kozy heat 936 Installation & Operating Manual

PATENT PENDING

INSTALLATION & OPERATING MANUAL

#936 DIRECT VENT

WALL FURNACE

READ INSTRUCTIONS CAREFULLY BEFORE I NSTALLATION.

FAILURE TO INSTALL THIS FIREPLACE CORRECTLY CAN

CAUSE SERIOUS STRUCTUAL AND FIRE HAZARDS AND

MAY VOID YOUR WARRANTY

IMPORTANT:

.

www.kozyheat.com

MAY 1998

INDEX

DESCRIPTION

PAGE

SAFETY REQUIREMENTS / SPECIFICATIONS ............................ 2-3

MINIMUM CLEARANCES ...............................................3

GAS CONVERSIONS ..................................................3

PREPARE THE UNIT ...................................................4

POSITION THE UNIT................................................. 5-6

ROUGH-IN CHIMNEY VENT DIMENSIONS .............5

ROUGH-IN DIMENSIONS ...........................6

VENTING REQUIREMENTS .......................................... 7-10

DIRECT VENT KIT INSTALLATION ......................................10

FAN INSTALLATION ............................................... 11-12

GAS LINE SPECIFICATIONS ........................................ 13-14

MILLIVOLT BOARD REMOVAL / INSTALLATION ........................15-16

LOG INSTALLATION ............................................... 16-17

WALL SWITCH - THERMOSTAT - REMOTE CONTROL INSTALLATION.........18

COMPLETE THE INSTALLATION........................................19

LIGHTING & SHUTDOWN........................................... 20-21

MANIFOLD & INCOMING PRESSURE CHECK PROCEDURES ................22

CLEANING & MAINTENANCE REQUIREMENTS............................23

TROUBLE SHOOTING ............................................. 24-25

REPLACEMENT PARTS LISTS

..................................... 26

IMPORTANT:

Page 1

READ THIS MANUAL BEFORE INSTALLING AND USING THIS FIREPLACE

MODEL #936 DV WALL FURNACE

INSTALLATION INSTRUCTIONS

This appliance has been tested to and complies

with ANSI Z21.44-1993, “GAS-FIRED DIRECT VENT

WALL FURNACES”, and applicable sections of

ANSI Z21.50-1996 “VENTED DECORATIVE

APPLIANCE”. Installation must conform with local

building codes, or, in the absence of local building

codes, with the national fuel gas code, ANSI

Z223.1-1992 NFPA 54, or the Manufactured Home

Construction and Safety Standard, Title 24 CFR,

Part 3280.

INSTALLATION AND/OR REPAIR OF THIS UNIT SHOULD ONLY BE

DONE BY A QUALIFIED INSTALLER

.

WARNING: Do not use this heater if any part

has been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any part of the control

system and any gas control which has been

under water.

WARNING: DO NOT REPLACE THIS BURNER

UNIT WITH ANY OTHER SIZED BURNER.

REPLACEMENT WITH AN UNAUTHORIZED

BURNER CAN RESULT IN TEMPERATURES

EXCEEDING THE LIMITS FOR THIS UNIT, AND

VOID YOUR WARRANTY.

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

FOR YOUR SAFETY: WHAT TO DO IF

YOU SMELL GAS:

! Do not touch any electrical switches.

! Do not try to light any appliance.

! Do not use the phone in your building.

! Immediately call you gas supplier from a

neighbor’s phone.

! Follow the gas suppliers instructions.

! If you cannot reach your gas supplier, call

the fire department.

! Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

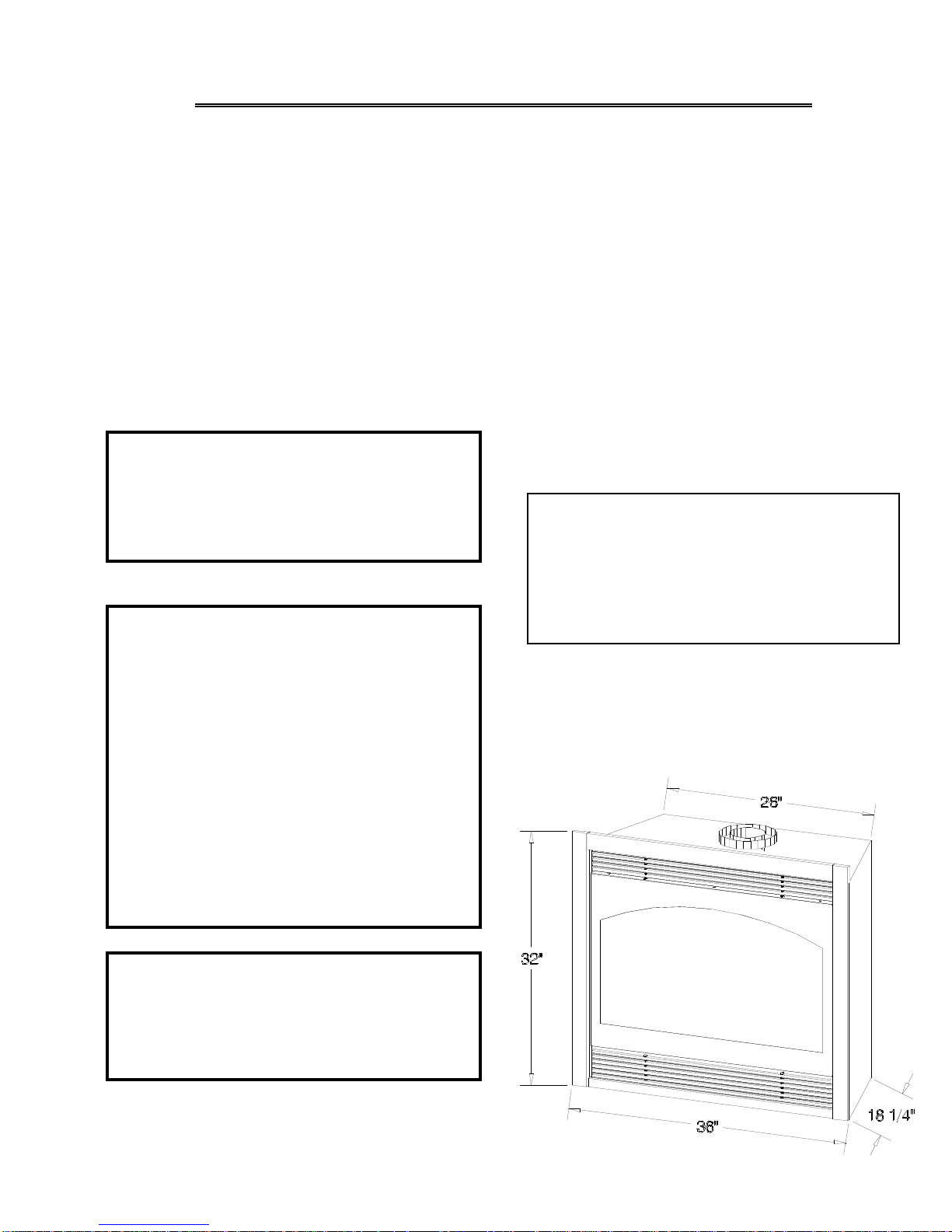

UNIT SPECIFICATIONS Height: 32"

Front width (w/o face): 36"

Back width: 26"

Depth(incl. face): 18 1/4"

Face to front of 7” intake 11 1/4”

Flue size: 4" exhaust, 7" intake

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional

information consult a qualified installer,

service agency, or the gas supplier.

Page 2

IMPORTANT: THIS UNIT IS APPROVED FOR USE ONLY WITH ONE OF THE FOLLOWING DIRECT VENT

SYSTEMS :

- #745 DIRECT VENT TERMINATION KIT - for

terminations 4' for less.

- SIMPSON DURA-VENT DV-GS DIRECT VENT

CHIMNEY SYSTEM: 4” x 6 5/8”. For vertical

terminations.

- #718 DIRECT VENT TERMINATION KIT - for

terminations greater than 4' but less than 8'.

*Adaptor #923-C is required to adapt the flue

collars to the chimney.

- #746 DIRECT VENT EXTENSION KIT - used in

conjunction with #745 or #718. The extension kit is

expandable to 6'.

Refer to pages #7 - # 11 for complete venting installation

instructions / requirements

.

For visual inspection of proper vent connection; upon completion of installing the direct vent kit, remove the nuts and

the baffle inside the unit to expose the lower end of the flue gas exit.

IMPORTANT: NON-COMBUSTIBLE FACING MATERIAL MAY BE APPLIED OVER THE FACE. TO PREVENT THE FACING

MATERIAL FROM CRACKING AND FALLING OFF DUE TO EXPANSION OF THE FACE WHEN HEATED, DO NOT ATTACH

FACING MATERIAL DIRECTLY TO THE FACE OF THE UNIT.

