 32 55 729

LAVE12308 94.1 141.2 188.3 235.4 92.8 139.2 185.6 232.1 12600 Compliant 13 48 55 773

LAVE12310 105.9 158.9 211.8 264.8 106.0 159.0 212.1 265.1 12400 Compliant 13 48 55 779

LAVE12312 114.2 171.2 228.3 285.4 116.6 175.0 233.3 291.6 12200 No 13 48 55 792

LAVE12408 111.9 167.8 223.8 279.7 113.1 169.7 226.3 282.8 12210 Compliant 17 64 55 830

LAVE12410 122.2 183.3 244.5 305.6 127.1 190.6 254.1 317.6 11950 Compliant 17 64 55 838

LAVE12412 129.5 194.2 258.9 323.7 136.6 205.0 273.3 341.6 11670 No 17 64 55 855

LAVE13210 123.8 185.6 247.5 309.4 121.5 182.2 242.9 303.7 19260 Compliant 13 48 57 1041

LAVE13212 137.8 206.7 275.6 344.5 137.1 205.7 274.3 342.9 19080 No 13 48 57 1060

LAVE13308 141.2 211.8 282.4 353.0 139.2 208.8 278.5 348.1 18900 Compliant 18 72 57 1126

LAVE13310 158.9 238.3 317.8 397.2 159.0 238.6 318.1 397.6 18600 Compliant 18 72 57 1135

LAVE13312 171.2 256.9 342.5 428.1 175.0 262.4 349.9 437.4 18300 No 18 72 57 1153

LAVE13408 167.8 251.7 335.6 419.5 169.7 254.5 339.4 424.2 18315 Compliant 24 96 57 1210

LAVE13410 183.3 275.0 366.7 458.4 190.6 285.9 381.2 476.4 17925 Compliant 24 96 57 1223

LAVE13412 194.2 291.3 388.4 485.5 205.0 307.4 409.9 512.4 17505 No 24 96 57 1247

LAVE14308 188.3 282.4 376.6 470.7 185.6 278.5 371.3 464.1 25200 Compliant 24 96 58 1437

LAVE14310 211.8 317.8 423.7 529.6 212.1 318.1 424.1 530.1 24800 Compliant 24 96 58 1449

LAVE14312 228.3 342.5 456.6 570.8 233.3 349.9 466.6 583.2 24400 No 24 96 58 1474

LAVE14408 223.8 335.6 447.5 559.4 226.3 339.4 452.5 565.7 24420 Compliant 32 127 58 1550

LAVE14410 244.5 366.7 488.9 611.1 254.1 381.2 508.2 635.3 23900 Compliant 32 127 58 1566

LAVE14412 258.9 388.4 517.9 647.3 273.3 409.9 546.6 683.2 23340 No 32 127 58 1599

LAVE15308 235.4 353.0 470.7 588.4 232.1 348.1 464.1 580.1 31500 Compliant 32 119 59 2020

LAVE15310 264.8 397.2 529.6 662.0 265.1 397.6 530.1 662.7 31000 Compliant 32 119 59 2035

LAVE15312 285.4 428.1 570.8 713.5 291.6 437.4 583.2 729.0 30500 No 32 119 59 2066

LAVE15408 279.7 419.5 559.4 699.2 282.8 424.2 565.7 707.1 30525 Compliant 41 159 59 2160

LAVE15410 305.6 458.4 611.1 763.9 317.6 476.4 635.3 794.1 29875 Compliant 41 159 59 2181

LAVE15412 323.7 485.5 647.3 809.2 341.6 512.4 683.2 854.0 29175 No 41 159 59 2222

LEVE16308 282.4 423.6 564.9 706.1 278.5 417.7 556.9 696.2 37800 Compliant 65 266 60 2554

LEVE16310 317.8 476.7 635.5 794.4 318.1 477.1 636.2 795.2 37200 Compliant 65 266 60 2573

LEVE16312 342.5 513.7 684.9 856.2 349.9 524.9 699.9 874.8 36600 No 65 266 60 2610

LEVE16408 335.6 503.5 671.3 839.1 339.4 509.1 678.8 848.5 36630 Compliant 84 354 60 2784

LEVE16410 366.7 550.0 733.4 916.7 381.2 571.7 762.3 952.9 35850 Compliant 84 354 60 2808

LEVE16412 388.4 582.6 776.8 971.0 409.9 614.9 819.8 1024.8 35010 No 84 354 60 2858

10°F

15°F 20°F 25°F 10°F 15°F

20°F

25°F

The temperature difference is between the saturated condensing temp. and the entering air temp.to the condenser.

