Page 1

Quantitative measurement equipment

A

600

for flare in the anterior chamber

Laser Flare Meter

W

KOWA FM-

EU

Page 2

INTRODUCTION

INTRODUCTION

Accept our congratulations on your purchase of Laser Flare Meter KOWA FM-600 (referred to as FM-600 in this

manual).

This manual provides a description of the operation procedures of FM-600 along with important precautions to

be observed during its use.

Please read this entire manual carefully to assure that the instrument can demonstrate its full capabilities and

be used effectively.

After you have finished reading it, please keep it in an easily accessible location near the instrument for future

reference.

INTENDED USE

FM-600 is an instrument to measure the protein level contained in aqueous humor of the anterior chamber.

Operational Considerations for Safety

This manual describes important precautions to be observed during its use to assure that the instrument can be

used safely without causing any damage to the human body and property of its purchaser and other persons.

The designations and their pictorial symbols have the following meanings. These should be fully comprehended before reading the text of this manual.

■ Meanings of Designations

WarningWarning

If the instrument should be operated wrongly, there may incur a risk of causing death or serious injury.

CautionCaution

If the instrument should be operated wrongly, there may result in a bodily injury (not so serious as to cause death)

damage to property

✽ 1: A bodily injury means an injury, burn, electrical shock and so forth that will not necessitate hospitalization or long-

term outpatient treatment.

✽ 2: Damage to property means an extensive damage to the house and household goods as well as the domestic animal

and pet.

■ Meanings of Symbols

Graphical indication of any danger (including warning and caution). What is warned is explicitly and

pictorially indicated by a picture or its associated message on or near a pictorial symbol.

Graphical indication of prohibited operation (prohibitive item). What is prohibited is explicitly and pictorially indicated by a picture or its associated message on or near a pictorial symbol.

Graphical indication of mandatory action (obligatory item). What must always be done is explicitly and

pictorially indicated by a picture or its associated message on or near a pictorial symbol.

✽ 2

.

✽ 1

or

■ Kowa is not responsible for;

• Any damage caused by fire, earthquake, third party’s action, any other accident or user’s intentional or

unintentional error, abuse or use under abnormal conditions;

• Any damage resulting from use of the product or its malfunction (e.g. operating loss, shutdown, change/

loss of stored data and so forth).

• Any damage resulting from disobedience of what is described in the instruction manual.

• Any damage resulting from, for instance, malfunctioning of instrument caused by a combination of connected devices.

1

Page 3

Unplug

Unplug

Obligatory

Obligatory

Obligatory

Warning

Prohibitory

Disassembly

prohibited

WarningWarning

If any abnormal smell or sound, or overheating or smoke should be detected, be sure to turn OFF the

main power immediately and then unplug the instrument from the power outlet. Continued use of the

instrument may cause the instrument to malfunction or cause a fire.

Contact your Kowa dealer where you have purchased the instrument or your nearest repair shop for inspection.

When replacing the fuse, be sure to turn OFF the main power and unplug the instrument from the

power outlet.

Warning

/ High-Voltage

Removing the fuse holder cover without unplugging the instrument may cause electrical shock.

Be sure to plug into the power outlet completely and securely.

Doing otherwise may cause a fire or electrical shock.

Use only a specified fuse.

Doing otherwise may cause a device failure or fire.

Be sure to ground the instrument properly and securely in order to avoid bodily injury. Be sure to

connect the plug in the three-wire grounding type socket. Doing otherwise may cause electrical shock.

Be sure that the tips of instrument are not in contact with the eye and the nose of the patient when in

operation.

(The patient may be injured.)

Do not place a cup or a glass containing liquid or the like on or near the instrument.

Spilling liquid into the instrument may cause electrical shock. If liquid should be spilled into the instrument, turn OFF the main power, and unplug the instrument from the power outlet. Contact your Kowa

dealer where you have purchased the instrument or your nearest repair shop for inspection.

Do not disassemble, modify or repair the instrument yourself. Doing so may cause a fire, electrical

shock, instrument malfunctioning or bodily injury.

Contact your Kowa dealer where you purchased the instrument for repair. The product assembled by

yourself will not be covered under warranty nor any other service.

Prohibitory

Obligatory

Prohibitory

Prohibitory

Prohibitory

Prohibitory

Do not load the socket or plug board with excess of its rated capacity.

If the main power cord should share a power outlet with other devices and the rated capacity is exceeded, there may cause a fire or electrical shock.

CautionCaution

The power supply must be provided for the sole use of this instrument.

Sharing one and the same power supply with other devices may cause FM-600 to malfunction.

Do not pull the electrical cord when unplugging.

Doing so may damage the cord and cause a fire or electrical shock. Be sure to hold the plug when

unplugging the instrument.

Do not plug or unplug the power cord with wet hand.

Doing so may cause electrical shock.

Do not install the power unit at unstable location such as on a shaky base or a tilting surface.

Doing so may cause the instrument to drop or fall over and result in a bodily injury.

Do not wipe the exterior of the instrument with solvent such as benzene, alcohol, thinner and ether.

Doing so may cause discoloration or degradation.

If the instrument is not to be in use for a long period of time, unplug the power cable.

Unplug

Leaving the power cable plugged may cause a fire.

2

Page 4

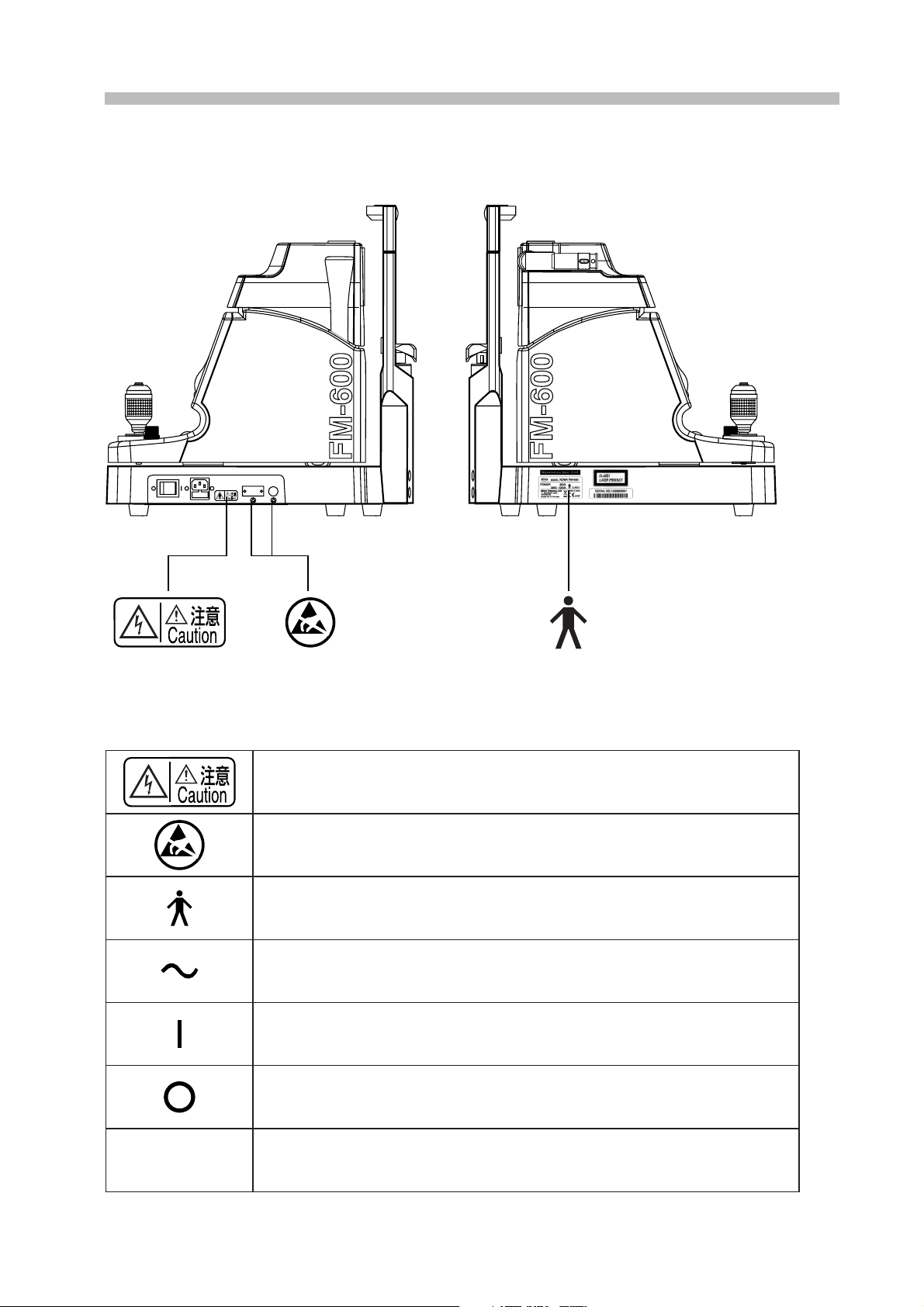

Location of Cautionary Marking

Description of Labels and Symbols

Before replacing fuse, be sure to turn OFF the main power and unplug the instrument.

Removing the fuse holder cover without unplugging the instrument may cause electrical

shock.

Do not touch directly the connector pins that are labeled with the symbols shown in the left.

❇ For details, please refer to p.36 [About electromagnetic compatibility (EMC)].

Type B applied parts (degree of protection of applied part against electric shock).

Alternative Current

ON

OFF

CLASS 1

LASER PRODUCT

Laser Class based on IEC60825-1:2001

3

Page 5

Precautions Concerning Use

• Handle the instrument with care, and do not apply strong shock to it.

Also, do not leave any objects on the instrument.

• Always cover the system when not in use in order to protect its components.

• Avoid high temperature and humidity, direct

sunlight, and dust when shipping, installing, and

storing the instrument. Strictly observe the following environmental conditions. When in use,

in storage or in transit, environmental conditions

described below must be observed strictly in order to protect the instrument from condensation.

In operation

Ambient Temperature

Relative Humidity

Precautions Concerning Use of Electrical System

• If the instrument is not to be in use for a long

period of time, turn OFF the main power and

unplug the instrument.

• Install the system in a location where there is

little risk of the plug being pulled out. If the plug

should be pulled out accidentally, be sure to turn

OFF the main power before plugging the system

back in.

• The manufacturer is not liable for malfunctions

and/or damages resulting from maintenance

and/or repairs performed by persons other than

the specified repair service.

10 - 40 °C -15 - +50 °C

30 - 60 % 10 - 95 %

Transportation, storage

• The manufacturer is not liable for malfunctions

and/or damages resulting from maintenance

and/or repairs using parts other than specified

repair parts.

• The input voltage should always be maintained

within ±10% of the rated voltage.

• Do not turn the main power on and off in succession. Allow an interval of at least 5 seconds before turning the main power on and off.

• Be sure to turn OFF the main power before plugging or unplugging the system.

Precautions Concerning Disposal of the

Instrument

• The liquid crystal display of this instrument contains mercury.

When disposing of this instrument, comply with

the regulations of countries or areas in which

the instrument is used.

Other Precautions

• Never disassemble or adjust this instrument by

yourself since it uses precision parts which requires special tool for doing so.

• It is recommended that this instrument be used

where ambient illumination is evenly distributed

at 100 lx or less (400 lx or less when using an

optional light shielding cover).

