Page 1

WARNING

INSTRUCTION MANUAL

FOR DD-01

DIGITAL DIVERT CONTROL SYSTEM VERSION 4.1.

WITH MAIN PROGRAM 8.5 OR HIGHER

The process medium may be hot or otherwise hazardous. Precautions when removing the sensor from

the process line:

Make sure that the process line is not under pressure. Open a vent valve to the atmosphere. For a retractor/isolation valve the line pressure should be within specifications.

For a prism wash system, close a hand valve for the wash medium and disable the wash valve. Loosen the clamp or flange bolts cautiously, be prepared to tighten again. Be out of the way of any possible splash and ensure the possibility of escape.

Use shields and protective clothing adequate for the process medium. Do not rely on avoidance of contact with the process medium.

After removal of the sensor, it may be necessary to mount a blind flange for security reasons.

Document/Revision No. IMD 1/5 Effective: June 20, 2005

This product manual is delivered to the end-user with a K-Patents product. Information in this manual is

subject to change without notice. The latest manual version is freely available at http//www.kpatents.com/.

You can also contact manuals@kpatents.com.

THE PASSWORD FOR PR-01-S IS 7 8 4 5 1 2 IN PROGRAM VERSIONS 4.0 AND HIGHER.

K-PATENTS OY

Postal address:

P.O. Box 77

FIN-01511 Vantaa, Finland

Tel. + 358-9-825 6640

Fax +358-9-825 66461

E-mail: info@kpatents.com

http://www.kpatents.com/

K-PATENTS OY

Street address:

Elannontie 5

FIN-01510 Vantaa, Finland

Tel. + 358-9-825 6640

Fax +358-9-825 66461

K-PATENTS,INC.

1804 Centre Point Circle,

Suite 106,

Naperville, IL 60563

Tel. 630-955 1545

Fax 630-955 1585

E-mail: info@kpatents.com

http://www.kpatents.com/

Page 2

1

1. TABLE OF CONTENTS

1 TABLE OF CONTENTS........................................................................................................................1

2 GENERAL INFORMATION .................................................................................................................2

2.1 Digital divert control system DD-01 .................................................................................................2

2.2 Operator panel...................................................................................................................................3

2.3 Alarms...............................................................................................................................................4

2.4 Prism wash ........................................................................................................................................4

2.5 Master divert control unit..................................................................................................................5

2.6 Indicating transmitters.......................................................................................................................6

2.7 K-Patents digital divert control unit specifications............................................................................7

3 MOUNTING...........................................................................................................................................8

3.1 Wiring ...............................................................................................................................................8

4 START-UP ...........................................................................................................................................12

4.1 Divert control unit start-up ..............................................................................................................12

4.2 Divert control system trimming.......................................................................................................12

5 CALIBRATION....................................................................................................................................13

5.1 Refractometer concentration measurement .....................................................................................13

5.2 Refractometer activation for divert control .....................................................................................13

5.3 Signal difference alarm ...................................................................................................................14

5.4 Low alarms......................................................................................................................................14

5.5 Refractometer malfunction alarm....................................................................................................14

5.6 Prism wash ......................................................................................................................................14

5.7 Divert decision rules........................................................................................................................15

6 MAINTENANCE .................................................................................................................................17

6.1 Information flow..............................................................................................................................17

6.2 Divert control circuit boards ...........................................................................................................18

6.3 Diagnostic messages........................................................................................................................23

6.4 Diagnostic lights..............................................................................................................................23

6.5 Push-button assembly......................................................................................................................24

6.6 Fuses................................................................................................................................................24

7 DIVERT CONTROL LOGIC...............................................................................................................25

7.1 Block diagram.................................................................................................................................25

7.2 Logical diagrams.............................................................................................................................26

7.3 Safety Decision Logics....................................................................................................................28

8 OPTIONAL CONFIGURATIONS.......................................................................................................30

8.1 Remote divert control unit...............................................................................................................30

8.2 Equipment .......................................................................................................................................30

8.3 Remote divert control unit in the control room ...............................................................................31

8.4 Wiring and mounting.......................................................................................................................32

8.5 Serial output ....................................................................................................................................34

8.6 Current output signal.......................................................................................................................34

8.7 External DC power supply ..............................................................................................................34

9 DIVERT CONTROL UNIT PARTS LISTS.........................................................................................35

9.1 Divert control unit and optional remote divert control unit.............................................................35

9.2 Remote divert control unit...............................................................................................................36

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 3

2

2. GENERAL INFORMATION

The K-Patents Digital Black Liquor Divert Control System DD-01 provides a divert signal preventing black

liquor with dangerously low solids to reach the black liquor burners. The system is built strictly according to

the principles of Recommended Good Practice "Safe Firing of Black Liquor in Black Liquor Recovery Boilers" (BLRBAC August, 1982 and revisions April, 1991, and March, 2001).

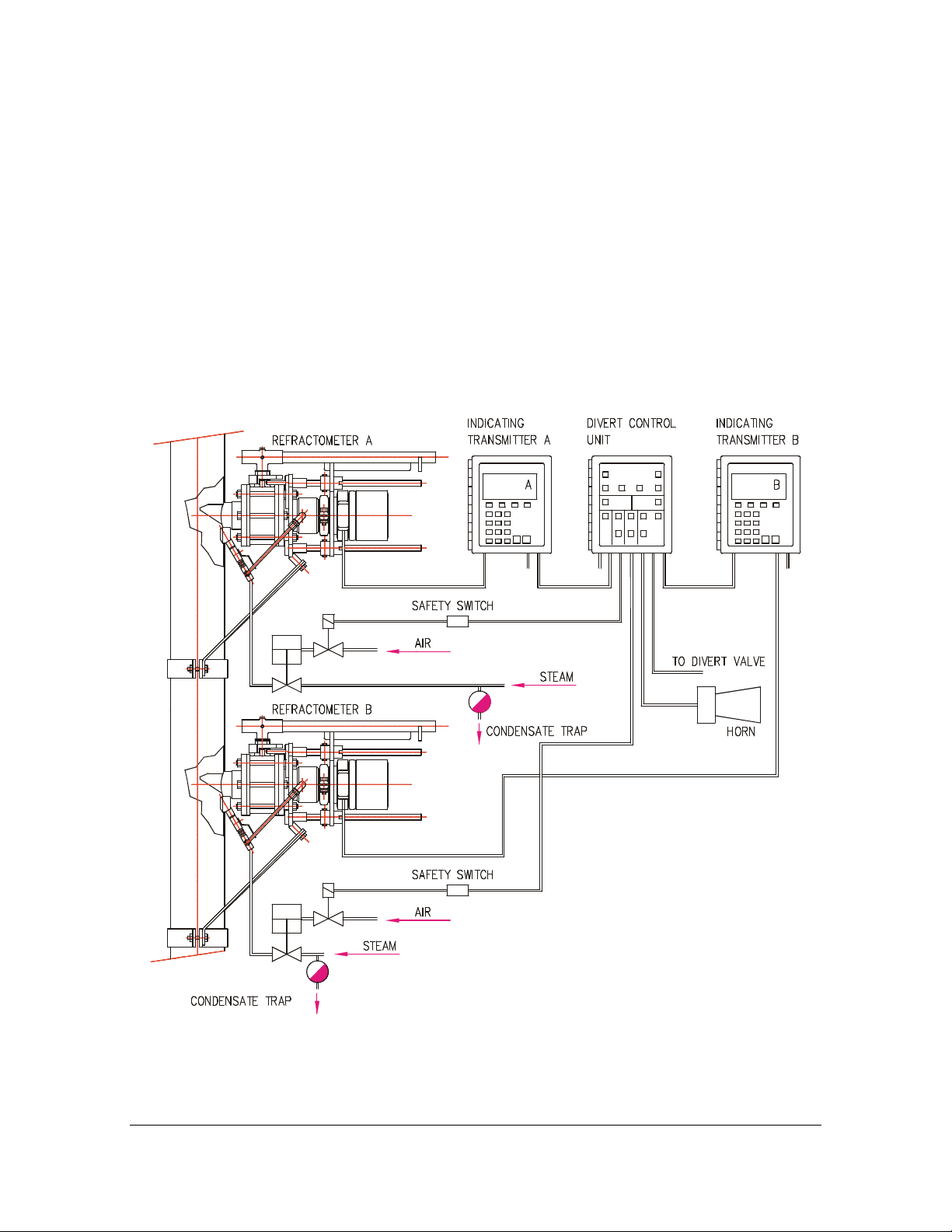

2.1. DIGITAL DIVERT CONTROL SYSTEM DD-01

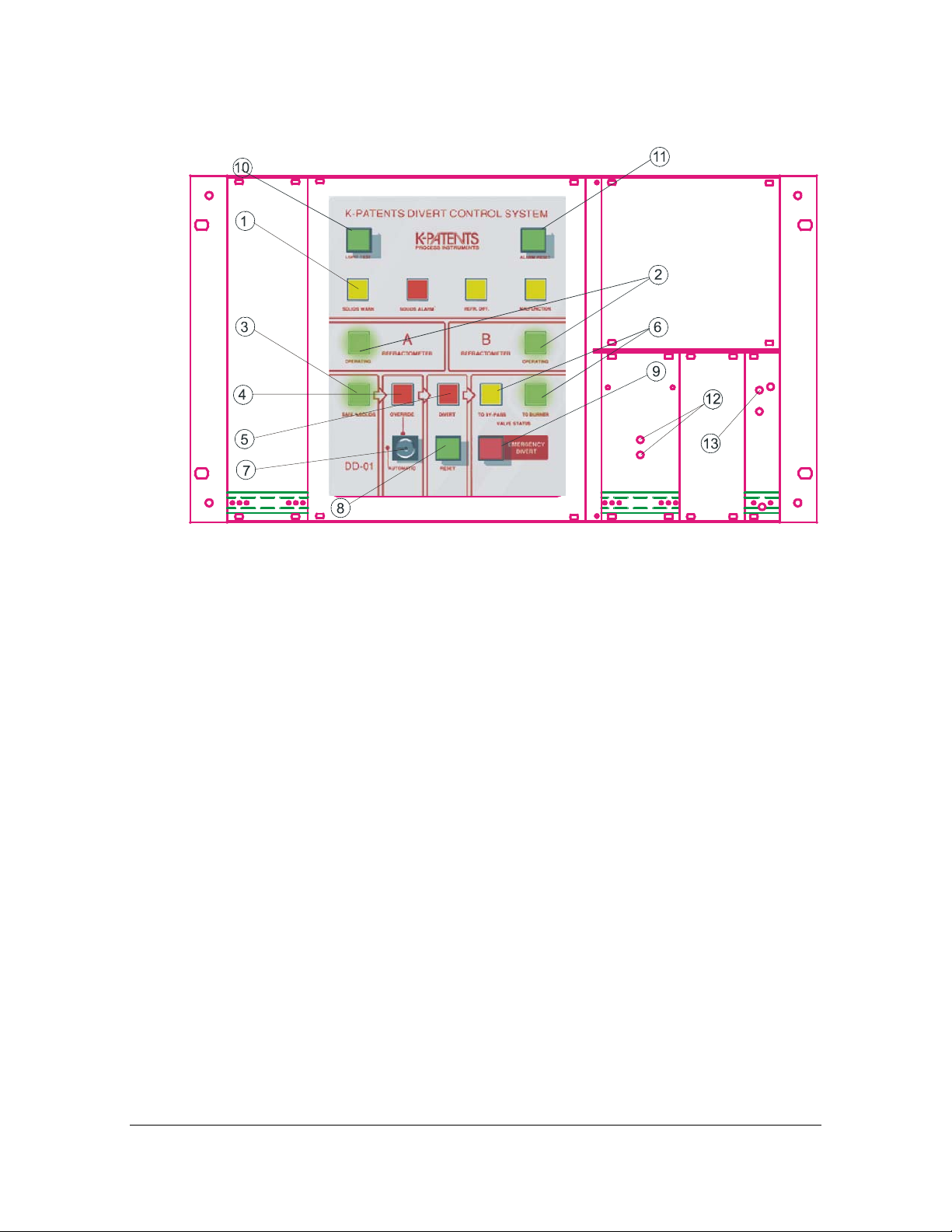

Figure 2.10 Complete Digital Divert Control System DD-01

The system consists of the following parts (Figure 2.10): Two K-Patents Process Refractometers PR-01-S (A

& B) are installed in series in the main black liquor line. Each refractometer is complete with a Sensor, an

Indicating transmitter and Interconnecting cables. Each refractometer provides also a 4-20 mA % solids output

signal not used by the divert control system.

