L

e

L

e

viitt

v

orr

o

S

S

errii

e

e

s IIII

e

s

Aiirr--

A

C

C

o

o

oll

o

O

O

n

IIn

e

d

e

p

p

stt

s

M

M

d

err

e

a

n

a

n

allll

a

a

n

a

n

C

o

C

o

attii

a

d

d

attii

a

u

u

n

n

n

n

o

o

all

a

d

d

g

g

n

n

e

e

n

n

s

s

err

e

s

s

Levitor Series II Air Cooled Condensers (PN E208035_B)

TABLE OF CONTENTS

1 RECEIPT OF EQUIPMENT ………………………………………………………………………………………………2

1.1 INSPECTION…………………………………………………………………………………………………………..……2

1.2 LOSS OF GAS HOLDING CHARGE……………………………………………………………………………………..2

2 MODELS AND DIMENSIONS…………………………………………………………………………………………….2

2.1 UNIT MODELS………………………………………………………………………………………………………………2

2.2 30” UNIT DIMENSIONS AND MOTOR AMPS……………………………………….………………………………….3

2.3 30” UNIT MOTOR AMPS…………………………………………………………………………………………………..4

2.4 30” UNIT WEIGHTS AND REFRIGERANT CHARGES………………………………………………………………..5

2.5 24” UNIT DIMENSIONS AND MOTOR AMPS…………………………………………………………………………..6

3 UNIT LOCATION………………………………………………………………………..………………………………..…7

4 RIGGING…………………………………………………………………………………………………………………..…8

5 UNIT ASSEMBLY………………………………………………………………………………………………………….11

5.1 LEG ASSEMBLY FOR 30” FAN UNITS………………………………………………………………………………...11

5.2 OPTIONAL GRAVITY DAMPERS FOR 30” FAN UNITS……………………………………………………………..11

5.3 HORIZONAL AIRFLOW BASE SUPPORT……………………………………………………………………………..12

5.4 LEG ASSEMBLY FOR 24” FAN UNITS………………………………………………………………………………...12

6 INSTALLATION AND PIPING…………………………………………………………………………………………...13

6.1 MOUNTING THE UNIT…………………………………………………………………………………………………...13

6.2 INTERCONNECTING PIPING FOR DOUBLE WIDE UNITS…………………………………… …………………...13

6.3 REFRIGERATION PIPING……………………………………………………………………………………………….13

6.4 HOLDBACK FLOODING CONTROL……………………………………………………………………………………16

7 ELECTRICAL……………………………………………………………………………………………………………...17

7.1 FIELD WIRING………………………………………………………………………………………………………..…..17

7.2 MOTORS WIRED TO TERMINAL BLOCKS………………………………………………………………………..…17

7.3 MOTORS WIRED TO STANDARD FAN CYCLING CONTROL PANEL………………………………………..….18

7.4 FAN CYCLE OPERATION……………………………………………………………………………………………....19

7.5 CONTROL SETTINGS……………………………………………………….………………………………………..…19

7.6 TEMPERATURE SENSOR……………………………………………………………………………………………...19

8 INSPECTION AND CLEANING…………………………………………………………………………………………22

9 REPLACEMENT PARTS LISTS……………………………………………………………………………………..…22

TABLES

Table 1 30” UNIT DIMENSIONS.................................................................................................................................. 3

Table 2 30” UNIT FULL LOAD MOTOR AMPS............................................................................................................ 4

Table 3 30” UNIT WEIGHTS AND REFRIGERANT CHARGES.................................................................................. 5

Table 4 24” UNIT DIMENSIONS, AMPS, AND WEIGHTS ..........................................................................................6

Table 5 24” REFRIGERANT LINE SIZING ................................................................................................................15

Table 6 CONTROL PANEL SETTINGS – PRESSURE SENSING............................................................................ 20

Table 7 CONTROL PANEL SETTINGS – TEMPERATURE SENSING..................................................................... 21

Table 8 TYPICAL REPLACEMENT PART NUMBERS.............................................................................................. 22

Table 9 MISCELLANIOUS REPLACEMENT PART NUMBERS................................................................................ 23

