Large Air-Cooled

Commercial Condensing Units

Technical Bulletin: LACC_001_071015

Products that provide lasting solutions.

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

Specifications subject to change without notice.

Large Air-Cooled Commercial Condensing Units

Table of Contents

Model Introduction

Nomenclature 2

Features for All Models 2

CSD Single Systems

CSD High Temperature R-22 (H2) 4

CSD Medium Temperature R-404A (M4) 5

CSD Low Temperature R-22 (L2) 6

CSD Low Temperature R-404A (L4) 7

CPD Parallel Systems

CPD High Temperature R-22 (H2) 8

CPD Medium Temperature R-404A (M4) 9

CPD Low Temperature R-22 (L2) 10

CPD Low Temperature R-404A (L4) 1 1

CDD Dual Systems

CDD High Temperature R-22 (H2) 12

CDD Medium Temperature R-404A (M4) 14

CDD Low Temperature R-22 (L2) 15

CDD Low Temperature R-404A (L4) 15

Model Specifications

CS Series 16

CP Series 17

CD Series 18

Dimensional Drawings

A and B Single Systems 19

C and D Single Systems 20

E Single Systems 2 1

F and G Parallel and Dual Systems 22

H, I, J, K, L and M Parallel and Dual Systems 23

Warranty

Please refer to our website at www.krack.com

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

Specifications subject to change without notice.

1

Model Introduction

Nomenclature

CONDENSING UNIT FAMILY:

CS – Single Compressor

CP – Parallel Compressors

CD – Dual Compressors

COMPRESSOR MANUFACTURER:

D – Copeland Discus

I – Bitzer Semi-Hermetic*

V – Copeland Screw (Consult Factory)

Total HP:

0100 = 10 HP w/Standard Condenser

0101 = 10 HP w/Oversized Condenser

0700 = (2) 35 HP w/Standard Condenser

0701 = (2) 35 HP w/Oversized Condenser

* Consult factory for special request.

CP

I - 0700 H2M

VOLTAGE:

K – 208-230/3/60

M – 460/3/60

P – 575/3/60

U – 380/3/50

REFRIGERANT:

2 (V) – R-22

4 (S) – R-404A

7 (P) – R-507

TEMPERATURE:

H – High

M – Medium

L – Low

Standard Features for All Models

Large Air-Cooled Condensing Units Available in Standard and High Capacity Model Configurations

n

High Temperature R-22

n

Medium Temperature R-404A and R-507

n

Low Temperature R-404A and R-507

n

Low Temperature R-22

Models

n

CSD Series Units are new, more efficiently sized units that have a reduced footprint,

more standard features and provide increased options for sizing large jobs.

n

CPD Series Parallel Units are two compressors piped together to provide one circuit.

n

CDD Series Dual Units are two compressors piped independently for a separate circuit operation.

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

2

Specifications subject to change without notice.

Model Introduction

Standard Features for All Models

Compressor

n

Bitzer Compressors or Copeland Discus Compressors

(CSD, CPD and CDD models).

n

Factory balanced and rigid mounted to reduce risk

of line fatigue failure and vibration eliminator leaks.

n

Internal motor overheat protection.

n

Crankcase heater is de-energized during compressor

operation for energy savings.

n

Oil level sight glass.

n

CSD, CPD and CDD models use an internal driven

shaft oil pump with manual reset oil safety control.

n

Back-seating suction and discharge valves.

n

Safety controls are factory installed using high

armored capillary tube to prevent cap tube leaks.

- Automatic reset low pressure control.

- Manual reset high pressure control.

Receiver

n

Amply sized to allow for unit flooding charge,

evaporator and 100 ft. liquid line.

- Pressure relief valve.

- Charging valve.

Condenser

n

Constructed with 3/8” grooved tubing for

maximum efficiency.

n

Separate sub-cooling circuit is piped through

receiver to insure liquid at TEV.

n

Adjustable head pressure system (flooding) for

low ambient operation.

n

Mechanically bonded, die formed, aluminum fin

stock with full self-spacing collars.

n

Maximum 10 FPI for efficiency and ease of

maintenance.

n

Generous sizing allows low head pressure operation.

n

Oversized, high capacity condenser option for critically

high ambient or capacity requirements.

n

Suspended coil design eliminates tube sheet leaks.

Fans

n

30” statically and dynamically balanced direct

drive fans with a separate motor for each fan.

n

Fan sections are divided by full width baffles to

prevent air by-pass.

n

Standard three phase, 1.5 HP motor achieves 1140 RPM.

n

Each fan is protected by a heavy gauge, corrosion

resistant fan guard.

n

Inverter Duty Suitable motor – K&M voltage

compatible.

Control Panel

n

Fully enclosed and weather proofed.

n

Single point connections provide reliable distribution

to panel components.

n

Dual compartments, separate line voltage and controls

for safety during service.

n

Lockable with field supplied padlock.

n

Manual pump down switch for ease of service.

n

230V; single phase control voltage is standard.

- A transformer is included where necessary.

n

Power and control circuit terminal strip.

Refrigerant Circuit

n

Replaceable core liquid line filter drier.

n

Sight glass at receiver outlet for charging.

n

Suction accumulator is included on L2, L4

and L7 units.

Construction Features

n

Galvanized cabinet.

Optional Features

n

115 control voltage with transformer.

n

Oil separator system to activate flow of oil.