• Take the history of the patient’s medical history;

once it is confirmed that there will not be a problem with using mydriatic agent, administer mydriatic drops to him/her regardless of the

level of ambient illumination.

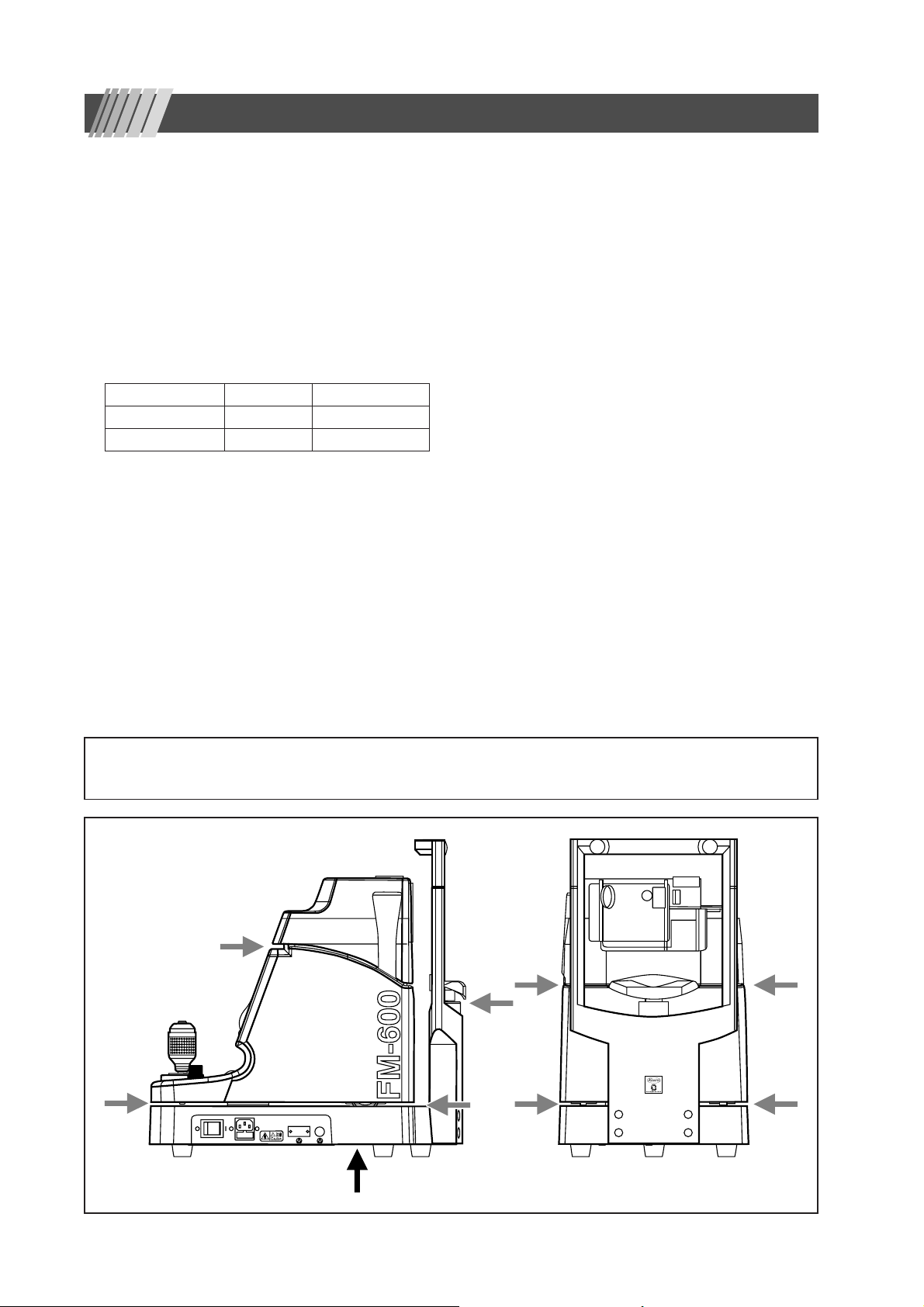

◆ Precautions during Operation

• Use special caution when operating the instrument to avoid hands being caught in the areas indicated with

arrows in the illustration below.

• There is an air vent on the bottom surface of the instrument. When installing the instrument, do not obstruct the vent.

Air vent

4

Page 6

Precautions (Safety Precautions and Hazard prevention) Concerning Use of Medical Electrical Instrument

1. Instrument should be operated only by qualified personnel.

2. The following precautions must be observed when installing the instrument:

(1) Install at a location free of moisture.

(2) Install at a location where there is no risk of detrimental effects caused by atmospheric pressure, temperature,

humidity, ventilation, sunlight, dust, salt, or air containing sulfur and so forth.

(3) Install the instrument in a stable manner, avoiding inclines, vibrations and shock (including those during transport).

(4) Do not install in locations where chemicals or pharmaceuticals are stored or where there is generation of gas.

(5) Use the proper power supply, frequency, voltage and allowable current values (or power).

(6) Check the status of battery-operated power supplies (degree of discharge, polarity, etc.).

(7) Be sure that the instrument is properly grounded.

3. The following precautions must be observed before using the instrument:

(1) The instrument must be inspected for switch contact, polarity, dial settings and meter readings to confirm its proper

operation.

(2) Be sure that the instrument is properly grounded.

(3) Be sure that all cords are connected properly and securely.

(4) Avoid combined use of instruments since this can lead to inaccurate diagnosis and hazards.

(5) Re-inspect any external circuits that come in direct contact with patients.

(6) Check all battery-operated power supplies if applicable.

4. The following precautions must be observed while using the instrument:

(1) Do not exceed the time and quantity required for diagnosis and treatment.

(2) Continuously monitor the instrument for any abnormalities as well as the condition of the patient.

(3) When an abnormality is noticed in the instrument or the patient, take appropriate measures, such as to terminating

operation of the instrument while ensuring the safety of the patient.

(4) Do not allow the patient to touch the instrument.

5. The following precautions must be observed following use of the instrument:

(1) Follow the specified procedures to return all operating switches, dials and other components to their positions prior

to use; then turn OFF the main power.

(2) When disconnecting cords, hold the plug body firmly so as not to apply excessive force to the cord itself.

(3) The following items must be observed with respect to the location where the instrument is stored.

(a) Store in a location free from moisture.

(b) Store in a location where there is no risk of detrimental effects caused by atmospheric pressure, temperature,

humidity, ventilation, sunlight, dust, salt, or air containing sulfur and so forth.

(c) Store in a stable manner while paying attention to inclines, vibrations and shock (including those during trans-

port).

(d) Do not store in locations where chemicals or pharmaceuticals are stored or where there is generation of gas.

(4) Store all accessories, cords, leads and other components in an organized manner after cleaning.

(5) Be sure to clean the instrument so that it functions properly the next time it is used.

6. If the instrument should malfunction, the operator should not attempt to correct the problem. Appropriately indicate that the instrument is not operating properly and await repairs by qualified personnel.

7. Never attempt to disassemble or modify the instrument.

8. Maintenance and inspection

(1) All instrument and components should be inspected regularly.

(2) When resuming use of instrument that has not been used for a long period of time, always confirm that the instru-

ment operates properly and safely before use.

9. Beware that strong electromagnetic waves may cause the instrument to operate incorrectly.

This instrument has been tested based on JIS T0601-1-2:2002 and IEC60601-1-2:2001. The purpose of these

standards is to maintain safety against the dangerous obstacle in typical medical facilities.

However, the instrument may affect or be affected by certain equipment such as cellular phones and pace

makers.

In case this instrument is influenced by other equipment, or it affects other equipment, or there is such fear,

relocate and/or increase the distance between FM-600 and affecting equipment.

Should there be any further questions and/or unknown points, please consult your Kowa sales representative

or dealership beforehand.

5

Page 7

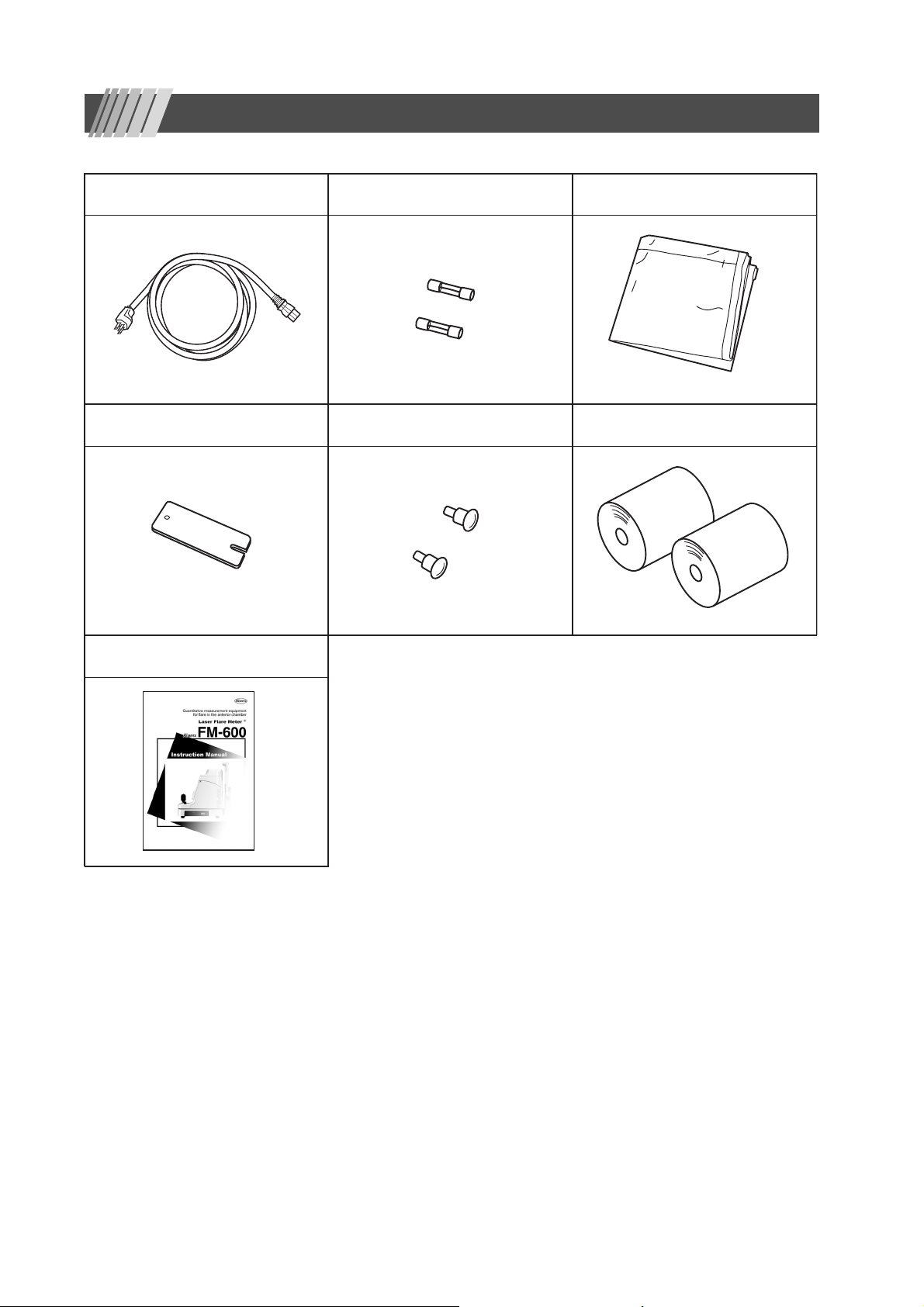

Accessories

Power cable (1) Fuse (2) Dust cover (1)