FIGURES

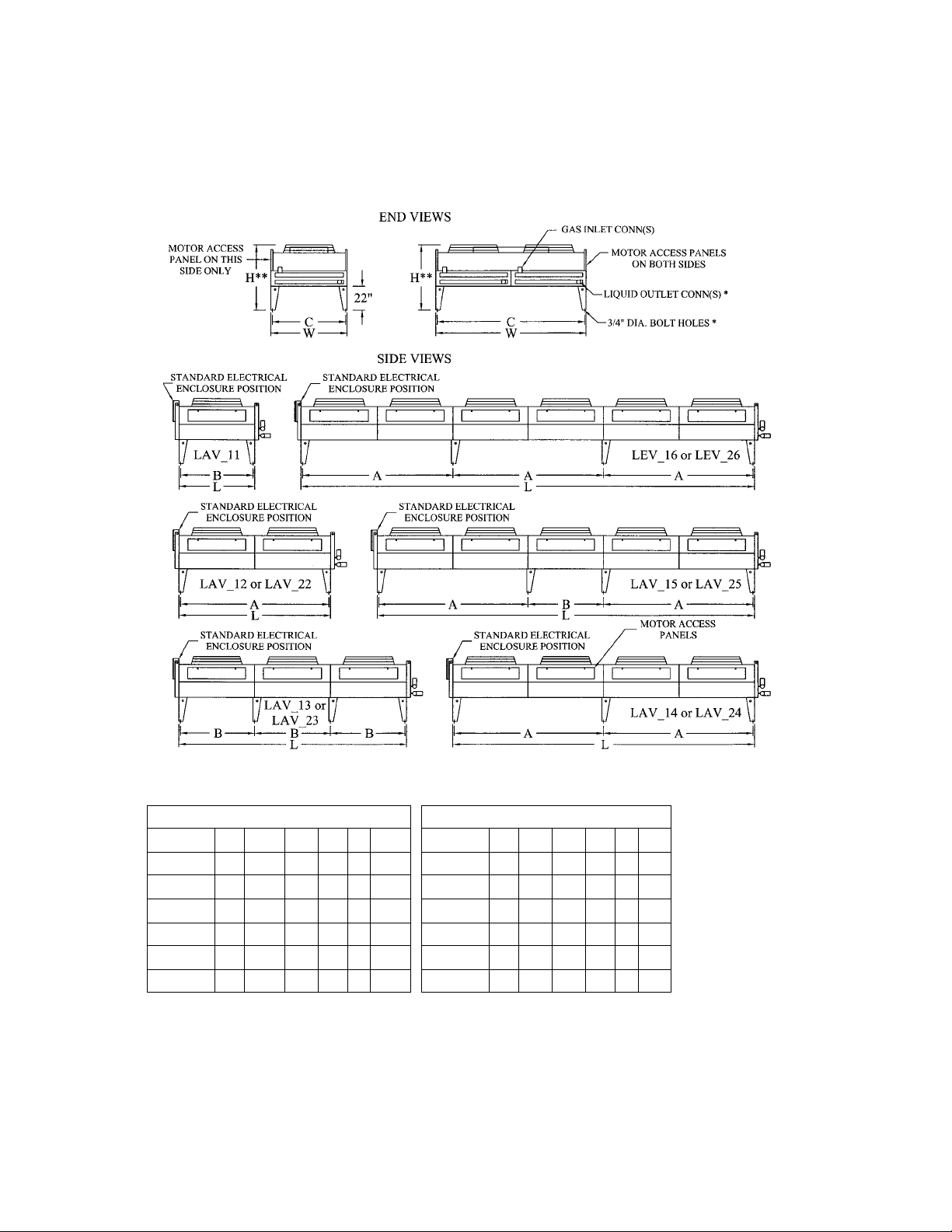

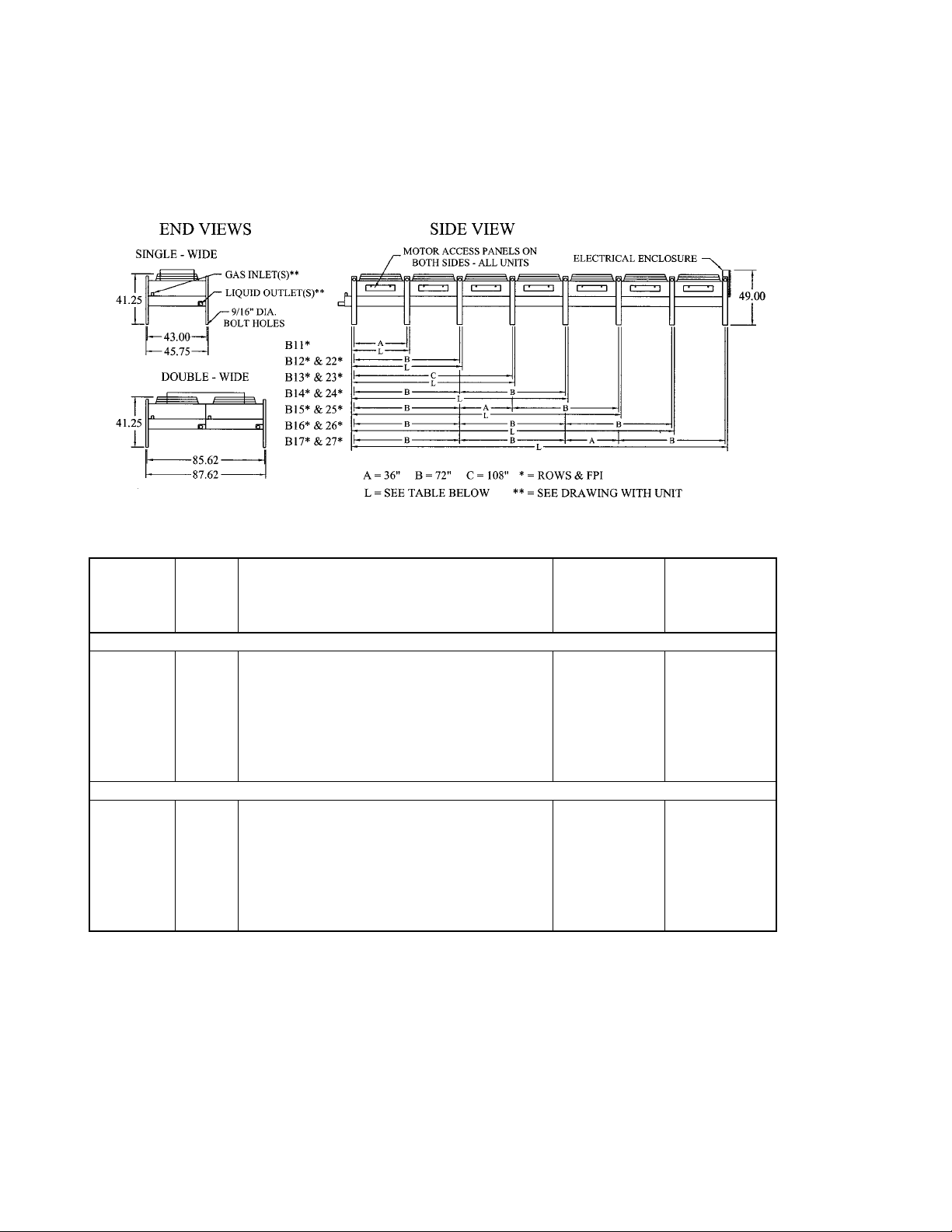

Figure 1 30” UNIT DRAWINGS ............................................................................................................................................ 3

Figure 2 24” UNIT DIMENSIONS ......................................................................................................................................... 6

