Page 1

PROCESS INSTRUMENTS

INSTRUCTION

MANUAL

IM-EN-DD23 Rev. 1.42

DIGITAL DIVERT

CONTROL SYSTEM

DD-23

Page 2

Page 3

Table of contents

1 Introducon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 The Divert Control System DD-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Divert Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Operator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.2 Green indicator lights: System ok . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.3 Yellow indicator lights: Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.4 Red indicator lights: Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.5 White pushbuons: Tesng and reseng . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.6 Header wash key: Enabling ring header wash . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.7 Emergency divert buon: Manual divert . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.8 External emergency divert buon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Prism wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Indicang transmiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Mounng . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Mounng prism wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Switch inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.1 External Divert switch/push buon - input J8 . . . . . . . . . . . . . . . . . . . . . . 10

3.3.2 External divert reset buon - input J9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3.3 Header wash key - input J10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Remote ethernet connecon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Divert system pre-startup checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Divert control unit DD-23 startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Configuraon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Calibraon lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Divert decision rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Refractometer concentraon measurement . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Refractometer acvaon for divert control . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 Signal difference alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.6 Low alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6.1 Solids warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6.2 Solids alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.7 Refractometer malfuncon alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.8 Prism wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page 4

6 Regular maintenance and troubleshoong . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Informaon flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Malfuncons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Diagnosc tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 Troubleshoong . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.1 A queson mark (?) on the refractometer display . . . . . . . . . . . . . . . . . . 23

6.4.2 A refractometer refuses to come on-line . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.3 No lights come up in the Divert Control Unit . . . . . . . . . . . . . . . . . . . . . . 24

6.4.4 All lights are blinking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7 Divert control logics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.1 Safety decision logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.2 Divert decision logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.3 In operaon logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.4 Malfuncon logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.5 Reseable alarm logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.6 Refractometer difference logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.7 Wash arbitraon logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.8 Wash check logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Remote control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.1 Divert Control Unit IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2 The remote interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2.1 Main page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2.2 Instrument pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2.3 Diagnoscs page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2.4 Log page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2.5 Parameters page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3 Data logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9 DD-23 specificaons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1 Divert Control Unit specificaons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.2 Divert control unit spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10 Oponal Remote Divert Terminal DD-23-RT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.1 Mounng instrucons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.2 Startup and use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10.3 Troubleshoong . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

A Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Page 5

1 Introducon

The K-Patents Digital Black Liquor Divert Control System DD-23 provides a divert signal preventingblack liquor with dangerously low solids to reach the black liquor burners. The system is built strictly according to the principles of Recommended Good

Practice "Safe Firing of Black Liquor in Black Liquor Recovery Boilers" (BLRBAC April

2010; the document is available at

http://www.blrbac.org/Sept2010Updates/Safe_Firing_of_Black_Liquor_April_2010.pdf).

The system consists of the following parts: Two K-Patents Process refractometers

PR-23-SD (A & B) are installed in series in the main black liquor line. Each refractometer is complete with a sensor, an Indicating transmitter and interconnecting cables. Each refractometer provides also two 4–20 mA output signal not used by the

divert control system. These can be used to give % solids output or temperature output signals. The sensors are also equipped with a steam wash nozzles although the

self-cleaning sensor design may eliminate the need for prism wash altogether.

1.1 Warranty

K-Patents warrants that all products made by K-Patents shall be free of defects in material and workmanship. K-Patents agrees to either replace or repair free of charge,

any such product or part thereof which shall be returned to the nearest authorized

K-Patents repair facility within two (2) years from the date of delivery.

1

Before returning a defective product for service or replacement, please contact K-Patents or your nearest K-Patents representative (see http://www.kpatents.com/ for

contact information). For the health and safety of personnel handling your return,

clean the instrument, especially the parts that have been in contact with the process

liquid, before packing it. Ship the cleaned instrument to the address given to you.

1.2 Disposal

When disposing of an obsolete instrument or any parts of an instrument, please observe the local and national requirements for the disposal of electrical and electronic

equipment. The aluminium or stainless steel sensor housing can be recycled with

other metallic waste of the same type.

Page 6

2

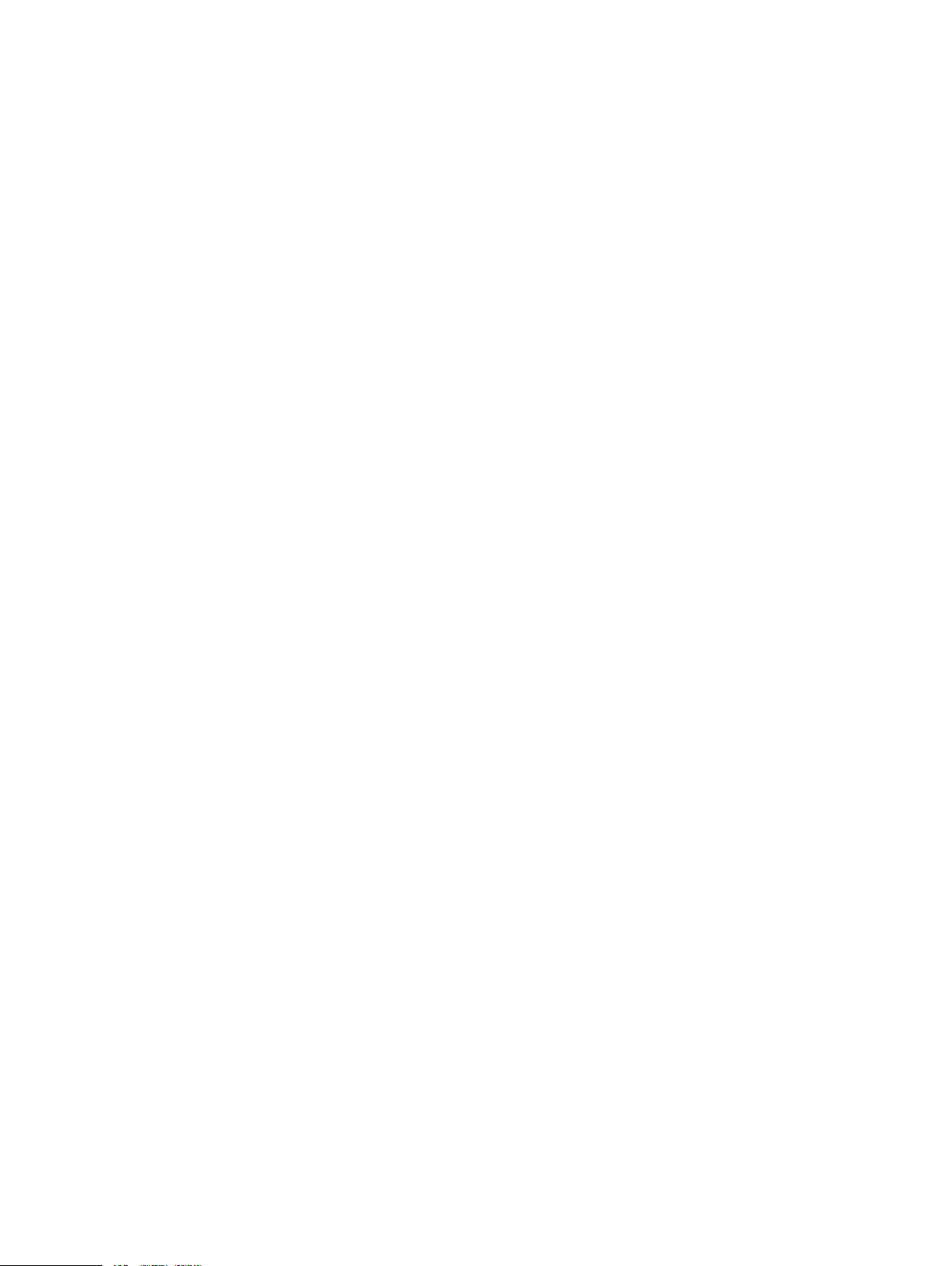

Figure 1.1 Complete Digital Black Liquor Divert Control System DD-23

Page 7

2 The Divert Control System DD-23

2.1 Overview

The Divert control system DD-23 includes:

− A Divert Control Unit

− Two isolation valves SDI for the refractometers above to allow removal of the re-

fractometers from a pipe with full low and pressure. The isolation valve includes

a prism wash nozzle and two check valves (one for prism wash, one for stufing

box lush).

− A roofed mounting plate to mount the two Indicating transmitters and the Divert

Control Unit together.

− Wiring to connect the Indicating transmitters with the Divert Control Unit.

− Two steam valves with steam traps for prism wash (pneumatic + solenoid valves).

− Two hand valves (one for prism wash, one for stufing box lush).

− A remote operator panel facility, accessible with a web browser over Ethernet

BLRBAC (The Black Liquor Recovery Boiler Advisory Committee) recommends a

spare refractometer sensor to be maintained in stock on-site.

