Page 1

Code

Condensing wall mounted boiler

ADAX

INSTALLATION AND SERVICING INSTRUCTIONS

EN

6322893 - 02/2015 - R0

Page 2

SAFETY WARNINGS AND REGULATIONS

RESTRICTIONS

m

WARNINGS

– After having removed the packaging make sure that

the product supplied is integral and complete in all

its parts. If this is not the case, please contact the

Dealer who sold the appliance.

– The appliance must be used as intended by

KOVARSON

caused to persons, animals or things, improper

installation, adjustment, maintenance and improper

use of the appliance.

– In the event of water leaks, disconnect the appliance

from the mains power supply, close the water

mains and promptly inform professionally qualified

personnel.

– Periodically check that the operating pressure of

the water heating system when cold is

this is not the case, increase the pressure or contact

professionally qualified personnel.

– If the appliance is not used for a long period of time,

at least one of the following operations must be

carried out:

set the main system switch to "OFF";

-

-

close the gas and water valves for the water

heating system.

– In order to ensure optimal appliance operations

KOVARSON

checks are carried out

who is not responsible for any damage

1-1.2 bar

recommends that maintenance and

ONCE A YEAR

.

. If

d

IT IS FORBIDDEN

– The appliance is not to be used by children or

unassisted disabled persons.

– Do not use electrical devices or appliances such as

switches, electrical appliances etc if you can smell

fuel. If this should happen:

open the doors and windows to air the room;

-

-

close the gas isolation device;

-

promptly call for professional assistance.

– Do not touch the appliance with bare feet or with any

wet part of the body.

– Do not carry out any technical intervention or

cleaning operation before having disconnected the

appliance from the mains power by setting the main

switch to "OFF", and closing the gas supply.

– Do not modify the safety or adjustment devices

without authorization and instructions from the

manufacturer.

– Do not block the condensate drain (if present).

– Do not pull, detach or twist the electrical cables

coming out of the appliance even if the appliance is

disconnected from the mains power supply.

– Do not expose the boiler to atmospheric agents.

These boilers can also be installed in partially

covered areas, as per EN 15502, with a maximum

ambient temperature of 60°C and a minimum

ambient temperature of - 5°C. It is recommended

that the boiler is installed below weathered roofs,

on the balcony or in a protected niche, to protect it

from exposure to weathering agents (rain, hail and

snow). The boiler is equipped as standard with an

antifreeze function.

– Do not block or reduce the size of the ventilation

openings of the room where the appliance is

installed, if present.

– Remove the mains power and gas supply from the

appliance if the external temperature could fall

below ZERO (risk of freezing).

– Do not leave containers with flammable substances

in the room where the appliance is installed.

– Do not leave packaging material around since it

could be dangerous. Therefore dispose of it as

prescribed by legislation in force.

m

2

WARNINGS

–

It is recommended that all operators

carefully in order to use the appliance in a safe and

rational manner.

This manual

–

must therefore be kept for future reference and

must always accompany the appliance in the event

the appliance is transferred or sold to another

Owner or User or is installed on another system.

Installation and maintenance

–

must be carried out by a qualified company or by

a professionally qualified technician in accordance

with the instructions contained in the manual. The

company or technician will, at the end of installation

operations, issue a statement of compliance

with national and local Technical Standards and

Legislation in force

is an integral part of the appliance. It

read this manual

of this appliance

Page 3

RANGE

1312

CONTENTS

MODEL CODE

ADAX 20 - (G20) 8114280

ADAX 25 - (G20) 8114282

ADAX 30 - (G20) 8114284

ADAX 35 - (G20) 8114286

CONFORMITY

ADAX

boilers comply with:

– Directive 2009/142/EC - Gas Appliances

– Boiler Efficiency Directive 92/42/EEC

– Low Voltage Directive 2006/95/EC

– Electromagnetic Compatibility Directive 2004/108/EC

– Thermal Efficiency

– Classified as "Condensing"

– Class NOx 5 (< 70 mg/kWh)

Please refer to the technical data plate for the serial number

and year of manufacture.

EC DECLARATION OF CONFORMITY

In accordance with "Gas Appliances" Directive 2009/142/EC,

"Electromagnetic Compatibility" Directive 2004/108/EC, "Boiler

Efficiency" Directive 92/42/EC and "Low Voltage" Directive

2006/95/EC, the manufacturer KOVARSON s.r.o., via Garbo 27,

37045 Legnago (VR),

comply with the European Directives.

The Technical Manager

(Franco Macchi)

DECLARES THAT

the boiler models

ADAX

SYMBOLS

a

f

d

m

DANGER

To indicate actions which, if not carried out correctly,

can result in injury of a general nature or may damage

or cause the appliance to malfunction; these actions

therefore require particular caution and adequate

preparation.

DANGER

To indicate actions which, if not carried out correctly,

could lead to injury of an electrical nature; these

actions therefore require particular caution and

adequate preparation.

IT IS FORBIDDEN

To indicate actions which MUST NOT BE carried out.

CAUTION

To indicate particularly important and useful

information.

1 DESCRIPTION OF THE APPLIANCE 4

1.1 Characteristics .................................4

1.2 Check and safety devices .........................4

1.3 Identification ...................................4

1.3.1 Data label ............................ 5

1.4 Structure ......................................6

1.5 Technical features ...............................7

1.6 Main water circuit ...............................8

1.7 Sensors........................................8

1.8 Expansion tank .................................9

1.9 Circulation pump ................................9

1.9.1 Pump equipped with LED................ 9

1.10 Control panel ..................................10

1.11 Wiring diagram ................................11

2 INSTALLATION 12

2.1 Unpacking the product ..........................12

2.2 Dimensions and weight..........................12

2.3 Handling......................................12

2.4 Installation room ...............................12

2.5 New installation or installation of a replacement

appliance .....................................13

2.6 Cleaning the system ............................13

2.7 Water system treatment.........................13

2.8 Boiler installation ..............................13

2.9 Hydraulic connections...........................14

2.9.1 Plumbing accessories (optional) ......... 14

2.10 Condensate outlet/collection .....................14

2.11 Gas supply ....................................14

2.12 Smoke outlet and combustion air inlet .............15

2.12.1 Coaxial duct (Ø 60/100mm and Ø 80/125mm) 16

2.12.2 Separate ducts (Ø 60mm and Ø 80mm) ... 16

2.13 Electrical connections...........................17

2.13.1 Outdoor sensor ....................... 19

2.13.2 Chrono-thermostat or Air Thermostat .... 19

2.13.3 EXAMPLE of use of the command/control

2.14 Refilling or emptying............................20

3 PUTTING INTO SERVICE 21

3.1 Preliminary operations ..........................21

3.2 Before commissioning ..........................21

3.3 Parameter setting and display ....................22

3.4 List of parameters..............................22

3.5 Fault / malfunction codes........................23

3.6 Display of operating data and counters.............24

3.7 Checks .......................................25

3.8 Domestic hot water comfort function (preheating) ...26

3.9 Gas conversion.................................26

4 MAINTENANCE 27

4.1 Adjustments...................................27

4.2 External cleaning...............................27

4.3 Cleaning the inside of the appliance ...............27

4.4 Checks .......................................28

4.5 Unscheduled maintenance .......................29

4.6 Troubleshooting................................29

4.7 Any pump faults and possible solutions ............30

device on some types of heating systems.. 19

2.14.1 REFILL operations .................... 20

2.14.2 EMPTYING operations ................. 20

3.2.1 Self-calibrating procedure .............. 21

3.7.1 Chimney sweep function ............... 25

4.2.1 Cleaning the cladding.................. 27

4.3.1 Removing components................. 27

4.3.2 Cleaning the burner and the combustion

chamber ............................ 28

4.3.3 Checking the ignition/detection electrode . 28

4.3.4 Final operations ...................... 28

4.4.1 Checking the smoke duct............... 28

4.4.2 Checking the expansion vessel pressure .. 28

3

Page 4

1 DESCRIPTION OF THE APPLIANCE

Cod. 6244745

1.1 Characteristics

ADAX

are last generation condensing wall mounted boilers

KOVARSON

which

water production. The main design choices made by

ADAX

for the

– the total pre-mix microflame burner combined with a steel

heat exchanger for heating and a rapid heat exchanger for

DHW

– the sealed combustion chamber which can be classified

"Type C" or "Type B" in relation to the room where the boiler

is installed, depending on the smoke outlet configuration

adopted during installation

– the command and control microprocessor electronic board

provides efficient management of both heating and hot water

production. It can also be connected to a remote control

with an Open Therm protocol or to room thermostat and/or

external sensor. If connected to an external sensor, the boiler

temperature varies on the basis of the external temperature

according to a selected optimal climatic curve providing

significant energy and economic savings.

Other special features of the

– the anti-freeze function which activates automatically if the

temperature of the water inside the boiler falls below the

threshold of the value set at parameter "PAR 10" and , if there

is an external sensor, if the external temperature falls below

the threshold of the value set at parameter "PAR 11"

– the anti-blocking function of the pump and diverter valve. This

activates automatically every 24 hours if no request for heat

has been made

– the chimney sweep function lasts 15 minutes and makes the

job of the qualified technician easier when measuring the

parameters and combustion efficiency

– domestic hot water comfort function which allows the time

necessary for the hot water to become available to be reduced

and ensures that the temperature is stable

– screen display of the operating and self-diagnostic

parameters with error code display when the fault occurs.

This makes repair interventions easier and allows appliance

operation to be restored correctly.

has produced for heating and domestic hot

boilers are:

ADAX

boilers are:

KOVARSON

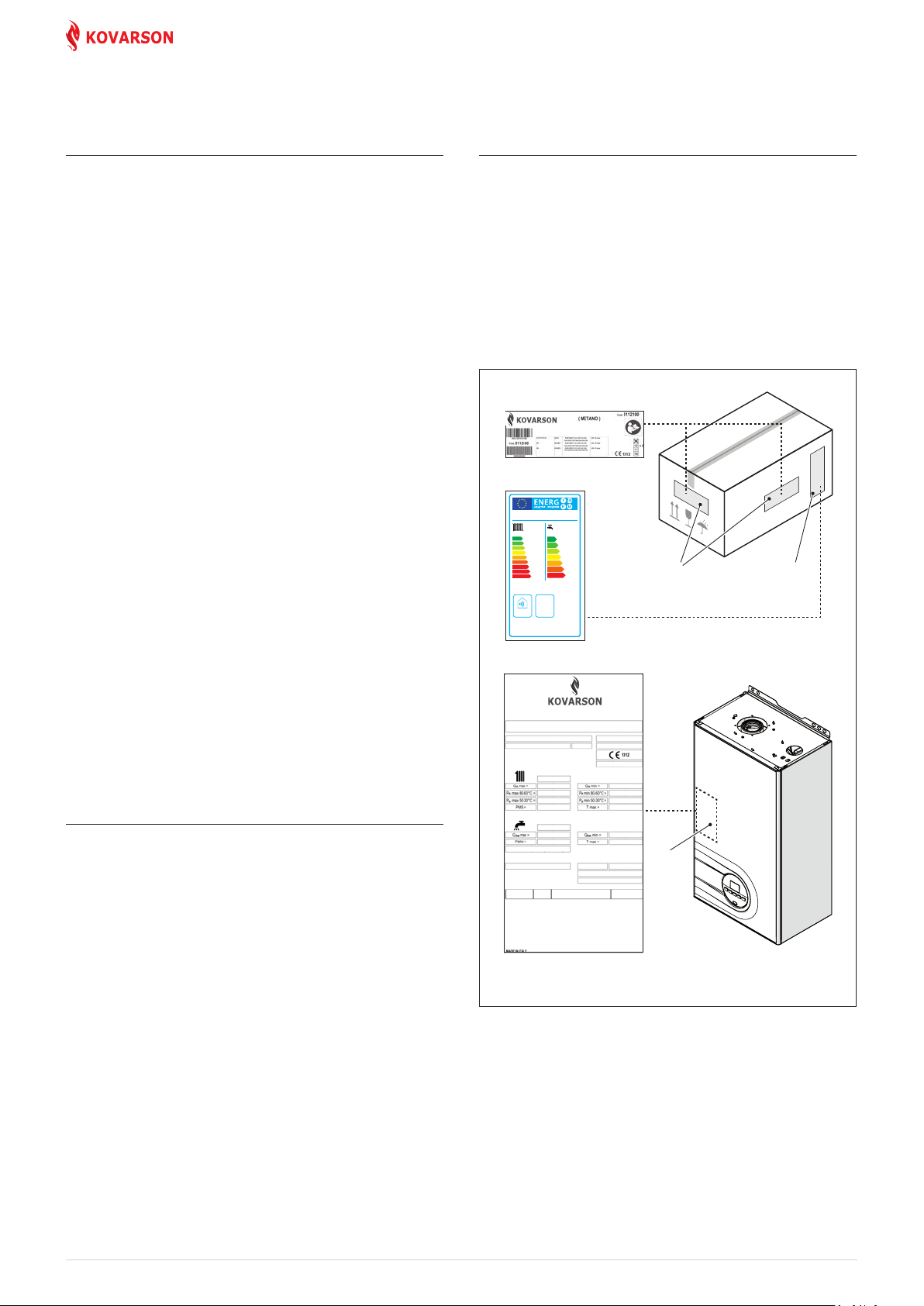

1.3 Identification

The

ADAX

boilers can be identified by means of:

1 Packaging label:

packaging and provides a code, the serial number of the

boiler and the bar code

2 Energy Efficiency Label:

of the packaging to notify the User of the level of energy

savings and reduced environmental pollution produced by

the appliance

3 Data plate:

boiler and provides the technical specification, appliance

performance and any other information required by law.