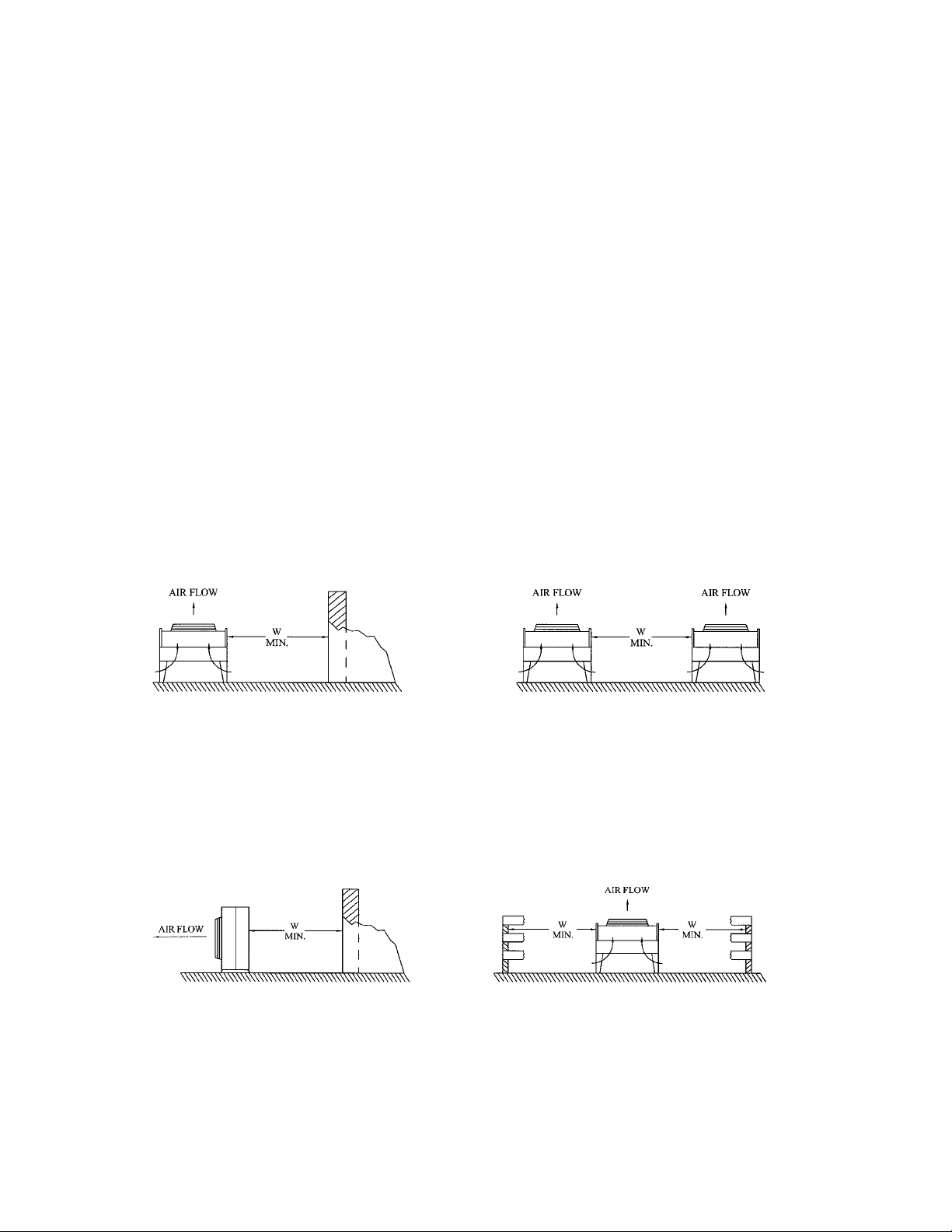

Figure 3 LOCATION REQUIREMENTS ............................................................................................................................... 7

Figure 4 RIGGING FOR 30” FAN UNITS ............................................................................................................................. 8

Figure 5 RIGGING FOR 30” FAN UNITS WITH RECEIVERS ............................................................................................. 9

Figure 6 RIGGING FOR 24” FAN UNITS ........................................................................................................................... 10

Figure 7 STANDARD 22” & 42” LEG ASSEMBLY ............................................................................................................. 11

Figure 8 GRAVITY DAMPER ASSEMBLY......................................................................................................................... 11

Figure 9 42” LEG & BRACING ASSEMBLY FOR 24"FAN UNITS ..................................................................................... 12

Figure 10 UNIT MOUNTING AND PIPING......................................................................................................................... 14

Figure 11 DOUBLE RISER DISCHARGE ARRANGEMENT ............................................................................................. 16

Figure 12 HOLDBACK FLOODING CONTROL ARRANGEMENTS .................................................................................. 16

Figure 13 TERMINAL BLOCK ONLY WIRING DIAGRAMS ( NC – C444 )........................................................................ 17

Figure 14 INDIVIDUAL FAN MOTOR CYCLING WIRING DIAGRAM ( -311 ) ................................................................... 18

Figure 15 FAN MOTOR CYCLING IN PAIRS WIRING DIAGRAM ( -331 )........................................................................ 18

Levitor Series II Air Cooled Condensers (PN E208035_B)

1

1 RECEIPT OF EQUIPMENT

1.1 INSPECTION

All equipment should be carefully checked for damage or shortages as soon as it is received. Each