Chin-rest paper (1)

Instruction Manual (1)

Chin-rest’s pin

(2) Printer paper (2)

6

Page 8

Table of Contents

Introduction ................................................................................................................................ 1

Precautions Concerning Use .................................................................................................... 4

Precautions (Safety Precautions and Hazard Prevention)

Concerning Use of Medical Electrical Instrument .................................................................. 5

Accessories ................................................................................................................................ 6

Table of Contents ....................................................................................................................... 7

1. Principle of operation ......................................................................................................... 9

2. Names and functions of components ............................................................................. 10

2-1 Names and functions of components ......................................................................................................... 10

2-2 Screen display details ................................................................................................................................ 13

3. Setting up .......................................................................................................................... 15

3-1 Installation .................................................................................................................................................. 15

3-2 Printer paper installation ............................................................................................................................ 15

4. Basic aligning procedure ................................................................................................. 16

4-1 Coarse lengthwise / crosswise adjustment ................................................................................................ 16

4-2 Fine lengthwise / crosswise adjustment ..................................................................................................... 16

4-3 Measurement switch .................................................................................................................................. 16

4-4 Frontal view switch ..................................................................................................................................... 16

5. Calibration ......................................................................................................................... 17

5-1 Calibration .................................................................................................................................................. 17

5-2 Light shielding cover .................................................................................................................................. 18

6. Procedure for measurements .......................................................................................... 19

6-1 Procedure for measurements: Overview .................................................................................................... 19

6-2 Ocular height adjustment ........................................................................................................................... 19

6-3 Frontal view alignment ............................................................................................................................... 19

6-4 Diagonal view alignment ............................................................................................................................ 20

6-5 BG check ................................................................................................................................................... 21

6-6 Measurement ............................................................................................................................................. 21

6-7 Displaying measurement results ................................................................................................................ 22

6-8 Viewing and editing acquired data ............................................................................................................. 23

7

Page 9

Table of Contents

7. Tips for measurements .................................................................................................... 24

7-1 How to block laser beams .......................................................................................................................... 24

7-2 Warning beep during BG check ................................................................................................................. 24

7-3 Recommended procedure when BG check obtains no correct alignment ................................................. 24

7-4 Recommended procedures when BG check obtains no good result ......................................................... 24

7-5 Recommended procedures when measured waveforms are offset to left or right ..................................... 25

8. Configuration and settings .............................................................................................. 26

9. Miscellaneous ................................................................................................................... 28

9-1 ID input ....................................................................................................................................................... 28

9-2 Connecting external devices ...................................................................................................................... 28

9-3 Display messages ...................................................................................................................................... 30

9-4 Function switches ...................................................................................................................................... 31

9-5 Relocation .................................................................................................................................................. 31

10. Troubleshooting ................................................................................................................ 32

10-1 Phenomena and validation ........................................................................................................................ 32

10-2 Error messages.......................................................................................................................................... 32

11. Maintenance/Inspection ................................................................................................... 33

11-1 Daily maintenance ..................................................................................................................................... 33

11-2 Daily inspection (by the user)..................................................................................................................... 33

11-3 Fuse replacement ...................................................................................................................................... 34

11-4 Chin-rest paper installation ........................................................................................................................ 34

11-5 Sterilization of Forehead stopper and Chin-rest ........................................................................................ 34

11-6 Refilling and replacing consumables ......................................................................................................... 34

11-7 Regular inspection (by the device supplier) ............................................................................................... 34

11-8 Repairing.................................................................................................................................................... 34

12. Specifications ................................................................................................................... 35

12-1 Specifications ............................................................................................................................................. 35

12-2 Applicable safety standards and Classification .......................................................................................... 35

13. Electromagnetic Compatibility ........................................................................................ 36

14. Photochemical Hazard (ISO 15004:1997)........................................................................ 39

8

Page 10

1. Principle of operation

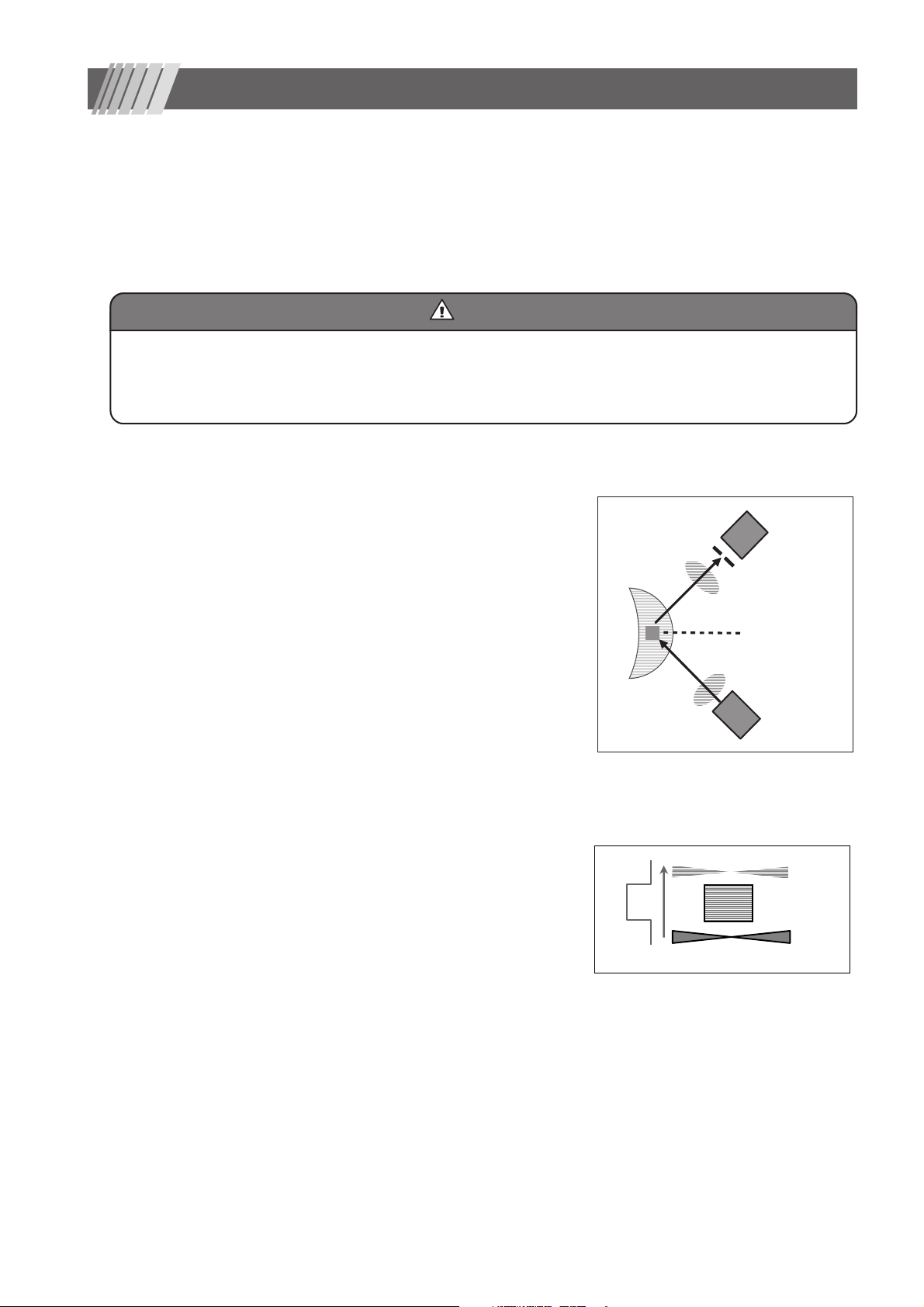

Weak scattered light induced by laser beam entered into the anterior chamber is detected and used for measurements.

It is known that intensity of the scattered light is proportional to the protein level contained in aqueous humor of the anterior

chamber. However, intensity of the scattered light may vary if there is a difference in the protein composition between aqueous

humor samples at the same protein concentration.

We refer to this scattered light intensity as “flare value" and indicates the value using photon count per millisecond in this device.

✽ Photon count is the number of pulses output from photomultiplier when scattered light is detected. This value may be converted

into an albumin level. Bovine albumin solution at 100mg/dl equals to 13 Photon counts per millisecond.

CautionCaution

Note that some factors including circadian rhythm, age, mydriasis, and drug may affect flare values. Measurement must be taken

carefully taking any of these factor in account. The accuracy of the reading may be affected by disorders shown below:

✽ Intensive lens clouding, corneal edema, corneal opacity, the anterior chamber with an artificial lens implanted, shallow anterior

chamber, and achromatic eye.

■ Details ■

Measurements

Optical system is composed of a laser beam emitter and a photoreceiver

positioned at a orthogonal to the axis of the beam. The scanning laser beam

emitted through a condensing lens is focused at the anterior chamber or

target point. Scattered light from the anterior chamber goes through a

photoreceiver lens and comes into a focus at a photoreceiver mask. The

photoreceiver mask has an important role to create a reading window within

aqueous humor of the anterior chamber. Scattered light coming through the

mask reach to a photoreceiver element (or a photomultiplier tube) where it

undergoes a photo-electro conversion process. Then, the collected data is

analyzed at the analyzer unit to determine a flare value. Results are shown

in the display.

Anterior

chamber

Photoreceiver

element

Photoreceiver

mask

Photoreceiver lens

Measurement

window

Condensing lens

Scanning laser

Details of flare reading

An area including the Measurement window is scanned with laser beam. As

a result, a waveform shown in Fig. 1-2 is obtained. Background Signal 1

(BG1) obtained when laser beam is located below the a Measurement window and Background Signal 2 (BG2) obtained when laser beam is located

above the a Measurement window are scattered light noise from intraocular

tissue, while Flare Signal (SIG) is a sum of scattered light from protein and

scattered light noise from intraocular tissue.

Therefore, intensity of the scattered light caused by the protein concentration

in aqueous humor of the anterior chamber is calculated using the formula:

SIG - (BG1 + BG2)/2.

A result obtained using this formula is called “flare value” and represented

as photon count per millisecond.