(Recommended for room temperatures of -10°F

and below.)

n

Suction accumulator (medium/high temperature).

n

Replaceable core suction filter.

n

Heated and insulated receiver.

n

Electrical control panel with all necessary controls

to run electric defrost evaporators (includes timer,

contactors).

n

Air defrost timer.

n

Fused disconnect shipped loose.

n

Mounted non-fused disconnect with interlock.

n

Cylinder unloaders for compressors.

n

Alternate fin materials, such as vinyl and copper, can

be specified for adverse environmental conditions.

n

1.5 HP 850 RPM with low noise fan blades.

n

Condenser access/clean out doors.

n

Screw compressor offers available, consult factory.

Note

n

Additional information will be given per model on

their respective pages.

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

Specifications subject to change without notice.

3

CSD Single Systems

105˚F

192.2

213.8

237.0

262.1

288.9

317.7

348.5

381.3

105˚F

193.6

215.5

239.2

264.7

292.1

321.6

353.2

386.9

4DA3R18ME

4DH3R22ME

4DJ3R28ME

6DH3R35ME

6DJ3R40ME

8DP1-5000**

CSD Performance Data

3DB3R12ME

8DS1-6000**

6DJ3R40ME

8DP1-5000**

MODEL

MODEL

COMPRESSOR

3DB3R12ME

3DS3R17ME

8DS1-6000**

COMPRESSOR

3DS3R17ME

4DA3R18ME

4DH3R22ME

4DJ3R28ME

6DH3R35ME

59.6 14.0 88.5 110 29.0 7.0 43.3 50 23.6 4.8 34.3 45 59.6 14.0 88.5 110 29.0 7.0 43.3 50 23.6 4.8 34.3 45

208-230/3/60

460/3/60

575/3/60

208-230/3/60

460/3/60

575/3/60

CSD Electric Data

MODEL

COMPRESSOR

MODEL

COMPRESSOR

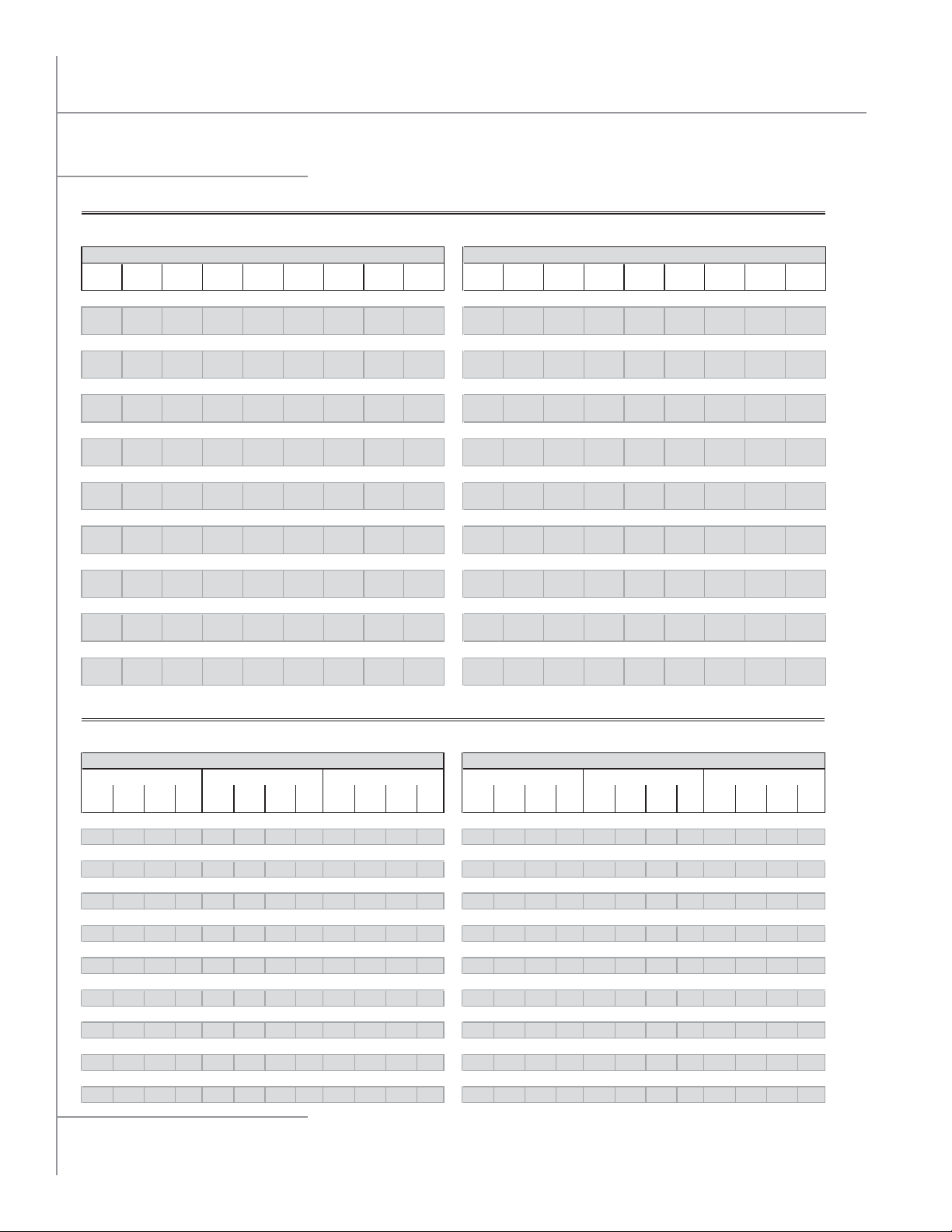

CSD High Temp R-22 (H2)