shipment should be carefully checked against the bill of lading. If any damage or shortage is evident, a

notation must be made on the delivery receipt before it is signed and a claim should then be filed

against the freight carrier. Inspection and claims are the responsibility of the recipient.

1.2 LOSS OF GAS HOLDING CHARGE

The refrigeration coil section of each Levitor Series II unit is leak tested, evacuated to remove moisture

and then shipped with a pressurized nitrogen gas holding charge. Absence of this charge may indicate

a leak has developed in transit. The system should not be charged with refrigerant until it is verified

that there is no leak, or the source of the leak is located and repaired if necessary.

2 MODELS AND DIMENSIONS

2.1 UNIT MODELS

Units are available with 24” and 30” diameter fans and a variety of motor speeds and horsepower’s. All

units are designed for vertical air discharge, with horizontal air discharge as an option. Each unit is

constructed for the refrigerant and internal working pressure that is indicated on the unit nameplate. All

units contain the UL, cUL, and CSA labels to indicate the unit was manufactured using acceptable

practices by the governing bodies.

MODEL KEY: L A V A – 2 4 4 10 M

Levitor Voltage In

A – 208-230/1/60 (LAVB only)

Tube Diameter

A – 3/8”

E – 1/2" P – 575/3/60

U – 380/3/50

Air Discharge

V – Vertical

H – Horizontal

X – Hinged Vertical Airflow 08, 10 or 12

E – Hinged Horizontal Airflow

No. Rows Deep

Fan/Motor Combination

A – 30” Fan, 1 HP, 850 RPM

B – 24” Fan, 0.5 HP, 1140 RPM

C – 30” Fan, 1.5 HP, 850 RPM 1 to 7 for 24” fan units

E – 30” Fan, 0.5 HP, 575 RPM 1 to 6 for 30” fan units

F – 30” Fan, 1.5 HP, 1140 RPM

1 for single-wide units (inline)

2 for double-wide units (side-by-side)

K – 208-230/3/60

2, 3, or 4

M – 460/3/60

W – 415/3/50

Fins Per Inch

No. Fans Long

No. Fans Wide

Levitor Series II Air Cooled Condensers (PN E208035_B)

2

2.2 30” UNIT DIMENSIONS AND MOTOR AMPS

Figure 1 and Table 1 contain the overall dimensions, bolt hole locations, and motor amp draws for all of

the 30” diameter fan units.