The Divert Control Unit DD-01 is contained in one enclosure with the same dimensions as the refractometer

Indicating transmitter enclosure. The control unit includes:

- an operator panel

- control logics

- contact outputs for prism wash, warnings, alarms and black liquor diversion

- Two isolation valves HIMP-2 (optional) for the refractometers above to allow removal of

the refractometers from a pipe with full flow and pressure. The isolation valve includes a

prism wash nozzle and two check valves (one for prism wash, one for stuffing box flush).

- A roofed mounting plate to mount the two Indicating transmitters and the Divert Control

Unit together.

- Two steam valves with steam traps for prism wash (pneumatic + solenoid valves).

- Two hand valves (one for prism wash, one for stuffing box flush).

- One alarm horn (supplied by the customer).

Note. BLRBAC (The Black Liquor Recovery Boiler Advisory Committee) recommends a spare sensor to be

maintained in stock on-site.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 4

3

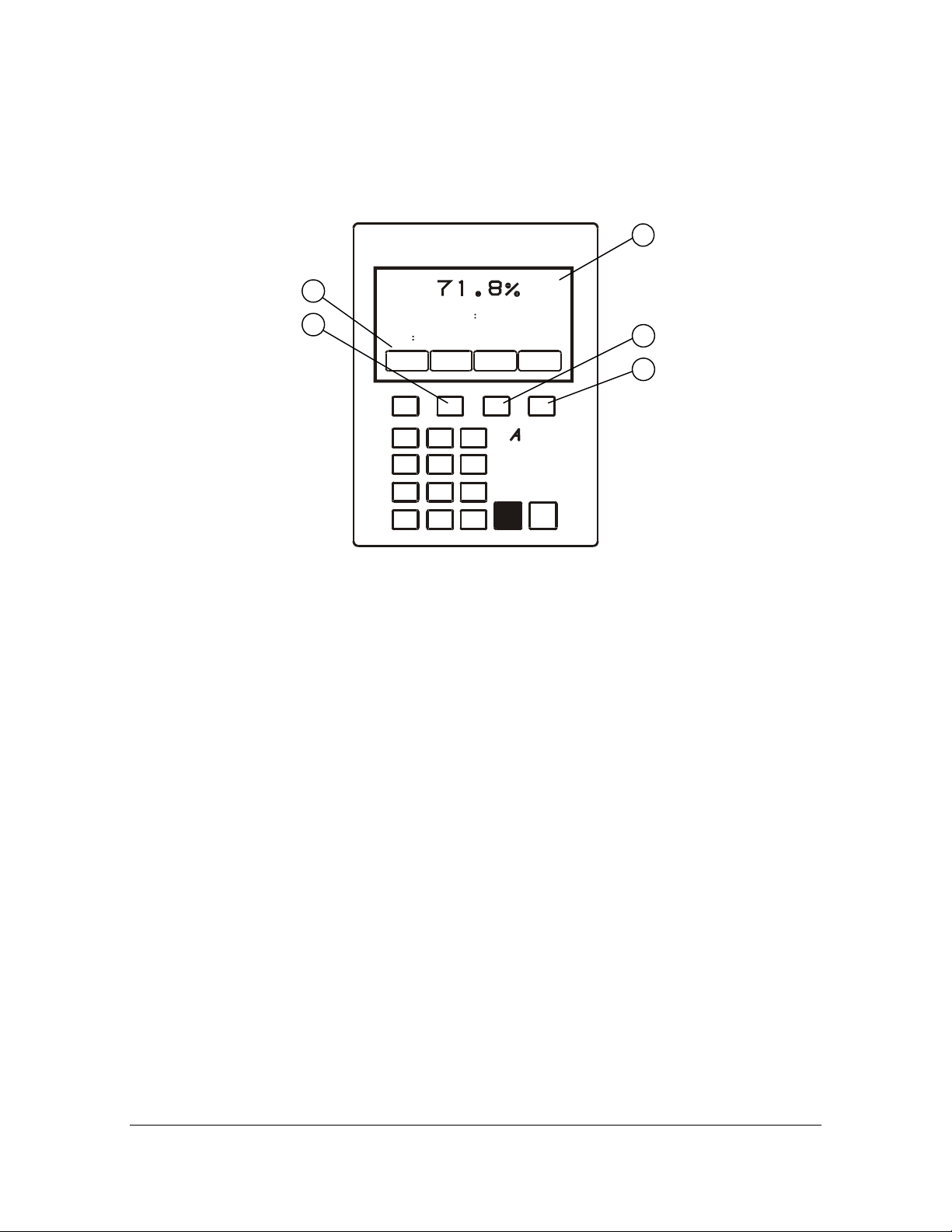

2.2. OPERATOR PANEL

3

4

5

7

6

Figure 2.20 The operator panel.

The operator panel has a clear layout and the operator can see all information at one glance. The divert decision is controlled from the operator panel which provides doubled security, since all information is simultaneously shown both as LED indication in the Divert Control Unit and as a diagnostic messages in the Indicating

Transmitters (Figure 2.20).

Each refractometer has a green OPERATING light (1), so the operator knows when he can rely on the refractometer measurement. A refractometer will influence the divert decision only when the green OPERATING

light is on. A malfunctioning refractometer is automatically taken out of operation. One green indicator light

SAFE% SOLIDS (2) is based on the two refractometers and the divert decision rules (Section 5.7).

One red DIVERT light (3) that will be switched on when the SAFE% SOLIDS goes off. The DIVERT light

indicates divert status of the divert relay. The divert relay has an output switch contact, for use in the Black

Liquor Firing Tripping Logic. The relay is OFF in the DIVERT position, because a power failure will give a

DIVERT decision.

A lockable OVERRIDE/AUTOMATIC switch (5) and a red OVERRIDE warning light (4) is ON always if

switch in OVERRIDE position. If the SAFE% SOLIDS goes OFF and this switch is in the OVERRIDE position, then the OVERRIDE light is lit instead of the DIVERT light. One RESET push-button (6) for the

DIVERT action. The DIVERT action always has to be manually reset. If the override switch is in Automatic

position and SAFE% SOLIDS is off, the DIVERT action cannot be reset.

One EMERGENCY DIVERT push-button (7) to manually initiate DIVERT in an OVERRIDE or emergency

situation. The DIVERT light is lit also after manual divert action. The EMERGENCY DIVERT button has a

protective hinged cover, to prevent inadvertent use.

Two indicator lights (8) for the divert valve status TO BY-PASS/TO BURNER from microswitches on the

valve. For intermediate valve positions both lights are off.

A row of four alarm lights (9) that indicate black liquor SOLIDS WARNING (at 60%), black liquor SOLIDS

ALARM (below 58%), refractometer reading more than 2% absolute difference and refractometer malfunction.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 5

4

A light test button (10) switches all 11 lights on. An alarm reset button (11) resets the alarm lights. For normal

operation the operator panel has four green lights on (A OPERATING/B OPERATING/ VALVE TO

BURNER/SAFE% SOLIDS).

2.3. ALARMS

The divert control system has four alarms, audible and indicating:

1. Black liquor SOLIDS WARNING, yellow light (60% or below)

2. Black liquor SOLIDS ALARM, red light (58% or below)

3. Refractometers reading more than 2% absolute DIFFERENCE, yellow light

4. Refractometer MALFUNCTION, yellow light

The alarms 1, 2 and 4 are initiated by either refractometer. System contains also optional alarms, see wiring

drawing 3.11.

The operator panel contains four indicator lights and an ALARM RESET button. The reset button will silence

the audible alarm, but the visual indication will remain until the condition has returned to normal.

To avoid unnecessary alarms the following interlocks are implemented:

- A refractometer can initiate an alarm only when it is operating.

- Alarm 4 can be initiated only if both refractometers are operating.

The parameters (2%, 58% and 60%) are default settings, which can be changed from the Indicating transmitter

keyboard (Sections 5.3 and 5.4). The parameter for 2% can be decreased and the parameter for 58% and 60%

can be increased.

2.4. PRISM WASH

For K-Patents Process Refractometer, the need of prism wash is reduced and even in some cases eliminated.

The prism keeps clean due to the probe design features:

- The prism is flush mounted in a surface deflecting the black liquor main flow, which causes

a strong mechanical cleaning action.

- The prism has the same temperature as the black liquor.

In any case, however, an automatic regular prism wash provides an efficient check that the refractometer reacts. A steam wash of 3 seconds every half hour should be sufficient. Automatic single (one-of-two) diversion

will occur if either of the refractometers is in wash cycle.

The Divert Control Unit contains two relays for prism wash, WASH A and WASH B. To follow the BLRBAC

recommendation not to wash both prisms at the same time, there is an interlock. If both refractometers try to

wash simultaneously, one will display "WAIT" and perform the wash when the other has finished.

K-Patents recommends to use a steam trap instead of preconditioning valve to remove condensate from the

steam line. The wash times can be seen pressing soft keys "Display"/"System configuration"/"Wash times". To

change the wash times, see Section 5.6.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 6

5

2.5. MASTER DIVERT CONTROL UNIT

Figure 2.50 Operator’s panel and functions of the master divert control unit in the field with LED

indications.

1. Black liquor SOLIDS WARNING (at

60%), Black liquor SOLIDS ALARM (below 58%), Refractometer reading more than

2% absolute difference, and Refractometer

malfunction).

2. Each refractometer A and B has an

OPERATING green light, A refractometer

will influence the divert decision only when

the green OPERATING light is on. A malfunctioning refractometer is automatically

taken out of operation.

3. One green indicator light SAFE%

SOLIDS, based on the two refractometers

and the divert decision rules.

4. A red OVERRIDE warning light is on

always if the override switch is switched on.

5. One red DIVERT light that will be

switched on when the SAFE% SOLIDS

goes off. The DIVERT light indicates divert

status of the divert relay.

6. Two indicator lights for the divert valve

status. TO BY-PASS/TO BURNER from

microswitches on the valve. For intermediate valve positions both lights are off.

7. A lockable Override/Automatic divert

switch

8. A DIVERT RESET push-button.

9. An EMERGENCY DIVERT push-button.

10. A light test button switches all 11 lights

on.

11. An alarm reset button resets the alarm

lights.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 7

6

2.6. INDICATING TRANSMITTERS

An Indicating transmitter in a Divert Control System is identical (both hardware and software) to a standard

transmitter described in the PR-01-S Instruction manual.

1

3

2

CONC

PROCESS TEMPERATURE

TEST

109.3

In divert co ntrol operation

Removed

Start

fro m d iv

prism

wash

A

7

4

1

0

C a lib ra te

control

B

8

9

56

2

3

.

-

22.1

A

°C

Display

D

C

K-PTENTS

PROCESS INSTRUMENTS

RESET

ENTER

5

4

Figure 2.60 The Indicating transmitter.

The display, Figure 2.60, will give the following additional information pertinent to the Divert system:

1. A or B in the upper right corner indicates that the

transmitter is OPERATING in the divert system as refractometer A or B, Figure 2.10. If a or b is displayed

instead, the refractometer is removed from divert control operation. (If the upper right corner is empty, see

Section 5.2). For A or B the corresponding green

OPERATING light, Figure 2.20, is on, for a or b it is

off.

If you see a ? in this corner, see Section 5.2.

2. A softkey (B) defined by "Remove from divert control"

or alternatively "Restore to divert control". The visible

effects of pressing "Remove" for refractometer A is

that the soft key changes to "Restore", A switches to a,

and the green OPERATING light goes off. Further the

"Remove" soft key disappears from refractometer B,

because B must not be removed if it is the only refractometer in operation.

