kozy heat #CSK-29-V, CSK-29-MV Installation And Operation Manual

HUSSONG MANUFACTURING CO., INC.

CHASKA 29-MILLIVOLT

OMNI-Test

Laboratories, Inc.

Model #CSK-29-MV

Direct Vent Gas Fireplace Insert

Installation and

Operation Manual

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

ͷ Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

ͷ WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the re department.

ͷ Installation and service must be performed

by a qualied installer, service agency or

the gas supplier.

Tested &

Listed By

C US

Portland

Oregon USA

This appliance may be installed in

an aftermarket, permanently located,

manufactured home (USA only) or mobile

home, where not prohibited by local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certied kit is used.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Hussong Mfg. Co., Inc. • CSK-29-MV Report No.: 0216GN047S • Rev. 01, January 2015

English and French installation manuals are

available through your local dealer. Visit our

website www.kozyheat.com or scan the QR

code for our mobile app.

Read this manual before installation or operating this appliance.

Please retain this owner’s manual for future reference.

CONGRATULATIONS!

We welcome you as a new owner of a Kozy Heat gas replace. Kozy Heat products are designed with superior components

and materials, and assembled by trained craftsmen who take pride in their work. To ensure you receive a quality product, the

burner and valve assembly are 100 percent test-red, and the complete replace is thoroughly inspected before packaging. Our

commitment to quality and customer satisfaction has remained the same for over 30 years. We offer a complete line of gas and

wood replaces, along with stylish accessories to complement any decor. Adding a replace is one of the best ways to increase

the value of your home, and we are proud to offer a network of dealers throughout the country to help make your experience

everything you imagine. We pride ourselves in being dedicated not only to functionality and reliability, but also customer

safety. We offer our continual support and guidance to help you achieve the maximum benet and enjoyment from your Kozy

Heat gas replace.

Jim Hussong

President

Homeowner Reference Information

We recommend you record the following information:

Model Name: ___________________________________________

Serial Number: __________________________________________

Dealership Purchased from: _______________________________

Notes: _____________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

Date purchased/installed: _________________________________

Location of fireplace: _____________________________________

Dealer phone: ___________________________________________

Dudley Hussong

Board Chairman

HOMEOWNER REFERENCE 3

TABLE OF CONTENTS

TABLE OF CONTENTS ................................................................... 5

1.0 INTRODUCTION ......................................................................7

1.1 Appliance Certification .................................................................. 7

1.2 Requirements for the Commonwealth of Massachusetts ......7

2.0 SPECIFICATIONS .................................................................... 8

2.1 Appliance Components ................................................................8

2.2 Heating Specifications .................................................................. 8

2.3 Appliance Dimensions ..................................................................9

2.4 Part Assembly Overview ...............................................................10

2.5 Safety Barriers ................................................................................11

3.0 EXISTING FIREPLACE REQUIREMENTS ............................. 12

3.1 Appliance Placement Considerations ........................................ 12

3.2 Existing Fireplace Specifications ............................................... 12

4.0 TERMINATION LOCATION .....................................................13

4.1 Vent Termination Clearances .......................................................13

5.0 INSTALLATION PREPARATION .............................................14

5.1 Inspect and Clean Existing Chimney ......................................... 14

5.2 Flue Damper ...................................................................................14

5.3 Gas Line...........................................................................................14

5.4 Electrical Wiring ............................................................................. 14

6.0 INSTALLATION ........................................................................15

6.1 Kozy Heat #816-CL Co-Linear Vent System ............................15

6.2 Remove Air Duct ............................................................................16

6.3 Run Vent System ............................................................................16

6.4 Connect Vent Pipe to Air Duct ....................................................17

6.5 Place and Secure Appliance ....................................................... 17

7.0 GAS LINE CONNECTION ........................................................ 18

7.1 Gas Conversion (sold separately) ..............................................18

7.2 Gas Line Installation ...................................................................... 18

8.0 FACING AND FINISHING ........................................................ 19

8.1 Clearances to Combustibles ....................................................... 19

8.2 Shroud Installation ......................................................................... 20

8.3 Safety Barrier Installation .............................................................20

9.0 GAS FIREPLACE INSERT SETUP .......................................... 21

9.1 Glass Assembly ............................................................................ 21

9.2 #CK29-500 Log Set Installation ................................................. 22