FIGURE 1 30” UNIT DRAWINGS

TABLE 1 30” UNIT DIMENSIONS

DIMENSIONS (inches) DIMENSIONS (inches)

MODEL L W H** A B C MODEL L W H** A B C

LAV_11*** 58 45.25 54 - 54 41.25 - - - - - - LAV_12*** 112 45.25 54 108 - 41.25 LAV_22*** 112 90.5 54 108 - 86.5

LAV_13*** 166 45.25 54 108 54 41.25 LAV_23*** 166 90.5 54 108 54 86.5

LAV_14*** 220 45.25 54 108 - 41.25 LAV_24*** 220 90.5 54 108 - 86.5

LAV_15*** 274 45.25 58.5 108 54 41.25 LAV_25*** 274 90.5 58.5 108 54 86.5

LEV_16*** 328 45.25 58.5 108 - 41.25 LEV_26*** 328 90.5 58.5 108 - 86.5

* -

Connection size is determined by computerized circuiting program. See drawing with unit.

** - Includes standard 22” legs. Increase height accordingly if 30”, 36”, 42”, 48”, or 60” extended legs

are used. If the 48” or 60” extended legs are used, every fan section down the length of the unit has a

leg and gusset. 60” legs also have cross bracing. Legs, gussets, and bracing require field installation.

See unit drawing for details.

*** - Rows & FPI

Levitor Series II Air Cooled Condensers (PN E208035_B)

3

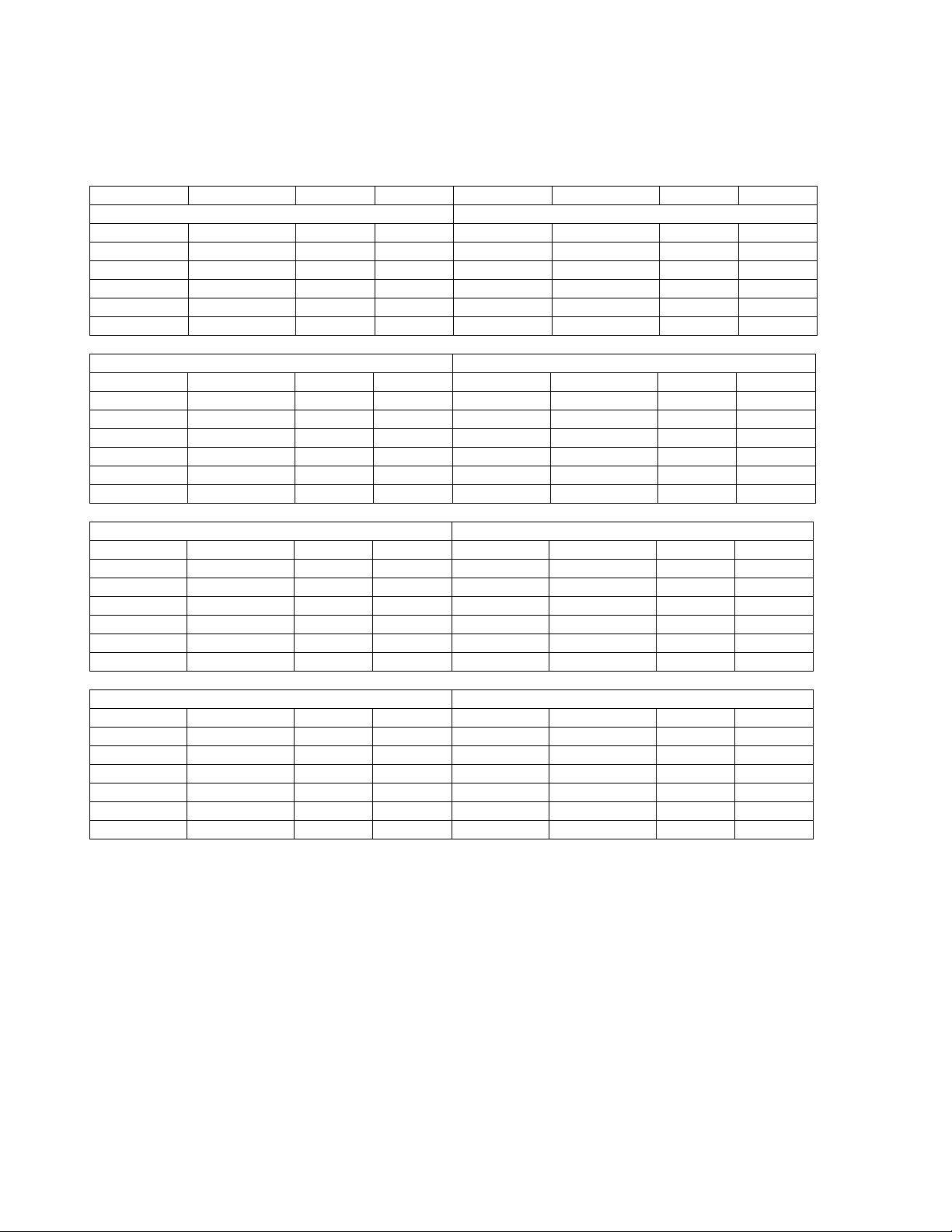

2.3 30” UNIT MOTOR AMPS

The following table contains the motor amps for the available fan motors.

