Kozlusan Propel 40, Propel 25 Owner's Manual

Green Energy Engineering Ltd, 198 Lurgan Road, Dromore, Craigavon, Co.Down, Northern Ireland. BT25 1HL

Tel: +44 (0) 28 38 820 043 Fax: +44 (0) 28 38 820 987 Email: info@geeltd.org

MODEL: PROPEL

BE SURE TO READ THIS MANUAL AND KEEP IT NEAR THE HEATING SYSTEM

FOR EASY REFERENCE

2 | P a g e

TABLE OF CONTENTS

Section Page

Introduction 3

Safety instructions 4

How to biomass system Works 6

Specifications 8

Installation 11

Operating the Heating system 14

Maintenance Overview 15

Troubleshooting 18

Installation Scheme 20

Electrical Scheme 22

3 | P a g e

INTRODUCTION

Congratulations on your purchase of a biomassfired heating system from KOZLUSAN HEATING

SYSTEMS.

With proper installation and maintenance, your heating system will provide years of non-polluting,

low cost heat for your home.

To insure correct installation and safe operation of your Kozlusan biomass heating system, you

should:

Hire a licensed heating contractor to install the biomass heating system and integrate it with

your heating system. This contractor should have experience with installation and operation of gas, oil,

and solid fuel heating appliances and be familiar with local building codes, fire codes and other

regulations.

Read this manual and learn how to safely operate and maintain your Kolzusan biomass heating

system.

The assembling and start up (setting) of Kozlusan biomass boiler has to be carried out by

our own customer service or by authorized qualified technicians.

Do not use any other fuels than specified below:

Ö-Norm M 7135

DIN-PLUS Norm

SWISSPELLET

Diameter: 6 mm Length: 5-30 mm (20% - 45 mm)

DD: CEN / TS 14961 : 2005

Only this way low-emission, economical and reliable operation can be guaranteed. Any disregard of

these requisites leads to immediate expiry of warranty.

The pellets must be stored in dry conditions to enable them to be transported without problems

and to achieve trouble-free operation with optimum combustion combined with the greatest possible

efficiency.

We do not assume any liability for unauthorized technical modifications, and resulting damages

are not covered by warranty.

Operational procedures or alterations of any sort, carried out by unauthorized persons, as well as

disregarding the general guidelines and the indicated safety instructions as specified here, result in

immediate termination of all warranty claims.

Please read the safety instructions below before operating the system. Disregarding the safety

instructions may lead to injuries, perilous situations or damage the pellet boiler.

4 | P a g e

SAFETY INSTRUCTIONS

The pellet heater system may only be operated be in faultless technical condition. Malfunctions

and damage which affect or could affect safety must be corrected immediately by our trained

personnel.

The assembly may only be conducted by our customer service, or by a certified specialist. The

system is equipped with rotating parts, which move with a relatively large turning movement

(crushing hazard).

Under the casing and in the terminal box there are voltaged components. Do not remove the casing

or terminal box.

Never open the inspection openings of the boiler while in continuous operation, hot exhaust gas

and dust may escape.

The system should be turned off before the implementation of maintenance work. Wait until the

pellet boiler has cooled down (check the temperature on the display).

The boiler needs to be switched off before carrying out the cleaning of the chimney. Wait until the

pellets have burned down completely (approx. 20 minutes – danger of explosion through back up of

exhaust gas.

Never pour flammable liquids into the burner.

Never perform independent repair work on our system, call trained personnel!

Put a signboard into the heating room that forbids to smoke or to use open light or fire.

A certified fire extinguisher must be installed in the boiler room.

Ensure enough air supply in the heating room.

Secure the boiler room against unauthorized access, especially by children.

Once a month, test the boiler doors and the water connections for leaks and damage.

Once a year, test the safety temperature limiter.

Safety and monitoring devices may not be removed, bypassed or taken out of service in any other

way.

5 | P a g e

Always wear a dust mask when cleaning the system and when removing ashes to avoid damages to

your health.

When setting the domestic water temperature above 60 °C, you have to ensure that the hot water is

mixed with cold water to avoid scald.

The pellet heater system may only be set up and operated in heating and plant rooms which

comply with legal requirements.

Provide an appropriate air relief valve on top of the boiler.

Annual control of safety devices by a specialist.

Regular control of expansion tank by a specialist.

Regular control of pellet feeding devices, automatic ignition devices and feeding features.

Please note that even when the system is turned off, different functions are in operation. (For

example the anti-freeze protective device; pumps and mixers are moved periodically during the night

avoid an accumulation of the storings). To ensure that no electricity runs through the system, take

off the system from electricity.

Make sure that the return temperature does not drop below 50 °C. Disregarding leads to expiry of

warranty!