9.3 Control Board Removal and Installation .................................... 23

10.0 THERMOSTAT, WALL SWITCH, REMOTE ........................... 24

10.1 Rocker Switch Operation ........................................................... 24

10.2 Remote Control ............................................................................ 24

10.3 Thermostat and Wall Switch ...................................................... 24

11.0 LIGHTING AND SHUTDOWN................................................ 25

12.0 ADJUSTMENT ....................................................................... 26

12.1 Pressure Testing ..........................................................................26

12.2 Burner Flame Adjustments ........................................................27

13.0 TROUBLESHOOTING ........................................................... 28

14.0 MAINTENANCE ..................................................................... 30

13.1 Burner and Pilot System ............................................................ 30

14.1 Fans ................................................................................................30

14.2 Vent System ..................................................................................30

14.3 Glass Assembly ........................................................................... 30

15.0 REPLACEMENT PARTS LIST ............................................... 31

LIMITED WARRANTY ..................................................................... 33

LIFETIME WARRANTY ...................................................................35

TABLE OF CONTENTS 5

1.0 INTRODUCTION

1.1 Appliance Certification

Laboratory: OMNI-Test Laboratories in Portland, Oregon

Standards:

• ANSI Z21.88-2014/CSA 2.33-2014, Vented Gas Fireplace

Heaters

• CGA 2.17-M91 (R2009) , Gas-Fired Appliances for Use at High

Altitudes

• CSA P.4.1-2009, Testing Method for Measuring Annual

Fireplace Efficiency

This installation must conform with local codes, or in the absence

of local codes, with the

NFPA 54, or the

B149.1.

Natural Gas and Propane Installation Code

National Fuel Gas Code

, ANSI Z223.1/

, CSA

1.2 Requirements for the

Commonwealth of Massachusetts

The following requirements reference various Massachusetts and

national codes not contained in this manual.

For all sidewall horizontally vented gas fueled equipment installed

in every dwelling, building or structure used in whole or in part

for residential purposes, including those owned or operated

by the Commonwealth and where the side wall exhaust vent

termination is less than (7) feet above finished grade in the area

of the venting, including but not limited to decks and porches, the

following requirements shall be satisfied:

1.2.1 Installation of Carbon

Monoxide Detectors

At time of installation of side wall horizontally vented gas fueled

equipment, the installing plumber or gas-fitter shall observe that

a hard wired carbon monoxide detector with an alarm and battery

back-up is installed on the floor level where the gas equipment is

to be installed. In addition, the installing plumber or gas-fitter shall

observe that a battery operated or hard wired carbon monoxide

detector is installed on each additional level of the dwelling,

building or structure served by the side wall horizontal vented gas

fueled equipment. It shall be the responsibility of the property

owner to secure the services of qualified licensed professionals

for the installation of hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or attic, the hard wired

carbon monoxide detector with alarm and battery back-up may

be installed on the next adjacent floor level. In the event that

the requirements of this subdivision can not be met at the time

of completion of installation, the owner shall have a period of

thirty (30) days to comply with the above requirements; provided,

however, that during said thirty (30) day period, a battery

operated carbon monoxide detector with an alarm shall be

installed.

for the horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print no less the one-half inch

(½) in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

1.2.4 Inspection

The state or local gas inspector of the side wall horizontally

vented gas fueled equipment shall not approve the installation

unless, upon inspection, the inspector observes carbon monoxide

detectors and signage installed in accordance with the provisions

of 248 CMR 5.08 (2) (a) 1 through 4.

1.2.5 Exemptions

The following equipment is exempt from 248 CMR 5.08 (2) (a) 1

through 4: The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented” in the most current edition of NFPA

54 as adopted by the Board; and Product Approved side wall

horizontally vented gas fueled equipment installed in a room or

structure separate from the dwelling, building or structure used in

whole or in part for residential purposes.

1.2.6 Manufacturer Requirements

1.2.6.1 Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall horizontally

vented gas equipment provides a venting system design or

venting system components with the equipment, the instructions

provided by the manufacturer for installation of the equipment and

the venting system shall include:

• Detailed instructions for the installation of the venting system

design or the venting system components; and

• A complete parts list for the venting system design or venting

system.