Note. Always press "Remove" for a refractometer before making service or switching the power off.

3. The "Normal operation" message is substituted by

"In divert control operation" or "Removed from divert control". Those messages may change to "Solids warning" or "Solids alarm" at low solids. An additional error message may occur: ** Divert control

fault ** combined with a ? in the upper right corner,

see Section 6.3.

4. The softkey "Display" (D) leads via "System configuration" (C) to "Divert control system" (D) which

gives the following information:

Refractometer difference alarm limit in % solids

Solids warning limit in % solids (default

value 60%)

solids alarm limit in % solids (default value 58%)

Divert rule and SW1/SW2 positions (Section 5.7)

5. The softkey "Calibrate" (C) gives possibilities to set

up for divert control and calibration, see Chapter 5.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 8

7

2.7. K-PATENTS DIGITAL DIVERT CONTROL UNIT SPECIFICATIONS

Model: DD-01

Enclosure: IP66 Nema 4X, dimensions 226 x 267 mm (8.91 x 10.5 in)

Supply: 24 V DC, provided by the Indicating transmitters

Ambient temperature: max 45 °C (113 °F)

Accessory: Roofed mounting plate for the Divert Control Unit and 2 Indicating

transmitters, Figure 2.60.

Material: AISI 316, dimensions 916 x 488 mm (36 x 19.2 in)

Figure 2.70 Divert Control Unit Mounting Plate: Dimensions (mm/in)

Figure 2.71 Divert Control Unit and Indicating Transmitter Enclosures: Dimensions (mm/in)

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 9

8

3. MOUNTING

For mounting of the process refractometer and the isolation valve, consult the separate Refractometer

PR-01-S(-EX/FM) Manual.

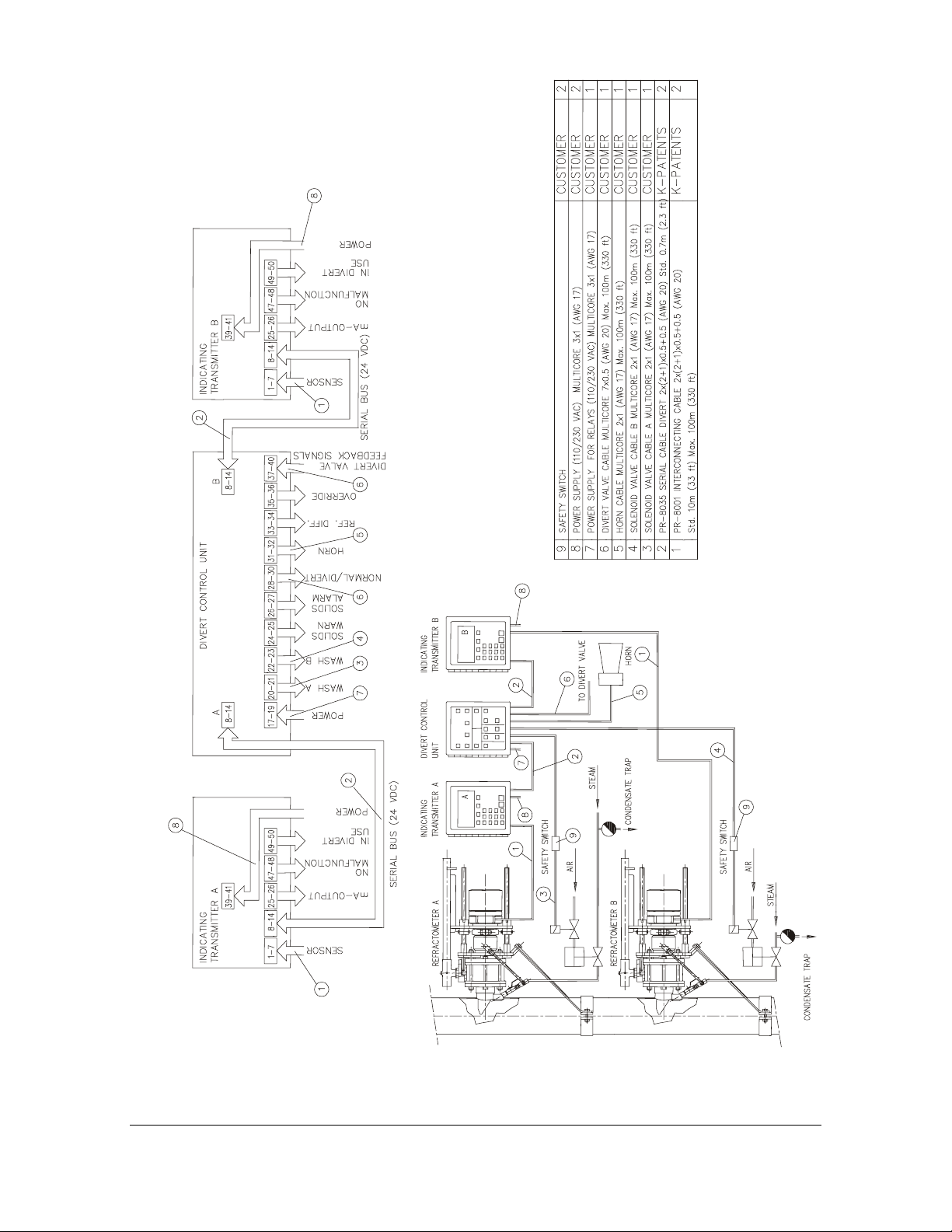

3.1. WIRING

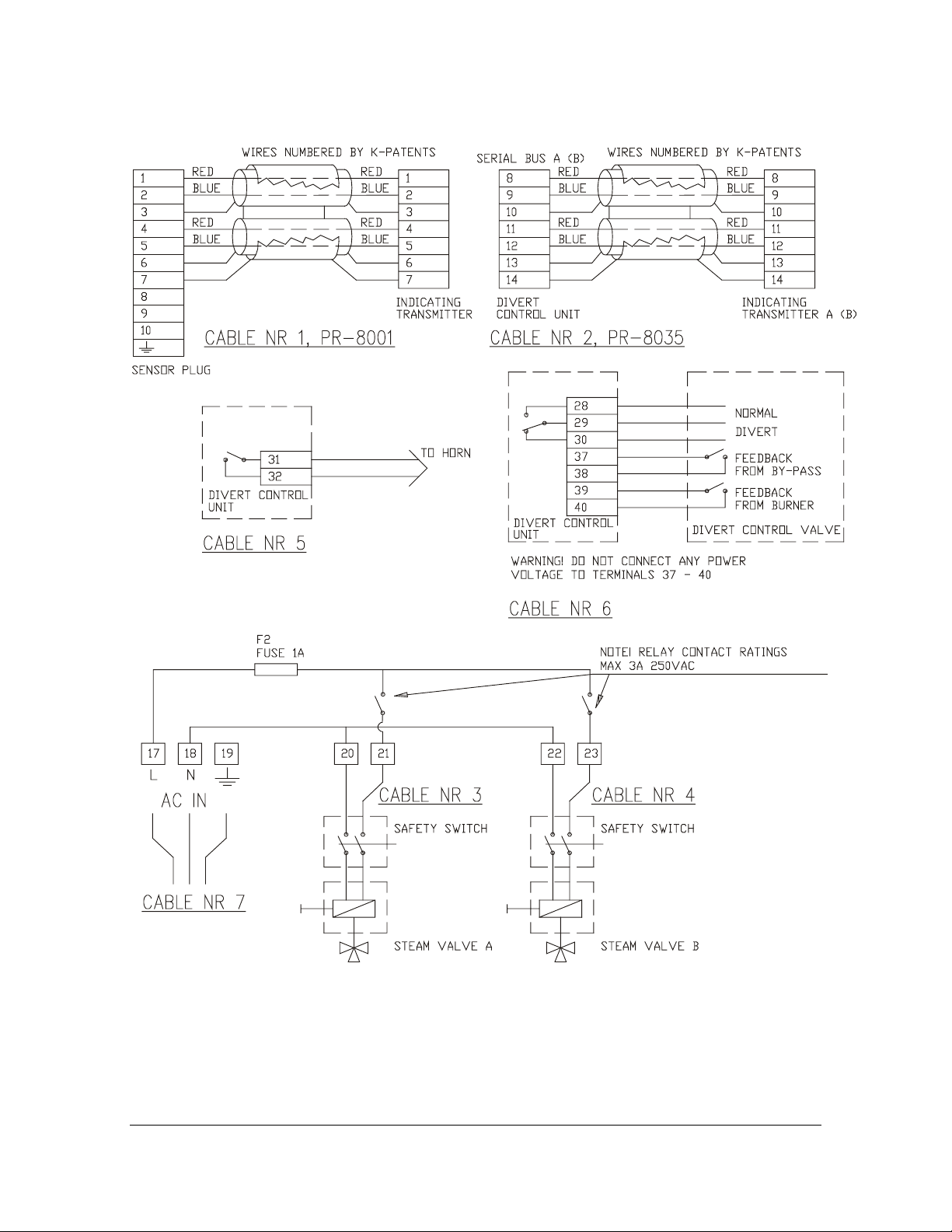

Wiring for the complete system, see Figure 3.10 and Figure 3.11 which describe also all cables and how each

cable is connected.

The cables 1 and 2 are included in the delivery. The terminal strip positions of the Divert Control Unit are

specified in Figure 3.11 and Figure 3.12.

Figure 3.10 Divert Control System Wiring Cables and Connections

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 10

9

Figure 3.11 Divert Control System Wiring and Connections

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 11

10

Figure 3.12 Cable connections

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 12

11

RN1

C43

C1

R2

C2

R3

C3

R4

C4

R5

C5

R6

C6

J1

L1

R1

R14

C18

C19C20

C46

K4

C44

C47

IC30

K-PATENTS PR-7310 Rev.C

F2

C8

IC2

IC1

R15

D2

1A

C7

C45

V1

D1

C48

C49

C9

C10

C23

1

IC11 IC10

IC12

RN4

IC13

RN5

C21

IC14

F1

1A

RE1 RE8RE7RE6RE5RE4RE3RE2

V2

IC15

D15

IC16

D16

V3

IC3

C11

IC5IC4

C24

C22

R16

V4

K7K6K5 K14

DIVERT CONTROL UNIT

RN2

C12

IC6

C13

IC7

C14

X1

R7

C25

C26

D10 D12

K1 K2

C27

IC17

D5

IC8

IC18

D7

C28

C29

R8

C30

IC19

D6

SW

D8

X2

87654321

IC22

SW1

C16 C15

C31 C33

IC23

R10

R9

C17

IC9

IC20IC21

RN7

C37

D13D11

14 1413 1312 1211 1110 109988

D17

D18

D26D25D24D23D22D21D20D19

R24R23R22R21R20R19R18R17

V6

V5 V9

K8 K13

V7

V8

K11K10

K12K9

TP1

+5V

D3

RN3

D4

IC24

J2

RN6

C32

IC27

D14

C35

D9

C52

C39

C34

IC26

C38

K3

1615

EXT24VSERIAL BUS BSERIAL BUS A

D27 D28

C50

R25

R26

D29

D30

D31

63mA 63mA

F3 F4

R28

TP4

D32

TP3

TP2

C36

C40

C41

R12

R13

C42

C51

GND

IC25

R11

SGND

IC28

IC29

R27

SWGND

VALVE

37 403938363534333231302928

BURNERBYPASS

L

N

AC-POWER

27191817 26252423222120

WARN.

SOLIDS

ALARM

NORM.

DIVERT

A

B

SOLIDS

HORNWASH WASH

REF.DIFF.