3

2.2 Divert Control Unit

The Divert Control Unit is contained in an enclosure with the same dimensions as the

refractometer transmitter enclosure. The control unit includes:

− An operator with system state indicators and pushbuttons

− Relay outputs for connecting to the control system

− Contact inputs for external control

− Ethernet interface for remote operator panel

2.3 Operator panel

The operator panel has a clear layout and the operator can see all information at one

glance. The divert decision is controlled from the operator panel which provides doubled security, since information is shown both as LED indication in the Divert control

unit and as a diagnostic messages in the Indicating transmitters. The same information is also available through the remote operator panel.

Page 8

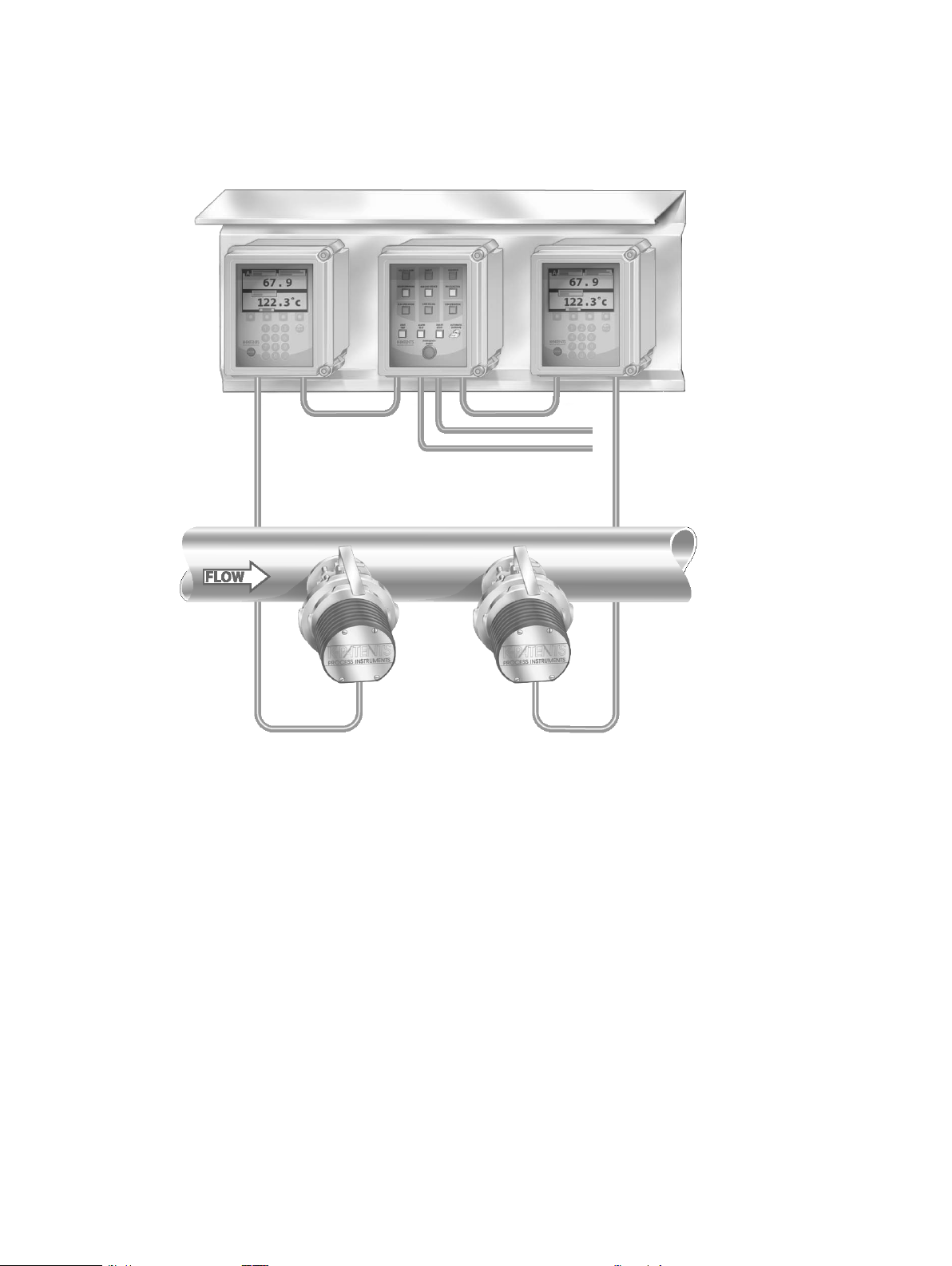

4

Red indicator

lights (alarms)

Yellow indicator

lights (warnings)

Green indicator

lights (all well)

White pushbuttons

Red push-button

2.3.1 Overview

Figure 2.1 DD-23 operator panel

The three top rows on the operator panel consist of indicator lights. The green A IN

OPERATION and B IN OPERATION lights are also push buttons used to include the refrac-

tometers in the Divert system. Below the lights there are push buttons and the HEADER

WASH key key used to operate the system.

The indicator lights on the operator panel are arranged like trafic lights: top row is

red for alarm, middle row is yellow for warning and bottom row is green for "system

ok". When the system is running normally, only the row of green lights should be lit.

The white LIGHT TEST button is used to check that all the LEDs behind the indicator

lights are working. It also veriies the data processing system in the control unit. The

other two white push buttons, ALARM RESET and DIVERT RESET can be used to reset

the system back to normal after all problems have been ixed. The HEADER WASH key

enables the use of ring header washing with water, when set to ON.

The big red EMERGENCY DIVERT push button is used to manually initiate divert in an

emergency situation. An external push button can also be connected to a switch input

in the control unit as External Emergency divert button, see Section 2.3.8.

Page 9

2.3.2 Green indicator lights: System ok

Each refractometer has a green operating light – A IN OPERATION and B IN OPERATION –

to let the operator know when he can rely on the refractometer measurement. A refractometer will only inluence the divert decision and activate warnings and alarms

when it is in divert operation, i.e. when its green operating light is lit.

When DIVERT is effective, the system may be reset to normal operation only when

SAFE SOLIDS is lit.

2.3.3 Yellow indicator lights: Warnings

The SOLIDS WARNING light indicates a black liquor concentration of below warning

limit (by default at 60%). This warning can be activated by either refractometer.

The A&B DIFFERENCE light is lit when the refractometer readings differ by at least 2%.

This warning will only be initiated if both refractometers are operating.

If the yellow MALFUNCTION light is switched on, some part of the system – a refractometer, an indicating transmitter or the control unit – is malfunctioning. A list over

malfunctions and critical malfunctions is given in Section 6.2. If a critical malfunction

occurs in a sensor or transmitter, the malfunctioning refractometer will be automatically removed from divert operation (its operating light will also be switched off).

Check the reason for the malfunction and correct the problem (see Section 6.4) before returning the refractometer back to divert operation.

5

2.3.4 Red indicator lights: Alarms

The black liquor SOLIDS ALARM is lit when the concentration reading goes below alarm

limit (by default below 58%). This alarm can be activated by either refractometer

depending on the operation rule setting.

The DIVERT light will be switched on when the SOLIDS ALARM is activated. The DIVERT

light indicates divert status of the divert relay. The relay is inactive in the divert position, because then a power failure will give a divert decision signal to the system.

The OVERRIDE light is lit to indicate that no automatic divert will happen as long as

the system is in the header wash state (see Section 2.3.6).

2.3.5 White pushbuons: Tesng and reseng

The LIGHT TEST button switches all 12 lights on. The ALARM RESET button resets the

alarm lights.

Page 10

6

2.3.6 Header wash key: Enabling ring header wash

The header wash key function is a 3-level procedure which can be used when ring

header washing with water is needed. When the HEADER WASH key is switched to ON

position and information from black liquor guns switch inputs connected in series tell

that guns are out from recovery boiler, then a ring header wash can be done without

activating Divert.

Pushing the EMERGENCY DIVERT button will always initiate divert regardless of the

header wash functionality.

2.3.7 Emergency divert buon: Manual divert

The EMERGENCY DIVERT push-button is used to manually initiate divert in an emergency situation.

2.3.8 External emergency divert buon

An external (remote) push button can also be connected to an input inside the Control

unit, see Figure 3.3.

External emergency divert button must be normally closed (NC). Opening the circuit

will initiate divert.

2.4 Prism wash

The wash parameters for the sensors are set through each transmitter (Section 2.4).

The transmitters contain a relay for prism wash. To follow the BLRBAC recommendation not to wash both prisms at the same time, the Divert Control Unit implements an

interlock which prevents the instrument from washing both sensors simultaneously.

2.5 Indicang transmiers

Mechanically the Indicating transmitters shipped with a DD-23 are the same than

PR-23 Indicating transmitter DTR. The transmitter will only allow single sensor connection and a special DD-23 transmitter software is used for the Divert system. When

Divert software is 2.01 or newer, Indicating transmitter software version has to be

4.12 or newer.

For more information on the basic functions of an indicating transmitter, please see

the PR-23 manual, chapters 3 and 10.