1.2.6.2 Gas Equipment Venting

System NOT Provided

When the manufacturer of Product Approved side wall horizontally

vented gas equipment does not provide the parts for venting the

flue gases, but identifies “special venting systems”, the following

requirements shall be satisfied by the manufacturer:

• The referenced “special venting systems” instructions shall

be included with the appliance or equipment installation

instructions and;

• The “special venting systems” shall be Product Approved by

the Board, and the instructions for that system shall include a

parts list and detailed installation instructions.

A copy of all installation instructions for all Product Approved

side wall horizontally vented gas fueled equipment, all venting

instructions, all parts lists for venting instructions, and/or all

venting design instructions shall remain with the appliance or

equipment at the completion of the installation.

1.2.2 Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance with

the above provisions shall comply with NFPA 720 and be ANSI/

UL 2034 listed and IAS certified.

1.2.3 Signage

A metal or plastic identification plate shall be permanently

mounted to the exterior of the building at a minimum of eight (8)

feet above grade directly in line with the exhaust vent terminal

INTRODUCTION 7

2.0 SPECIFICATIONS

2.1 Appliance Components

Part Number Description

CK29MV-770 Millivolt Control Board Assembly

700-203 Manual Gas Shut-off Valve

CK29L-135 Burner Assembly

CK29-500 Log Package

701-009T Glass Assembly

CK29-028-MV Fan Kit (1)-69 CFM

500-CK29 Grill Assembly

2.1.1 Additional Components Required

2.1.1.1 Shrouds

Part Number Description

CK29-004 Blank Shroud (4 pc.)

CK29-2538 25” x 38” shroud (1 pc.)

CK29-27542 27½” x 42” shroud (1 pc.)

CK29-3044 30” x 44” shroud (1 pc.)

CK29-A2838 28” X 38” Arched shroud (1 pc.)

2.1.1.2 Approved Vent Systems

Kozy Heat #816-CL co-linear vent system

For use with minimum 6” x 8” I.D. masonry or 7” I.D. Class A metal

chimneys; includes 12 ft. (3.66 m) compressed, expandable colinear 3” x 3” flexible pipes and termination cap.

Other approved vent manufacturers

BDM, American Metals (Amerivent), Metal Fab, Selkirk, Simpson

Dura-Vent, and ICC TM-IVT cap only.

2.2.1 Altitude Adjustment

This appliance may be installed at higher altitudes. Please refer

to National Fuel Gas Code ANSI Z223.1/NFPA 54, CSA-B149.1

Natural Gas and Propane Installation Code, local authorities,

or codes having jurisdiction in you area regarding derate

guidelines.

2.2.1.1 US Installations

Refer to the American Gas Association guidelines for the gas

designed appliances derating method. For elevations above 2,000

ft (610 m) , input ratings are to be reduced by 4% for each 1,000 ft

(305 m) above sea level.

2.2.1.2 Canadian Installations

When the appliance is installed at elevations above 4,500 ft (1,372

m), the certified high altitude rating shall be reduced at the rate of

4% for each additional 1,000 ft (305 m).