6 | P a g e

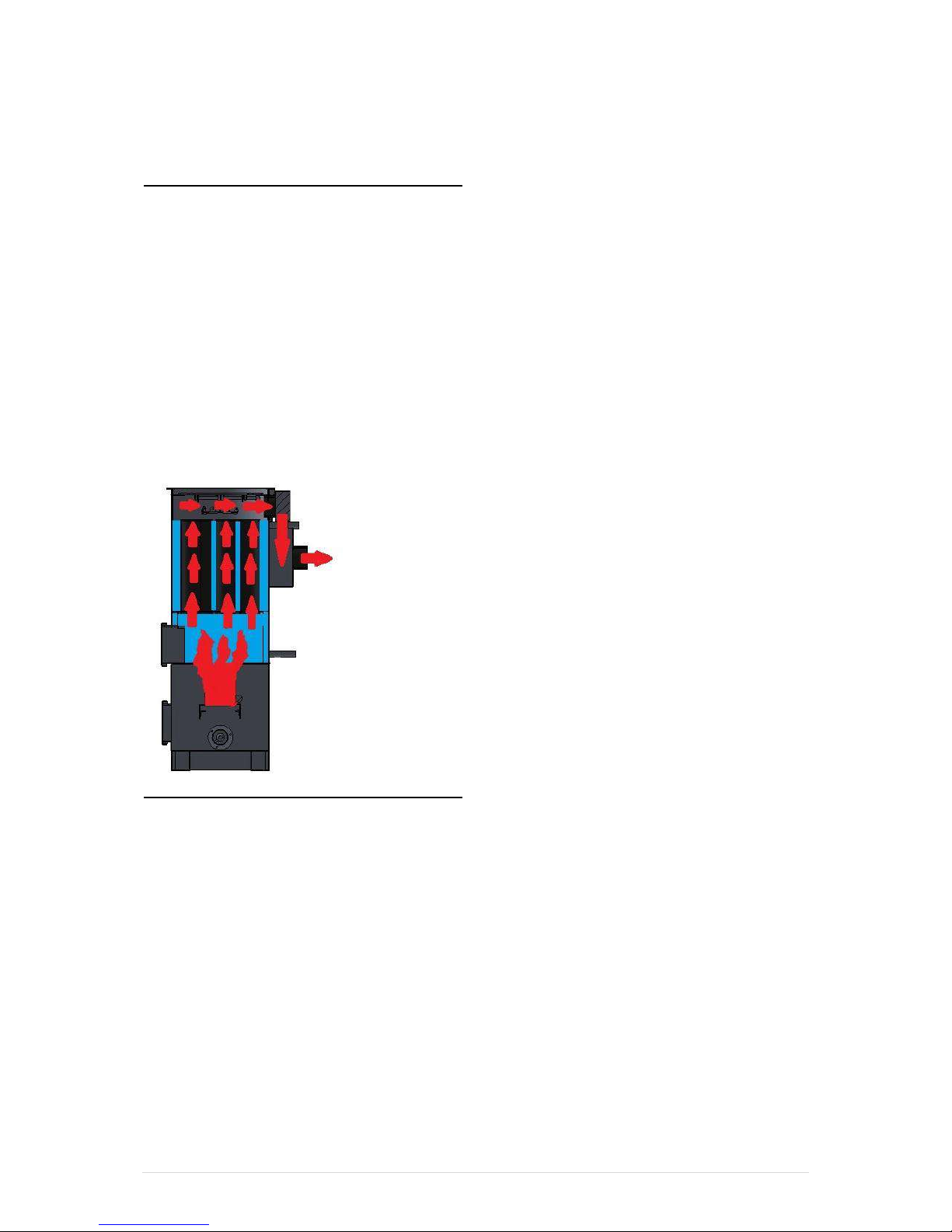

How the biomass heating system works

The Kozlusan biomass heating system produces few emissions and achieves a high level of heating

efficiency because of its unique design. The fully automated fuel delivery is „poured from top‟ into

an air fed burn pot where the fuel is self ignited before the full modulation control system controls

the burn for minimum emissions with maximum heat output.

To understand how the Kozlusan heating system works, have a to look at the flow of air, fuel

and gases through the heating system and the transfer of heat from the superheated gases to

the thermal transfer fluid. We also need to understand some of the terminology used to

describe the systems operation;

Air Flow through the Biomass heating system

1. Fuel is fed from the fuel store via an auger. The fuel is poured from the top into the cylindrical burn

pot to maintain a physical separation between the fuel store and the fuel feed. There is sucktion fan

availabe for the combustion. Various sensors measure temperature in the boiler (a thermostat that

works in water) a flue gas temperature sensor (probe in the chimney), outside temperature sensor (the

weather or room temperature) and a safety cut off temperature sensor to protect against overheating

(high limit stat).

2. As air flows through the firebox, its temperature rises to nearly 1000º C.

3. This superheated air rises upwards and then through a series of heat tubes where the heat is

transferred into the thermal fluid.

7 | P a g e

4. By the time the exhaust air reaches the flue, most of its thermal energy has been absorbed. The final

temperature of the escaping flue gas is less than 175° C.

