Page 1

INSTRUCTION MANUAL

FOR INLINE REFRACTOMETER

PR-03

WARNING

The process medium may be hot or otherwise hazardous.

Protected by one or more of

the following U.S. patents:

Patent No. 4,571,075

Patent No. 5,563,737

Patent No. 5,009,113

Patent No. 5,617,201

Patent No. 5,309,288

Patent No. 6,067,151

Precautions when removing the sensor from the process line:

Make positively sure that the process line is not under pressure. Open a vent valve to the atmosphere.

For a prism wash system, close a hand valve for the wash medium and disable the wash valve.

Loosen the clamp cautiously, be prepared to tighten again.

Be out of the way of any possible splash and ensure the possibility of escape.

Use shields and protective clothing adequate for the process medium.

Do not rely on avoidance of contact with the process medium.

After removal of the sensor, it may be necessary to mount a blind cover for security reasons.

Document/Revision No. INM-3: Rev. 2/4 Effective: February 15th, 2005

This product manual is delivered to the end user with a K-Patents product.

Information in this manual is subject to change without notice. When the manual is changed,

a revised copy is made available at http://www.kpatents.com/.

Feedback on this manual can be sent by email to manuals@kpatents.com.

THE PASSWORD FOR PR-03 IS 7 8 4 5 1 2 IN PROGRAM VERSIONS 4.0 AND HIGHER.

K-PATENTS OY

Postal address:

P.O. Box 77

FIN-01511 Vantaa, Finland

Tel. + 358-9-825 6640

Fax +358-9-8256 6461

info@kpatents.com

www.kpatents.com

K-PATENTS OY

Street address:

Elannontie 5

FIN-01510 Vantaa, Finland

K-PATENTS, INC.

1804 Centre Point Circle,

Suite 106,

Naperville, IL 60563

Tel. +1-630-955 1545

Fax +1-630-955 1585

Info@kpatents-usa.com

www.kpatents.com

Page 2

Page 3

Table of contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 PR-03 refractometer models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Principle of measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 General safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Inline refractometer sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Sensor description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Mounting the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.1 Choosing sensor mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.2 Check list for pipe mounting (PR-03-A, PR-03-D, PR-03-M) . . . . . . . . . . . . . . . . . . . . . 7

2.2.3 Check list for mounting in a tank, a vessel or a large pipe (PR-03-P) . . . . . . . . . . . . . . . 8

3 Indicating transmitter (IT-R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Indicating transmitter description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Mounting Indicating transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Mounting the Interconnecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2.1 Connecting with sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2.2 AC power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2.3 +24 V DC power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.2.4 Current output connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2.5 Serial bus connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2.6 Input switch connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.3 Serial output connections: connecting a computer with the IT-R . . . . . . . . . . . . . . . . . 14

3.2.4 Demo mode connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Cable signals between IT-R and sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 Accessory units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Separate relay units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1 Relay unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.1.1 Relay unit PR-7080 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1.2 Relay unit -WR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 Prism wash system description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3 Relay unit mounting and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3.1 Mounting and connecting Relay unit PR-7080 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3.2 Mounting and connecting Relay unit -WR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.4 Mounting and connecting prism wash systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.4.1 Recommended wash pressures and times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.4.2 Prism wash nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.4.3 Mounting of prism wash systems with steam and water . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.4.4 Mounting of prism wash systems with high pressure water . . . . . . . . . . . . . . . . . . . . 25

4.2 External output unit PR-7090 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.2 External output unit mounting and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Page 4

5 Startup, configuration and calibration adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 System check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.1 Checking accessory units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.2 Testing prism wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3 Using Indicating transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3.1 Keyboard functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4 Soft key Display: Getting information on the process

and the settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.4.1 Viewing the Optical image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.4.2 Viewing System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.4.3 Checking conditions inside sensor head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.5 Soft key Calibrate: Viewing and changing system settings . . . . . . . . . . . . . . . . . . . 34

5.5.1 Viewing Optical image and raw data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.5.2 Raw data explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.5.3 Viewing Scaled image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.5.4 Viewing slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.5.5 Viewing Image diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.6 Configuring input switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.7 Configuring relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.8 Configuring external output unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.9 Configuring automatic prism wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.9.1 Timed wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.9.2 Smart wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.9.3 Preventing automatic wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.9.4 Prism wash check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.10 Adjusting concentration calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.10.1 Checking current calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.10.2 Concentration calibration from keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.10.3 Output current range selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.10.4 Temperature calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.10.5 Adjusting damping time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.10.6 Field calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.10.7 Bench calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6 Regular maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1 Checking the sensor moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Checking and replacing prism or prism gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Disassembling and assembling a standard length sensor . . . . . . . . . . . . . . . . . . . . . . . 48

6.3.1 Disassembling the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3.2 Replacing the prism and prism gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3.3 Assembling the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.4 Disassembling and assembling a probe sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.4.1 Disassembling the probe sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.4.2 Replacing the prism and prism gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.4.3 Assembling the probe sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Page 5

7 Troubleshooting and correcting problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.1 Troubleshooting Indicating transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Troubleshooting sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.1 LED value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.2 Sensor temperature and humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2.3 Slope value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.2.4 Image diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8 Sensor specifications and

other sensor information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.1 Sensor labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.2 Sensor compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3 Sanitary refractometer PR-03-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.3.1 PR-03-A sensor model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.3.2 PR-03-A mounting hardware model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.3.3 PR-03-A specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.3.4 PR-03-A parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.3.5 PR-03-A mounting specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.4 Probe refractometer PR-03-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.4.1 PR-03-P sensor model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.4.2 PR-03-P mounting hardware model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.4.3 PR-03-P specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.4.4 PR-03-P parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.4.5 PR-03-P mounting specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.4.6 PR-03-P programming specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.5 Compact process refractometer PR-03-D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.5.1 PR-03-D sensor model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.5.2 PR-03-D mounting hardware model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.5.3 PR-03-D specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.5.4 PR-03-D parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.5.5 PR-03-D mounting specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.6 Process refractometer PR-03-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.6.1 PR-03-M sensor model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.6.2 PR-03-M specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.6.3 PR-03-M parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.6.4 PR-03-M mounting specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.7 Valve body refractometer PR-03-W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

8.7.1 PR-03-W sensor model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.7.2 PR-03-W specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.7.3 PR-03-W parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.7.4 PR-03-W mounting specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Page 6

9 Indicating transmitter specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.1 IT-R label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2 IT-R compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2.1 Upgrading IT-R program version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.3 Model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3.1 IT-R model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3.2 Interconnecting cable model code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.4 IT-R Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.4.1 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.4.2 Serial output specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.4.3 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.5 IT-R Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9.6 Command selection tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.7 Display messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10 PR-03 process refractometers in potentially explosive atmosphere . . . . . . . . . . . . . 101

10.1 Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.3 PR-03-...-AX parts list: differences to standard sensors . . . . . . . . . . . . . . . . . . . . . . . 103

A Glossary and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

B Information about Delivery data sheet (DDS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

C K-Patents inline refractometer calibration data report . . . . . . . . . . . . . . . . . . . . . . . . . 109

D Instrument verification ISO 9000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Page 7

1 Introduction 1

C: Indicating Transmitter

ABCD

7

4

1

0

8

5

2

.

9

6

3

-

ENTER RESET

K-PATENTS

PROCESSINSTRUMENTS

B: Interconnecting cable

A: Sensor

1 Introduction

The K-Patents inline refractometer is an instrument for measuring liquid concentration in the process line.

The measurement is based on the refraction of light in the process medium, an accurate and safe way of

measuring liquid concentration.

The refractometer sensor (A in figure Figure 1.1), mounted inline, sends a ray of light into the process

medium and measures the angle in which the light is refracted back from the liquid. This information is

then sent via the interconnecting cable (B) to the Indicating transmitter (C). The Indicating transmitter (ITR) then calculates the concentration of the process liquid based on the refractive angle, taking temperature

and pre-defined process conditions into account. The output the IT-R provides is a 4 to 20 mA DC output

signal proportional to process solution concentration, but a serial output is also available as a standard.

Figure 1.1 Refractometer equipment.

1.1 PR-03 refractometer models

The basic system of a sensor and an Indicating transmitter connected with a cable is the same in all PR-03

Inline refractometer models. However, there are different sensor models, each adapted for different process

requirements.

The Sanitary refractometer sensor PR-03-A and the Probe refractometer sensor PR-03-P both meet

the 3-A Sanitary Standard requirements. The model PR-03-A is an all-purpose instrument for a variety of

alimentary processes while the PR-03-P is especially designed for cookers and tanks and can even be used

in combination with a scraper in alimentary as well as other processes.

The Compact process refractometer PR-03-D is an all-round instrument for measuring the concentration

of a wide range of chemicals and liquids. The Process refractometer PR-03-M is built for chemically

aggressive solutions and ultra-pure processes, all of its wetted parts are made of non-metallic materials.

The Valve body refractometer PR-03-W is very similar to the Process refractometer PR-03-M, but the

special valve body makes it possibly to use it in large-scale production and large pipelines.

The model number of a refractometer system is displayed on the serial number label on the sensor head

(see Chapter 8, “Sensor specifications and other sensor information”). The serial numbers on the sensor

identification label (see Chapter 8) and the transmitter’s identification label (see Chapter 9) should always

match.

Page 8

2 PR-03 instruction manual

L

P

MM

S

A C B

BB

C

C

A

A

Low concentration High concentration

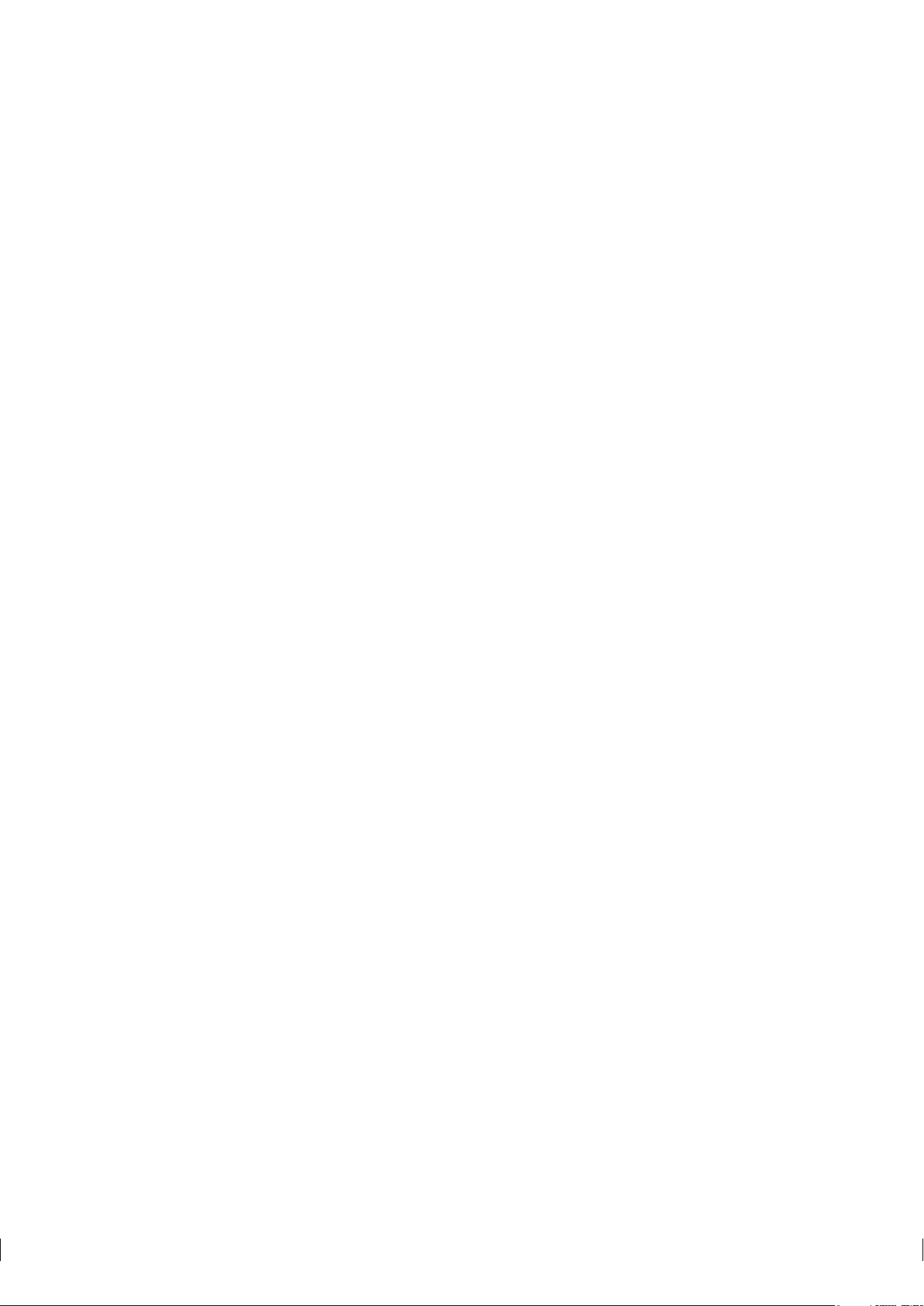

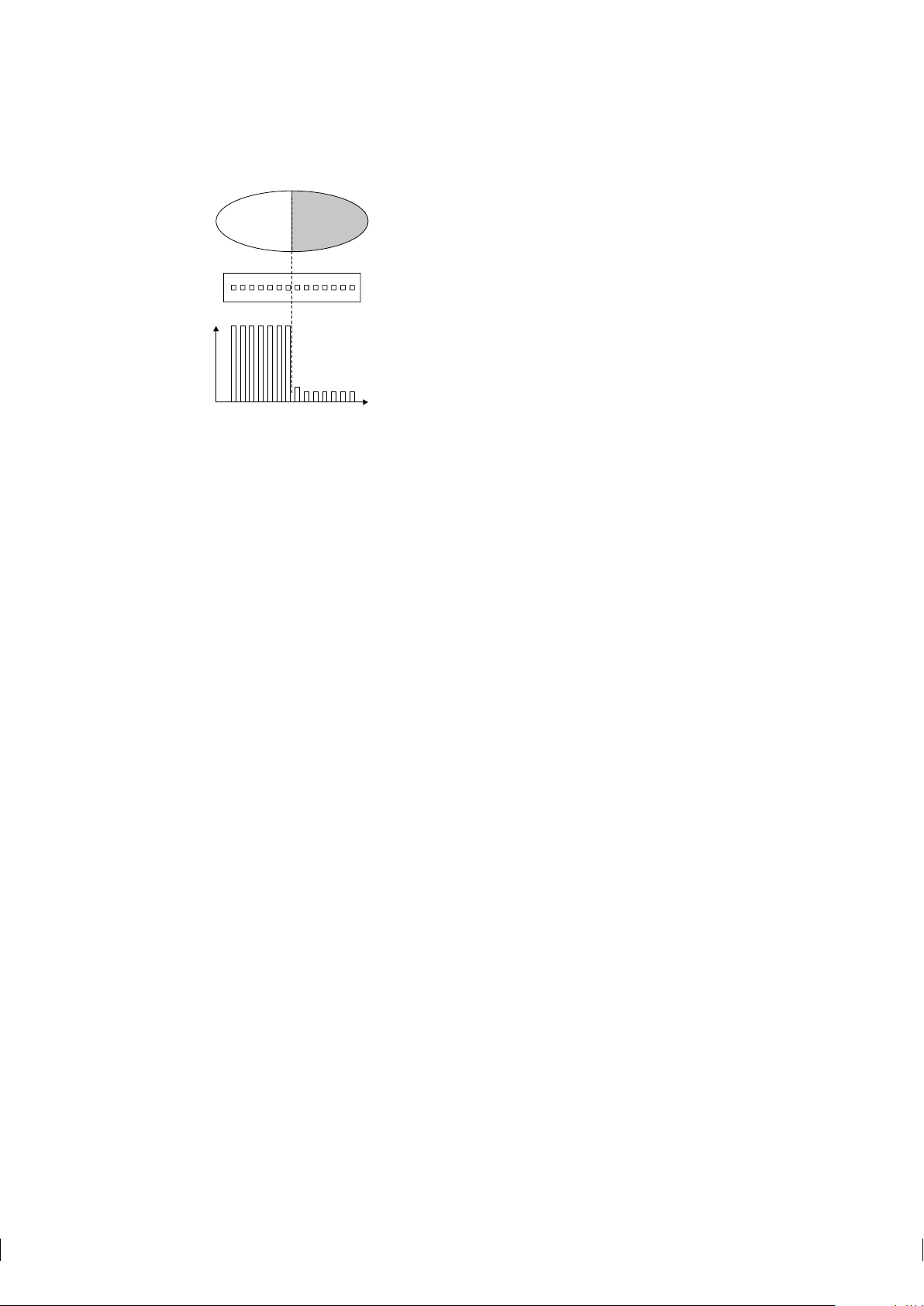

1.2 Principle of measurement

The K-Patents inline refractometer sensor determines the refractive index (R.I.) of the process solution by

measuring the critical angle of refraction. Light from a light source ((L) in Figure 1.2) in the sensor is

directed to this interface. Two of the prism surfaces (M) are total-reflecting mirrors bending the light rays

that thus meet the inter face at different angles.