Page 11

3 Mounng

For mounting of the process refractometers and the isolation valves, consult the separate process refractometer PR-23 instruction manual.

7

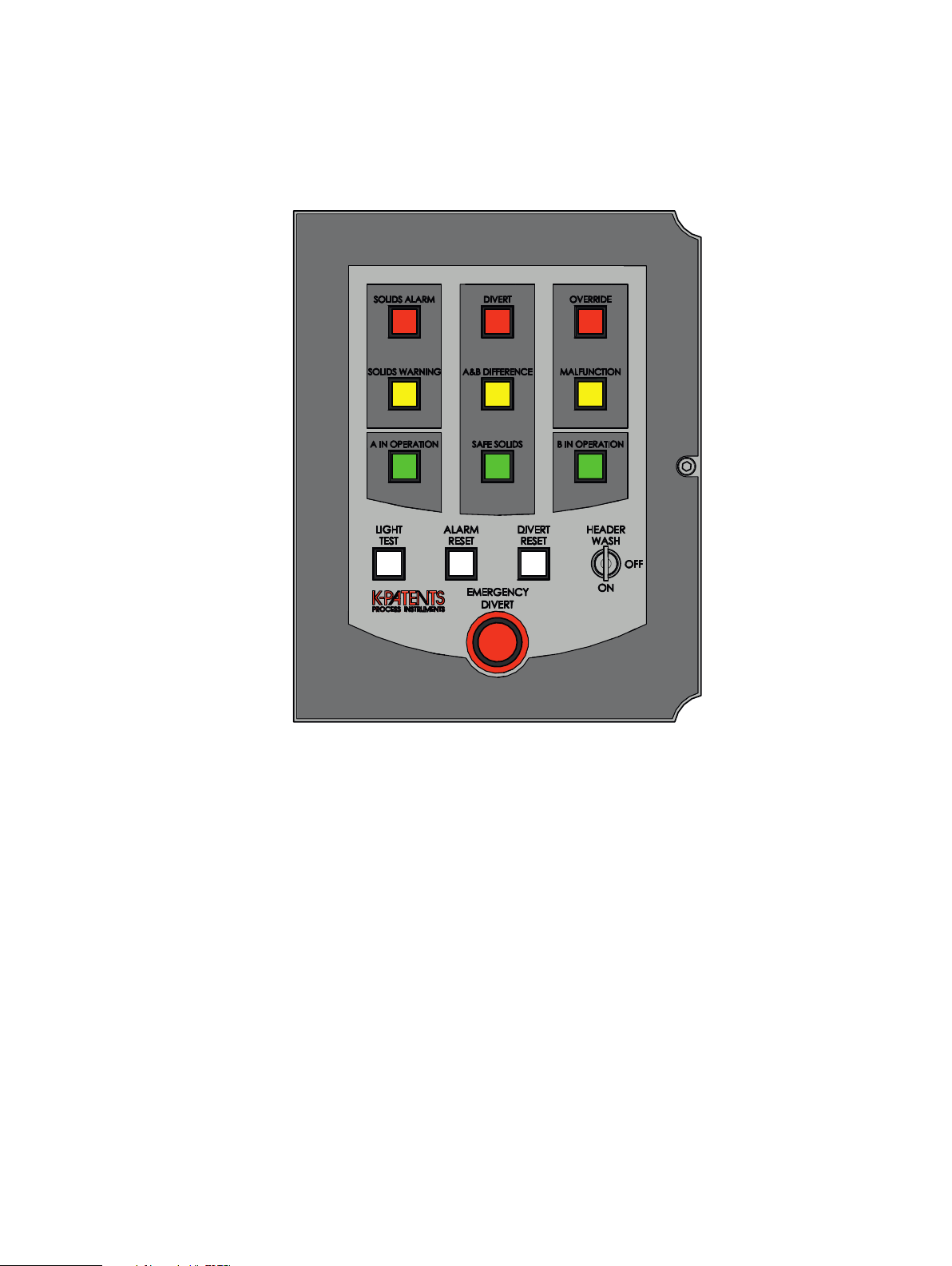

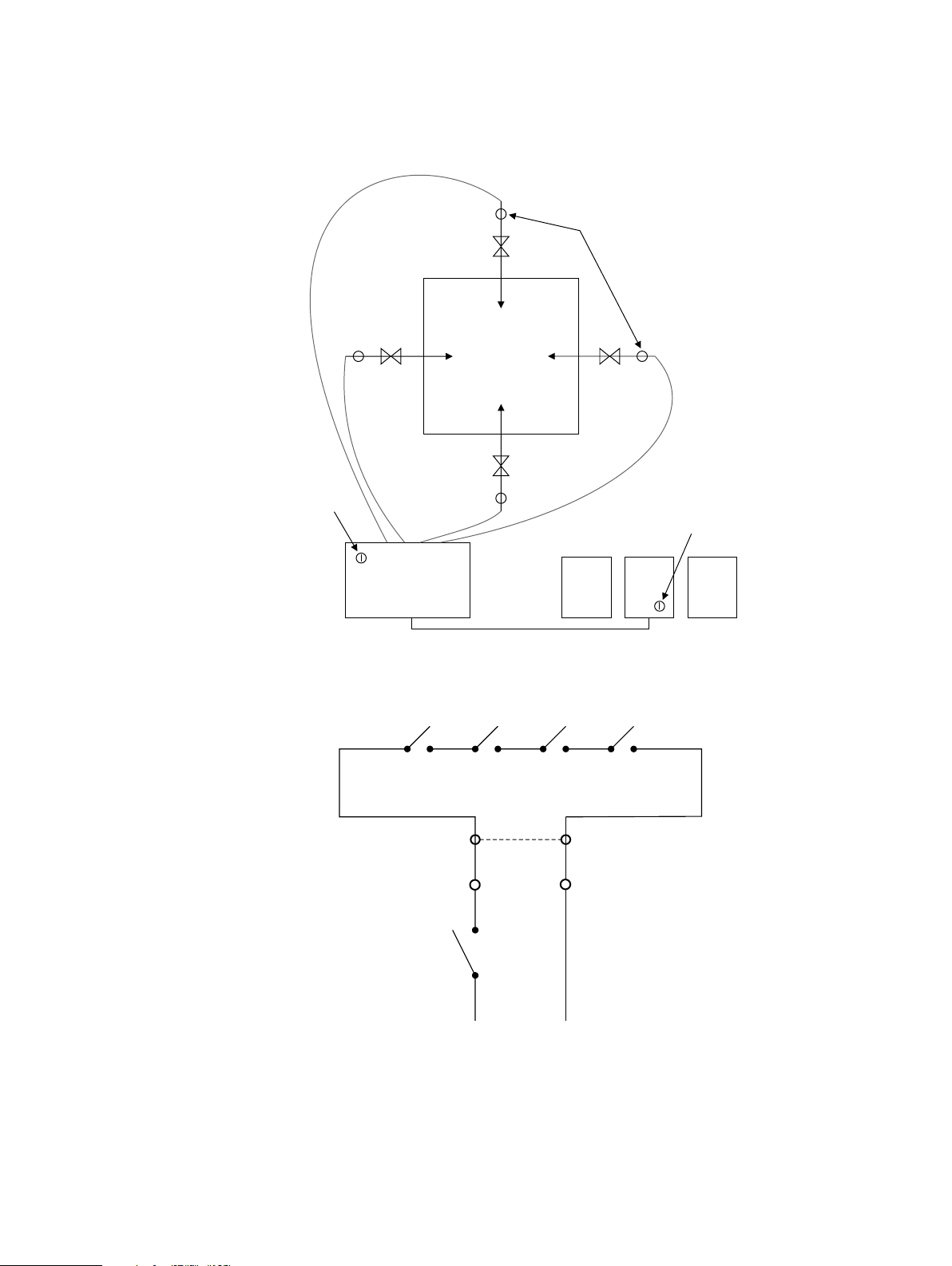

Figure 3.1 Mounng the Divert control system

3.1 Mounng prism wash

K-Patents recommends to use a steam trap instead of a preconditioning valve to remove condensate from the steam line.