OVERRIDE

POSITION

DANGER HIGH VOLTAGE

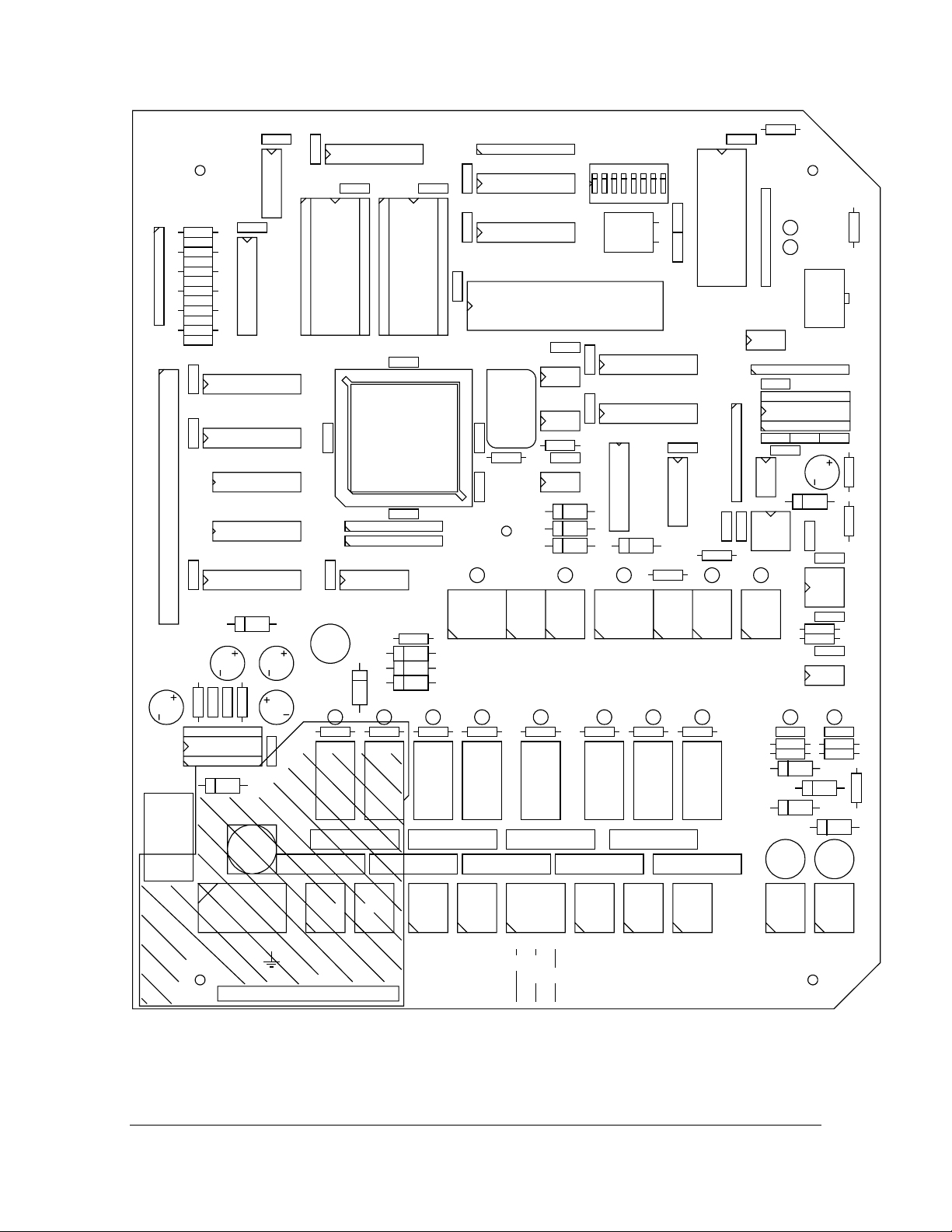

Figure 3.13 Divert control circuit board, layout.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 13

12

4. START-UP

For refractometer start-up consult the separate Refractometer PR-01-S(-EX/FM) Manual and the Mounting

and start-up check list.

4.1. DIVERT CONTROL UNIT START-UP

1. Check the wiring and supply voltage.

Note: Before the power is switched on, the DIVERT output relay is in DIVERT position.

2. Switch the power on for both Indicating transmitters.

The control system is now in the DIVERT mode, and the red DIVERT light is on.

3. Press the LIGHT TEST button. All eleven lights should switch on.

4. The upper right corner of the Indicating transmitter displays should now state a or b respectively. If

not, see Section 5.2.

If the message is "Removed from divert control" the refractometer is ready to "Restore to

divert control", softkey B.

If the message is "Solids warning" or "Solids alarm" then "Restore" provokes an alarm.

Press the ALARM RESET button.

For any other message, see Section 6.3.

5. Observe that the VALVE STATUS lights follow the position of the valve.

Now the Divert Control System is set for normal monitoring operation.

6. Check that the prism wash is working. Press the "Start prism wash", softkey A.

7. When the SAFE % SOLIDS has turned on and also the other conditions for safe boiler operation are

satisfied, the DIVERT can be turned off using the RESET button.

4.2. DIVERT CONTROL SYSTEM TRIMMING

During the trimming of a new system, it is recommended to keep the key in the OVERRIDE position.

When the key is in the OVERRIDE position, the DIVERT action has to be initiated manually using the

EMERGENCY DIVERT button. This should be done when the green SAFE %SOLIDS light turns off.

The trim procedures are described in Chapter 5, the measurement calibration in Section 5.1 and the prism

wash in Section 5.6.

The key should be turned to the AUTOMATIC position only after it has been decided that sufficient experience has been gained.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 14

13

5. CALIBRATION

The K-Patents Divert Control System is calibrated by the manufacturer. This chapter contains instructions how

to make the fine adjustment of the system.

5.1. REFRACTOMETER CONCENTRATION MEASUREMENT

For refractometer calibration consult also the separate Refractometer PR-01-S(-EX/FM) Manual.

The CONC% displays of the two Indicating transmitters have to show the same value. If there is a difference,

this can be eliminated by changing the Bias for one of the refractometers. Key in the sequence Calibrate / Parameters / CONC(RI) / Parameters / Bias. Comparison with sample determination can decide which one

should be corrected.

Example: If the Indicating transmitter of A displays CONC% = 63.2% and B displays CONC% = 63.8%, the

difference can be eliminated e.g. by lowering B by 0.6%. Read bias from the display of refractometer B. If

bias = 52.923 then enter a new bias = 52.323.

Due to its digital measurement principle, the readings of the K-Patents Process Refractometer do not drift by

time. Frequent recalibrations based on off-line moisture analysis must be avoided, as they will introduce random fluctuations to the refractometer readings.

If the concentration reading is noisy, the damping can be increased. Enter Calibrate / Parameters / CONC(RI) /

Damping time. The Damping time is the time in seconds for the signal to reach half of its final value after a

step change. Increase the damping time in small steps, and wait for the result.

5.2. REFRACTOMETER ACTIVATION FOR DIVERT CONTROL

When a refractometer is activated for Divert control, the upper right corner of the display shows alternatively

A, a, B, b or ?. If the corner is blank the divert function must be activated by pressing the sequence Calibrate/Parameters/Divert control/Divert control and select "1 Activated".

The program has to be version 4.0 or higher, otherwise "8 Divert control" is missing from the CALIBRATE

menu. The program EPROM has then to be changed to an up-dated version.

The decision to display A (a) or alternatively B (b) is not programmed, it depends on to which SERIAL BUS

port in the Divert unit (Figure 3.13) the Indicating transmitter is connected.

If a Divert activated refractometer is used in another type of application, the divert function has to be deactivated by selecting "0 Not activated". After de-activation all references to Divert functions disappear except "8

Divert control" in the CALIBRATE menu.

Note. If a message DIVERT CONTROL FAULT and a ? appear on the IT-R display, the reason is one of the

following:

1. Cables between the IT-R and the terminals 8-14 on the DD-01 are not properly connected. Re-

connect to fix.

2. Communication 485 component IC 17 (A) or IC 19 C (B) is broken on the PR-7310 board inside

the DD-01. Replace board.

3. Communication 485 component IC 1r is broken on the PR-7010 board inside the IT-R. Replace

board.

4. Dip switch 3. is in the “up” position which means that the PR-7310 card is configured to work in

the remote mode. Change the dip switch back to low (=off) position.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 15

14

5.3. SIGNAL DIFFERENCE ALARM

According to BLRBAC, if a difference of 2% solids (absolute value) or greater exists between refractometer

readings, an alarm shall be activated.

The alarm limit 2% can be changed from the keyboard using the sequence Calibrate/Parameters/Divert control/Ref. difference limit. If the deviation alarm trips seem too frequent, it may help to increase the signal

damping, Section 5.1.

Note. If the two refractometers have different limit values, the lower value is used by alarm system.

5.4. LOW ALARMS

The low alarm limits are set from the keyboard of the Indicating transmitter. Enter sequence Calibrate/Parameters/Divert control. The menu will show “3 Low conc warning limit” and “4 Low conc divert

limit”. The latter has a double function: Both LOW SOLIDS ALARM and DIVERT limit.

The Indicating transmitter display will carry the messages “Solids warning” and “Solids alarm” when the corresponding alarms occur.

Note. The alarm limits are set separately for the two refractometers. Each refractometer gives an alarm according to its own settings.

5.5. REFRACTOMETER MALFUNCTION ALARM

The built-in intelligent diagnostics of K-Patents Process Refractometer provides a tight control of the operation. A full test cycle is completed with an interval less than one second. A description of the microprocessor

implemented diagnostics is given below. For details consult the Instruction Manual of the refractometer PR01-S. Only errors classified as Equipment malfunctions will cause alarm and removal from the Divert control system. Process related faults will only cause a message in the Indicating transmitter display. See also

Section 6.3 for additional diagnostics.

The most important test is to check the signal coming from the digital image sensor during measurement. Improper function of light source, optical components, image sensor and sensor driver are recognized by this

test.

The compensation for temperature measurement is checked, both the temperature element and the A/D converter.

The cable between Sensor and Indicating transmitter is checked using a check sum method, thus recognizing

short circuits, open circuits and excessive disturbances.

The microprocessor system has also a self-checking test program to ensure the proper operation of the CPU

and the memories. The constants in the EEPROM memory are tested to be within strict limits of acceptance.

The performance of the microprocessor is of critical importance for the measurement control. A separate

hardware watch-dog circuit ensures the proper microprocessor operation by checking that the microprocessor

regularly sends out a predetermined pulse sequence. Another hardware circuit checks that the supply voltage

to the microprocessor is within safe limits, to prevent any brownout stray output pulses.

5.6. PRISM WASH

A prerequisite for a proper function of the divert system, is that the prism wash works. The TEST value in the

display should increase at least 20 steps during WASH, provided TEST is not close to its maximum value 248.

See Sections 8.1, 8.5 and 9.2 in PR-01-S Instruction Manual.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 16

15

WASH TIMES

The wash times can be seen by pressing Display/System configuration/Wash times. The values set at delivery

are the following:

Preconditioning = 0 seconds

Wash time = 3 seconds

Recovery time = 30 seconds

Interval = 20 min

The wash times are changed by pressing the sequence Calibrate/Parameters/Prism wash.

Note maximum wash time is 30 seconds and maximum recovery time 30 seconds.

WASH CHECK

This function can be defined from the prism wash menu: Calibrate/Parameters/Prism wash/Wash test. A prism

wash is accepted if:

a. TEST exceeds “TEST limit”

b. TEST increases more than “TEST difference”

The default values of “TEST limit” and “TEST difference” are zero (0), which makes the wash check inactive.

If the wash is not accepted, the diagnostic message will be “Prism wash failure”.

A “Wash retries” parameter can also be set to repeat the wash if the wash check fails. The default value is zero

(0).

WASH STOP

Wash stop function can be defined from the prism wash menu. Wash can be prevented when the process temperature is below the set limit, thus indicating that the pipe is not in use. To activate the “wash stop” key sequence: Calibrate/Parameters/1. Prism wash/Wash stop/1. Active and set the temperature limit.

The default value for wash stop is inactivate. When the wash is not accepted the diagnostics message is “Wash

stop/temp. limit”.