Figure 1.2 Refractometer principle

The reflected rays of light form an image (ACB), where (C) is the position of the critical angle ray. The

rays at (A) are totally reflected at the process interface, the rays at (B) are partially reflected and partially

refracted into the process solution. In this way the optical image is divided into a light area (A) and a dark

area (B). The position of the borderline (C) between the areas shows the value of the critical angle and thus

of the refractive index (R.I.) of the process solution.

The R.I. changes with the process solution temperature and concentration. In higher temperatures the R.I. is

smaller than in room temperature (standard R.I. 25◦C). When the concentration changes, the R.I. normally

increases when the concentration increases. From this follows that the optical image changes with the

process solution concentration as shown in Figure 1.3. The color of the solution, gas bubbles or undissolved

particles do not affect the result.

Figure 1.3 Optical images

The optical image thus achieved is converted to an electric signal by a digitizer inside the sensor. This

electric signal is then sent via an interconnecting cable to the Indicating transmitter’s microprocessor for

further processing, displaying and transmitting.

Page 9

1 Introduction 3

1.3 General safety considerations

The process medium may be hot or otherwise hazardous. Use shields and protective clothing adequate for

the process medium - do not rely on avoidance of contact with the process medium.

Precautions when removing the sensor from the process line:

• Make positively sure that the process line is not under pressure. Open a vent valve to the atmosphere.

• For a prism wash system, close a hand valve for the wash medium and disable the wash valve.

• Loosen the clamp cautiously, be prepared to tighten again.

• Be out of the way of any possible splash and ensure t he possibility of escape.

• After removal of the sensor, it may be necessary to mount a blind cover for security reasons.

1.4 Warranty

K-Patents warrants that all products made by K-Patents shall be free of defects in material and workmanship.

K-Patents agrees to either replace or repair free of charge, any such product or part thereof which shall be

returned to the nearest authorized K-Patents repair facility within two (2) years from the date of delivery.

Before returning a defective product for service or replacement, please contact K-Patents or your nearest

K-Patents representative (see http://www.kpatents.com/ for contact information). For the health and safety

of personnel handling your return, clean the instrument, especially the parts that have been in contact with

the process liquid, before packing it. Ship the cleaned instrument to the address given to you.

1.5 Disposal

When disposing of an obsolete instrument or any parts of an instrument, please observe the local and national requirements for the disposal of electrical and electronic equipment. The steel Indicating transmitter

enclosure and the aluminium or stainless steel sensor housing can be recycled with other metallic waste of

the same type.