Figure 1-1

BG2

SIG

BG1

Figure 1-2

Measurement

window

Laser scanning light

9

Page 11

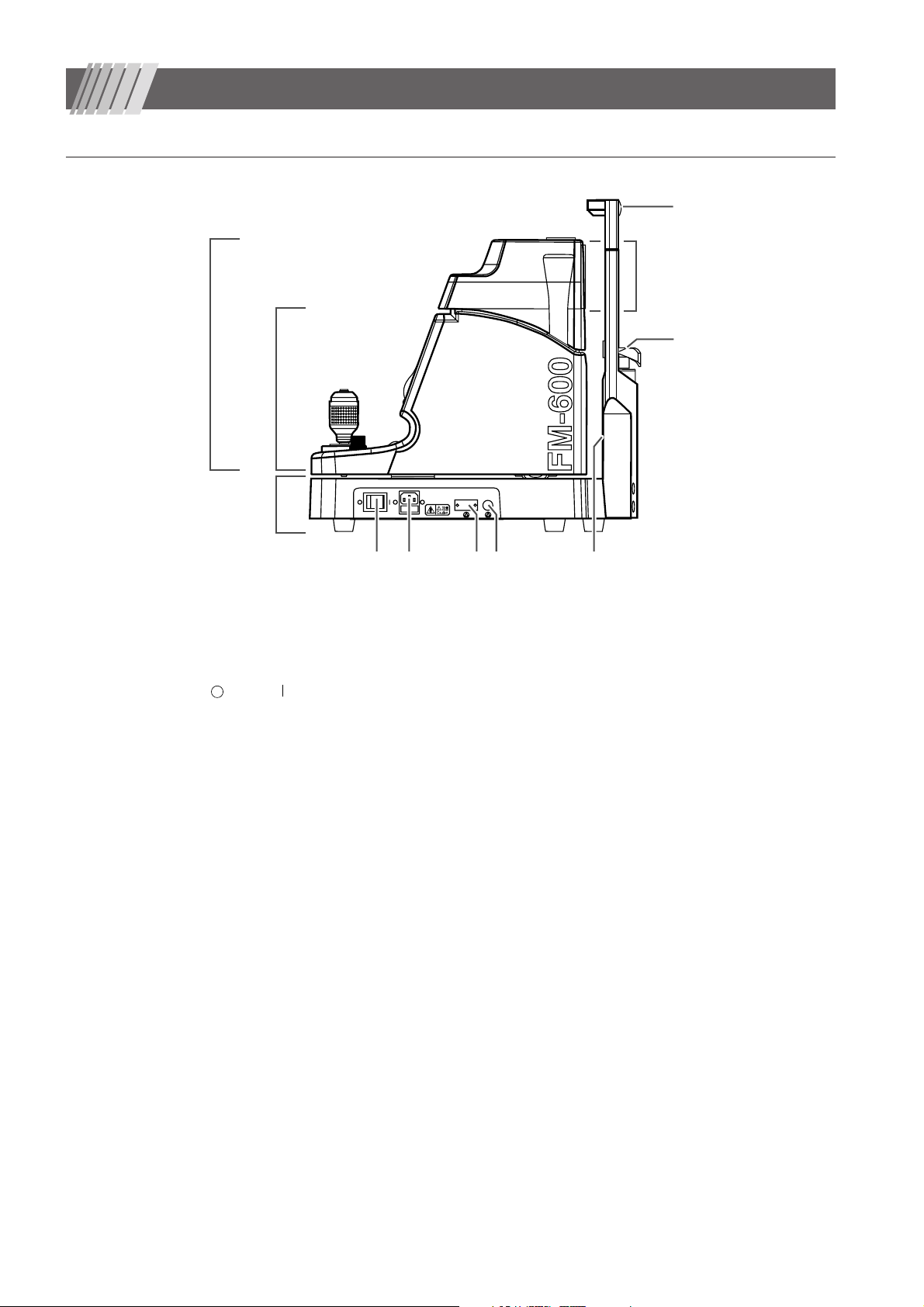

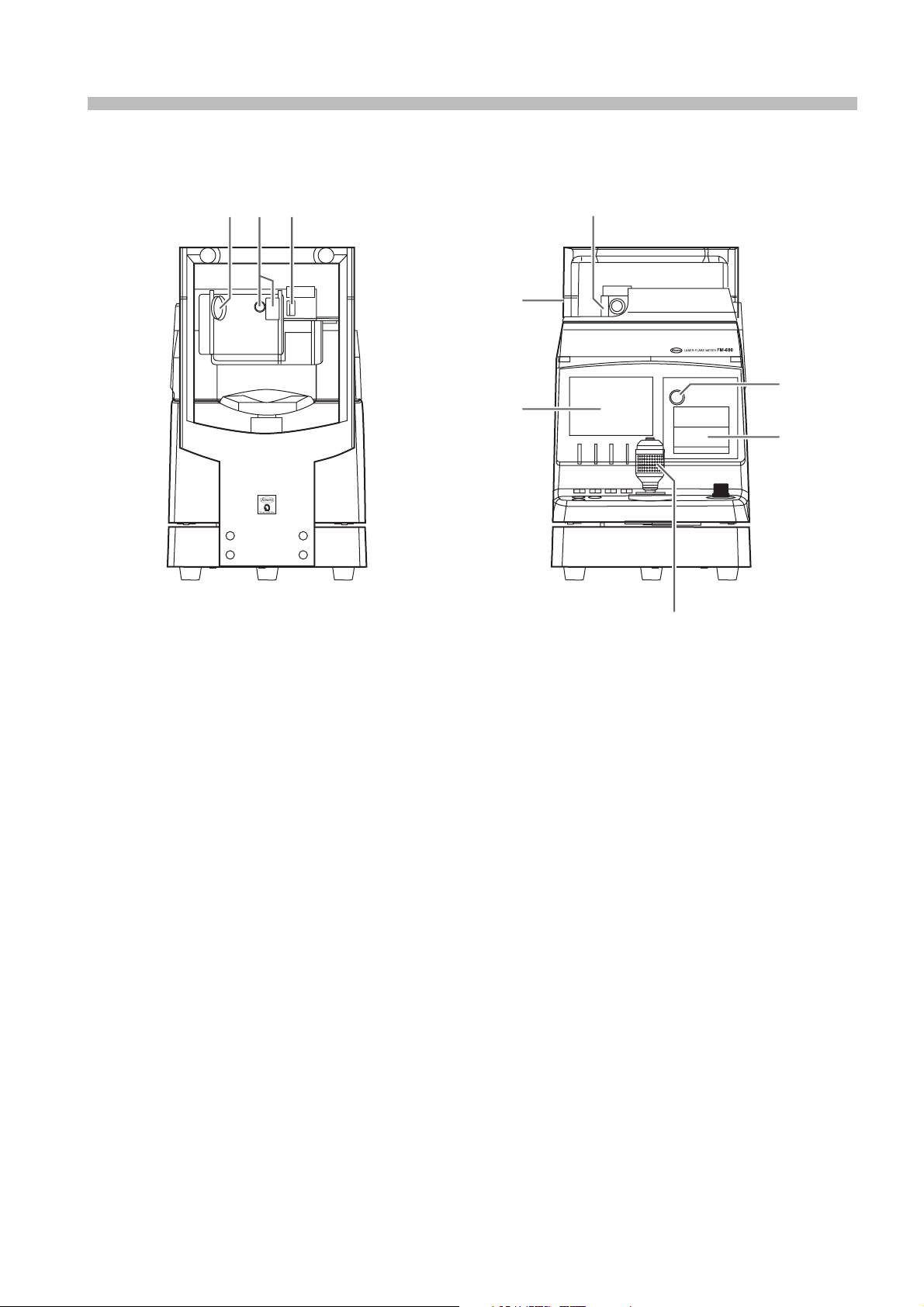

2. Names and functions of components

■

2-1 Names and functions of components

7

Measurement unit

Main unit

Operating

unit

Power supply unit

1 Power switch

: OFF : ON

2 Power supply inlet

Where a power supply cord is connected.

A fuse holder is provided.

3 External device I/O terminal (for a communication cable)

Used for connecting a PC to which measurement data outputs are transmitted.

4 External device I/O terminal (for a ten key pad)

Used for connecting a ten key pad.

5 Chin-rest illumination

Used for illuminating indirectly the patient’s eyes from a lower level than the eyes

(used in dark room).

6 Chin-rest

Used for holding patient's chin on it. A sheet of chin-rest paper may be attached.

7 Forehead rest

Used for holding patient's forehead.

The screw holes on the top are used for installing a light shade (optional

accessory) .

6

12 34 5

10

Page 12

2. Names and functions of components

89 0 A

F

E

C

B

D

8 Photoreceiver lens

The lens that mainly receives scattered light.

9 Front camera and Eye fixation lamp window

Used for monitoring a patient’s eye. The patient may see the eye fixation lamp inside.

0 Light emitting lens

Used for emitting laser beam and alignment light.

A Calibrator

Used for calibrating the device.

This may be used as a laser beam attenuator when located in between a measuring

position and a calibrating position.

B Printer

Used for printing the results obtained.

C Printer lid button

The printer lid opens when the round dimple is pushed.

Used for replacing printer paper.

D Joy stick (rubber ring)

Hold and move this joy stick to move the Main unit lengthwise or crosswise for a

longer distance.

Tilt this joy stick to move the Main unit lengthwise or crosswise for a shorter

distance.

Turn the rubber ring to ascend or descend the Measurement unit.

E Display

Used for displaying Images for monitoring and obtained measurement results.

Also used for displaying each function.

F Eye level mark

This mark is a suitable position of the patient’s eye on measurement.

11

Page 13

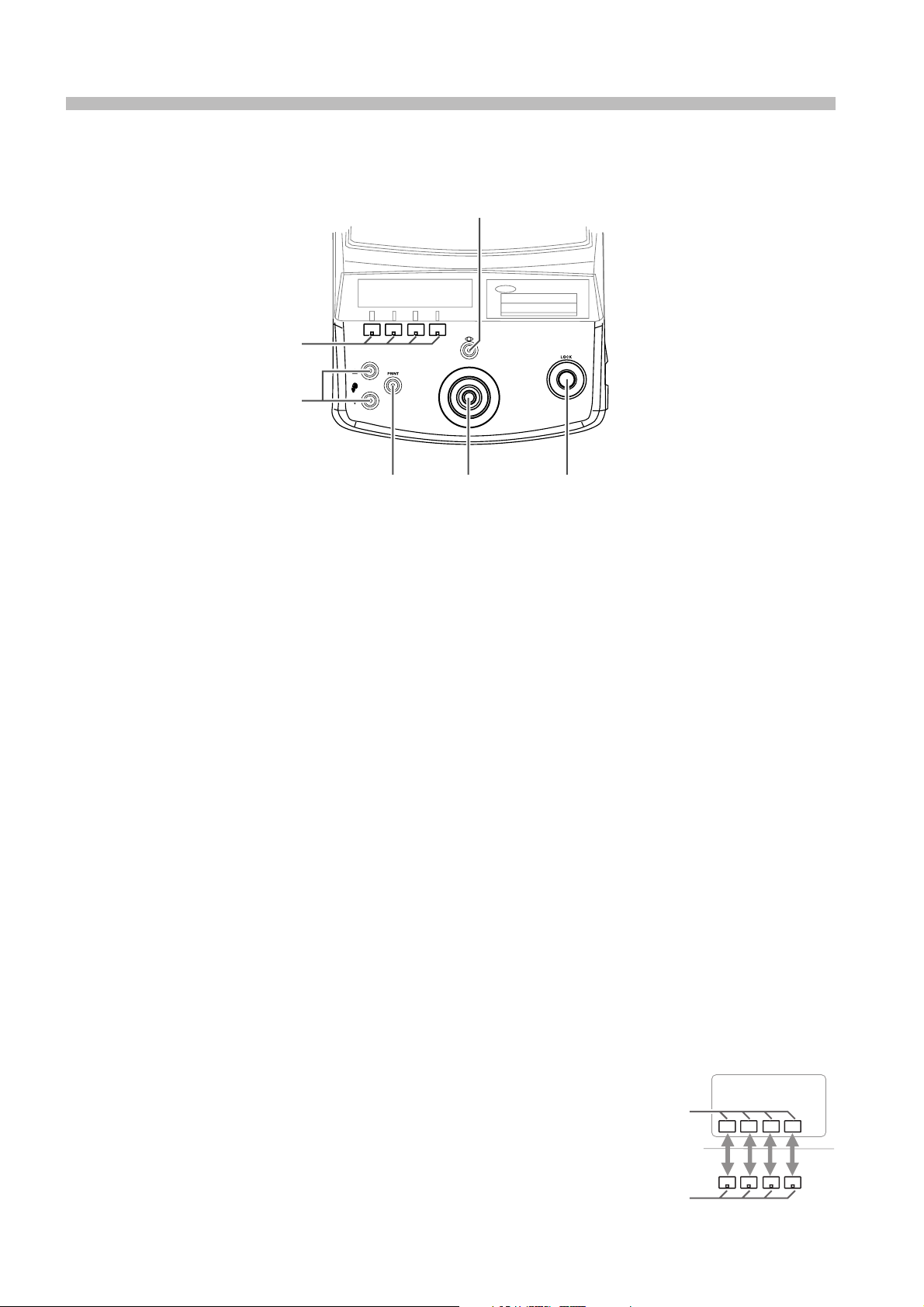

2. Names and functions of components

K

J

L

GHI

G Self-locking screw

Tightening this screw lock the Main unit.