1

2

I II

++

A

A

+

A

B

A

C

B

D

C

D

E

E

F

F

G

G

kW

dB

2015 811/2013

3

this is located on the outside of the

this is positioned on the outside

this is located inside the front panel of the

1

2

1.2 Check and safety devices

The

ADAX

boilers are equipped with the following check and

safety devices:

– thermal safety thermostat 100°C

– 3 bar relief valve

– heating water pressure transducer

– delivery sensor

– DHW sensor

– smoke probe.

d

a

4

IT IS FORBIDDEN

to commission the appliance with safety devices which

do not work or which have been tampered with.

DANGER

Safety device may only be replaced by professional

qualified personnel using

parts.

KOVARSON

original spare

KEY:

1

Packaging label

2

Energy Efficiency Label

3

Data plate

3

Fig. 1

Page 5

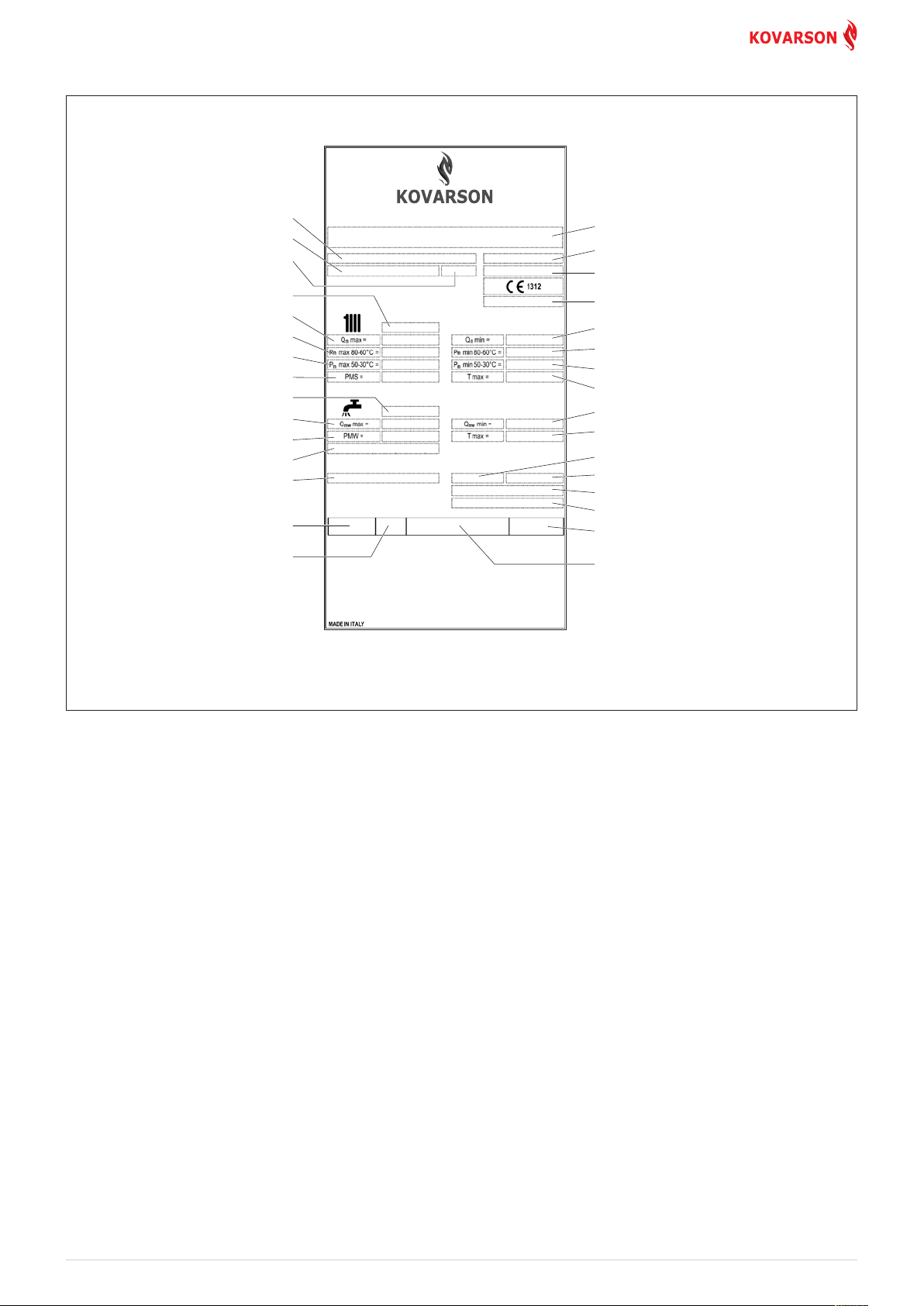

1.3.1 Data label

NAME

SERIAL NUMBER

YEAR OF MANUFACTURE

WATER CONTENT IN BOILER

MAX HEAT INPUT

MAX USEFUL OUTPUT (80-60°C)

MAX USEFUL OUTPUT (50-30°C)

MAX OPERATING PRESSURE

D.H.W. CONTENT

MAX HEAT INPUT

MAX OPERATING PRESSURE

FLOW RATE

ELECTRICAL SUPPLY

MAXIMUM ABSORBED POWER

COUNTRY OF INTENDED

INSTALLTION

APPLIANCE CATEGORY

APPLIANCE TYPE

CODE

REFERENCE DIRECTIVE

PIN NO.

MIN HEAT INPUT

MIN USEFUL OUTPUT (80-60°C)

MIN USEFUL INPUT (50-30°C)

MAX OPERATING TEMPERATURE

MIN HEAT INPUT

MAX D.H.W. TEMPERATURE

ELECTRICAL PROTECTION DEGREE

NOx CLASS

GAS COUNCIL NUMBER CODE (UK)

WRAS CERTIFICATION (UK)

TYPE OF GAS

SUPPLY PRESSURE

APPLIANCE CLASSIFICATION

m

Fig. 2

CAUTION

Tampering with, removing or failing to display the identification plate or carrying out any other operation which does not

allow safe identification of the product or which may hinder installation and maintenance operations.

5

Page 6

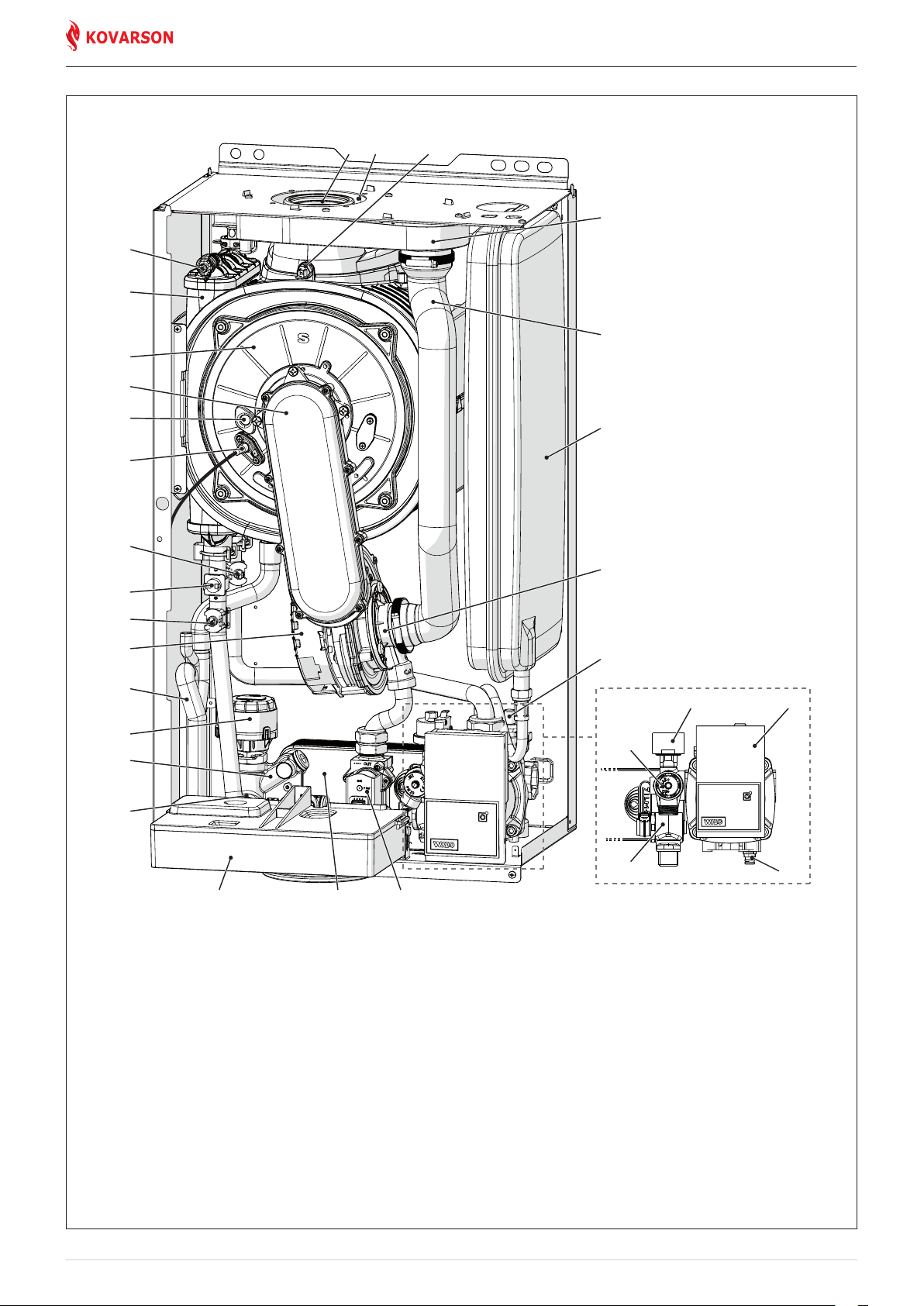

1.4 Structure

28

15 16 17

11

12

13

14

10

2930

1

2

3

4

27

26

5

25

6

7

24

8

9

23

22

21

19

18

20

1

Heat exchanger bleed point

2

Heat exchanger

3

Combustion chamber door

4

Oversleeve

5

Flame inspection window

6

Ignition/detection electrode

7

Return probe

8

Heat safety thermostat

9

Flow probe

10

Fan

11

Condensate siphon

12

Diverter valve

13

System filling unit

14

Domestic hot water sensor

15

Control panel

16

Domestic hot water heat exchanger

6

17

Gas valve

18

Domestic hot water filter

19

System safety valve

20

Boiler drain

21

System pump

22

Water pressure transducer

23

Automatic vent valve

24

Air-gas mixer

25

Expansion vessel

26

Air inlet pipe

27

Air-smoke chamber

28

Exhaust flue probe

29

Air inlet

30

Smoke outlet

Fig. 3

Page 7

1.5 Technical features

DESCRIPTION

20 25 30 35

CERTIFICATIONS

Country of intended installation IT – ES – PT – GR – SI

Fuel G20 / G31

PIN number 1312CP5936

Category II2H3P

Appliance classification B23P - B33P - B53P - C13 - C33 - C43 - C53 - C63 - C83

NO

x

class 5 (< 70 mg/kWh)

HEATING PERFORMANCE

HEAT INPUT (*)

Nominal flow (Q

Minimum flow (Q

n

max) kW 20 24 30 35

nw

min) kW 4 4,8 6 7

HEAT OUTPUT

Nominal (80-60°C) (P

Nominal (50-30°C) (P

Minimum G20 (80-60°C) (P

Minimum G20 (50-30°C) (P

Minimum G31 (80-60°C) (P

Minimum G31 (50-30°C) (P

n

max) kW 19,7 23,6 29,5 34,5

n

max) kW 21,4 25,7 32,2 37,5

n

min) kW 3,9 4,7 5,9 6,9

n

min) kW 4,3 5,1 6,5 7,5

n

min) kW 3,9 4,7 5,9 6,9

n

min) kW 4,3 5,1 6,5 7,5

EFFICIENCY

Max useful efficiency (80-60°C) % 98,5 98,3 98,3 98,6

Min useful efficiency (80-60°C) % 97,5 97,9 98,3 98,6

Max useful efficiency (50-30°C) % 107 107,1 107,3 107,1

Min useful efficiency (50-30°C) % 107,5 106,3 108,3 107,1

Useful efficiency at 30% of load (40-30°C) % 107,0 107,0 107,0 107,0

Thermal efficiency (EEC 92/42)