EXTERNAL WASH STOP

An input switch can be configurated to an external wash stop to prevent the prism wash when the corresponding input switch is connected. “External wash stop”-message will show when automatic wash is activated from

the soft keys. The input switch can be set to protect the refractometer e.g. if the process is stopped.

AUTOMATIC SINGLE DIVERSION CONTROL DURING PRISM WASH CYCLE

Automatic single (one-of-two) diversion control will take place if either of sensors are in prism WASH cycle.

5.7. DIVERT DECISION RULES

TWO REFRACTOMETERS IN OPERATION:

BLRBAC states the following: For the solids measurements, two refractometers in series must be used. When

both refractometers are in service, the requirement for an automatic black liquor diversion can be satisfied by

either of the following options:

1. If either refractometer reads dissolved solids content 58% (default) or below, an automatic

black liquor diversion must take place.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 17

16

2. When both refractometers read dissolved solids content 58% (default) or below, an auto-

matic black liquor diversion must take place.

Either option is satisfactory.

The rules are listed in decreasing order of security. Only rule 1 satisfies the high safety requirements set by

BLRBAC, August, 1982. On the other hand, the probability of false trips decreases with decreasing safety. It

means that if false trips are too frequent, the rule 2 may be preferred at the cost of safety. The rule 2 has later

been accepted by BLRBAC.

A third conceivable alternative is to base the decision on only one refractometer (the master) and use the other

refractometer (the slave) for comparison only (and difference alarm). Concerning security and false trips, this

rule is a compromise between rules 1 and 2.

The divert decision rule is selected by the switch SW on the divert control board (Figure 3.13). ON position is

upwards.

Switch SW

Rule

SW1 SW2

OFF OFF One-of-two (BLRBAC) Rule 1

ON OFF A master, B slave -

OFF ON B master, A slave -

ON ON Two-of-Two Rule 2

Table 5.70 Divert decision rule selection.

ONLY ONE REFRACTOMETER IN OPERATION:

When only one instrument is IN OPERATION the divert action takes place if this instrument reads 58 % or

below. The status of SW (Table 5.70) has no influence on the divert decision in this case.

NO REFRACTOMETER IN OPERATION:

If both instruments are out of operation (due to malfunction or maintenance), then according to BLRBAC

divert action must take place. See also Section 8.7 about external DC supply.

REMOTE DIVERT SWITCH CONFIGURATION

Switch SW Rule

SW 3

OFF DD-01 normal operation

ON Remote divert card activated

See Section 8.8.

See Section 5.2 if you have on the screen the message DIVERT CONTROL FAULT.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 18

17

6. MAINTENANCE

As the Divert Control System is a pure digital system, no special maintenance is needed. The LIGHT TEST

button on the operator panel (Figure 2.50) sends a signal to the microprocessor, and the microprocessor

switches all 11 LED lights on as long as the button is pressed. This way not only the lights but also the processing system is checked.

To assist the identification of a faulty component, the information flow and the circuit diagrams are given in

Sections 6.1 and 6.2. Also the logic diagrams of Chapter 7 may be of help.

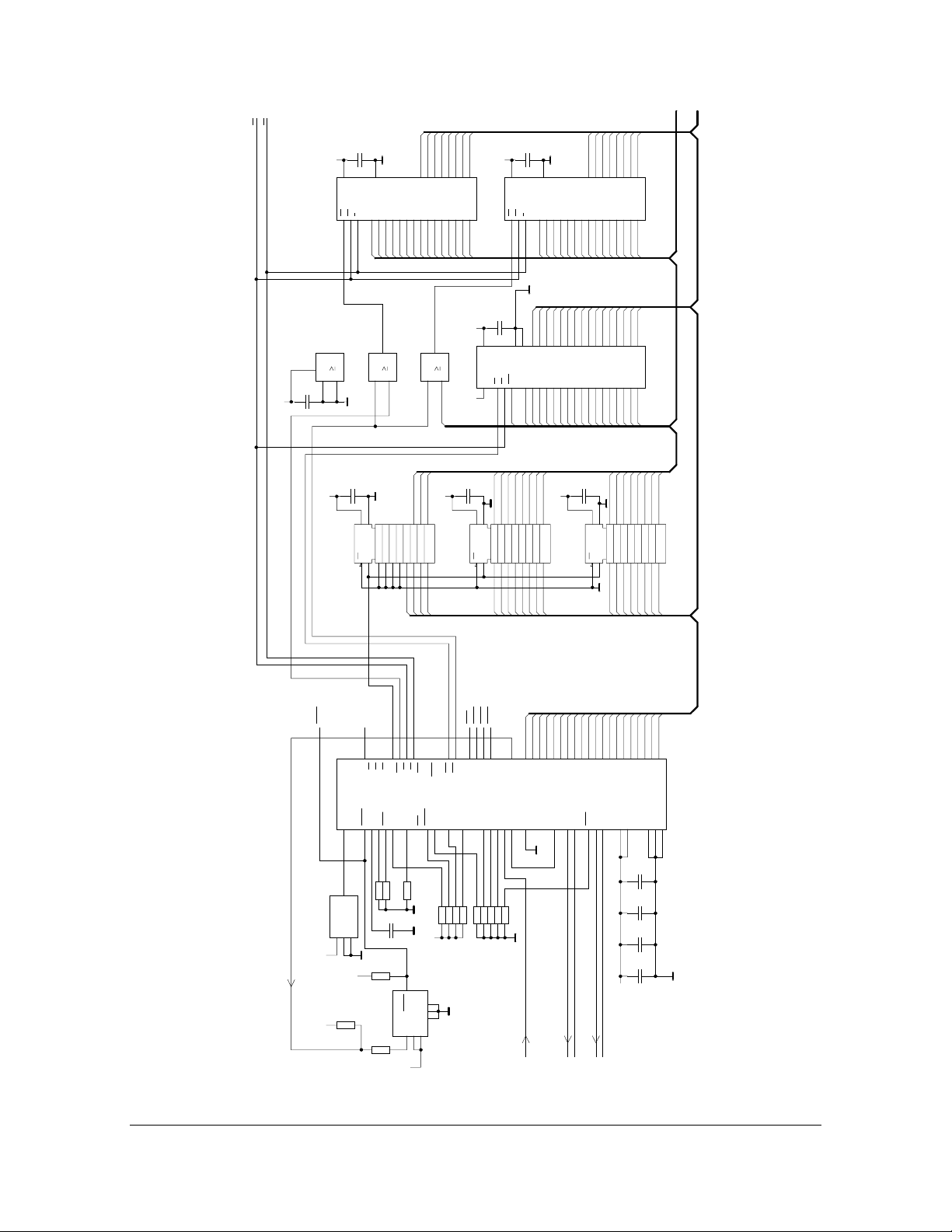

6.1. INFORMATION FLOW

The power and information flow of the total Divert system is shown by Figure 6.10. Additional information

about the cable connections is found in Figures 3.10, 3.11 and 3.12.

Figure 6.10 Information and power flow.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 19

18

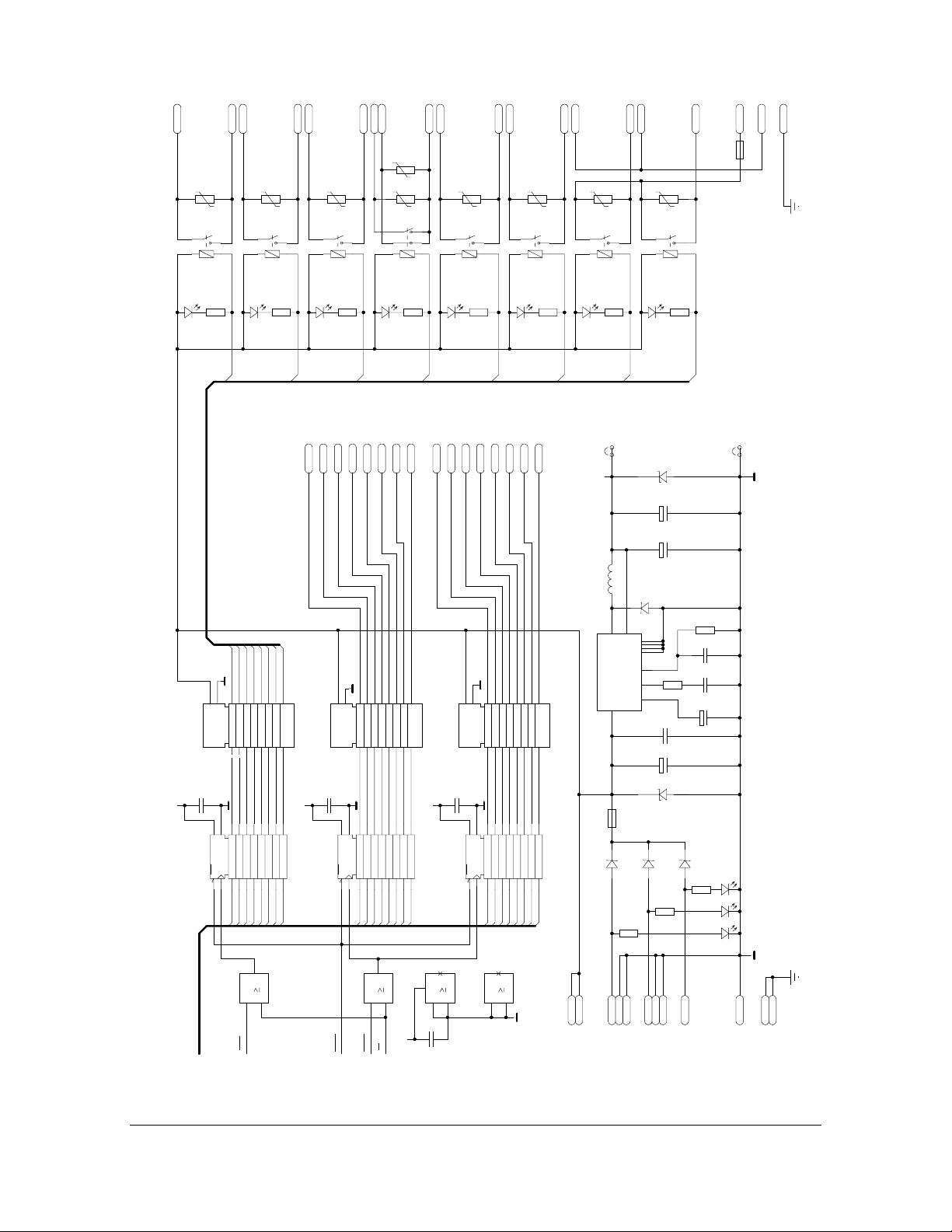

6.2. DIVERT CONTROL CIRCUIT BOARDS

The component lay-out of the divert control circuit board is shown by Figure 3.12 and the circuit diagram by

Figures 6.20 to 6.25.

Figure 6.20 Operator panel board, component layout.