H Measurement switch

Pushing this switch proceeds with Frontal view alignment screen ➔ Diagonal alignment screen ( BG check ) ➔ Start measurement.

I Print switch

Pushing this switch allows contents in the display to be printed or output (only when

light is lit).

J Chin-rest ascending/descending switch

Used for ascending and descending Chin-rest.

K Function switches

✽

Operates as they are assigned in accordance with each screen.

L Switches for frontal view

Pushing this switch switches the current display screen to Frontal view alignment

screen (only when the light is ).

✽

Function switches

Functions assigned to the [Function Switch Display Area]

(refer to Page 13) may vary depending on the screen you

have chosen. Each of functions shown in each screen is

selected and executed by pushing the corresponding function switch. In this manual, “select [xxx]” means pushing

the corresponding function switch.

Display

Function switch display area

Operating segment

function swiches

12

Page 14

■

2-2 Screen display details

Detail of each screen display

■ Frontal view alignment screen ■

Previous data

2. Names and functions of components

Flare value

Additional

information

Number of data saved

FLARE: 9. 5

WA: C

N: 5

Function switch display area

ID:1234567890

L

List

To change the summary data screen

Patient ID

R: Right eye

L: Left eye

Alignment mark

Corneal reflection

luminous dot

(image)

■ Diagonal alignment screen ■

Alignment mark

(for Spot light)

Measurement window

FLARE: 9. 5

WA: C

N: 5

ID:1234567890

L

ListStop

To change the summary data screenTo stop laser scanning

Pupil guide

(indicates the minimum

pupil diameter)

Alignment mark

(for laser beam)

BG level

13

Page 15

2. Names and functions of components

■ Measurements graph screen ■

BG1 SIG BG2

BG deviation =

I BG1 - BG2 I

BG1 + BG2

Background Signal 1

X 100

Obtained waveform

Background Signal 2

Flare Signal

Flare Value

= SIG - ( BG1 + BG2 ) /2

■ Summary data screen ■

Measurement No. BG average Flare value

BG1:12

BG2:10 (9%)

SIG:20

FLARE : 9

Del Scale

To save no data To change vertical scale for waveform

BG deviation

N:3

BG

S/N CELL

List

Warning

Reliability may be poor when any of the following warning

codes appears.

Warning code :Description

BG or B :Deviation between BG1 and BG2 > 15%

S / N or S :BG > Flare

CELL or C :Cell contamination

F :False data

T :Outlier candidate data

Number of data saved

Flare value average

Flare value standard deviation

To continue the ongoing

measurements using

the same eye

14

FLARE W/ANBG (%)

1 1.3 7 5.3

2 1.0 1 6.1

3 1.2 0 5.7

4 0.7 2 4.7

5 0.7 2 4.3

AV. :5.2

SD. :0.8

Cont. Edit Stat End

To edit

summary data

Statistic evaluation

for summary data

(throw out) is done

B

S

Measurements using

the same eye is completed

Page 16

3. Setting up

■

3-1 Installation

Fig. 1

Make sure that

POWER Switch is off.

■

3-2 Printer paper installation

Fig. 2 Printer lid button

Place the device on a motorized table (optional accessory).

Make sure that POWER Switch shown in Fig. 1 is at OFF position (O).

Connect the power cable to the power supply inlet and connect the other end of the

cable to a nearby wall outlet.

The printer lid opens when the round dimple “Printer lid button” is pushed.

Install a printer paper as shown in Fig. 2 and close the lid.

WarningWarning

Connect a ground cable securely to avoid injury. Connect the power supply cable to a

grounding receptacle for a triplex cable.

Fig. 3

Error 5

(Printer)

Please check printer paper. If paper is remaining.

Call a service Person.

Set

When no printer paper is installed or Printer switch is pressed while the lid is kept open,

“Please check printer paper. If paper is remaining. Call a service Person.” (see Fig. 3)

is displayed.

Make sure there is a printer paper and the lid is closed and push “Set”.

If the same message appears continuously, call a service person.

✽

This message does not appear when output mode is set to EXT. See “8.Con-

figuration and settings” for details.

✽

15

Page 17

4. Basic aligning procedure

Explanation how to operete.

■

4-1 Coarse lengthwise / crosswise adjustment

Fig. 1

■

4-2 Fine lengthwise / crosswise adjustment

Fig. 2

To move the Main unit lengthwise or crosswise for a longer distance, hold and move

the joy stick steadily (Fig. 1).

To move the Main unit lengthwise or crosswise for a shorter distance, lightly hold the

joy stick end with your finger tips and tilt the joy stick (Fig. 1).

Turn the rubber ring to ascend or descend the Measurement unit (Fig. 2).

■

4-3 Measurement switch

Fig. 3

■

4-4 Frontal view switch

Fig. 4

Use this switch to change from coarse adjustment (Frontal view alignment screen) to fine adjustment (Diagonal alignment screen) or start a Measurement (Fig. 3).

Use this switch to change from fine adjustment (Diagonal alignment screen) to coarse

adjustment (Frontal view alignment screen) or return to fine adjustment (Diagonal

alignment screen) from post-measurement (Measurements graph screen) (Fig. 4).

CautionCaution

Assure that the patient’s eye or nose does not contact with the device during this procedure.

CautionCaution

When handling the Main unit, try not to place your hand between the Main unit and the Power Supply unit or the chin-rest post and

the Forehead Rest, or into the space underneath the chin-rest.

16

Page 18

5. Calibration

CautionCaution

Stained lens may affect measurements.

It is recommended to calibrate regularly in order to obtain accurate measurements.

A message will appear during device start-up if the device had no calibration done for more than a month. Calibrate the device as

soon as possible when the message appears.

Follow the calibration procedure described below.

It is recommended to calibrate the device in a dark room.Use a light shade (optional) when calibrating in a well-lighted room.

■

5-1 Calibration

Fig. 1

Fig. 2

1 While Frontal view alignment screen is displayed, turn Calibrator to

CALIBRATION position.

If the display shows “LD Temp check Please wait”, wait until the message disappears.

If the display shows “Laser Attenuating …”, turn Calibrator until the message shown

in Fig. 3 appears in the display.

If the display shows “The acquired data is deleted. Is a calibration carried out ?”

indicating there is acquired data, select “Yes” to proceed to the calibration.

2 Slide the protective cap aside to expose the window (Fig. 2).

Caution: Do not stain the glass surface located deep inside the calibrator.

Fig. 3

Calibration

Step 1

Open the Cali. Tool the Cover

Calibration START ?

Yes No

Fig. 4

Calibration

Step 2

Input Calibration Value

Please Press "Set" After Input

2 4 0 . 0

Set

3 When “OK” is selected in the screen shown Fig. 3, “Calibration Tool's

Value” input screen appears.

4 Input the number shown in the label attached to the calibrator with

using “ ” “ ” “ ” ✽.

After this input, select “Set” to start calibration.

Calibration is automatically executed in accordance with pre-programmed steps.

✽

Although the number has been already input into the device at the factory, please verify if

the number was input correctly.

17

Page 19

5. Calibration

Fig.5

Calibration

Result

Calibration Cmplete

PMT Sens: 97.1 (%)

Corr.Value: 1.030

Set the Position Calibration tool

to the Measurement.

Fig. 6

■

5-2 Light shade

Fig. 7

5 Fig. 5 is displayed when calibration is completed.

6 Slide the protective cap back into the original position, and turn Calibrator

counterclockwise to MEASUREMENT position (Fig. 6).

Remove the white cap using a paper crip or other pointed object and

install a light shade (optional) using the screw holes on the top of the

device (Fig. 7).

Fig. 8

Fig. 9

18

When you need to directly check the level of a patient’s eye, lift the light

shade as shown in Fig. 8.

Close the light shade as shown in Fig. 9 for calibration, BG check, and

measurement.

Page 20

6. Procedure for measurements

■

6-1 Procedure for measurements: Overview

Fig. 1 shows overview of measurement procedure.

Fig. 1

Ocular height adjustment

Frontal view alignment

Diagonal alignment/

BG check

Measurement

Data summary

End

■

6-2 Ocular height adjustment

Fig. 2

Align Eye Level Mark with the patient’s eye.

Put POWER Switch into ON position “ ” .Pull back Main unit and ask the patient to sit

in front of the device.Ask the patient to rest his or her chin on Chin-rest and forehead on

Forehead rest.Move Main unit to the right proximal position where you can see the right

eye directly.Ascend or descend Chin-rest to align Eye Level Mark ( Fig. 2

the patient’s eye.Using Calibrator as an index, place Measurement unit to the same

position.Adjust crosswise position of Main unit to the patient’s eye.

[BG check] verifies the alignment status. During the

check, from the upper to lower ends including [Measurement window] are scanned. Verification results

appear in the display (see “ ■ 6-5 BG Check” ).

Data output

Data output

) with

■

6-3 Frontal view alignment

Fig. 3

Flr: 0

WA:

N: 0

ID:12345

L

Fig. 4

Flr: 0

WA:

N: 0

ID:12345

L

Perform the frontal view alignment while monitoring Frontal view

alignment screen shown in the display.

1 Frontal view of the patient’s eye is shown in the display.Move Main unit until the

luminous dot comes in the center of the display as shown in Fig. 3.

2 As shown in Fig. 4, move the luminous dot into “ ” mark and adjust the position of

Main unit or Measurement unit to reduce the size of the luminous dot as small as

possible.

After all adjustments are completed, push “Measurement switch”.

19

Page 21

6. Procedure for measurements

■

6-4 Diagonal view alignment

Fig. 5

Perform the diagonal view alignment while monitoring Diagonal view

alignment screen shown in the display.

OK

Flr: 0

WA:

N: 0

NG

Flr: 0

WA:

N: 0

ID:1234567890

ID:1234567890

Diagonal view of the patient’s eye is shown in the display.Laser beam is emitted and

L

Measurement window is shown in the display. Use Joy stick to position Measurement

window and Reflected lights as shown in Fig. 5 (OK) (see Fig.7).

When the display shows their position as shown in this picture, laser beam is hitting the

L

iris and background lights are not distributed evenly which would cause false

measurements.See Fig. 6 and re-align.