Losses after shutdown at 50°C W 84 88 88 92

DOMESTIC HOT WATER PERFORMANCE

Nominal heat input (Q

Minimum heat input (Q

nw

max) kW 24 28 34,8 40

nw

min) kW 4 4,8 6 7

Specific D.H.W. flow rate ∆t 30°C (EN 13203) l/min 11,2 12,9 16,5 19,4

Continuous D.H.W. flow rate (∆t 25°C / ∆t 35°C) l/min 13,6 / 9,7 16,1 / 11,5 20 / 14,3 22,9 / 16,4

Minimum D.H.W. flow rate l/min 2 2 2 2

Max (PMW) / Min Pressure

bar 7 / 0,5 7 / 0,5 7 / 0,5 7 / 0,7

kpa 700 / 50 700 / 50 700 / 50 700 / 70

ENERGY PERFORMANCE

HEATING

Heating seasonal energy efficiency class A A A A

Heating seasonal energy efficiency % 90 90 90 91

Sound power db(A) 59 61 58 60

DOMESTIC HOT WATER

Domestic hot water energy efficiency class A A A B

Domestic hot water energy efficiency % 81 80 80 81

Stated domestic hot water profile load XL XL XL XXL

ELECTRICAL SPECIFICATIONS

Power supply voltage V 230

Frequency Hz 50

Absorbed electrical power (Q

Absorbed electrical power at (Q

n

max) W 70 85 92 111

n

min) W 52 52 57 58

Absorbed electrical power in stand-by W 3,6 3,6 3,6 3,6

Electric degree of protection IP X5D

COMBUSTION DATA

Smoke temperature at Max/Min flow (80-60°C) °C 82 / 66 89 / 71 77 / 67 75 / 62

Smoke temperature at Max/Min flow (50-30°C) °C 59 / 45 71 / 51 58 / 49 54 / 39

Maximum smoke flow Min/Max g/s 11,2 / 1,9 13,1 / 2,2 16,3 / 2,8 18,6 / 3,3

CO

2

at Max/Min flow rate (G20) % 9,0 / 9,0 9,0 / 9,0 9,0 / 9,0 9,0 / 9,0

CO

2

at Max/Min flow rate (G31) % 10,0 /10,0 10,0 /10,0 10,0 / 10,0 10,0 / 10,0

NOx measured mg/kWh 39 41 37 65

NOZZLES GAS

Number of nozzles n° 1 1 1 1

ADAX

7

Page 8

18

M U G E RSc S

TR

DESCRIPTION

Nozzle diameter (G20-G31) mm 5,3 5,3 5,3 5,3

Gas consumption at Max/Min flow rate (G20) m

Gas consumption at Max/Min flow rate (G31) Kg/h 1,86 / 0,31 2,17 / 0,37 2,71 / 0,46 3,10 / 0,74

Gas supply pressure (G20/G31)

TEMPERATURE PRESSURE

Max operating temperature (T max) °C 85

Heating adjustment range °C 20÷80

Domestic hot water adjustment range °C 10÷60

Max operating pressure (PMS)

Water content in boiler l 4,65 4,75 4,95 5,60

3

/h 2,53 / 0,42 2,96 / 0,50 3,70 / 0,63 4,23 / 0,74

mbar 20 / 37 20 / 37 20 / 37 20 / 37

kpa 2 / 3,7 2 / 3,7 2 / 3,7 2 / 3,7

bar 3

kpa 300

20 25 30 35

ADAX

(*) Heat input calculated using the lower heat output (Hi)

Lower Heat Output (Hi)

G20 Hi.

9.45 kW/m3 (15°C, 1013 mbar) -

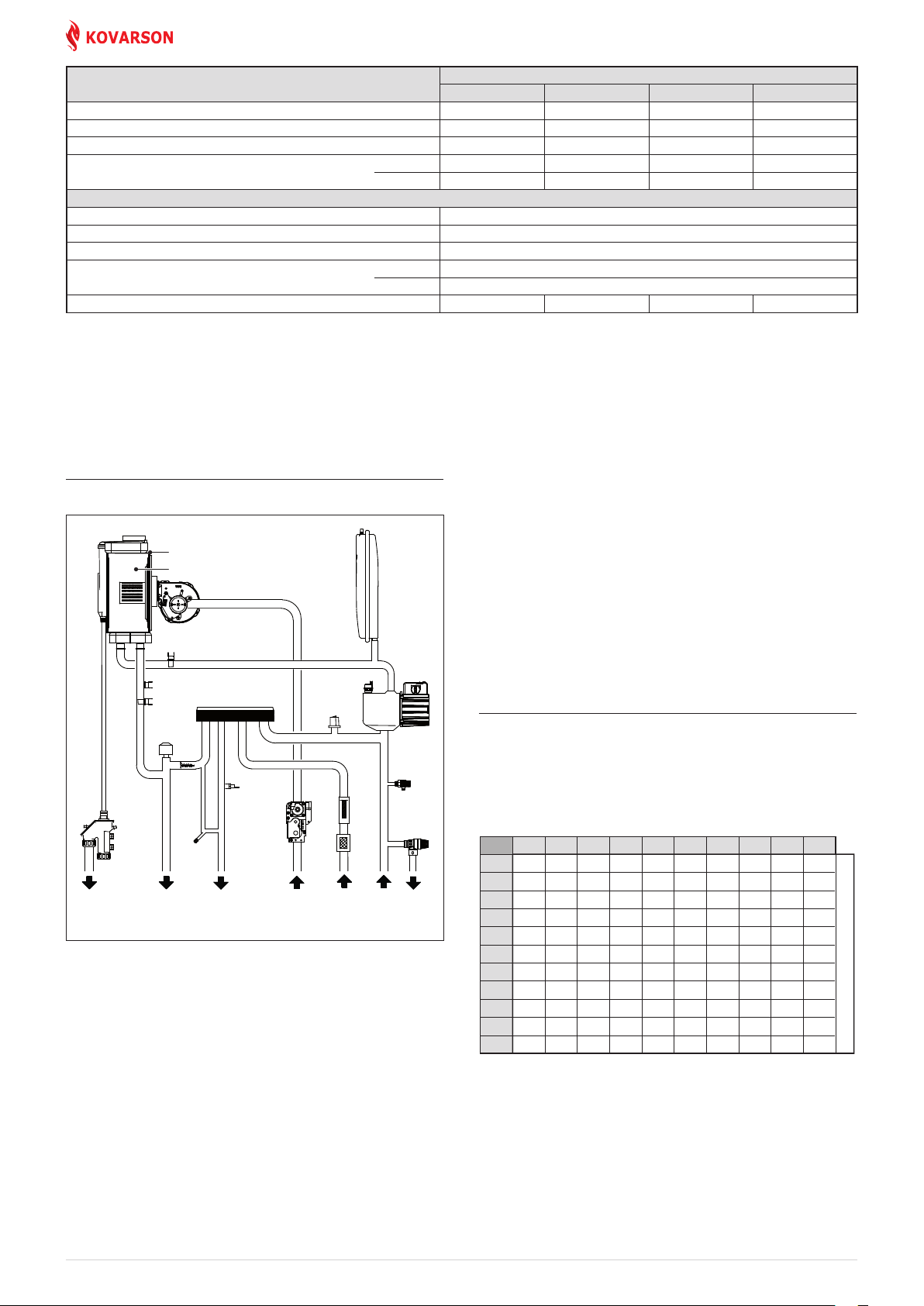

1.6 Main water circuit

1

2

3

4

5

6

12

7

G31 Hi.

12.87 kW/kg (15°C, 1013 mbar)

11

9

10

8

9

Automatic vent valve

10

Pump

11

CH expansion vessel

12

Diverter valve

13

Automatic by-pass

14

Domestic hot water sensor

15

Gas valve

16

Domestic hot water flow meter

17

Domestic hot water filter

18

Boiler drain

19

System relief valve

20

System filling cock

21

Condensate drain siphon

1.7 Sensors

The sensors installed have the following characteristics:

– Dual sensor (thermal safety/output) NTC R25°C; 10kΩ β25°-

13

21

20

KEY:

M System delivery

R System return

U Domestic hot water outlet

E Domesti hot water inlet

S Safety valve outlet

14

15

16

19

17

Fig. 4

85°C: 3435

– domestic hot water sensor NTC R25°C; 10kΩ β25°-85°C: 3435

– external sensor NTC R25°C; 10kΩ β25°-85°C: 3435

0°C 1°C 2°C 3°C 4°C 5°C 6°C 7°C 8°C 9°C

0°C

27279

26135

25044

24004

23014

22069

21168

20309

19489

18706

17959

17245

16563

15912

15289

14694

14126

13582

13062

8945

6247

4444

3216

2365

1766

1336

1024

12565

8622

6033

4300

3116

2296

1717

1300

998

10°C

20°C

30°C

40°C

50°C

60°C

70°C

80°C

90°C

100°C

12090

8313

5828

4161

3021

2229

1669

1266

973

11634

8016

5630

4026

2928

2164

1622

1232

11199

7731

5440

3897

2839

2101

1577

1199

10781

7458

5258

3773

2753

2040

1534

1168

10382

7196

5082

3653

2669

1982

1491

1137

9999

6944

4913

3538

2589

1925

1451

1108

9633

6702

4751

3426

2512

1870

1411

1079

9281

6470

4595

3319

2437

1817

1373

1051

G Gas supply

Sc Condensate outlet

1

Condensing heat exchanger

2

Combustion chamber

3

Fan

4

Return probe

5

Thermal safety thermostat

6

Flow probe

7

Domestic hot water heat exchanger

8

Pressure transducer

Correspondence of Temperature Detected/Resistance

Examples of reading:

TR=75°C → R=1925Ω

TR=80°C → R=1669Ω.

Resistance R (Ω)

8

Page 9

1.8 Expansion tank

0 800 1000 1200600400200

100

200

300

400

500

600

The expansion vessel installed on the boilers has the following

characteristics:

Description U/M

Total capacity l 9,0 10,0

Prefilling pressure

Useful capacity l 5,0 6,0

Maximum system

content (*)

(*) Conditions of:

Average maximum temperature of the system 85°C

Start temperature at system filling 10°C.

m

CAUTION

– For systems with water content exceeding the

maximum system content (as indicated in the

table) an additional expansion vessel must be

prearranged.

– The difference in height between the relief valve

and the highest point of the system cannot exceed

6 metres. If the difference is greater than 6 metres,

increase the prefilling pressure of the expansion

vessel and the system when cold by 0.1 bar for each

meter increase.

kPa 100

bar 1,0

20 25 30 35

l 124 140

ADAX

1.9 Circulation pump

The flow-head performance curve available for the heating

system is shown in the graph below.

1.9.1 Pump equipped with LED

LED

Fig. 6

ADAX 30

warning lights which indicate:

For the "Any pump faults and possible solutions" see the

relevant section at the end of the manual.

and

ADAX 35

LED colour Status Trouble-shooting

LED off No electrical power

Green

Red/Green Flashing

Red Flashing Permanent safety shutdown

boilers use the pump equipped with LED

Permanently

on

Normal operation

"Transient safety shutdown"

Anomaly in progress

RESIDUAL HEAD (mbar)

0

m

CAUTION

The appliance is equipped with a by-pass which

ensures water circulation in the boiler when the

thermostatic valves or cocks are used in the system.

40

35

25

30

FLOW RATE (l/h)

Fig. 5

9

Page 10

1.10 Control panel

21

1

FUNCTIONAL BUTTONS

If pressed once or more than once for at least 1 second

y

during normal operation, this button allows the user

to change the boiler operating mode in a cyclical

sequence (Stand-by – Summer – Winter). If the boiler is

experiencing a fault which can be reset, it allows boiler

operation to be unblocked.

During normal operation, pressing the button displays

r

the domestic hot water set point which can be between

10 and 60°C. In "parameter setting", the user can scroll

through the parameter index (decreasing) by pressing

this button.

During normal operation, pressing the button displays

t

the heating set point which can be between 20 and

80°C. In "parameter setting", the user can scroll

through the parameter index (increasing) by pressing

this button.

Fig. 7

NOTE:

pressing any one of these buttons for more than 30

seconds generates a fault on the display without preventing

boiler operation. The warning disappears when normal

conditions are restored.

2

DISPLAY

“SUMMER”

l

operating in "Summer" mode or if only the domestic

hot water mode is enabled via the remote control. If the

symbols

chimney sweep function is active.