AIR

FLOW

(CFM)

CEC

TITLE 24

COMPLIANT

NOTE: Ratings are based on 85°F-115°F entering air temperature and 0˚F sub-cooling.

CONDE

CHARGE R-404A

SUMMER WINTER

NSER

(LBS)

EST

SOUND

10’

(dBA)

SHIP

WEIGHT

(LBS)

See Corrections Factor Table on page 6. See Electrical Motor AMP Data table on page 13.

LEVITOR II AIR-COOLED CONDENSER

Specifications subject to change without notice.

5

Levitor II Air-Cooled Condenser

LAVE/LEVE Performance Data

LAVE Performance Data

TWO FANS WIDE

TOTAL HEAT OF REJECTION (MBH)

R-407AR-404A, R-507

TEMPERATURE DIFFERENCE TEMPERATURE DIFFERENCE

MODEL

LAVE22208 140.7 211.0 281.4 351.7 137.6 206.4 275.2 344.0 25920 Compliant 18 64 58 1311

LAVE22210 165.0 247.5 330.0 412.5 162.0 242.9 323.9 404.9 25680 Compliant 18 64 58 1320

LAVE22212 183.7 275.6 367.4 459.3 182.9 274.3 365.7 457.2 25440 No 18 64 58 1336

LAVE22308 188.3 282.4 376.6 470.7 185.6 278.5 371.3 464.1 25200 Compliant 26 96 58 1425

LAVE22310 211.8 317.8 423.7 529.6 212.1 318.1 424.1 530.1 24800 Compliant 26 96 58 1437

LAVE22312 228.3 342.5 456.6 570.8 233.3 349.9 466.6 583.2 24400 No 26 96 58 1462

LAVE22408 223.8 335.6 447.5 559.4 226.3 339.4 452.5 565.7 24420 Compliant 34 128 58 1539

LAVE22410 244.5 366.7 488.9 611.1 254.1 381.2 508.2 635.3 23900 Compliant 34 128 58 1555

LAVE22412 258.9 388.4 517.9 647.3 273.3 409.9 546.6 683.2 23340 No 34 128 58 1588

LAVE23210 247.5 371.3 495.0 618.8 242.9 364.4 485.9 607.4 38520 Compliant 26 96 60 1875

LAVE23212 275.6 413.4 551.1 688.9 274.3 411.4 548.6 685.7 38160 No 26 96 60 1912

LAVE23308 282.4 423.6 564.9 706.1 278.5 417.7 556.9 696.2 37800 Compliant 36 144 60 2044

LAVE23310 317.8 476.7 635.5 794.4 318.1 477.1 636.2 795.2 37200 Compliant 36 144 60 2063

LAVE23312 342.5 513.7 684.9 856.2 349.9 524.9 699.9 874.8 36600 No 36 144 60 2100

LAVE23408 335.6 503.5 671.3 839.1 339.4 509.1 678.8 848.5 36630 Compliant 48 192 60 2214

LAVE23410 366.7 550.0 733.4 916.7 381.2 571.7 762.3 952.9 35850 Compliant 48 192 60 2238

LAVE23412 388.4 582.6 776.8 971.0 409.9 614.9 819.8 1024.8 35010 No 48 192 60 2287

LAVE24308 376.6 564.9 753.1 941.4 371.3 556.9 742.6 928.2 50400 Compliant 48 192 61 2526

LAVE24310 423.7 635.5 847.4 1059.2 424.1 636.2 848.2 1060.3 49600 Compliant 48 192 61 2651

LAVE24312 456.6 684.9 913.3 1141.6 466.6 699.9 933.1 1166.4 48800 No 48 192 61 2700

LAVE24408 447.5 671.3 895.0 1118.8 452.5 678.8 905.1 1131.3 48840 Compliant 64 254 61 2851

LAVE24410 488.9 733.4 977.8 1222.3 508.2 762.3 1016.4 1270.5 47800 Compliant 64 254 61 2884

LAVE24412 517.9 776.8 1035.7 1294.6 546.6 819.8 1093.1 1366.4 46680 No 64 254 61 2950

LAVE25308 470.7 706.1 941.4 1176.8 464.1 696.2 928.2 1160.3 63000 Compliant 64 238 62 3725

LAVE25310 529.6 794.4 1059.2 1324.1 530.1 795.2 1060.3 1325.4 62000 Compliant 64 238 62 3755

LAVE25312 570.8 856.2 1141.6 1427.0 583.2 874.8 1166.4 1458.0 61000 No 64 238 62 3817

LAVE25408 559.4 839.1 1118.8 1398.5 565.7 848.5 1131.3 1414.2 61050 Compliant 82 318 62 4005

LAVE25410 611.1 916.7 1222.3 1527.9 635.3 952.9 1270.5 1588.2 59750 Compliant 82 318 62 4046