Page 12

8

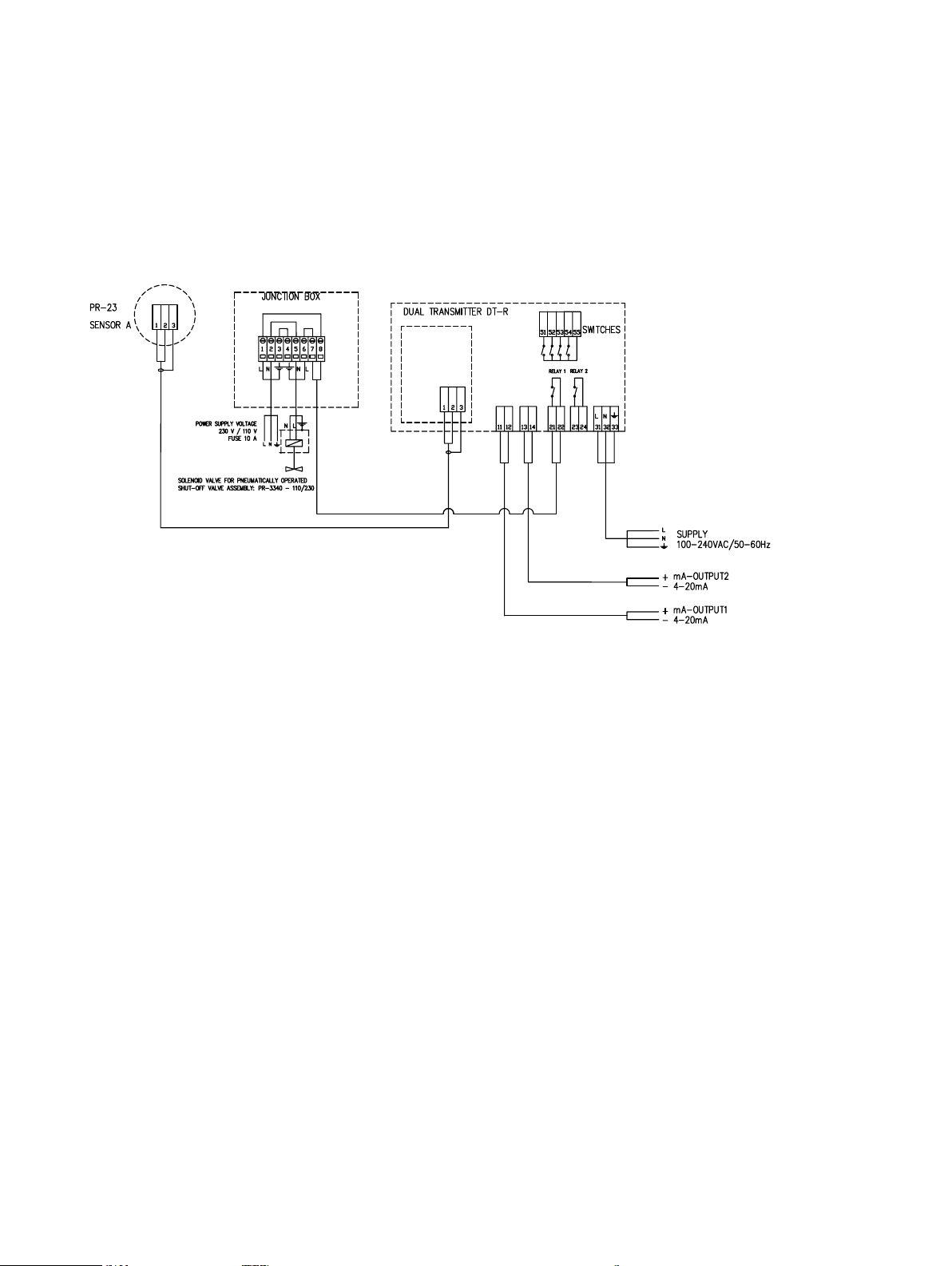

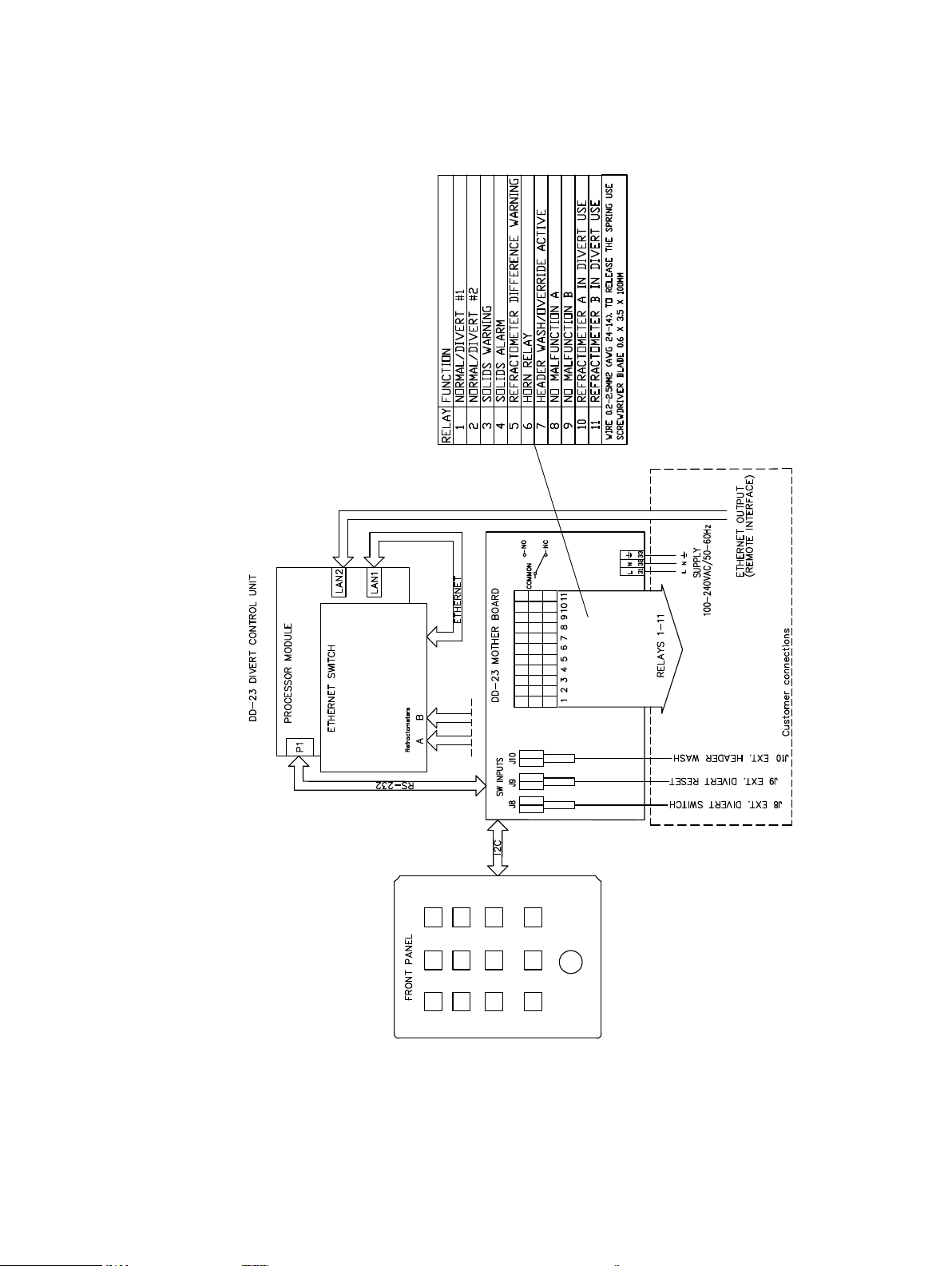

3.2 Wiring

For wiring for complete system, see Figure 3.2 which shows the connections to the

Indicating transmitters and to steam washing. Figure 3.3 has information of all connections to the Divert control unit.

Figure 3.2 Transmier wiring cables and connecons

3.2.1 Relays

Relay 1 NORMAL/DIVERT information

Relay 2 NORMAL/DIVERT information

Relay 3 SOLIDS WARNING: when one of the refractometers goes lower than the

solids warning limit, typically 60% or higher. See Section 5.6.1.

Relay 4 SOLIDS ALARM: when one of the refractometers goes lower than the solids

alarm limit, typically 58% or higher. See Section 5.6.2.

Relay 5 Refractometer signal difference warning: when the refractometerreadings

have more than 2% difference in concentration. See Section 5.5.

Relay 6 Horn relay: connection to the audible alarm. See Section 7.5.

Relay 7 Header wash key information. See Section 3.3.3.

Relay 8 Refractometer A malfunction information. See Sections 6.2 and 7.4.

Relay 9 Refractometer B malfunction information. See Sections 6.2 and 7.4.

Relay 10 Information on if refractometer A is active in the Divert Control System or

dropped off.

Relay 11 Information on if refractomter B is active in the Divert Control System or

dropped off.

Page 13

9

Figure 3.3 Divert control unit internal wiring

Page 14

10

3.3 Switch inputs

3.3.1 External Divert switch/push buon - input J8

An external divert switch can be connected to the DD-23 Divert Control Unit, input J8.

If the external divert switch is not used, a jumper has to be connected across J8. The

unit is delivered with this jumper connected.

3.3.2 External divert reset buon - input J9

If you want to use external Divert reset button, it can be connected max. 200 m (600 ft)

from the DD-23 Divert control unit. Use normal instrument cable 2x0.5 (AWG 20) and

connect cable to DD-23 motherboard input J9.

You must make sure both refractometers A and B are working OK before starting to

use the remote divert button (the remote interface can be used to check on the refractometers, see Chapter 8).