“WINTER”

n

operating in "Winter" mode or if both the domestic hot

water and heating modes are enabled via the remote

control. With the remote control, if no operating modes

have been enabled both symbols

“RESET REQUIRED”

d

having repaired the fault, normal boiler operation can be

restored by pressing the button

“DOMESTIC HOT WATER”

r

a DHW request or during the "chimney sweep function"

It flashes during the selection of the domestic hot water

set point.

“HEATING”

t

operation or during the "chimney sweep function It

flashes during the selection of the heating set point.

“BLOCK” DUE TO NO FLAME

f

“FLAME PRESENCE”

F

“POWER LEVEL”

v

the boiler is operating.

“PARAMETER”

p

parameter setting/display, or "info" or "counter", or in

"activated alarms" (history).

“ALARM”

A

number specifies the cause which generated the alarm.

“CHIMNEY SWEEP”

z

sweep function" has been activated.

. This symbol appears when the boiler is

and n are flashing, this indicates that the

l

. This symbol appears when the boiler is

and n will be off.

l

. The message indicates that after

.

y

. This symbol is present during

. This symbol lights up during heating

.

.

. This indicates the power level at which

. This indicates that the user may be in

. This indicates that a fault has occurred. The

. This indicates that the "chimney

During normal operation, pressing this button allows

<

the user to reduce the heating or DHW set point on

the basis of the selection made previously. If there is a

Remote Control (Open Therm), after having selected the

heating button, the user can modify the incline of the

climatic curve (decreasing it) by pressing the button (

In "parameter setting/display", the user can modify the

parameter setting or value (decreasing) by pressing this

button.

During normal operation, pressing this button allows

>

the user to increase the heating or DHW set point on

the basis of the selection made previously. If there is a

Remote Control (Open Therm), after having selected the

heating button, the user can modify the incline of the

climatic curve (increasing it) by pressing the button (

In "parameter setting/display", the user can modify the

parameter setting or value (increasing) by pressing this

button.

Programming connector cover plug.

c

10

-

).

+

).

Page 11

1.11 Wiring diagram

BLUE

230 V - 50 Hz

PI

VD

2 3

L

N

CN11

BROWN

BLACK

BROWN

BLUE

BROWN

BLUE

BROWN

BLUE

BLUE

FLM

VCC

RED

BROWN

GND

IN

WHITE

GREEN

SF

V

4 3 2 1

BLUE

BLACK

GREEN

RED

BLUE

BLACK

BLACK

CR

TA

CN15

TA2

BLACK

BLACK

SS

RED

RED

TPA

GND

RED

5V

OUT

GREEN

ORANGE

RED

RED

SR

SE

321 4 5 6

BLUE

GREEN

GREEN

EV

CN13CN12

CN14

F

BLACK

BLACK

CN2

CN3

BLUE

BLUE

TS

EAR

m

CN5

CN4 CN1

SM

BLUE

BROWN

RED

GREEN

BLACK

BLUE

SR

Return Probe

TS

Safety thermostat

TFU

Thermal fuse

SF

Exhaust flue probe

FLM

Flow meter

VD

Diverter valve

TPA

Pressure transducer

TA-TA2

Air thermostat

SE

External sensor

CR

Remote control (instead of air thermostat)

TRA

L

Line

N

Neutral

F

Fuse (3.15AT)

TRA

Ignition transformer

PI

System pump

V

Fan

EAR

Ignition / Detection electrode

EV

Gas supply solenoid valve

SS

Domestic hot water sensor

SM

Flow probe

CD. 6324920

CN17

CN6

To connect the "Air Thermostat" or, alternatively the "Remote Control", remove the bridge

between terminals 5-6.

CAUTION

Users must:

d

IT IS FORBIDDEN

To use water pipes for earthing the appliance.

– Use an omnipolar cut-off switch, disconnect switch

in compliance with EN Standards

– Respect the connections L (Live) - N (Neutral)

– Ensure that the special power cable is only replaced

with a cable ordered as a spare part and connected

by professionally qualified personnel

– Connect the earth wire to an effective earthing

system. The manufacturer is not responsible for any

damage caused by failure to earth the appliance or

failure to observe the information provided in the

wiring diagrams.

TFU

Fig. 8

11

Page 12

2 INSTALLATION

H

2.1 Unpacking the product

ADAX

appliances are delivered in a single unit protected by

cardboard packaging.

Fig. 9

The plastic bag found inside the packaging contains the

following:

– Installation, use and maintenance manual

– Paper template for boiler installation

– Certificate of warranty

– Hydraulic test certificate

– System booklet

– Bag with expansion plugs

Description

L (mm) 400

D (mm) 250 250 250 300

H (mm) 700

Weight (kg) 28,5 28,5 30,0 32,5

20 25 30 35

ADAX

2.3 Handling

Once the packaging has been removed, the appliance is to

be handled manually, tilting it slightly, lifting it and applying

pressure in the points indicated in the figure.

Fig. 11

d

2.2 Dimensions and weight

IT IS FORBIDDEN

Do not leave packaging material around or near

children since it could be dangerous. Dispose of it as

prescribed by legislation in force.

d

a

IT IS FORBIDDEN

DO NOT

"solid" parts such as the base and the rear structure.

DANGER

Use suitable tools and accident protection when

removing the packaging and when handling the

appliance.

hold onto the appliance cladding but use the

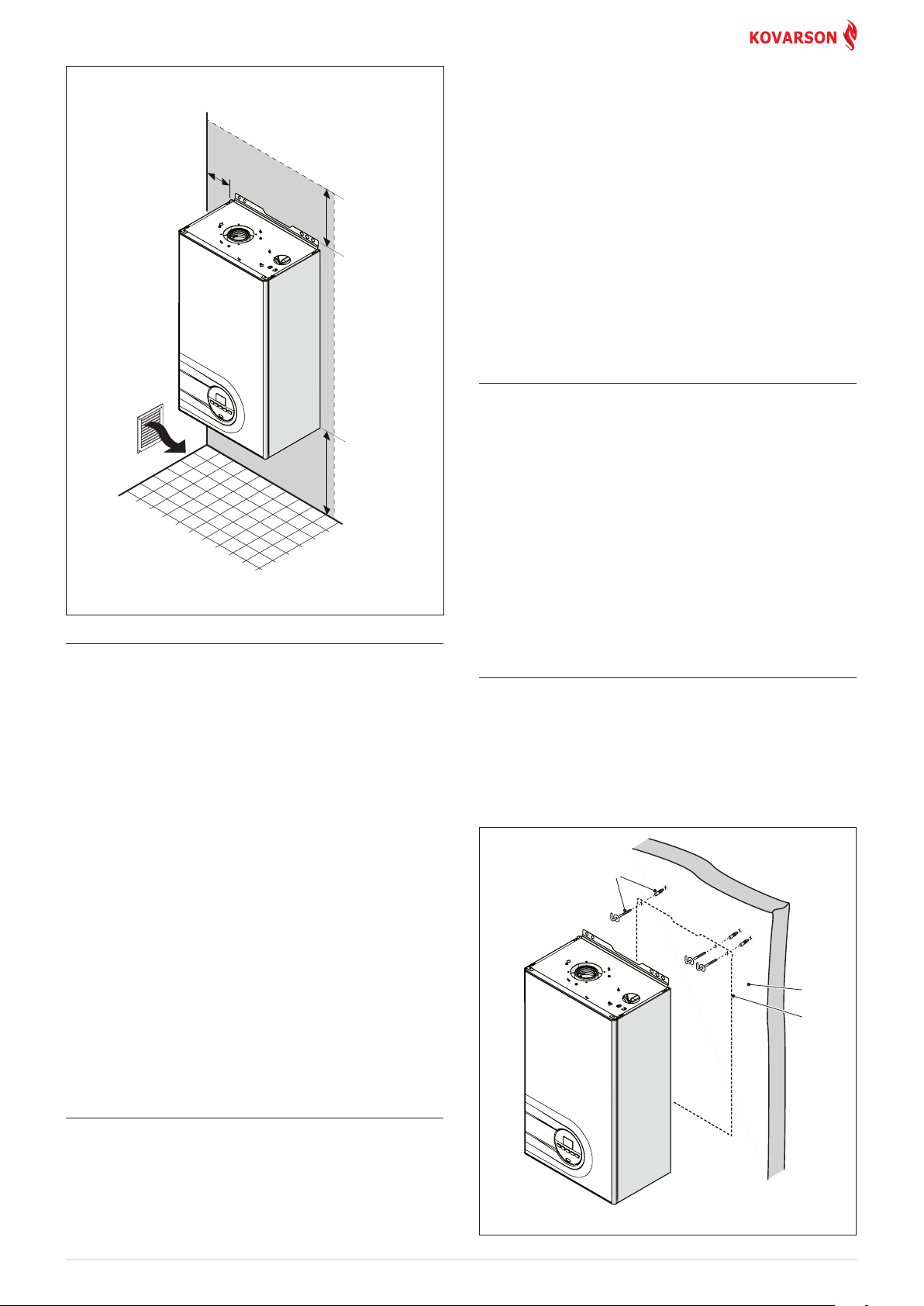

2.4 Installation room

The room where the appliance is to be installed must comply

with the Technical Regulations and Legislation in force. It must

be equipped with suitably sized ventilation openings when the

installation is a "TYPE B" installation.

The minimum temperature of the installation room must NOT

-5 °C

be lower than

m

L

P

CAUTION

Remember to consider the space needed in order to

access the safety/adjustment devices and to carry out

maintenance interventions (see Fig. 12).

.

Fig. 10

12

Page 13

APPROXIMATE MINIMUM DISTANCES

≥ 300 mm

≥ 900 mm

1

2

≥ 50 mm

Before removing an old heat generator from an existing system,

it is recommended that the user:

– puts a descaling additive into the water system

– allows the system to work with the generator active for a few

days

– drains the dirty water from the system and flushes the system

with clean water once or more than once.

If the old generator has already been removed or is not available,

replace it with a pump to circulate water in the system and then

proceed as described above.

Once cleaning operations have been carried out and before

installing the new appliance, it is recommended that a fluid

is added to the water system to protect it from corrosion and

deposits.

Fig. 12

2.5 New installation or installation of a

replacement appliance

When

ADAX

boilers are installed on old systems or systems

requiring updating, it is recommended the installer checks that:

– the connecting flue pipe is suitable for the combustion

temperature of the appliance, calculated and manufactured in

compliance with Standards, that it is as straight as possible,

air tight, isolated, with no obstructions or restriction and

that it has appropriate condensate collection and evacuation

systems

– the electrical system has been manufactured in compliance

with specific Standards and by professionally qualified

personnel

– the fuel delivery line and the tank (LPG) comply fully with

specific Standards

– the expansion vessel ensures total absorption of the fluid

dilation in the system

– the pump flow-head performance is sufficient for the system

characteristics

– the system is clean, free of any sludge, deposits, de aerated

and air tight. For system cleaning, please refer to the relevant

paragraph.

m

CAUTION

For further information on the type of additive and

usage, please contact the appliance manufacturer.

2.7 Water system treatment

When filling and restoring the system it is good practice to use

water with:

– aspect: clear if possible

– pH: 6÷8

– hardness: < 25°f.

If the water characteristics are different from those indicated, it

is recommended that a safety filter is used on the water delivery

pipe to retain impurities, and a chemical treatment system to

protect against possible deposits and corrosion which could

affect boiler operation.

If the systems are only low temperature systems, it is

recommended that a product is used to prevent the development

of bacteria.

In any case, please refer to and comply with Legislation and

specific Technical Standards in force.