TABLE 2 30” UNIT FULL LOAD MOTOR AMPS

MODEL 208/230/3/60 460/3/60 575/3/60 MODEL 208/230/3/60 460/3/60 575/3/60

ONE FAN WIDE 1 HP 850 RPM TWO FANS WIDE 1 HP 850 RPM

LAVA11*** 4.4 2.0 1.5 - - - LAVA12*** 8.8 4.0 3.0 LAVA22*** 17.6 8.0 6.0

LAVA13*** 13.2 6.0 4.5 LAVA23*** 26.4 12.0 9.0

LAVA14*** 17.6 8.0 6.0 LAVA24*** 35.2 16.0 12.0

LAVA15*** 22.0 10.0 7.5 LAVA25*** 44.0 20.0 15.0

LEVA16*** 26.4 12.0 9.0 LEVA26*** 52.8 24.0 18.0

ONE FAN WIDE 1.5 HP 850 RPM TWO FANS WIDE 1.5 HP 850 RPM

MODEL 208/230/3/60 460/3/60 575/3/60 MODEL 208/230/3/60 460/3/60 575/3/60

LAVC11*** 6.0 3.0 2.5 - - - LAVC12*** 12.0 6.0 5.0 LAVC22*** 24.0 12.0 10.0

LAVC13*** 18.0 9.0 7.5 LAVC23*** 36.0 18.0 15.0

LAVC14*** 24.0 12.0 10.0 LAVC24*** 48.0 24.0 20.0

LAVC15*** 30.0 15.0 12.5 LAVC25*** 60.0 30.0 25.0

LEVC16*** 36.0 18.0 15.0 LEVC26*** 72.0 36.0 30.0

ONE FAN WIDE 1/2 HP 575 RPM TWO FANS WIDE 1/2 HP 575 RPM

MODEL 208/230/3/60 460/3/60 575/3/60 MODEL 208/230/3/60 460/3/60 575/3/60

LAVE11*** 3.4 1.7 1.2 - - - LAVE12*** 6.8 3.4 2.4 LAVE22*** 13.6 6.8 4.8

LAVE13*** 10.2 5.1 3.6 LAVE23*** 20.4 10.2 7.2

LAVE14*** 13.6 6.8 4.8 LAVE24*** 27.2 13.6 9.6

LAVE15*** 17.0 8.5 6.0 LAVE25*** 34.0 17.0 12.0

LEVE16*** 20.4 10.2 7.2 LEVE26*** 40.8 20.4 14.4

ONE FAN WIDE 1.5 HP 1140 RPM TWO FANS WIDE 1.5 HP 1140 RPM

MODEL 208/230/3/60 460/3/60 575/3/60 MODEL 208/230/3/60 460/3/60 575/3/60

LAVF11*** 7.0 3.5 2.4 - - - LAVF12*** 14.0 7.0 4.8 LAVF22*** 28.0 14.0 9.6

LAVF13*** 21.0 10.5 7.2 LAVF23*** 42.0 21.0 14.4

LAVF14*** 28.0 14.0 9.6 LAVF24*** 56.0 28.0 19.2

LAVF15*** 35.0 17.5 12.0 LAVF25*** 70.0 35.0 24.0

LEVF16*** 42.0 21.0 14.4 LEVF26*** 84.0 42.0 28.8

*** - Model number shown does not include rows or fins per inch.

For unit Minimum unit Circuit Amps (MCA) and Maximum unit Overload Protection (MOP)

consult the factory wiring diagram supplied with the unit.

Levitor Series II Air Cooled Condensers (PN E208035_B)

4

2.4 30” UNIT WEIGHTS AND REFRIGERANT CHARGES

The following table contain approximate unit shipping weights and refrigerant charges for the 30” fan

units. The Summer Charge is based on 25% of condenser volume with 86°F liquid. The Winter Charge

is based on 90% of condenser volume with –20°F liquid.