Figure 6.21 Operator panel PR-7311 circuit diagram, page 2 of 2

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 20

19

Figure 6.22 Operator panel PR-7311 circuit diagram, page 1 of 2.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 21

20

RD

WR

AD11

AD10

AD8

AD12

AD13

AD14

AD9

14

A14

A13

A12

A11

A10A9A8A7A6A5A4A3A2A1A0

2

232425

26

A13

A14

A11

A10

A12

8

1

IC2

HC32

9

10

AD15

IO8

IO7

IO6

3456789

A9

A8

A7

A6

11

IC2

12

12131516171819

IO5

IO4

IO3

IO2

IO1

32K x 8bit SRAM

55257

10 11

A5

A4

A3

A2

A1

+5V

40

1

IC8

HC32

VPPNCOECEA15

13

1

+5V

A0

100n

C11

+5V

1

2

28

IC5

W

CE

OE

1

202122

27

A15

6

1

14

IC2

HC32

4

5

7

100n

C8

1

2

+5V

100n

C10

+5V

14

28

IC4

A14

A13

WCEOE

1

202122

26

27

A15

A14

AD13

AD14

AD15

100n

C14

1

2

34567891012131415161718

30

11

O13

O14

O15

PGM

A14

2

A13

20

39

A18

A17

A15

A16

A14

IO8

IO7

A12

A11

A10A9A8A7A6A5A4A3A2A1A0

2

3456789

232425

A13

A9

A8

A7

A11

A10

A12

AD11

AD10

AD8

AD12

AD9

AD7 AD7

AD6 AD6

O8

O9

O7O6O5O4O3O2O1

O10

O11

O12

64K x 16bit EPROM

A12

A11

A10A9A8A7A6A5A4A3A2A1A0

A13

A9

A8

A7

A11

A10

A12

A0-9

12131516171819

IO6

IO5

IO4

IO3

IO2

IO1

32K x 8bit SRAM

AD0-15

55257

10 11

A6

A5

A4

A3

A2

A1

AD5 AD5

AD2 AD2

AD1 AD1

AD0 AD0

AD4 AD4

AD3 AD3

19

O0

27C210

2122232425262728293132333435363738

A6

A5

A4

A3

A2

A1

A18

A17

100n

C9

1

2

+5V

19

10

20

IC3

OC

2345678

1

11

RESET

RESOUT

CLOCKOUTCLKIN

A16

+5V

12131415161718

1Q

8Q7Q6Q5Q4Q3Q2Q

8D7D6D5D4D3D2D1DC

74HC573

9

AD16

AD17

AD18

AD19

45678910

11

15

16

29

30

RD

WR

DT

S0S1S2

ALE

BHE

UCS

DEN

LCS

LOCK

A15

100n

C13

1

2

19

10

20

1Q

IC7

OC

2345678

1

11

AD15

SDISP

SRLY

ISOSWISOSW

SSER2SSER2

19202124252627

P1.7

P1.6

P1.5

P1.4

P1.3

A13

A9

A8

A14

A11

A10

A12

12131415161718

9

AD11

AD10

AD8

AD12

AD13

AD14

AD9

AD17

AD18

AD19

28

A17

A18

A19

P1.2

P1.1

P1.0

100n

C18

1

2

+5V

20

8Q7Q6Q5Q4Q3Q2Q

IC10

8D7D6D5D4D3D2D1DC

74HC573

1

AD11

AD10

AD12

AD13

AD14

AD15

AD16

7980818283

A16

AD10

AD11

AD12

AD13

AD14

AD15

16bit MICROPROCESSOR

IC15

T0IN

T1IN

T0OUT

T1OUT

INT4

INT1

INT0

INT3

INT2

P2.7

P2.6

PEREQ

ERROR

READY

HOLD

HOLDA

RESIN RESOUT

OSCOUT

PDTMR

36

37 383940

41 44

8

OUT

Osc.

X1

32.0MHz

VCC

N.C.

GND

1

7

14

12

+5V

3K32

R7

12

+5V +5V

NCS

NMI

TEST

12

13

14

17

18

60

RN5

RN5

RN5

10K0

13

14

12

100n

C26

1

2

RN1

10K0

RESET

IC18

MAX699

WDI

VCC

10R0

1

23467

R8

12

+5V

3

454647

RN4

10K0

RN4

RN4

15

14

16

+5V

8

GND

48

RN5

RN5

RN4

RN5

18

16

13

17

P2.5

3132333435

49

50

5455565758

10K0

RN5

RN5

15

19

INT1

CTS0

P2.0

P2.4

P2.2

P2.1

P2.3

515253

59

RXD1

TXD1

Figure 6.23 Divert control board PR-7310 circuit diagram. Page 1 of 3.

A7

19

10

1Q

OC

2345678

11

AD8

AD7 AD7

AD9

AD7

AD8

AD9

TXD0

RXD0

RXD0

TXD0

A6

A5

A4

A3

A2

A1

A0

12131415161718

8Q7Q6Q5Q4Q3Q2Q

8D7D6D5D4D3D2D1DC

74HC573

9

AD5 AD5

AD2 AD2

AD1 AD1

AD0 AD0

AD4 AD4

AD3 AD3

AD6 AD6

616266676869707172737475767778

AD0

AD1

AD2

AD3

AD4

AD5

AD6

80C186EB

VSS

VCC

8465

6343

22

6442

23

2

1

100n

C22

1

2

100n

C24

1

2

100n

C23

1

2

100n

C25

1

2

+5V

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 22

21

(8)

(9)

K1A2

K1A1

A

SER0-

SER0+

D7

SA5.0

1

2

D6

SA5.0

1

2

100n

+5V

IC17

VCC

ROREDE

123

RXD0

+5V

3

IC2

1

C27

1

2

678

DO

DO

GND

LTC485

DI

45

TXD0

1k00

15

RN3

14

RN3

D10

1

2

43

1

1

IC23

1k00

13

D4

RN3

1

2

12

D3

RN3

1

2

100n

C28

1

2

20

10

IC20

R1DC1

CLR

CP

1118137144173

1

HC32

2

100n

C7

+5V

1

2

20

10

EN

IC1

&

G2

1192345678

IC28

C40

1

+5V

DC/DC

R27

R26

RD

ISOSW

C41

1

1

45

VCC

GND

conv.

NME0505D

VOUT

0V

7

100n

2

500R

12

500R

12

F3

12

BYPASS

X13 1

WR

RESET

(9)

(10)

K2A2

K1A3

B

SER1-

+5V

DO

VCC

IC19

ROREDE

123

RTS

D12

1

2

65

1

IC23

74HC05

9126155162

1Q2Q3Q4Q5Q6Q7Q

1D2D3D4D5D6D7D

AD2AD2

AD1AD1

AD0AD0

AD3 AD3

AD4 AD4

18171615141312

Y1Y2Y3Y4Y5Y6Y7

A5A3A4A6A7

A1A2G1

KN2

KN1

KN3

1K

R12

R13

100n

1K

2

8

VCC

IC29

123

D27

F4

12

BURNER

X13 2

X14 1

(8)

(10)

K2A3

K2A1

SER1+

D5

SA5.0

1

2

D8

SA5.0

1

2

100n

C30

1

2

678

DO

GND

LTC485

DI

45

TXD1

1

74HC05

19

8Q

HC273

8D

18

AD7AD7

AD6AD6

AD5AD5

AD0-18

11

Y8

HC541

A8

9

KN6

KN5

KN4

12

12

C42

1

765

VO1

VO2

GND

Opto-isol.

1+1-2-

2+

4

D28

12

12

1

1

1

C50

R28

R25

3K3

3K3

2

2

1

D29

2

D32

1N4007

X14 2

2

SA5.0

1

100n

2

HCPL2731

C51

1

2

100n

1

2

+5V

D30

SA5.0

D31

C12

1

IC6

1

100n

2

2

1N4007

1

100n

2

20

10

EN

&

G2

1192345678

SWGND

TEST POINT

2

TP4

5VSER

D9

SA5.0

1

2

100n

C39

1

2

7

0V

VOUT

IC27

NME0505D

VCC

GND

conv.

DC/DC

1

45

100n

C38

1

2

100n

C37

+5V

1

2

AD9

AD8

AD15

AD14

AD13

AD12

AD11

AD10

18171615141312

11

Y1Y2Y3Y4Y5Y6Y7

Y8

HC541

A5A3A4A6A7

A8

A1A2G1

9

DIP1

DIP2

DIP3

DIP4

DIP5

DIP6

DIP7

DIP8

3K32

12

RN2

+5V

13

RN2

14

RN2

15

RN2

16

RN2

17

RN2

18

RN2

19

RN2

SW1

1234567

100n

C32

1

2

100n

C34

1

2

100n

C36

1

2

7

161718

OFF

VCC

GND

+9V

-9V

POWER

IC25

C1+

C1-

C2+

C2-

LT1180

23456

100n

C35

100n

C33

1

2

1

2

RN6

15

RN6

13

RN6

14

RN6

12

1K0

123

4

1+1-2-

2+

VO1

VO2

VCC

765

8

1K0

RN7

RN7

RN7

RN7

33pF

C15

1

2

33pF

C16

1

2

100n

C17

1

2

7

21

X1

VCC

VSS

IC9

D0D1D2D3D4D5D6D7A0A1A2

123

252627

28

AD3

AD2

AD1

AD4

AD0

KN2

KN1

KN3

12

R1

100R

12

R2

12

RN1

RN1

RN1

RN1

RN1

RN1

3K32

OVERRIDE

LAMP TEST

ALARM RESET

J1 12

J1 10

Opto-isol.

GND

R3

J1 14

IC24

+5V

12

13

14

15

X2

12

18.432MHz

+5V

+5V

12

13

14

15

16

17

10111213141516

SW8

89

J26

J23

J25

UARTS

UACTS

910

15

R

R

T

12

13 14

CTSI

RXDI

RTSI

R11

12

10R0

765

8

VO1

VCC

IC26

1+1-2-

HCPL2731

123

RTS

RXD RD

TXD

CTS

INT1

15169

86513101411

X2

RI

TXD

INT

RXD

RTS

DTR

82510

4

22232420191817

A1

A2

A3

AD7

AD6

AD5

KN6

KN5

KN4

C1

1

2

C2

1

2

C3

1

2

C4

1

2

C5

1

2

12

R4

C6

1

2

12

R5

12

R6

DIVERT RESET

EMERGENCY DIVERT

J1 46

J1 44

J1 40

SD

8

11

TXDI

CTS

RD

J22

T

100n

100n

100n

100n

100n

100n

C52

1

12

DSR

DCD

WRCSRESET

J24

J21

SGND

SGND

TEST POINT

1

2

TP3

100u

2

VO2

GND

Opto-isol.

2+

HCPL2731

IC23

A1-3

1213

IC23

14

1

1

74HC05

7

1

2

100n

C31

1011

1

1

IC23

74HC05

89

1

1

IC23

74HC05

21

1

1

74HC05

WR

RD

SSER2

RESOUT

4

+5V

AD0-15

Figure 6.24 Divert control board PR-7310 circuit diagram. Page 2 of 3.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 23

22

5

E

K41

5

1

A WASH

V1

. .

RE1

K52

12

..

F2

1A

L

12

8

16

N

K91

K93

HORN

V7

5

RE6 RE7

1

K102

. .

12

5

8

12

1

16

K121

K111

K122

NO MALF.

V9

. .

8

5

1

RE8

5

1

16

K101

K112

REF. DIFF

V8

. .

12

8

16

K81

K92

DIVERT/NORM

V6

. .

12

V5

. .

12

8

5

9

RE5

1

16

K71

K82

SOLIDS ALARM

V4

. .

12

8

5

RE4

1

16

K61

K72

SOLIDS WARN.

V3

. .

12

8

5

RE3

1

16

K51

K62

B WASH

V2

. .

12

8

RE2

16

LIN

K42

K43

P

D26

12

VIO24V

RE1-8

VIO24V

IC22

V

C29

.

+

1

IC21

AD0-18

4K7

R24

12

RE1

RE1

9

10

GND

DCOM

1234567

100n

.

2

10

20

2569121516

CP

CLR

111347

AD0

D25

12

RE6

RE5

RE2

RE3

RE4

Q0Q1Q2Q3Q4Q5Q6

1Q2Q3Q4Q5Q6Q7Q

1D2D3D4D5D6D7D

8

131417

AD5

AD1

AD3

AD2

AD4

3

1

IC16

1

2

SRLY

RE8

RE7

12131415161718

D6D5D4D3D2D1D0

19

18

AD6

AD7

HC32

4K7

R23

RE2

Q7D7

811

8Q

HC273

8D

D24

12

12

J119

J121

WARN

ALARM

REFRDIF

VIO24V

IC12

ULN2803A

100n

C19

.

+5V

1

2

IC11

J120

DCOM

20

111347

RESET

4K7

R22

12

RE3

J122

AOPER

MALFUNC

Q0Q1Q2Q3Q4Q5Q6

GND

1234567

.

10

2569121516

1Q2Q3Q4Q5Q6Q7Q

CP

1D2D3D4D5D6D7D

CLR

AD1

AD0

IC16

J125

AD2

4

SDISP

D23

12

J126

SAFE

BOPER

8

131417

AD3

AD4

6

1

5

WR

J127

J129

OVERRIDE

12131415161718109

Q7D7

D6D5D4D3D2D1D0

811

19

8Q

8D

18

AD5

AD6

AD7

HC32

+5V

4K7

R21

12

RE4

J128

DIVERT

VBYPASS

ULN2803A

.