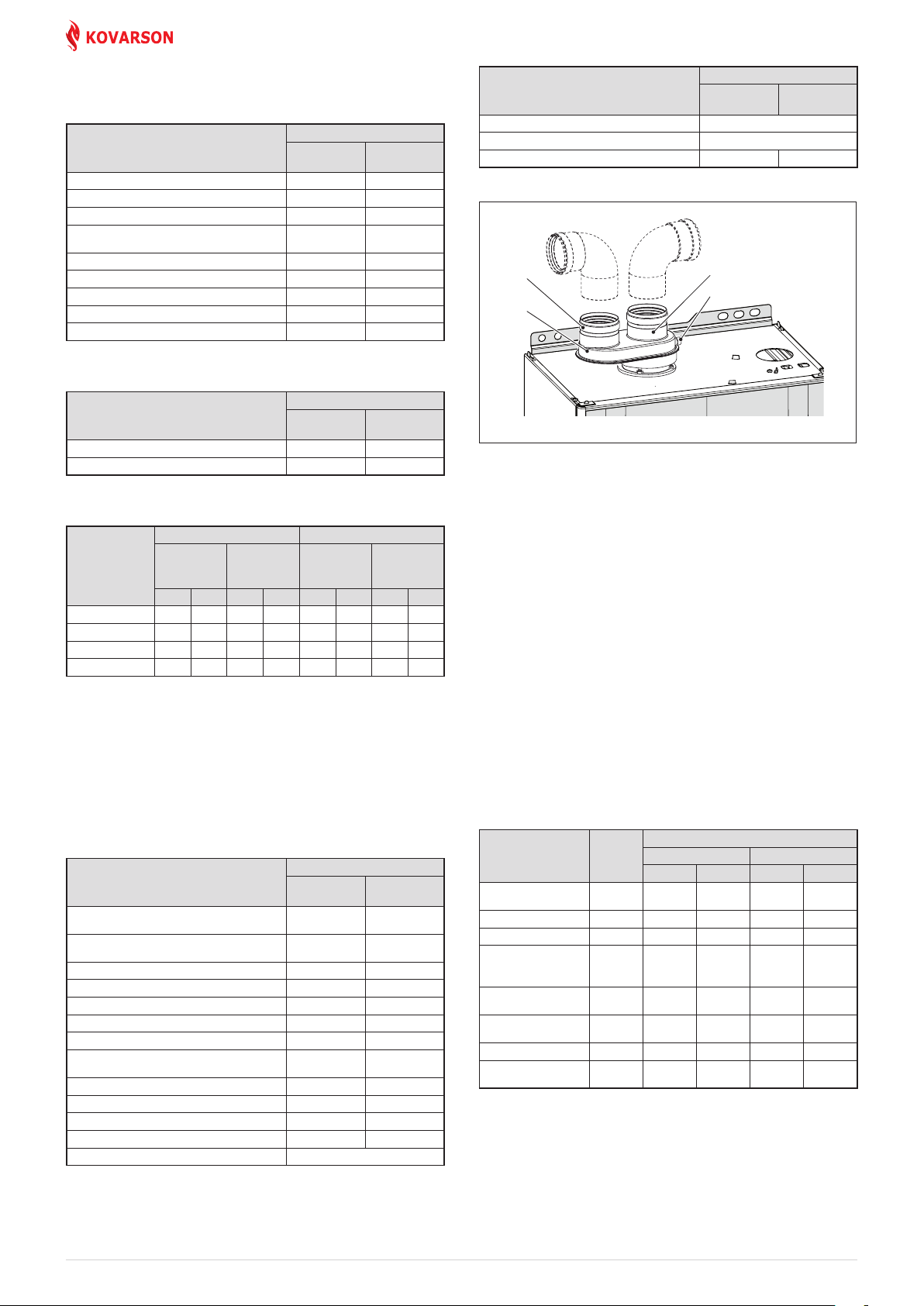

2.8 Boiler installation

ADAX

boilers leave the factory with a paper template for

installation onto a solid wall.

For installation:

– position the paper template (1) on the wall (2) where the boiler

is to be mounted

– make the holes and insert the expansion plugs (3)

– hook the boiler onto the plugs.

3

m

CAUTION

The manufacturer declines all liability for any damage

caused by an incorrect implementation of the smoke

outlet.

2.6 Cleaning the system

Before installing the appliance on a newly constructed system or

replacing a heat generator on an existing system, it is important

that the system is thoroughly cleaned to remove sludge, slag,

dirt, residue etc.

Fig. 13

13

Page 14

m

CAUTION

– The height of the boiler is to be such that disassembly

and maintenance interventions are facilitated.

2.9 Hydraulic connections

The plumbing connections have the following characteristics

and dimensions.

2.9.1 Plumbing accessories (optional)

To facilitate plumbing and gas connections to the systems, the

accessories as shown in the table below are available and are to

be ordered separately from the boiler.

DESCRIPTION CODE

Installation plate 8075441

Curve kit 8075418

Curve and valve kit with connections from DIN to

SIME

Cocks kit 8091806

Valve kit with connections from DIN to SIME 8075442

Wall mount replacement kit for other makers 8093900

Connection protection kit (for models 25-30-35 kW) 8094530

Polyphosphate dosing kit 8101700

Dosing recharge kit 8101710

Solar kit for instant combination boilers 8105101

NOTE:

kit instructions are supplied with the accessory itself or

are to be found on the packaging.

8075443

2.10 Condensate outlet/collection

In order to collect the condensate, it is recommended that:

– the appliance condensate outlets and the smoke outlet are

ducted

– a neutralising device is prearranged

>3%

– the outlet incline is

.

48

Sc

65 65 65 65 ==

M

U G E R

400

Description

M - System delivery Ø 3/4" G

R - System return Ø 3/4" G

U - Domestic hot water output Ø 1/2" G

E - Domestic hot water inlet Ø 1/2" G

G - Gas supply Ø 3/4" G

Sc - Condensate outlet Ø 20 mm

20 25 30 35

95

175

ADAX

Sc

Fig. 14

m

CAUTION

– The condensate outlet duct must be airtight,

suitably sized to that of the siphon and must not be

restricted at any point.

– The condensate outlet must be constructed in full

compliance of the National or Local regulations in

force.

– Before commissioning the appliance, fill the siphon

with water.

2.11 Gas supply

ADAX

boilers leave the factory prearranged for gas G20 and can

also work with G31 without the need for any type of mechanical

”03”

conversion. Simply select parameter

setting and display") and set the type of gas to be used.

If changing the type of gas to be used, carry out the entire

appliance

Boiler connection to the gas mains must be carried out in full

compliance with installation Standards in force.

Perform the following checks before making the connection:

– check that the boiler is compatible with the type of gas supply

– the pipes are clean

– the gas supply pipe is the same dimension as or greater than

that of the boiler fitting (G3/4") and with a load loss less than

or equal to that contemplated between the gas mains and the

boiler.

“COMMISSIONING”

phase.

(see “Parameter

a

m

14

DANGER

Once installation has been completed, check that

the joints are air tight as indicated in the installation

Standards.

CAUTION

It is recommended that the gas line has a suitable

filter.

Page 15

2.12 Smoke outlet and combustion air inlet

max 0,5 m

ADAX

boilers must be equipped with appropriate smoke flue ducts and combustion air inlet ducts. These ducts are considered an

integral part of the boiler and are provided by

of the type permitted and the system requirements.

Permitted outlets

KOVARSON

as an accessory kit, to be ordered separately from the appliance on the basis

B33P

C53

C83

B23P

B53P

B23P-B53P

Combustion air inlet into the atmosphere and smoke

outlet to open air.

B33P

Combustion air inlet into the atmosphere and smoke

outlet into single flue.

NOTE:

opening for combustion air (6 cm2 x kW).

C13

Concentric wall smoke outlet The pipes can start from

the boiler but the outlets must be concentric or close

together (no more than 50 cm) to be subject to similar

wind conditions.

C43

C43

C33

C63

Same type as C42 but with outlet and inlet made from

pipes which are sold and certified separately.

C53

Separate wall or roof inlet and outlet in different

pressure areas.

NOTE:

the inlet and outlet must never be positioned on

opposing walls.

C83

Outlet in single or shared flue or with inlet on wall.

C33

C13

C13

max 0,5 m

C33

Concentric roof smoke outlet The pipes can start from

the boiler but the outlets must be concentric or close

together (no more than 50 cm) to be subject to similar

wind conditions.

C43

Outlet and inlet in shared or separate flue pipes but

subjected to similar wind conditions.

m

P:

smoke outlet system designed to operate with

positive pressure.

Fig. 15

WARNINGS

– The smoke flue and the connection to the flue pipe must be in compliance with the national and local Standards and

Legislation in force.

– The use of rigid ducts which are resistant to temperature, condensate, mechanical stress and are air-tight is compulsory.

– Outlet ducts which are not isolated are a risk of danger.

15

Page 16

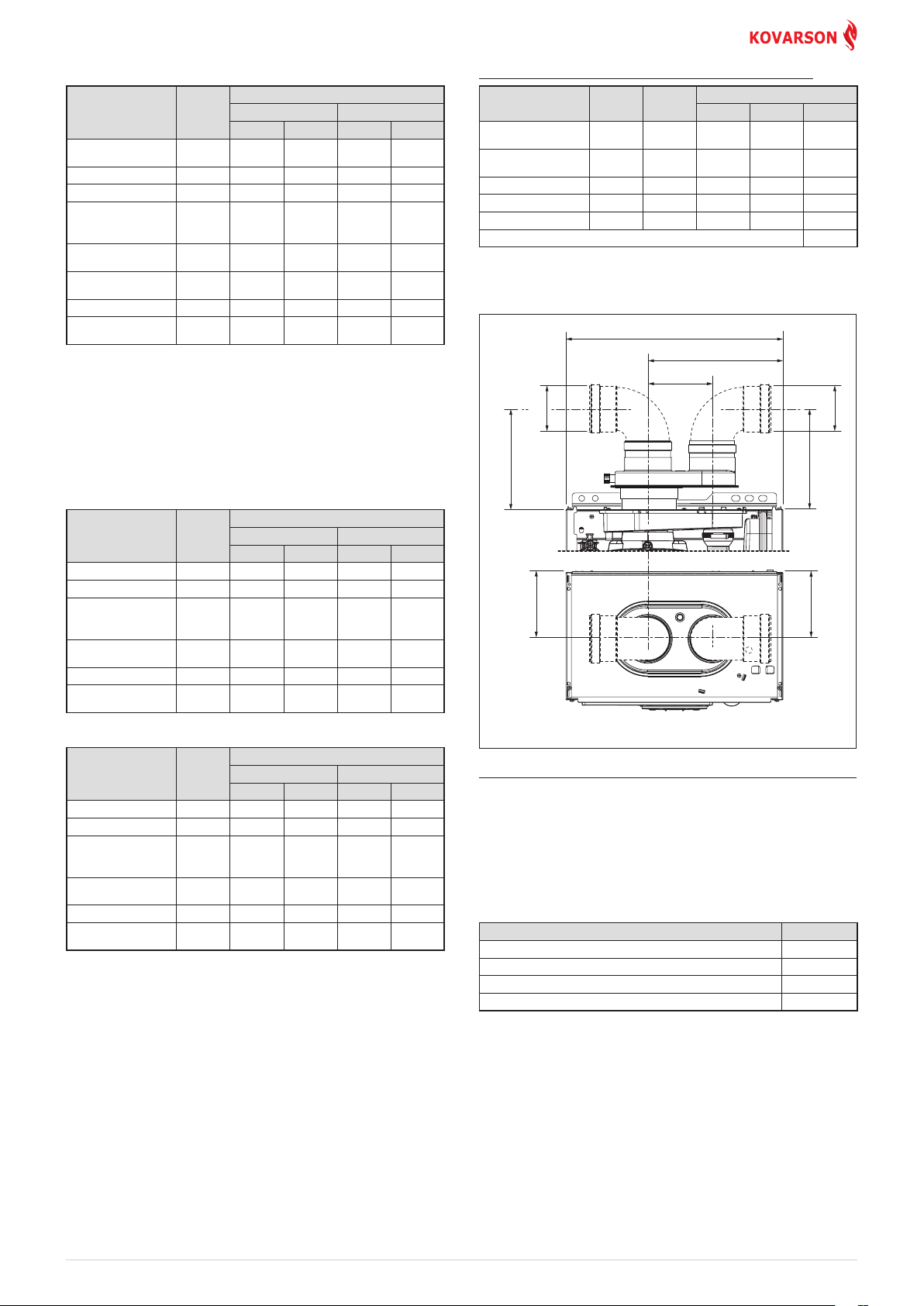

2.12.1 Coaxial duct (Ø 60/100mm and Ø 80/125mm)

Coaxial accessories

Description

Coaxial duct kit 8096250 8096253

Extension W. 1000 mm 8096150 8096171

Extension W. 500 mm 8096151 8096170

Vertical extension W. 140 mm with

smoke analysis take-off point

Adapter for Ø 80/125 mm - 8093150

Additional 90° curve 8095850 8095870

Additional 45° curve 8095950 8095970

Tile with joint 8091300 8091300

Roof outlet terminal W. 1284 mm 8091205 8091205

Ø 60/100 mmØ 80/125

8086950 -

Code

mm

Load loss - Equivalent lengths

Model

90° curve 1,5 2

45° curve 1 1

Leq (linear metres)

Ø 60/100 mmØ 80/125

mm

Minimum-Maximum Lengths

Duct Length Ø 60/100 Duct Length Ø 80/125

Model

ADAX 20

ADAX 25

ADAX 30

ADAX 35

W

Horizontal

(m)

Min.

- 6 1,3 8 - 12 1,2 15

- 6 1,3 7 - 10 1,2 13

- 4 1,3 6 - 10 1,2 13

- 4 1,3 6 - 10 1,2 13

Max.

H Vertical

(m)

Min.

Max.

W

Horizontal

(m)

Min.

Max.

H Vertical

(m)

Min.

Max.

2.12.2 Separate ducts (Ø 60mm and Ø 80mm)

Constructing outlets for separate ducts indicates the use of the

"air-smoke split pipe system". This is to be ordered separately

from the boiler and when connected to the other accessories,

from those listed in the table below, completes the smokeoutlet/ combustion air inlet assembly.