Flr: 0

WA:

N: 0

ID:1234567890

When the display shows their position as shown in this picture, there is no window

L

between two laser beams and the Measurement point is placed far away from the anterior chamber which would cause false measurements. See Fig. 6 and re-align.

Points for alignment

1. Measurement window must be between the left

and right laser beams.

2. Measurement window must be located below the

Spot light.

3. Measurement window and the right laser beam

must be within the pupil.

Fig. 6

Spot light Pupil

Points for operation

It is recommended to tilt the joy stick lightly in diagonal

directions while monitoring Diagonal view alignment

screen.

Fig. 7

20

Left laser

beam

Measurement

window

Right laser

beam

Page 22

■ 6-5 BG check

Fig. 8

Flr: 88.2

WA: B

N: 1

ID:1234567890

Stop

6. Procedure for measurements

BG check starts when Diagonal view alignment screen is displayed.

BG level appears in Measurement window.

L

(Laser emission stops automatically when a certain period of time elapses. Pressing

“Measurement switch” restarts the emission.)

Fig. 9

■

6-6 Measurement

High

Low

Level 5

Level 4

Level 3

Level 2

Level 1

Level 0

Fig. 10

BG level indicator

BG check finds out the uniformity of background lights by determining the background lights around Measurement window. Level of the uniformity appears in

Measurement window shown in the display. This is what we call “BG level indicator”. Details are shown in Figure 9.

Level 5 is the highest level that indicates background lights are distributed most

evenly, while Level 0 is the worst level that indicates the worst uniformity.

You may proceed to the measurement when the color of BG level indicator

turns to green.

You can not start the measurement when it is white.

BG level may be changed when the level does not become high. You may also

force to start the measurement regardless of the level.

Refer to “8. Configuration and setting”.

However , measurements taken at a low BG level, reliability of them would be

lowered.

Press “Measurement switch” when the color of BG level indicator turns

to green.

Measurement starts and completes in 0.5 second.

21

Page 23

6. Procedure for measurements

■

6-7 Displaying measurement results

Fig. 11

100

Results are presented in graphs and values in the display as shown in

Fig. 11. Data is automatically saved per measurement (the automatic

save function may be disabled).

50

0

0.0 0.1 0.2 0.3 0.4 0.5

BG1: 9.1 N : 7

BG2: 5.1 (28.5%)

SIG: 92.8 BG

FLARE : 85.7

Scale

Del List

Fig. 12

100

50

0

0.0 0.1 0.2 0.3 0.4 0.5

BG1: 50.1 N : 7

BG2: 23.1 (38.5%)

SIG: 50.8 BG

FLARE : 13.8

Del

Inappropriate Data Form.

Delete?

Store

Fig. 13

NAME: SEX: M / F

ID: Eye: R

100

YY / MM / DD HH:MM

● When it is not needed to save data

If you do not need data to be saved, select “Del”.

The vertical scale for graphs can be changed between 4 levels including

“0 - 100”, “0 - 200”, “0 - 500” and “0 - 1000”, when “ Scale ” is selected.

● Waveform evaluation

Flare is compared with |BG1 - BG2 | per measurement.

(SIG – BBG

(SIG – BBG

Form. Delete?

Select “ Del ” to delete or “ Store ” to save.

✽

✽

) - |BG1 - BG2 | > 0 is acceptable and no message is displayed.

✽

) - |BG1 - BG2 | 0 is unacceptable and the message “

” is displayed.

BBG is BG1 or BG2, whichever the larger.

Inappropriate Data

● Printing out the display

Pressing “Print switch” prints out the display contents as seen in the print out sheet

sample shown in Fig. 13.

● When continuously conducting multiple measurements

If you want to continue taking additional measurements, press “Measurement switch”.

BG check screen appears and you may continue the measurement.

50

0

0.0 0.1 0.2 0.3 0.4 0.5

BG1: 5.3 N: 3

BG1: 4.6 ( 6.4%)

SIG: 51.8

FLARE: 46.8

KOWA FM-600 Ver. 1.0

Print out sheet sample

● Maximum number of data savings

When measurements are repeated on the same eye, up to 10 data savings are allowed.

● Switching the display to Summary data screen

When you want to have the display to show Summary data screen, select “List”.

22

Page 24

■

6-8 Showing and editing acquired data

Fig. 14

N BG (%) FLARE W/A

1 9.8 17 20 BC

2 8.5 6 22

3 8.0 9 21

4 8.3 55

5 9.0 8 19

AV: 20.5

SD: 1.1

Summary data screen

Test Result

No. of outliers : 1

After the Test.

No. of data : 4

AV.:20.5

S.D.:1.1

Erase Outliers?

Yes No

If you have selected “List” in the display shown in the previous step,

Summary data screen appears which shows a summary listing an

average flare value and standard deviation (Fig. 14).

At the same time an outlier test is performed.

● Outlier test of acquired data

When 5 or more data has been acquired, an outlier test is performed to find any outlier

(or throw-out) candidate datum (see Additional Information below).

When the message “Erase Outliers?” appears, select “Yes” to delete or “No” to save.

Selecting “Yes” deletes the candidate data and recalculates an average flare value

(Fig. 15).

6. Procedure for measurements

Fig. 15

N BG (%) FLARE W/A

1 9.8 17 20 BC

2 8.5 6 22

3 8.0 9 21

4 9.0 8 19

AV: 20.5

SD: 1.1

Cont Edit Stat End

Fig. 16

N BG % FLARE W/A

1 9.8 17 20 BC

2 8.5 6 22

3 8.0 9 21

4 9.0 8 19

AV: 20.5

SD: 1.1

Del Set

Example:

Fig. 14 shows an example. When a significance level of 0.05 is selected and five flare

values are 20, 22, 21, 55, then 19, 55 would be a candidate.

Additional Information:

Outlier test requires at least five data. The required number of data may be changed

•

to any number between 5 and 10 (see “8. Configuration and settings”).

This outlier test uses Smirnov and Grubbs’ method and the significance level may

•

be 0.001, 0.025, 0.05, 0.1, 0.15 or 0.2 (see “8. Configuration and settings” for

details).The greater the significance level, the greater the number of throw-out candidate data would be detected.

You may also select not to perform an outlier test (see “8. Configuration and set-

•

tings”).

When there is no candidate the message “The result No. of Outliers:0 No outliers”

•

appears.

● Editing summary data

When you want to delete some data from Summary data screen, select “Edit”.

” and “ ” to select and highlight a datum.

Use “

When you select “Del”, two lines are placed over the datum (Fig. 16).

After you select all data you want to delete and select “Del”, the message “Delete the

selected data?” appears.

Selecting “Yes” deletes all the data selected and exit the editing step.

Fig. 17

NAME: SEX: M / F

ID: Eye: R

N BG (%) FLARE W/A

1 0.7 7.4 82.9

2 0.9 23.0 77.6 B

3 0.9 55.6 81.8 B

AV : 80.8

SD : 2.8

YY / MM / DD HH:MM

KOWA FM-600 Ver. 1.0

● Printing out the display

Pressing “Print switch” prints out Summary data screen contents as seen in the print

out sheet sample shown in Fig. 17.

● Continuing / ending measurement

If you want to continue taking additional measurements, select “Cont” in Summary data

screen.

Frontal view alignment screen appears (Maximum number of measurements is 10).

If you finish measurement of the current eye, select “End” in Summary data screen.

When the message “Proceed ? (Erase all data ?) ” appears, select “OK” to delete all

data and go back to Frontal view alignment screen.

Selecting “No” deletes no datum and takes you back to Frontal view alignment screen.

23

Page 25

7. Tips for measurements

■

7-1 How to block laser beams

Fig. 1

Turning Calibrator until it comes to the position shown in Fig. 1 makes a

click-sound and blocks laser beams.

Use this method to block laser beams immediately and securely. The following message appears.

If Measure / Calibrate

Set the position of Cali. Tool as follows.

Measure = Measurement

Calibrate = Calibration

■

7-2 Warning beep during BG check

Fig. 2

When intensive laser beam comes into Measuring window as shown

Laser Attenuating …

When you start measuring, turn Calibrator

counter-clockwise until it comes to MEASUREMENT.

When you start calibrating, turn Calibrator

clockwise until it comes to CALIBRATION.

in Fig. 2, Excessive light detector automatically emits a series of highpitch short repeated alarm.

When you hear this alarm, move Main unit and Measurement unit away to keep excessive laser beam from entering into Measuring window.

Caution: Excessive laser beam may cause a photoreceiver element failure.

ListStop

■

7-3 Recommended procedures when BG check obtains no correct alignment

Fig. 3

When Excessive light detector does not stop the alarm in BG check

screen, press “Frontal view switch” to go back to Frontal view alignment

screen or select “Stop” on Fig. 2.

Selecting “Stop” terminates the ongoing laser scanning and stops BG check. Realign

while monitoring the laser beam position. In order to perform BG check again, press

“Measurement switch” (Fig. 3).

■

7-4 Recommended procedures when BG check obtains no good result

Fig. 4

Reading on the eye. BG check may result in good without using the

alignment mark (Fig. 4).

Important point is to align the device so that no iris image or reflected glare comes into

Measurement window (see ■ 6-4 Diagonal view alignment).

ListStop

24

Page 26

7. Tips for measurements

■

7-5 Recommended procedures when measured waveforms are offset to left or right

Fig. 6

Wide

Fig. 7

Narrow

You may encounter waveform offset to the left as shown in Fig. 6 when

attempting a measurement at an excessively lower part of the anterior

chamber.

You can not obtain a correct flare value in this condition.

1 Select “ON” for “Laser : Position” as described in “8. Configuration and

settings” and change the laser position in BG check screen to solve this

problem.

2 Use “ ” and “ ” several times to change the laser position.

L

3 Press “Measurement switch” to perform a measurement after the position

change. This setting is effective until all measurement data for the one

examined eye are cleared✽.

ListStop

✽

Select “End” in Summary data screen.

25

Page 27

8. Configuration and settings

Fig. 1

Setting

Calibration

End

Fig. 2

Setting

Calibration

Continue Measure

End Measure

Fig. 3

Meas. Process

Illumination

Laser

Output mode

Date/Time

Sleep Time

End

Laser Flare Meter

FM-600

Ver. 1.0

Laser Flare Meter

FM-600

Ver. 1.0

Setting

Ent

Ent

1 Press and hold “Print switch” for more than 4 seconds to display the menu

screen (Fig. 1).

2 Select “Setting” using

“ ” or “ ” and select “Ent” to display Setting menu

screen.

When collected data exists, contents of the menu would be as shown in Fig. 2.

Select “ setting ” using “ ”or “ ” then select “ Ent ” to display Setting menu screen.In order to

end the setting and move to other screen, you must decide the next procedure. Use “ ” or “ ”

to select an item and select “Ent”.

Calibration (to delete collected data and perform calibration)

Continue Measure (to keep collected data and exit the menu screen)

End Measure (to open Summary data screen)

3 Use “ ” or “ ” to select an item from the screen shown in Fig. 3 and select

“Ent” to open the menu screen corresponding to the selected item.

Changing the mode of each item you may change the state of this device.