LAVE25412 647.3 971.0 1294.6 1618.3 683.2 1024.8 1366.4 1708.0 58350 No 82 318 62 4129

LEVE26308 564.9 847.3 1129.7 1412.1 556.9 835.4 1113.9 1392.3 75600 Compliant 130 532 63 4759

LEVE26310 635.5 953.3 1271.1 1588.9 636.2 954.3 1272.3 1590.4 74400 Compliant 130 532 63 4796

LEVE26312 684.9 1027.4 1369.9 1712.4 699.9 1049.8 1399.7 1749.6 73200 No 130 532 63 4870

LEVE26408 671.3 1006.9 1342.5 1678.2 678.8 1018.2 1357.6 1697.0 73260 Compliant 168 708 63 5218

LEVE26410 733.4 1100.1 1466.7 1833.4 762.3 1143.5 1524.6 1905.8 71700 Compliant 168 708 63 5268

LEVE26412 776.8 1165.2 1553.6 1942.0 819.8 1229.8 1639.7 2049.6 70020 No 168 708 63 5366

10°F

15°F 20°F 25°F 10°F 15°F

20°F

25°F

AIR

FLOW

(CFM)

CEC

TITLE 24

COMPLIANT

CONDENSER

CHARGE R-404A

(LBS)

SUMMER WINTER

EST

SOUND

10’

(dBA)

SHIP

WEIGHT

(LBS)

CORRECTIONS FACTOR TABLE

MULTIPLY R-404A BY

REFRIGERANTS CAPACITY FACTOR SUMMER WINTER

R-404A 1.00 1.00 1.00

R-134A 0.97 1.17 1.11

R-410A 1.02 1.02 1.03

R-22 1.02 1.14 1.09

R-407A See R-407A Chart 1.10 1.08

R-407C 0.98 x R-407A 1.09 1.07

For units using 380/3/50, multiply capacity by 0.90.

LEVITOR II AIR-COOLED CONDENSER

6

Specifications subject to change without notice.

CHARGE CORRECTION FACTOR

NOTE: Ratings are based on 85°F-115°F entering air temperature and 0˚F sub-cooling.

The temperature difference is between the saturated condensing temp. and the entering air temp.

to the condenser.

See Electrical Motor AMP Data tables on page 13.

Levitor II Air-Cooled Condenser

LAVA R-404A Performance Data

LAVA Performance Data

ONE FAN WIDE

TOTAL HEAT OF REJECTION (MBH)

R-407AR-404A, R-507

TEMPERATURE DIFFERENCE TEMPERATURE DIFFERENCE

MODEL

LAVA11208 41.9 62.8 83.8 104.7 40.3 60.5 80.7 100.8 9260 No 4 17 63 437

LAVA11210 48.8 73.2 97.6 122.0 47.3 71.0 94.6 118.3 9151 No 4 17 63 439

LAVA11212 54.3 81.5 108.7 135.8 53.4 80.1 106.8 133.5 9040 No 4 17 63 444

LAVA11308 58.4 87.6 116.9 146.1 56.4 84.5 112.7 140.9 8933 No 6 25 63 466

LAVA11310 65.4 98.1 130.8 163.5 65.0 97.5 130.0 162.4 8760 Compliant 6 25 63 469

LAVA11312 71.9 107.9 143.9 179.8 72.3 108.5 144.6 180.8 8574 No 6 25 63 478

LAVA11408 69.6 104.5 139.3 174.1 68.8 103.1 137.5 171.9 8582 Compliant 8 33 63 495

LAVA11410 76.2 114.3 152.4 190.5 77.4 116.2 154.9 193.6 8314 Compliant 8 33 63 499

LAVA11412 81.2 121.7 162.3 202.9 83.8 125.8 167.7 209.6 8025 No 8 33 63 508

LAVA12208 83.8 125.6 167.5 209.4 80.7 121.0 161.3 201.7 18520 No 9 32 66 718

LAVA12210 97.6 146.4 195.1 243.9 94.6 141.9 189.2 236.5 18302 No 9 32 66 721

LAVA12212 108.7 163.0 217.3 271.7 106.8 160.2 213.7 267.1 18080 No 9 32 66 729

LAVA12308 116.9 175.3 233.7 292.2 112.7 169.1 225.5 281.8 17866 No 13 48 66 773

LAVA12310 130.8 196.2 261.6 327.0 130.0 194.9 259.9 324.9 17520 Compliant 13 48 66 779

LAVA12312 143.9 215.8 287.7 359.6 144.6 217.0 289.3 361.6 17148 No 13 48 66 792

LAVA12408 139.3 208.9 278.5 348.2 137.5 206.3 275.0 343.8 17164 Compliant 17 64 66 830