+5V

HC273

8

14

1

IC16

9

10

100n

C21

.

.

1

2

D22

12

J130

IC13

C20

1

7

J132

OUT4

BURNER

VIO24V

GND

DCOM

100n

.

2

10

20

IC14

CLR

111347

HC32

4K7

R20

12

RE5

J135

J137

OUT5

OUT6

Q0Q1Q2Q3Q4Q5Q6

1234567

2569121516

1Q2Q3Q4Q5Q6Q7Q

CP

1D2D3D4D5D6D7D

8

AD8

AD9

AD11

AD10

11

1

IC16

12

13

J136

131417

AD12

D21

12

J138

OUT7

AD13

AD14

HC32

OUT8

12131415161718109

D6D5D4D3D2D1D0

811

19

18

AD15

4K7

R19

J139

Q7D7

ULN2803A

8Q

HC273

8D

D20

12

12

RE6

+5V

L1

IC30

F1

VIO24V

J1 49

J1 47

4K7

R18

12

RE7

TP1

+5V

12

TEST POINT

.

.

..

12

150uH

D2

.

1

10

2

13

FB

VOUT

GND

4

OSC

L4962

SS FRC

VIN

7

.

VIO24V

1A

..

12

.

.

12

D16

D17

1N4007

.

.

4K7

R16

1

2

SR224V

SR124V

K1C 1

K1B 1

K1B 2

(13)

(12)

(11)

A

14

15 11

K2B 1

(11)

D19

D1

1

C44

1

C45

1

BYV27/50

2

512

.

C48

1

D15

1

2

C49

12

12

2

2

+

2

+

.

12

33nF

1

2

100u

2

+

SA26

2

1N4007

1N4007

4K7

R9

K2C 1

K2B 2

(13)

(12)

B

4K7

R17

12

RE8

SA5.0

220u

.

220u

.

12

C46

.

1

15K0

R15

C47

.

1

C43

.

1

+

.

.

.

12

D18

.

1

EXT24V

K3 1

(15)

TP2

4K64

R14

2n2

.

2

33n

.

2

2u2

.

2

4K7

12

R10

1

2

1

2

1

2

GND

GND

12

TEST POINT

D14

D13

D11

P

K3 2

K2C 2

K1C 2

(16)

(14)

(14)

B

A

Figure 6.25 Divert Control board PR-7310 circuit diagram. Page 3 of 3.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 24

23

6.3. DIAGNOSTIC MESSAGES

For diagnostic messages in the Indicating transmitter display, see the PR-01-S manual. The following messages appear only in divert systems:

- "In divert control operation" or "Removed from divert control", Section 2.6.

- "Solids warning" and "Solids alarm", Section 5.4.

- ** Divert control fault **

This message indicates that there is no communication to the divert control unit, probably cable error, Figure

3.12, cable 2.

If the instrument is not applied in a divert control system, de-activate the divert function, see end of Section

5.2.

Further the message ** Relay unit fault ** may appear. This indicates that the Relay unit PR-7080 functions

are defined, but no Relay unit is connected. Normally a Relay unit is not used in a Divert system because the

wash contacts are in the Divert control unit. Clear the relay functions by the key sequence Calibrate/Relay unit

and select an "0 Not Defined" for all four relays. For using an optional relay unit, see PR-01-S Manual, section 9.1.

6.4. DIAGNOSTIC LIGHTS

The Divert circuit board, Figure 3.12, contains the following diagnostic LEDS:

D3 Processor cycles: should flash

D4 Processor reads serial bus: should flash

D10 Serial bus A input: should flash

D11 On if 24 V DC supply from A is OK

D12 Serial bus B input: should flash

D13 On if 24 V DC supply from B is OK

D14 On if external 24 V DC is applied

D19 Wash relay A on

D20 Wash relay B on

D21 Solids warning relay on

D22 Solids alarm relay on

D23 Divert relay on = not DIVERT (Section 2.2)

D24 Horn on

D25 Refractometer difference relay on = difference alarm

D26 Override

D27 Valve to bypass

D28 Valve to burner

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 25

24

6.5. PUSH-BUTTON ASSEMBLY

Before removing the push button or the lockable Override/Automatic switch from the front panel turn the

screw 1/4 to the left, Figure 6.50. This will release the contact element.

Figure 6.50 Securing and removal of the contact element.

6.6. FUSES

The following fuses are printed on circuit board PR-7130:

Fuse F1: Microfuse IEC 127-3/1 DC Power (24 VDC) main fuse. Protects UL 198G 1A, fast

divert electronics againts wrong voltages especially from external DC supply.

Fuse F2: 5 x 20 mm fuse

IEC 60127, 1A, fast

AC supply to solenoid valves. Protects cable and coil, if faults

appear.

Fuses F3, F4: Microfuse IEC 127-3/1, Fuses protect switch of divert valve position UL 198G 63 mA,

fast feedback. Any external voltage connected to these circuits

causes fuse blow.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 26

25

7. DIVERT CONTROL LOGIC

A logical description of the system is provided as a complement to the previous information about the electronics.

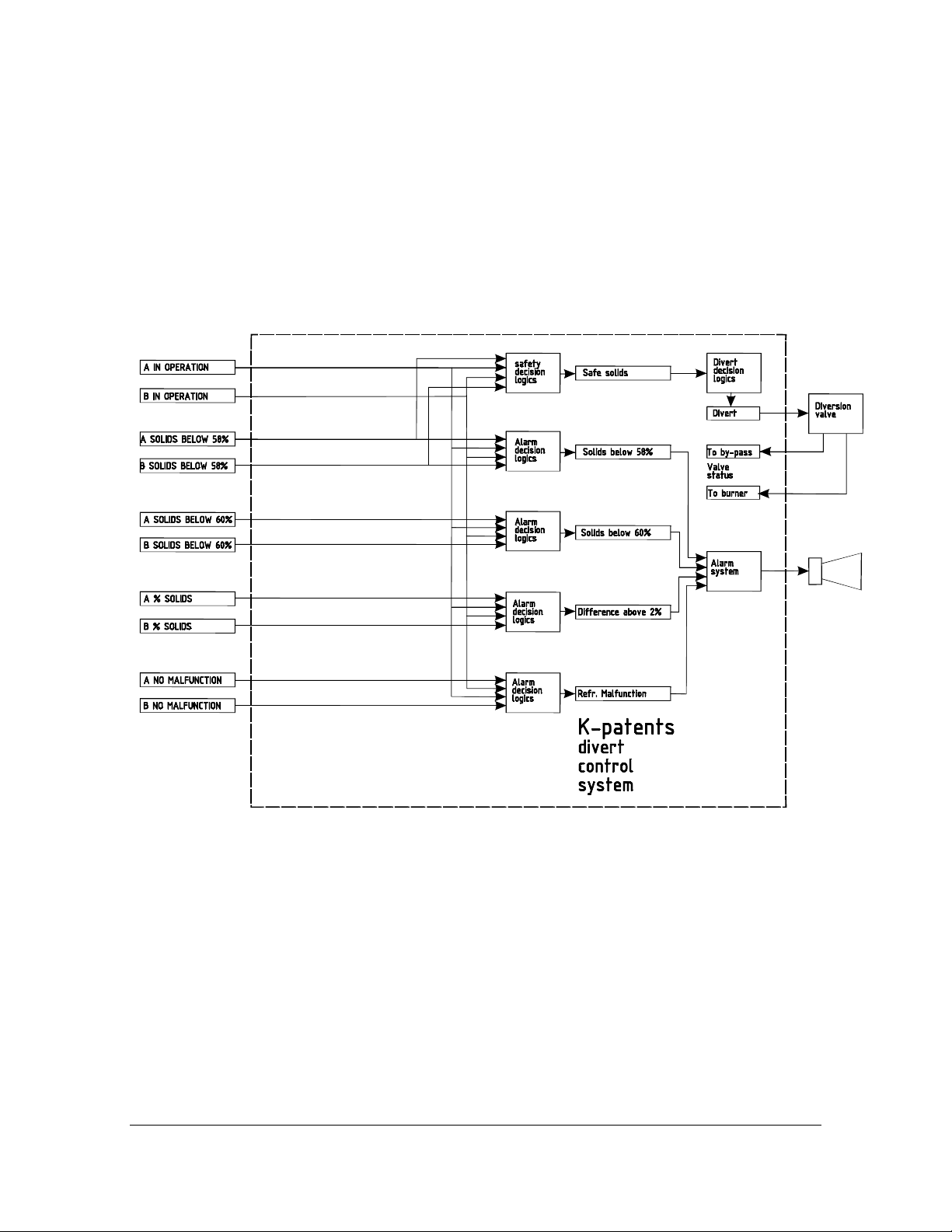

7.1. BLOCK DIAGRAM

The block diagram Figure 7.10 shows the connections between the different logical subsystems.

Figure 7.10 Block diagram of the divert control system

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 27

26

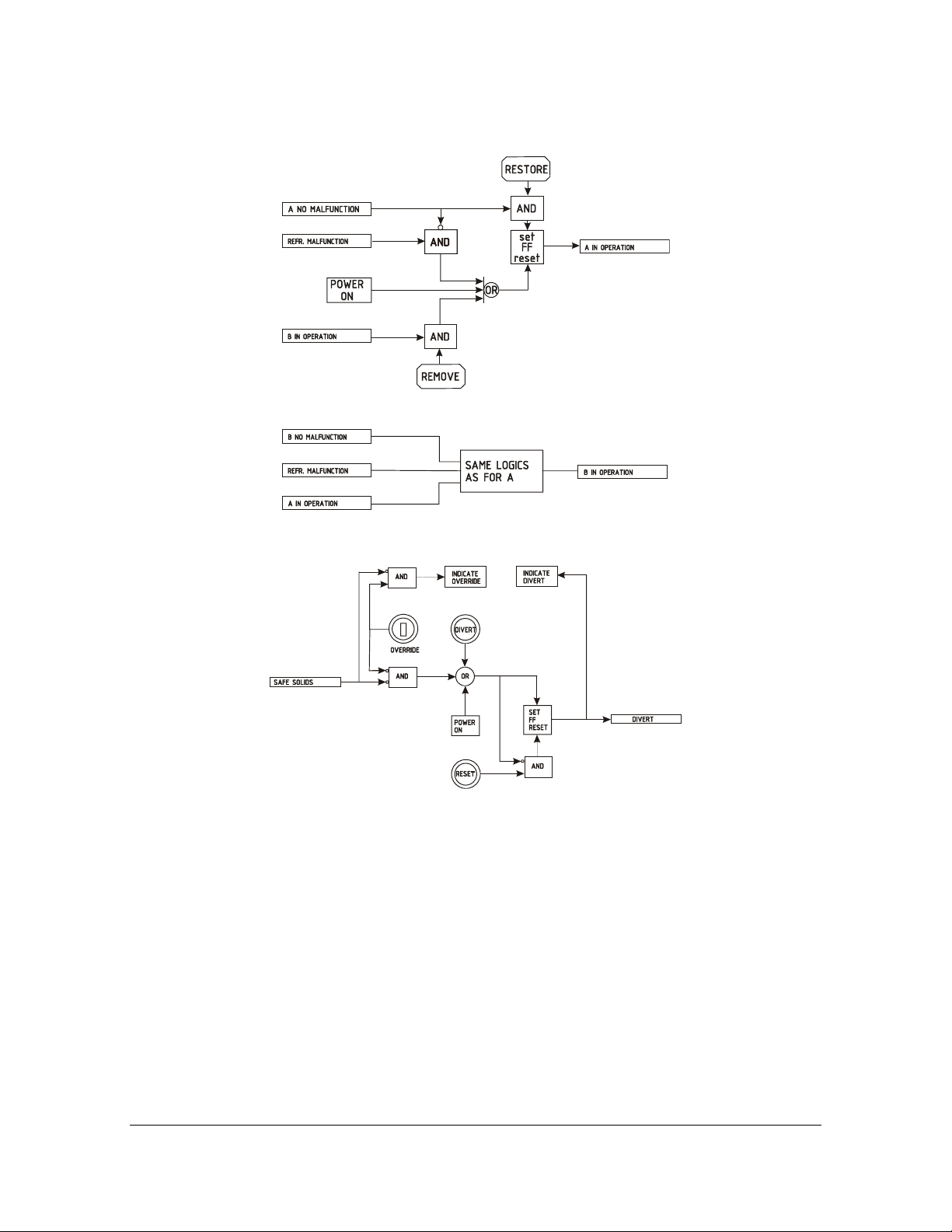

7.2. LOGICAL DIAGRAMS

Figure 7.20 The operation logics.

