Krack KR14G-037 Installation Manual

G

G

a

a

s

s

D

D

K

K

effrr

e

R

R

o

o

S

S

stt

s

errii

e

U

niitt

U

n

e

e

s

s

C

C

o

o

oll

o

err

e

s

s

O

p

p

err

e

O

a

n

IIn

stt

M

s

M

allll

a

a

a

a

attii

a

n

d

n

attii

a

n

u

n

d

u

n

g

n

o

o

all

a

g

n

n

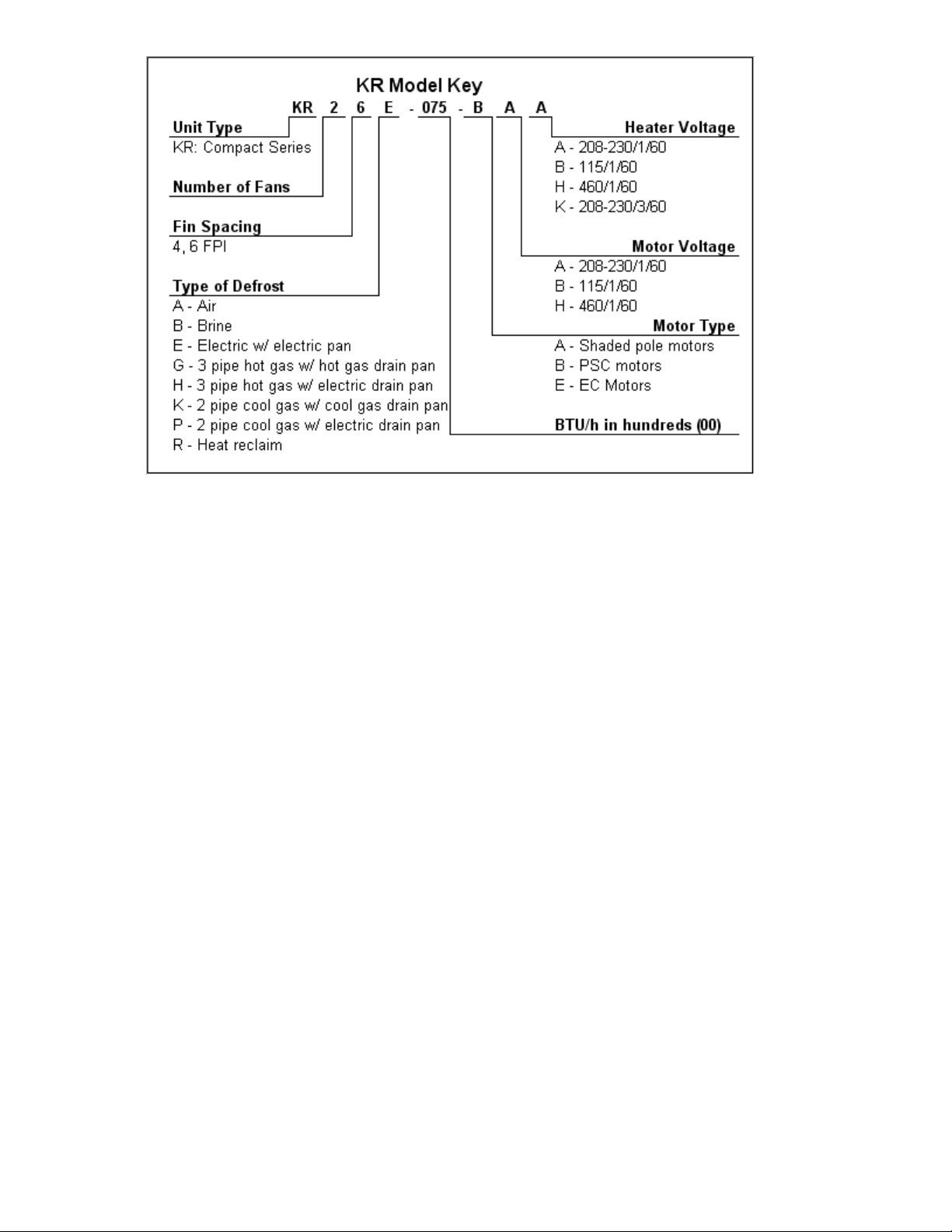

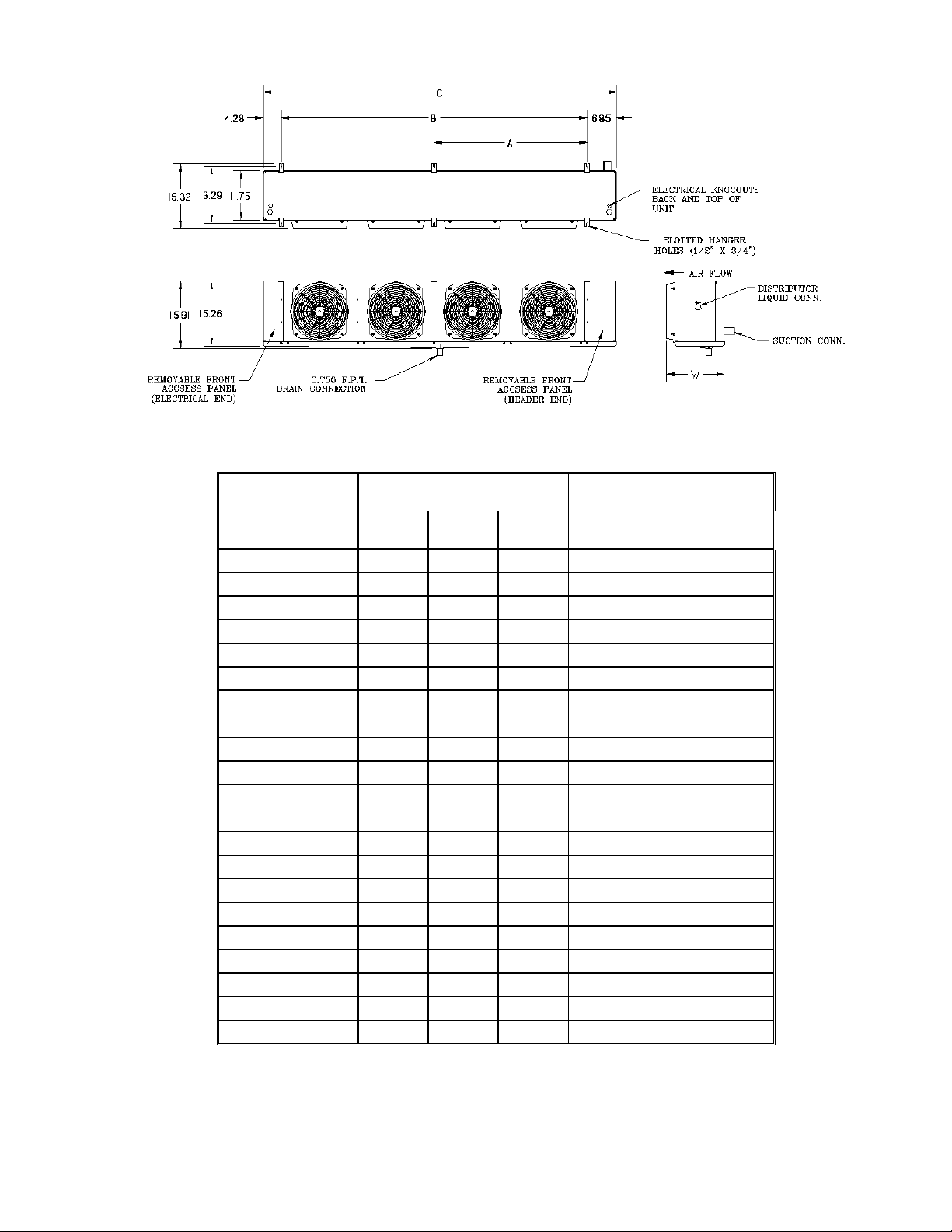

Gas Defrost Unit Coolers (E108319_D)