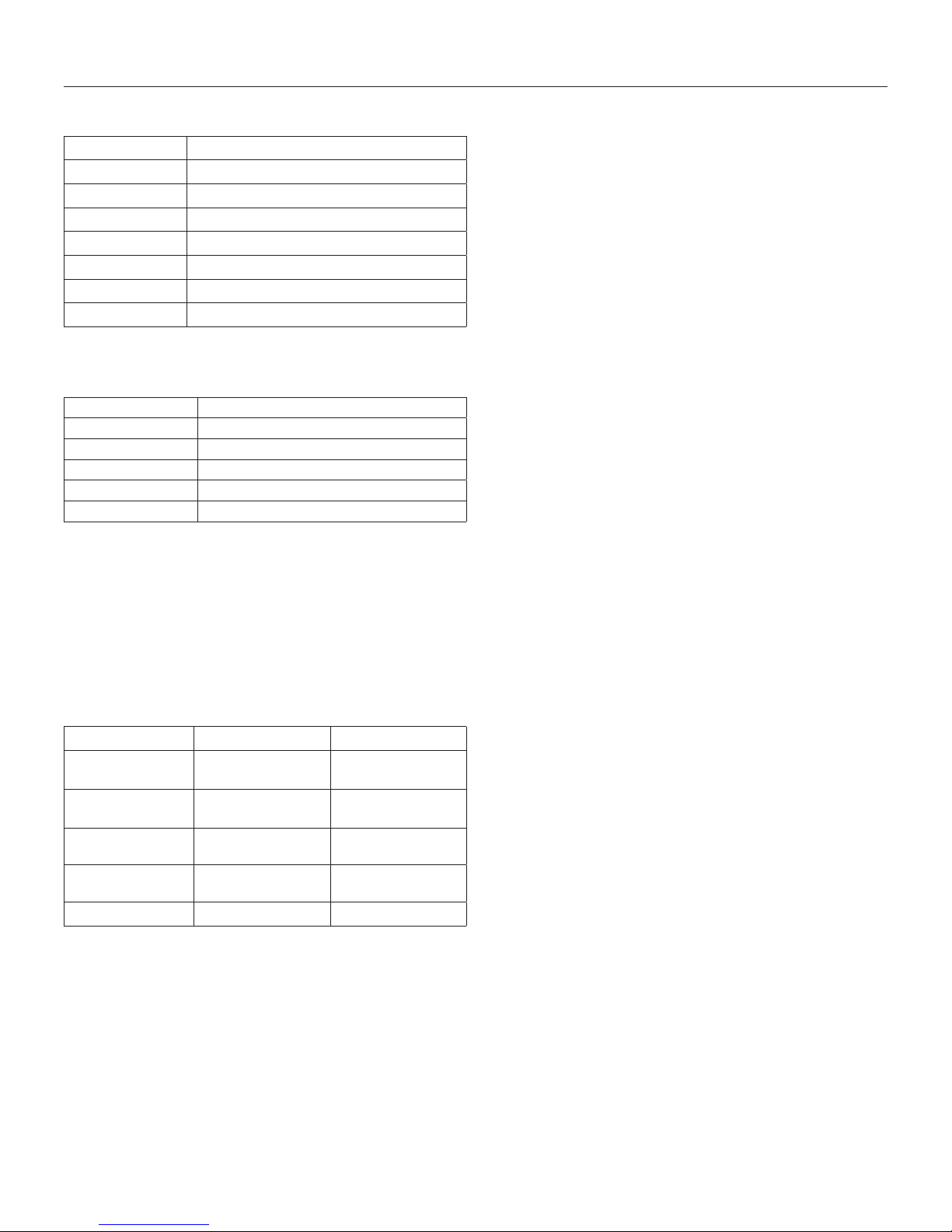

2.2 Heating Specifications

Natural Gas LP Gas

Maximum

Input Rating

Minimum

Input Rating

Manifold Pressure

(High)

Manifold Pressure

(Low)

Orifice Size (DMS) #42 #53

28,500 BTU/h

(8.35 kW)

18,500 BTU/h

(5.42 kW)

3.5” WC (.87 kPa) 10” WC (2.49 kPa)

1.6” WC (.40 kPa) 6.4” WC (1.59 kPa)

29,000 BTU/h

(8.5 kW)

22,000 BTU/h

(6.45 kW)

