Page 1

INSTRUCTION MANUAL FOR THE

SeedMaster 2

Crystallization Transmitter and Automatic Seeding

Device

Document/Revision No. SeedMaster 2: Rev. 1/06 Effective: January 16, 2014.

PROCESS CONTROL KFT. PROFICON Industrial Controls Ltd.

Postal address: Postal address:

1091 BUDAPEST 1025 BUDAPEST

Haller u. 88. Mandula u. 24.

HUNGARY HUNGARY

E-mail: info@processcontrol.hu E-mail: LajosRozsa@mail.datanet.hu

www.processcontrol.hu

Page 2

2

2

CONTENTS

1

INTRODUCTION ......................................................................................................................................... 4

2 SUGAR CRYSTALLIZATION IN BRIEF ................................................................................................ 6

2.1 THE LAST STEP: CRYSTALLIZATION .......................................................................................................... 6

2.2 SUPERSATURATION: THE DRIVING FORCE OF CRYSTALLIZATION .............................................................. 6

2.3 SEEDING METHODS .................................................................................................................................. 6

2.4 CRYSTAL CONTENT .................................................................................................................................. 9

2.5 PRODUCT QUALITY AND SUPERSATURATION ............................................................................................ 9

2.6 COST OF PRODUCTION AND THE MAJOR PARAMETERS ............................................................................ 10

2.7 COMMON INSTRUMENTS IN USE FOR CRYSTALLIZATION CONTROL ......................................................... 11

2.8 MOUNTING THE K-PATENTS REFRACTOMETER ................................................................................... 12

3 THE SEEDMASTER 2 CRYSTALLIZATION TR ANSMITTER AND SEEDING DEVICE........... 14

3.1 SEEDMASTER 2 DESCRIPTION ................................................................................................................ 14

3.2 SEEDMASTER 2: A FRON T-END DEVICE .................................................................................................. 14

3.3 PRINCIPLE OF OPERATION ...................................................................................................................... 15

3.4 CALCULATED DATA ............................................................................................................................... 16

3.5 ON-LINE DATA INPUTS ........................................................................................................................... 17

3.5.1 Receiving syrup concentration data from the K-PATENTS refractometer(s) ...................................... 17

3.5.2 Receiving temperature data ................................................................................................................. 17

3.5.3 Selecting the “THIRD INPUT” transmitter ......................................................................................... 18

3.5.4 Using laboratory data instead of “THIRD INPUT” ............................................................................ 18

3.5.5 Optional data input .............................................................................................................................. 18

3.6 DIGITAL INPUTS ..................................................................................................................................... 18

3.6.1 “STRIKE ACTIVE” input DIN1 ........................................................................................................... 18

3.6.2 “SEEDED” input DIN2 ....................................................................................................................... 19

3.6.3 “CHANGE FEED SYRUP” input DIN3 .............................................................................................. 19

3.7 DATA OUTPUTS ...................................................................................................................................... 19

3.7.1 Data available for transmission ........................................................................................................... 19

3.7.2 Standard current outputs ...................................................................................................................... 20

3.8 DIGITAL (ON / OFF) OUTPUTS ............................................................................................................... 20

3.8.1 “SEED WARNING” output DO1 ......................................................................................................... 20

3.8.2 “SEEDING” output DO2 ..................................................................................................................... 20

3.9 THE MAN-MACH IN E INTERF ACE ............................................................................................................. 20

4 TECHNICAL DATA, MOUNTING AND ELECTRIC AL CONNECTIONS ...................................... 22

4.1 SPECIFICATIONS ..................................................................................................................................... 22

4.2 ELECTRICAL CONNECTIONS ................................................................................................................... 24

4.2.1 Power supply ........................................................................................................................................ 24

4.2.2 Process inputs and output s ................................................................................................................... 25

4.2.3 Digital communication ......................................................................................................................... 25

4.2.4 I / O wirings ......................................................................................................................................... 26

4.3 CONSTRUCTION DETAILS ....................................................................................................................... 28

5 SEEDMASTER 2 FEATURES IN BRIEF ............................................................................................... 31

5.1 SEEDMASTER 2: OPERATOR STATION FEATURES ............................................................................ 31

5.1.1 CONFIGURE ....................................................................................................................................... 31

5.1.2 SET UP ................................................................................................................................................. 31

5.1.3 DISPLAY .............................................................................................................................................. 31

5.1.4 MANUAL OPERATIONS ..................................................................................................................... 31

5.2 SEEDMASTER 2: TRANSMITTER FEATURES ....................................................................................... 32

5.2.1 Analog output ....................................................................................................................................... 32

5.2.2 Digital data communication ................................................................................................................. 32

5.3 SEEDMASTER 2: SEEDING FEATURES ................................................................................................. 32

5.3.1 Seeding based on DIGITAL INPUT DIN2 ........................................................................................... 33

5.3.2 Seeding on a command from a PCS using digital communication ....................................................... 33

5.3.3 MANUAL seeding................................................................................................................................. 33

Page 3

3

3

5.3.4 AUTOMATIC seeding based on SUPERSATURATION ...................................................................... 33

5.3.5 AUTOMATIC seeding based on DENSITY .......................................................................................... 33

6

START UP AND USE ............................................................................................................................. 34

6.1 START UP ............................................................................................................................................... 34

6.2 DEFAULT SETTINGS ................................................................................................................................ 34

6.3 DEVICE CONFIGURATION ....................................................................................................................... 35

6.4 BASIC KEY OPERAT IONS ......................................................................................................................... 35

7 CONFIGURE SEEDMASTER 2 ....................................................................................................... 37

7.1 START CONFIGURATION ......................................................................................................................... 37

7.2 ORGANIZING SEEDMASTER 2 INPUT / OUTPUT TRAFFIC ........................................................................ 37

7.3 CONFIGURING THE STRIKE ACTIVE SIGNAL ....................................................................................... 41

7.4 THIRD INPUT ...................................................................................................................................... 42

7.4.1 Third input: MASSECUITE DENSITY or MASSECUITE SOLIDS CONTENT ................................... 43

7.4.2 Third input: MOTOR CONSUMPTION .............................................................................................. 45

7.4.3 Third input: CRYSTAL CONTENT (laboratory) .................................................................................. 48

7.5 SEEDING .............................................................................................................................................. 50

7.6 ACTIVE INSTRUMENT ...................................................................................................................... 51

7.7 PASSWORD ......................................................................................................................................... 51

7.8 COMMUNICATION ............................................................................................................................ 52

7.8.1 Using the serial communication (COMX) ports. .................................................................................. 52

7.8.2 Using the ETHERNET. ......................................................................................................................... 53

7.8.3 Organizing the two-way data transfer.................................................................................................. 54

8 SET UP SEEDMASTER 2 ......................................................................................................................... 55

8.1 SET UP DISPLAY .................................................................................................................................. 55

8.2 SET UP INPUTS ..................................................................................................................................... 57

8.2.1 Data types and specifications. ............................................................................................................ 527

8.2.2 Handling the use of several feed syrups with different purities............................................................ 60

8.2.3 Set up syrup parameters. ...................................................................................................................... 61

8.3 SET UP DIGITAL I / O ........................................................................................................................... 62

8.4 SET UP ANALOG OUTPUT .................................................................................................................. 64

9 MANUAL SEEDING .................................................................................................................................. 65

10 DISPLAY ............................................................................................................................................. 67

10.1 MAIN DISPLAY .............................................................................................................................. 67

10.2 TREND ............................................................................................................................................. 69

10.3 STRIKE HISTORY ........................................................................................................................... 70

10.4 STANDARD DISPLAY ................................................................................................................... 70

10.5 SYSTEM INFORMATION .............................................................................................................. 71

10.6 TEST DATA ..................................................................................................................................... 72

11 COMMUNICATION ................................................................................................................................ 77

11.1 ETHERNET COMMUNICATION ................................................................................................... 77

Data transmission using the Ethernet ........................................................................................................... 77

Cable requirements and connection ............................................................................................................ 77

Cable specification ........................................................................................................................................ 77

Connecting the Ethernet cable ...................................................................................................................... 77

Connection settings ....................................................................................................................................... 78

Testing the connection .................................................................................................................................. 78

Troubleshooting ............................................................................................................................................ 79

MODBUS TCP / IP as implemented in SeedMaster 2 .................................................................................. 79

11.2 MODBUS PROTOCOL USING ONE OF THE COMX PORTS ................................................................... 81

11.3 DATA TYPES USED IN THE MODBUS REGISTERS ............................................................................... 85

11.4 REGISTER SET .................................................................................................................................... 86

Page 4

4

4

APPENDIX 2 : CONFIGURATION DATA SHEETS……………………………………………94

12 APPENDIX 1 : PROCEDURE TO EVALUATE THE “M”, “B” AND “C” COEFFICIENTS OF

THE WIKLUND-VAVR IN ECZ SATURATION FUNCTION. ..................................................................... 90

12.1 INTRODUCING THE SOLUBILITY COEFFICIENT ............................................................................................. 90

12.2 DETERMINING THE LOCAL SYRUP PARAMETERS ................................................................................. 90

12.2.1 Sample preparation for the saturation test ......................................................................................... 90

12.2.2 Saturation test .................................................................................................................................... 91

12.2.3 Evaluation .......................................................................................................................................... 91

SUBJECT INDEX……………………………………………………………………………………………..100

Page 5

1 INTRODUCTION

5

5

1 INTRODUCTION

Sugar manufacturing dates back more than one and a half century. World sugar production in year 2000

reached 150 million tons, which probably represents the largest amount of a product produced in crystalline

form.

Due to the long history of sugar manufacturing the sugar industry is regarded as a mature one, where no

exciting new developments can be expected. It has long traditions based on the work of skilled people, who

acquired their skill in controlling the various parts of the technology often during their lifetime. However, times

are changing. The fierce competition in the industry and in the market forces even industries with long

traditions to make effective use of the advanced methods of production in order to survive.

It became evident that besides better machinery and equipment in the technology, the use of new types of

equipment and know-how is a must for the plants if they wish to be competitive.

Some of the new equipment comes in the form of

• new instruments and

• computer-based automatic contr ol syste ms,

never heard of before, but there are substantial changes in the required know-how, too. In addition to the

usual chemical- and mechanical-engineering background experience in instrumentation, automatic process

control and in the use of computers and informatics became vital. Conclusion: there are substantial changes

even in a “mature” industry.

Crystalli zation is a very important step in sugar manufacturing. Final product quality and cost of production

depend very much on its execution. For quite a long time its control was the sole responsibility of the

“artisan” pan-man, but these times are over now. Instruments to provide some objective information on the

process appeared in the plants around the middle of the 20

information on syrup concentration (correlated to supersaturation) and on massecuite density or consistency

(correlated to crystal content). None of the instruments in use today are able to serve well both of these basic

needs.

Some of the common instruments are based on the change of an electrical parameter of the massecuite

(conductivity or / and capacitance). Due to their less than satisfactory operation, the frequency of the

electrical signal used kept increasing. The first conductivity probes used signals of only a few kHz frequency.

The RF (Radio Frequency) probes use signals in the 100 MHz range, while the fairly new microwave probes

use even much higher signal frequency. It is interesting to note that the well proven method to measure liquid

concentration, that is the use of refractometers dates back well over a century, and makes use of even

higher frequency, that is the frequency of light. The modern process refractometer which is available since

the 1980-s became the most accurate and reliable workhorse in this field.

Realising the potential and importance of the modern process refractometer, original research and

development was started by PROFICON Ltd., Hungary in the second half of the 1990-s to develop new

instruments providing reliable information on the most important parameter of crystallization: supersaturation,

combined with automatic seeding. The first result of this effort was the SeedMaster optional software,

which is available with the PR-01-S type K-PATENTS process refractometers. In a new development, the

SeedMaster 2 Crystallization Transmitter And Automatic Seeding Device offers more and advanced

features. Both devices are unique, represent a completely new class of instruments and are based on

several decades of experience in carrying out mill-wide automatic control projects in several countries of the

world.

IMPORTANT NOTICE:

Realizing that SeedMaster 2 is a device not comparable to any of the common ones used in crystallization,

this manual probably discusses in more detail some special issues related to the subject, than usual. While

doing so the main effort was directed to increase the realization of the importance of supersaturation in

crystallization control, a long neglected field because of the lack of a reliable instrument capable to provide

on-line data on it. Recommendations on some issues, for example: method of seeding, the value of

supersaturation during a crystallization process are really only recommendations, and though they certainly

are in line with the latest results of research in this field, it is up to the end user how she / he wants to use the

instrument.

The manufacturer of SeedMaster 2 can not be made responsible for any type of damage that might be

caused by its use.

th

century. They were intended to provide

Page 6

2 SUGAR CRYSTALLIZATION IN BRIEF

6

6

2 SUGAR CRYSTALLIZATION IN BRIEF

2.1 The last step: crystallization

The main steps of sugar manufacturing are:

• sugar extraction (from cane or beet),

• juice purification and concentr ation , and

• crystallization.

SeedMaster 2 was designed to provide all the vital information required to control the process of sugar

crystallization on an unprecedented level. It is therefore logical to concentrate further discussions on t he

process of crystallization.

Two methods to produce sugar crystals can be distinguished:

• cooling crystallization and

• evaporative crystallization.

Most of the sugar crystallized is produced in evaporative crystallization in batch or lately in continuous

evaporative crystallizers, but the basic principles of operation are the same in both types of crystallization

methods. Traditionally the vacuum pan operating in batch mode became the major piece of machinery and

enjoys wide use all over the world.

Crystallization is a very important part of sugar manufactur ing. This is a p roc ess which has a large influence

on product quality and on the cost of production, both of which are very important when competitiveness is

at stake.

During most of its long history the control of sugar crystallization in batch pans was the undisputed authority

of the pan-men, who acquired their skill during a large number of years in practice. Working mostly without

any real instruments, they used only their eyes and fingers to keep the process under control. No wonder,

they still are being regarded as “artisans” of their profession. However, artisans can be quite different, and

quite often tend to behave rather unpredictably, which is far from being compatible with the quality- and cost-

conscious requirements of industrial mass production, so representative of our times.

Modern control of crystallization must rely on the reliable on-line measurement of the parameters which are

vital in the control of the process performed by a local operator (manual control), or by an advanced

automatic process control system (PCS).

2.2 Supersaturation: the driving force of crystallization

It is well known that crystallization can take place only in solutions which contain more solids in solution than

required to saturation. In case of sugar solutions the same mass of water can dissolve different amounts of

sugar depending on its temperature: the amount of sugar is larger, if temperature is higher. A saturated

sugar solution therefore can be supersaturated either by decreasing its temperature (cooling), or by

decreasing the mass of water (evaporation).

Supersaturation is defined as the amount of sugar dissolved divided by the amount of sugar required for

saturation in the same amount of water at the same temperature. We have real supersaturation only if this

ratio is larger than 1,0 (saturation).