The external reset button connection is normally open (NO).

3.3.3 Header wash key - input J10

Black liquor is injected to the recovery boiler through liquor guns. Occassionally the

header ring needs washing and during that procedure the divert system has to be

by-passed and the liquor guns have to be removed from the furnace. The Digital Divert

Control System DD-23 allows for a safe override of divert logic during header ring

wash.

The override is mounted by connecting the gun micro switches in series to the Header

wash/override key switch input J10, see Figure 3.5.

The Header wash key may be used without the external switch information if a jumper

(dotted line in Figure 3.5) is placed to swith input J10. If the input is left open, the key

does not have any effect.

Page 15

11

DD-23

Operator panel

OVERRIDE

HEADER WASH

HEADER

WASH

KEY

MICROSWITCH

on each liquor gun or

on liquor gun door

Recovery

boiler

Guns out microswitches

HEADER

WASH

KEY

SWITCH INPUT

J10

Figure 3.4 Header wash key funconality

Figure 3.5 Header wash key connecons

Page 16

12

Ethernet output

3.4 Remote ethernet connecon

The Ethernet connection for the remote interface and data logging purposes is located

inside the Divert control unit on the right side of the processor unit. It is marked

Ethernet output.

Figure 3.6 Ethernet connecon

Page 17

4 Startup

4.1 Divert system pre-startup checklist

1. SDI Isolation valves mounted correctly

a. Vertical pipe; MTG453

b. Horizontal pipe; MTG471

2. DD-23 control unit installed; DIM243, Figure 9.1 on page 37

3. Pressure reducing valve, solenoid valve, steam trap installed and connected to the

prism wash nozzle on each sensor

a. Steam pipes for black liquor; MTG470

b. Nozzle; MTG482

4. 9–15 bar (130–220 psi) steam connected to the solenoid valve on each sensor

5. Instrumentation air 4–6 bar (60–90 psi) connect to the solenoid valve on each

sensor

13

6. Power supply (230/110Vac/24Vdc) connected; SYS358/Figure 3.1 on page 7, and

WRG366, Figure 3.1 on page 7

a. Transmitter A

b. Transmitter B

c. Divert control unit

d. Solenoid valve A

e. Solenoid valve B

7. Cables connected; SYS358/Figure 3.1 on page 7, WRG366, Figure 3.1 on page 7

a. Transmitter A to sensor A

b. Transmitter B to sensor B

c. Transmitter A to solenoid valve A

d. Transmitter B to solenoid valve B

e. Relay information from the Divert control unit to your control system or the

Divert valve

f. Transmitter A mA output to your control system

g. Transmitter B mA output to your control system

h. Ethernet to your control system (optional)

Page 18

14

4.2 Divert control unit DD-23 startup

Forthe refractometer startup, consult Chapter 5 in the separate Process refractometer

PR-23 manual.

1. Check the wiring and supply voltage.

Before the power is switched on, the divert output relay ’normal operation’ is in

divert position.

2. Connect the mains power to start the system.

There are no power switches in the instruments. They are always On when the

mains power is connected.

3. While the Control unit is powering up, the DIVERT and SOLIDS ALARM lights are both

blinking. When the unit is fully functional, it is in the divert mode: the DIVERT light

is on and the SOLIDS ALARM light is blinking.

4. Press the LIGHT TEST button on the Divert control unit. All 12 lights should switch

on.

5. Reset the solids alarm by pressing the ALARM RESET button.

The indicator stops blinking and should stay on.

6. Each indicating transmitter should now state refractometer letter, either a or b, in

the upper left corner of the transmitter display. If there’s a question mark instead

of a letter on either of the transmitters, see Chapter 6.

If the process pipe is full, the message for each refractometer should be NORMAL

OPERATION; if process pipe is still empty, message will be NO SAMPLE.

Now activate refractometer A into the Divert by pushing the button A IN OPERATION

on the Divert control unit panel. The button lights up and on the transmitter display the refractometer letter changes to capital A. Then activate refractometer B

similarly by pushing the button B IN OPERATION.

If the green IN OPERATION light blinks, the refractometer in question is perform-

ing wash. The refractometer will automatically come into operation after it has

inished washing.

7. Now the Divert control system DD-23 is set for normal monitoring operation.

8. When black liquor is in the line, check that the prism wash is working for each

refractometer. First press soft key MENU on the transmitter keyboard, then choose

3 SYSTEM STATUS to get to the system status display. Now press soft key WASH to

initiate manual wash; follow the optical image and check that it changes during

the steam wash. If wash was successful, wait until message is NORMAL OPERATION

and then proceed with startup. If wash doesn’t seem to work, see Chapter 6.

9. If the three green lights on the third row are all on and all conditions for safe boiler

operation are satisied, turn off diversion by pressing the DIVERT RESET button. All

warning lights are now turned off and only the 3 green lights are on.

Page 19

5 Configuraon

CALIBRATION

LOCK

CALIBRATION

LOCK

The K-Patents Divert control system is shipped fully calibrated by the manufacturer.

This chapter contains instructions on how to make ine adjustments of the system.

5.1 Calibraon lock

Parameter changes are possible only when the calibration lock is open. The calibration lock can be closed by a switch inside the control unit cover (see Figure 5.1). When

the lock is open, a red led is illuminated next to the lock switch. For safety reasons,

keep the calibration lock open only during parameter changes, done through the web

interface (see Chapter 8).

15

Figure 5.1 Locaon of the calibraon lock

Page 20

16

5.2 Divert decision rules

Two refractometers in operation:

BLRBAC states the following: For the solids measurements, two refractometers in series must be used. When both refractometers are in service, the requirement for an automatic black liquor diversion can be satisied by either of the following options:

1. If either refractometer reads dissolved solids content 58% (default) or below,

an automatic black liquor diversion must take place.

2. When both refractometers read dissolved solids content 58% (default) or be-

low, an automatic black liquor diversion must take place.

Either option is satisfactory.

The rules are listed in decreasing order of security. Only rule 1 satisies the high safety

requirements set by BLRBAC, August, 1982. On the other hand, the probability of false

trips decreases with decreasing safety. It means that if false trips are too frequent, the

rule 2 may be preferred at the cost of safety. The rule 2 has later been accepted by

BLRBAC.

The divert decision rule is selected by the rule switch inside the divert control unit

cover (Figure 5.1). The state of the switch is indicated by a yellow indicator LED for

rule #2 and a green one for rule #1.

Rule switch Rule

1-of-2 Rule #1

2-of-2 Rule #2

Table 5.1 Divert decision rule selecon.

The logical description of the safety decision logics is given Tables 5.3 and 5.2 below.

A

under 58% over 58%

B

B

under 58% divert divert

over 58% divert safe

Table 5.2 Two instruments in operaon, rule 1-of-2

A

under 58% over 58%

under 58% divert unsafe

over 58% unsafe safe

Table 5.3 Two instruments in operaon, rule 2-of-2

Page 21

Only one refractometer in operation:

When only one instrument is in operation the divert action takes place if this instrument reads 58 % or below. The rule selection has no inluence on the divert decision

in this case.

A or B

under 58% unsafe

over 58% safe

Table 5.4 Operaon logic when only one instrument operang

No refractometer in operation:

If both instruments are out of operation (due to malfunction or maintenance), then

according to BLRBAC divert action must take place.

Emergency divert

In all cases the system may be set to DIVERT by pressing the EMERGENCY DIVERT button

(or an external emergency divert button, see Section 2.3.8).

17

5.3 Refractometer concentraon measurement

For refractometer calibration consult also Chapter 6 in the separate Process refractometer PR-23 Instruction manual.

The CONC% displays of the two indicating transmitters have to show the same value

within 0.5 %. If there is a difference, this can be eliminated by adjusting the bias for

one of the refractomers; comparison with sample determination can decide which

one should be corrected.

In the PR-23 refractometer system, bias is the parameter F00, the third parameter in

the ield adjustment parameter list. To change it, irst press the MENU soft key, then

5 CALIBRATION, then 1 CHEMICAL & FIELD PARAMETERSand then 2 FIELD CALIBRATION PARAMETERS. Choose 3 F00 (BIAS) to change the bias (see Section 6.2.5 in the PR-23 manual).

If the Indicating transmitter A displays 68.2% and B displays 68.8%, the difference can

be eliminated by lowering B by 0.6%. This is done by setting the ield calibration

parameter F00 to -0.6 in Indicating transmitter B.

Due to its digital measurement principle, the readings of the K-Patents Process refractometer do not drift by time. Frequent recalibrations based on ofline moisture analysis must be avoided, as they will introduce random luctuations to the refractometer

readings.

Page 22

18

5.4 Refractometer acvaon for divert control

When a refractometeris activated for Divert control, the upper left corner of the transmitter display shows alternatively A, a, B, b or ?. If the corner is blank, the instrument

is not suitable for divert operation.