Page 10

4 PR-03 instruction manual

Page 11

2 Inline refractometer sensor 5

2 Inline refractometer sensor

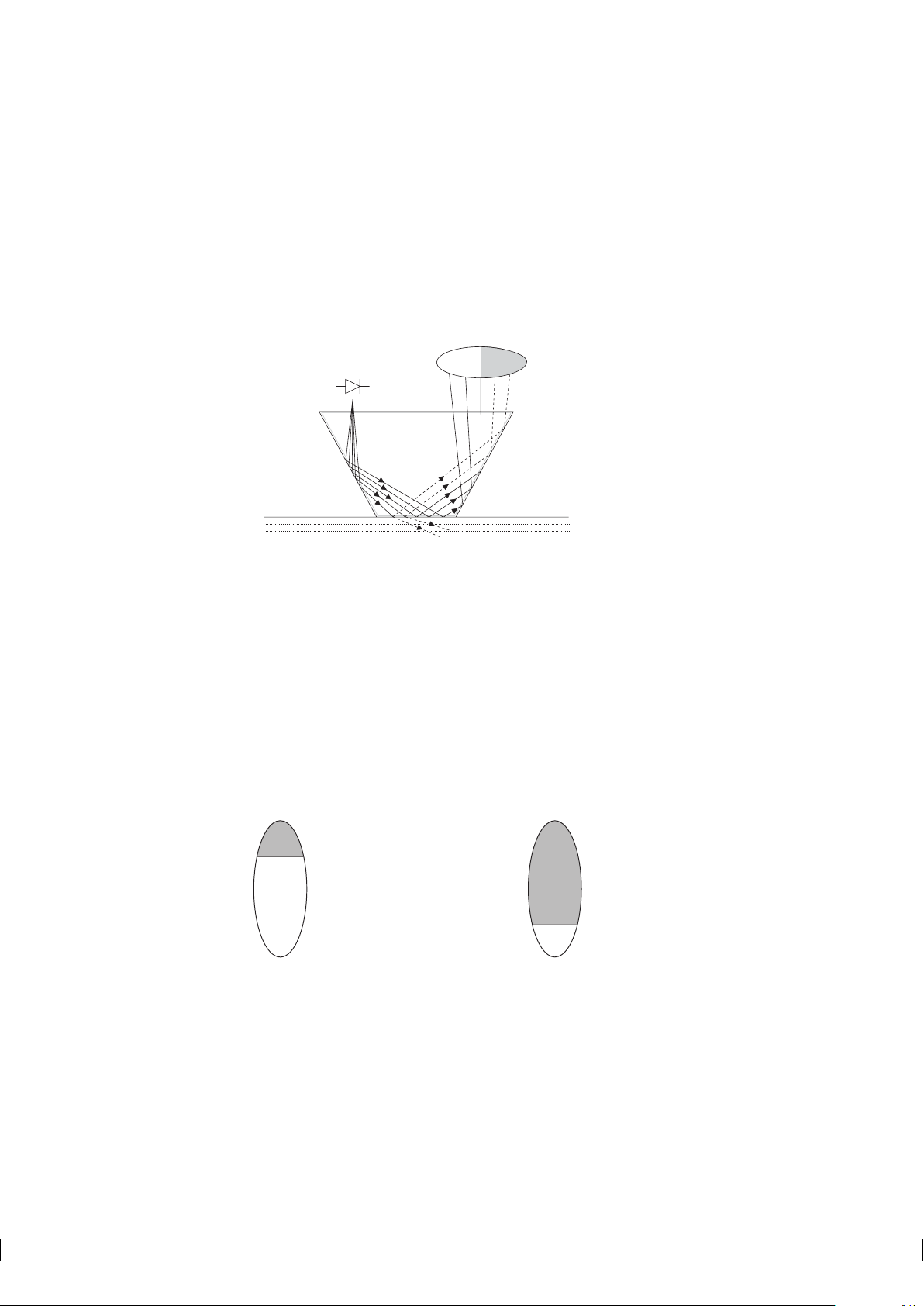

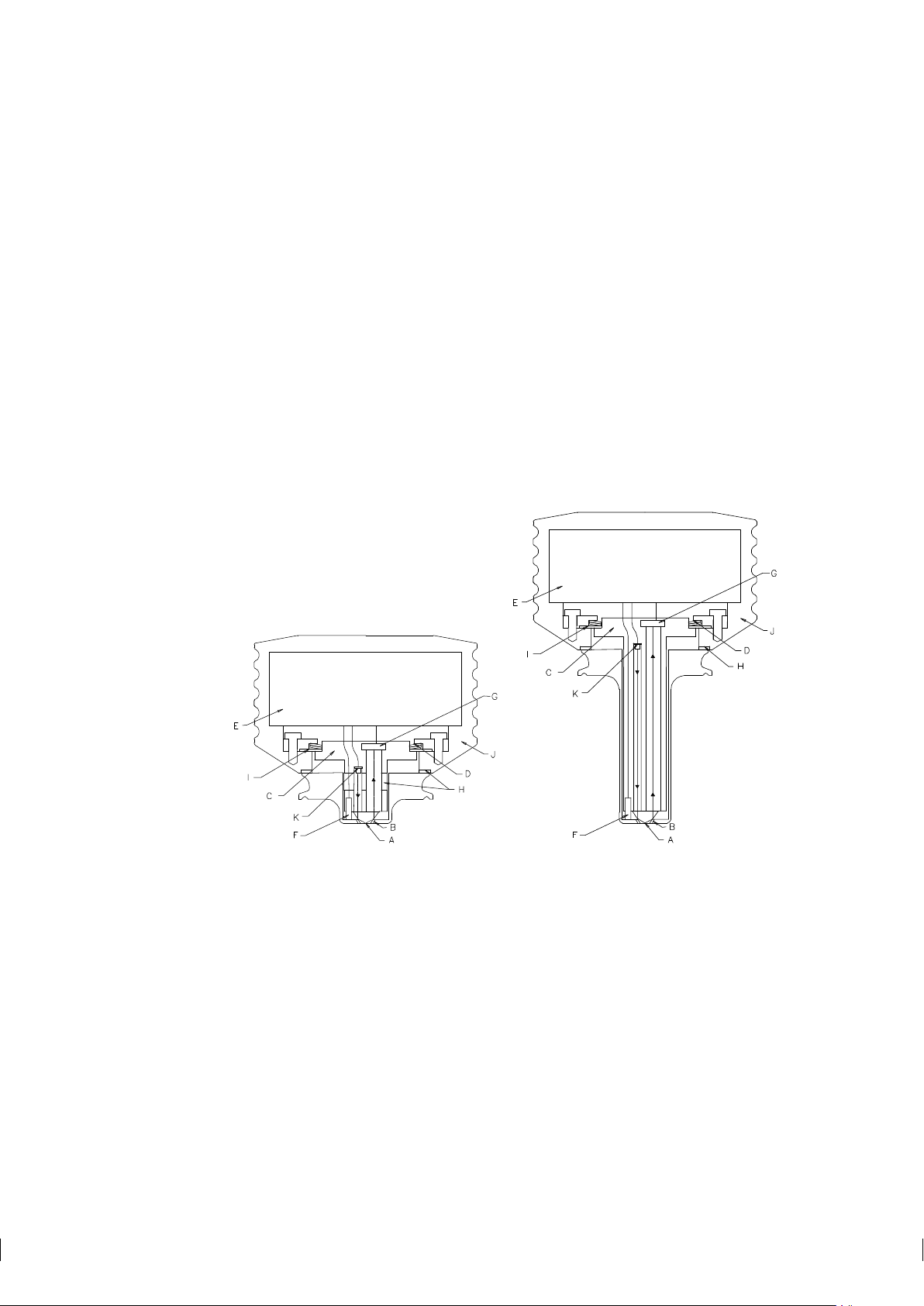

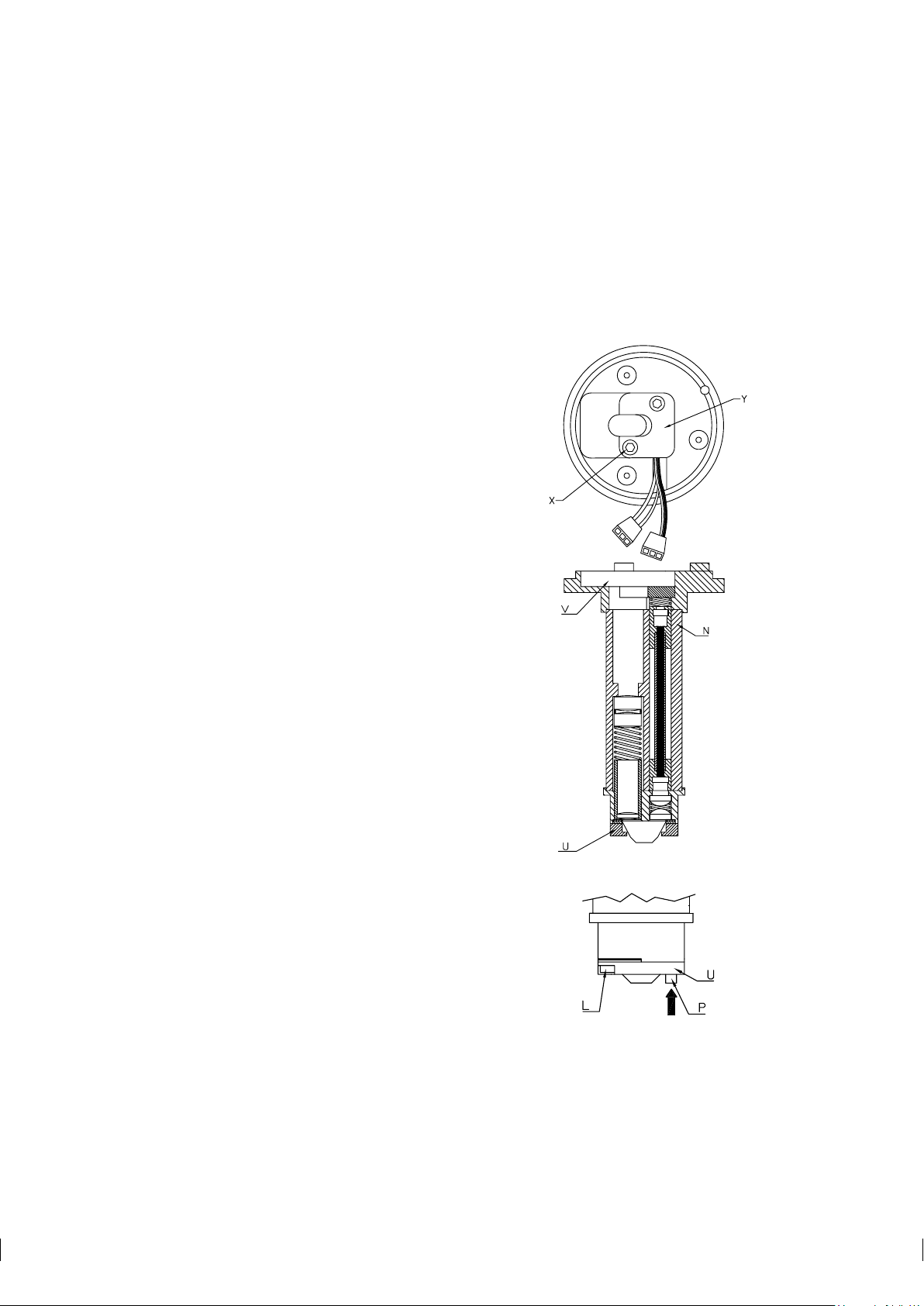

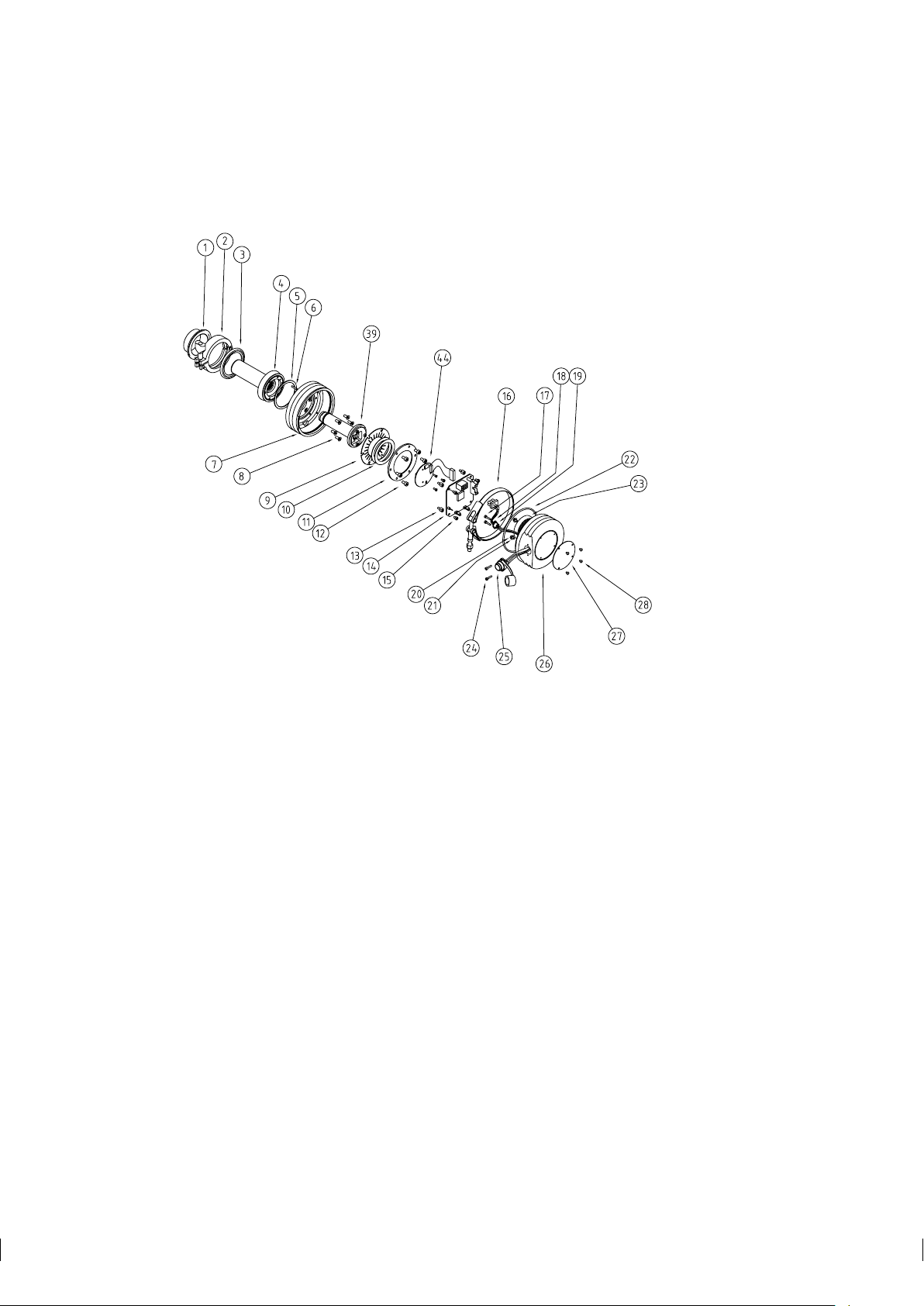

2.1 Sensor description

Figure 2.1 below shows cutaway pictures of two refractometer sensors. These sensors are otherwise similar in structure, but the sensor on the right has a longer probe. The short probe is the more common

refractometer sensor design, only the Probe Refractometer PR-03-P is built like the sensor to the right in

Figure 2.1.

In the sensor the measurement prism (A) is flush mounted to the surface of the probe tip. The prism is fixed

to the analyzer module (C) which is spring-loaded (D) against the prism gasket (B). The light source is a

light emitting diode (K). The digital image detector (G) is a CCD element consisting of 1024 photocells

in a row integrated on one chip. The image sensor (G) is protected from the process heat by two isolating

parts (H). Excess heat is transferred by a heat conductor (I) to the air cooled sensor cover (J). For automatic

temperature compensation, the sensor tip contains a process temperature probe (F), Pt-100.

Figure 2.1 PR-03 sensor structure

The image detector output is a pulse train as shown in Figure 2.2. The number of high pulses corresponds

to the position of the shadow edge in the optical image and is thus a direct measure of t he critical angle.

The image digitizer (E) transforms this pulse train to a serial digital signal. This serial signal transmits to

the Indicating transmitter a package containing temperature data and a complete description of the optical

image.

Note: K-Patents in-line refractometer PR-03 is using a 1024-pixel CCD-element. To keep the supporting

transmitter software compatible for all K-Patents refractometers, the TEST value (= number of photocells

at the light side) is scaled to the range 8-248. That is, for PR-03 the number of high pulses (Figure 2.2) is

divided by four.

Page 12

6 PR-03 instruction manual

a: optical image

b: detector window and the photocells

c: pulse train from detector

TIME

V

Figure 2.2 Image detector system

Note: In the Probe refractometer PR-03-P the image is inverted by the optics. That is, the shadow comes

in from the left. The image is inverted back to normal (as in Figure 2.2) by the indicating transmitter before

any further processing.

2.2 Mounting the sensor

The sensor mounting location should be chosen with care to ensure that you get reliable readings from

your process. Some basic rules, described in this section, apply to all sensor models. The model specific

instructions can be found in Chapter 8.

2.2.1 Choosing sensor mounting location

A K-Patents in-line refractometer sensor can be located either indoors or outdoors in most climates. However, if the sensor is located outdoors, some basic protection against direct exposure to sunlight and rain

should be provided. Special care should be taken if the pipe wall is translucent (e.g. of fiberglass), because

light from outside reaching the prism will disturb the measurement.

The mounting location needs to be such that sediments or gas bubbles cannot accumulate by the sensor.

Good flow velocity is essential in keeping the prism clean.

Always check that the sensor head is kept cool enough, the sensor head should not be too hot to keep a hand

on. The red sensor cover should not be exposed to high temperature radiation. Normally, draft and natural

convection provide sufficient air cooling if the air gets to flow freely around the sensor head.

Additional cooling is necessary when the ambient temperature is higher than 45◦C (113◦F) or when the

process temperature is above 110◦C (230◦F) and the ambient temperature is above 35◦C (95◦F). The aircooling is improved by blowing pressurized air against the red sensor cover. The pressurized air can be

supplied by the ventilation system. If no air is available it is also possible to wind a copper coil for cooling

water around the sensor head cover.

Page 13

2 Inline refractometer sensor 7

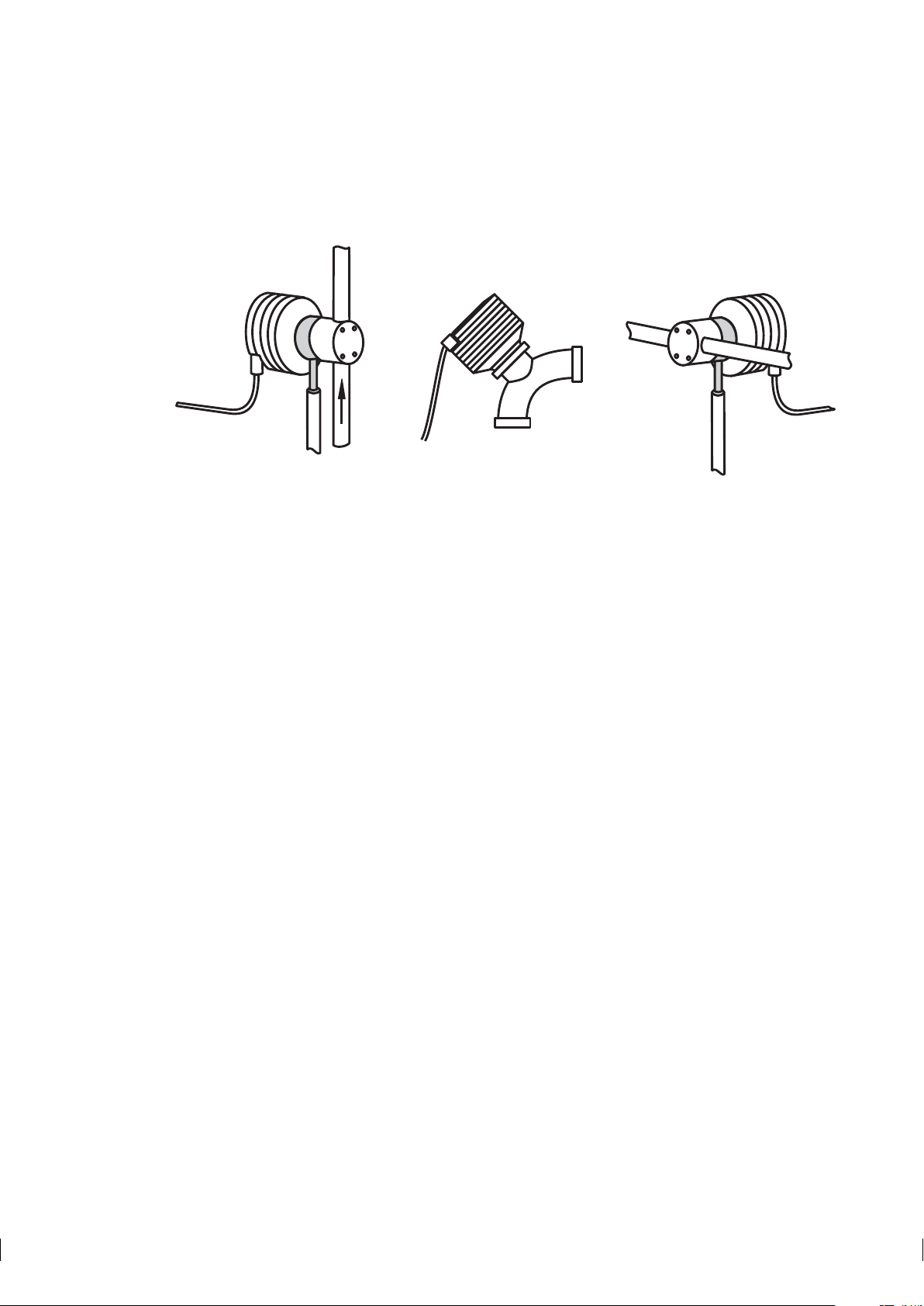

Important: Always mount the sensor so that the cable plug socket on the sensor head points downwards,

i.e. so that when the interconnecting cable is plugged into the sensor, the cable hangs down.

Figure 2.3 Refractometer cable plug direction

2.2.2 Check list for pipe mounting (PR-03-A, PR-03-D, PR-03-M)

1. If the process pipe diameter varies, select the position with the smallest diameter (and accordingly

highest velocity). Then the prism keeps better clean. If the pipe is coned up after a pump, valve or

magnetic flow meter, then add a length of straight pipe before the coning up and mount the refractometer

there.

2. If the refractometer is used in a feed-back control loop, make the time lag short. E.g. when a dilution

valve is controlled, mount the refractometer as near the dilution point as possible.

3. If the temperature varies along the process pipe, select the position with the highest temperature. Then

the risk of prism coating is minimized, because higher temperature means higher solubility and also

lower viscosity.

4. Often the position with the highest pressure (= after pump + before valve) has favorable flow conditions

without sedimentation or air trapping risks.

5. The sensor should be conveniently accessible for service.

Important: If the process pipe vibrates, support the pipe. A vibrating pipe might damage the inline sensor

mounted on it.

Page 14

8 PR-03 instruction manual

2.2.3 Check list for mounting in a tank, a vessel or a large pipe (PR-03-P)

A Probe sensor PR-03-P can be inserted with a sanitary clamp into tanks and vessels which either don’t

have a scraper or where the mixer doesn’t touch the vessel wall. A Probe sensor can also be flush mounted

in a cooker where the scraper touches the wall.

1. Both the inserted and the flush mounted Probe sensor are mounted on the vessel wall with the cable

socket downwards.

2. The inserted probe sensor is mounted close to a stirrer to ensure representative sample of the process

liquid and to keep the prism clean.

3. The sensor should be conveniently accessible for service.

Page 15

3 Indicating transmitter (IT-R) 9

ABCD

7

4

1

0

8

5

2

.

9

6

3

-

ENTER RESET

K-PATENTS

PROCESSINSTRUMENTS

Raw data

Curve fitted to the data

10

20

30

40

50

60

70

1.35 1.40 1.45

R.I.

BRIX

3 Indicating transmitter (IT-R)

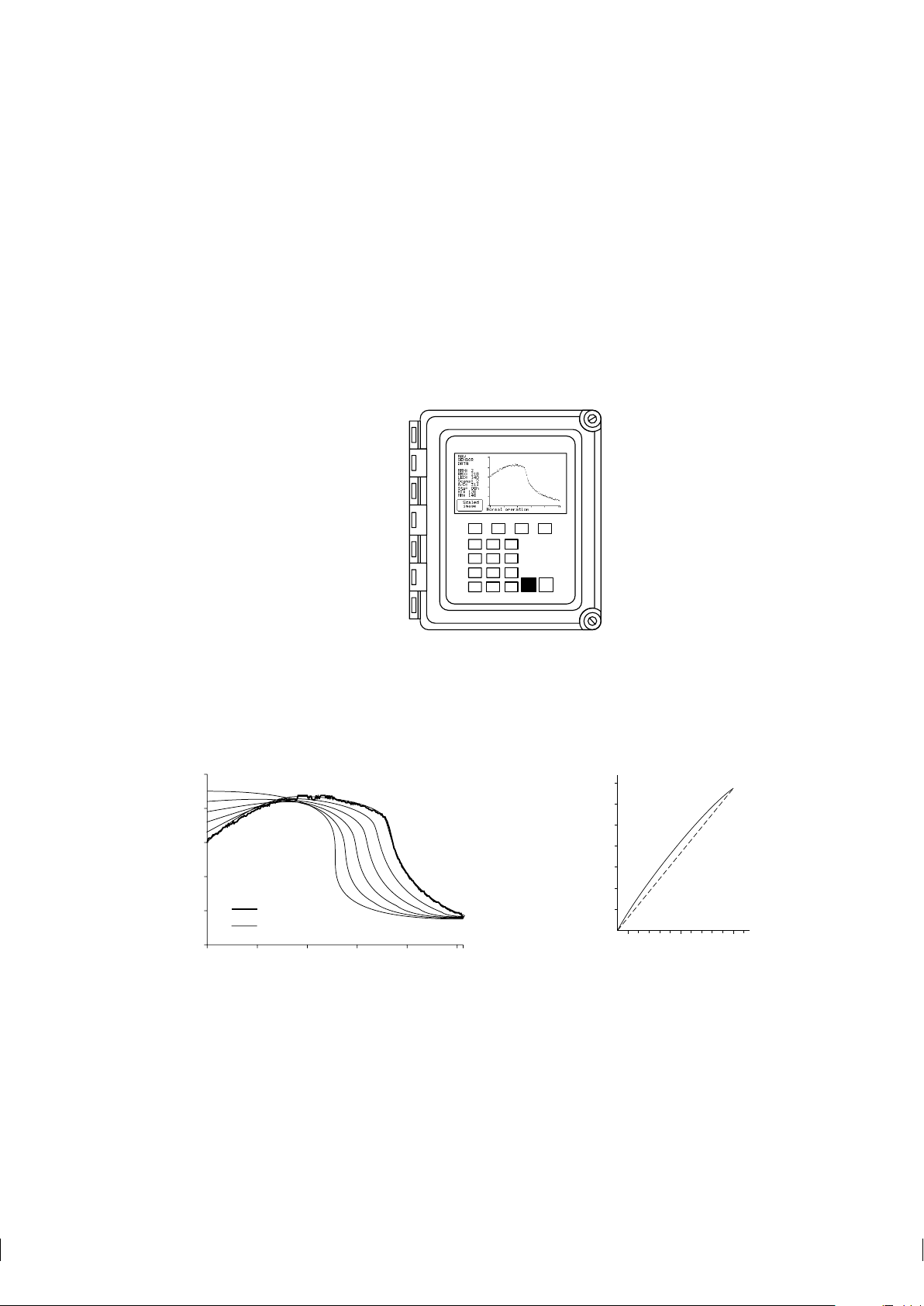

3.1 Indicating transmitter description

The indicating transmitter (abbr. IT-R) is a small, specialized computer designed to process data received

from the sensor. The Indicating transmitter enclosure (see Figure 3.1) contains a front panel with a Liquid

Crystal Display (LCD) and a keyboard. The IT-R’s microprocessor system and the power supply are hidden

under the front panel that swings open for service. Knockout padlock provisions for locks are included in

the enclosure’s both cover latches to prevent unauthorized access.

Figure 3.1 The Indicating transmitter enclosure

The IT-R receives from the sensor data that describes the optical image and gives the process temperature.

It then displays the optical image (Figure 1.3) and implements an image analyzing algorithm (Figure 3.2),

which identifies the exact position of the shadow edge (Figure 2.2). Finally, the microprocessor system

linearizes the concentration reading (example in Figure 3.3), and performs an automatic temperature compensation.