STANDARD CONDENSER OVERSIZED CONDENSER

AMB˚F10 ˚F

MBH

15 ˚F

MBH

20 ˚F

MBH

25 ˚F

MBH

30 ˚F

MBH

35 ˚F

MBH

40 ˚F

MBH

45 ˚F

MBH

AMB˚F10 ˚F

MBH

CSD0100H2 CSD0101H2

95˚F

77.1

85.9

95.3

105.4

116.2

127.6

139.9

105˚F

71.9

80.1

88.9

98.4

108.5

119.2

130.6

152.8

142.8

95˚F

105˚F

79.1

73.9

CSD0150H2 CSD0151H2

95˚F

103.2

115.1

127.9

141.5

156.1

171.6

188.2

105˚F

97.0

108.2

120.0

132.7

146.3

160.7

176.1

205.8

192.5

95˚F

105˚F

104.3

98.1

CSD0200H2 CSD0201H2

95˚F

108.2

121.5

135.9

151.4

168.1

186.1

205.3

105˚F

101.6

113.7

126.8

141.0

156.2

172.5

190.0

225.8

208.7

95˚F

105˚F

109.4

102.9

CSD0250H2 CSD0251H2

95˚F

138.2

156.1

175.4

195.9

217.4

239.7

262.6

105˚F

127.3

144.0

162.1

181.4

201.7

222.7

244.3

285.9

266.3

95˚F

105˚F

139.0

129.0

CSD0300H2 CSD0301H2

95˚F

163.8

184.0

205.7

228.8

253.2

279.0

306.0

105˚F

152.3

170.9

190.9

212.4

235.1

259.2

284.4

334.1

310.7

95˚F

105˚F

166.7

155.2

CSD0350H2 CSD0351H2

95˚F

205.9

229.1

254.2

281.1

310.1

341.2

374.4

409.7

95˚F

207.3

CSD0400H2 CSD0401H2

95˚F

247.2

275.1

304.8

336.3

369.4

404.3

440.8

105˚F

231.5

257.3

284.7

313.8

344.4

376.6

410.3

479.0

445.5

95˚F

105˚F

253.0

237.2

CSD0500H2 CSD0501H2

95˚F

311.4

347.2

386.1

428.3

473.7

522.4

574.5

105˚F

290.1

323.7

360.4

400.1

443.0

489.0

538.3

630.0

590.8

95˚F

105˚F

319.1

297.7

CSD0600H2 CSD0601H2

95˚F

358.0

401.4

448.0

497.8

550.6

606.3

665.0

105˚F

330.5

370.6

413.6

459.5

508.2

559.7

613.7

726.3

670.2

95˚F

105˚F

367.0

339.9

15 ˚F

MBH

88.3

82.5

116.5

109.5

123.0

115.5

158.1

146.1

187.6

174.6

230.9

282.4

264.6

356.3

332.8

412.4

382.2

20 ˚F

MBH

98.2

91.9

129.6

121.7

137.9

129.1

177.9

164.6

210.1

195.6

256.4

313.9

293.8

397.0

371.3

461.5

427.9

25 ˚F

MBH

108.8

101.9

143.7

134.8

154.0

143.9

198.9

184.4

234.2

218.1

283.9

347.5

325.0

441.2

413.1

514.1

477.0

30 ˚F

MBH

120.3

112.7

158.8

148.8

171.4

159.9

221.0

205.2

259.8

242.0

313.5

383.1

358.1

488.9

458.4

570.4

529.4

35 ˚F

MBH

132.5

124.2

174.9

163.8

190.2

177.2

243.9

226.8

286.8

267.4

345.3

420.9

393.2

540.5

507.3

630.2

585.1

40 ˚F

MBH

145.7

136.6

192.2

179.9

210.5

195.8

267.5

249.1

315.2

294.2

379.3

460.8

430.3

595.5

559.8

693.6

644.1

45 ˚F

MBH

159.7

149.8

210.6

197.0

232.2

215.8

291.5

271.8

345.0

322.2

415.6

502.9

469.3

654.6

616.0

760.5

706.4

STANDARD CONDENSER OVERSIZED CONDENSER

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

CSD0100H2 3DB3R12ME CSD0101H2 3DB3R12ME

43.6 7.0 61.5 80 20.0 3.5 28.5 35 16.5 2.4 23.0 30 43.6

CSD0150H2 3DS3R17ME CSD0151H2 3DS3R17ME

CSD0200H2 4DA3R18ME CSD0201H2 4DA3R18ME

66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.7 4.8 35.7 45 66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.7 4.8 35.7 45

CSD0250H2 4DH3R22ME CSD0251H2 4DH3R22ME

82.2 14.0 116.8 150 41.1 7.0 58.4 70 34.4 4.8 47.8 60 82.2 21.0 123.8 150 41.1 10.5 61.9 80 34.4 7.2 50.2 60

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

14.0 68.5 90 20.0 7.0 32.0 40 16.5 4.8 25.4 30

FLA

MCA*

AMPS

CSD0300H2 4DJ3R28ME CSD0301H2 4DJ3R28ME

94.0 14.0 131.5 175 47.0 7.0 65.8 80 39.3 4.8 53.9 70 94.0 21.0 138.5 175 47.0 10.5 69.3 90 39.3 7.2 56.3 70

CSD0350H2 6DH3R35ME CSD0351H2 6DH3R35ME

125.2 21.0 177.5 225 62.6 10.5 88.8 110 42.5 7.2 60.3 70 125.2 21.0 177.5 225 62.6 10.5 88.8 110 42.5 7.2 60.3 70

CSD0400H2 6DJ3R40ME CSD0401H2 6DJ3R40ME

142.0 21.0 198.5 250 71.0 10.5 99.3 125 53.5 7.2 74.1 100 142.0 28.0 205.5 250 71.0 14.0 102.8 125 53.5 9.6 76.5 100

CSD0500H2 8DP1-5000** CSD0501H2 8DP1-5000**

180.0 28.0 253.0 300 90.0 14.0 126.5 150 75.0 9.6 103.4 125 180.0 42.0 267.0 350 90.0 21.0 133.5 175 75.0 14.4 108.2 125

CSD0600H2 8DS1-6000** CSD0601H2 8DS1-6000**

224.0 42.0 322.0 400 112.0 21.0 161.0 200 80.0 14.4 114.4 150 224.0 42.0 322.0 400 112.0 21.0 161.0 200 80.0 14.4 114.4 150

** 8 cylinder compressor shipped with mineral oil. Refer to additional notes on page 17.

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

4

Specifications subject to change without notice.