Transmier A, in

Divert operaon

Figure 5.2 Indicang transmiers (STR) acvated to Divert control

The decision to display A (a) or alternatively B (b) depends on the IP address settings

in the transmitter. The IP address of instrument A is 172.16.23.2 and that of instrument B is 172.16.23.3. These addresses have been set in the factory and should not be

changed. (See Chapter 8 for information on system IP address and connecting to the

DD-23 system.)

If a question mark appears on the transmitter display, the reason is usually that the

Ethernet cable between the transmitter and the Control unit is not properly connected

or the Divertcontrol unit is not powered on. Reconnect (or replace cable, if necessary)

to ix.

The refractometer program version has to be 3.00 or higher to have divert system

functionality. Divert version 2.01 or higher requires DTR software version 4.12 or

higher. Also, the refractometer has to have the correct software parameters to be used

in a divert control system. In order to convert a stand-alone refractometer into one

used on the Divert control system, please contact K-Patents. The easiest way to check

if a refractometer is conigured for DD-23 use is to look at the main display. If the

?/a/A/b/B letter is present (see Figure 5.2), the instrument may be used in the Divert

control system.

If a DD-23 activated transmitter is used in another type of application, the divert function has to be deactivated by K-Patents.

Transmier B, not

in Divert operaon

Ethernet connecon failure

5.5 Signal difference alarm

According to BLRBAC, if a difference of 2% in solids (absolute value) or greater exists

between refractometer readings, an alarm shall be activated.

The alarm limit of 2% is the maximum difference. The limit can be changed into a

smaller number through the remote interface, see Chapter 8.

Page 23

5.6 Low alarms

5.6.1 Solids warning

If the concentration reading of either refractometer falls below this limit (60% by default), the warning is activated. The limit can be changed through the remoteinterface,

see Section 8.2.5.

Minimum low warning level is 60% according to BLRBAC.

5.6.2 Solids alarm

If the concentration reading of either refractometer falls below this limit (58% by default), the alarm is activated. The limit can be changed through the remote interface,

see Chapter 8.

Minimum low alarm level is 58% according to BLRBAC.

5.7 Refractometer malfuncon alarm

The built-in intelligent diagnostics of a K-Patents Process refractometer provide a

tight control of the operation. A full test cycle is completed with an interval of less than

one second. For details consult the Process refractometer PR-23 instruction manual.

19

Not all malfunctions cause the instrument to be removed from the Divert control system. However, all malfunction alarms need to be checked, see Section 6.2 for more

information.

5.8 Prism wash

Even though the sensors are equipped with a steam wash facility, it is not necessarily

needed. For K-Patents Process Refractometer, the need of prism wash is reduced and

even in some cases eliminated.

However, an automatic regular prism wash provides an eficient check that the refractometer reacts. A steam wash of 3 seconds every half hour should be suficient.

Only one instrument is washing at a time, and during the wash the system acts in the

single-instrument mode.

To change wash times or relay conigurations, consult the PR-23 process refractometer system manual, sections 6.1.3. Coniguring relays and 6.3.1. Setting prism wash

parameters.

Page 24

20

The recommended wash pressures and times are given in the table below..

Wash parameters for Safe-Drive™ Isolaon valve nozzle SDI

Minimum above

process pressure

Steam (SN) 5 bar (70 psi) 8 bar (115 psi) 3–5 s 20–30 s 20–30 min

Maximum above

process pressure

Wash

me

Reco-

very

Do not exceed the recommended wash times, because some process media may burn

to the prism surface if steamed for longer time. In case of coating, shorten the wash

interval.

It should be noted that if wash check is enabled on the instrument it can cause the

instrument to be taken out of divert use if during the set wash tolerance time no wash

cycles have been noted as successful. This can cause a divert if both instruments fail

wash checks in sequence.

Interval

Page 25

6 Regular maintenance and troubleshoong

As the Divert control system is a pure digital system, no special maintenance is needed.

The LIGHT TEST button on the operator panel (Figure 2.1) sends a signal to the microprocessor, and the microprocessor switches all 12 LED lights on as long as the button

is pressed. This way not only the lights but also the processing system is checked.

To assist the identiication of a faulty component, the information low is given in Section 6.1. Also the logic diagrams of Chapter 7 may be of help.

6.1 Informaon flow

The divert control unit is connected to the refractometers through an Ethernet connection. The Control system asks for the measurement data from the instruments

several times each second. Based on the data received the divert operation decisions

are made.

Each refractometer performs its measurement functions independently. The instruments also have their own internal diagnostics, which are used in the divert decision

logic, as well (see Section 6.2).

21

As the Divert Control System requests information several times a second, all communication problems are found immediately. In case one of the refractometers does not

respond to the control unit, the non-responding instrument is dropped from operation and the malfunction alarm is set.

An important information when troubleshooting communication problems is the letter on the upper left corner of each refractometer (see Figure 5.2). If the instrument

has not received any data requests from the DivertControl Unit during the last second,

the letter turns into a question mark (?). If the letter is a/A/b/B, then the communication link between the Divert control unit and the instrument is fully functional.

6.2 Malfuncons

If the Divert Control Unit cannot communicate with a refractometer, or if the internal diagnostics of a refractometer indicate a measurement problem, the Malfunction

indicator (see Figure 2.1) is illuminated and the corresponding relay 8 or 9 (see Figure 3.3) is activated.

The diagnostic message of the refractometer can be seen on the transmitter screen

(see Figure 5.1). Some of these messages, e.g. PRISM WASH, are only informative and

do not indicate a measurement problem. Table 6.1 below summarizes all diagnostic

messages and their effect on the Divert control system operation.

Page 26

22

If the malfunction is severe enough to make the measurement result unreliable,

the refractometer cannot be used in making the divert decision. In that case the

instrument is dropped from the Divert Control System, and cannot be taken on-line

manually until the problem is ixed.

For more information on possible causes of each error, see the PR-23 instruction manual, Chapter 8.

Message Instrument will be

dropped from the

Divert Control System

EXTERNAL HOLD

EXTERNAL WASH STOP

HIGH SENSOR HUMIDITY

HIGH SENSOR TEMP

HIGH TRANSMITTER TEMP

LOW IMAGE QUALITY X

LOW TEMP WASH STOP

LOW TRANSMITTER VOLT

NO OPTICAL IMAGE X

NO SAMPLE X

NO SAMPLE/WASH STOP

NO SENSOR X

NO SENSOR SIGNAL X

NORMAL OPERATION

OUTSIDE LIGHT ERROR X

OUTSIDE LIGHT TO PRISM X

PRECONDITIONING

PRISM COATED X

PRISM WASH

PWASHFAIL X

PWASHWARN

RECOVERING

SHORT-CIRCUIT X

STARTING UP... X

TEMP MEASUREMENT FAULT X

Table 6.1 Diagnosc messages and their effect on Divert operaon

Page 27

6.3 Diagnosc tools

In order to make troubleshooting easier, there are several built-in diagnostic tools.

An event log is built in the system. A short log showing last 6 events can be accessed

from the transmitter main display by pressing the soft key DD23. A more complete

event log can be found in the web-based remote interface (see Section 8.2.4).

Figure 6.1 Transmier log page for instrument A

The remote interface also provides a diagnostic page which gives full information on

the system state (concentrations, relay state, switch state, indicator state), see Section 8.2.3.

23

6.4 Troubleshoong

6.4.1 A queson mark (?) on the refractometer display

Cause: The refractometer does not receive information request packets from the Divert Control Unit. This may be caused by a faulty cable, faulty parameters, or equipment malfunction either in the refractometer or in the Divert Control Unit.

Action: If the instrument has never been functional, or if it is possible someone has

changed the instrument parameters, there may be a coniguration problem with the

IP addresses. The IP address in the refractometer should be set as givenin Section 5.4.

If possible, cross-check the addresses from the diagnostic web page.

A physicalproblem can be ruled out by looking at a small LED close to the transmitter’s

Ethernet connector. If the LED is green, the cable is ok. One way to isolate the problem

is to swap the cables between the refractometers. A standard Ethernet cable can be

used as a troubleshooting aid (either straight-through or cross-over).

6.4.2 A refractometer refuses to come on-line

Cause: Either there is no communication to the refractometer or there is a malfunction on the refractometer. It is also possible the transmitter is not conigured for Divert

use.

Page 28

24

Action: Check that there is a/A/b/B on the refractometer display. If there is a question

mark (?) instead, see above.

Check that there is a soft key DD23 on the refractometer main display (see Figure 6.2

below). If the soft key is not present in the main display, the instrument is not conigured for Divert use. If this is the case, please contact K-Patents.

In other cases, check the diagnostic message on the refractometer screen (see Section 6.2).

Figure 6.2 Transmier main display, instrument in Divert use

6.4.3 No lights come up in the Divert Control Unit

Cause: There is no power on the instrument or there is a hardware fault.

Action: Check that the instrument receives power. In normal operation several relays

have their associated LEDs lit. If there are any LEDs lit in the Divert Control Unit, the

unit receives power.