Separate accessories

Description

Air-smoke split pipe system (without

take-off point)

Air-smoke split pipe system (with takeoff point)

90° curve M-F (6 pieces) 8089921 8077450

90° curve M-F (with take-off point) 8089924 M-F 80/60 reduction 8089923 Extension W. 1000 mm (6 pieces) 8089920 8077351

Extension W. 500 mm (6 pieces) - 8077350

Extension W. 135 mm (with take-off

point)

Wall outlet terminal 8089541 8089501

Internal and external ring nut kit 8091510 8091500

Inlet terminal 8089540 8089500

45° curve M-F (6 pieces) 8089922 8077451

Collector 8091400

Diameter Ø

60 (mm)

8093060 -

Code

Diameter Ø

80 (mm)

- 8093050

- 8077304

Description

Tile with joint 8091300

Roof outlet terminal W. 1390 mm 8091204

Inlet/outlet fitting Ø 80/125 mm - 8091210

Diameter Ø

60 (mm)

Code

Diameter Ø

80 (mm)

Split pipe system

2

3

4

1

Fig. 16

KEY:

1

Split pipe system with take-off point

2

Air inlet

3

Smoke outlet

4

Flue gas analysis socket

m

CAUTION

–

The maximum total length of the ducts

, obtained by

adding the lengths of the inlet and outlet pipes, is

determined by the load losses of the individual

accessories used and

For all boiler versions, the total extension

–

must not exceed 15 mm H2O

must not in

.

any case exceed 25 m (inlet) + 25 m (outlet) for ducts

Ø 80 mm. |b|The total extension must not in any case

exceed 6 m (inlet) + 6 m (outlet) for ducts Ø 60mm

for models

ADAX 20

m (outlet) for models

and

ADAX 30

ADAX 25

and

, and 4 m (inlet) + 4

ADAX 35

, even if

the total load loss is less than the maximum which

can be applied.

Load loss accessory Ø 60 mm

Load loss (mm H2O)

Description Code

Air/smoke split

pipe system

90° curve MF 8089921 0,4 0,9 0,5 1,1

45° curve MF 8089922 0,35 0,7 0,45 0,9

Horizontal

extension W. 1000 mm8089920 0,4 0,9 0,5 1,1

Vertical extension

W. 1000 mm

Wall outlet

terminal

Wall inlet terminal 8089540 0,5 _ 0,8 _

Roof outlet

terminal (*)

8093060 2,5 0,5 2,5 0,5

8089920 0,4 0,6 0,5 0,7

8089541 _ 1,2 _ 1,4

8091204 0,8 0,1 1,1 0,15

ADAX 20 ADAX 25

Inlet

Drain

Inlet

Drain

(*) The losses of the roof outlet terminal at inlet include the

manifold code 8091400.

16

Page 17

Load loss accessory Ø 60 mm

185

400

Load loss (mm H2O)

Description Code

Air/smoke split

pipe system

90° curve MF 8089921 0,6 1,4 0,6 1,4

45° curve MF 8089922 0,55 1,2 0,55 1,2

Horizontal

extension W. 1000 mm8089920 0,6 1,4 0,6 1,4

Vertical extension

W. 1000 mm

Wall outlet

terminal

Wall inlet terminal 8089540 1,1 _ 1,1 _

Roof outlet

terminal (*)

8093060 2,5 0,5 2,5 0,5

8089920 0,6 0,8 0,6 0,8

8089541 _ 1,6 _ 1,6

8091204 1,5 0,2 1,5 0,2

ADAX 30 ADAX 35

Inlet

Drain

Inlet

Drain

(*) The losses of the roof outlet terminal at inlet include the

manifold code 8091400.

NOTE:

for the boiler to operate correctly it is necessary that a

minimum distance of 0.50 m of the duct is respected with a 90°

inlet curve.

Load loss accessory Ø 80 mm

Load loss (mm H2O)

Description Code

90° curve MF 8077450 0,20 0,25 0,25 0,30

45° curve MF 8077451 0,15 0,15 0,20 0,20

Horizontal

extension W. 1000 mm8077351 0,15 0,15 0,20 0,20

ADAX 20 ADAX 25

Inlet

Drain

Inlet

Drain

Example: calculation of the load loss of a

Accessories Ø 80

mm

Extension W. 1000

mm (horizontal)

Extension W. 1000

mm (horizontal)

90° curve 8077450 2 2 x 0,20 - 0,40

90° curve 8077450 2 - 2 x 0,25 0,50

Wall terminal 8089501 2 0,10 0,25 0,35

TOTAL 3,35

8077351 7 7 x 0,15 - 1,05

8077351 7 - 7 x 0,15 1,05

Code

Quantity

ADAX 20

Load loss (mm H2O)

Inlet

boiler.

Drain Total

(installation permitted since the total of the load loss of the

accessories used is less than

15 mm H2O

).

250

120

Ø 80

Ø 80

185

169

169

Vertical extension

W. 1000 mm

Wall terminal 8089501 0,10 0,25 0,10 0,35

Roof outlet

terminal (*)

8077351 0,15 0,15 0,20 0,20

8091204 0,80 0,10 1,10 0,15

Load loss accessory Ø 80 mm

Load loss (mm H2O)

Description Code

90° curve MF 8077450 0,30 0,4 0,30 0,4

45° curve MF 8077451 0,25 0,25 0,25 0,25

Horizontal

extension W. 1000 mm8077351 0,25 0,25 0,25 0,25

Vertical extension

W. 1000 mm

Wall terminal 8089501 0,15 0,50 0,15 0,50

Roof outlet

terminal (*)

8077351 0,25 0,25 0,25 0,25

8091204 1,5 0,2 1,5 0,2

ADAX 30 ADAX 35

Inlet

Drain

Inlet

Drain

(*) The losses of the roof outlet terminal at inlet include the

manifold code 8091400.

NOTE:

for the boiler to operate correctly it is necessary that a

minimum distance of 0.50 m of the duct is respected with a 90°

inlet curve.

Fig. 17

2.13 Electrical connections

The boiler is equipped with a ready wired power cable which is

to be connected to a 230V~50 Hz network.

If this cable needs to be replaced, an original spare must be

requested from

KOVARSON

Therefore only the connections of the original components

as shown in the table are needed. These are to be ordered

separately from the boiler.

DESCRIPTION CODE

External sensor kit (ß=3435, NTC 10KOhm at 25°C) 8094101

Power cable (dedicated) 6323875

Remote control HOME (open therm) 8092280

Remote control HOME PLUS (open therm) 8092281

m

CAUTION

The maintenance interventions described must ONLY

be carried out the professionally qualified personnel.

.

17

Page 18

a

OFF

To facilitate introduction of the connection wires of the optional

components into the boiler:

– remove the two screws (1), pull the front panel (2) forwards

DANGER

Before carrying out any interventions described:

– set the main system switch to "OFF"

– close the gas valve

– make sure that no hot parts inside the appliance are

touched.

Fig. 18

and release it from the top by lifting it

– insert the connection wires into the cable gland (6) and the

opening (7) on the control panel

6

7

Fig. 21

– bring the control panel (4) to the original position and secure

it with the screws (3) which were removed previously

– connect the component wires to the terminal board (8)

following the indications provided on the data plate (9).

2

1

Fig. 19

– remove the screws (3) securing the control panel (4)

– move the panel (4) upwards (a) but keeping it in the side

guides (5) to the end of travel

– bring it forwards and down (b) until it is horizontal

4

4

9

8

TA

SE

m

6

5

4

3

2

1

3

Fig. 22

CAUTION

The following is mandatory:

– to use an omnipolar cut-off switch, disconnect

switch in compliance with EN Standards

– if the power cable is to be replaced, that ONLY

a special cable is used with a factory produced

re-wired connector, ordered as a spare part and

connected by a professionally qualified person

– to connect the earth wire to an effective earthing

system (*)

– that before any intervention on the boiler, the mains

power is disconnected by setting the main system

switch to "OFF".

b

3

a

18

5

Fig. 20

(*) The manufacturer is not responsible for any damage caused

by failure to earth the appliance or failure to observe the

information provided in the wiring diagrams.

Page 19

d

20 15 10 5 0 -10 -15-5 -20

°C

CR

SE

SE

IT IS FORBIDDEN

To use water pipes for earthing the appliance.

2.13.1 Outdoor sensor

The boiler is prearranged for connection to an external air

temperature sensor and can operate with a sliding temperature.

This means that the delivery temperature sent to the boiler can

vary on the basis of the external temperature depending on the

climatic curve selected from those shown in the diagram (Fig.

23).

When fitting the sensor on the outside of the building, follow

the instructions provided on the packaging of the product itself.

Climatic curve

ONE DIRECT ZONE system , external sensor and air thermostat.

SE

M

R

TA

CH flow temperature

90

80

70

60

50

40

30

20

m

K=9 K=6 K=4,5 K=3

CAUTION

If there is an external sensor, in order to select the

optimal climatic curve for the system and therefore

the delivery temperature based on the external

temperature:

– press the button

– press buttons

been selected (within the range

K=2,2

K=1,5

K=0,75

°C

Outdoor temperature

Fig. 23

for 1 second

t

or < until the required curve K has

>

K=0.0 - K=9.0

).

Fig. 24

MULTI ZONE system - with pump, air thermostat and external

sensor.

TA1

TA

M

MULTI ZONE system - with zone valve, air thermostat and

external sensor.

RL1

R

SP

TA2

RL2 RL3

TA3

P2P1

P3

Fig. 25

2.13.2 Chrono-thermostat or Air Thermostat

The electrical connection of the chrono-thermostat or air

thermostat has already been described. When fitting the

component in the room where the readings are to be taken,

follow the instructions provided on the packaging of the product

itself.

2.13.3 EXAMPLE of use of the command/control

TA

TA1

M

R

VZ1 VZ2 VZ3

TA2 TA 3

device on some types of heating systems

KEY

M System delivery

R System return

CR Remote control

SE Outdoor sensor

TA÷TA3 Air thermostat for the zone

VZ1-VZ3 Zone valves

RL1-RL3 Zone relays

P1-P3 Zone pump

SP Hydraulic separator

m

CAUTION

Set the parameter "tS 17 = DELAY SYSTEM PUMP

ACTIVATION to allow the opening of zone valve Vz.

Fig. 26

19

Page 20

2.14 Refilling or emptying

1

4

Before carrying out the operations described below, make

sure that the main system switch is set to "ON" in order for the

display to show the pressure level in the system during refilling.

Make sure that the operating mode is set to "Stand-by";

the case, press the button

mode has been selected.

ON

for at least 1 second until this

y

if this is not

3

Fig. 27

2.14.1 REFILL operations

Remove the front panel:

– remove the two screws (1), pull the front panel (2) forwards

and release it from the top by lifting it.

2

Fig. 28

Domestic hot water circuit:

– open the isolation valves of the domestic hot water circuit (if

present)

– open one or more than one hot water valve to fill and bleed the

domestic hot water circuit

– once bleeding has been completed, close the hot water valves.

4

Fig. 29

NOTE:

to completely remove all air from the system, it is

recommended that this operation is repeated a number of times.

– check the pressure on the display and if necessary top up until

the correct pressure reading appears

– close the automatic bleed valve (3)

– fill the siphon disconnecting it from the pipe or using (by

means of) the smoke take-off point.

Refit the front panel of the boiler hooking it on at the top,

pushing it forwards and securing it with the screw (1) which was

removed previously.

2.14.2 EMPTYING operations

Domestic hot water circuit:

– close the domestic hot water circuit isolation valve

(prearranged in installation)

– open one or more than one hot water valve to fill and bleed the

domestic hot water circuit.

Boiler:

– loosen the automatic bleed valve (3)

– close the heating circuit isolation valves (prearranged in

installation)

– check that the filling valve (4) is closed

– connect a rubber hose to the boiler drain valve (7) and open it

– when it has fully emptied, close the drain valve (7)

– close the automatic bleed valve (3).

Heating circuit:

– open the isolation and air bleeding valves in the highest points

of the system

– loosen the automatic bleed valve (3)

– open the isolation valves of the heating circuit (if present)

– open the filling valve (4) and fill the heating system until a

pressure of

– close the filling valve (4)

– check that there is no air in the system by bleeding all the

radiators and the circuit on the high points of the system

20

1-1.2 bar

is shown on the display

3

7

Fig. 30

Page 21

3 PUTTING INTO SERVICE

3.1 Preliminary operations

Before commissioning the appliance, check that:

– the type of gas is correct for the appliance

– the gas isolation valves for the heating system and the water

system are open

– the pump impeller rotates freely

– the siphon has been filled.