Supersaturation is the driving force of crystallization: crystal growth (speed of crystallization) depends very

much on this parameter. High supersaturation means faster crystal growth and vice-versa. There is no

crystal growth if supersaturation is less than 1,0, in which case instead of growing, already existing crystals

begin to dissolve. It is important to emphasise that supersaturation is a complex multivariable function of the

liquid phase (mother liquor) parameters and should be calculated taking into account all of its governing

parameters:

Supersaturation = f(C, Q, T, m, b, c) (Eq. 1.)

where:

C : syrup / mother liquor concentration (%)

Q : syrup / mother liquor purity (%)

T : temperature (˚ C)

m, b, c : syrup quality parameters (-)

Syrup quality parameters are discussed in detail in Ch. 12 APPENDIX.

It follows from its definition that, among others, concentration of the mother liquor should be measured online, undisturbed by the presence of crystals in the massecuite in order to be able to calculate it.

2.3 Seeding methods

Seeding is a very important step in the process of crystallization, which has a large influence on the quality

of the product. When completed, the crystals begin to grow in size, if supersaturation is larger than 1,0.

Page 7

2 SUGAR CRYSTALLIZATION IN BRIEF

7

7

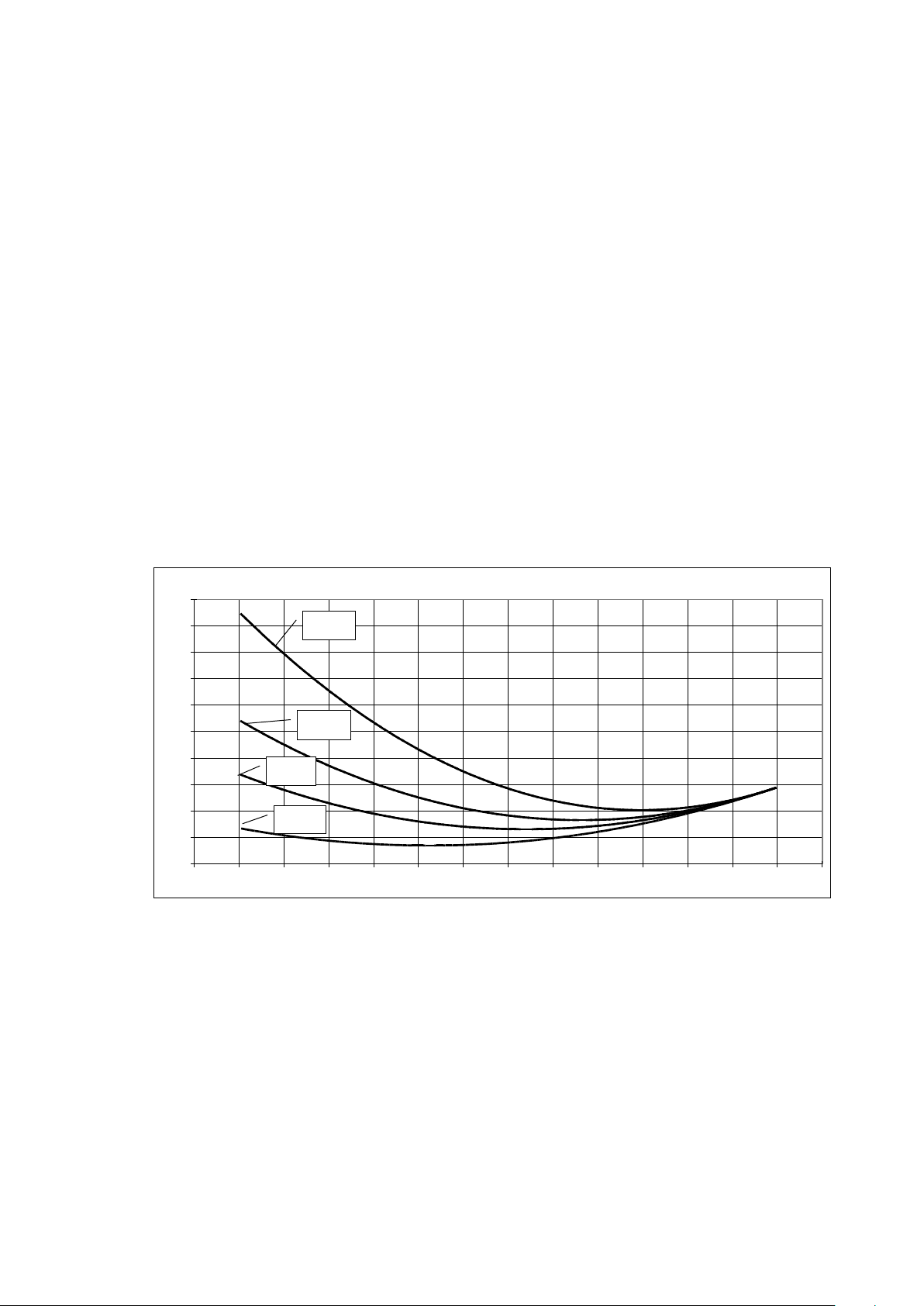

CRITICAL SUPERSATURATION TO START NUCLEATION

1,1

1,11

1,12

1,13

1,14

1,15

1,16

1,17

1,18

1,19

1,2

74 76 78 80 82 84 86 88 90 92 94 96 98 100 102

SYRUP / MOTHER LIQUOR PURITY (%)

SUPERSTURATION.

TEMP.

60 C

TEMP.

70 C

TEMP.

75 C

TEMP.

80 C

Shock seeding is t he traditional way of seeding. It relies on the building up of high supersaturation in the

solution, when a small amount of seed crystals entered into the pan results in the formation of new crystals

(nucleation). The number of these crystals keeps growing as long as the value of supersaturation is above a

“safe” (nucleation-free) limit. The final number depends very much

• on the actual value of supersaturation, and

• on the time (time of nucleation) spent in the region of high supersaturation above the “safe” limit.

There are at least 3 important parameters in this method of seeding:

1. the actual value of supersaturation maintained in the “seeding point” and during nucleation;

2. the length of nucleation;

3. the limit value of supersaturation above which nucleation begins, if there are already crystals in the

solution.

Point 1. calls for a reliable measurement of supersaturation.

Point 2. has some difficulties of its own, too. How to determine the correct length of nucleation? The method

of trial and error can only be used, if supersaturation was the same all over the trials, which again calls for its

measurement. Even if it is known, in case of manual control of crystallization is it possible to ensure exactly

the same time for nucleation from strike to strike, even during the night shift?

Point 3. requires the knowledge of the critical supersaturation, above which nucleation begins in the

presence of already existing (seed) crystals. There are not many reliable data on this limit. A recent

publication (see below) provides data depending somewhat on syrup purity and temperature, too (the

dependence on temperature is more pronounced with low-purity syrups). In case of high syrup purity (larger

than 94 %) this supersaturation limit is about 1,12…1,13. An important point is that the formation of new

(often unwanted) crystals can begin any time supersa tur at io n excee ds the criti ca l super sat ur atio n limi t.

Fig. 2.1

(This figure is based on the equation published in:

M.Saska: Boiling point elevation of technical sugar cane solutions and its use in automatic pan boiling.

International Sugar Journal 2002, VOL. 104., No.1247., 500-507).

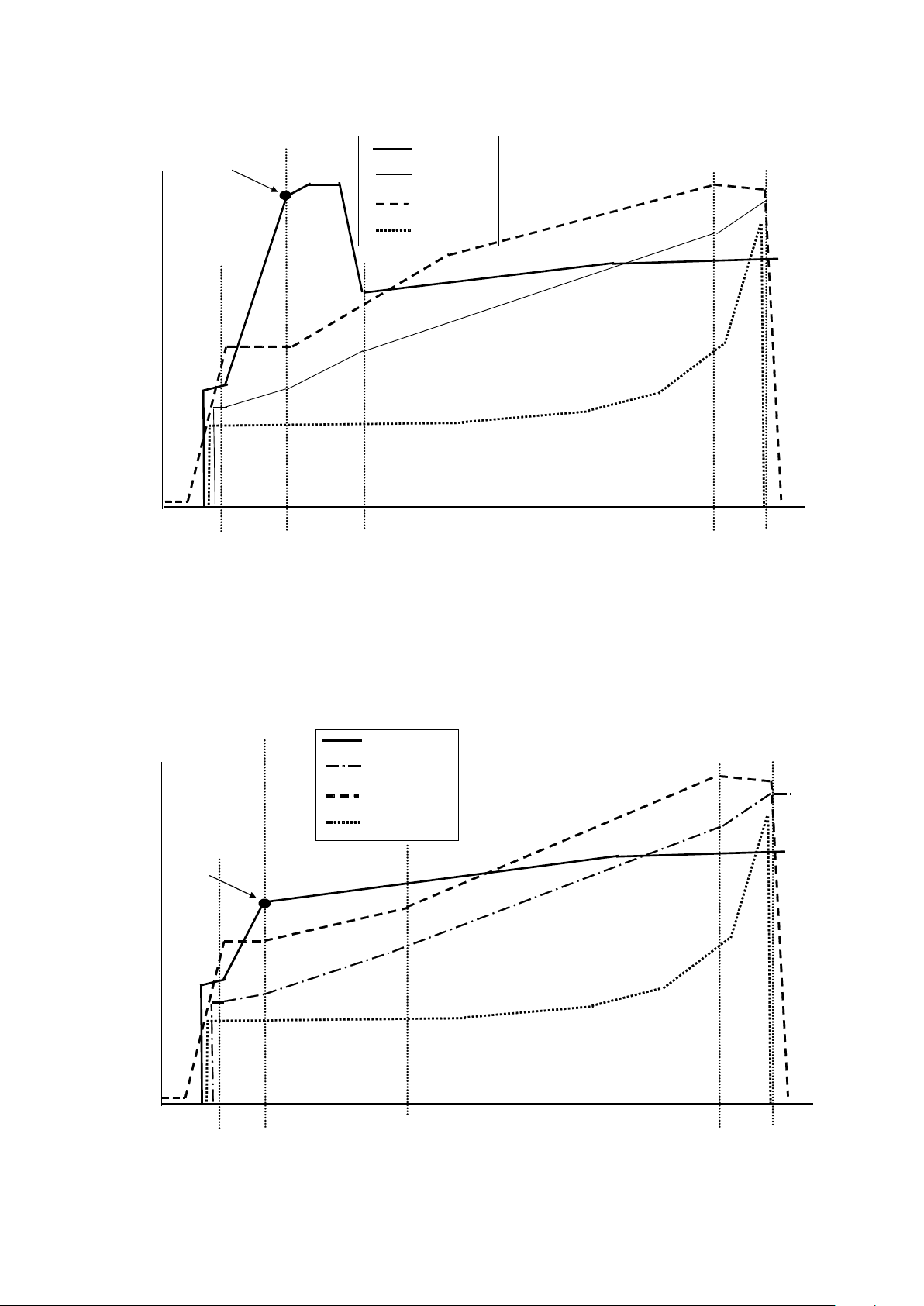

Fig.2.2 shows some of the trends typical of shock seeding. It is evident that shock seeding has quite a few

uncertainties and consequences, which make its use in modern practice unde sir able .

Page 8

2 SUGAR CRYSTALLIZATION IN BRIEF

8

8

Supersaturation

SEEDING POINT

Density

Level

Motor power

Draw in Concentrate

Graining

Boiling Boiling Discharge

up

Supersaturation

Density

Level

Motor power

SEEDING POINT

Draw in Concentrate Graining Boiling Boiling Discharge

up

Fig. 2.2

Full seeding is the advanced mode of seeding. In ideal case there are no new crystals formed during

seeding: the full required crystal crop is supplied during seeding in the form of well prepared slurry. It is

assumed that only crystal growth and no nucleation will take place during the complete length of

crystallization (during a strike in batch pans), that is the number of crystals in the end product is in ideal case

equal to the one of the seeding material.

Besides using slurry, full seeding can be implemented by using the right amount of crystal footing (magma),

too. It follows from the above that in case of full seeding and during the complete crystallization

supersaturation must not exceed its limit value. This requirement may result in somewhat longer times of

crystallization than accustomed, but will result in better sugar quality.

Fig.2.3

Fig. 2.3 shows some of the trends typical of full seeding.

Page 9

2 SUGAR CRYSTALLIZATION IN BRIEF

9

9

NOTE:

The use of slurry (or crystal footing) alone is no guarantee for correct full seeding. Besides the right amount

of slurry or footing (with the right number of crystals in it) supersaturation must not exceed its limit value.

2.4 Crystal content

Good control of the process of crystallization requires some information on the crystal content of the

massecuite, too. The amount of sugar needed to feed the growth of crystals increases as the surface area of

the crystal mass increases. Feed syrup is supplied to fill the need.

The control of crystallization in a vacuum pan, for example, should be a co-ordinated process. Control

parameters, like vacuum, heating steam (vapour) pressure, feed syrup input are connected in a complex

way to the massecuite parameters. The actual value of supersaturation depends on quite a few parameters

(see Eq. 1.) From these, concentration depends on the rate of evaporation and syrup feed, while

temperature is basically determined by the absolute pressure above the massecuite.

In batch crystallization some indirect measure of crystal content is being used to signal the end of the strike.