TABLE 3 30” UNIT WEIGHTS AND REFRIGERANT CHARGES

CONDENSER CHARGE (LBS)

APPROX. R - 22 R – 404A

UNIT WT. (LBS) SUMMER WINTER SUMMER WINTER

ONE FAN WIDE UNITS

LAV_112** 445 4.3 20.2 3.8 18.4

LAV_113** 480 6.5 30.4 5.7 27.6

LAV_114** 510 8.6 40.5 7.5 36.8

LAV_122** 730 8.3 39.1 7.3 35.5

LAV_123** 790 12.4 58.6 10.9 53.3

LAV_124** 860 16.6 78.2 14.6 71.1

LAV_132** 1060 12.3 58.0 10.8 52.7

LAV_133** 1150 18.5 86.9 16.2 79.0

LAV_134** 1250 24.6 115.9 21.6 105.4

LAV_143** 1475 24.5 115.2 21.5 104.7

LAV_144** 1600 32.6 153.8 28.6 139.8

LAV_153** 2070 30.4 143.4 26.7 130.4

LAV_154** 2220 40.6 191.3 35.6 173.9

LEV_163** 2610 68.1 320.7 59.7 291.5

LEV_164** 2860 90.7 427.6 79.6 388.7

TWO FAN WIDE UNITS

LAV_222** 1340 16.6 78.2 14.6 71.1

LAV_223** 1460 24.6 117.3 21.6 106.6

LAV_224** 1590 33.2 156.4 29.1 142.2

LAV_232** 1910 24.6 115.9 21.6 105.4

LAV_233** 2100 36.9 173.8 32.4 158.0

LAV_234** 2290 49.2 231.8 43.2 210.7

LAV_243** 2700 48.9 230.3 42.9 209.4

LAV_244** 2950 65.2 307.2 57.2 279.3

LAV_253** 3820 61.0 308.9 53.5 280.8

LAV_254** 4130 81.3 382.6 71.3 347.8

LEV_263** 4870 136.2 641.3 119.5 583.0

LEV_264** 5370 181.6 855.0 159.3 777.3

** - Fins per inch

_ - Motors A, C, E, or F

Levitor Series II Air Cooled Condensers (PN E208035_B)