Figure 3.2 Image analyzing algorithm

Figure 3.3 A Brix diagram

The IT-R output signals are a 4-20 mA concentration signal and a serial output signal, RS232 or RS485

alternatively, which enables connections to for example a PC (See Section 3.2.3).

In the IT-R there are also two built-in signal relays on the power supply card. These signal relays can

be configured to any relay function except preconditioning or wash control (see Section 5.7, “Configuring

relays”).

Page 16

10 PR-03 instruction manual

Furthermore, the Indicating transmitter accepts four input switches which can be configured for example to

signal HOLD during external wash or to contain different scale settings each (see Section 5.6, “Configuring

input switches”).

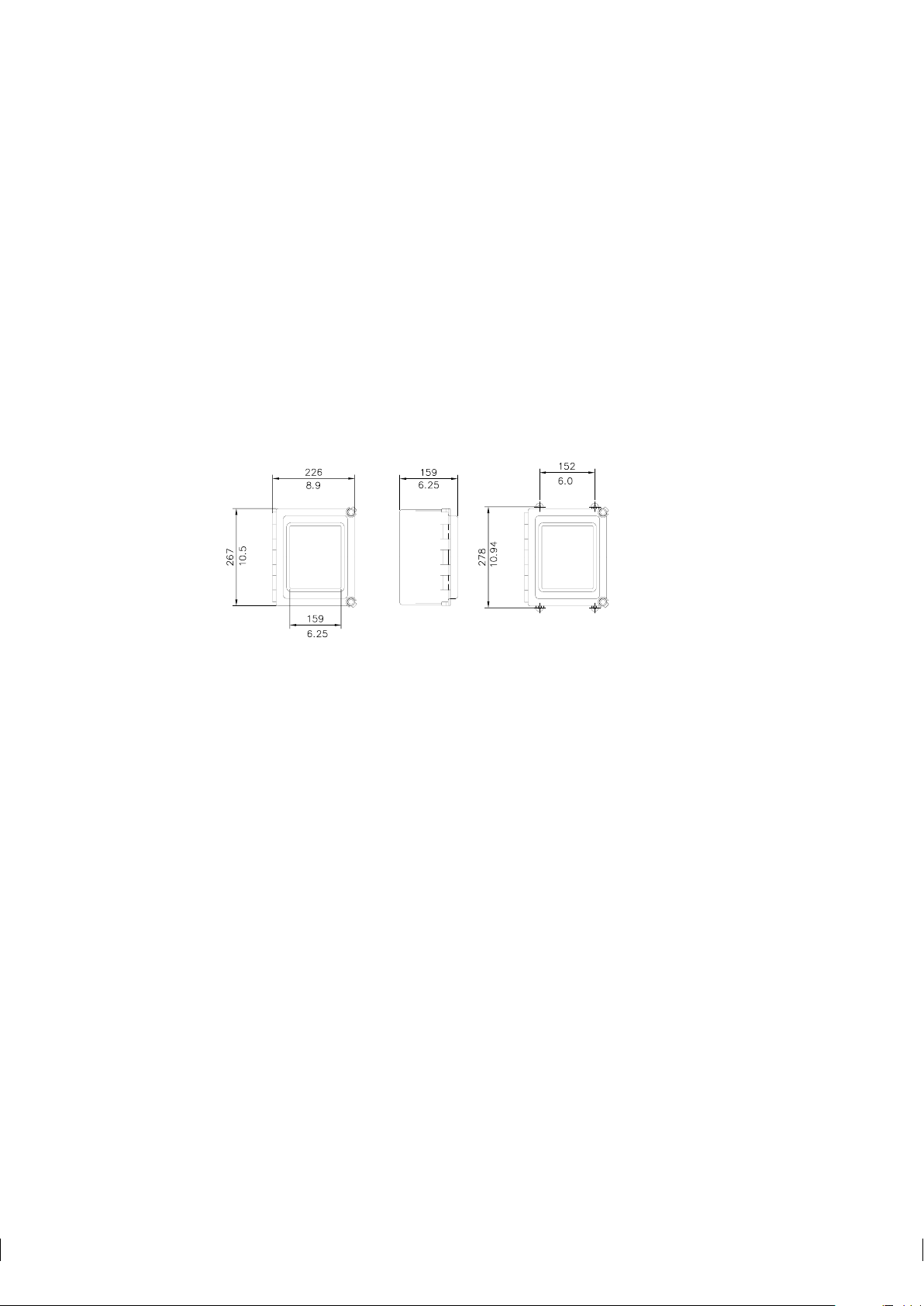

3.2 Mounting Indicating transmitter

The Indicating transmitter should preferably be located in an easily accessible, well lighted and dry area.

The enclosure must not be exposed to rain or direct sunlight. Avoid vibration. Take interconnecting cable

length into consideration when choosing mounting location.

The enclosure is mounted vertically on an upright surface (wall) using four mounting feet, see Figure 3.4.

Important: Do not drill mounting holes in the enclosure as that will affect the protection class of the

enclosure and may expose the electronics of the IT-R.

Figure 3.4 Mounting the Indicating transmitter

Note: The LCD display has an operating temperature range of 0–50

-20–60◦C. If exposed to very low storage temperatures, let the IT-R reach the ambient temperature before

turning it on, as the LCD may not be able to display anything in temperatures below zero.

3.2.1 Mounting the Interconnecting cable

The interconnecting cable PR-8300 is made at the K-Patents factory according to the specifications given

in your order (see Section 9.4). The maximum length of an interconnecting cable is 100 meters (330 feet).

When mounting the cable, check that the ends easily reach the sensor respectively the IT-R.

Warning! Do not try to shorten or lengthen the interconnecting cable! If a new cable is needed for example

!

after the IT-R has been moved further away from the process line, you can order a spare part cable from

K-Patents or your local K-Patents representative.

◦

C and a storage temperature range of

Page 17

3 Indicating transmitter (IT-R) 11

11

POWER

SELECTOR

POWER

CONNECTION

SERIAL CABLE

(pc)

SENSOR

CABLE

ACCESSORY UNIT

(serial bus)

SWITCHES

RELAYS

3.2.2 Electrical connections

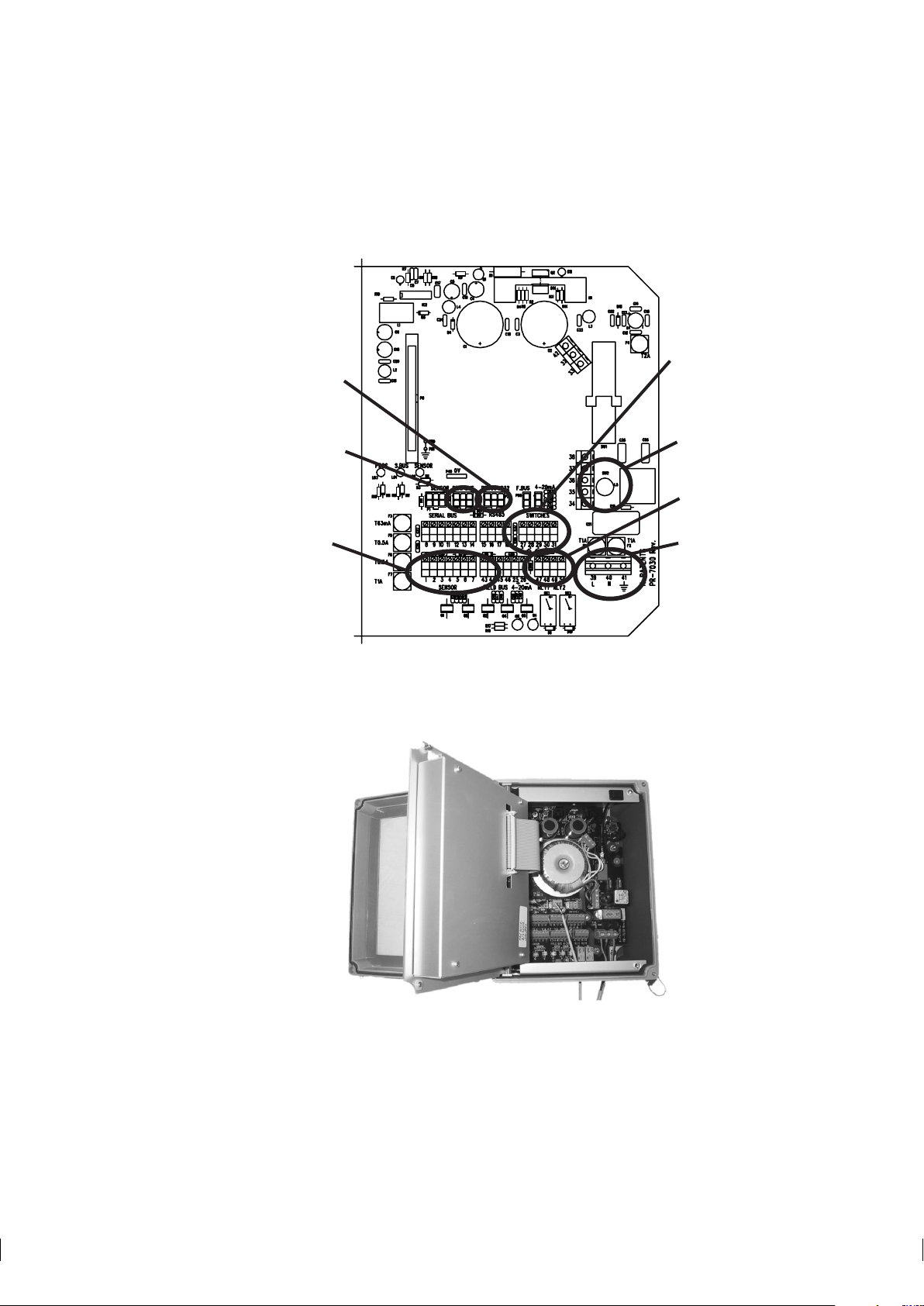

All the electric terminals of the Indicating transmitter are on the Power supply card (Figure 3.5).

Figure 3.5 Power supply card layout

To access the Power supply card, first open the enclosure cover. Then loosen the two screws on the righthand corners of the front panel and swing open the front panel to see the card.

Figure 3.6 IT-R with opened front panel.

Page 18

12 PR-03 instruction manual

NEUTRAL

LINE

GROUND

3.2.2.1 Connecting with sensor

The sensor end of the interconnecting cable is terminated by a plug. The plug goes into the cable plug

socket on the sensor head. After connecting the cable with the sensor, join the two connector protecting

caps to keep t hem clean inside.

The Indicating transmitter end of the interconnecting cable has leads numbered from 1 to 7 to be connected

to the terminals with the same numbers on the Power supply card. The seven leads to the plug on the cable

are colored Red, Blue, Black, Red, Blue, Black and Black.

3.2.2.2 AC power connection

The primary AC power is connected to a separate terminal strip 39/40/41 marked POWER in the lower

right-hand corner of the Power supply card (Figure 3.5). The three terminals are marked 39/L, 40/N and

41/ground symbol. The connection is made by inserting each lead into the corresponding slot and tightening

the screws above the slots (Figure 3.7).

The power terminals Line and Neutral are directly connected to the transformer primary loop, and galvanically separated from the rest of the instrument. The ground terminal (41) is connected to the bottom plate of

the Indicating transmitter, to the transformer shield winding and to the outer shield of the interconnecting

cable.

Figure 3.7 Power terminals on the Power supply card

Important: Before connecting the IT-R power, check the position of the power selector switch, marked

SW2 on the Power supply card. The power selector switch has two positions: 220–240 V/50–60 Hz or

100–115 V/50–60 Hz.

Figure 3.8 Power selector switch in the 220 V position

3.2.2.3 +24 V DC power connection

The primary DC power is connected to a separate terminal strip 39/40/41 marked POWER in the lower righthand corner of the Power supply card (Figure 3.5). The terminals are marked 39/+24V, 40/0 and 41/ground

Page 19

3 Indicating transmitter (IT-R) 13

symbol. The connection is made by inserting each lead into the corresponding slot and tightening the screws

above the slots (Figure 3.7).

The ground terminal (41) is connected to the bottom plate of the Indicating transmitter, to the transformer

shield winding and to the outer shield of the interconnecting cable.

Important: The power selector switch on the Power supply card, marked SW2, must be in 110 position

(Figure 3.9) when input voltage is +24 V DC. If the switch is in the wrong position, the refractometer system

does not work.

Figure 3.9 Power selector switch in the 110 V +24 V DC position

3.2.2.4 Current output connection

The current output connection terminals are 25 and 26. The terminal 25 is plus (+) and 26 minus (-) for the

4-20 mA output signal (The detailed signal specifications are listed in Section 9.4, “IT-R Specifications”).

Recorders, controllers, indicators etc. must be connected to form a closed current loop, starting from terminal 25 passing each device, in at plus and out at minus, ending at terminal 26.

Important: Be careful not to exceed the specified load resistance, 1800 Ohm.

3.2.2.5 Serial bus connections

Terminals 8-14 on the Power supply card provide connection to K-Patents accessory units, like a Relay Unit

(see Section 4.1) and External output unit (see Section 4.2). The connection cable is of the same type as the

interconnecting cable and follows the same specifications (see Section 9.4). See Section 4.1.3, “Relay unit

mounting and connections” and Section 4.2.2, “External output unit mounting and connections” for more

information.