2.5 Product quality and supersaturation

The importance of supersaturation in product quality can not be overstated. Its role in seeding has already

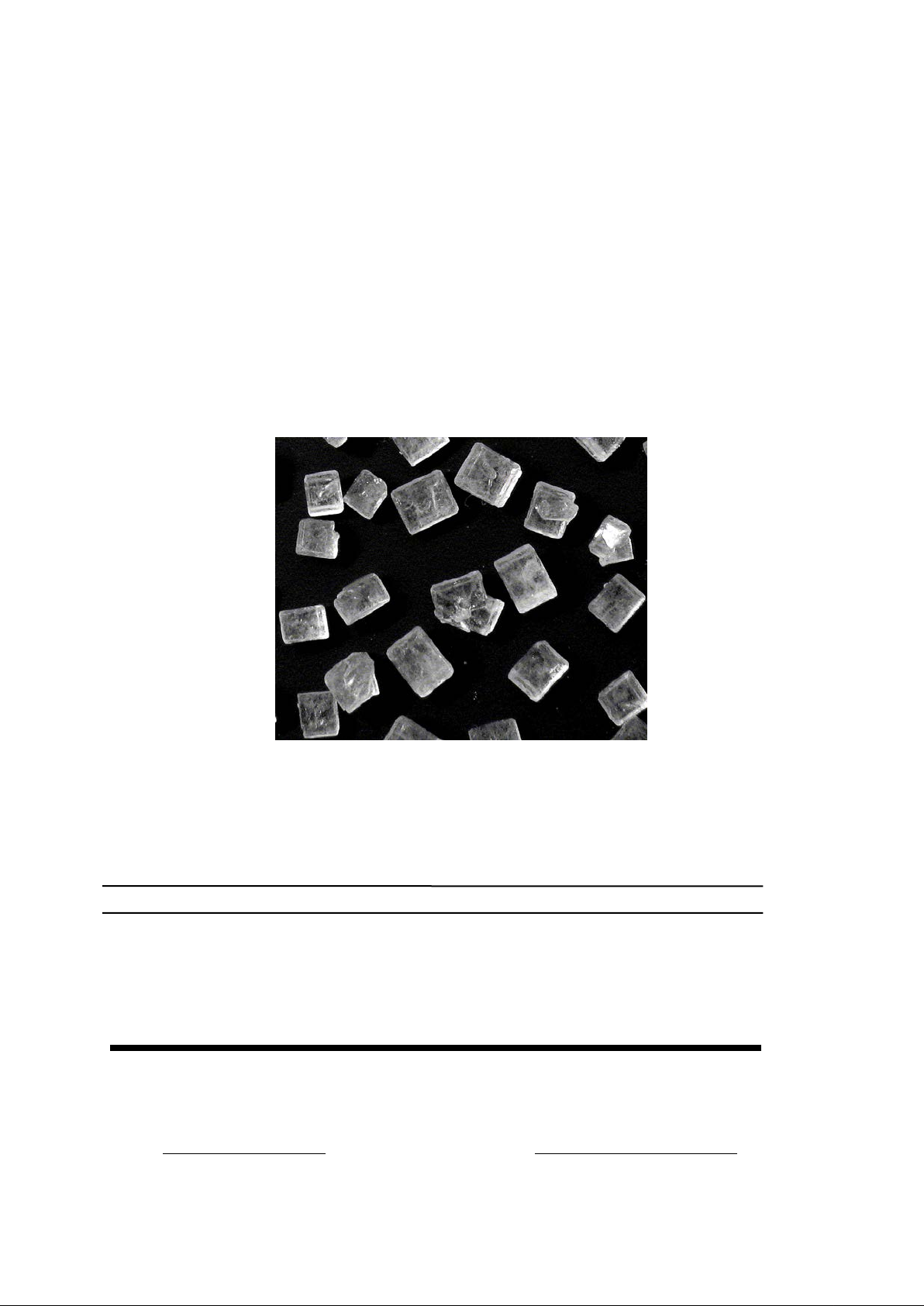

been discussed, while Fig. 2.4 (scale: 1 by 1 mm) proves its effect all over the strike. In this figure a fairly

wide crystal size (from 1 mm to perhaps 0,05 mm) distribution can be observed. Most probably there were

much smaller size crystals, too, but they had escaped through the screen of the centrifuge only to increase

the amount of recirculated crystallized sugar in the green syrup (Fig. 2.6). It is evident that the smaller

crystals (the “young generation”) are due to spontaneous nucleation in the later phases of the strike. These

crystals therefore did not have time enough to grow to a larger size till the end of the strike (it is assumed

that the size of the seed crystals (the “old ones”) was fairly equal).

Fig. 2.4

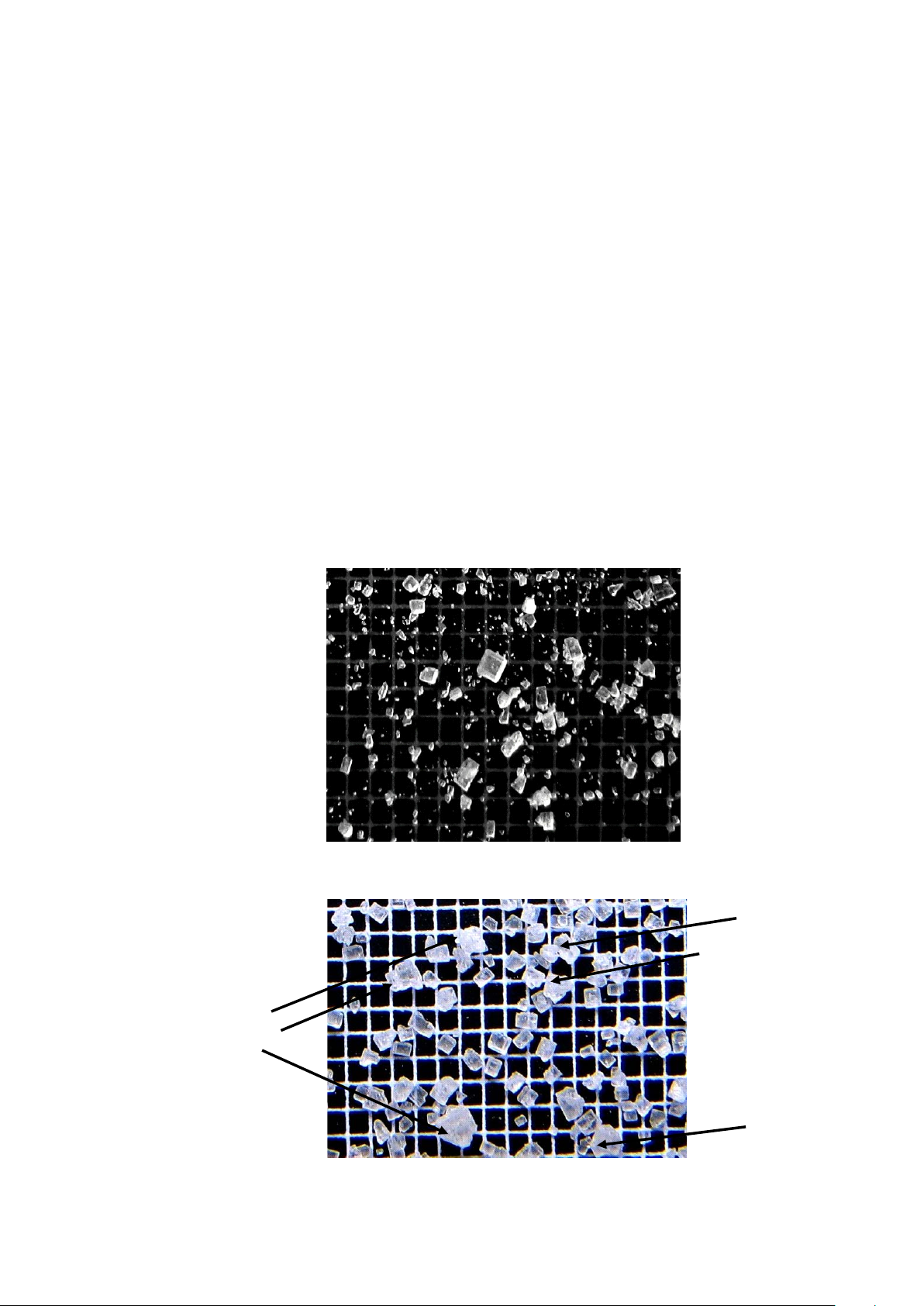

In Fig. 2.5 (scale: 1 by 1 mm) among well developed crystals quite a few conglomerates (a cluster of

mutually intergrown crystals) of different sizes can be observed.

Fig. 2.5

conglomerates

Page 10

10

10

Product

Crystals

F

conglomerates

Recirculated

sugar

Tank

Product

screen

Melter

Mixer

Centrifugals

2 SUGAR CRYSTALLIZATION IN BRIEF

It has been proved that formation of conglomerates mostly happens when the size of the crystals is in the 40

to 250 micron range. This means that the formation of conglomerates in the early phase of crystallization

(not long after seeding) results in large conglomerates at the end of the strike, while smaller conglomerates

in the end product are due to unwanted nucleation (because of too high supersaturation) in the later phases

of the strike. Bad circulation, probably resulting in high local supersaturation in some parts of the pan also

contributes to the formation of conglomerates.

It is quite common nowadays that special products require well defined grain sizes, which call for a tight

crystal size distribution. This can be achieved by good boiling control (including, of course, good control of

supersaturation), or by screening of the product, if it has a wide size distribution. This later method, however,

requires additional machinery , time and ener gy and natur ally incre ase s the cost of produ cti o n.

Besides wide crystal size distribution conglomerate content also contributes to poor product quality. It is well

known that the colour of the product has strong correlation to conglomerate content, because intergrown

crystals are more likely to retain some of the mother liquor during centrifuging. If conglomerate content is

high, product colour can only be improved with the excessive use of water in the centrifuges, which will

result – because of dissolution - in consider ab le los s of the cry stal mass.

2.6 Cost of production and the major parameters

It has bee n demonstrate d that wide crystal size distribution and conglomerates of varying sizes in the end

product are due to excessive supersaturation, which, if not controlled properly, can be present during the

complete course of crystallization (Figures 2.4 and 2.5). This proves that statements on the decreasing

importance of supersaturation after seeding has been completed are totally unfounded and false.

Conglomerate and fines content have very important effect on the cost of production. Too high fines content

makes centrifuging difficult and results in considerable loss of already crystallized sugar through the screen

baskets of the centrifuges. It is difficult to determine the amount of this loss and quite often it is neglected. It

should be realised, that the number of strikes per shift, often used in practice, is not a correct measure of the

rate of production. Fines and conglomerates result in recirculated sugar only to be melted, concentrated and

crystallized again, the end result of which is

• waste of time and energy,

• decreased effective yield of product sugar per strike and shift,

• increased use of water and

• increased cost of production.

It is well known that the speed of crystallization is higher if supersaturation is higher, that is the rate of

production increases with increasing supersaturation. It is therefore tempting to push production by

maintaining high supersaturation, but exceeding the safe limit, where spontaneous nucleation begins and

the risk of conglomeration increases, too, is accompanied with the unpleasant consequences discussed

above.

Selecting the correct supersaturation set point trajectory for a strike is therefore a kind of compromise (or

optimisation). However, any type of supersaturation control is un-conceivable without the correct on-line

measurement of supersaturati on.

Green liquor

and fines

Fig. 2.6

ines and

Page 11

2 SUGAR CRYSTALLIZATION IN BRIEF

11

11

2.7 Common instruments in use for crystallization control

There are two major types of data needed for good control of crystallization:

1. supersaturation, and

2. information related to crystal content.

The basic requirements concerning the sources of these data are:

accuracy:

supersaturation : fairly high,

crystal content : modest;

in - and on-line instruments:

should provide reliable data in real time during the full course of crystallization;

long-term stability:

it is a basic requirement.

Besides instruments providing data on vacuum, massecuite temperature, level and vapour pressure in the

calandria, common instruments in use for boiling control measure

• electrical parameters of the massecuite (conductivity, conductivity and capacitance (RF sensors),

• viscosity / consistency,

• stirrer motor consumption,

• density / solids content (nuclear),

• density / solids content (microwave),

• boil ing poi nt rise and

• refractive index.

None of these instruments provide reliable and quantitative data neither on supersaturation, nor on

crystal content, the real massecuite parameters that matter.

Conductivity is due to the presence of different types of ions in the syrup or mother liquor. It depends on

several parameters like concentration, composition and amount of non-sugars present, crystal content and

temperature. It certainly has (through syrup / mother liquor concentration) some correlation to

supersaturation (see Eq. 1.), but due to changes in other parameters governing it, it is far from being able to

provide reliable information on supersaturation.

Capacitance (RF sensors) depends mostly on the water content of syrup / mother liquor in a unit volume of

massecuite, therefore, besides concentration it show s stron g depen den ce on crys tal con tent .

Viscosity of the syrup / mother liquor depends on their concentration and temperature, but instruments in

use for boiling control do not have temperature compensation feature.

Consistency is the property of the liquid / solids (mother liquor / crystals) mixture. Viscosity / consistency are

measured in crystallization control practice by the same instrument. Consistency, however, sharply

increas es with incre asing c rystal content. At the end of a strike consistency can be 20-30 times larger than

the viscosity of the mother syrup alone.

Stirrer motor current or power consumption provide data on viscosity / consistency in a different form.

Density of the massecuite comes from two sources: density of the mother liquor and that of the solid

crystals. Besid es t he se the crystal to mother liquor ratio in the massecuite will determine its value.

Solids content of the massecuite is similarly determined by the solids content of the mother liquor, that of the

crystals and by the crystal to mother liquor ratio.

The common features of all instrument types discussed above are:

1. None of them is able to provide selective and accurate enough information on mother liquor

concentration in the presence of crystals, therefore they are unfit to give even approximate, indirect

information on supersaturation all over a strike (see Eq. 1).

2. Having completed seeding all instruments discussed above provide data which are more and more

governed by the increasing crystal content. It is logical therefore that these instruments can be put to good

use only to provide – though indirect and only approximate - information on crystal content.

There are only two principles of measurement which can be used to measure syrup concentration

selectively even in the presence of sugar crystals.

Boling point rise of a solution depends – among others – on its concentration, therefore it is correlated to

supersaturation. Supersaturation, however, is a multivariable function of several parameters. On the other

hand: boiling point rise depends on syrup / mother liquor purity and non-sugar composition, too. Boiling point

Page 12

2 SUGAR CRYSTALLIZATION IN BRIEF

12

12

rise is small with high-purity syrups and therefore requires very accurate measurement. Due to these

problems its use in the determination of supersaturation with the required accuracy and stability is very

questionable.

Refractive index of a solution has very strong and well-known correlation to its concentration. The

principle of measurement is in use all over the world since over one and a half century in laboratory,

and nowadays in process refractometer types, too. The data provided meet the requirements stated

earlier regarding its use in the calculation of supersaturation.

Summing up:

1. Supersaturation is the most important parameter of crystallization.

2. Supersaturation is a multivariable function of several syrup / mother liquor parameters (see Eq. 1).

3. Common instruments in use measure only a single parameter of the syrup or massecuite, therefore they

are unable to provide real quantitative data on supersaturation.

4. Supersaturation can only be calculated on-line by taking into account all of the parameters that govern

it. It is therefore logical that reliable and accurate on-line data on syrup / mother liquor concentration

are required. The only way to get them is by the use of a reliable process refractometer.

5. Information on supersaturation and on crystal content (even in indi rect form) is required for advanced

boiling control.

2.8 Mounting the K-PATENTS refractometer

The K-PATENTS process refractometers have proved their worth in thousands of applications including

crystallization in the sugar industry worldwide. They consist of 2 main parts:

• the Sensor Head (1 or 2) and

• the Indicating Transmitter

connected by a 10 to 100 m long cable.

Mounting the Sensor Head.

In crystallizer applications it is recommended to use the long probe version providing longer insertion length.

Selecting the best location to mount the Sensor Head is usually a case of compromise. Crystallizers are far

from being perfect: despite the use of stirrers, circulation of the massecuite becomes more and more

sluggish when the crystal content increases. This means that syrup / mother liquor concentration and

temperature, which have large influence on supersaturation will not be the same in the full massecuite

volume. The following considerations should be taken into account:

1. Select a location, where measured concentration is representative for the largest volume of the syrup or

massecuite. This requirement means that locations close to the feed syrup entry and above the calandria

should be avoided. Too short distance from the entry point results in misleading data valid for a diluted

massecuite in a relatively small volume. A too fast drop of measured concentration after opening the feed

valve is real cause for concern.

2. Supersaturation increases with decreasing temperature if syrup / mother liquor concentration is kept

constant. This means that highest supersaturation is expected where temperature is the lowest.