3.2 Before commissioning

After having carried out the preliminary operations, perform the

following to start the boiler:

– set the main system switch to "ON"

ON

– as soon as the symbols begin to flash, release the buttons <

and press the button y,

and

>

– the "Automatic self-calibrating procedure" starts

open one or more than one hot water tap

–

– the values flash on the display:

followed by an "intermediate value" and finally

value)

within 3 seconds

“100”

(maximum value),

“00”

(minimum

Fig. 31

– the type of gas for which the boiler has been calibrated,

“LG”

(methane) or

After this the correct representation of the symbols will be

checked and finally

– check that the system pressure as shown on the pressure

gauge when the system is cold , is between

– press the button Y once for at least 1 second to select "SUMMER

mode"

l

moment will appear on the display

(LPG,) will appear followed by the power.

“- -”

will appear on the display

1 and 1.2 bar

. the value of the delivery sensor detected at that

“nG”

The operator must wait for approximately 15 minutes for the

"self-calibrating procedure" to end and the message "SUMMER

mode"

terminated:

– close the taps opened previously and check that the appliance

shuts down.

if there is a fault, the message

the fault code (eg.

d

m

– press the button

mode"

detected at that moment will appear on the display

to reappear on the display Once the procedure has

l

“ALL”

will appear on the display,

“06”

- no flame detected) and the message

.

CAUTION

To restore the start conditions press and hold the

button

can be performed up to a maximum of 6 times without

the "self-calibrating procedure" being interrupted.

. The value of the heating water temperature

n

for more than 3 seconds. This operation

y

once for at least 1 second to select "WINTER

Y

3.2.1 Self-calibrating procedure

Carry out the "Automatic self-calibrating procedure" as follows:

– press button

maximum using the button

– press and hold down the buttons < and > at the same time for

approximately 10 seconds until the flashing symbols

appear on the display

n

and set the DOMESTIC HOT WATER SET to

r

>

l

and

– adjust the air thermostat and check that the boiler starts and

operates correctly

– carry out the procedure"Chimney sweep function", to check

the mains gas pressure, detect the combustion parameters

and to measure the combustion efficiency required by

legislation in force.

21

Page 22

3.3 Parameter setting and display

To go into the parameter menu:

– from the selected mode (eg. WINTER)

– once the required parameter has been reached, press the

buttons

or <to modify the value within the permitted range.

>

The modifications are stored automatically.

– press the buttons r and t (for approximately 5 seconds) at

the same time until

“PAR 01”

(parameter number) and the

value set (0÷4) appears on the display

When all the parameter modifications have been made, exit the

parameter menu by pressing and holding down the buttons

all at the same time

and

t

for at least 5 seconds until the initial

screen is displayed.

– press the button t to scroll up the list of parameters and

to scroll down the list

then

r

NOTE:

holding the buttons r or t increases the speed of the

scrolling movement.

3.4 List of parameters

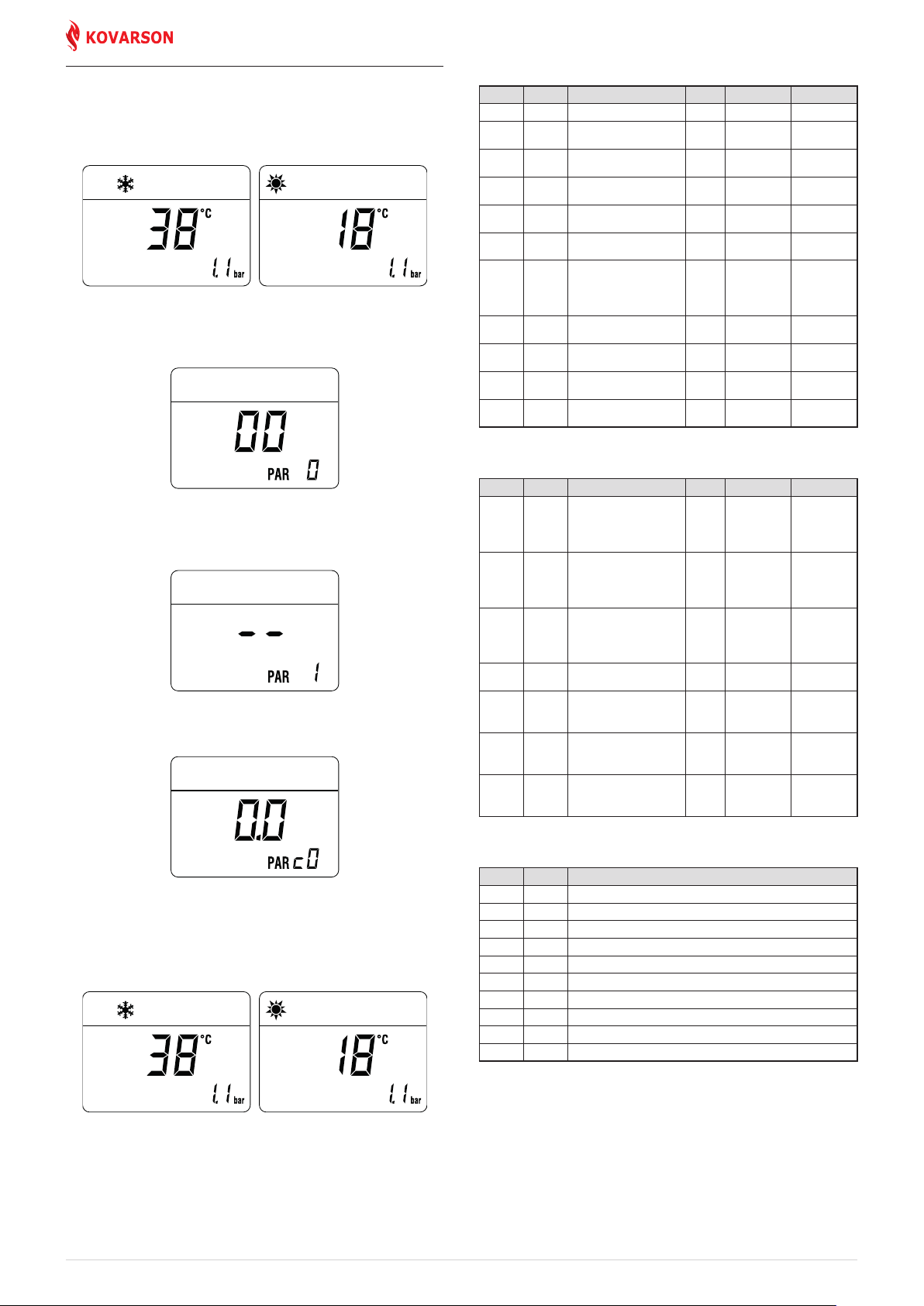

Type Nr. Description Range U/M Step Default

CONFIGURATION

PAR 01

PAR 02

PAR 03

PAR 04

PAR 08 External sensor value correction -5 .. +5 °C 1 0

PAR 09 Ignition fan speed 80 .. 160 RPMx25 1 128

PAR 10 Boiler Antifreeze Threshold 0 .. +10 °C 1 3

PAR 11

PAR 12 Heating Curve Incline 0 .. 80 - 1 20

PAR 13 Minimum Heating Temperature Adjustment 20 .. PAR 14 °C 1 20

PAR 14 Maximum Heating Temperature Adjustment PAR 13 .. 80 °C 1 80

PAR 15 Maximum power heating 0 .. 100 % 1 100

PAR 16 Heating Post-Circulation Time 0 .. 99

PAR 17 Heating Pump Activation Delay 0 .. 60

PAR 18 Re-ignition Delay 0 .. 60 Min 1 3

PAR 19

PAR 20 Maximum power domestic hot water 0 .. 100 % 1 100

PAR 21 Minimum power heating/domestic hot water (premixed) 0 .. 100 % 1 0

PAR 22

PAR 23

22

Index showing boiler power in kW

1 = 20; 2 = 25; 3 = 30; 4 = 35

Hydraulic configuration

0 = rapid

1 = storage tank with thermostat or heating only

2 = hot water tank with sensor

3 = two programmer

4=instant with solar power input

5 = open vent

Gas Type Configuration

0 = G20; 1 = G31

Combustion configuration

0 = sealed chamber with combustion control

DOMESTIC HOT WATER - HEATING

External Sensor Antifreeze Threshold

-- = Disabled

Domestic Hot Water Modulation with Flow meter

0 = Disabled

1 = Enabled

Domestic hot water preheating enabling

0 = OFF; 1 = ON

External relay 1 function

0 = not used; 1 = remote alarm NO; 2 = remote alarm NC; 3 = zone

valve; 4 = automatic filling; 5 = external request; 6 = recirculation

pump; 7 = zone valve with OT; 8 = relaunch pump

1 .. 4 - 1

0 .. 5 - 1 0

0 .. 1 - 1 0

- - - 0

-9 .. +5 °C 1 -2

seconds

x 10

seconds

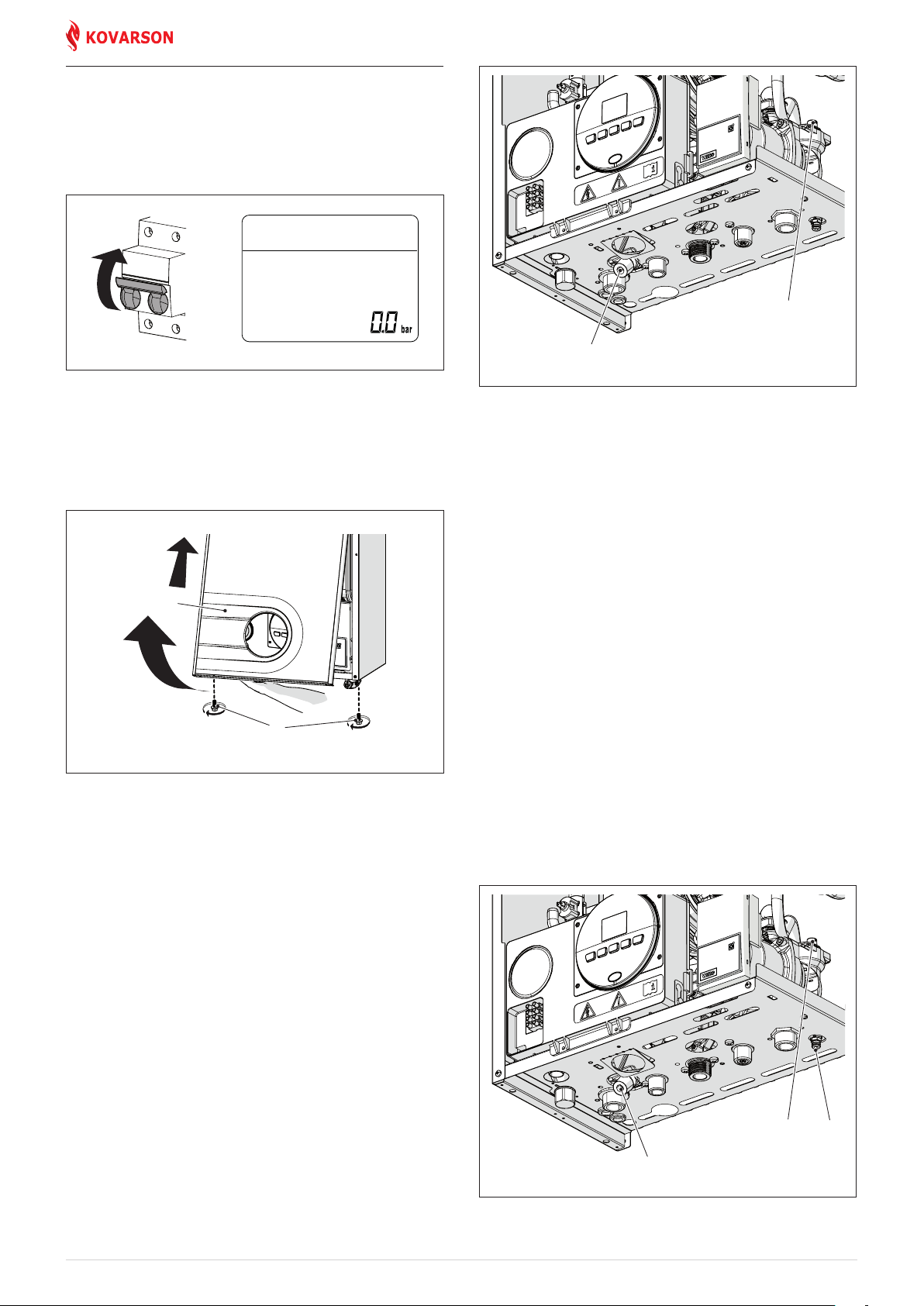

x 10

0 .. 1 - 1 1

0 .. 1 - 1 0

0 .. 8 - - 0

1 3

1 0

r

1 or 2 or 3

or 4

Page 23

Type Nr. Description Range U/M Step Default

OFF

CONFIGURATION

External relay 2 function

PAR 24

PAR 25

PAR 26 Zone Valve / Pump Relaunch Delay 0 .. 99 Min 1 1

PAR 28 DHW activation delay with solar power 0 .. 30 Min 1 0

PAR 29

PAR 30 Maximum domestic hot water temperature 35 .. 67 °C 1 60

PAR 35

PAR 40 Modulating Pump Speed

PAR 41 ∆T Modulating pump delivery/Return 10 .. 40 % 1 20

PAR 47

PAR 48 INST Parameter set to default 0 .. 1 - - 0

0 = not used; 1 = remote alarm NO; 2 = remote alarm NC; 3 = zone

valve; 4 = automatic filling; 5 = external request; 6 = recirculation

pump; 7 = zone valve with OT; 8 = relaunch pump

Auxiliary TA function

0 = according to TA

1 = TA Antifreeze

2= domestic hot water disabled

Anti-legionella Function (Only hot water tank)

-- = Disabled

Digital / analogue Pressure switch

0 = water pressure switch

1 = water pressure transducer

2 = water pressure transducer (only pressure displayed)

System pump forcing (only in winter mode)

0 = Disabled

1 = Enabled

RESET

0 .. 8 - - 0

0 .. 2 - 1 0

50 .. 80 - 1 --

0 .. 2 - 1 1

-- = No modulation

AU = Automatic 30

.. 100

0 .. 1 - 1 0

% 10 AU

In the event of a fault/malfunction the message

on the display with the alarm number eg.