MIN*

BKR

CSD Single Systems

105˚F

71.0

79.4

88.4

98.0

108.1

119.0

130.4

N/A

N/A

105˚F

2.2

80.9

90.2

100.2

110.9

122.4

134.6

147.6

161.3

CSD Performance Data

MODEL

MODEL

3DS3R17ME

4DA3R18ME

4DH3R22ME

4DJ3R28ME

6DH3R35ME

6DJ3R40ME

3DS3R17ME

4DA3R18ME

4DH3R22ME

4DJ3R28ME

6DH3R35ME

6DJ3R40ME

59.6 14.0 88.5 110 29.0 7.0 43.3 50 23.6 4.8 34.3 45 59.6 14.0 88.5 110 29.0 7.0 43.3 50 23.6 4.8 34.3 45

208-230/3/60

460/3/60

575/3/60

208-230/3/60

460/3/60

575/3/60

CSD Electric Data

MODEL

COMPRESSOR

MODEL

COMPRESSOR

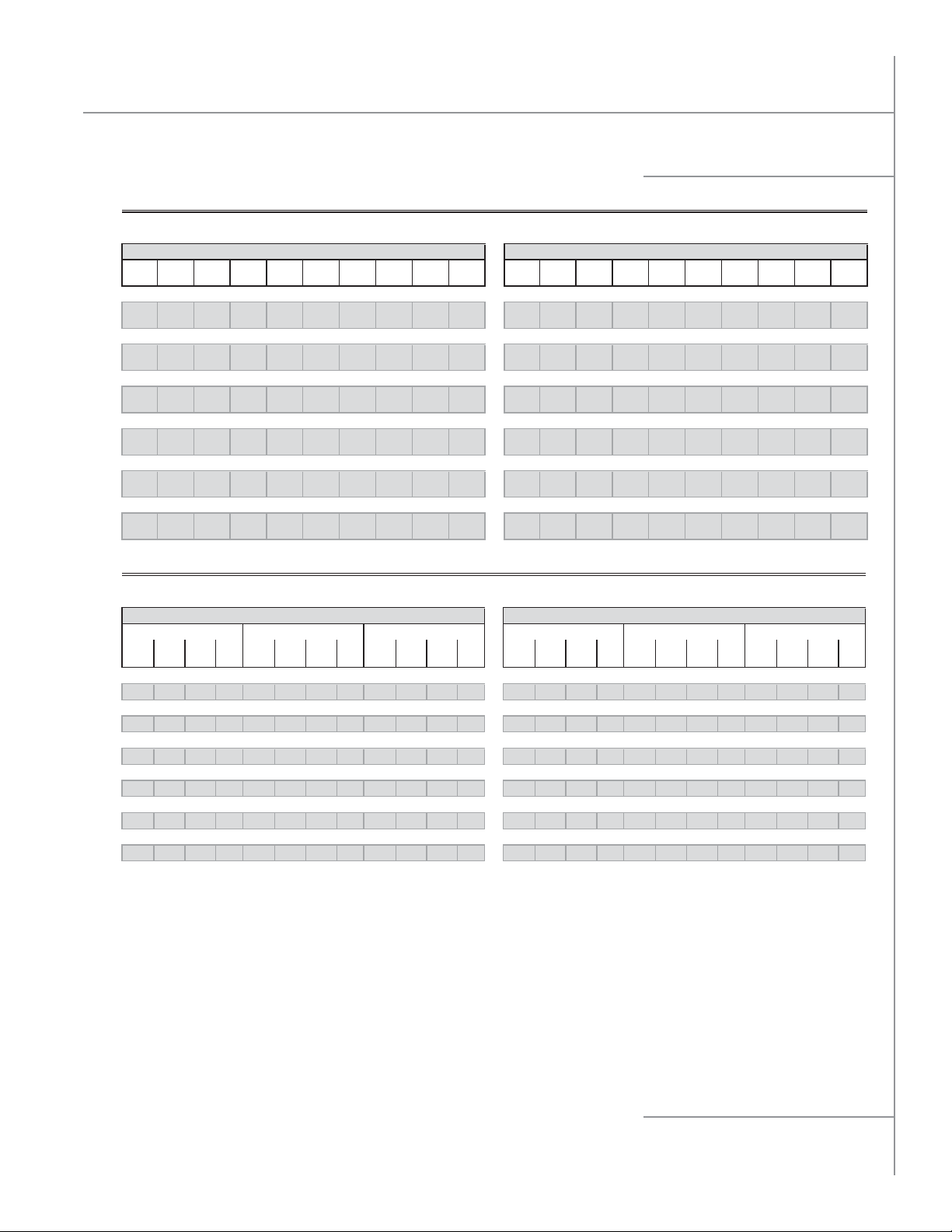

CSD Medium Temp R-404A (M4)