CLEARANCES Mantel Projection

Minimum clearance to combustibles, see Figure 1:

From unit sides & back: 0"

From unit top stand-off: 0"

To flooring: 0"

From flue vent: 1"

From unit glazing to adjacent sidewall: 8"

From heat outlet to mantle: 12"

GAS CONVERSIONS

If a gas conversion is necessary, one of the following conversions kits must be used:

OCK-331- Natural Gas Converisons Kit - used to convert an LP Millivolt

board to natural gas.

OCK-349 - LP Gas Conversion Kit - used to convert a Natural Gas

Millivolt board to LP Gas.

The conversion shall be carried out in accordance with the requ irements of the provincial authorities having

jurisdiction and in accordance with the requirements of the ANSI Z223.1 installation code.

A) PREPARE THE UNIT

Page 3

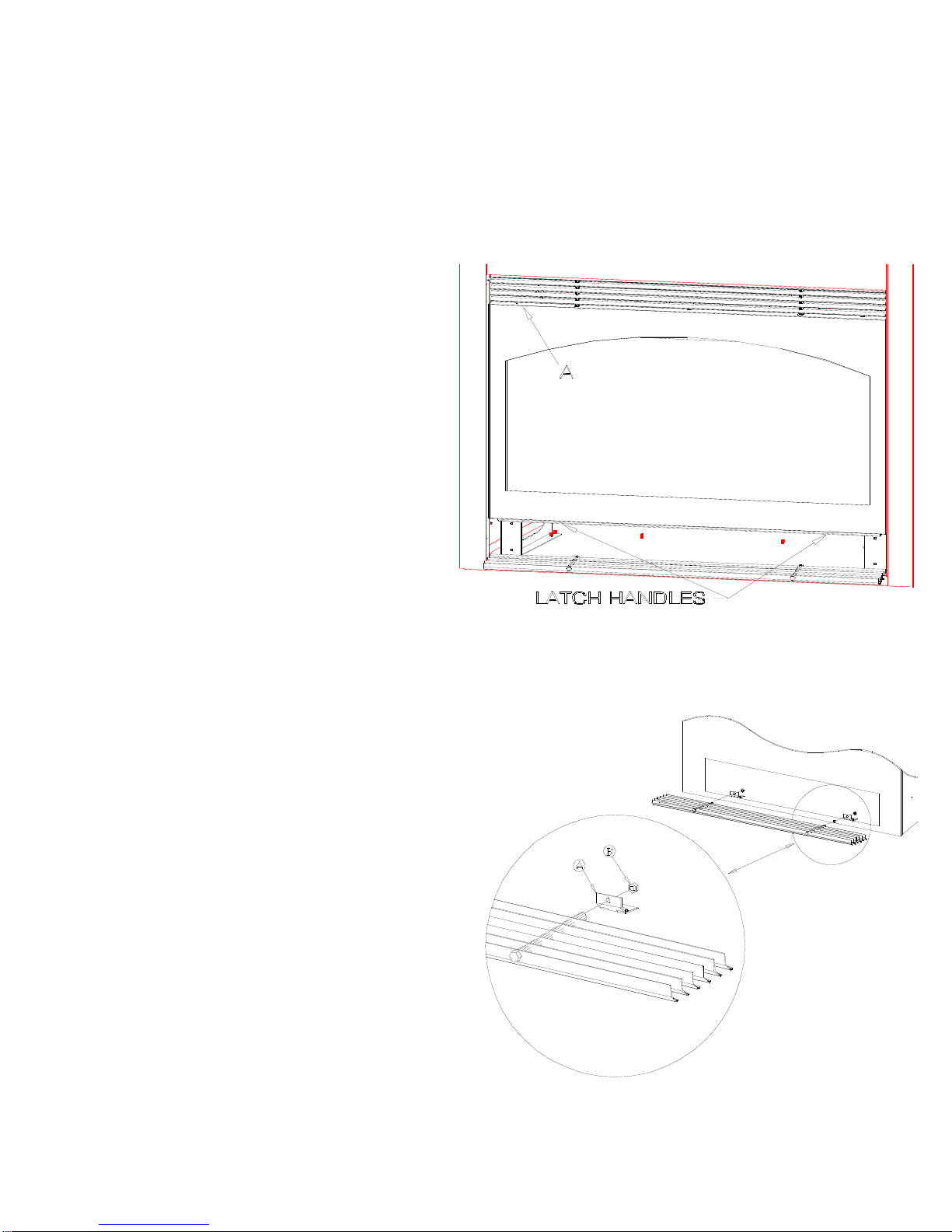

1. REMOVE THE UPPER GRILL

A. Remove the upper grill (A) by lifting it up far

enough to clear the bottom holes and pull the

bottom of the grill out.