Temperature is the lowest at the surface of the massecuite, while it is the largest just above the calandria.

Naturally, the rising surface can not be followed with the sensor. In practice temperature in the pan bottom is

fairly close to surface temperature.

In practice, unfortunately enough, feed syrup most often enters the downtake just above the calandria or at

the lower end of the downtake. These are rather questionable designs because of two reasons:

• Due to the increasing difference between the density of the massecuite and that of the feed syrup due

to increasing crystal content, syrup entering the pan reverses direction and flows upwards in the downtake,

working more and more against the much needed circulation of the massecuite.

• This design is in complete disregard of the needs of the on-line measurement of any massecuite

parameter (see point 1 above).

A much better solution is when feed syrup enters the pan under the calandria through a circular ring pipe.

Feed should be distributed and directe d upwar ds at sever al l ocat ion s around the pan w all. T his soluti on

• instead of degrading, improves massecuite circulation, and

• provides good location under the feed pipe for instrument sensors.

Figure 2.7 shows recommended sensor locations for the two cases.

Page 13

2 SUGAR CRYSTALLIZATION IN BRIEF

13

13

Fig. 2.7 Recommended sensor head locations

NOTE:

Sensor location in a crystallizer is a problem independent from the type of sensor used. If a separate

temperature sensor is used, it should be mounted close to the refractometer Sensor Head. The same

applies to massecuite density and solids content (brix) sensors as well.

Mounting the Indicating Transmitter

It is general practice to mount the Indicating Transmitter close to the vacuum pans. The enclosure must not

be exposed to rain or direct sunshine. Avoid vibration.

FURTHER READING:

1. L. Rózsa : On-line monitoring of supersaturation in sugar cry stal liz ati on

I.S.J., 1996, 98, 660-675

2. L. Rózsa : Sensor performance in monitoring of supersaturation

I.S.J., 1997, 99, 263-268

3. L. Rózsa : The SeedMaster device

I.S.J., 1998, 100, 601-607

4. L. Rózsa : Sucrose Solubility in Impure Cane Sugar Solutions

i.S.J., 2000, 102, 230-235

5. L. Rózsa : Sensor Selection: Still an Issue in Sugar Crystallization Control

PHILSUTEC Convention 2003, Bacolod City, PHILIPPINES

6. L. Rózsa : SeedMaster 2: A universal crystallization transmitter and automatic seeding device

I.S.J. 2006, 108, 683-695

7. L. Rózsa : Sugar crystallization: Look for the devil in the details – Part 1

I.S.J. 2008, 110, 403-413

8. L. Rózsa : Sugar crystallization: Look for the devil in the details – Part 2

I.S.J. 2008, 110, 729-739

Page 14

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

14

14

DENSITY

THIRD PARTY TRANSMITTER :

DENSITY

MOTOR CONS.

THIRD PARTY TRANSMITTER:

MOTOR CONSUMPTION

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER AND SEEDING

DEVICE

3.1 SeedMaster 2 description

The heart of SeedMaster 2 is a high performance computer specifically designed to calculate, displa y and

transmit all of the vital parameters characterising sugar crystallization simultaneously for up to 2 crystallizers.

Besides that it can perform reliable automatic seeding of the crystallizers as well. Both features require the

input of some data measured on-line by 1 (or 2) K-PATENTS process refractometer(s) and by some selected

instrument(s). Input of a few laboratory data and status information (digital inputs) are also required.

Based on these data SeedMaster 2 is able to calc ula te 7 massecuite parameters per crystallizer in real tim e,

only 2 of which are considered adequate for the advanced control of crystallization.

Some of these parameters (for example: crystal content, mother liquor purity, mean crystal size etc.), though

they are important ones, are usually rarely determined by the local laboratory, if at all. Due to the time delay

(dead-time) involved, these data, however, are more or less useless in closed loop, real time control of

crystallization.

Other instruments in use provide data only on a single massecuite parameter.