STANDARD CONDENSER OVERSIZED CONDENSER

AMB˚F-5 ˚F

MBH

0 ˚F

MBH

CSD0150M4 CSD0151M4

95˚F

78.0

87.2

CSD0200M4 CSD0201M4

95˚F

78.7

69.6

88.7

78.5

105˚F

CSD0250M4 CSD0251M4

95˚F

103.4

93.5

115.3

104.1

105˚F

CSD0300M4 CSD0301M4

95˚F

122.0

110.5

137.2

124.0

105˚F

CSD0350M4 CSD0351M4

95˚F

152.7

136.9

170.8

153.4

105˚F

CSD0400M4 CSD0401M4

95˚F

185.8

168.1

207.5

187.8

105˚F

COMPRESSOR COMPRESSOR

5 ˚F

10 ˚F

15 ˚F

20 ˚F

25 ˚F

30 ˚F

MBH

97.2

99.7

88.3

128.8

116.2

153.6

138.5

190.2

170.9

231.0

208.9

MBH

107.8

111.4

98.8

143.6

129.5

171.0

154.0

210.8

189.4

256.1

231.5

MBH

119.3

123.9

110.0

159.5

143.7

189.6

170.5

232.7

208.9

282.8

255.4

MBH

131.4

137.2

121.9

176.2

158.8

209.2

187.9

255.8

229.3

311.0

280.7

MBH

144.4

151.0

134.3

193.5

174.5

229.8

206.2

280.1

250.8

340.6

307.1

MBH

158.0

165.4

N/A

211.3

N/A

251.4

N/A

305.6

N/A

371.5

N/A

35 ˚F

MBH

172.5

180.3

N/A

229.3

N/A

273.8

N/A

332.3

N/A

403.6

N/A

AMB˚F-5 ˚F

95˚F

95˚F

105˚F

95˚F

106.2

105˚F

95˚F

124.7

105˚F

113.1

95˚F

160.3

105˚F

144.2

95˚F

190.0

105˚F

172.2

MBH

79.2

80.5

71.2

96.3

0 ˚F

MBH

88.7

91.0

80.6

119.0

107.7

140.7

127.3

180.0

162.3

212.7

192.8

5 ˚F

MBH

99.0

102.4

90.8

133.5

120.6

157.9

142.6

201.3

181.7

237.3

215.1

10 ˚F

MBH

110.2

114.7

101.9

149.4

134.9

176.5

159.2

224.3

202.6

263.8

239.1

15 ˚F

MBH

122.1

128.0

113.7

166.6

150.3

196.3

176.9

249.2

225.0

292.2

264.7

20 ˚F

MBH

135.0

142.0

126.4

184.7

166.8

217.4

195.7

275.9

249.0

322.3

291.8

25 ˚F

MBH

148.7

156.8

139.6

203.8

184.0

239.7

215.7

304.5

274.6

354.2

320.6

30 ˚F

MBH

163.3

172.2

153.5

223.4

201.7

263.3

236.7

335.0

301.9

387.7

350.7

35 ˚F

MBH

178.9

188.3

168.0

243.5

219.9

288.0

258.9

367.6

330.9

422.8

382.3

STANDARD CONDENSER OVERSIZED CONDENSER

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

MIN*

BKR

CSD0150M4 3DS3R17ME CSD0151M4 3DS3R17ME

CSD0200M4 4DA3R18ME CSD0201M4 4DA3R18ME

66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.7 4.8 35.7 45 66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.7 4.8 35.7 45

CSD0250M4 4DH3R22ME CSD0251M4 4DH3R22ME

82.2 14.0 116.8 150 41.1 7.0 58.4 70 34.4 4.8 47.8 60 82.2 21.0 123.8 150 41.1 10.5 61.9 80 34.4 7.2 50.2 60

CSD0300M4 4DJ3R28ME CSD0301M4 4DJ3R28ME

94.0 14.0 131.5 175 47.0 7.0 65.8 80 39.3 4.8 53.9 70 94.0 21.0 138.5 175 47.0 10.5 69.3 90 39.3 7.2 56.3 70

CSD0350M4 6DH3R35ME CSD0351M4 6DH3R35ME

125.2 21.0 177.5 225 62.6 10.5 88.8 110 42.5 7.2 60.3 80 125.2 28.0 184.5 225 62.6 14.0 92.3 110 42.5 9.6 62.7 80

CSD0400M4 6DJ3R40ME CSD0401M4 6DJ3R40ME

142.0 21.0 198.5 250 71.0 10.5 99.3 125 53.5 7.2 74.1 100 142.0 28.0 205.5 250 71.0 14.0 102.8 125 53.5 9.6 76.5 100

NOTES PERTAIN TO BOTH R-22 and R-404A:

1. *Minimum circuit amps and minimum circuit breaker sizes are based on Air Defrost system which utilizes a separate power

supply for evaporator fans. If evaporators are Electric Defrost with its power supply furnished through the condensing

unit, evaporator fan amps must be added to both the condensing unit minimum circuit amps and minimum breaker size.

When calculating Minimum Circuit Amps (MCA) on Electric Defrost systems, use the larger of:

1) Minimum condenser amps + evaporator fan amps or 2) Evaporator defrost heater amps x 1.25.

2. Condensing unit capacities based on LAVF condensers.

3. FOR R-404A ONLY: May also be used with R-507. For capacity, multiply by 1.03.

4. FOR MEDIUM TEMPERATURE R-404A (M4) ONLY: 15, 20, 25, 30 HP units also available with optimized compressors.

Contact factory for electrical specs.

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

Specifications subject to change without notice.