2. REMOVE THE GLASS ASSEMBLY.

See Figure 3.

A. Open the lower grill and locate the spring-

loaded handles securing the glass

assembly (under the firebox).

B. Pull the handles out, then down to release the

glass assembly.

C. Pull the bottom of the glass assembly out and

lift up off the tabs.

D. Set aside where it will not be broken.

E. Remove the box of logs from the firebox and

set aside.

Figure 1

3. REMOVE THE LOWER GRILL.

(FOR OPTIONAL FAN INSTALLATION).

A. Grasp the center of the lower grill and pull

down to open.

B. Remove the 1/4” nuts (B) from the grill

assembly.

C. Pull the entire assembly out of the hinges(A).

D. Re-attach the 1/4” nuts (B) to the grill

assembly and set aside for reinstallation later

in this manual.

Figure 2

Page 4

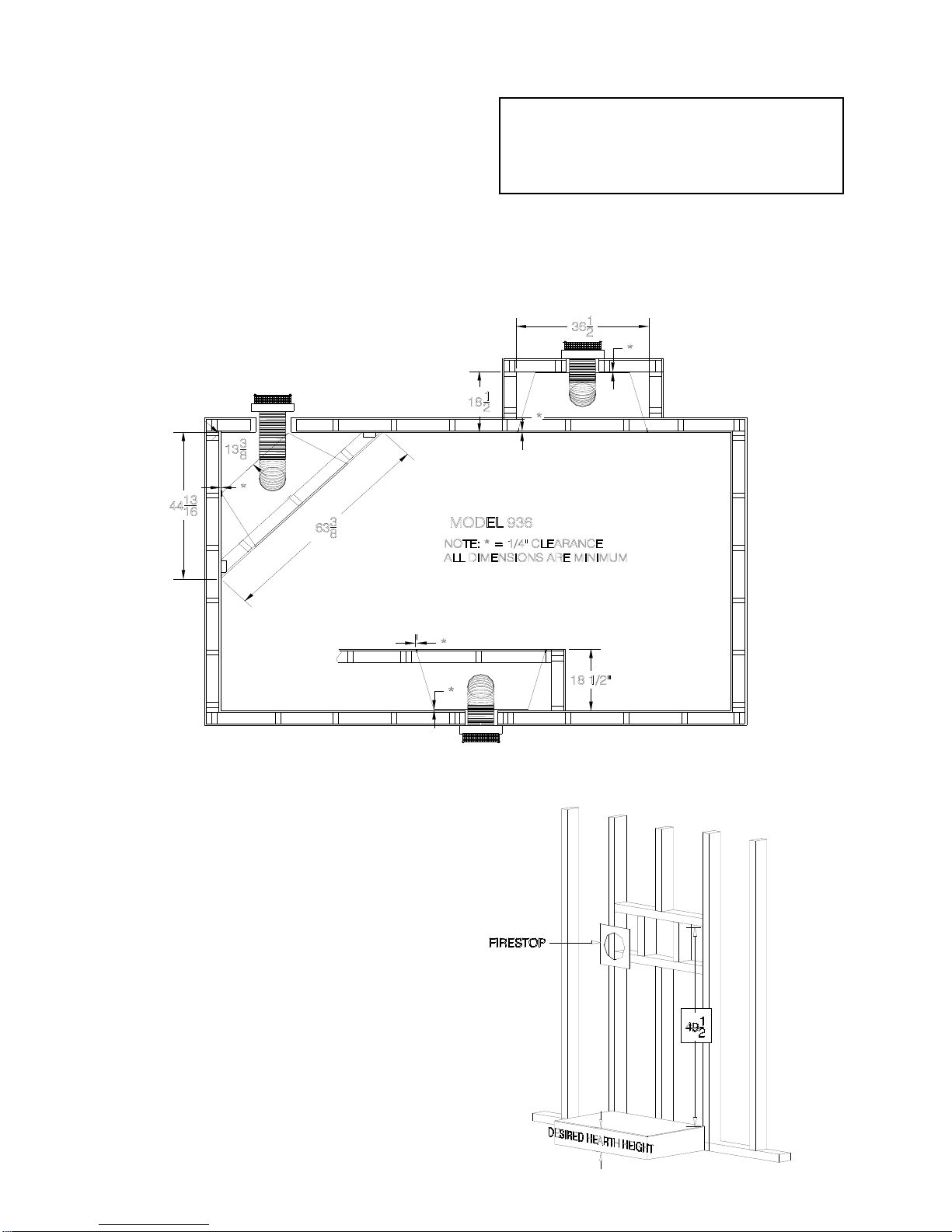

B) POSITION THE UNIT. See Figure 3.

1. Determine the exact position of your fireplace.

If possible, place the fireplace in such a manner

that the piping will be placed between two studs so

additional framing is not necessary. Determine the

width and depth of the (optional) hearth.

2. The unit may be installed on either the outside

or inside of an exterior wall. See Figure 1 for

various installation options. Follow clearance

requirements listed above.

CAUTION: COLD AIR TRANSFER AREA. THE

SURROUNDING WOOD CHASE OF THE

OUTSIDE WALL MUST BE INSULATED TO

PREVENT COLD AIR FROM ENTERING THE

ROOM.

NOTE: Due to high temperatures, this

unit should be located out of traffic areas

and away from furniture and draperies.

Figure 3

3. Cut a hole for the firestop, 9 1/2" x 9 1/2". The top

of this hole must be a minimum of 49 1/2" * above

the height of the hearth (optional). See Figure 4A.

*Important: This measurement is

determined by the vertical height and

horizontal length of the venting

application desired. The measurement

is to the top of the pipe. Please refer to

page #7 of this installation manual for

requirements and restrictions.