TABLE OF CONTENTS

1 LOCATION RECOMINDATIONS………………………………………………………………….2

2 UNIT MOUNTING…………………………………………………………………………………….2

3 DRAIN LINE………………………………………………………………………………………….3

4 REFRIGERATION PIPING………………………………………………………………………... 4

5 REFRIGERANT DISTRIBUTOR…………………………………………………………………...4

6 EXPANSION VALVE………………………………………………………………………………..6

7 WIRING……………………………………………………………………………………………….7

8 SEQUENCE OF OPERARIONS.………………………………………………………………….8

9 PRE-STARTUP………..………………………………………………………………………….…9

10 REPLACEMENT PARTS…………………………………………………………………………..9

CHARTS

TABLE 1 UNIT DIMENSIONS……………………………………………………………………….…3

TABLE 2 DISTRIBUTOR NOZZLES…………………………………………………………………. 5

TABLE 3 EXPANSIONS VALVES……………………………………………………………………..6

TABLE 4 FAN & HEATERS AMPERS………………………………………………………………...7

FIGURES

Figure 1 Unit Dimensions .............................................................................................................................. 3

Figure 2 H(HGE) – 3 Pipe Hot Gas Defrost with Electric Pan Heat ................................................. 9

Figure 3 G(HGG) – 3 Pipe Hot Gas Defrost with Hot Gas Pan Heat .............................................. 9

Figure 4 P(KGE) – 2Pipe Kool Gas Defrost with Electric Pan Heat ............................................. 10

Figure 5 K(KGG) – 2 Pipe Kool Gas Defrost with Gas Pan Defrost .............................................. 10

Figure 6 Wiring H(HGE)– 3 Pipe Hot Gas defrost with Electric Pan Heat ................................... 11

Figure 7 Wiring G(HGG) – 3 Pipe Hot Gas Defrost with Hot Gas Pan Heat ............................... 11

Figure 8 Wiring P(KGE) – 2 Pipe Kool Gas Defrost with Electric Pan Heat ................................ 12

Figure 9 Wiring K(KGG) – 2 Pipe Kool Gas Defrost with Gas Pan Defrost ............................................ 12

Gas Defrost Unit Coolers (E108319_D) 1

1 LOCATION RECOMMENDATIONS

Hot gas defrost unit coolers must have proper airflow to maintain a uniform room

temperature and have a complete defrost.

These units are draw thru design thus drawing air thru the cooling coil and discharging it

into the room via the unit fans. For best performance it is desirable to arrange the air

discharge toward the door of the cooler to minimize the entrance of warm moist air when

the door is open. The unit must be at least 12 inches from the wall to assure proper air

intake.

2 UNIT MOUNTING

The unit cooler may be suspended with 3/8" diameter hanger rods or flush mounted to

the ceiling using 5/16 minimum lag screws with flat washers. Rods should be double

nutted top and bottom.

The unit must be level in all directions to insure proper drainage of condensate.

Suspended units must have sufficient clearance above for cleaning the top.

Gas Defrost Unit Coolers (E108319_D) 2

Figure 1 Unit Dimensions

MODEL

NUMBERS

DIMENSIONS (INCHES)

CONNECTIONS ODS (IN)