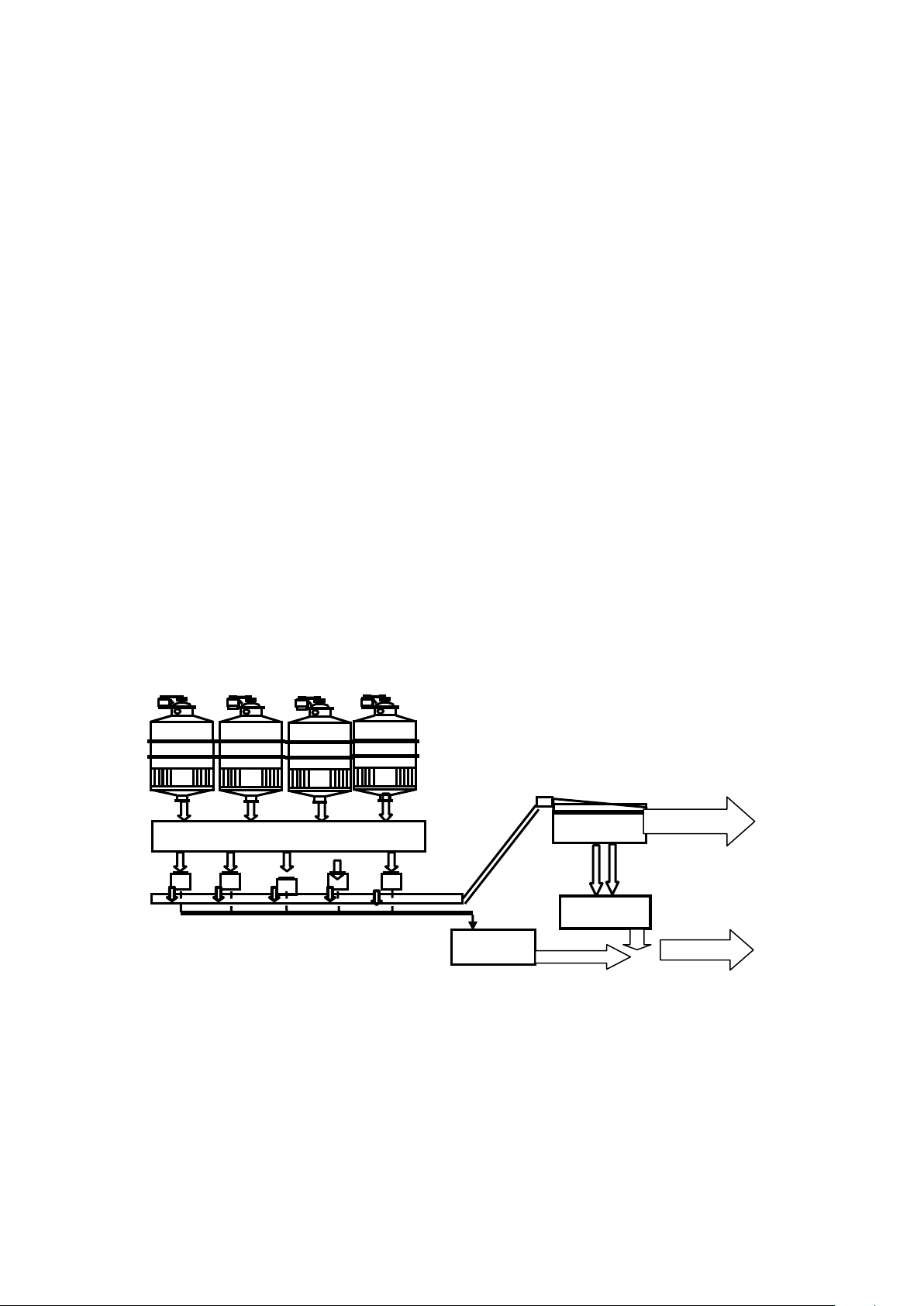

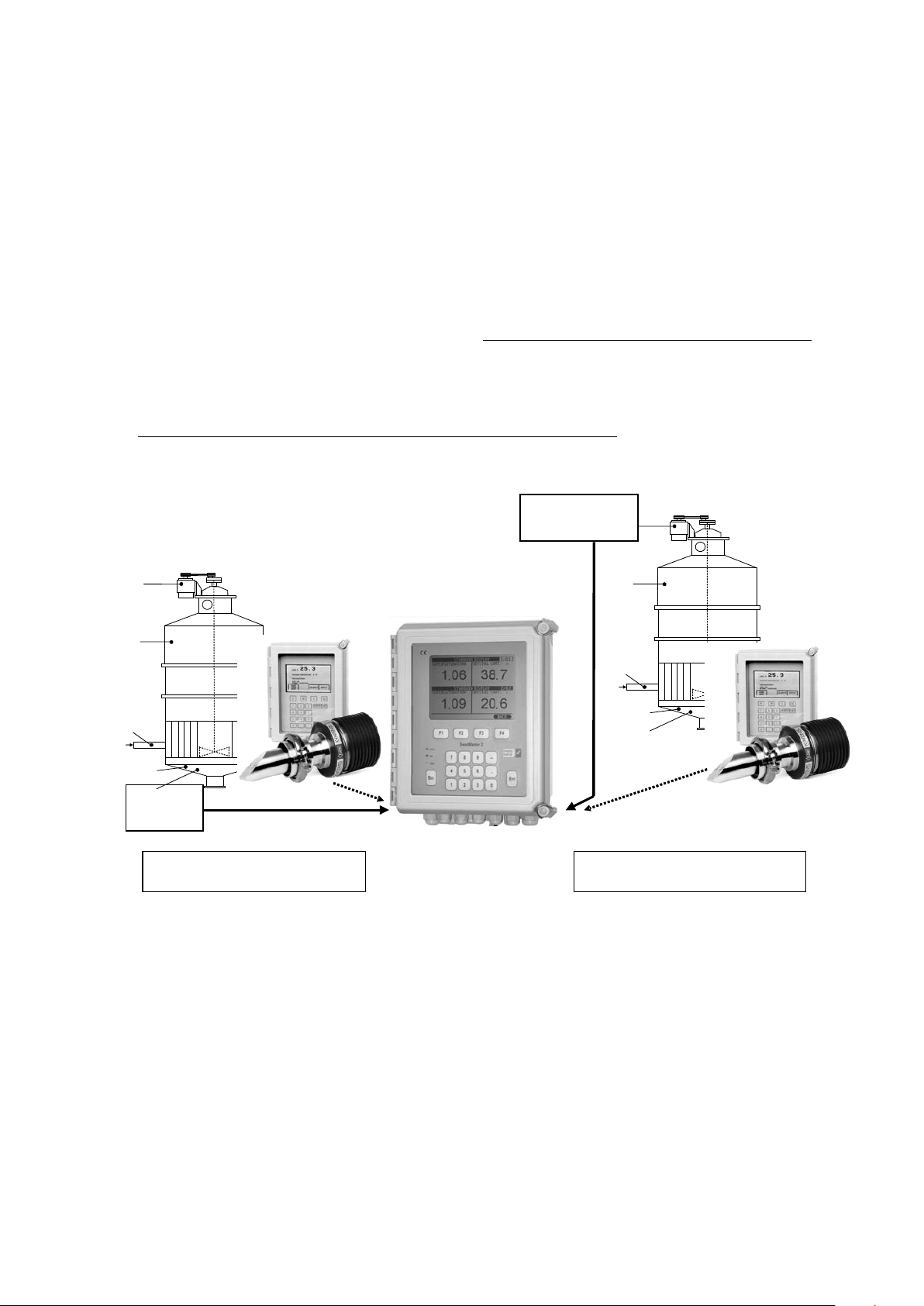

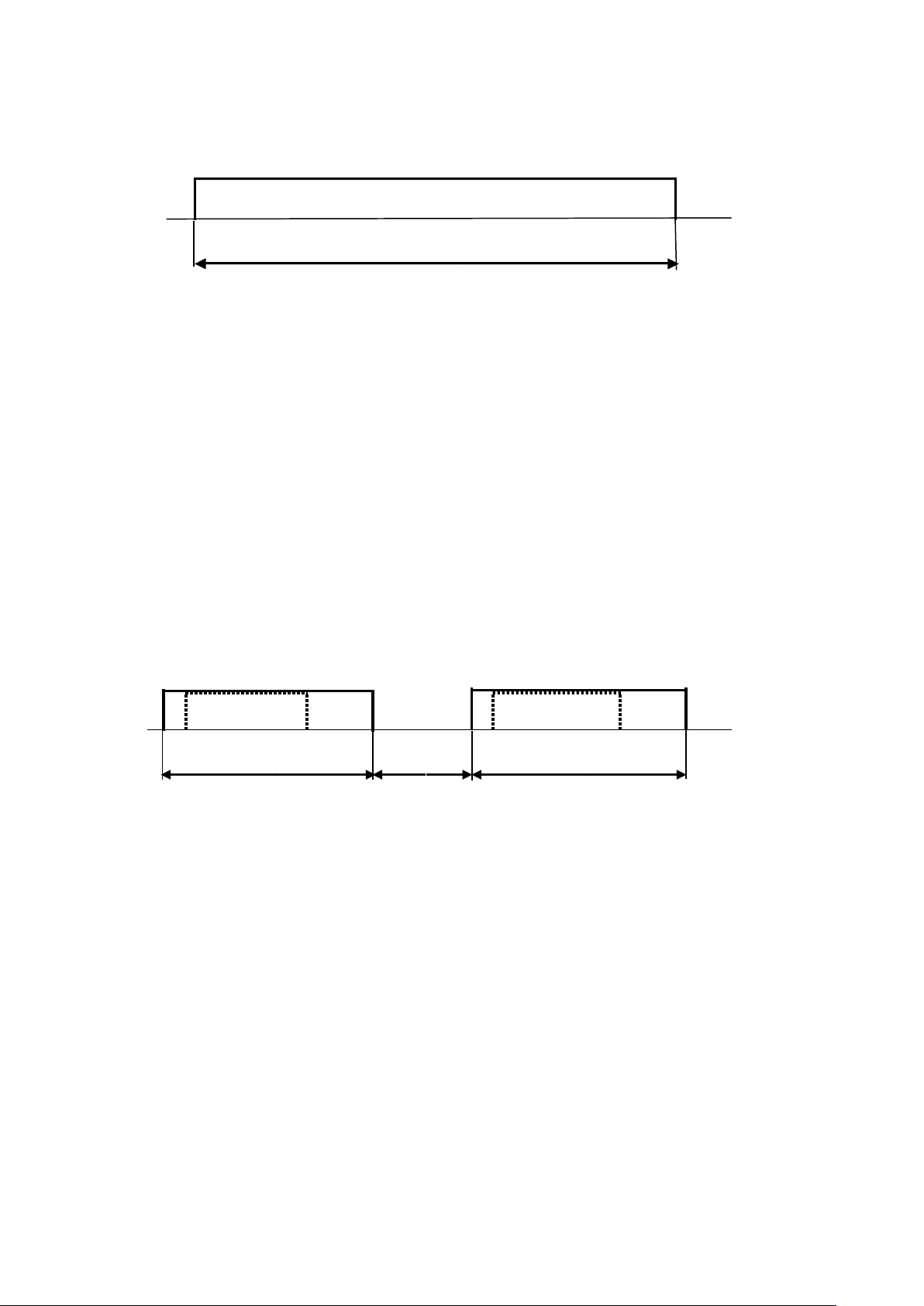

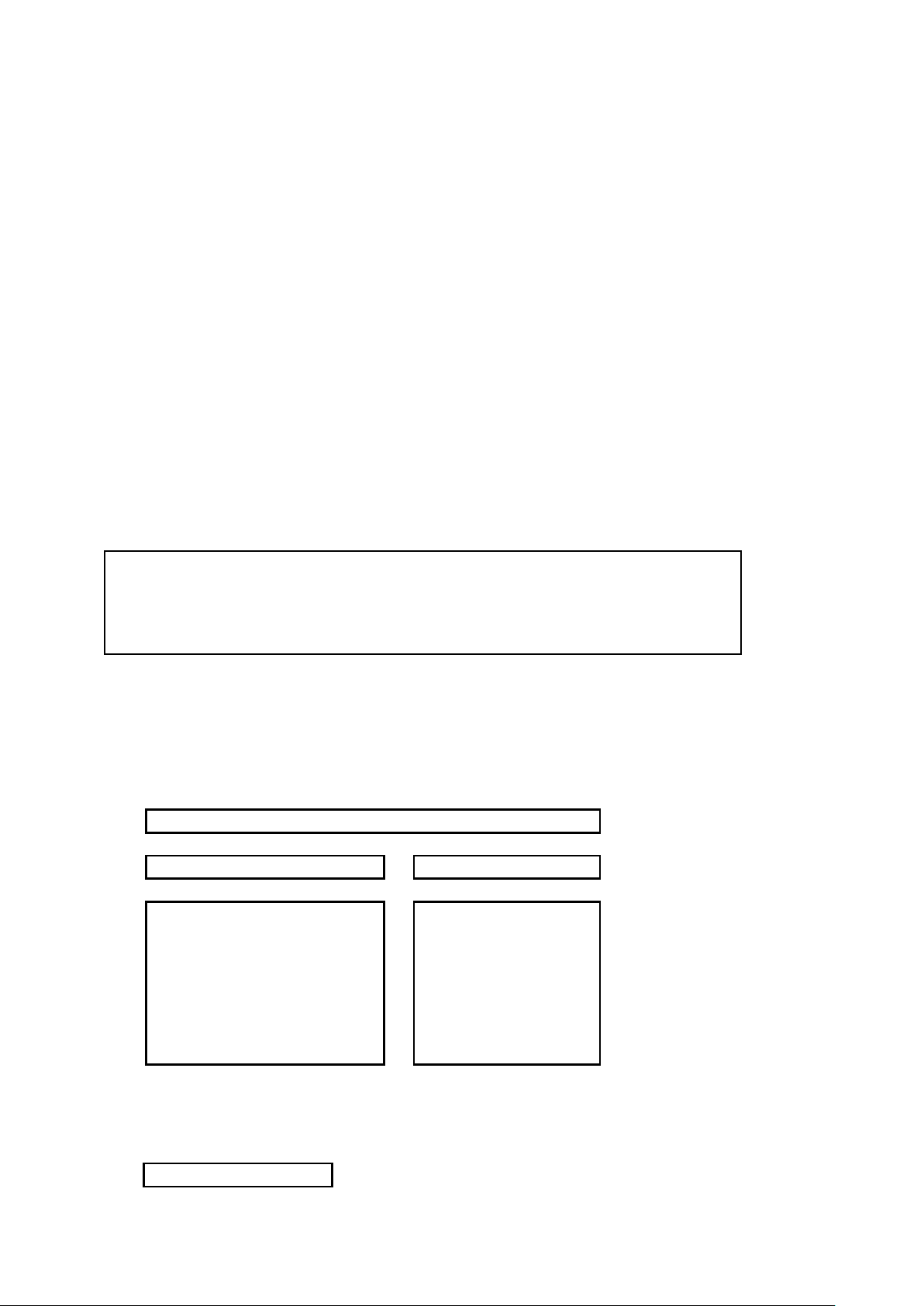

Fig. 3.1 SeedMaster 2 serving 2 vacuum pans

3.2 SeedMaster 2: a front-end device

The device was designed to be used as a “front-end” instrument mounted close to the vacuum pans or

crystallizers in order to provide all of the information required by operating personnel on site. It has a large

backlit LCD display and a keyboard (Fig. 3.2). Naturally enough, it has advanced digital communication

features to send a large amount of acquired and calculated data on-line to a Process Control System, too.

The LCD display is specified to operate in the 0 – 50 C temperature range (environment) and this applies to

SeedMaster 2 as a whole, too.

Page 15

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

15

15

Fig. 3.2 The SeedMaster 2 enclosure

(Display: supersaturation and cry stal co ntent )

3.3 Principle of operation

Contrary to commonly used sensors that measure massecuite parameters only indirectly linked to the really

important ones (supersaturation and crystal content), SeedMaster 2 was designed to provide information online on all of the parameters which are important for the up-to-date control of crystallizati on .

Its operation is based on the use of the K-PATENTS process refractometer, which became the workhorse of

different industries, including sugar, when accurate on- and in-li ne measu rement of liquid concentration is a

must. Syrup / mother liquor concentration data are not disturbed by the presence of crystals, steam and

vapour bubbles and the colour of the liquid. At the same time the refractometer provides data on massecuite

temperature as well. This means that data on C and T (concentration and temperature) in Eq. 1. are directly

provided by the refractometer. Though not advised, it is possible to use a separate temperature probe and

transmitter, too. Besides these data information on mother liquor purity Q is also required for the on-line

calculation of supersaturation.

Mother liquor purity is equal to feed syrup purity only up to the point of seeding. When the crystals begin and

continue to grow, mother syrup purity begins to drop accordingly. It is therefore not constant during the strike,

and should be calculated on-line together with changing crystal content. This, however, needs the use of

additional on-line data (“Third input”) from some already existing sensor (density, massecuite solids content

(brix), or stirrer motor consumption).

NOTES:

1. The use of stirrer motor power or current consumption as “Third input” is limited to batch vacuum

pans operating without strike cut(s), that is without discharging some part of the massecuite before

the end of the strike. The trend of motor consumption data should look like one of those shown in

Fig. 7.5 or Fig. 7.6.

2. As a last resort, if none of these sensors is available, a single data from the laboratory (updated

from time to time) on crystal content (% by volume) when dropping the charge (vacuum pans

operating in batch mode without strike cut(s)) can be used.

Finally, it is well known that feed syrup quality, characterised by its “m”, “b” and “c” parameters can show

considerable changes, which have to be taken into account when calculating the massecuite parameters.

Syrup quality parameters should be determined by the local laboratory (see: APPENDIX). If it is not possible,

data typical for beet and cane syrups are available. Besides these some additional laboratory data are also

required.

SeedMaster 2 operates in two differ ent mod es:

1. in “Stand-by mode” it is waiting for the start (“activation”) of a new strike (vacuum pans

operating in batch mode);

2. in “Active mode” it is carrying out all of the calculations and operations it was designed for

(batch vacuum pans and continuous crystallizers).

Page 16

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

16

16

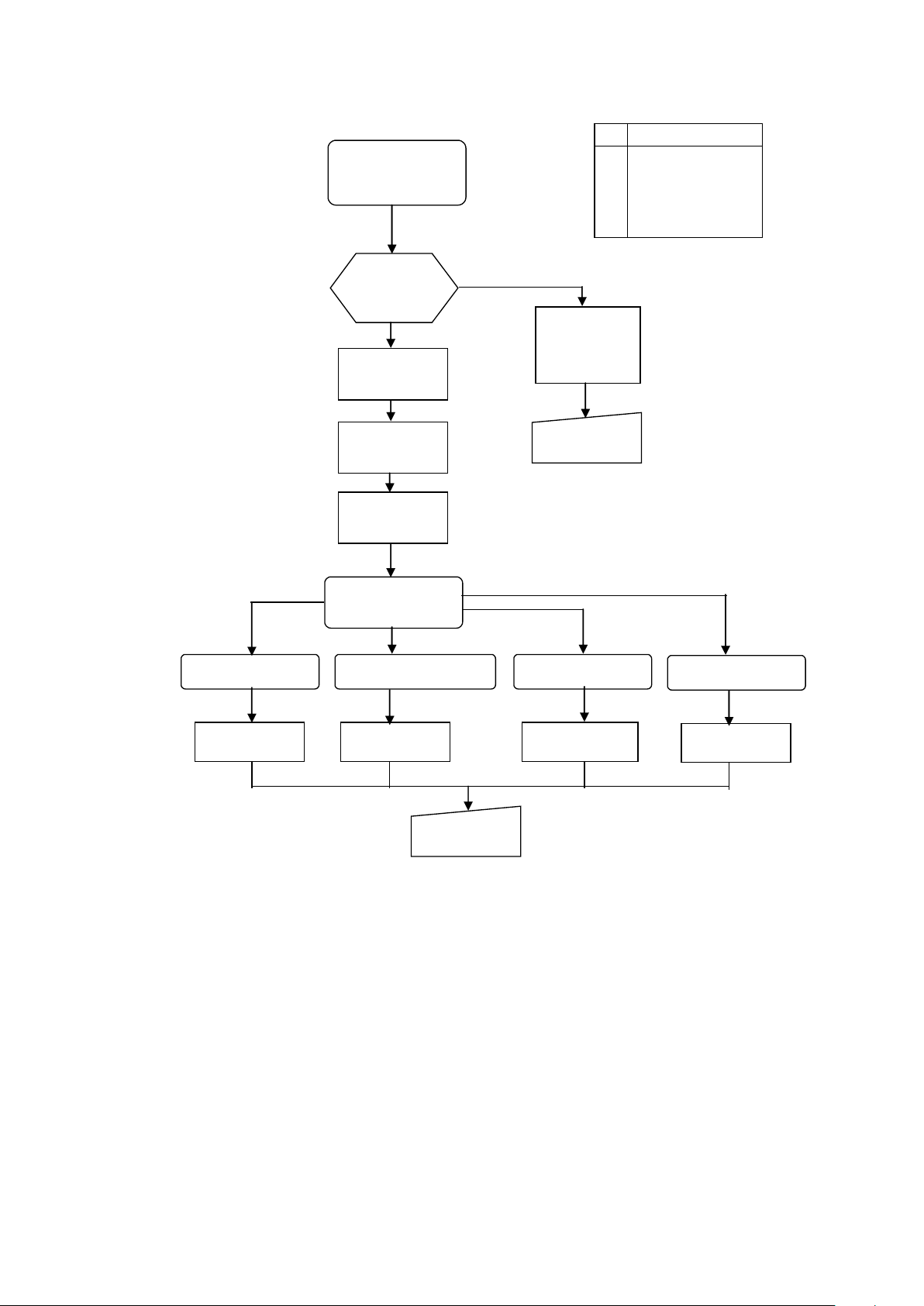

Data base

START On-line inputs

program once Parameters

every 10 sec Digital I/O

Calculated outputs

Archive data

Strike

ACTIVE?

ACTIVE YES STAND-BY

MODE MODE

Calculations operations

Archive END

data

Seeding

operations

Decision based on

THIRD INPUT

MASS. DENSITY MASS. SOLIDS CONT. MOTOR CONS. LAB. CR. CONT.

Calculations Calculations Calculations Calculations

END

Fig. 3.4 The basic SeedMaster 2 operations

Based on the calculated data SeedMaster 2 can be programmed to carry out automatic seeding of the

crystallizer on its own, when

• supersaturation, or

• massecuite density

becomes equal to the supersaturation or density set-point selected by the technologist or pan operator.

Actual seeding is carried out by opening the seed valve (digital output) for a pre-set time interval.

If seeding of the crystallizer is carried out not by SeedMaster 2, but by another device (a control system, for

example), or by the operator, SeedMaster 2 must be notified accordingly by a digital input, or via digital

communication.

All operations discussed above can be performed independently with two crystallizers at the same time.

3.4 Calculated data

Based on the information received SeedMaster 2 carries out involved calculations on-line. These, and one or

the other of the measured data used (density, solids content, motor consumption, or laboratory crystal

content data) are combined providing information on 7 massecuite parameters (set of massecuite

parameters) per crystallizer. These are:

Page 17

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

17

17

1. supersaturation (-)

2. crystal content (% by volume)

3. mother liquor purity (%)

4. massecuite density (kg / m)

5. massecuite solids content (%)

6. massecuite consistency (%)

7. mean c rystal size (mm)

Parameters No.1. and No.2. are the important ones for the advanced control of crystallization.

Parameters No.1. … No.3. and No.7. represent a drastic change in the type of information available in

real time for crystallization control, while No.4….No.6 provide accustomed data.

NOTES:

1. Any 2 out of the 7 (per crystallizer) listed above can be selected for transmission by standard (0…20 mA,

or 4…20 mA) current output.

2. All of these and some other data can be transmitted to a PC (Personal Computer), or PCS (Process

Control System) via digital communication.

3. Mean crystal size data are approximate and valid only if full seeding is practiced and no dissolution

of crystals or further nucleation takes place during crystallization.

3.5 On-line data inputs

The 2 obligatory on-line (real-time) data inputs required for the correct operation of SeedMaster 2 are:

1. syrup / mother liquor concentration, and

2. massecuite temperature.

It is highly recommended to use a third on-line data input (“Third input”) as well, which can be selected

from those listed below:

3. massecuite density (kg / m), or

massecuite solids content (%), or

stirrer motor power consumption (kW), or

stirrer motor current (A).

It does not matter what kind of instrument (nuclear, microwave etc.) is being used to measure density, or

solids content. If stirrer motor consumption provides the 3

preferred.

rd

data input, power consumption (kW) data are

3.5.1 Receiving syrup concentration data from the K-PATENTS refractometer(s)

There are several ways to transmit concentration data originating from a K-PATENTS refractometer to

SeedMaster 2 (see Ch. 7.2):

1. Standard current transmission (4 – 20 mA).

The transmitter can be the refractometer itself, or the standard current may come as current output from a

DCS-, or PLC-based Process Control System (PCS) already receiving the data from the refractometer. In this

case an analogue input channel of SeedMaster 2 sh oul d be used.

2. Digital communication using ports COM1, COM2, or COM3.

It is possible to transmit concentration (and temperature) data measured by K-PATENTS PR-01-S type

refractometer(s) by using serial data communication (RS232, RS422, RS485). SeedMaster 2 has 3 serial

ports (COM1, COM2, COM3). Two of these can be used to receive data directly from 2 PR-01-S type

refractometers at the same time . Cable length should be short, not exceeding 15 meters.

3. All data exchange (inputs and outputs) between SeedMaster 2 and a PCS can be implemented by

using one of the COM1…COM3 ports and MODBUS SLAVE (ASCII RTU) protocol.