5

CSD Single Systems

105˚F

33.8

42.0

50.3

58.8

67.8

77.8

89.0

101.6

116.1

105˚F

34.2

42.6

51.0

59.6

68.9

79.1

90.6

103.6

118.4

6DL3F93KE

CSD Performance Data

MODEL

MODEL

4DL3F63KE

4DT3F76KE

6DT3F11ME

4DL3F63KE

4DT3F76KE

6DL3F93KE

6DT3F11ME

208-230/3/60

460/3/60

575/3/60

208-230/3/60

460/3/60

575/3/60

CSD Electric Data

MODEL

COMPRESSOR

MODEL

COMPRESSOR

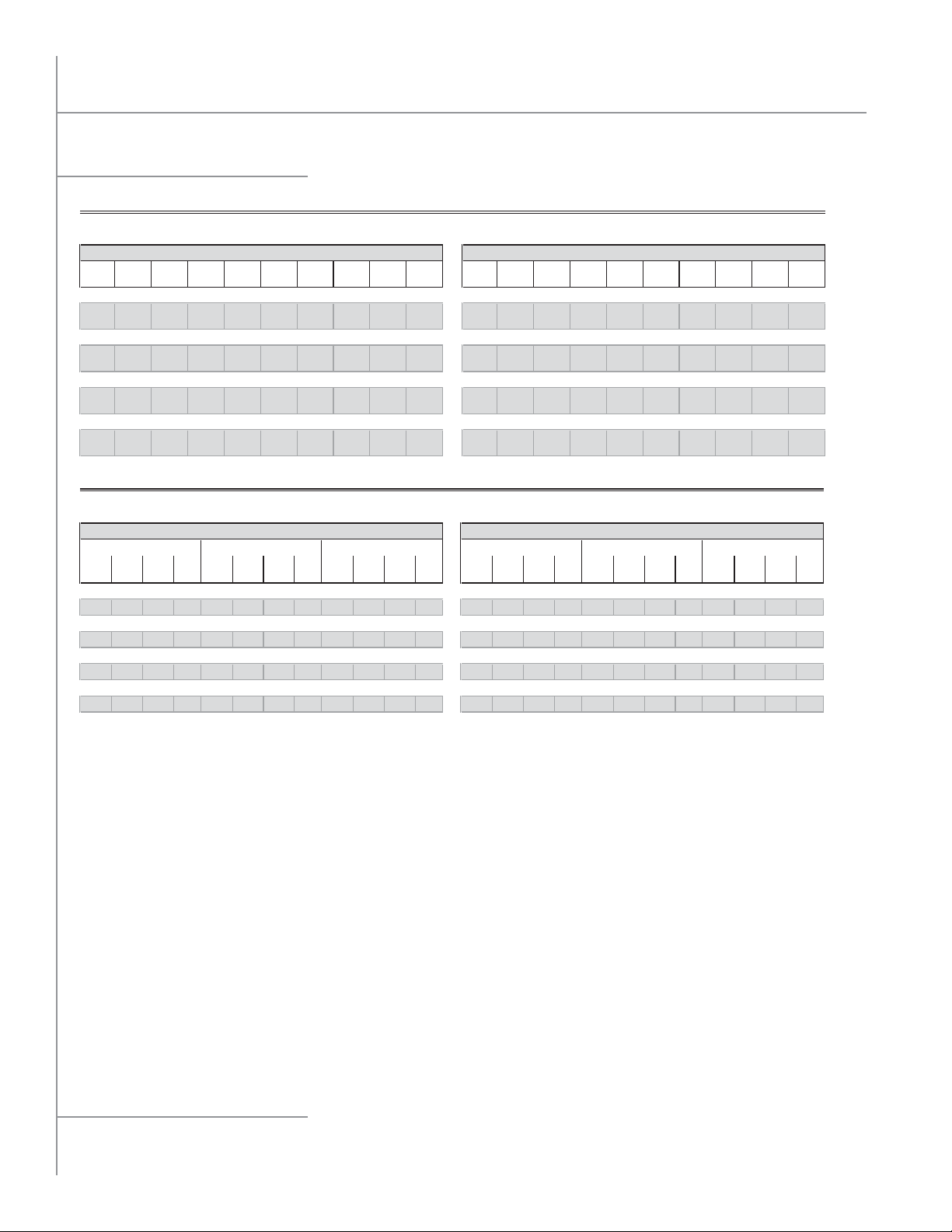

CSD Low Temp R-22 (L2)