8 SPECIFICATIONS

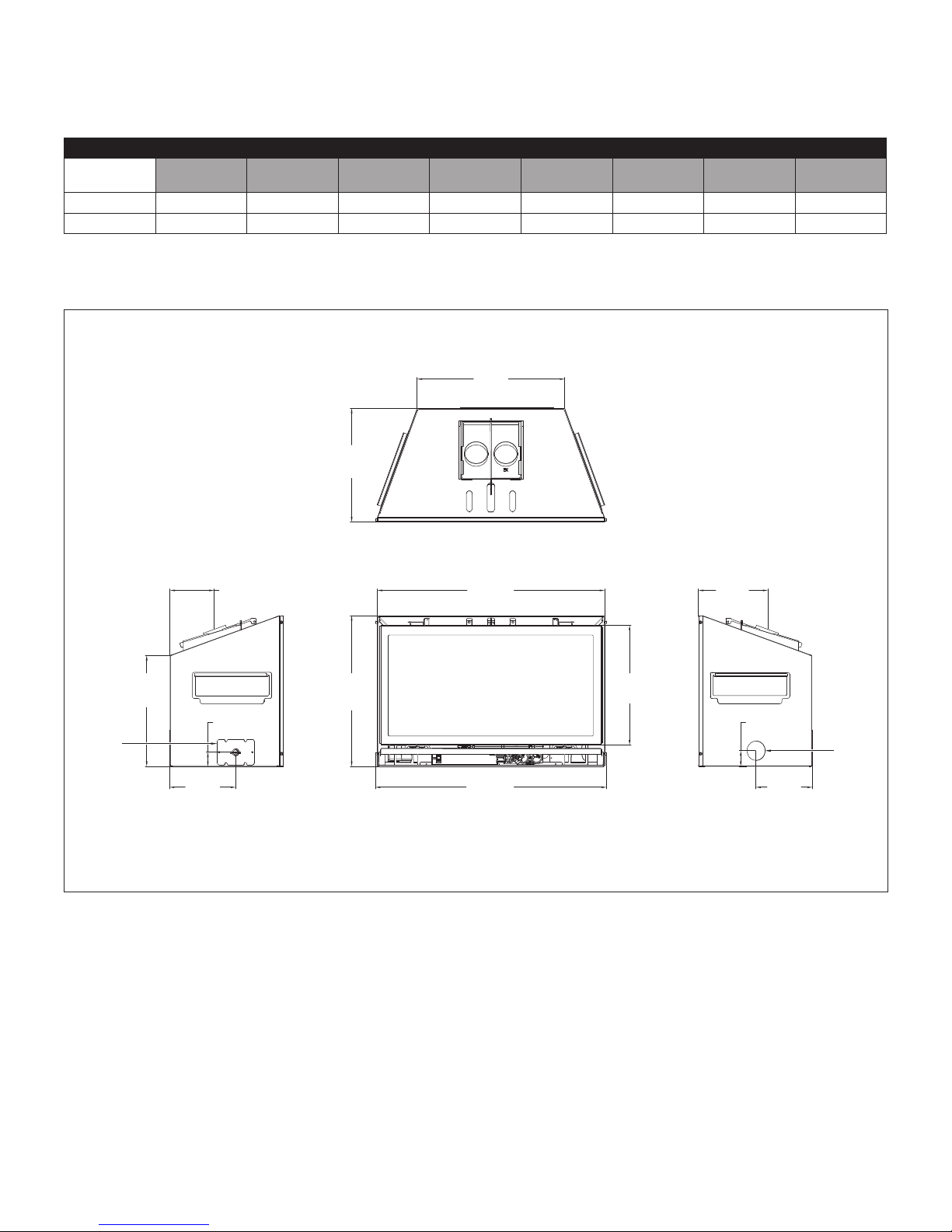

2.3 Appliance Dimensions

Table 2.1, Physical Dimensions

Description Height Width Back Width Depth Back Height Back to Gas

Line Access

Inches 19-1/4 29 18-7/8 14-1/2 14-1/8 7-3/16 8-7/8 5-5/8

Millimeters 488 737 479 368 360 183 225 143

TOP

⁄”

18

(479mm)

14½”

(368mm)

Front to Vent

Center

Back to Vent

Center

(143mm)

⁄”

14

(360mm)

⁄”

1

⁄”

8

(214mm)

(46mm)

ELECTRICAL

ACCESS

LEFT FRONT RIGHT

Figure 2.1, CSK-29 Unit Dimensions

⁄”

5

¼”

19

(488mm)

29”

(737mm)

29

½”

(750mm)

15

⁄”

(388mm)

⁄”

8

(225mm)

2”

(51mm)

7

⁄”

(183mm)