Fig. 4A

Page 5

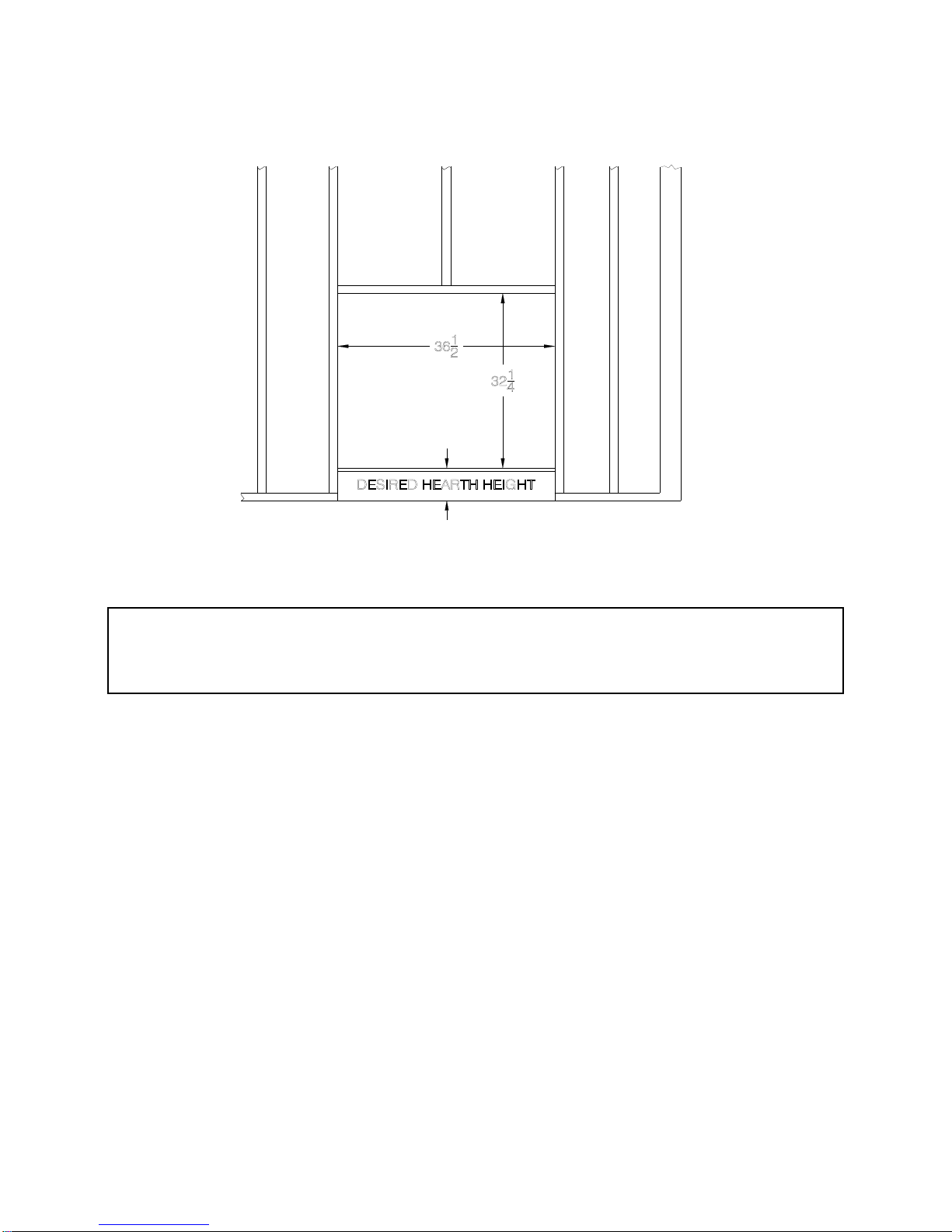

4. Rough in the wall enclosure. The minimum rough opening dimensions are 32 1/4" high,

36 1/2" wide and 18 1/2" deep. Build the hearth to the desired size, and height. See Fig. 4B.

Figure 4B

NOTE: When the unit is installed directly on carpeting, tile, or other combustible materials other than wood flooring, it

must be installed on a metal or wood panel extending the full width and depth of the unit. The minimum for the support

platform under the unit is 18 1/4" deep by 36" wide. If masonry is to be used (optional), prepare the necessary

foundation for the masonry load. When masonry construction is being used, a lintel must be used over the top of the unit

to support the added weight.

NOTE: A non-combustible hearth extension is not required. If a hearth extension is desired,

combustible materials may be used.

NOTE: Provide for a minimum of 6" of clearance in front of the lower grill. This will provide

adequate space for opening to open the lower grill and operate the controls.