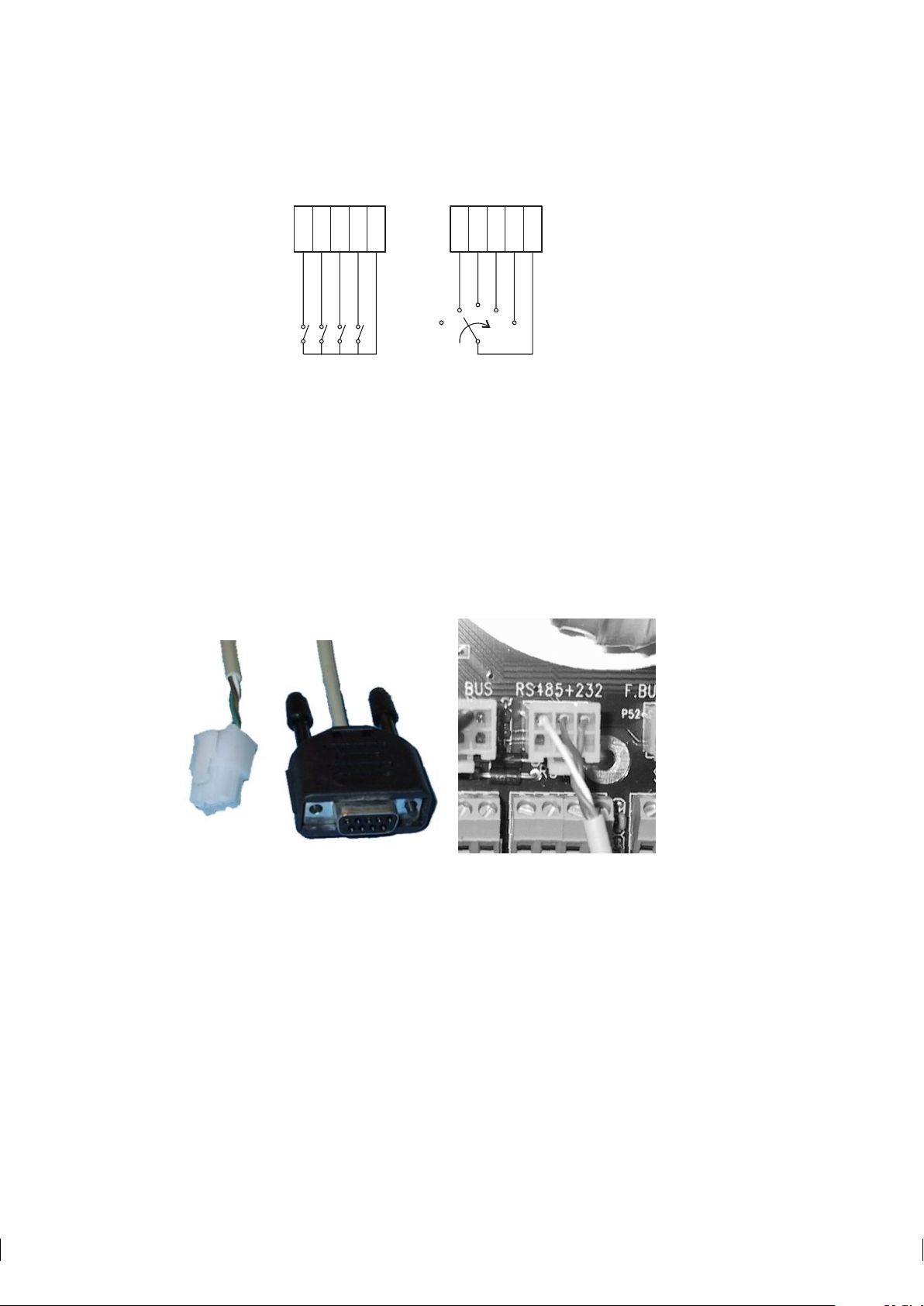

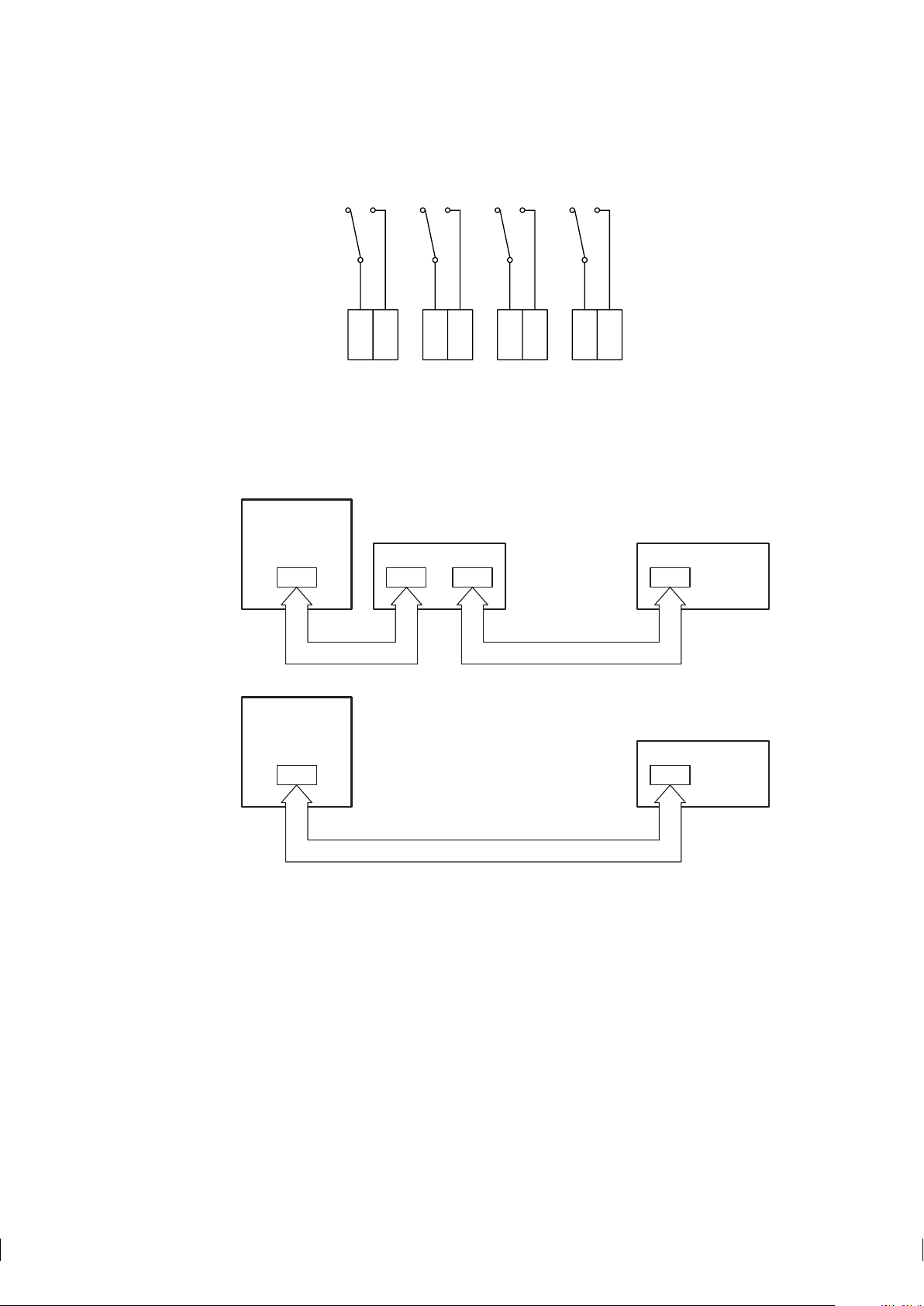

3.2.2.6 Input switch connections

Altogether four input switches A, B, C and D can be connected: Terminals 27-A, 28-B, 29-C, 30-D, 31Common, Figure 3.10. To use a switch, you will have to connect that switch with terminal 31, which short

circuits that switch. Thus, to use switch A, connect terminal 27 with terminal 31.

The switches may be separate, or together in one rotary switch. Input switch functions are configured

through software, Section 5.6. Most commonly input switches are used for easy switching between calibration settings for different process mediums or for preventing accidental or unauthorized calibration changes.

A 5V voltage is provided over each switch. The switch terminals are all galvanically isolated from ground

and from the rest of the electronics.

Page 20

14 PR-03 instruction manual

27 28 29 30 31

SWITCHES

BCDA

27 28 29 30 31

SWITCHES

D

C

B

A

Figure 3.10 Input switch connections

3.2.3 Serial output connections: connecting a computer with the IT-R

The serial output connections on the Power supply card allow you to download information from the IT-R

with a PC computer that has a 9-pin COM port (or a USB-to-COM adapter that simulates a 9-pin COM

port).

Note: The serial output connection is for output only, i.e. it cannot be used to give commands to the IT-R.

To connect your PC with an IT-R to download process data, you need to order a communications package

from K-Patents. The package contains a cable with a plug for the P3 plug connector on the Indicating

transmitter Power supply card. The other end of the cable is a 9-hole COM plug for your computer’s COM

port.

Serial connection cable plugs Cable plugged into an IT-R

Figure 3.11 Serial (PC) connection

Page 21

3 Indicating transmitter (IT-R) 15

18293104

11 27

43 47

29

45 49

15

5

12 28

44 48

30

46 50

3116

6

13 17

7

14 18

SENSOR

SERIAL BUS RS-485 SWITCHES

RLY1 RLY2

25 26

4-20mA

+-

The K-Patents communications package contains Windows software for downloading data from the IT-R.

The software has been preset so that it normally star ts directly after the installation and it has built-in

instructions. However, you can also use any standard communications software to download data. In

such case see Section 9.4.2, “Serial output specifications” for more information on the data format and

the communications settings.

3.2.4 Demo mode connection

The Indicating transmitter can be used as stand-alone for demos and to train keyboard handling. The built-in

Demo program contains a sensor simulator, so when the demo connection is on, you only need an IT-R to

show how the refractometer system works.

The Demo mode is activated by changing connections on the Power supply card:

1. Turn off the power from the IT-R. Open the enclosure cover and the front panel.

2. Disconnect the sensor cable (connections 1-7) (Section 3.2.2.1) and all connections to Serial bus (connections 8-14), i.e. all external units (see Section 4.1.3 and Section 4.2.2).

3. Connect terminal 1 to terminal 8 and terminal 2 to terminal 9, Figure 3.12

Figure 3.12 Making demo connection

4. Close the front panel and turn on the IT-R.

Page 22

16 PR-03 instruction manual

A

B

C

D

CONC

68.0%

PROCESS TEMPERATURE: 31.2 °C

STANDARD RI(25°C): 1.4194

TEST: 115.7

Normal operation

Calibrate

Display

*

11

44

22

55

33

66

RED

RED

RED

RED

BLUE

BLUE

BLUE

BLUE

SEN+

+24V

SEN-

0V

GND

GND

PGND

1

4

2

5

3

6

7

Indicating transmitter

Plug

WHITE

BLACK

BLUE

BROWN

Cable Image Digitizer

Note: When the IT-R has been turned on in demo mode, a small star appears in the top left corner of the

display. Because the external units have been disconnected, the Normal display will not have a soft key for

Prism wash. Other than that, the Indicating transmitter will behave as if it was connected to a sensor in the

process line.

Figure 3.13 IT-R display when in demo mode

Note: For more information on how to use the Indicating transmitter, see Section 5.3, “Using Indicating

transmitter”.

3.3 Cable signals between IT-R and sensor

Figure 3.14 Cable signals

Page 23

4 Accessory units 17

4 Accessor y units

4.1 Separate relay units

When necessary, a K-Patents inline refractometer system can be equipped with a separate relay unit with

either four (PR-7080) or two (-WR) relays. The separate relay units can be added to any refractometer model

when additional relays are needed.

Unlike the built-in relays, both separate relay units can be configured for preconditioning and prism wash.

That is, if a prism wash (Sanitary refractometer PR-03-A and Probe refractometer PR-03-P only) is installed

because of sticky process medium, a separate relay unit is also needed.

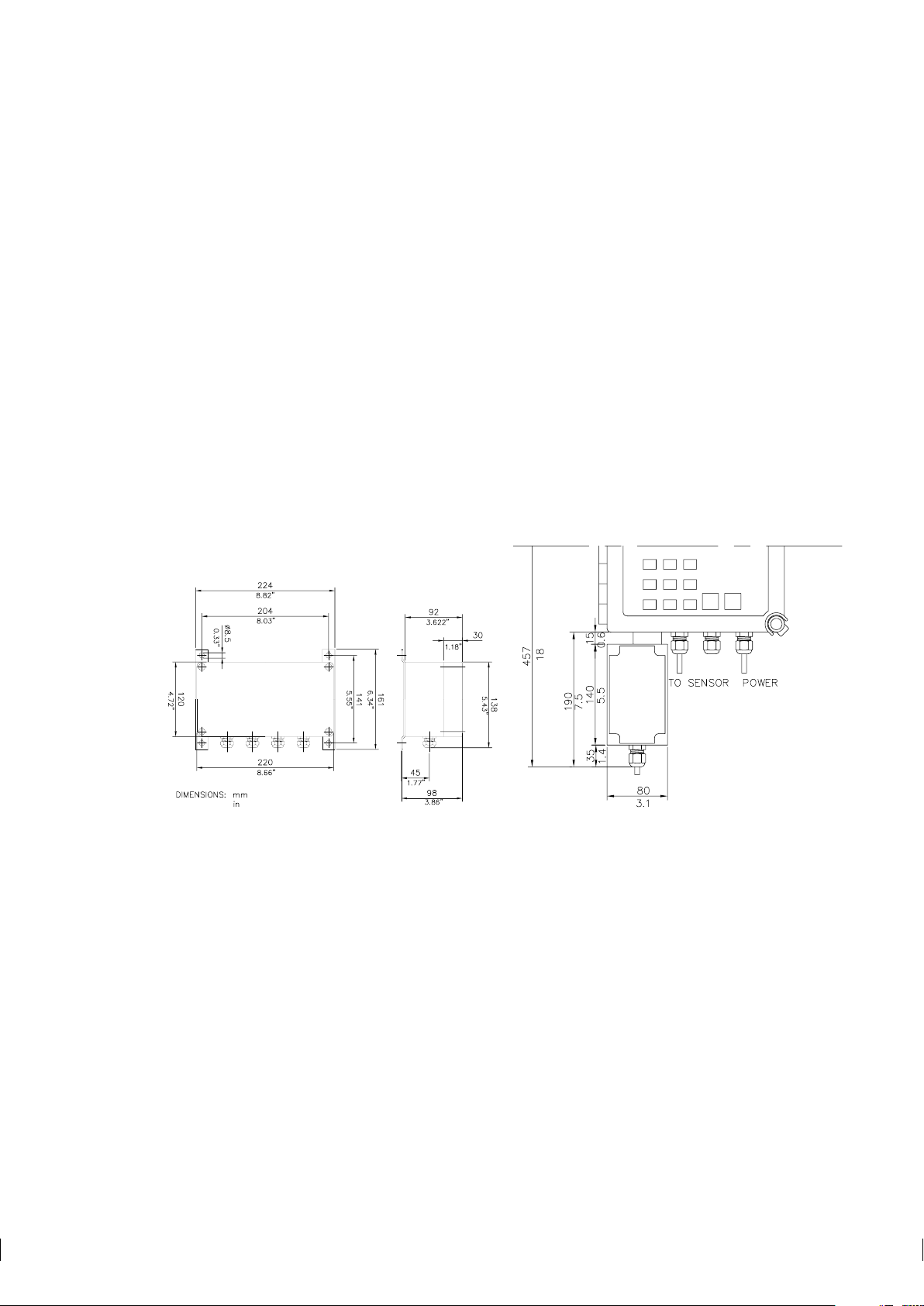

4.1.1 Relay unit description

Both separate relay units are built in an enclosure with IP 65 (Nema 4X) classification. Figure 4.1 shows

the dimensions of the four-relay unit PR-7080 and the two-relay unit -WR.

PR-7080 -WR

Figure 4.1 Relay unit dimensions

To see the relays and to make all necessary connections, open the screws in the four top corners of the relay

enclosure and lift off the enclosure cover.

The cable fittings are delivered as one of the three alternatives:

US 1/2 NPT-TYPE ST-1 conduit hubs 4 pcs

European BF11/PG11 cable glands 4 pcs

M20x1.5 cable glands 4 pcs

Page 24

18 PR-03 instruction manual

4.1.1.1 Relay unit PR-7080

The Relay unit PR-7080 contains 4 relays from left to right: Relay A, relay B, relay C and relay D. There is

a yellow LED above each relay. If the LED is lighted, the corresponding relay is ON and the output contact

is closed. There is also one green and one red indicator led to inform on system status. After startup the red

led is lighted only when the relay unit has problem.

The Relay unit PR-7080 is connected with the IT-R with an interconnecting cable PR-8011 . The last three

numbers in t he cable code indicate the cable length in meters, the shortest available cable is PR-8011-001

(1 meter; 3.3 feet) and the longest possible cable is PR-8011-100 (100 meters; 330 feet).

4.1.1.2 Relay unit -WR

The Relay Unit -WR contains 2 relays from left to right: Relay A and Relay B. There is a yellow LED

above each relay. If the LED is lighted, the corresponding relay is ON and the output contact is closed.

4.1.2 Prism wash system description

Deposit build-up on the prism surface disturbs the measurement. Look out for an abnormally high concentration reading, low slope value or an upward CONC drift.

In most applications the prism will keep clean due to the self-cleaning effect. If coating occurs, check the

following:

− Sufficient flow velocity, see Section 2.2.2, “Check list for pipe mounting (PR-03-A, PR-03-D, PR-03-M)”.

− A temperature difference between process fluid and sensor probe may cause coating. This may happen

with small flows if the thermal insulation is inadequate. In some cases it helps to insulate also the clamp

connector.

In case of a coating problem, the preferred solution is to try to increase the flow velocity, e.g. by installing

a pipe portion with smaller diameter. Installing a wash nozzle can be considered, if increasing the velocity

does not provide a solution (Section 4.1.4).

Three alternative media can be used for prism wash: steam, water, high pressure water. Only external relays

(accessory units) can be configured to control the prism wash cycle, see Section 5.9 “Configuring automatic

prism wash”.

4.1.3 Relay unit mounting and connections

Note: When mounting a separate relay unit, seal all unused fittings with blind washers.

4.1.3.1 Mounting and connecting Relay unit PR-7080

The four-relay Relay unit PR-7080 is mounted on a wall or similar vertical surface using its four mounting

feet. Take the length of the interconnecting cable PR-8011 and easy access for service into account when

choosing mounting spot for the Relay unit.

Open the screws on the Relay unit and lift off cover to get access to the relay card to make the connections.

The relay contacts go to the connector strip (Figure 4.2) on the relay unit card.

Page 25

4 Accessory units 19

ABCD

44 46 48 5045 47 49 51

Indicating

transmitter

Indicating

transmitter

8-14

8-14

8-14 8-14

8-14

8-14

AB

External output unit

Relay unit

Relay unit

PR-8011

PR-8011

PR-8011

Figure 4.2 Relay unit PR-7080 connector strip

Connect the numbered leads of the interconnecting cable with the same numbers (8-14) on the serial bus.