GAS LINE

HOLE

SPECIFICATIONS 9

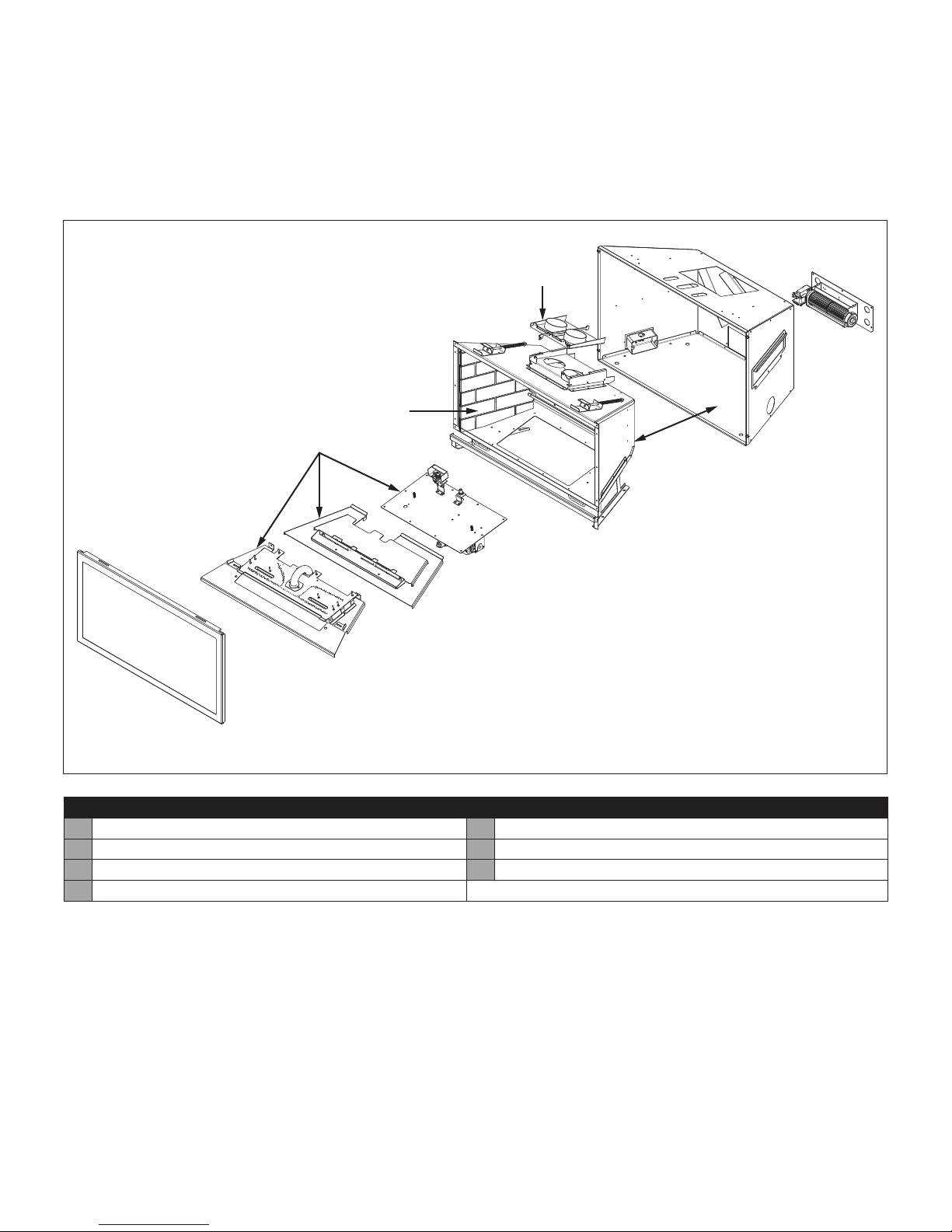

2.4 Part Assembly Overview

WARNING: Failure to position these parts in accordance with

these diagrams, or failure to use only specified approved parts

with this appliance, may result in property damage or personal

injury.

B

C

F

D

E

A

Figure 2.2, Proper Positioning of CSK-29-MV (Exploded View)

A Fireplace insert E Fan kit

B Spring-loaded latch glass assembly F Refractory panels

C Control board with burner assembly G Log set (not shown)