6.4.4 All lights are blinking

Cause: There is an unrecoverable hardware fault in the Divert Control Unit.

Action: Please contact K-Patents.

Page 29

7 Divert control logics

no

no no

no

yes

UNSAFE SOLIDS

SAFE SOLIDS

NO INSTRU-

MENTS!

Rule 2-of-2

2 instruments

available?

1 instrument

available?

Both ≥ 58%?

Either ≥ 58%?

CONC ≥58%?

yes

yesyes

yes

no

Rule 1-of-2?

yes

no

DIVERT

A logical description of the system is provided to complement the operational description given in the previous chapters.

7.1 Safety decision logic

The core of the Divert control system is the safety decision logic, which makes the

ultimate decision whether the black liquor can be safely fed to the burner or not.

The logic is described in the low diagram in Figure 7.1. The factors affecting the decision are the number of instruments in operation (none, one or two) and their measurement results. Also the selected divert rule is taken into account when two instruments are in operation. For a description of different rules, see Section 5.2.

As a result of this logic, the system is either in SAFE SOLIDS or UNSAFE SOLIDS state.

When the system is in the SAFE SOLIDS state, the SAFE SOLIDS light is illuminated.

25

"One instrument available" may mean that only one instrument is in operation or that

both instruments are in operation, but one of them is washing when queried.

Figure 7.1 Safe solids decision logic

Page 30

26

NO DIVERT

DIVERT

HEADER WASH

active?

Divert from

safe solids logic?

EMERGENCY

DIVERT

pressed?

DIVERT RESET

pressed?

yes

no

yes

no

yes

no

no

yes

7.2 Divert decision logic

After the system has evaluated the solid contents to be either safe or unsafe (see Section 7.1), it decides whether the the system should be in the DIVERT state. This decision is made according to the low diagram in Figure 7.2.

The defaultstate of the system is the DIVERT state. It can be changed to the NO DIVERT

state only by manually pressing the DIVERT RESET push-button when the solid content

is suficient (SAFE SOLIDS). If the solid content drops to UNSAFE, the system drops

into the DIVERT state.

The only exception to this is when the HEADER WASH is active. In that case the solid

content checking is skipped. The system may then be switched between the DIVERT

and NO DIVERT states by using the EMERGENCY DIVERT and DIVERT RESET push buttons

in the operator panel (or the equivalent external emergency divert and divert reset

buttons).

The system will drop to the DIVERT state in all cases when the EMERGENCY DIVERT

button (or its external counterpart) is pressed.

Figure 7.2 The divert decision logics

Page 31

7.3 In operaon logic

IN OPERATION

button pressed

yes

yes

yes

yes

no

no

wash done

no

no

no

Only

instrument?

Washing?

IN OPER.

pressed?

Critical

malfunction?

WAIT

(LIGHT BLINKING)

IN OPERATION

(LIGHT ON, RELAYS

10, 11 ACTIVE)

Critical

malfunction?

NOT IN OPERATION

(LIGHT OFF)

yes

Whether an instrument is in operation depends on the operator’s commands and the instrument’s diagnostics. The decision

is carried out as outlined in Figure 7.3

An instrument can be in one of

three different states: IN OPERATION, NOT IN OPERATION, and

WAIT. When the instrument is IN

OPERATION, it is used in deciding whether the solid content is

in the safe level (see Section 7.1).

When the instrument is NOT IN

OPERATION or WAIT states, it is

not used.

27

The WAIT state occurs when the

operator has requested the instrument to come into operation

by pressing the button, but the

instrument is in the wash cycle

and will come into operation after the wash cycle is completed.

The actual state can be seen from

the IN OPERATION light. If the light

is on, the instrument is IN OPERATION. If the light is off, the instrument is NOT IN OPERATION,

and if the light is blinking it is in

the WAIT state.

The default state of an instrument is to be NOT IN OPERATION. It can be taken into operation by pressing the IN OP-

ERATION button unless there is

a critical malfunction (see Section 6.2).

Figure 7.3 Operaon logic

An instrument automatically drops

into NOT IN OPERATION if there

is a critical malfunction. It may also be dropped by the IN OPERATION button unless it

is the only instrument used.

Page 32

28

Timeout from

instrument?

Malfunction in

instrument?

no

yes

yes

yes

no

no

Critical malfunc-

tion in instr.?

NO

MALFUNCTION

Remove instr.

from Divert use

MALFUNCTION

7.4 Malfuncon logic

The MALFUNCTION light is illuminated when the internal diagnostics of either of the two instruments indicates a malfunction or

there is a communication timeout

to either of the instruments (Figure 7.4).

It should be noted that not all malfunctions are critical malfunctions

which drop the instrument from

operation (see Section 7.3). For a

complete list of possible malfunctions, see Section 6.2.

The MALFUNCTION light relects the

decision taken by this logic. However, as the MALFUNCTION light is

one of the resettable alarms, it

may be blinking even when the

malfunction itself is cleared if the

ALARM RESET button has not been

pressed (see Section 7.5).

Figure 7.4 Malfuncon logic (repeated for each sensor)

Page 33

UNACKNOWLEDGED

ALARM

(Blinking, Relay 6 active)

ALARM

(Light on, Relay 6 inactive)

Alarm source active?

ALARM RESET

pressed?

Alarm source active?

yes

no

no

no

yes

yes

NO ALARM

(Light off, Relay 6 inactive)

29

7.5 Reseable alarm logic

In order to identify new alarms, there

is a resettable alarm logic in the Divert control unit. There are four possible alarm sources: SOLIDS ALARM,

SOLIDS WARNING, A&B DIFFERENCE,

and MALFUNCTION. All of these follow the same alarm reset rules (see

Figure 7.5).

When a new (unacknowledged) alarm

activates,the corresponding light starts

blinking in the operator panel, and relay 6 is activated. When the ALARM RE-

SET button is pressed, relay 6 is inacti-

vated.

The state of the alarm indicator in the

operator panel depends on whether

the cause for the alarm is still present.

If the cause has cleared (e.g. solids

content has risen above the warning limit), the light goes off when

the ALARM RESET is pressed. If the

cause has not cleared, the light will be

steadily illuminated.

A non-illuminated light means there

is no alarm. A steadily illuminated

alarm light means there is a problem

which persists but the problem has

been acknowledged by pressing the

ALARM RESET. A blinking light means

the problem has not been acknowledged, but gives no information whether

the problem is still there or not.

Figure 7.5 The reseable alarm logic

Page 34

30

no REFRACTO-

METER

DIFFERENCE

|A-B| > 2%?

2 instruments

available?

yes

no

no

yes

REFRACTO-

METER

DIFFERENCE

7.6 Refractometer difference logic

If there are two refractometers in operation (taken into operation, not washing), the

Control unit monitors the difference in reading between the two instruments (igure 7.6). If the difference is more than 2%, a refractometer difference warning is given

with the corresponding front panel indicator and relay.

The divert decision logic (section 7.2) is not affected by the refractometer difference,

but a signiicant difference between the two instruments indicates one of the instruments is not measuring reliably. In this case the instruments and wash systems have

to be checked immediately. Ignoring to do this may result in an erroneous divert decision.

Figure 7.6 Refractometer difference logic

Page 35

7.7 Wash arbitraon logic

no

WAIT

WASH

IDLE

The other

instrument

washing?

yes

wash interval

elapsed

wash done

the other instrument

done washing

The Divert Control Unit takes care that if there are two instruments in operation, they

won’twash at the same time (as that would trip the system). This is done by the simple

logic described in Figure 7.7

Each instrument control their own wash cycle. Before the start washing, they request

a wash permission from the Divert Control Unit. If the other instrument is already

washing, the unit does not grant this permission until the wash cycle is completed.

31

Figure 7.7 Wash arbitraon logic

Page 36

32

Wash check?

Wash tolerance

time > 0?

no

yes

yes

off

yes

on

no

Prism wash

succesful?

Drop from

Divert use

Malfunction

Succesful wash

within tolerance

time?

Prism wash failure

Prism wash

warning

no

Normal operation

One wash cycle

7.8 Wash check logic

By default the wash tolerance time is 0.

Figure 7.8 Wash check logic

Page 37

8 Remote control interface

The remote interface is based on a web server inside the Divert Control Unit. It consists of several web pages, easily accessible through the links on the navigation bar in

the left (see Figure 8.1).

The remote interface is optimized for the Firefox browser, version 2.0 or newer, although it may work with other browsers. Firefox is free and exists for Windows, Mac

OS X and Linux, it can be downloaded through http://www.mozilla.com/.

8.1 Divert Control Unit IP address

The Divert Control Unit can be reached through two different IP addresses. In

non-networked applications (only a DD-23 and a single computer) the IP address is

169.254.23.23. This IP address is factory set and cannot be changed. If the Divert Control Unit is to be connected to a network, the network settings can be changed through

the parameter page of the remote interface (see Section 8.2.5).

8.2 The remote interface

33

8.2.1 Main page

The remote indicator main page gives a quick overview over system status.