Do not obstruct the upper and lower grill areas to allow proper ventilation air around the unit. Air

enters the unit at the lower grill, and exits at the upper grill. Do not block this passage.

5. Place the unit into position.

Page 6

C) VENTING REQUIREMENTS

IMPORTANT: THIS UNIT IS APPROVED FOR USE ONLY WITH THE FOLLOWING DIRECT

VENT SYSTEMS:

HORIZONTAL TERMINATIONS

#700 SERIES DIRECT VENT TERMINATION KITS:

- #745 KOZY HEAT DIRECT VENT KIT - For terminations of 4' or less.

- #718 KOZY HEAT DIRECT VENT KIT - For terminations greater than 4' but less than 8'.

- #746 KOZY HEAT DIRECT VENT EXTENSION KIT #746 - Used to extend the

#745 or #718 kit an additional 6'. Used for horizontal terminations.

VERTICAL TERMINATIONS

-SIMPSON DURA-VENT DV-GS DIRECT VENT CHIMNEY SYSTEM* ( 4” x 6 5/8”).

- Used for vertical terminations only.

- Adaptor #923-C is required to adapt the flue collars on the unit to the chimney system

- Vent runs must be in compliance as outlined below.

o

- 45

elbows only - Follow installation instructions included with the #923-C adaptor & chimney

system.

.