STANDARD CONDENSER OVERSIZED CONDENSER

AMB˚F-40˚F

MBH

-35˚F

MBH

CSD0150L2 CSD0151L2

95˚F

30.7

26.2

37.5

32.7

105˚F

CSD0220L2 CSD0221L2

95˚F

37.9

46.5

CSD0270L2 CSD0271L2

95˚F

46.3

40.0

57.2

50.6

105˚F

CSD0300L2 CSD0301L2

95˚F

56.1

50.5

68.6

62.3

105˚F

STANDARD CONDENSER OVERSIZED CONDENSER

COMPRESSOR COMPRESSOR

-30˚F

-25˚F

-20˚F

-15˚F

-10˚F

-5 ˚F

MBH

44.9

39.6

55.1

68.4

61.4

81.4

74.2

MBH

52.8

47.1

64.0

80.3

72.8

94.7

86.5

MBH

61.4

55.2

73.7

92.9

84.8

109.0

99.8

MBH

70.7

64.0

84.2

106.6

97.9

124.7

114.2

MBH

80.9

73.6

96.1

121.5

112.0

142.0

130.2

MBH

91.9

84.1

109.6

137.9

127.5

161.4

148.1

0 ˚F

MBH

104.0

95.6

124.9

155.9

144.5

183.2

168.1

AMB˚F-40˚F

MBH

95˚F

31.5

105˚F

27.0

95˚F

38.3

95˚F

46.8

105˚F

40.5

95˚F

57.2

105˚F

51.7

-35˚F

MBH

38.5

33.7

47.0

57.8

51.2

70.0

63.8

-30˚F

MBH

46.1

40.8

55.7

69.1

62.2

83.0

76.2

-25˚F

MBH

54.2

48.6

64.8

81.1

73.7

96.8

89.1

-20˚F

MBH

63.1

57.0

74.6

93.9

85.9

111.6

102.9

-15˚F

MBH

72.8

66.2

85.4

107.7

99.1

128.0

118.2

-10˚F

MBH

83.3

76.2

97.5

122.9

113.5

146.2

135.2

-5 ˚F

MBH

94.8

87.2

111.3

139.5

129.3

166.7

154.3

0 ˚F

MBH

107.3

99.2

127.0

157.8

146.7

189.8

175.9

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

MCA*

AMPS

CSD0150L2 4DL3F63KE CSD0151L2 4DL3F63KE

52.6 7.0 72.8 90 26.3 3.5 36.4 45 20.9 2.4 28.5 35 52.6

14.0 79.8 100 26.3 7.0 39.9 50 20.9 4.8 30.9 40

CSD0220L2 4DT3F76KE CSD0221L2 4DT3F76KE

66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.2 4.8 35.1 45 66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.2 4.8 35.1 45

CSD0270L2 6DL3F93KE CSD0271L2 6DL3F93KE

80.8 14.0 115.0 150 40.4 7.0 57.5 70 32.5 4.8 45.4 60 80.8 21.0 122.0 150 40.4 10.5 61.0 80 32.5 7.2 47.8 60

CSD0300L2 6DT3F11ME CSD0301L2 6DT3F11ME

95.6 14.0 133.5 175 47.8 7.0 66.8 90 39.6 4.8 54.3 70 95.6 21.0 140.5 175 47.8 10.5 70.3 90 39.6 7.2 56.7 70

NOTES PERTAIN TO BOTH R-22 and R-404A:

1. * Minimum circuit amps and minimum circuit breaker sizes are based on Air Defrost system which utilizes a separate power

supply for evaporator fans. If evaporators are Electric Defrost with its power supply furnished through the condensing unit,

evaporator fan amps must be added to both the condensing unit minimum circuit amps and minimum breaker size.

When calculating Minimum Circuit Amps (MCA) on Electric Defrost systems, use the larger of:

1) Minimum condenser amps + evaporator fan amps or 2) Evaporator defrost heater amps x 1.25.

2. Condensing unit capacities based on LAVF condensers.

3. FOR R-404A ONLY: May also be used with R-507. For capacity, multiply by 1.03.

MIN*

BKR

6

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

Specifications subject to change without notice.