Figure 8.1 DD-23 Remote control, main page

Page 38

34

8.2.2 Instrument pages

The pages for instrument A and instrument B are normal transmitter homepages. See

the PR-23 instruction manual, Chapter 12, for more information.

By default, the instrument pages open in a new tab in your browser; the DD-23 page

you started from will stay open in the original tab.

8.2.3 Diagnoscs page

The diagnostics page gives a full account on instrument settings and the instrument’s

status at the moment, including information about relays, switches, pushbuttons, etc.

Figure 8.2 Remote diagnoscs page

Page 39

8.2.4 Log page

The log page gives a more extensive, printable log of events.

Figure 8.3 Remote log page

35

Page 40

36

8.2.5 Parameters page

The Divert Control Unit parameters can only be changed through the parameter page.

However, note that the calibration lock (see Section 5.1) has to be open (off) before

parameters can be changed. If calibration lock is on, parameter changes are not possible. The calibration lock status is given on top of the parameter page and if the lock

is on, i.e. changes are not permitted, the Submit button is missing.

Figure 8.4 Parameter page

8.3 Data logging

K-Patents provides free of chargea data logging software called K-Patents Toolkit (or

PR-11111). Divert logging functionality was introduced in Toolkit version 2.20. If you

have an earlier version of the Toolkit, please contact your K-Patents representative for

a version that is compatible with DD-23.

Page 41

9 DD-23 specificaons

9.1 Divert Control Unit specificaons

Model: DD-23

Enclosure: IP66 Nema 4X, dimensions 226 x 267 mm (8.91 x 10.5 in)

Supply: 86–240 V AC, 20 VA, 50-60 Hz

Ambient temperature: max 45C(113F)

Accessory: Roofed stainless steel mounting plate for the Divert Control

Unit and 2 Indicating transmitters, Figure 9.1

Material: AISI 316, dimensions 916 x 488 mm x 250 mm

(36 x 19.2 x 10 in)

Relays 1-11: 3A, 250V NO/NC

37

Figure 9.1 Divert Control Unit mounng plate: Dimensions (mm/in)

Figure 9.2 Divert control unit and Indicang transmier closures: Dimensions (mm/in)

Page 42

38

7

1

4

2

3

5

6

9

8

9.2 Divert control unit spare parts

Figure 9.3 Divert Control Unit spare parts

No. Part name Spare part no.

1 DD-23 front panel PR-12100

2 Nikkai LB-15WK switch PR-12101

3 Nikkai SK-12AA key switch PR-12102

4 PR-12020 card PR-12020

5 Moxa switch EDS-205 PR-12103

6 Connector card PR-12010 PR-12010

7 Moxa US-7110-LX processor PR-12104

8 WRA24SX-U power supply PR-10810

9 Enclosure PR-7602

DD-23 motherboard–keyboard cable PR-12105

DD-23 motherboard–Moxa cable PR-12106

Page 43

10 Oponal Remote Divert Terminal DD-23-RT

The Remote Divert Terminal DD-23-RT is an optional extension to the normal DD-23

remote (web) interface. The system consists of a terminal with a touch screen for

navigating the remote interface menus and under the display buttons for the Divert

and Divert Reset operations.

10.1 Mounng instrucons

The DD-23-RT panel is compatible with VESA 100 wall mounts and swivel arms. It

can also be mounted in a rack or a table stand. An optional table stand is available

from K-Patents.

39

Figure 10.1 DD-23-RT display dimensions

Figure 10.2 DD-23-RT with K-Patents Table stand.

Page 44

40

Figure 10.3 Connecng DD-23-RT

Page 45

41

Figure 10.4 Wiring DD-23-RT

Page 46

42

Panel front

Power

0

1

10.2 Startup and use

Connect wires and cables according to Figure 10.4. In the Divert Control Unit the Remote Panel is connected to the Ethernet output, see Figure 3.6 on page 12. The Indicating transmitters (STRs) and the Divert Control Unit can stay powered on all the

time. The remote panel can also be connected to a factory network.

Switch on remote panel power. The power switch is located at the bottom of the

PR-23-RT panel.

Figure 10.5 Locang the power buon

The remote panel is a touch screen, tap the screen to operate. For remote interface

use, please see Chapter 8, “Remote control interface”.

10.3 Troubleshoong

Contact your nearest K-Patents representative, see http://www.kpatents.com/contacts.php,

or contact K-Patents, Inc, US phone (630) 955 1545, or the K-Patents headquarters,

phone +358 207 291 570.

Page 47

A Index

43

A

A IN OPERATION 4

ALARM RESET 4

A&B DIFFERENCE 5

alarm

see horn relay

logic 29

refractometer malfuncon 19

reset 4

signal difference 18

solids alarm 19

solids warning 19

B

B IN OPERATION 4

BLRBAC 3, 6, 16–19

buon

ALARM RESET 4–5, 14

DIVERT RESET 4, 14

EMERGENCY DIVERT 4, 6

external emergency divert 6

LIGHT TEST 4–5

C

calibraon lock 15, 36

coang

see prism coang

D

DD-23-RT 39

DIVERT 5

DIVERT RESET 4

Divert Control System 1

mounng 7

overview 3

parts 1

Divert Control Unit 3

IP address 33

mounng 37

spare parts 39

specificaons 39

wiring 9

diagnosc

message 21

tools 23

web page 34

disposal 1

divert decision logic 26

divert reset

external 10

divert rule

decision 16

switch 15

E

EMERGENCY DIVERT 4, 26

ethernet connecon 12

event log 23

saving 36

web page 35

external

divert reset buon 10

emergency divert buon 6, 10

H

HEADER WASH 4

header wash key 4, 6

mounng 10

horn relay 8

I

Indicang transmier 6

IP address 18

wiring 8

IP address

Divert Control Unit 33

Indicang transmier 18

indicator light 4

input

see switch input

instrument web page 34

J

J9, J10, J11

see switch input

K

key

see header wash key

L

LIGHT TEST 4

light

A IN OPERATION 4

A&B DIFFERENCE 5

B IN OPERATION 4

blinking DIVERT 14

blinking SOLIDS ALARM 14

blinking, all 24

DIVERT 5

green 5

MALFUNCTION 5

OVERRIDE 5

red 5

Page 48

44

SAFE SOLIDS 5

SOLIDS WARNING 5

yellow 5

logic

alarms 29

divert decision 26

in divert operaon 27

malfuncon 28

prism wash 31

refractometer difference 30

safe solids 25

safety decision 16, 25

M

MALFUNCTION 5

malfuncon 21

light 5

logic 28

message

NO SAMPLE 14

NORMAL OPERATION 14

messages 22

mounng

Divert Control System 7

Divert Control Unit 37

external Divert reset buon 10

external emergency divert 10

header wash key 10

prism wash 7

N

NO SAMPLE 14

NORMAL OPERATION 14

network sengs 33

O

OVERRIDE 5

one-of-two 16

operator panel 4

P

panel

see operator panel

parameters

Divert Control System 36

prism wash 19

web page 36

prism coang 20

prism wash 6, 19

arbitraon logic 31

mounng 7

steam pressure 20

mes 20

push buon 4

Q

queson mark 23

R

Remote Divert Terminal DD-23-RT 39

refractometer

bias 17

difference logic 30

malfuncon alarm 19

relay

wiring 10

remote

diagnoscs page 34

ethernet connecon 12

instrument page 34

interface 33

log page 35

parameters page 36

terminal DD-23-RT 39

reset

alarm 4

divert 4

ring header wash

see header wash key

rule

1-of-2 16

2-of-2 16

S

SAFE SOLIDS 5

SOLIDS ALARM 5

SOLIDS WARNING 5

safety decision logic 16, 25

sengs

network 33

signal difference alarm 18

solids alarm 19

solids warning 19

spare parts

Divert Control Unit 39

startup

Divert control unit 14

refractometer 14

steam trap 7

steam wash

see prism wash

switch

divert decision rule 16

1-of-2 16

2-of-2 16

switch input 6, 10

T

tesng

Page 49

45

Divert Control Unit 21

lights 21

transmier

see Indicang transmier

two-of-two 16

W

warning

see solids warning

warranty 1

wash

see prism wash

web pages 33

web server 33

wiring

Divert control unit 9

Indicang transmier 8

relay 10

Page 50

PROCESS INSTRUMENTS

K-Patents Oy

P.O. Box 77

fi-01511 Vantaa, Finland

tel. +358 207 291 570

fax +358 207 291 577

info@kpatents.com

K-Patents, Inc.

1804 Centre Point Circle, Suite 106

Naperville, IL 60653, USA

tel. (630) 955 1545

fax (630) 955 1585

info@kpatents-usa.com

K-Patents (Shanghai) Co., Ltd

17-05H, 17F, Times Square, No.500

Zhang Yang Road

Pudong District, Shanghai, China

tel. +86 21 5178 2775/5178 2787

fax +86 21 5178 2799

www.kpatents.com

Loading...

Loading...