Then proceed to connect the cable with your refractometer system. If you have an External output unit, the

Relay unit is connected to that. If no other external units are used, the Relay unit connects directly with the

IT-R (Figure 4.3).

Important: Before connecting the relay unit with your refractometer system, power off your system. If you

have an external output unit, open its cover to access the card inside for connections. If you don’t have an

external output unit, open the IT-R’s enclosure and display panel to access t he processor card.

Connect the numbered leads of the free cable end with terminals with the same numbers (8-14) on the

serial bus output (serial bus B) on the Output unit card or on the serial bus on the Indicating transmitter’s

processor card.

Figure 4.3 Connecting Relay unit PR-7080

Page 26

20 PR-03 instruction manual

4.1.3.2 Mounting and connecting Relay unit -WR

The Relay unit -WR is always mounted directly underneath the IT-R. If the IT-R and the Relay unit -WR are

delivered together, they are already fully connected. If the Relay unit is delivered separately, the connection

cable is included in the Relay unit delivery. The cable is plugged in the P2 plug on the IT-R’s processor

card (next to the sensor cable, see Figure 3.5). The relay contacts go to the connector strip.

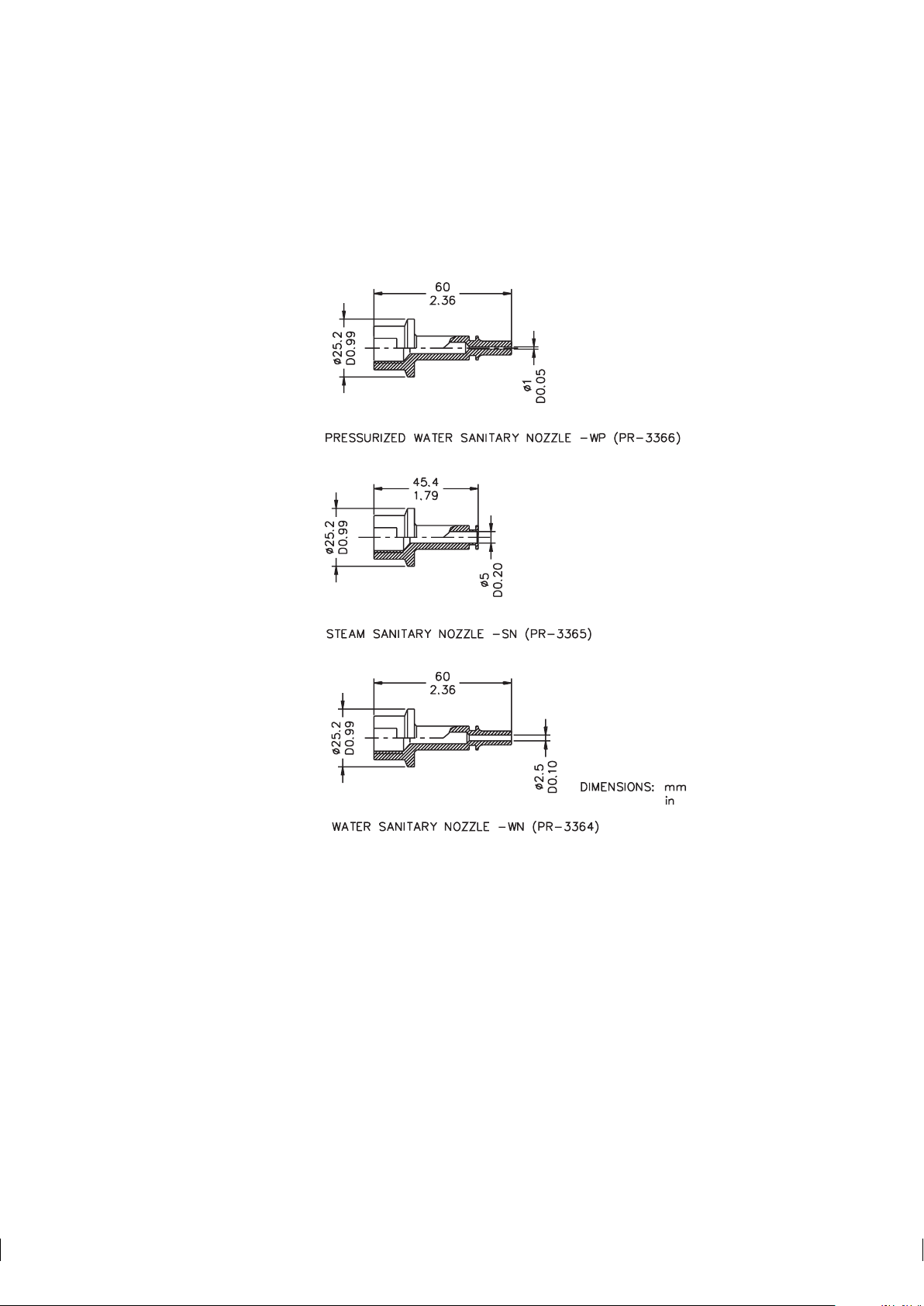

4.1.4 Mounting and connecting prism wash systems

The prism wash system for steam is described by Figures 4.7 and 4.8 and for high pressure water by Figure 4.9.

4.1.4.1 Recommended wash pressures and times

The recommended wash pressures and times are given in Table 4.1 below.

Wash medium pressure

Minimum Maximum Wash time Recovery Interval

above process allowed

pressure pressure

Steam 2 bar (30 psi) 6 bar (90 psi) 3–5 s 20–30 s 20–30 min

Water 2 bar (30 psi) 6 bar (90 psi) 10–15 s 20–30 s 10–20 min

High pressure water 40 bar (600 psi) 70 bar (1000 psi) 10–15 s 20–30 s 10–20 min

Table 4.1 Recommended prism wash parameters

Important: In steam wash, do not exceed the recommended wash times, because some process media may

burn to the prism surface if steamed for longer time. In case of coating, shorten the wash interval.

Note: In water wash, water temperature should be above the process temperature.

Note: The check valve pressure drop is 0.7 bar (10 psi).

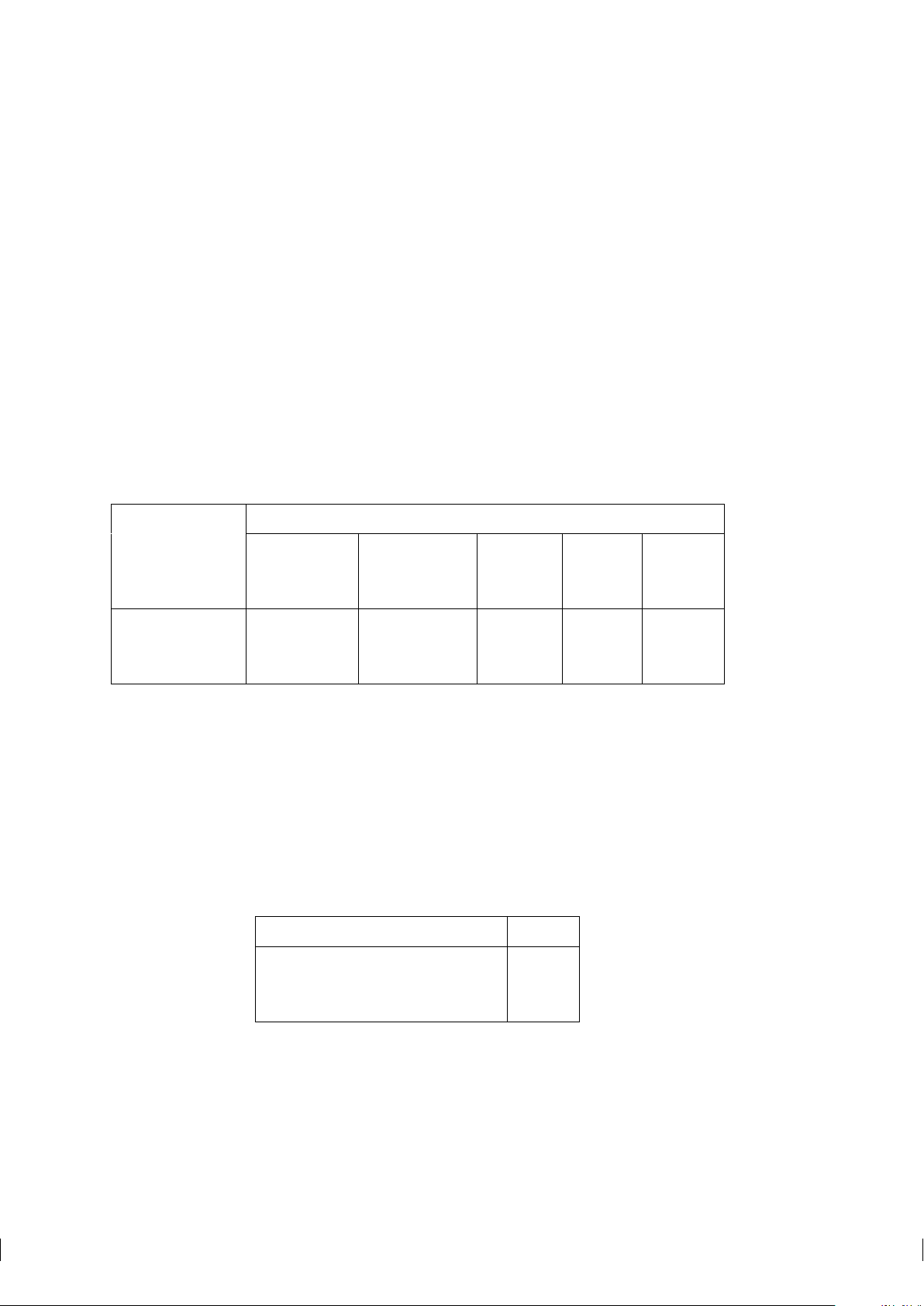

4.1.4.2 Prism wash nozzles

Select wash nozzle according to wash medium and refractometer model, Table 4.2.

PR-03-A

Pressurized water sanitary nozzle -WP PR-3366

Steam sanitary nozzle -SN PR-3365

Water nozzle -WN PR-3364

Table 4.2 Pr ism wash nozzle selection

Page 27

4 Accessory units 21

The three versions of a prism wash nozzle are shown in Figure 4.4. How they are mounted to the process is

shown in Figure 4.5, which also shows the connection of a check valve. K-Patents provides flow cells with

stud for a wash nozzle. Figure 4.6 shows an example with the correct position of the nozzle in relation to

the prism surface.

Figure 4.4 Wash nozzle selection

Page 28

22 PR-03 instruction manual

Figure 4.5 Process connection of a wash nozzle

Figure 4.6 Example of wash nozzle installed in a flow cell

Page 29

4 Accessory units 23

8

STEAM

PART SPECIFICATIONSPART SUPPLIED BY

FLOW

6

2

RELAY UNIT PR-7080

TO DRAIN

WIRING SEE WRG-314

1/2"

12

119

7

CABLE PR-8011 BETWEEN INDICATING TRANSMITTER AND RELAY UNIT

SHUT-OFF VALVE&STEAM TRAP PR-3340-230/110

CABLE PR-8300 BETWEEN INDICATING TRANSMITTER AND SENSOR

INDICATING TRANSMITTER IT-R

EFC (ELBOW FLOW CELL)

SENSOR PR-03-A62-HSS

RELAY UNIT PR-7080

7

6

5

412

3

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

111

111

1

5

AC POWER SUPPLY 230/110 V

SOLENOID CABLE, 3x1 (AWG 17)

STEAM PIPE 1/4"

STRAINER PR-3342

STEAM PIPE 1/2"

CHECK VALVE PR-3302

13

111012

9

8

10

4

13

3

CUSTOMER

CUSTOMER

CUSTOMER

CUSTOMER 2

111

111

13

1

K-PATENTS

K-PATENTS

K-PATENTS

AIR

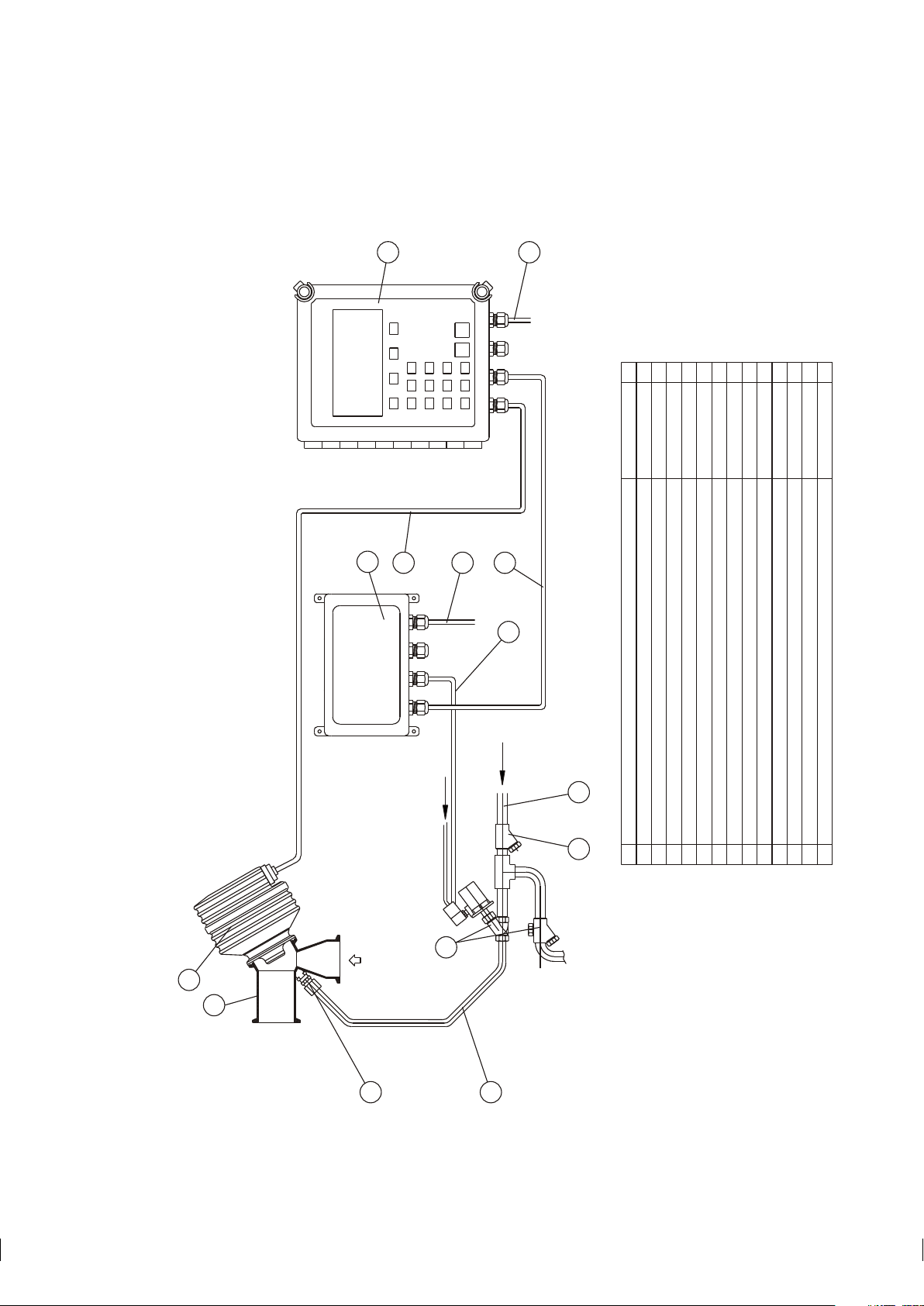

4.1.4.3 Mounting of prism wash systems with steam and water

Figure 4.7 Mounting of a prism wash system with steam and Relay unit PR-7080

Page 30

24 PR-03 instruction manual

STEAM

AIR

PART SPECIFICATIONSPART

SUPPLIED BY

SWITCH

POWER

SAFETY

0

I

5

FLOW

TO DRAIN

1/2"

WIRING SEE WRG-313

10

8

6

SHUT-OFF VALVE&STEAM TRAP PR-3340-230/110

CABLE PR-8300 BETWEEN INDICATING TRANSMITTER AND SENSOR

INDICATING TRANSMITTER IT-R

EFC (ELBOW FLOW CELL)

SENSOR PR-03-A62-HSS

WASH RELAY UNIT

654

1

2

3

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

1

1

1

1

1

1

AC POWER SUPPLY 230/110 V

SOLENOID CABLE, 3x1 (AWG 17)