4. Data input (concentration and temperature) to SeedMaster 2 from a K-PATENTS PR-23 type

refractometer with 1 or 2 sensor heads can be implemented by directly connecting them using the standard

ETHERNET connection and UDP / IP K-PATENTS refractometer protocol.

5. All data exchange (inputs and outputs) between SeedMaster 2 and a PCS can be implemented by

using the standard ETHERNET connection and TCP / IP MODBUS TCP protocol.

3.5.2 Receiving temperature data

Massecuite temperature is always measured by the sensor probe of the K-PATENTS refractometer and may

be available for transmission as standard current (4 – 20 mA) output (option). The Indicating Transmitter of

Page 18

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

18

18

the refractometer has (depending on the model used) two, or only a single current output. It is possible to use

an independent temperature sensor and standard current transmitter to transmit temperature data to

SeedMaster 2 as well. SeedMaster 2 has 2 (optional) RTD Pt100 type (Resistance Temperature Detector)

inputs as well. In these cases the temperature sensor should be located as close to the refractometer sensor

head as possible in order to measure the same sample temperature. From time to time re-calibration of the

temperature transmitter is advised.

Temperature measured by the refractometer can be transmitted (together with concentration data) by using

digital data communication (C OM1, COM2, COM3 and ETHERNET ports), too.

All data input versions listed with concentration data input (3.5.1) are available.

NOTE:

It is preferred to use temperature data measured by the refractometer.

3.5.3 Selecting the “THIRD INPUT” transmitter

Whenever available a “THIRD INPUT” transmitter should be used. If there are more than one available from

those already listed, massecuite density or solids content data are preferred. From these two the one offering

higher accuracy and stability should be used. Based on practical experience it is rather difficult to calibrate

and verify these devices. It is possible to make slight corrections in the data provided by them in SeedMaster

2 itself in order to achieve a better match with more accurate refractometer and laboratory data.

If stirrer motor data are used it is preferred to use motor power consumption (kW) data, because they better

reflect the mechanical power required to drive the stirrer (voltage fluctuations and the changing power factor

are also taken into account). As a last resort, motor current data can also be used.

NOTE:

The use of stirrer motor power or current consumption as “Third input” is limited to batch vacuum

pans operating without strike cut(s), that is without discharging some part of the massecuite before

the end of the strike. The trend of motor consumption data should look like one of those shown in

Fig. 7.5 or Fig. 7.6.

3.5.4 Using laboratory data instead of “THIRD INPUT”

It is always preferred to have on-line feedback (that is: on-line information from one of the instruments listed).

However, if there is no instrument available to use as “THIRD INPUT”, laboratory data on crystal content (%

by volume) at the end of a strike can be used with batch vacuum pan applications. In this case the instrument

carries out involved calculations in order to simulate the process of crystallization on-line. Based on

occasional crystal content data from the laboratory, the simulated process of crystallization is adapted by the

instrument using these data from the laboratory. All feat ures of SeedMaster 2 are available.

3.5.5 Optional data input

An optional LEVEL transmitter can be connected to one of the analogue input channels of SeedMaster 2.

The level data may come from a PCS via digital communication, too. The use of level data is optional: if

available, they are used to refine some of the calculations and to implement a smoo th transition from one

feed syrup to an other one, if feed syrups with different purities are used in the same batch strike. It can

.provide additional information on site for the pan operator, too. If there is no on-line data on level, instead of

level mean crystal size will be displayed on the Main Display.

3.6 Digital inputs

The 2 digital inputs (per pan) are typically contact (relay or switch) types. An “ACTIVE” digital input can be

configured either as an OPEN, or CLOSED relay (or switch) contact.

3.6.1 “STRIKE ACTIVE” input DIN1

SeedMaster 2 can be operated in “Stand-by”, or in “Active” mode (Fig. 3.4). In Stand-by mode it waits for the

start of a new strike (batch pans) and no calculations are performed. Displayed data might be not correct.

The Active mode should be evoked by the start of a new strike (feeding syrup in the pan begins), and s h o uld

usually end with the drop of the charge and motor switch OFF. In the time between two active strikes

(SeedMaster 2 in Stand-by mode) the pan is usually washed and is under normal pressure. Temperature and

concentration data can be quite far from their normal ranges.

Information on the “ACTIVE “status of a pan or crystallizer might come from 3 sources, namely:

• from a relay or switch contact (digital input DIN1), or

Page 19

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

19

19

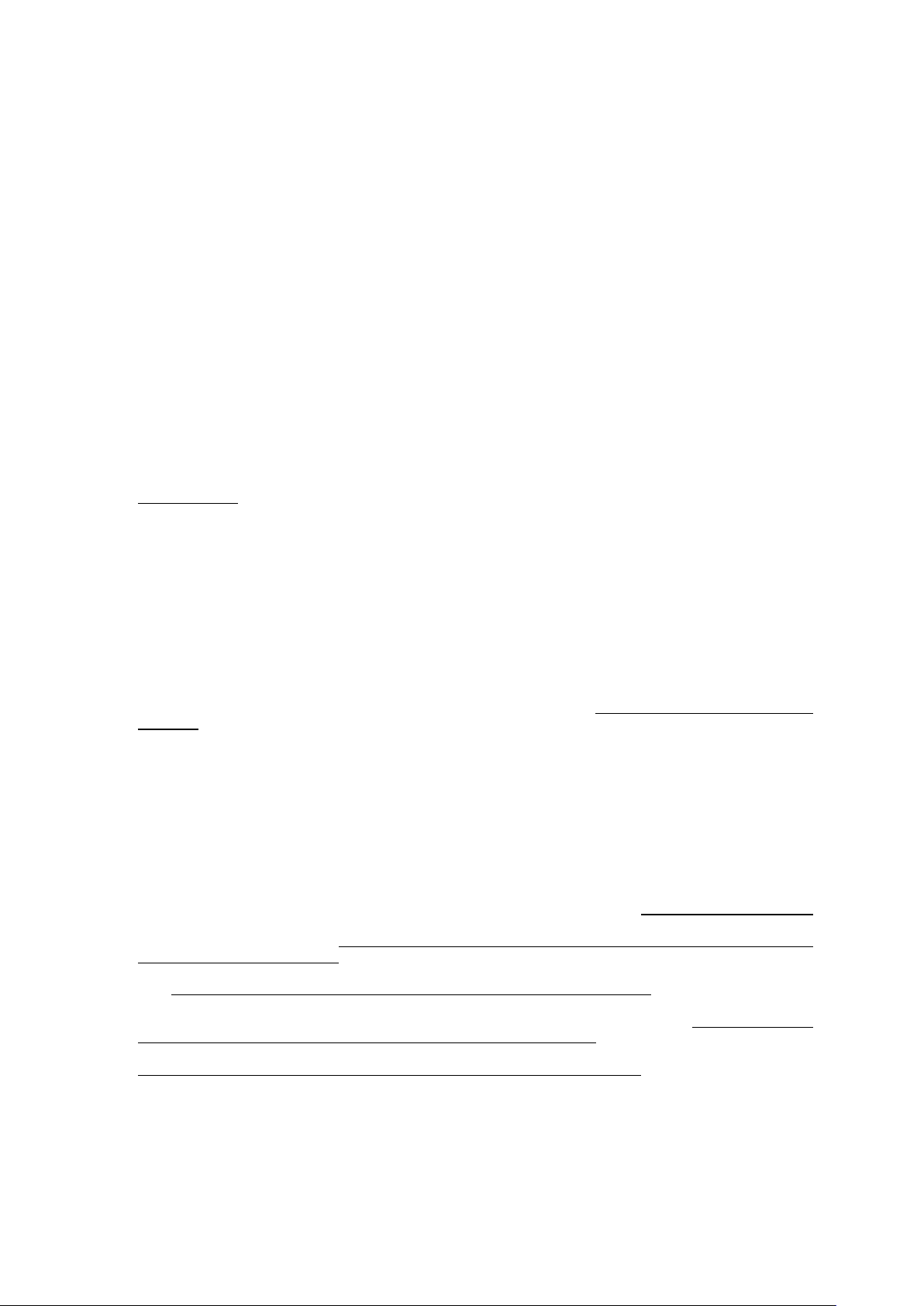

SEEDED DIN2

SEEDED DIN2

WAIT

STRIKE 1 ACTIVE

STRIKE 2 ACTIVE

Time

Time

S T R I K E A C T I V E

DIN1

• from the fact, that the current or power consumption of the stirrer motor exceeds a pre-set low

limit (cut off value, motor ON/OFF)), or

• from a PCS via digital communication.

NOTES:

1. The source of the “STRIKE ACTIVE” information can be selected from the above 3 during configuration.

If motor consumption or information from a PCS is being used to synchronise the operation of SeedMaster 2

to crystallizer status, digital input DIN1 can be left un-connected.

2. If motor consumption (power, or current) is used as “STRIKE ACTIVE”, un-intentional stop (due to mains

failure, motor problems etc.) of the stirrer motor during a strike will be treated as an “End of strike” signal.

3. It is advised to use a contact input for “STRIKE ACTIVE” signalisation.

3.6.2 “SEEDED” input DIN2

In order to perform the calculations correctly SeedMaster 2 needs information on the seeding of the pan.

There is no need for this input if seeding of the pan is carried out by SeedMaster 2 itself, that is if

• AUTOMATIC SEEDING was configured, or

• the operator uses the “MANUAL SEEDING” feature regularly (not advised).

However, if seeding is carried out

• either by an independent process control system (PCS), or

• the PCS commands SeedMaster 2 to do the seeding, or

• manually by the operator (pan-man) without using the “MANUAL SEEDING” feature of

SeedMaster 2,

the device must be notified on the seeding of the pan by a digital input lasting for at least 20 seconds.

In this case information may come in the form of a digital input (DIN2) signal, or via digital commu nication

from an independent control system (PCS).

NOTES:

1. Failing to provide information on seeding when needed will result in erroneous op er ation.

2. When SeedMaster 2 receives information from a PCS on seeding, it will operate the same way as it would

if MANUAL SEEDING were configured, that is it will OPEN the seeding valve (DO2, if connected) for the

configured Ton time.

3.6.3 “CHANGE FEED SYRUP” input DIN3.

If instead of a single one, 2 or 3 (maximum) feed syrups having different syrup purities are to be fed to the same batch strike the device must be informed on the execution of the change. One way to do it is to use a digital input (DIN3).

In this case information on purity and pan level may come in the form of 4-20 mA current from a PLC or DCS.

If there are no level data available, the SeedMaster 2 will use typical simulated level data in the 35-80 %

range. Operation of the DIN3 digital input will step the feed syrup purity to the one determined by the actual

current input (maximum 3 times). (For more information on feed syrup change see: 5.1.4 and 8.2.2).

3.7 Data outputs

3.7.1 Data available for transmission

Besides the 6 (out of 7) massecuite parameters 4 additional ones per pan are displayed on the LCD of

SeedMaster 2. Altogether 11 are available for transmission to an other device (PCS).

Page 20

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

20

20

Set of massecuite parameters:

1. supersaturation (-)

2. massecuite density (kg / m3)

3. massecuite solids content (%)

4. crystal content (% by volume)

5. massecuite consistency (%)

6. mother liquor purity (%)

7. mean c rystal size (mm)

Additional data:

8. syrup / mother liquor concentration (%)

9. stirrer motor consumption (if used) (kW, or A)

10. temperature (˚C)

11. level (%)

3.7.2 Standard current outputs

SeedMaster 2 hardware provides 2 standard current (4 – 20 mA, or 0 – 20 mA, configurable) output channels

per crystallizer. Any 2 out of the possible 11 parameters can be selected for transmission.

3.8 Digital (ON / OFF) outputs

There are 2 digital outputs available per crystallizer (DO1, DO2). These are implemented by switching

transistors (open collector) capable to switch 0,1 A (DC) current at 40 VDC, max.. The outputs are protected

against overload and overvoltage.

3.8.1 “SEED WARNING” output DO1

It is common practice to have the operator (pan-man) prepare the seed material (slurry) in advance and later

carefully stirring it for homogenisation, and fill it in the seeding vessel when seeding of the pan approaches.

The “SEED WARNING” output is configurable according to a supersaturation or density limit, and when this

limit has been reached the DO1 output will be turned ON activating a lamp or horn in order to signal the

operator that it is time to fill the seed slurry in its vessel. Having completed seeding this output will be turned

OFF automatically.

Alternatively this output can serve a different purpose, too. For example: if the seeding vessel has its own

small, motor driven stirrer, this output can be used to turn this stirrer ON in advance to homogenise the slurry

already filled in it.

3.8.2 “SEEDING” output DO2

Actual seeding of the pan is carried out by turning the DO2 output ON and opening the seeding valve for a

selected Ton time interval (configurable). This output will be operated in 3 cases:

• when AUTOMATIC SEEDING by SeedMaster 2 was configured,

• when MANUAL SEEDING by using SeedMaster 2 was carried out by the operator, and

• when it receives a command for seeding via input DIN2, or digital communication.

This same output can be used also when crystal footing is being used for seeding.

3.9 The man-machine interface

The man-machine interface of SeedMaster 2 consists of two main parts:

1. Parameterization of the device is basically tailoring (customizing) it to the application, taking into

account local circumstances and preferen ce s.

2. Operation of the device needs the built-in features of the different forms of data display, including

strike history, alarm and test data. Besides AUTOMATIC SEEDING it also provides a tool for MANUAL

SEEDING. Information on seeding details, strike

status and time are also displayed.