Figure 7.21 The divert decision logics.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 28

27

Figure 7.22 The alarm decision logics.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 29

28

Figure 7.23 The alarm system.

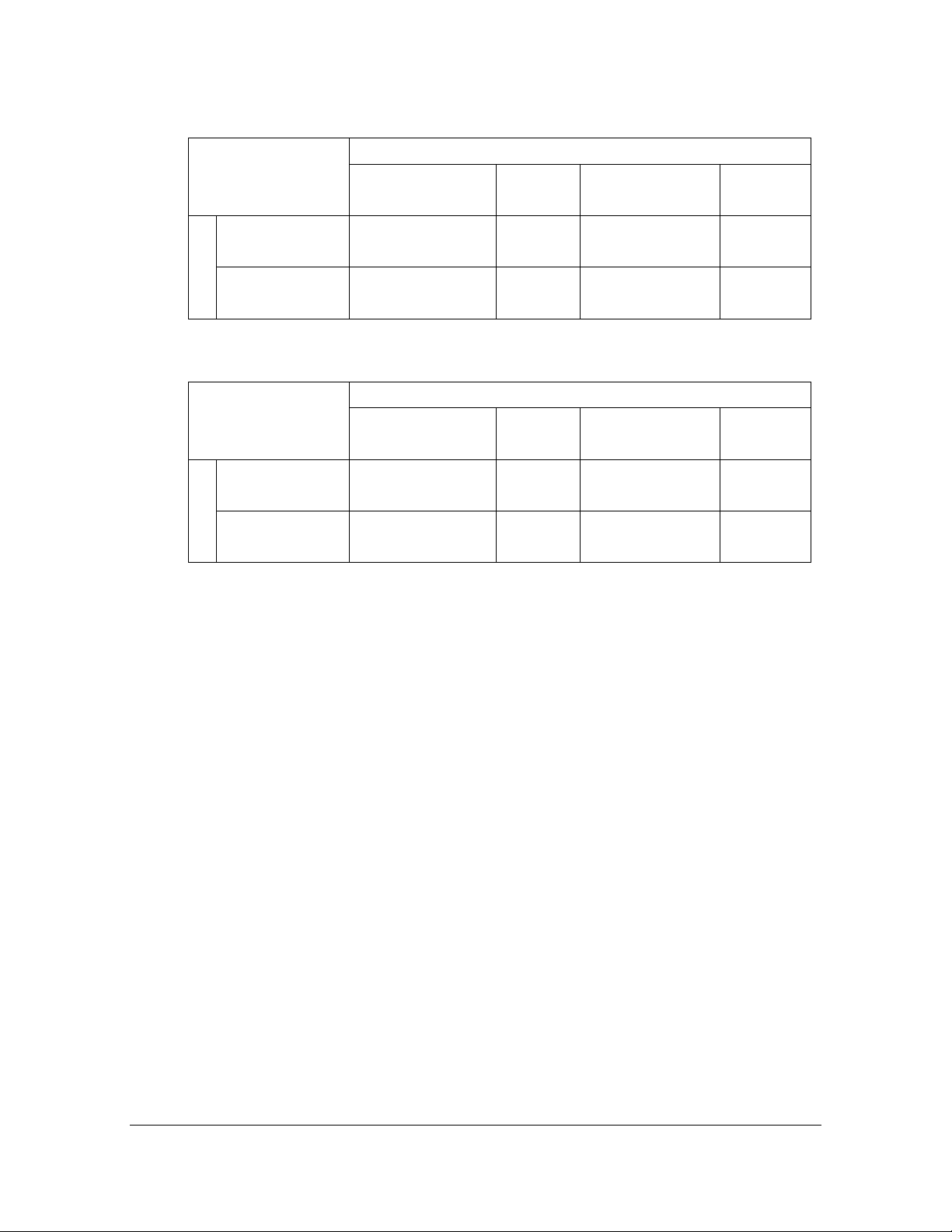

7.3. SAFETY DECISION LOGICS

The logical description of the Safety Decision Logics in Figure 7.10 is given by the following tables:

- Table 7.30 One - of - two

- Table 7.31 A master, B slave

- Table 7.32 Two - of - two

Note. NOT OPERATING includes the wash cycle.

See also Section 5.7.

A

<58

OPERATING

B <58 OPERATING

NOT OP

>58 OPERATING

NOT OP

Unsafe

Unsafe

Unsafe

Unsafe

NOT OP

Unsafe

Unsafe

Safe

Unsafe

>58

OPERATING

Unsafe

Safe

Safe

Safe

NOT OP

Unsafe

Unsafe

Safe

Unsafe

Table 7.30 One-of-two decision rule

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 30

29

A

<58

OPERATING

<58 OPERATING

B

NOT OP

>58 OPERATING

NOT OP

Unsafe

Unsafe

Unsafe

Unsafe

NOT OP

Unsafe

Unsafe

Safe

Unsafe

>58

OPERATING

Safe

Safe

Safe

Safe

Table 7.31 A master, B slave

A

<58

OPERATING

B <58 OPERATING

NOT OP

>58 OPERATING

NOT OP

Unsafe

Unsafe

Safe

Unsafe

NOT OP

Unsafe

Unsafe

Safe

Unsafe

>58

OPERATING

Safe

Safe

Safe

Safe

NOT OP

Unsafe

Unsafe

Safe

Unsafe

NOT OP

Unsafe

Unsafe

Safe

Unsafe

Table 7.32 Two-of-two decision rule

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 31

30

8. OPTIONAL CONFIGURATIONS

8.1. REMOTE DIVERT CONTROL UNIT

The remote divert control unit is an option of the digital divert control system DD-01, see Figure 8.20.

The remote divert control unit operates as a main unit, which means that the master divert unit is for indication

only. If the remote divert control unit is not in operation, the master divert unit in the field operates as a main

unit.

The remote control unit communicates with the master divert unit in the field through a modem. Connection

and wiring is made according to Figure 8.40.

For contact terminals see Figure 8.41. Contact terminals 24 and 25 are for communication OK signal.

8.2. EQUIPMENT

Figure 8.20 Complete remote divert control system.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 32

31

8.3. REMOTE DIVERT CONTROL UNIT IN THE CONTROL ROOM

Figure 8.30 Operator’s panel and functions of the remote divert control in the control room.

The remote divert control unit contains all information for the deviation decision. The operation is clearly

indicated with LED lights as follows:

1. A row of four alarms (indicating Black liquor SOLIDS WARNING (at 60%), Black liquor SOLIDS ALARM (below 58%), Refractometer reading more than 2% absolute difference, and Refractometer malfunction).

2. Each refractometer A and B has an

OPERATING green light, so the operator

knows when he can rely on the refractometer

measurement.

A refractometer will influence the divert decision only when the green OPERATING light is

on. A malfunctioning refractometer is automatically taken out of operation.

3. One green indicator light SAFE% SOLIDS,

based on the two refractometers and the divert

decision rules.

4. A red OVERRIDE warning light.

6. Two indicator lights for the divert valve

status. TO BY-PASS/TO BURNER from microswitches on the valve. For intermediate

valve positions both lights are off.

7. A lockable Override/Automatic switch.

8. One RESET push-button for the DIVERT

action. The DIVERT action always has to be

manually reset. If the override swithc is in

automatic position and SAFE% SOLIDS is off,

the DIVERT cannot be reset.

9. EMERGENCY DIVERT push-button.

10. A light test button switches all 11 lights on.

11. An alarm reset button resets the alarm

lights.

12. Communication to MASTER DIVERT ok,

indication light blinking.

5. One red DIVERT light that will be switched

on when the SAFE% SOLIDS goes off, providing OVERRIDE is off. The DIVERT light

indicates divert status of the divert relay.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

13. Power supply ok, indication light on.

Note when remote divert in use, master divert unit in the field is for indication only!

Page 33

32

8.4. WIRING AND MOUNTING

For wiring of the complete system, see Figure 8.40, which also specifies the cables and connections.

Figure 8.40 Digital Divert Control System with Remote Divert Control Unit Wiring.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 34

33

Figure 8.41 Remote Divert Control Unit terminals.

Figure 8.42 Digital Divert Control System: Remote Divert Control Unit mounting.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 35

34

8.5. SERIAL OUTPUT

Each Indicating transmitter has a serial output not used by the Divert Control unit. This serial output is selectable RS-232/RS-485 (see PR-01-S Manual) and contains concentration, temperature and error data. It contains

also information whether the refractometer is in divert operation or not.

Possible uses of the Serial output: To communicate with a computer substituting the Divert Control unit.

8.6. CURRENT OUTPUT SIGNAL

Each Indicating transmitter provides a 4-20 mA output concentration signal not used by the Divert system. To

calibrate this signal for suitable %Solids range, press Calibrate/Output signal/Current output, see PR-01-S

Manual.

8.7. EXTERNAL DC POWER SUPPLY

The Divert Control unit may be connected to a DC power supply as a back-up. At AC power failure the refractometers will black-out, but the Divert Control unit will still work. In this case the DIVERT signal can be prevented by turning the key to OVERRIDE. Terminals are 15 (+24VDC) and 16 (ground).

The power requirement is 24 VDC, 500 mA.

8.8. DIVERT CONTROL UNIT CARD IN THE REMOTE UNIT

In the remote unit the divert control card the third dip switch SW3 must be in the ON position (“up”).

See Figure 3.13 and Sections 5.2. and 5.7.

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 36

35

9. DIVERT CONTROL UNIT PARTS LISTS

9.1. DIVERT CONTROL UNIT AND OPTIONAL REMOTE DIVERT CONTROL UNIT

ltem Pcs. Part No. Description Item Pcs. Part No. Description

1 1 Enclosure 6.1 2 PR-6551 Switch unit, green

1.1 7 Conduit hubs 1/2”

NPT-Type ST-1 (US)

2.

3.1

3.2

3.3

1

1

1

1

PR-7310 Divert Control Unit

Card

Modem transformer

Modem card

Modem cable

4 1 PR-7028 Ribbon cable

5 1 PR-7311 LED Display card

6.2 1 PR-6551 Switch unit, red for Emergency divert

6.3

6.4

7.

1

1

1

PR-6551

PR-6552

PR-6501

Switch unit, green for Emergency divert reset

Lock unit for Automatic/Override divert operation

Divert Fuse set: 9 fuses (3 x

Microfuse 1A, fast IEC 1273/1, UL 198G; 3 x 5x20mm

Fuse 1A, fast; 3 x Microfuse

63 mA, fast IEC 127-3/1, UL

198G)

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Page 37

36

9.2. REMOTE DIVERT CONTROL UNIT

ltem Pcs. Part No. Description

6.1 2 PR-6551 Switch unit, green

6.2 1 PR-6551 Switch unit, red for Emergency divert

6.3 1 PR-6551 Switch unit, green for Emergency divert

6.4 1 PR-6552 Lock unit for Automatic/Override divert

8.1 1 PR-7310-RACK

8.2 RACK-modem

8.3 1 RACK Power 24V

reset

operation

INSTRUCTION MANUAL FOR DD-01 DOCUMENT/REVISION: IMD 1/5

Effective: June 20, 2005

Loading...

Loading...