STEAM PIPE 1/4"

STRAINER PR-3342

STEAM PIPE 1/2"

CHECK VALVE PR-3302

13

12

10911

8

7

CUSTOMER

CUSTOMER

CUSTOMER

CUSTOMER

2

111

111

9

12

12

4

3

1

13

SAFETY SWITCH 1

7

2

11

K-PATENTS

K-PATENTS

K-PATENTS

CUSTOMER

14 CUSTOMERCABLE 2x1 (AWG 17) 1

14

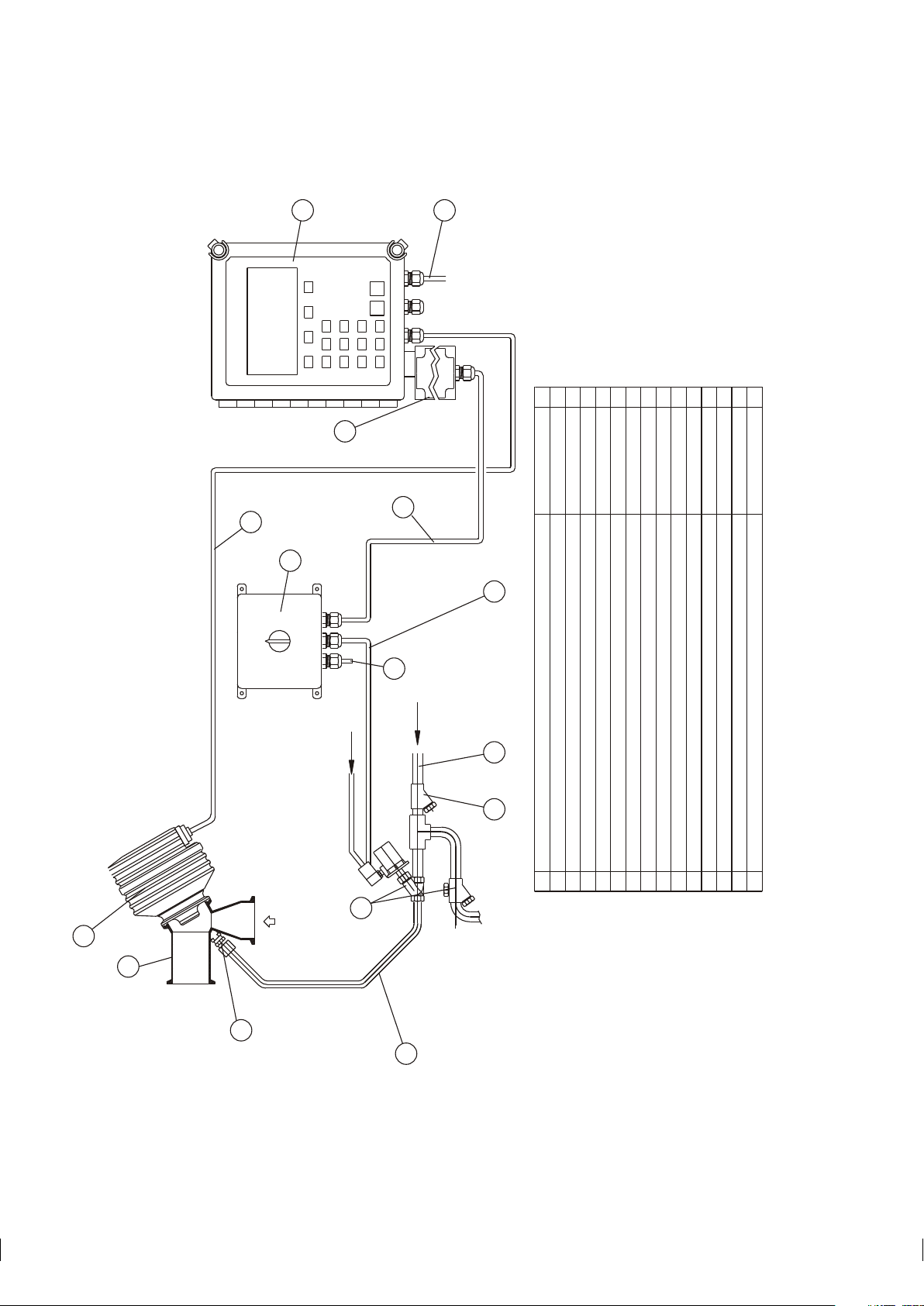

Figure 4.8 Mounting of a prism wash system with steam and Relay unit -WR

Page 31

4 Accessory units 25

FLOW

PART SPECIFICATIONSPART SUPPLIED BY

TAP WATER, TEMP MAX 60 °C / 140 °F

SWITCH

MAIN

POWER

POWER

0

I

3/8"

POWER RELAY UNIT

PR-3603-___

12

9

1

2345687

11

CUSTOMER

AC POWER SUPPLY 230/110 V

CABLE BETWEEN INDICATING TRANSMITTER AND SENSOR PR-8300

INDICATING TRANSMITTER IT-R

EFC (ELBOW FLOW CELL)

WASH RELAY UNIT (WR)

SENSOR PR-03-A62-HSS

CHECK VALVE R 1/4" PR-3302

HIGH PRESSURE HOSE 8M

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

K-PATENTS

K-P / CUSTOMER

POWER SUPPLY CABLE 3 METERS FOR WATER VALVE

HIGH PRESSURE PUMP PR-3602-110/230/400/550 INCLUDING WATER VALVE

CUSTOMER

2

1

11111

1

1

1

8

1

9

7

10

8

11

12

10

POWER RELAY UNIT PR-3603-110/230/400/550 K-PATENTS 1

POWER SUPPLY CABLE 3 METERS FOR HIGH PRESSURE PUMP K-PATENTS 1

3

4

6

2

5

K-PATENTS

13

13 CABLE 2x1 (AWG 17) CUSTOMER 1

4.1.4.4 Mounting of prism wash systems with high pressure water

Warning! In high pressure wash systems, pressure increase can occur in a closed pipe section when the

!

high pressure pump is operated. K–Patents recommends to mount a pressure relief valve in the pipe section.

Relief pressure should be according to pipe pressure rating.

Figure 4.9 Mounting summary of prism wash system for high pressure water with -WR relay unit

Page 32

26 PR-03 instruction manual

4.2 External output unit PR-7090

The K-Patents inline refractometer can be provided with a separate current output unit to give e.g. a temperature mA signal.

4.2.1 Description

The External output unit PR-7090 has the same dimensions as the four-relay unit PR-7080 (Figure 4.1).

The enclosure has IP 65 (Nema 4X) classification. To open the enclosure, loosen the screws in the four top

corners of the enclosure and lift off cover. This will give access to the output unit’s circuit card.

The cable fittings are delivered as one of the three alternatives:

US 1/2 NPT-TYPE ST-1 conduit hubs 4 pcs

European BF11/PG11 cable glands 4 pcs

M20x1.5 cable glands 4 pcs

The mA output range of the Output unit is the same as the built-in mA output of the IT-R, i.e. either

4-20 mA or 0-20 mA. The output range is chosen through the IT-R’s software, see Section 5.8.

Two monitoring LEDs on the output unit’s circuit card indicate its status: Green LED L1 is lit when the

output unit is in order. Red LED L2 is lit when correct input dat a are missing. Red light means that either the

connection to the IT-R is broken (no interconnecting cable, badly plugged cable or dead cable) or that there’s

a problem on either the output unit’s circuit card or the IT-R’s processor card. Under normal operation the

green LED should be lighted and the red LED should be dark.

The External output unit is connected with the IT-R with an interconnecting cable PR-8011 . The last three

numbers in t he cable code indicate the cable length in meters, the shortest available cable is PR-8011-001

(1 meter; 3.3 feet) and the longest possible cable is PR-8011-100 (100 meters; 330 feet).

4.2.2 External output unit mounting and connections

Note: Seal all unused fittings with blind washers.

The External output unit PR-7090 is mounted on a wall or similar vertical surface using its four mounting

feet. Take the length of the interconnecting cable(s) PR-8011 and easy access for service into account when

choosing mounting spot for the External output unit.

Open the screws on the External output unit and lift off cover to get access to the circuit card to make the

connections. The output mA signal is connected to the terminals 42+ and 43-.

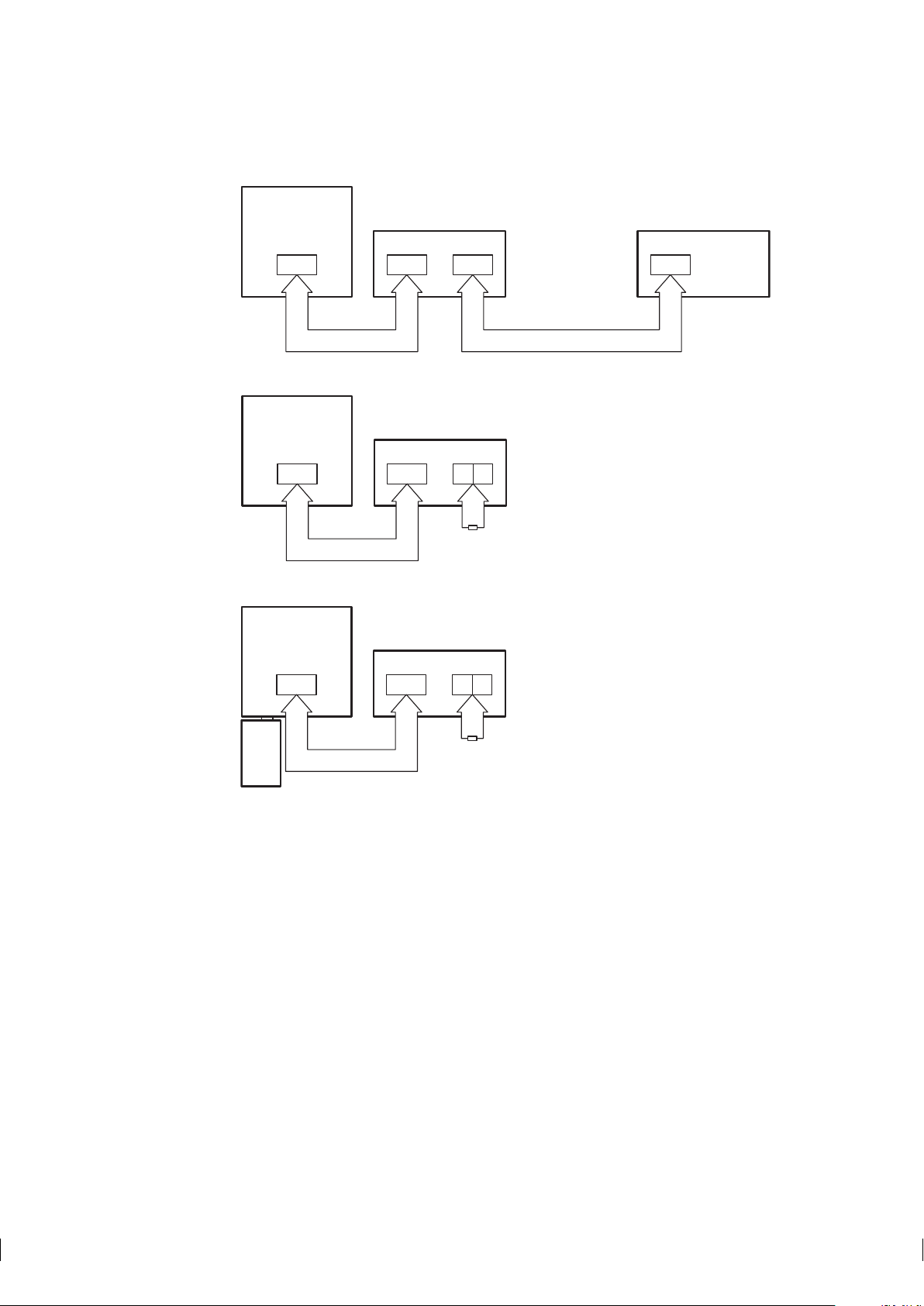

Connect the numbered leads of the interconnecting cable with the same numbers (8-14) on the serial bus A

on the circuit card. If you have a Relay unit PR-7080, the Relay unit’s interconnecting cable is connected to

the Serial bus B.

Important: If the refractometer system does not include a Relay unit PR-7080, close the circuit with a

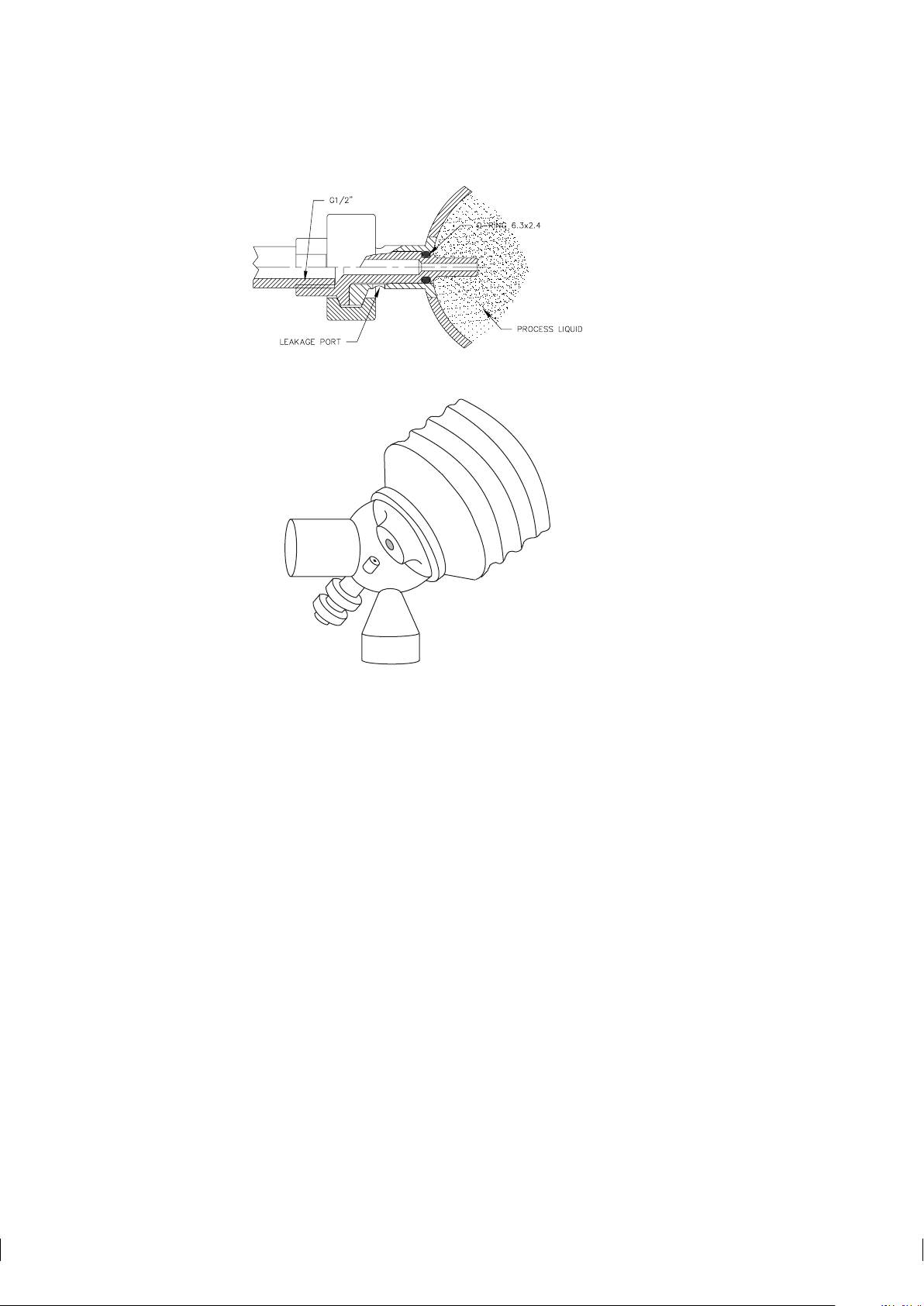

120 Ohm closing resistor (Figure 4.10).

Page 33

4 Accessory units 27

Indicating

transmitter

Indicating

transmitter

8-14

8-14

8-14

8-14

8-148-14

A

A

B

B

External output unit

External output unit

Relay unit

120

Ohm

89

PR-8011

Indicating

transmitter

8-14 8-14

AB

External output unit

120

Ohm

89

-WR

PR-8011

PR-8011

PR-8011

Important: Before connecting the Output unit with your refractometer system, power off your system. Then

open the IT-R’s enclosure and display panel to access the processor card.