Page 21

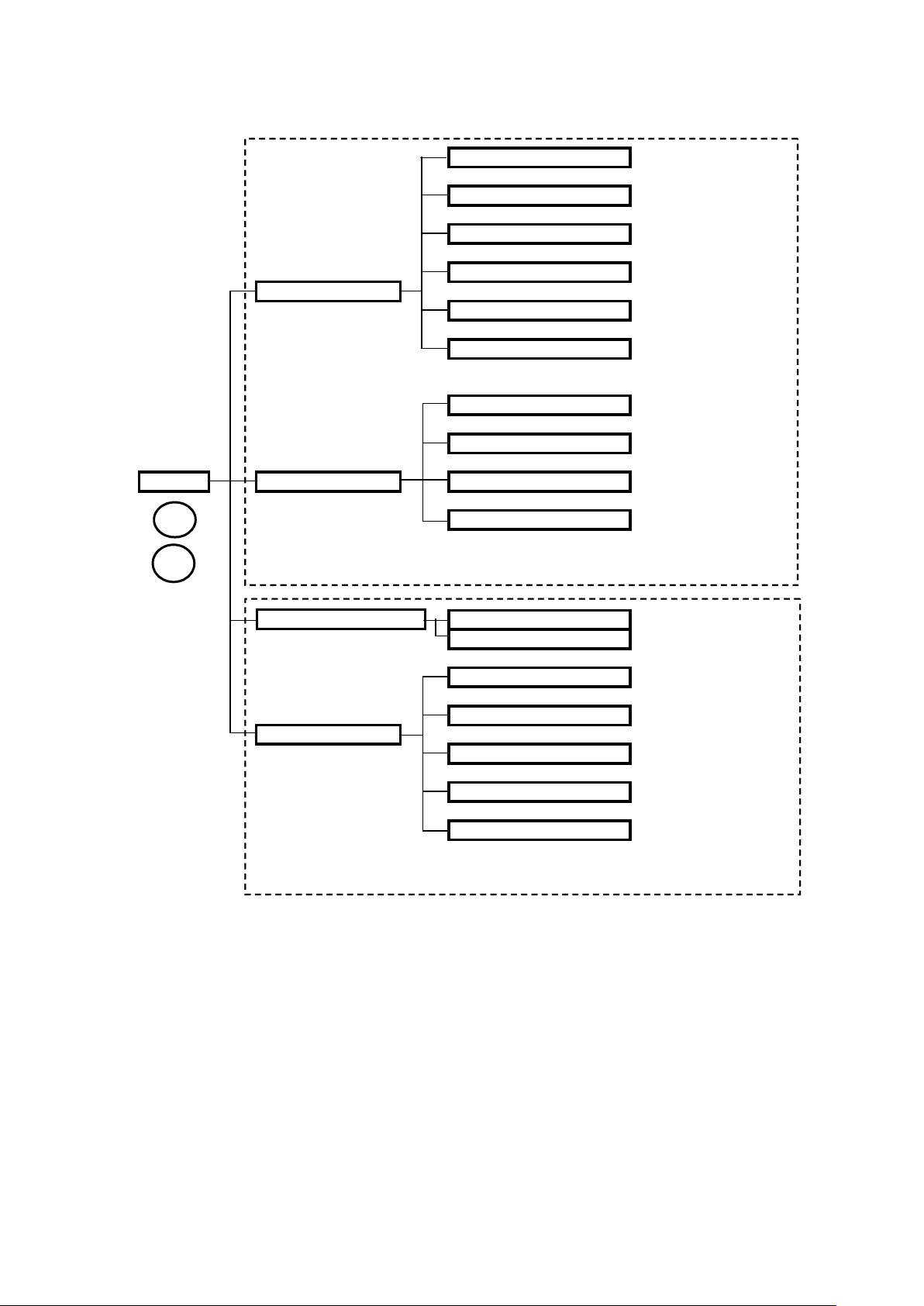

3 THE SEEDMASTER 2 CRYSTALLIZATION TRANSMITTER …

21

21

STRIKE ACTIVE SIGNAL

THIRD INPUT

SEEDING

ACTIVE INSTRUMENT

CONFIGURATION

PASSWORD

COMMUNICATION

DISPLAY

INPUTS

MENU SET UP DIGITAL I / O

1 ANALOG OUTPUT

2

DEVICE PARAMETERIZATION TOOLS

MANUAL OPERATIONS MANUAL SEEDING

CHANGE FSYRUP

TREND

STRIKE HISTORY

DISPLAY

STANDARD DISPLAY

SYTEM INFORMATION

TEST DATA

DEVICE OPERATION TOOLS

Fig. 3.5 The main branches of the SELECTION TREE

Page 22

4 TECHNICAL DATA, MOUNTING AND ELECTRICAL CONNECTIONS

22

22

4 TECHNICAL DATA, MOUNTING AND ELECTRICAL CONNECTIONS

SeedMaster 2 is based on the use of a high-power 32 bit microprocessor and a high capacity (32 MB)

memory operating under a real-time operating system. This, the application program of the device together

with parameters, measured and calculated data are stored in CF (Compact Flash) memory. Parameters,

calculated and archive data are stored every minute in the memory, therefore eventual loss of power supply

will not result in loss of these data. The real-time clock chip (DALLAS DS12887) used in the device has its

own lithium battery and needs replacement only after 10 years.

In order to increase reliability and to reduce servicing, no potentiometers are used in the instrument.

4.1 Specifications

Main device features

1. On-line calculation, display and transmission of up to 7 massecuite parameters and up to 4

additional monitored data during sugar crystallization for up to 2 pans simultaneously.

2. Automatic seeding of vacuum pans based on calculated supersaturation or density set-point for

seeding selected by the local technologist.

3. Collecting all calculated and measured data for the last 4 strikes in strike history archives, which can

be displayed as trends with appropriate time data. Brief (numerical) supersaturation strike history

(last 4 strikes).

4. Advanced communication features including the Ethernet.

5. Large LCD numeric and graphic display, robust design.

Data available for transmission

1. Calculated data (all over a complete strike):

1. Supersaturation (-)

2. Crystal content (% by volume)

3. Density (kg / m)

4. Consistency (%)

5. Solids content (%)

6. Mother liquor purity (%)

7. Mean crystal size (mm)

2. Additional data monitored in real time:

1. Syrup / mother liquor concentration (%)

2. Stirrer motor consumption (if used) (kW, or A)

3. Temperature (˚C)

4. Level (optional) (%)

Inputs for calculation

1. Process inputs:

1. Syrup / mother liquor concentration measured by K-PATENTS refractometer(s)

2. Massecuite temperature measured by K-PATENTS refractometer(s), or separate

transmitter(s).

3. Third par ty tran smi tter mea s ur ing

• density, OR

• massecuite solids content, OR

• stirrer motor power, or current consumption.

4. Optional input: massecuite level.

2. Digital (ON / OFF) inputs (depending on the selected mode of operation):

1. None.

2. Maximum 3 (DIN1: “Strike active”, DIN2: “Seeded”, DIN3:”Change feed syrup”).

3. Laboratory data:

1. Feed syrup purity (%).

2. Syrup quality (“m”, “b”, “c”) parameters. Typical data and a description of a procedure to

determ ine lo cal para meter s are prov ided.

NOTE:

All inputs can be also received via digital communication.

Page 23

4 TECHNICAL DATA, MOUNTING AND ELECTRICAL CONNECTIONS

23

23

Calculated outputs

1. Analog (0-20, 4-20 mA) outputs:

Any 2 of the 7 calculated massecuite parameters (per pan).

2. Digital (ON / OFF) outputs:

1. DO1: Warning on approaching seeding (programmable).

2. DO2: Opening the seeding valve for a selected time interval.

NOTE:

All calculated and measured data can be also transmitted via digital communication.

Process interface

Inputs

1. Analog current 8 channels

Symmetr ical, galvanically isolated

Range 0(4)-20 mA, keyboard selectable

Input impedance 100 Ohm

Common mode voltage 50 V max.

2. RTD (Pt 100) (option) 2 channels

4 wire connecting mode

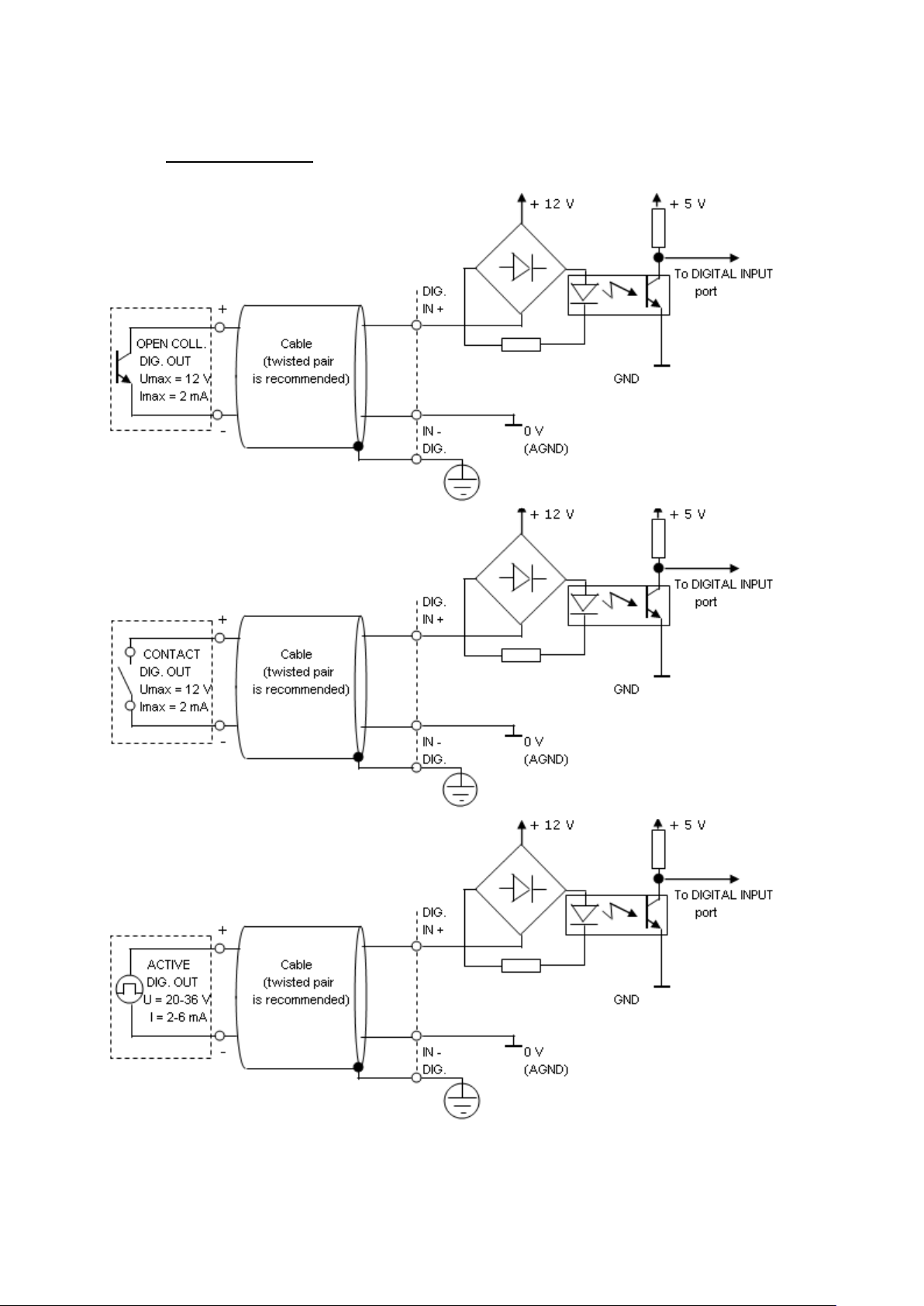

3. Digital (ON / OFF) 8 channels

Signal sources: passive, contact or open collector

active, + 24 Vdc

automatic signal detection

Outputs

1. Analog current 4 channels

Galvanically isolated

Range 0(4)-20 mA, keyboard selectable

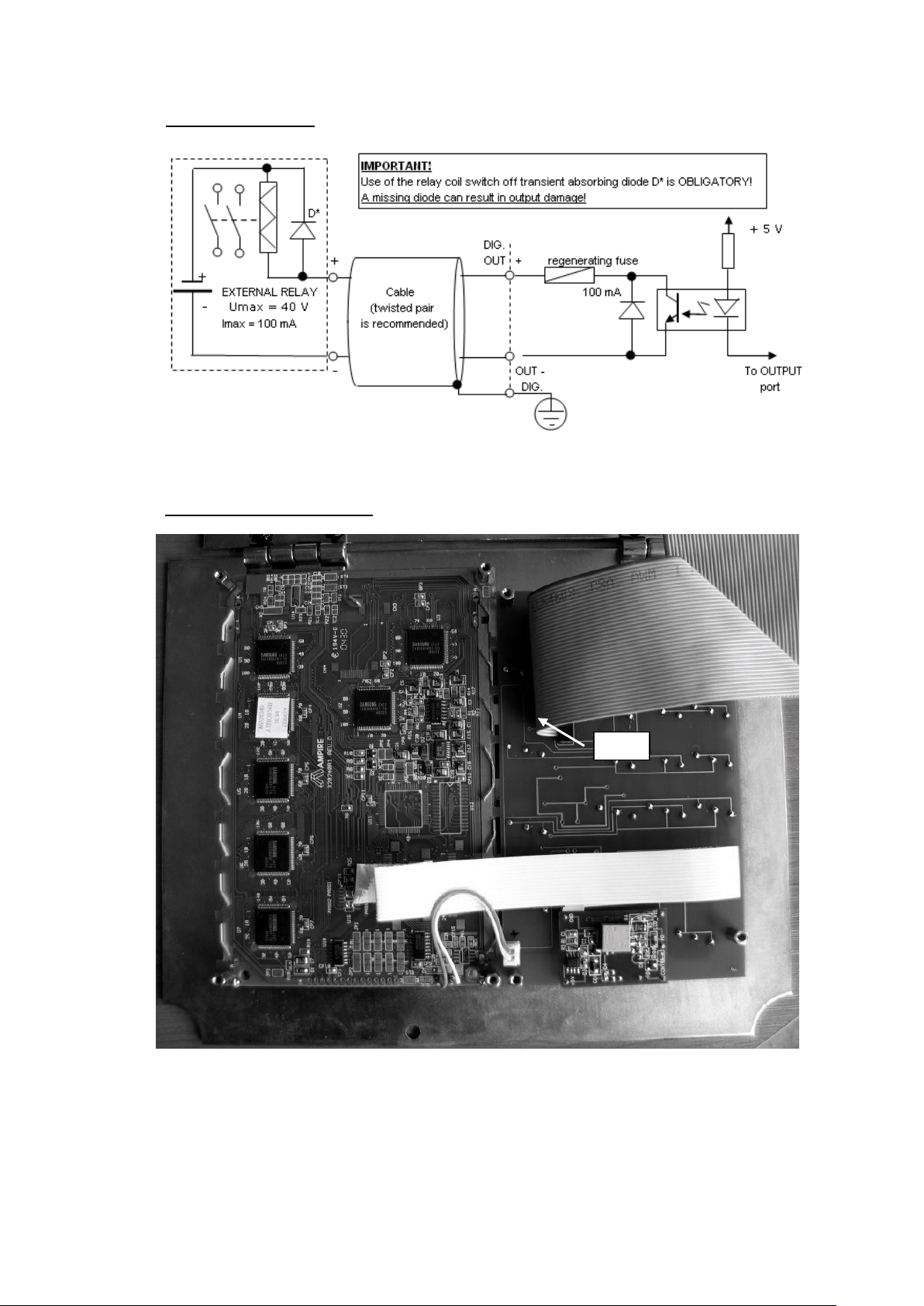

Max. load 600 Ohm

2. Digital ON / OFF) 4 channels

Isolated open collector,

overvoltage and short circuit protected

3. Power supply for transmitters 1 X 24 Vdc, 200 mA max.

4. Device Status (ON/OFF) Operating / Error

Communication

1. Serial (COM1, COM2, COM3) 3 ports

Galvanically isolated

Standards RS232, RS422, RS485 (keyboard selectable)

Control signals CTS, RTS (keyboard selectable)

Baud rates 1200…38400 Baud (keyboard selectable)

Length of cable RS232 15 m max.

RS422 /485 1200 m max.