D Co-linear air duct

10 SPECIFICATIONS

Table 2.2, Field-Assembled Parts

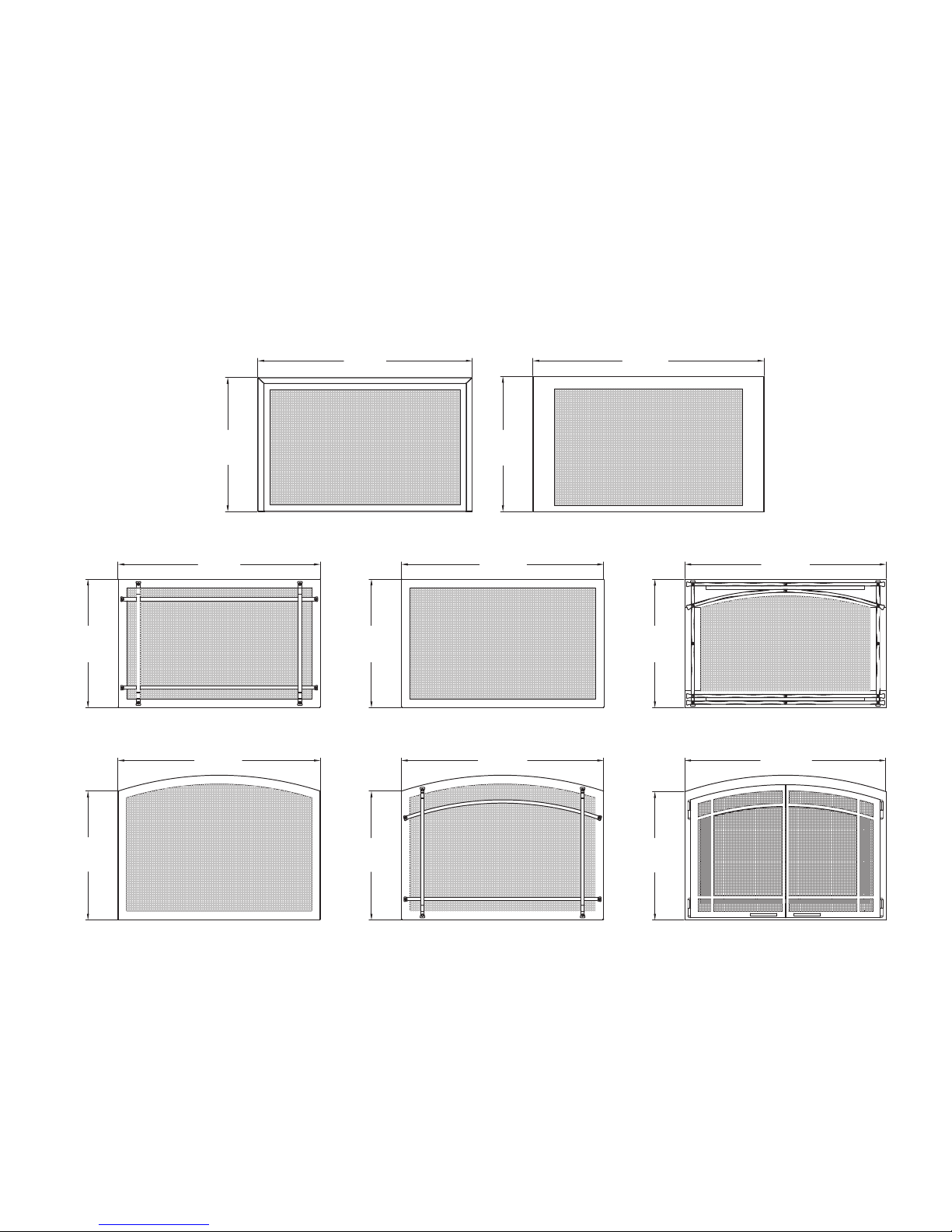

2.5 Safety Barriers

WARNING: A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this appliance and shall

be installed for the protection of children and other at-risk

individuals.

If the barrier becomes damaged, the barrier shall be replaced

with Hussong Mfg.’s barriers for this appliance. Only doors

certified with the appliance shall be used.

Please refer to Section 8.3 Safety Barrier Installation on page

20 for installation instructions.

20

⁄”

(513mm)

21⁄”

(535mm)

33

⁄”

(855mm)

¼”

21

(539mm)

36

¼”

(922mm)

CK29-BSF CK29-CXF

¾”

31

(807mm)

⁄”

20

(513mm)

¾”

31

(807mm)

20

⁄”

(513mm)

31⁄”

(802mm)

CK29-PSF CK29-RSF CK29A-MSF

¾”

31

(807mm)

31

¾”

(807mm)

31⁄”

(802mm)

¼”

20

(515mm)

CK29A-SF CK29A-PSF CK29A-FPDSF

20¼”

(515mm)

⁄”

20

(513mm)

SPECIFICATIONS 11

Loading...

Loading...