Fluid Flow through the Heating system

1. Kozlusan heating systems recommends a mixture of water and propylene glycol as a heat transfer

fluid. Glycol is a non-toxic solution that works like the antifreeze in your car to prevent corrosion and

freezing.

2. A pump pushes fluid around the heat transfer jacket which absorbs heat from the combustion gases.

The fluid exits the internal manifold at about 80-85º C.

3. The fluid flows past an aquastat (water thermostat) that regulates the burn rate of the heating system

in conjunction with the flue gas temperature sensor that measure the temperature in the flue. This

information is used to determine the amount of air and fuel being used to ensure efficient heat transfer

and to ensure the fan does not simply blow the heat up the flue. The heated fluid is used to transfers

the heated fluid to your home system where it provides warmth to your home, garage, basement and

other structures; preheats your domestic hot water; heats your pool; and/or melts snow on your

driveway.

4. Having transferred the heat to the home system, the fluid exits the external heat exchanger and

repeats its path through the internal manifold.

8 | P a g e

SPECIFICATIONS

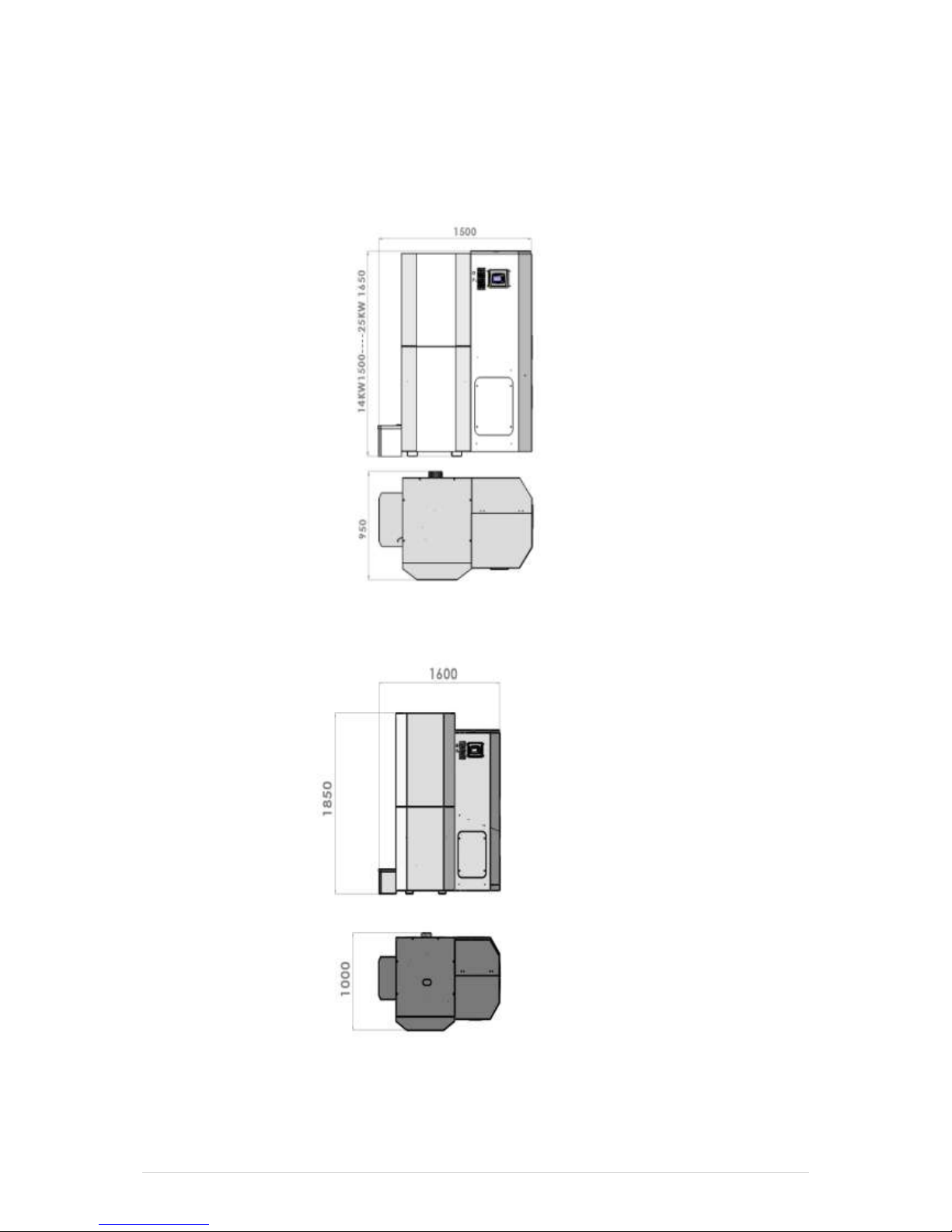

Propel-25

Propel 40

Loading...

Loading...