Details of each item are described below:

Ent

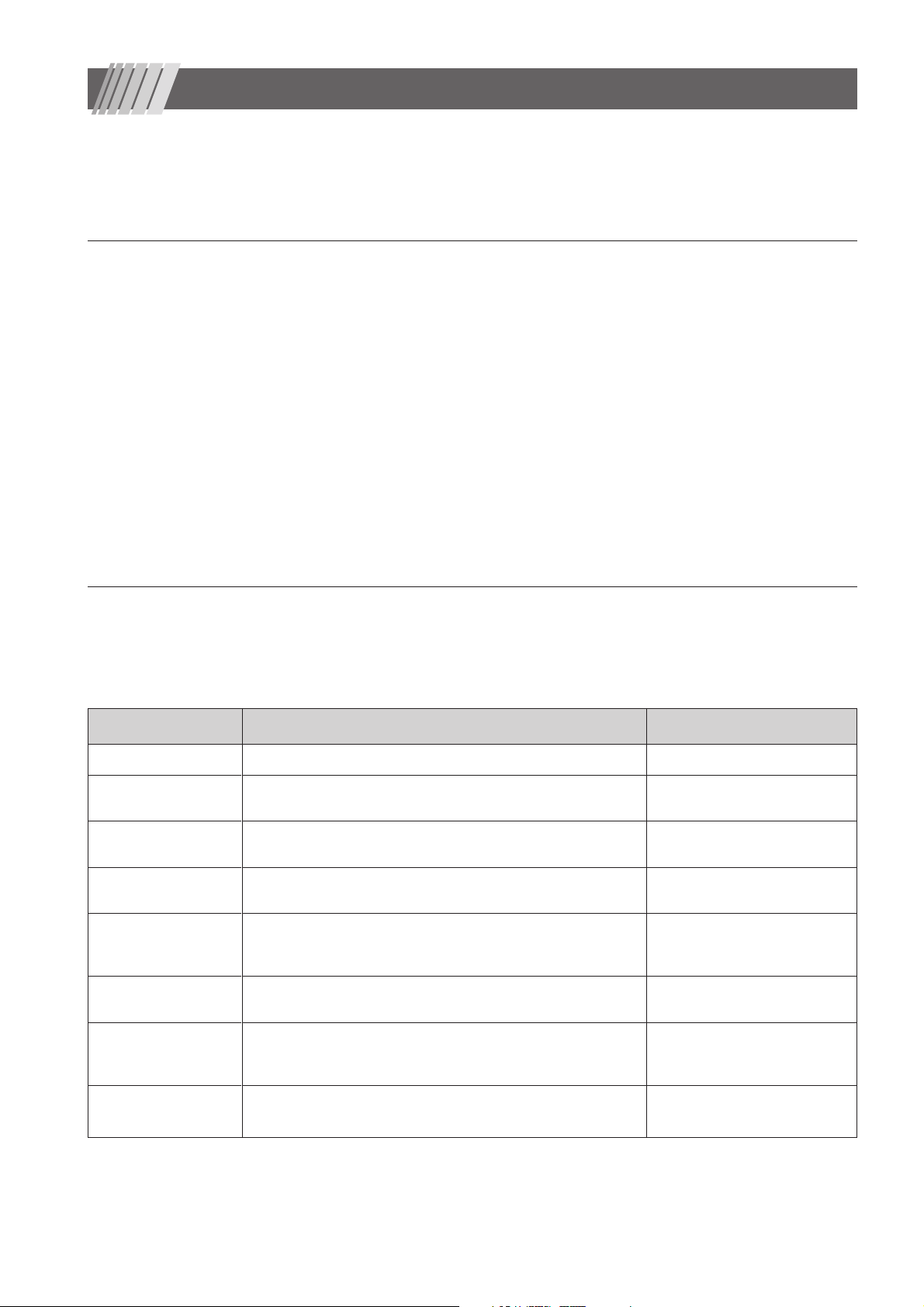

Meas. Process (common settings regarding measurement)

Setting menu Description Selection

“

BG Error Check

BG Error Level

Prohibiting

with a quality below BG error level.

BG error level setting, “H” for rigorous or “L” for reduced error level.

Meas. TRG Auto or manual measurement after BG error check. Auto / Manual

Alighnment Mode

Diagonal view alignment, "1" for single step or "2" for double step.

Graph View Displaying “On” or not displaying “Off” Graph View. On / Off

ID No. Input Allowing “On” or not allowing “Off” ID input. On / Off

Graph Review

Displaying

“Del” is selected to delete some data in Summary data screen.

Data Store Saving measurements automatically or manually. Manual / Auto

Data Form Evaluation Executing “On” or not executing “Off” a data shape evaluation. On / Off

Auto Statistics

Automatic, significance level, and minimum number of data

settings for outlier test.

Yes” or not prohibiting “No” a measurement

“On”

or not displaying “Off” Graph View when,

Yes / No

H / M / L

1 / 2

On / Off

Auto | 5% | 5

Shadowed items and numbers within brackets are default settings.

26

Page 28

8. Configuration and settings

Illumination settings

Setting menu Description Selection

Front View Illumination intensity settings of Frontal view alignment screen. 1 - 10

Side View Illumination intensity settings of Diagonal alignment screen. 1 - 10

Chin Light White LED illumination, “On” or “Off” . On / Off

Monitor Bright Monitor Brightness adjustment. -63 - +64 (-40)

Monitor Contrast Monitor Contrast adjustment. -63 - +64 (-40)

Laser settings

Setting menu Description Selection

Position

Default Default setting of permanent laser scanning position. -3 - +4 (0)

Off Time Setting of a period of time elapsed before aborting laser emission. 01 - 10

Allowing “On” or not allowing “Off” to change laser scanning position temporally.

Data output settings

Setting menu Description Selection

Selecting devices to which data are output.

Output to PRN : Printer only, EXT : External device only,

PRN EXT : Printer and external device.

Form Selecting “On” or not selecting “Off” contents to be printed.

Name Patient name On / Off

ID Patient ID On / Off

Sex Patient sex On / Off

Eye Examined patient eye On / Off

Data Collected data All / Result

(time when data was acquired for Measurements

Date

Date

graph screen and time when data was outputted for

Summary data screen)

.

On / Off

PRN / EXT / PRN+EXT

On / Off

Equipment Name of equipment On / Off

Date/Time settings

Setting menu Description Selection

Date Form Selecting “yy/mm/dd”, “mm/dd/yy”, or “dd/mm/yy”. YY / MM / DD

Date

Time(24h) Displaying the time (24h) when settings were made. — — —

Displaying the date when settings were made. Values may be

changed using .

Sleep time settings

Setting menu Description Selection

Sleep Time

Shadowed items and numbers within brackets are default settings.

Time setting for power saving function to become active

In order to terminate the power saving mode, press any key.

— — —

0 – 99 (10)

27

Page 29

9. Miscellaneous

■

9-1 ID input

Fig. 1

ID Input

ID No.

0000000000

SetCLR

In order to input an ID number, “ID No. Input” must be “On” (refer to “8. Configuration

and settings”). Use function keys, ten keys, or a barcode reader to input an ID number.

9-1-1 Inputting an ID number using function keys

1 Select “CLR” to clear the number shown if any

2 Use “

(the larger digit field next to the current one))

3 Use “ ” to increase the number within the current field.

4 Use “Set” to confirm the input.

” to move within the digits shown (selecting “ ” moves you to the left

9-1-2 Inputting an ID number using function keys

You need a ten key pad with a PS/2 connector. This device accepts 0 to 9 and Enter

key only. Any other key are not accepted. The primary field for a ten key pad is the right

end field (other field you have selected using a function key will be ignored and you

need to start from the right end field).

Function keys are active even when you have connected a ten key pad.

9-1-3 Inputting an ID number using a bar code reader

You need a bar code reader with a PS/2 connector. For details of configuration and

settings of a bar code reader, refer to the users’ manual supplied with your reader.

Should you have any question, contact Kowa sales representative or dealership.

■

9-2 Connecting external devices

When you use external device or software to acquire and control data, refer to the communication specifications and data

structure.

CautionCaution

The RS232C cable must be less than 2 m.

•

When you use a peripheral device and/or other device connected to the peripheral device must meet all applicable IEC stan-

•

dards.

Data processing devices must meet IEC60601-1-1 or IEC60950.

•

The system that combines such data processing devices must meet IEC60601-1-1.

The system administrator who builds such system bears all responsibility to have the system comply with requirements of

IEC60601-1-1.

Should you have any question, contact Kowa sales representative or dealership.

28

Page 30

9. Miscellaneous

1 1

1 Communication specifications

1 1

Baud rate 38400bps

Data 8bit

Parity Even

Stop 1bit

Flow control none

All data must be made of ASCII codes.

The double type is index display.

3. Data

Name or data Description Data type

YY/MM/DD HH:MM YY/MM/DD HH:MM YY/MM/DD HH:MM

L/R Examined eye (left or right) 0 = left, 1 = right

rank BG rank during measurement 0 - 5

SN Waring: S/N 0 = OK, -1 = NG

BG Waring: BG 0 = OK, -1 = NG

CELL Waring: CELL 0 = OK, -1 = NG

DF

ST Waring: ST (SG test results) 0 = OK, -1 = NG

DARK DARK Double type

BG1 BG1 Double type

BG2 BG2 Double type

Signal SIG Double type

Flare FLARE Double type

Sens Sens Double type

PMTTemp PMTTemp Double type

Waring: D/F (data form evaluation)

2 2

2 Output data structure 1: Graph data

2 2

1. Data structure

Header

Data

Graph data 512

Footer

0 = OK, -1 = NG

2. Header

Name or data Description Data type

:LSS50 HEAD Fixed

:LSS50 HEAD Fixed

ID ID No. 10digits, numeric

TempCorrect

CaliCorrect

LD_TempCheck LDTemp check ON/OFF 0/1

LD_AlarmCheck LDAlarm check ON/OFF 0/1

asterisk

0 Data type (graph) Fixed

4. Graph data

Name or data Description Data type

flr_dt Graph data Short type

5. Footer

Name or data Description Data type

:END Fixed

Temperature compensation ON/OFF

Calibrator compensation ON/OFF

Calibration execution request OFF/ON

0/1

0/1

0/1

3 3

3 Output data structure 2: Summary data

3 3

1. Data structure

Header

Data (common)

Data (individual) Repeated for as many data as collected

Footer transmission

2. Header

Name or data Description Data type

:LSS50 HEAD Fixed

:LSS50 HEAD Fixed

ID ID No. 10digits, numeric

TempCorrect

CaliCorrect

LD_TempCheck LDTemp check ON/OFF 0/1

LD_AlarmCheck LDAlarm check ON/OFF 0/1

asterisk

1 Data type (list) Fixed

3. Data (common)

Name or data Description Data type

YY/MM/DD HH:MM

L/R Examined eye (left or right) 0 = left, 1 = right

N Number of data 1 - 10

AV. Average Double type

S.D. S.D. Double type

Temperature compensation ON/OFF

Calibrator compensation ON/OFF

Calibration execution request OFF/ON

YY/MM/DD HH:MM YY/MM/DD HH:MM,

0/1

0/1

0/1

4. Data (individual)

Name or data Description Data type

Num Data number 1 - 10

BG BG average Double type

BG_diff BG amplitude (%) Double type

Flare FLARE evaluation result Double type

Sens Sens Double type

PMTTemp PMTTemp Double type

Warning_SN Waring: S/N 0 = OK, -1 = NG

Warning_BG Waring: BG 0 = OK, -1 = NG

Warning_CELL Waring: CELL 0 = OK, -1 = NG

Warning_DF

Warning_ST Waring: ST (SG test results) 0 = OK, -1 = NG

5. Send Footer

Name or data Description Data type

:END End code Fixed

Waring: D/F(data form evaluation)

0 = OK, -1 = NG

29

Page 31

9. Miscellaneous

■

9-3 Display messages

This section explains the massages that appear in the screens.