Protocols K-PATENTS refractometer protocol

MODBUS SLAVE (ASCII, RTU)

2. Ethernet 10 6 100 Base T

Connector RJ45

Protocols TCP / IP, MODBUS TCP,

UDP / IP (K-PATENTS refractometer protocol)

Front panel

Display 5,7 ‘ QVGA 320x240 graphic LCD

Keyboard Membrane switches with flexible foil cover

LED indicators Power, Run, Alarm

Power supply 100…240 V ac, 50 / 60 Hz; 10-25 VA

24 (18…30) Vdc

Page 24

4 TECHNICAL DATA, MOUNTING AND ELECTRICAL CONNECTIONS

24

24

NOTE:

AC and DC types of supply can be connected to the device at the same time. When AC supply is available it

will be selected for use, otherwise the DC supply will be the active one. Switch-over from one to the other is

automatic and bumpless.

Temperature range (ambient)

Operation 0…50 ˚C

Storage - 25…70 ˚C

Enclosure

IP66, NEMA 4X

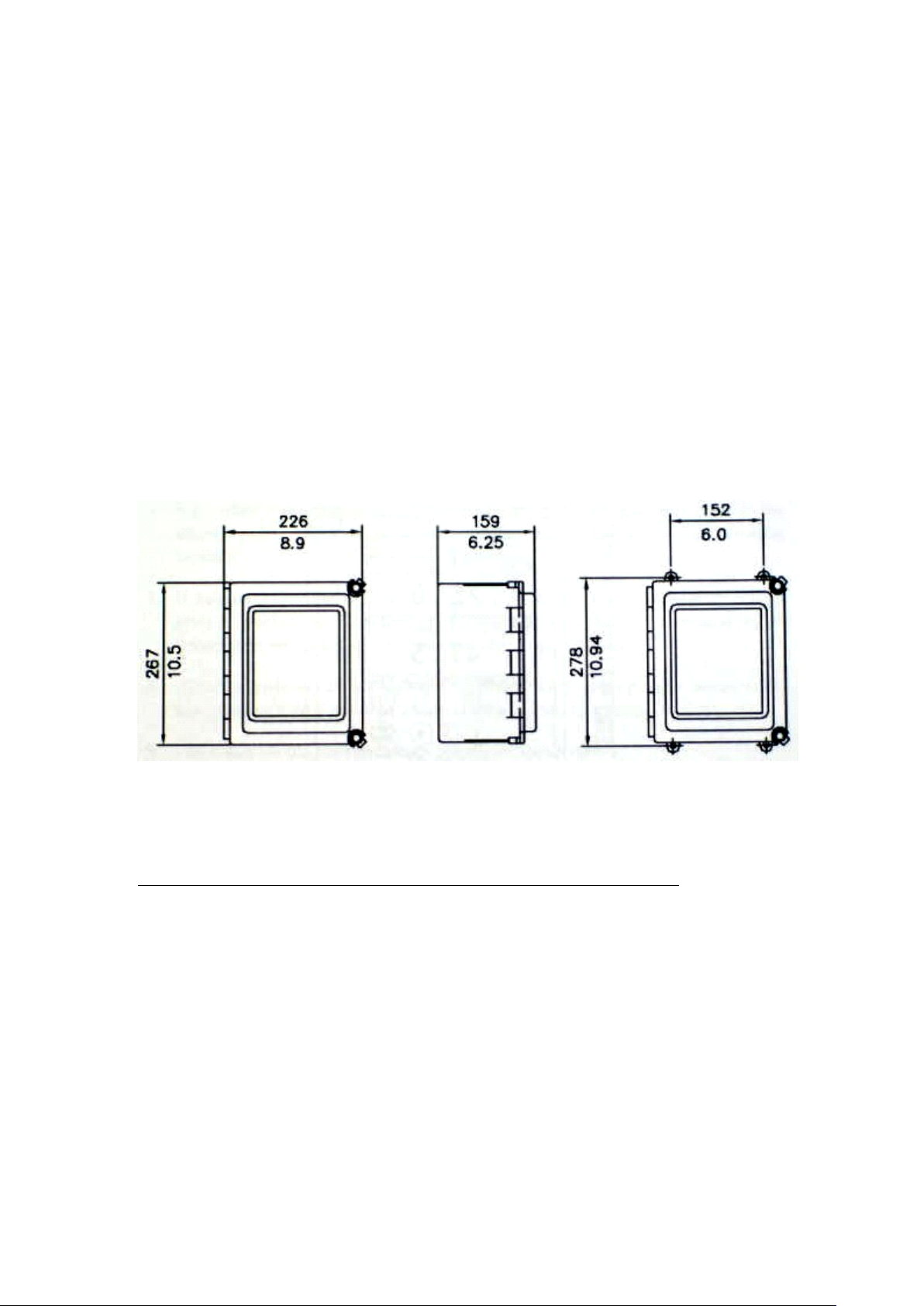

Size (mm / inch) H: 267 / 10,5; W: 226 / 8,9; D: 159 / 6,25

NOTE:

The SeedMaster 2 enclosure is identical to the one used by the Indicating Transmitters of the K-PATENTS

refractometer family and should be mounted taking into account the same considerations, that is:

• do not expose it to direct sunlight and rain, or splash water,

• avoid vibration,

• mount it vertically on an upright surface in a dry and well-lit area,

• do not drill mounting holes in the enclosure.

Fig. 4.1 SeedMaster 2 dimensions and mounting feet measures

4.2 Electrical connections

4.2.1 Power supply

Power to the instrument must be connected by a cable with protective earth connection. Even if DC supply is

used (see Ch. 4.1), in order to maintain the accuracy of the analog inputs the protective earth connection

must be used via the mains connector.

NOTES:

1. There is no mains switch in the instrument! An external power switch should be used.

2. Check if your mains voltage specification and that of the instrument are identical before first

switching on the instrument!

WARNING!

Check if the power is off before opening the Front panel. If the red POWER LED on the Front panel is

ON, turn off the power first by unplugging the power supply cable or switch it OFF with the external power

switch.

Page 25

4 TECHNICAL DATA, MOUNTING AND ELECTRICAL CONNECTIONS

25

25

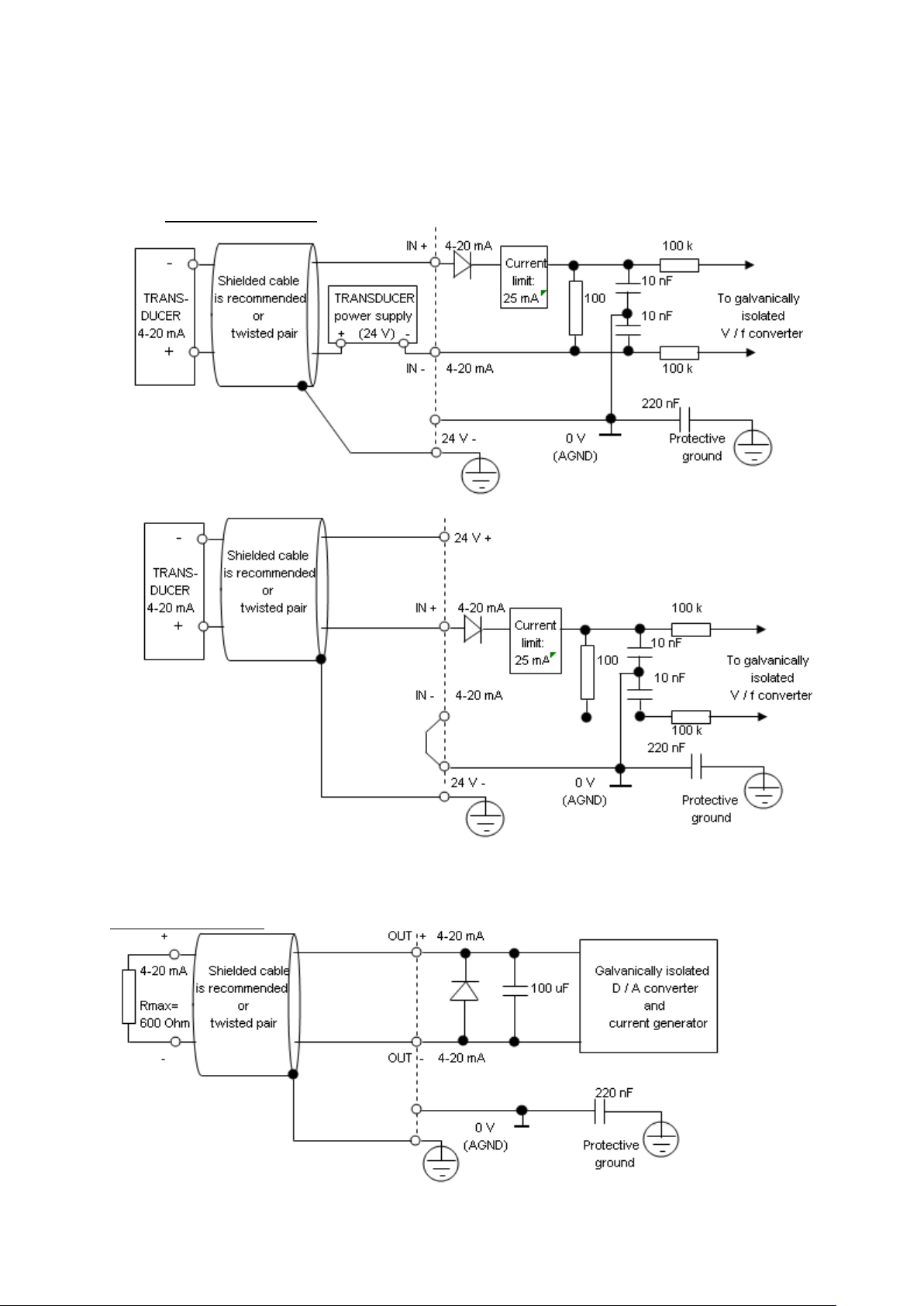

Fig. 4.2 Electrical connections

There are two screw-type terminals for power connection in the bottom of the enclosure (se e Fig. 4.2). The

one on the right side has 3 terminals (L: line, G: ground, N: neutral) to connect the AC power input, while the

one on the left has 2 terminals with polarity markings for 24 V DC input. Both power inputs have their

dedicated fuses.

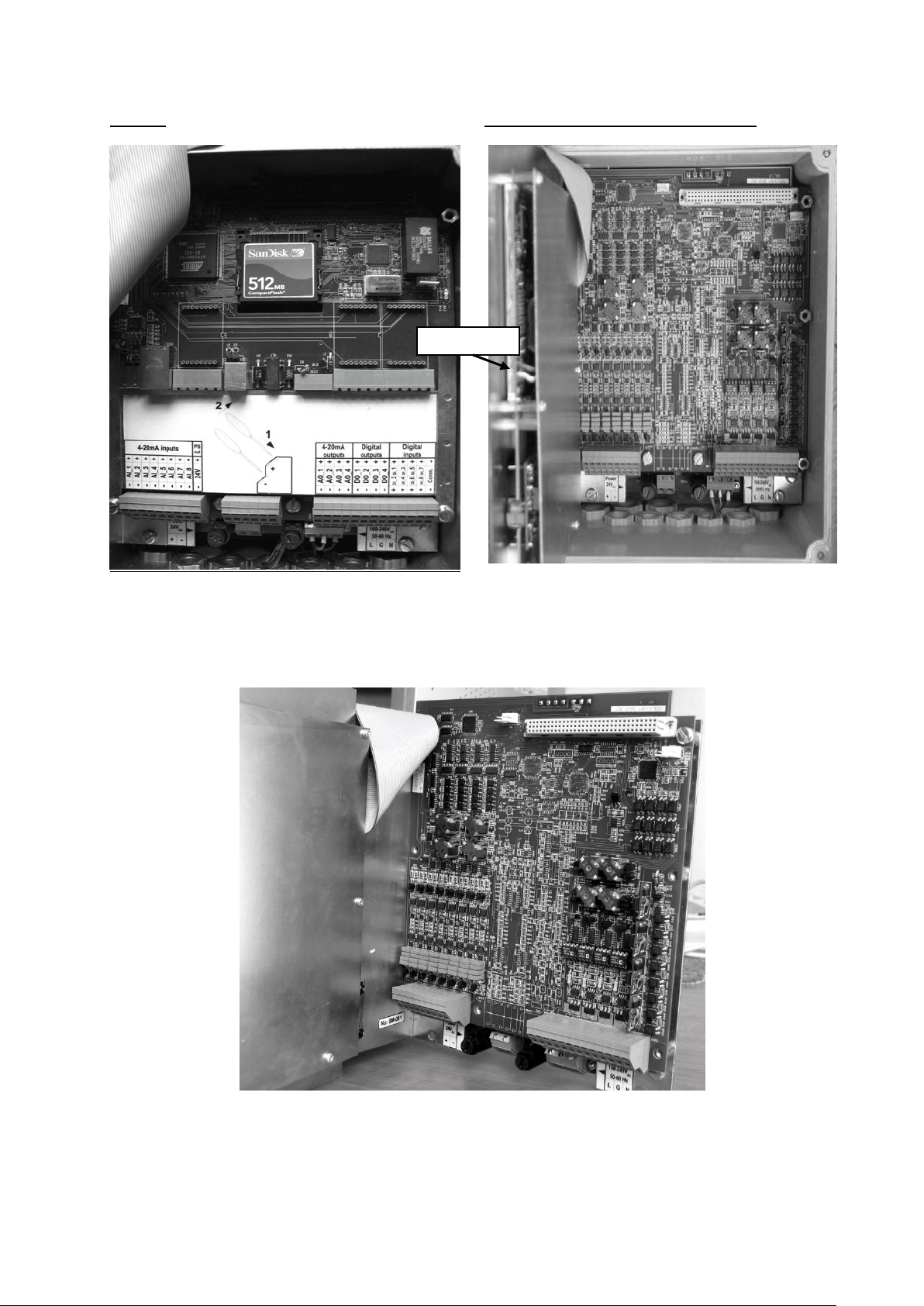

4.2.2 Process inputs and outputs

Process inputs and outputs use printed circuit spring cage terminal blocks. There are 2 connection points

(polarity is marked) per terminal block. Just above the power input level on the left side there are terminals for

8 analog input (AI) channels (0-20, or 4-20 mA, keyboard selectable) and a 24 V DC output (PS out) to

supply power for transmitters (max. load: 200 mA).

On the same level on the right side similar terminals for 4 analog output (4-20 mA) channels (AO, channels

1…4) are located. These are followed by 4 digital output channels (DO, channels 1…4), then by 8 digital

inputs (DI, channels 1…8). The digital inputs have their common terminal point (common) in the rightmost

position. All terminal points have their appropriate polarity markings.

4.2.3 Digital communication

There are screw-type terminals on the highest level (Fig. 4.2) for 3 serial communication ports (Com1, Com2,

Com3). Their connection points are colour-coded according to the selected type of communication (black:

RS232, red: RS485, blue: RS422).

The Ethernet 10/100 port is located to the left of the Com1 port.

Page 26