CSD Single Systems

105˚F

36.6

43.5

50.3

57.3

64.5

72.1

80.3

89.1

98.7

105˚F

37.5

44.7

51.8

59.1

66.7

74.8

83.5

93.0

103.5

6DL3F93KE

CSD Performance Data

MODEL

MODEL

4DL3F63KE

4DT3F76KE

6DT3F11ME

4DL3F63KE

4DT3F76KE

6DL3F93KE

6DT3F11ME

14.0 79.8 90 26.3 7.0 39.9 50 20.9 4.8 30.9 35

208-230/3/60

460/3/60

575/3/60

208-230/3/60

460/3/60

575/3/60

CSD Electric Data

COMPRESSOR

COMPRESSOR

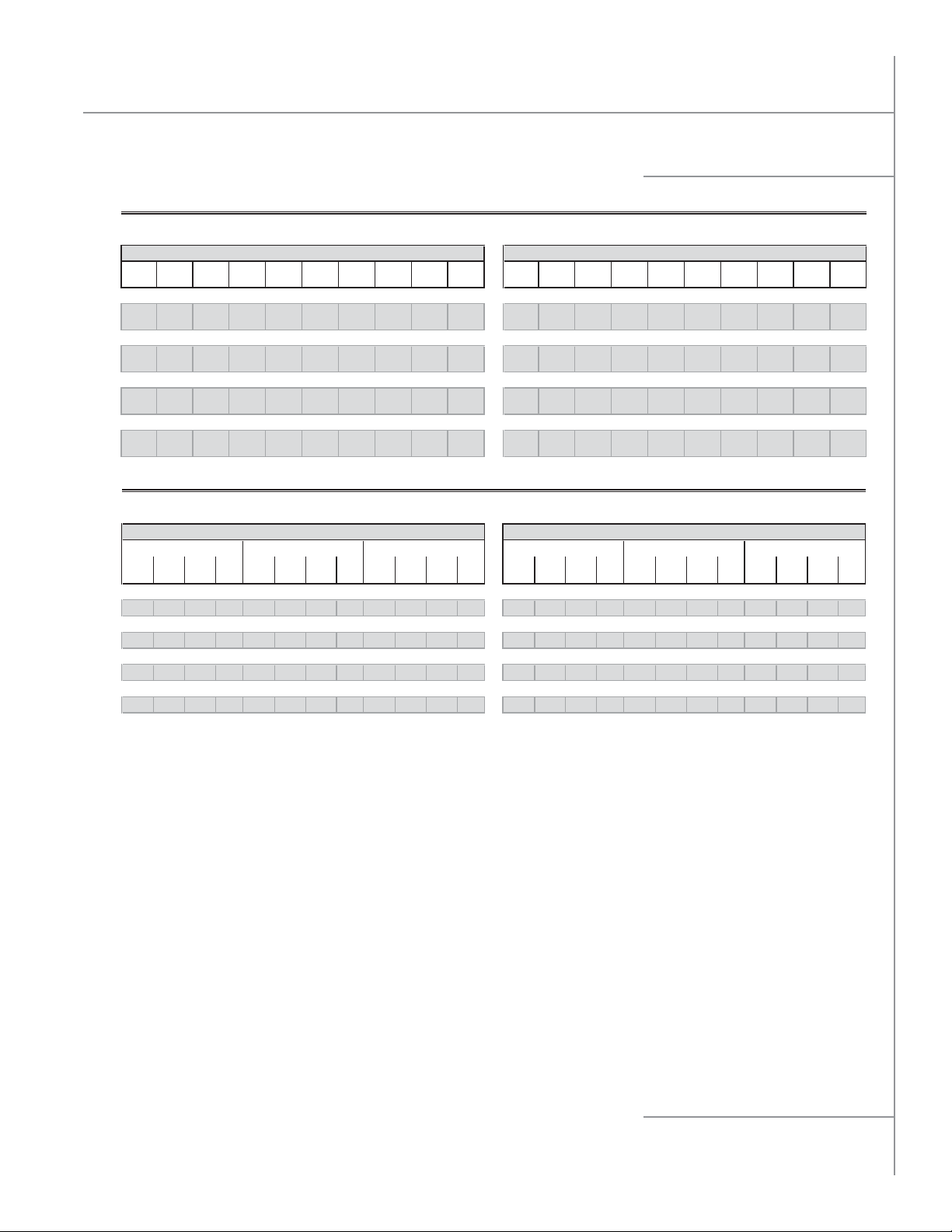

CSD Low Temp R-404A (L4)

STANDARD CONDENSER OVERSIZED CONDENSER

AMB ˚F-40˚F

MBH

-35˚F

MBH

CSD0150L4 CSD0151L4

95˚F

40.9

48.3

CSD0220L4 CSD0221L4

95˚F

48.9

41.9

57.5

50.5

105˚F

CSD0270L4 CSD0271L4

95˚F

60.0

52.4

70.4

62.4

105˚F

CSD0300L4 CSD0301L4

95˚F

68.0

59.1

79.6

70.3

105˚F

STANDARD CONDENSER OVERSIZED CONDENSER

MODEL

COMPRESSOR COMPRESSOR

-30˚F

-25˚F

-20˚F

-15˚F

-10˚F

-5 ˚F

MBH

55.6

66.8

59.3

81.9

73.2

92.2

82.2

MBH

63.2

76.4

68.3

94.4

85.0

105.8

94.8

MBH

71.1

86.3

77.6

107.9

97.5

120.3

108.1

MBH

79.4

96.8

87.3

122.2

110.7

135.8

122.3

MBH

88.4

107.8

97.5

137.2

124.5

152.4

137.2

MBH

98.1

119.5

108.1

152.9

138.8

169.9

152.9

0 ˚F

MBH

108.7

131.7

119.3

169.1

153.4

188.3

169.4

AMB ˚F-40˚F

95˚F

95˚F

105˚F

95˚F

105˚F

95˚F

105˚F

MODEL

MBH

41.7

49.5

42.8

60.7

53.2

69.4

60.5

-35˚F

MBH

49.3

58.6

51.6

71.2

63.2

81.3

72.0

-30˚F

MBH

56.9

68.1

60.6

82.9

74.3

94.3

84.2

-25˚F

MBH

64.8

77.9

69.8

95.6

86.3

108.3

97.2

-20˚F

MBH

73.1

88.3

79.4

109.4

99.0

123.4

111.1

-15˚F

MBH

81.9

99.2

89.5

124.0

112.6

139.7

126.0

-10˚F

MBH

91.5

110.7

100.0

139.5

126.8

157.1

141.7

-5 ˚F

MBH

101.9

122.9

111.1

155.7

141.6

175.8

158.5

0 ˚F

MBH

113.3

135.8

122.9

172.6

156.9

195.7

176.3

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

MCA*

MIN*

COMP

COND

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

AMPS

BKR

RLA

FLA

MCA*

AMPS

CSD0150L4 4DL3F63KE CSD0151L4 4DL3F63KE

52.6 7.0 72.8 90 26.3 3.5 36.4 45 20.9 2.4 28.5 35 52.6

CSD0220L4 4DT3F76KE CSD0221L4 4DT3F76KE

66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.2 4.8 35.1 45 66.0 14.0 96.5 125 33.0 7.0 48.3 60 24.2 4.8 35.1 45

CSD0270L4 6DL3F93KE CSD0271L4 6DL3F93KE

80.8 14.0 115.0 150 40.4 7.0 57.5 70 32.5 4.8 45.4 60 80.8 21.0 122.0 150 40.4 10.5 61.0 80 32.5 7.2 47.8 60

CSD0300L4 6DT3F11ME CSD0301L4 6DT3F11ME

95.6 14.0 133.5 175 47.8 7.0 66.8 90 39.6 4.8 54.3 70 95.6 21.0 140.5 175 47.8 10.5 70.3 90 39.6 7.2 56.7 70

NOTES PERTAIN TO BOTH R-22 and R-404A:

1. *Minimum circuit amps and minimum circuit breaker sizes are based on Air Defrost system which utilizes a separate power

supply for evaporator fans. If evaporators are Electric Defrost with its power supply furnished through the condensing

unit, evaporator fan amps must be added to both the condensing unit minimum circuit amps and minimum breaker size.

When calculating Minimum Circuit Amps (MCA) on Electric Defrost systems, use the larger of:

1) Minimum condenser amps + evaporator fan amps or 2) Evaporator defrost heater amps x 1.25.

2. Condensing unit capacities based on LAVF condensers.

3. FOR R-404A ONLY: May also be used with R-507. For capacity, multiply by 1.03.

MIN*

BKR

LARGE AIR-COOLED COMMERCIAL CONDENSING UNITS

7

Specifications subject to change without notice.

Loading...

Loading...