5

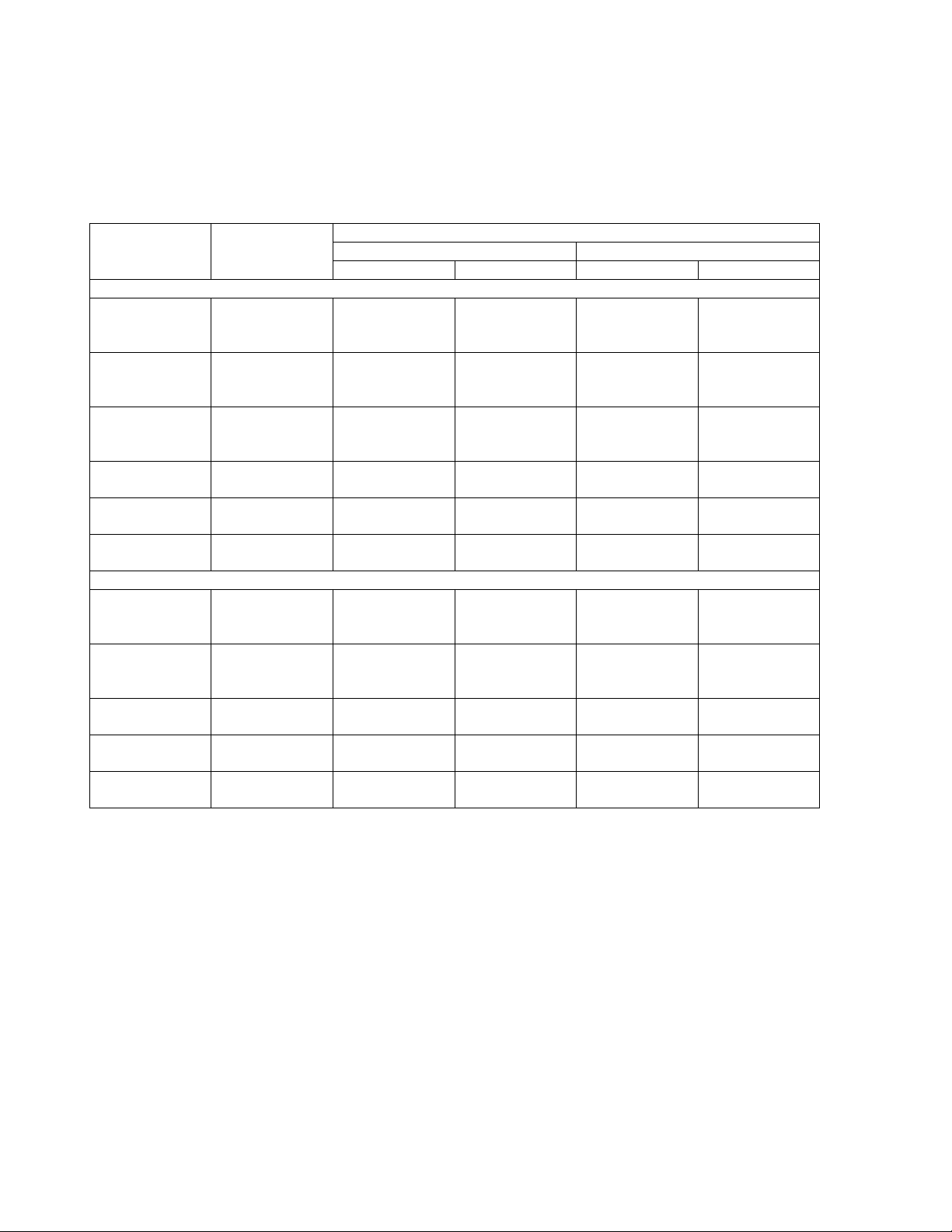

2.5 24” UNIT DIMENSIONS AND MOTOR AMPS

(2)

Figure 2 and Table 4 contain the overall dimensions, leg bolt hole locations, motor full load amps, and

weights for all of the units with 24” diameter fans.

Figure 2 24” UNIT DIMENSIONS

TABLE 4 24” UNIT DIMENSIONS, AMPS, AND WEIGHTS

TOTAL MOTOR FULL LOAD AMPS (1) FLOOD INCL.

DIM. CHARGE FLOOD

UNIT L 208/230/1 208-3 230-3 460-3 575 -3 (LBS)(R-22) CHRG. (LBS)

ONE FAN WIDE UNITS

LAVB11* 39 4.2 2.8 2.6 1.3 0.76 19 180

LAVB12* 75 8.4 5.6 5.2 2.6 1.52 39 360

LAVB13* 111 12.6 8.4 7.8 3.9 2.28 58 540

LAVB14* 147 16.8 11.2 10.4 5.2 3.04 86 720

LAVB15* 183 21.0 14.0 13.0 6.5 3.80 97 900

LAVB16* 219 25.2 16.8 15.6 7.8 4.56 116 1080

LAVB17* 262 29.4 19.6 18.2 9.1 5.32 144 1260

TWO FAN WIDE UNITS

- - - - - - - - LAVB22* 75 16.8 11.2 10.4 5.2 3.04 86 700

LAVB23* 111 25.2 16.8 15.6 7.8 4.56 116 1050

LAVB24* 147 33.6 22.4 20.8 10.4 6.08 172 1400

LAVB25* 183 42.0 28.0 26.0 13.0 7.60 194 1750

LAVB26* 219 50.4 33.6 31.2 15.6 9.12 232 2100

LAVB27* 262 58.8 39.2 36.4 18.2 10.64 288 2450

* - Model number shown does not include rows or fins per inch.

(1) For unit Minimum unit Circuit Amps (MCA) and Maximum unit Overload Protection (MOP)

consult the factory wiring diagram supplied with the unit.

(2) Values listed are for 4 Row units. For 3 Row units multiply by 0.75. For 2 Row units multiply

by 0.5.

WINTER WEIGHT

Levitor Series II Air Cooled Condensers (PN E208035_B)

6

3 UNIT LOCATION

The Levitor Series II units require adequate space to allow unrestricted ambient airflow in to and out of

the fan section. Figure 3 gives general rules of the location of an air-cooled condenser in different

situations. The distances shown in the sketches should be increased whenever possible. The unit

position relative to the prevailing winds should be taken into account. Note that higher than expected

head pressures will result in poor system operation if the following suggested distances are not used.

So that the unit performs as predicted it should be located away from heated air exhausts, steam vents,

or corrosive airflow, whether it comes from the job site, or from another nearby source. A corrosive

atmosphere will require an appropriate coil coating, or copper fins to protect the coil and extend the life

of the unit.

Unit location with regard to noise should also be considered. An air-cooled condensing unit should be

located away from noise and vibration sensitive spaces to avoid transmission into workspaces.

Figure 3 LOCATION REQUIREMENTS

Walls or Barriers Multiple Units

For proper airflow and access, all sides of the

unit should be a minimum of “W” away from

any wall or barrier. Enough space should be

allowed for all maintenance work. Overhead

obstructions are not allowed.

For units placed side by side, the minimum

distance between units is the width of the

largest unit. If units are placed end to end, the

minimum distance between units is one fan

section long.

Walls or Barriers for Horizontal Airflow Decorative Fences

Units with horizontal airflow should be a

minimum of “W” away from any wall or barrier,

plus the air discharge should be free flowing

away from the unit.

Fences must have 50% free area, with 1 foot

undercut, a “W” minimum clearance, and must

not exceed the top of the unit.

W = Total width of the air-cooled condensing unit.

Levitor Series II Air Cooled Condensers (PN E208035_B)

7

Loading...

Loading...