A B C

LIQUID

SUCTION

KR14*-037

-

18

29-1/8

1/2

5/8

KR24*-065

-

36

47-1/8

1/2

7/8

KR24*-074

-

36

47-1/8

1/2

7/8

KR34*-111

-

54

65-1/8

1/2

7/8

KR44*-148

36

72

83-1/8

1/2

1-1/8

KR54*-185

36

90

101-1/8

1/2

1-1/8

KR64*-213

54

108

119-1/8

1/2

1-1/8

KR64*-220

54

108

119-1/8

1/2

1-1/8

KR16*-035

-

18

29-1/8

1/2

5/8

KR16*-041

-

18

29-1/8

1/2

5/8

KR16*-045

-

18

29-1/8

1/2

5/8

KR26*-067

-

36

47-1/8

1/2

7/8

KR26*-075

-

36

47-1/8

1/2

7/8

KR26*-090

-

36

47-1/8

1/2

7/8

KR36*-126

-

54

65-1/8

1/2

7/8

KR36*-135

-

54

65-1/8

1/2

7/8

KR46*-160

36

72

83-1/8

1/2

1-1/8

KR46*-180

36

72

83-1/8

1/2

1-1/8

KR56*-192

36

90

101-1/8

1/2

1-1/8

KR66*-240

54

108

119-1/8

1/2

1-1/8

KR66*-270

54

108

119-1/8

1/2

1-1/8

Table 1 Unit Dimensions and Connection Sizes

Table1 lists mounting dimensions and sizes of suction, liquid and drain connections.

* May be G, H, K or P depending on type of defrost and type of

drain pan heat.

Gas Defrost Unit Coolers (E108319_D) 3

3 DRAIN LINE

The drain line should be as short and as steeply pitched as possible with a minimum of

1/4" drop per running foot. Any traps in the drain line must be located in an ambient

above freezing. If the temperature surrounding the trap or drain line is below freezing it

must be wrapped with a drain line heater. Be sure to also wrap the unit drain coupling.

Cover the drain line, drain coupling and heat tape with insulation. Be sure to follow the

manufacturer's recommendation when installing the drain line heat tape.

A union is recommended for ease of installation and future servicing. The union should

be located as close to the drain pan as possible. Use two wrenches when tightening to

prevent the drain fitting from twisting and damaging the unit.

Support long runs of drain line (i.e. more than a few feet) by hangers to avoid damage to

the drain pan.

4 REFRIGERATION PIPING

System design must conform to all codes, laws and regulations applying to the site of

installation. In addition the safety code for mechanical refrigeration.

Refrigerant line sizes and piping techniques should be obtained from the ASHRAE

Guide or equivalent reference. Under no circumstances should the refrigerant

connection size of the unit be used as the basis for sizing the lines.

The horizontal suction line should slope away from the unit toward the compressor.

Vertical suction risers may require a trap at the bottom of the riser for proper oil return.

There are two typical methods of defrosting a unit with hot gas. Figures 1 and 2 show

typical piping arrangements for 3 pipe hot gas defrost. Figures 3 and 4 show typical

piping arrangements for reverse cycle defrost.

For Food Service installations – seal any joint between unit cooler and cooler wall with a

sealant Listed by the National Sanitation Foundation.

5 REFRIGERANT DISTRIBUTOR

Distributor nozzles are included using a refrigerant distributor with a changeable nozzle

design. The nozzle(s) are packed in individual plastic envelopes along with a retainer

ring and instruction card. The instruction card tells what refrigerant the nozzle is to be

used with. There may be 1, 2 or 3 envelopes with nozzles located near the distributor.

The nozzles provided with the unit have been selected for design conditions of 9°F to

11°F T.D. and 95°F liquid refrigerant at the expansion valve inlet. If the unit will be

operated at conditions that are substantially different from these conditions, it may be

necessary to select a different size nozzle. Contact the factory for advice.

The nozzle must be installed before the expansion valve is installed. There are nozzle

identification numbers stamped on one side of the nozzle. Be sure to insert the nozzle

into the distributor with these numbers visible in case identification is required later. The

nozzle is held in place by a retainer ring that is easily inserted or removed with a pair of

needle nose pliers.

Gas Defrost Unit Coolers (E108319_D) 4

Loading...

Loading...