Connect the numbered leads of the free cable end with terminals with the same numbers (8-14) on the

serial bus on the Indicating transmitter’s processor card (if there’s an earlier Relay unit connection, move

the Relay unit’s interconnecting cable to the Output unit’s circuit card, serial bus B, and then connect the

Output unit with the IT-R).

Figure 4.10 Connecting External output unit

Page 34

28 PR-03 instruction manual

Page 35

5 Startup, configuration and calibration adjustment 29

POWER

OFF 0

ON

I

A

B

C

D

CONC

68.0%

PROCESS TEMPERATURE: 31.2 °C

STANDARD RI(25°C): 1.4194

TEST: 115.7

Normal operation

Calibrate

Display

A

B

C

D

CONC

68.0%

PROCESS TEMPERATURE: 31.2 °C

STANDARD RI(25°C): 1.4194

TEST: 115.7

Normal operation

Start

prism

wash

Calibrate

Display

5 Startup, configuration and calibration adjustment

5.1 Startup

First check that the serial number of your sensor (Figure 8.1) and your Indicating transmitter (Figure 9.1)

match. If you ordered a new sensor to go with an old IT-R, ask K-Patents to send a new label for your IT-R.

Check wiring and supply voltage, Section 3.2.2.

Open the IT-R cover and press the main power switch (Figure 5.1) underneath down to ON position to power

up your refractometer system.

Figure 5.1 The power switch

5.2 System check

After the power has been switched on, the IT-R checks the type of the sensor, which should be identified

as PR-03. The sensor code PR-03 is shown on the display for a short time. Then the Normal display

(Figure 5.2) appears. The diagnostic message should be Normal operation or, if the process pipe is

empty, Low conc/no sample. For any other message see Section 9.7.

Without wash With wash

Figure 5.2 Normal displays

The display also shows the current process temperature.

The TEST value in the display should be in the range of 8-248. The value 248 indicates a clean prism in an

empty process pipe. The value 8 means that the prism is coated and no reliable optical image is available.

As the instrument is precalibrated to your process, the concentration reading should be on scale, although it

may need some final adjustment (see Section 5.10.1). If the concentration reading is off, check your process

conditions (see Section 7, “Troubleshooting and correcting problems”).

Page 36

30 PR-03 instruction manual

A

B

C

D

CONC

36.7%

TEMPERATURE: 30.2 °C 86.4 °F

STANDARD RI(25°C): 1.3960

TEST: 133.6

Normal operation

Optical

image

System

configuration

Sensor

head

Output signal: 16.7 mA

A

B

C

D

RI(25ºC

1.4412

PR-03 version 8.5

Sensor interface version 4.0

Sensor processor version 4.0

Relay unit not connected

External output unit not connected

Output: 4..20 mA = 1.4260..1.4900 RI(25

Relay

configur-

ation

Switch

configur-

ation

Wash

times

A

B

C

D

RI(25ºC

1.4412

SENSOR HEAD

Head temperature: 20 ºC

Head humidity: 32 %

Normal operation

Press the key D (soft key Display) for additional data, e.g. output in mA. Further data is obtained in the

Information display by soft keys Optical image (Figure 5.3), System configuration and Sensor

head. Return to Normal display by pressing the RESET key as many times as necessary.

Note: Use the keyboard’s keys A, B, C, D for the soft key commands, do not touch the display screen (see

Section 5.3.1).

Information display System configuration display Sensor head display

Figure 5.3 Getting additional information

Measure the output signal. It should agree with the mA display.

If there are problems in the system check, proceed to Chapter 7, “Troubleshooting and correcting problems”.

5.2.1 Checking accessory units

All the accessory units, both relay units -WR and PR-7080 and external output unit, have two indicator

LEDs that tell about their status. Open the enclosure cover to see these LEDs. When the refractometer

system is on and the IT-R is finished with the initial check (i.e. the Normal display has appeared, see at

page 29), only the green led should be lit. If the red led stays lit, there’s problem in the accessory unit

configuration, see Section 5.7 and Section 5.8.

Note: When the refractometer system is powering up, both LEDs light up for a short time during the system

check. After a while the red led should be turned off, in a working system only the green led is lit.

5.2.2 Testing prism wash

Important: Before you test prism wash, check that there is liquid in the pipe in front of the refractometer

and that the steam washing parts are properly installed and connected.

If you are using prism wash controlled by a relay unit check the wash sequence by pressing in the Normal display soft key Start prism wash (Figure 5.2). The TEST value should clearly increase (and the

concentration reading decrease) during wash.

Note: The manual wash command cannot override External hold (see Section 5.6).

Note: The Start prism wash soft key appears in the Normal display only when a relay has been con-

figured as wash relay (Section 5.7). In demo mode it never appears, because the external units have been

disconnected.

Page 37

5 Startup, configuration and calibration adjustment 31

A

B

C

D

CONC

68.0%

PROCESS TEMPERATURE: 31.2 °C

STANDARD RI(25°C): 1.4194

TEST: 115.7

Normal operation

Calibrate

Display

A

B

C

D

CONC

68.0%

PROCESS TEMPERATURE: 31.2 °C

STANDARD RI(25°C): 1.4194

TEST: 115.7

Normal operation

Start

prism

wash

Calibrate

Display

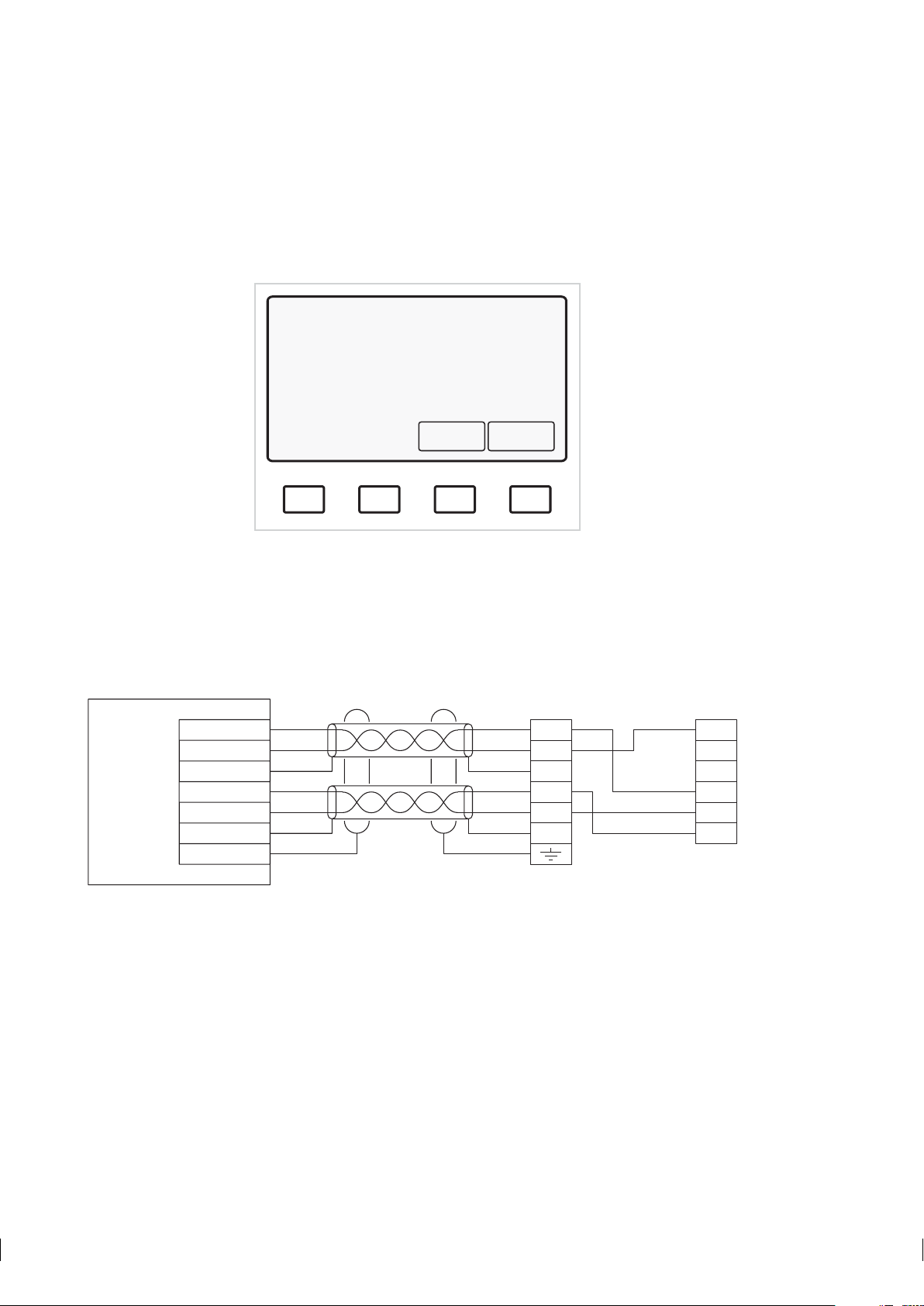

5.3 Using Indicating transmitter

5.3.1 Keyboard functions

The keyboard has 10 number keys and four soft keys, marked with letters A-D. The meaning of a soft key

changes depending on what has been entered previously, i.e. what display is shown. The meaning of a soft

key is always displayed on the screen above the key, for example the Normal display always has soft keys

C=Calibrate and D=Display and, if the system has prism wash, also A=Start prism wash (see

Figure 5.4).

The ENTER key is used to accept entered numeral values (to "OK" them) and the RESET key is used to

cancel input and to move "backwards" in the command structure.

The commands that can be given to the Indicating transmitter have been arranged into a selection tree, i.e.

command groups and subgroups (see Figure 9.5). The "root" of the selection tree is the Normal display

(Figure 5.4), to which the IT-R always returns if it doesn’t receive any keyboard commands for a predefined

reset time (normally 60 seconds).

Figure 5.4 Normal display

Each command in the selection tree can be reached from the Normal display with its own, unique key

sequence. For example you can view the relay configuration with the sequence D (Display) - C (System

configuration) - A (Relay configuration), i.e. starting from the Normal display, press first soft

key D, t hen soft key C, then soft key A. After viewing the configuration you can go backwards to the Normal

display by pressing the Reset key three times.

Whenever New value: _ _ _ _ is displayed, new parameter values can be entered by the numerical

keys. If you accidentally enter a wrong number, you can erase it with RESET. When the number (value)

is complete, press ENTER. After this the IT-R will ask for reconfirmation with the following text: Press

ENTER to change (Otherwise press RESET). Thus, press ENTER if you want the new value

to become effective. If you want to discard the new value and return to the old value, press RESET.

Page 38

32 PR-03 instruction manual

A

B

C

D

CONC

36.7%

TEMPERATURE: 30.2 °C 86.4 °F

STANDARD RI(25°C): 1.3960

TEST: 133.6

Normal operation

Optical

image

System

configuration

Sensor

head

Output signal: 16.7 mA

Example: You need to change the bias (see Section 5.10.2) to be 25.456 (as in the example in

Section 5.10.2). Starting from the Normal display (Section 5.3), you have to perform following

steps:

1. Give the right command sequence to get to the value to be changed, in this case

Calibrate/Parameters/CONC (R.I.)/Parameters/Bias

(key sequence C-B-A-A-1).

2. Type the new value.

3. When the new value is finished, press ENTER.

4. Accept (=reconfirm) the new value by pressing ENTER again. The new value now appears on

the screen as the current value.

5. Finally, withdraw from the current display by pressing the RESET key as many times as necessary (five times to get to the Normal display from the Bias setting).

5.4 Soft key Display: Getting information on the process

and the settings

Pressing the soft key Display (key D) in the Normal display brings up the Information display , Figure 5.5 below. Through the Information display you can get information about the process, the process

parameters and other settings that have been entered to the Indicating transmitter. This branch of the selection tree (Figure 9.5) is safe, because it doesn’t allow you to make changes to the settings, it will only

display the existing information.

As you can see in Figure 5.5, the Information display contains additional data compared to the Normal

display:

− The process temperature in both◦C and◦F

− The standard RI (25◦C). This shows the Refractive Index of liquid applied to the prism, referenced to

25◦C

− output current in mA

Figure 5.5 The Information display

Page 39

5 Startup, configuration and calibration adjustment 33

A

B

C

D

Slope

TEST: 248.0

30.2 ºC

Endp: 11

L): 30.5

R(: 5.3

HT: 20 ºC

HH: 4 %

SCALED

OPTICAL

IMAGE

Low concentration / No sample

A

B

C

D

Slope

TEST: 133.6

30.2 ºC

Endp: 11

L): 16.5

R(: 30.3

HT: 20 ºC

HH: 4 %

SCALED

OPTICAL

IMAGE

Normal operation

5.4.1 Viewing the Optical image

You can view the Optical image (Figure 5.6) by pressing the soft key Optical image (key A) in the

Information display. The light area (high pulses) is to the left, the dark area (low pulses) is to the right,

compare to Figure 2.2. The vertical scale is 0–100% of highest pulse amplitude, the horizontal scale

expresses the numbers of the photocells 0–1024.

Figures 5.6 below show some typical optical images appearing at startup.

Empty pipe Normal conditions

Figure 5.6 Typical optical images

Press the RESET key to return to the Information display from the Optical image display.

5.4.2 Viewing System configuration

You can view the System configuration, i.e. information about your refractometer system settings, by pressing the soft key C (= System configuration) in the Information display. The System configuration

display contains:

− Main program and sensor processor and sensor interface processor versions

− Connection and processor versions of accessory units

− Current output scale: E.g. 4–20 mA = 40.0–60.0 CONC%

− Three soft keys:

− Relay configuration (key A); for details see Section 5.7, “Configuring relays”.

− Switch configuration (key B); for details see Section 5.6, “Configuring input switches”.

− Wash times (key C); for details see Section 5.9, “Configuring automatic prism wash”.

Press the RESET key to return to the Information display from the System configuration display.

5.4.3 Checking conditions inside sensor head

By pressing the soft key D (= Sensor head) in the Information display you will find out what the

conditions are inside the sensor head:

− Head temperature

− Head humidity

This is very useful information when suspecting a problem in the sensor head, for details see Section 7.2.2.

Page 40

34 PR-03 instruction manual

A

B

C

D

RAW

SENSOR

DATA

RMN: 2

RMX: 216

LED: 96

Scans: 2

A/D: 314

Sts: 00h

HT: 143

HH: 10

Scaled

image

Normal operation

5.5 Soft key Calibrate: Viewing and changing system settings

5.5.1 Viewing Optical image and raw data

It is possible to view all raw data from the sensor including the optical image followed by the Scaled

Image, Slope and Image Diagnostics displays (see the selection tree, figure 9.5). Starting from the Normal

display, select Calibrate/Optical image to get the complete optical image. The display (Figure 5.7)

contains now all raw data from the Sensor including the signals from each photo cell, i.e. the raw video

signal. This differs from the Optical image, Figure 5.6, selected through the Display key.

Figure 5.7 Complete optical image with raw data

For information on the diagnostic messages shown on this screen, see Section 9.7.

5.5.2 Raw data explanations

RMN, RMX Minimum and maximum of the raw video signal. This signal is calculated on the Processor

card from the video signal. The scale is 0-255, corresponding to full scale on display. The

light intensity is controlled to keep RMX in the range 170-190.

LED The LED exposure control signal on a light intensity scale 1-255. The flashing red light of

the LED can be seen directly. If the operation is correct, the displayed LED value should be

above 20 and below 200.

Scans Number of optical images during one calculation cycle, typically 1 or 2. The scan pulses

(with 5 V amplitude) can be measured at TP 3

A/D This refers to the temperature measurement

Sts Sensor status bits determined by the type of Image Detector card: "04h" indicates a Process

refractometer PR-03. One bit added, "05h", indicates DETECTOR TIMEOUT.

Page 41

5 Startup, configuration and calibration adjustment 35

A

B

C

D

SCALED

OPTICAL

IMAGE

TEST: 115.9

51.2 °C

Endp: 21

L): 9.8

R): 25.9

HT: 20 °C

HH: 3%

Slope

Normal operation