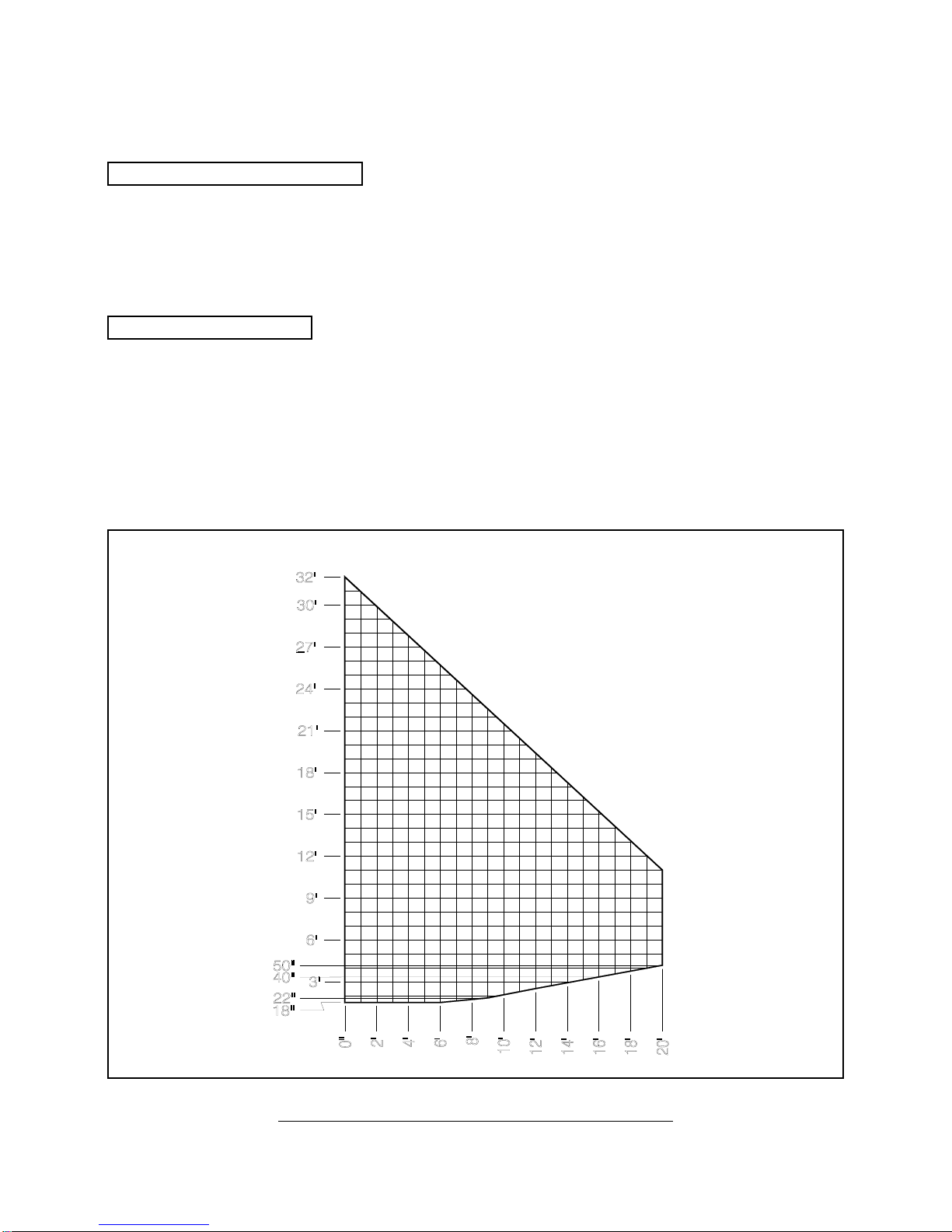

Vertical Rise

HORIZONTAL & VERTICAL VENTING CHART

HORIZONTAL VENTING REQUIREMENTS

Horizontal Run

Page 7

MINIMUM VERTICAL RISE* FROM TOP OF UNIT: 18 IN. (to top of 7” pipe)

MINIMUM HORIZONTAL RUN: 6 IN.

MAXIMUM HORIZONTAL RUN: 20 FT. (Horizontal runs must maintain 1/4” rise per ft.)

TOTAL HORIZONTAL & VERTICAL RUN MUST NOT EXCEED 32 FT.

*Miniminum vertical rise directly off the top of the unit is determined by the length of the horizontal run. Refer

to the venting diagram on page 7.

1. #700 Series vent kits must be supported every

3 ft. to maintain proper rise.

2. NOTE: IF TERMINATING AGAINST VINYL

SIDING, A VINYL SIDING PROTECTOR , INCLUDED

WITH THE #745 AND #718 DIRECT VENT KIT, MUST

BE USED. FOLLOW INSTALLATION

INSTRUCTIONS INCLUDED.

3. IMPORTANT: DO NOT RECESS

TERMINATION KIT INTO OUTSIDE BUILDING

MATERIALS - brick, stone, etc. If necessary,

extend framing so that termination kit will be

exposed once building materials are installed.