LAVA12410 152.4 228.7 304.9 381.1 154.9 232.3 309.8 387.2 16628 Compliant 17 64 66 838

LAVA12412 162.3 243.5 324.6 405.8 167.7 251.5 335.3 419.2 16050 No 17 64 66 855

LAVA13210 146.4 219.5 292.7 365.9 141.9 212.9 283.8 354.8 27453 No 13 48 68 1041

LAVA13212 163.0 244.5 326.0 407.5 160.2 240.4 320.5 400.6 27120 No 13 48 68 1060

LAVA13308 175.3 262.9 350.6 438.2 169.1 253.6 338.2 422.7 26799 No 18 72 68 1126

LAVA13310 196.2 294.3 392.4 490.5 194.9 292.4 389.9 487.3 26280 Compliant 18 72 68 1135

LAVA13312 215.8 323.7 431.6 539.4 217.0 325.5 433.9 542.4 25722 No 18 72 68 1153

LAVA13408 208.9 313.4 417.8 522.3 206.3 309.4 412.5 515.6 25746 Compliant 24 96 68 1210

LAVA13410 228.7 343.0 457.3 571.6 232.3 348.5 464.6 580.8 24942 Compliant 24 96 68 1223

LAVA13412 243.5 365.2 486.9 608.7 251.5 377.3 503.0 628.8 24075 No 24 96 68 1247

LAVA14308 233.7 350.6 467.4 584.3 225.5 338.2 450.9 563.7 35732 No 24 96 69 1437

LAVA14310 261.6 392.4 523.2 654.0 259.9 389.9 519.8 649.8 35040 Compliant 24 96 69 1449

LAVA14312 287.7 431.6 575.4 719.3 289.3 433.9 578.6 723.2 34296 No 24 96 69 1474

LAVA14408 278.5 417.8 557.1 696.3 275.0 412.5 550.0 687.5 34328 Compliant 32 127 69 1550

LAVA14410 304.9 457.3 609.7 762.2 309.8 464.6 619.5 774.4 33256 Compliant 32 127 69 1566

LAVA14412 324.6 486.9 649.2 811.6 335.3 503.0 670.7 838.4 32100 No 32 127 69 1599

LAVA15308 292.2 438.2 584.3 730.4 281.8 422.7 563.7 704.6 44665 No 32 119 70 2020

LAVA15310 327.0 490.5 654.0 817.5 324.9 487.3 649.8 812.2 43800 Compliant 32 119 70 2035

LAVA15312 359.6 539.4 719.3 899.1 361.6 542.4 723.2 904.1 42870 No 32 119 70 2066

LAVA15408 348.2 522.3 696.3 870.4 343.8 515.6 687.5 859.4 42910 Compliant 41 159 70 2160

LAVA15410 381.1 571.6 762.2 952.7 387.2 580.8 774.4 968.0 41570 Compliant 41 159 70 2181

LAVA15412 405.8 608.7 811.6 1014.5 419.2 628.8 838.4 1047.9 40125 No 41 159 70 2222

LEVA16308 350.6 525.9 701.2 876.5 338.2 507.3 676.4 845.5 53598 No 65 266 71 2554

LEVA16310 392.4 588.6 784.8 981.0 389.9 584.8 779.7 974.7 52560 Compliant 65 266 71 2573

LEVA16312 431.6 647.3 863.1 1078.9 433.9 650.9 867.9 1084.9 51444 No 65 266 71 2610

LEVA16408 417.8 626.7 835.6 1044.5 412.5 618.8 825.0 1031.3 51492 Compliant 84 354 71 2784

LEVA16410 457.3 686.0 914.6 1143.3 464.6 697.0 929.3 1161.6 49884 Compliant 84 354 71 2808

LEVA16412 486.9 730.4 973.9 1217.3 503.0 754.5 1006.0 1257.5 48150 No 84 354 71 2858

10°F

15°F 20°F 25°F 10°F 15°F

20°F

25°F

The temperature difference is between the saturated condensing temp. and the entering air temp.to the condenser.

AIR

FLOW

(CFM)

CEC

TITLE 24

COMPLIANT

NOTE: Ratings are based on 85°F-115°F entering air temperature and 0˚F sub-cooling.

CO

NDENSER

CHARGE R-404A

(LBS)

SUMMER WINTER

EST

SOUND

10’

(dBA)

SHIP

WEIGHT

(LBS)

See Corrections Factor Table on page 8. See Electrical Motor AMP Data table on page 13.

LEVITOR II AIR-COOLED CONDENSER

Specifications subject to change without notice.

7

Loading...

Loading...