Message Description Action

LD Temp Check

Please wait

Latest Calibration Data:

(YY/MM/DD HH:mm)

Calibrate Now?

Laser Attenuating…

If Measure / Calibrate

Set the positions of Cali. Tool as follows.

Measure : Measurement

Calibrate : Calibration

ALERT

Can't hold both R&L eye data.

Keep on Measuring “L- eye”.

Or Erase all data.

Press the Joystick Button.

To Return Scanning.

Inappropriate Data Form Delete ?

Test Result

No. of Outliers, After the Test.

No. of Data, AV , S.D.

Erase Outliers ?

Temperature at the laser source

is not within the specified range.

One month has passed since last

calibration. It is recommended to

calibrate.

Laser beam may attenuate depending on the calibrator position.

While retaining the right (left) eye

data, Measurement switch is

pressed for the left (right) eye.

Time limit has passed over and

laser emission is terminated automatically.

Obtained waveform is not appropriate.

Results of the outlier test are

shown. Average and standard deviation is recalculated and displayed If any outlier datum is

cleared.

You need to wait until the temperature becomes appropriate.

Selecting “Yes” starts calibration.

Selecting “No” aborts calibration.

If you need no laser attenuation,

turn the calibrator until it comes

to MEASUREMENT or CALIBRATION.

Select “End” on the summary

table and proceed to the left

(right) eye measurement.

Pressing Measurement switch

restarts laser emission.

Selecting “Del” clears the data.

Selecting “Store” saves the data.

Selecting “Yes” clears the candidate data. Selecting “No” does

not clear them.

The result

No. of Outliers: 0.

No. Outliers.

Disply List Data.

“Unstored Data ” exists.

Press “Graph ” to store.

Clear Selected Data?

PROCEED ?

(Erase all data? )

Now transferring.

Results of the outlier test presented

no candidate data.

This message warns you about

data that need to be saved.

This message reminds you that

the data selected on Summary

screen will be cleared.

This message reminds you that

the data collected for the examined eye will be cleared before

proceeding to next measurement.

Data are now being transferred

out from the device.

You need anything to do.

By selecting “Graph” you can go

back to Measurements graph

screen where you save the data.

Selecting “List” clears the unsaved data.

Selecting “Yes” clears the data.

Selecting “No” does not clear

the data.

Selecting “Yes” clears the data,

completes a measurement, and

desplays Diagonal alignment

screen.

Wait until the data output completes.

30

Page 32

■

9-4 Function switches

Details of function switches are described in this section.

9. Miscellaneous

Function switch

Moves the cursor upwards.

Moves the cursor downwards.

Moves the cursor to the left or right.

Ent

Set

End

Yes

No

Stop

Store

Del

■

9-5 Relocation

Confirms the selected setting or item.

Confirms the setting.

Terminates the current setting screen.

Increases a parameter value.

Decreases a parameter value.

Accepts the setting.

Cancels the setting.

Poses laser scanning.

Saves the measurement(s) shown.

Deletes the measurement(s) shown.

Fig. 1

NG

Description

Follow the precautions shown below when you relocate this device:

•

•

•

•

•

•

Function switch

List

Scale

Edit

ID

CLR

Stat

Graph

Cont

Not. Cali

Move Main unit so that Main unit sits right on the top of Power Supply unit as shown

in Fig. 1.

Press down and tighten Self-locking screw clockwise as shown in Fig. 2.

Place your both hands under the Power Supply unit and lift the device. Do not lift

the device using any other part.

Make sure there is no bump or dip on the place where you relocate the device.

Make sure not to pinch your hands when placing the device in place.

Turn counterclockwise and undo Self-locking screw after placing the device.

Changes the current screen to Summary data screen.

Changes the vertical scale for waveform

graphs.

Changes the current screen to Editing

screen.

Changes the current screen to ID input

screen.

Clear the number(s) shown in ID input

fields.

Starts statistic processing.

Regenerates measurements graph from

unsaved data.

Performs additional measurement.

Performs no calibration.

Description

OK

Fig. 2

Fig. 3

Tighten

Undo

31

Page 33

10. Troubleshooting

■

10-1 Phenomena and validation

In this section, we discuss what you can do when you encounter a problem. When a problem occurs, check the items shown

below first. If none of the items is the case or if the specified remedy solve your problem, please contact your Kowa dealer

where you have purchased the instrument.

Situation Phenomena Validation (possible cause) Remedy

Alignment

Measurement

mode

Measurement

data

The display does not show the

patient’s eye (Frontal alignment

screen).

The display does not show the

patient’s eye (Diagonal alignment

screen).

The display is whitened and the

luminous dot for alignment does

not appear.

No measurement is started (Measuring window does not turn to

green).

No measurement is started (alarm

is emitted).

Data can not be saved.

BG value and BG% are too high.

There are excessive variations in

collected data.

Vertical level and the position of the

eye are not aligned with those of the

device.

The position of the eye not aligned

with the device.

No light shade is used in a welllighted room.

The ratio of BG1 to BG2 is not good.

“Yes” is selected for the setting of BG

error check.

Excessive light is detected blocking

a measurement.

Flare value is zero (0). “Store” button is not selected.

The target point is not good. The

room is well-lighted.

The target point is not good.

Pull back Base segment and perform Ocular height adjustment again (see “■ 6-2

Ocular height adjustment” on Page 19)ask

the patient to sit in front of the device.

Align the position again using Frontal alignment screen.

Settings of the display are incorrect.

Use a light shade. Adjust settings of

the display correctly. Darken the

room.

Change the target point.

Change the settings:

•

Change the laser position

•

Change BG level

• Select “No” for BG error check.

Change the target point.

Perform measurement again.

Change the target point.

Darken the room or use a light

shade.

Perform an additional measurement and

perform a test.

.

.

Nothing is printed out.

Print

Nothing is printed out.

■

10-2 Error messages

This section describes error messages that appear when a device malfunction occurs.

Any printer is not selected for Output mode.

No printer paper left.

Message Description Remedy

Error1 DARK

Error2 PMT sens

DARK count exceeded the limit.

Sensitivity of the photoreceiver element dropped below the limit.

Error3 PMT Temp. Alarm

Temperature of the photoreceiver element exceeded the limit.

Error4 LD Temp. Uncontrolled

Temperature of the laser source became uncontrollable.

Error5 Printer

Please Check Printer Paper

Error6 – 11

The printer paper roll or the lid is

wrongly positioned (see Page 15).

A system error occurred.

Select “PRN” or “PRN + EXIT” for

the output setting.

Replace with a new printer paper

roll.

Turn off the power supply and contact

Kowa sales representative.

Turn off the power supply and contact

Kowa sales representative.

Turn off the power supply and contact

Kowa sales representative.

Turn off the power supply and contact

Kowa sales representative.

If the problem continues, turn off the

power supply and contact Kowa sales

representative.

Turn off the power supply and contact

Kowa sales representative.

32

Page 34

11. Maintenance/Inspection

This instrument is a controlled medical device, of which the measurements obtained using this instrument may be affected

by daily maintenance and inspection.

In order to use this instrument safely and correctly, carefully read the items listed in this section.

■

11-1 Daily maintenance

1 Perform a calibration of this instrument a month in accordance with the procedure specified in “5. Calibration”.

2 Turn off POWER switch and place the dust cover on the instrument after use.

3 Make sure that the photoreceiver lens and the light emitting lens are not contaminated with dust, finger prints, and/or

tear fluid. When they are contaminated wipe them clean first and re-clean using a soft gauze pad or sheets of lens

cleaning paper dampened with 1:1 solution made of absolute alcohol and ether. Do not use any other agent or cloth.

4 Make sure that Eye fixation lamp window is not contaminated with dust, finger prints, and/or tear fluid. When it is

contaminated, clean using sheets of lens cleaning paper dampened with neutral detergent solution. Do not use alcohol

for cleaning.

5 When the main part of the device gets soiled, clean it with soft cloth. When the main part of the instrument gets soiled,

clean it with soft cloth. Do not use chemicals or solvents such as thinner and benzene, which cause alteration, deformation, paint-loss.

6 If the instrument is not to be in use for a long period of time, turn OFF the Power switch and unplug the instrument.

7 When resuming use of instrument that has not been used for a long period of time, calibrate the instrument in accor-

dance with the procedure specified in “5. Calibration”.

■

11-2 Daily inspection (by the user)

Perform daily inspection in accordance with “ FM-600 Daily Inspection Table ”.

When a problem is detected but can not solved with Daily maintenance procedure described above, contact Kowa or your

Kowa dealer where you have purchased the instrument.

FM-600 Daily Inspection Table

Item Inspection Criteria

Power supply cable

Printer paper

Outer shell

Rating plate, Pre-

caution plate

Light emitting lens,

photoreceiver lens

Chin-rest

Visually inspect that the power supply cable has no damage.

Determine that an appropriate amount is left.

Visually inspect that the main part does not have any crack or

deformation.

Visually inspect that contents shown on the plates are readable.

Visually inspect that the window surfaces on these lenses are

not soiled.

Press Chin-rest ascending/descending switch and visually inspect that it operates properly.

There is no damage.

There is an appropriate amount is left.

There is no crack or deformation.

Contents shown on the plates

are readable.

The lenses are not contaminated with dust, finger prints,

and/or tear fluid.

Chin-rest ascends and descends properly.

Ascending and de-

scending of Operat-

ing unit

Calibration

Turn the joy stick and visually inspect that Operating unit ascends and descends properly.

Calibrate the device in accordance with the procedure specified in “5.Calibration”.

Operating unit ascends and

descends properly.

Calibration successfully completes without any error.

33

Page 35

11 Maintenance/Inspection

■

11-3 Fuse replacement

When replacing a fuse, be sure to turn OFF the Power switch and unplug instrument from the power outlet.

Unplug

Doing otherwise may result in electrical shock.

Turn the power switch OFF, unplug the power supply plug off from the power supply

inlet and remove the fuse holder using a flat-head driver. Replace the blown fuse with a

spare fuse. Use only a specified replacement fuse.

Manufacturer: Littelfuse

Part Name (Part #): 0218001M

WarningWarning

Warning/

High-Voltage

■

11-4 Chin-rest paper installation

Chin-rest paper

Chin-rest paper

Chin-rest

■

11-5 Sterilization of Forehead rest and Chin-rest

Forehead stopper must be wiped clean with alcohol disinfectant solution every time a patient finishes an examination with

this instrument.

When you do not use a sheet of Chin-rest paper, Chin-rest must be wiped clean with alcohol disinfectant solution.

■

11-6 Refilling and replacing consumables

Item Order Number

Chin-rest paper K9L-TB45 #102

Chin-rest pins K9L-TB45 #101

Printer paper STH -148

Fuse 0218001M(T1.0A L250V)

retaining pins

Use only a specified replacement fuse. Using other fuse may cause a device failure or fire.

Place a sheet of Chin-rest paper on Chin-rest and hold the sheet with Chin-rest pins.

Use a sheet of Chin-rest paper per patient and replace it with a new sheet for a next

patient.

Order any of the required consumables with the order number

to your supplier.

■

11-7 Regular inspection (by the device supplier)