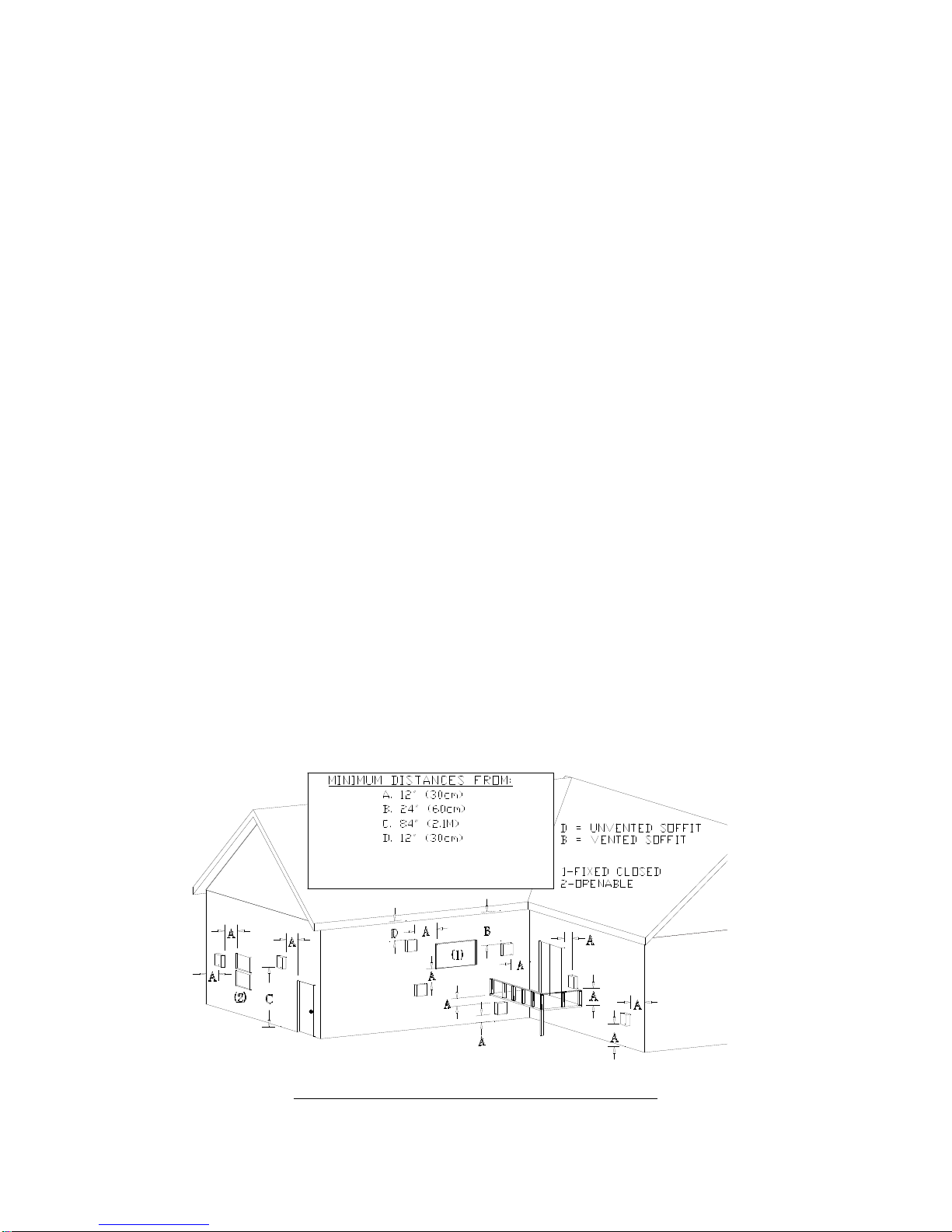

Follow Figure 5 for clearances to doors, window s

and ground level.

4. IMPORTANT: VENT TERMINATION MUST

NOT BE LOCATED WHERE IT WILL BE

BECOME PLUGGED BY SNOW OR OTHER

MATERIAL.

5. Fo r each additional elbow used after the first

elbow, you must subtract 5 ft. from the maximum

horizontal run allowed.

For example: A vertical rise of 18” directly off the top of

the unit with a 90

1/4” rise per ft.. If an additional elbow is used within this

vent run, the maximum horizontal run allowed would be

3’ ’ with 1/4” rise per ft.. (8 ft - 5 ft. (for additional elbow)

= 3 ft.

)

o

elbow would be allowed to run 8’ with

Fig. 5

VERTICAL VENTING REQUIREMENTS

Page 8

Loading...

Loading...