“ALL”

“ALL 04”

will appear

(Domestic

Hot Water Sensor Fault).

Before repairing the fault:

– disconnect the appliance from the mains power by setting the

main switch to "OFF"

Fig. 32

– as a precautionary measure, close the gas isolation valve.

Repair the fault and start-up the boiler again.

NOTE:

after having repaired the fault, when the alarm number

appears on the display together with the message

(see figure), press the button

for approximately 3 seconds

y

d

to start the appliance up again.

3.5 Fault / malfunction codes

Type Nr. Description

ALL 02 Low water pressure in system

ALL 03 High water pressure in system

ALL 04 Domestic hot water sensor fault

ALL 05 Delivery sensor fault

ALL 06 No flame detection

ALL 07 Safety thermostat intervention

ALL 08 Fault in the flame detection circuit

ALL 09 No water circulating in the system

ALL 10 Auxiliary sensor fault

ALL 11 Gas valve modulator disconnected

ALL 12 Incorrect configuration of the open /sealed chamber

ALL 13 Flue gas thermostat tripped

ALL 14 Smoke probe fault

ALL 15 Fan check cable disconnected

ALL 18 Condensate level fault

ALL 28 Maximum number of consecutive releases

ALL 37 Fault due to low network voltage

ALL 40 Incorrect network frequency detected

ALL 41 Flame loss more than 6 consecutive times

ALL 42 Button fault

ALL 43 Open Therm communication fault

ALL 62 Self-calibrating procedure is required

ALL 72 Incorrect positioning of the delivery sensor

ALL 81 Block due combustion during start-up

ALL 83 Irregular combustion (temporary error)

ALL 96 Block due to clogging in smoke outlet

23

Page 24

3.6 Display of operating data and counters

Once the boiler is operating a qualified technician can view the

operating data and the counters as follows:

– from the operating screen in the mode enabled at that

moment (WINTER

– go into

same time

“DISPLAY”

for more than 3 seconds until the following screen

appears

From this point, the technician has 2 options:

– scroll through the list of

(PARc)”

by pressing the button t. Scrolling will be in sequence

– display the

the button

“activated alarms”

r

or SUMMER l)

n

by pressing the buttons r and <

“information (PAR)”

and

“counters

(no more than 10) by pressing

at the

TABLE OF INFORMATION DISPLAYED

Type Nr. Description

PAR 00 SW version

PAR 01 External sensor

PAR 02

PAR 03 Smoke probe

PAR 04

PAR 05 AUX auxiliary sensor

PAR 06

PAR 07 Power level

PAR 08 Flow meter rate

PAR 09

PAR 10

Delivery sensor

temperature

Domestic hot water

sensor temperature

Actual heating SET

temperature

Water pressure

transducer reading

Display of current

fan revolutions

TABLE OF COUNTER DISPLAYED

Type Nr. Description

PAR c0

PAR c1

PAR c2

PAR c3 total no. faults

PAR c4

PAR c5

PAR c6

total no. of boiler

operating hours

total no. of burner

operating hours

total no. of burner

ignitions

total no. of times

installer parameters

"ALL"accessed

total no. of times

OEM parameters

accessed

time unitl next

maintenance

intervention

Range

- 9 ..

99

- 9 ..

99

- 9 ..

99

- 9 ..

99

- 9 ..

99

Pa r.

13 …

Pa r.

14

0 ..

99

0 ..

99

0 ..

99

0 ..

RPM x 100 1

99

Range

0 ..

h x 1000

99

0 ..

h x 1000

99

0 ..

h x 1000

99

0 ..

99

0 ..

99

0 ..

99

1 ..

months 1

199

U/M Step

°C 1

°C 1

°C 1

°C 1

°C 1

°C 1

% 1

l/min 0.1

bar 0.1

U/M Step

0.1; from

0.0 to 9.9;

1; from 10

to 99

0.1; from

0.0 to 9.9;

1; from 10

to 99

0.1; from

0.0 to 9.9;

1; from 10

to 99

x 1 1

x 1 1

x 1 1

– Once in this section, proceed with button t or r.

When all the values have been displayed, exit the menu by

pressing and holding down the button yfor approximately 5

seconds until the initial screen is displayed.

24

TABLE OF ACTIVATED ALARMS/FAULTS

Type Nr. Description

PAR A0 Last activated alarm/fault

PAR A1 Last but one activated alarm/fault

PAR A2 Third from last activated alarm/fault

PAR A3 Previous activated alarm/fault

PAR A4 Previous activated alarm/fault

PAR A5 Previous activated alarm/fault

PAR A6 Previous activated alarm/fault

PAR A7 Previous activated alarm/fault

PAR A8 Previous activated alarm/fault

PAR A9 Previous activated alarm/fault

Page 25

3.7 Checks

3

3.7.1 Chimney sweep function

The chimney sweep function is used by the qualified

maintenance technician to check the mains gas pressure, detect

the combustion parameters and to measure the combustion

efficiency required by legislation in force.

This function lasts 15 minutes and is activated by proceeding

as follows:

– if the panel (2) has not already been removed, remove the

two screws (1), pull the front panel (2) forwards and release it

from the top by lifting it

6

Fig. 35

2

1

Fig. 33

– remove the screws (3) securing the control panel (4)

– move the panel (4) upwards (a) but keeping it in the side

guides (5) to the end of travel

– bring it forwards and down (b) until it is horizontal

4

b

a

5

– open the gas valve

– power the boiler by setting the main switch to "ON"

ON

Fig. 36

– press the button y for at least 1 second until "SUMMER"

mode

– press and hold down the buttons

for approximately 10 seconds until the message “Hi” appears

on the display together with the flashing symbols

– press the button > to make the boiler operate at maximum

power "Hi" and check that the mains gas pressure value on the

pressure gauge is correct. Take a reading of the combustion

data and measure the combustion efficiency.

– press the button

power "Lo". The message

together with the flashing symbols

has been selected

l

<

and > at the same time

<

and

l

to make the boiler operate at minimum

“Lo”

will appear on the display

and

l

n

n

Fig. 34

– close the gas valve

– loosen the screw of the "mains pressure" point (6) and connect

a pressure gauge

25

Page 26

– take the combustion data reading

– press the button

The boiler water delivery temperature will appear on the

display

– disconnect the pressure gauge, carefully close the pressure

point (6), put the control panel back to the original position

and refit the front panel (2).

Gas supply pressure

Type of gas G20 G31

Pressure (mbar) 20 37

to exit the "Chimney sweep Procedure”.

y

3.9 Gas conversion

ADAX

models can work with G20 or G31 without the need for

any mechanical conversion. Simply select parameter

(see "Parameter setting and display") and set the type of gas

to be used.

If changing the type of gas to be used, carry out the entire

appliance

“COMMISSIONING”

phase.

”PAR 03”

3.8 Domestic hot water comfort function

(preheating)

ADAX

models have a "domestic hot water comfort" function

which ensures the best performance in terms of domestic hot

water, reducing the time necessary for the hot water to become

available and ensuring that the temperature is stable.

To activate the function:

– select parameter

display") and set it to

– exit parameter settings and press button > for approximately

5 seconds until the symbol

and begins to flash indicating that the function has been

activated.

To deactivate the function:

– press button

symbols

indicating that the function has been deactivated.

r

”PAR 22”

again for approximately 5 seconds until the

>

and R appear on the display and begin to flash

(see "Parameter setting and

a 1

and R appears on the display

r

26

Page 27

4 MAINTENANCE

OFF

4.1 Adjustments

For the appliance to operate correctly and efficiently it is

recommended that the User calls upon the services of a

Professionally Qualified Technician to carry out

maintenance.

m

a

CAUTION

The maintenance interventions described must ONLY

be carried out the professionally qualified personnel.

DANGER

Before carrying out any interventions described:

– set the main system switch to "OFF"

– close the gas valve

– make sure that no hot parts inside the appliance are

touched.

ANNUAL

Fig. 37

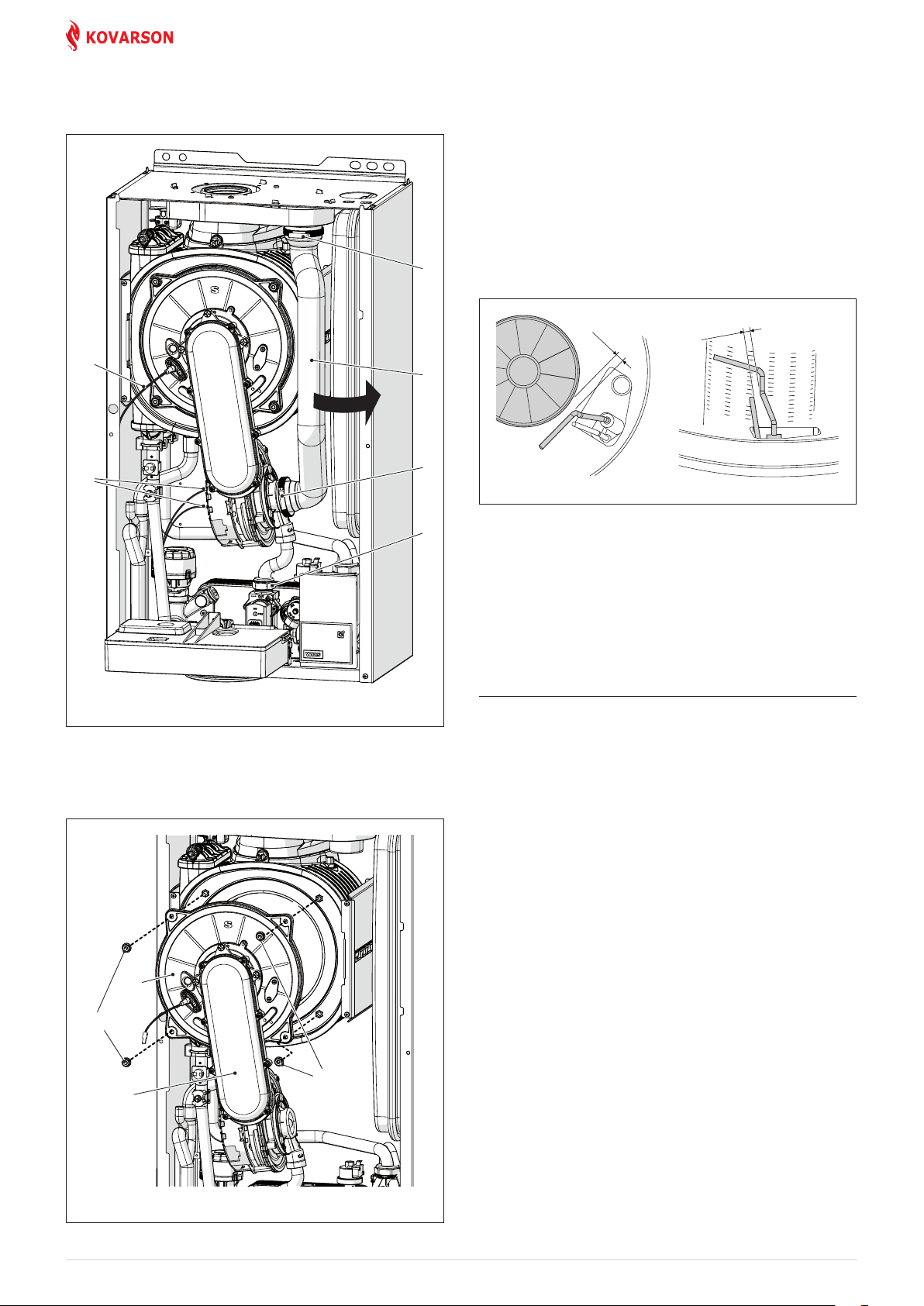

4.3 Cleaning the inside of the appliance

4.3.1 Removing components

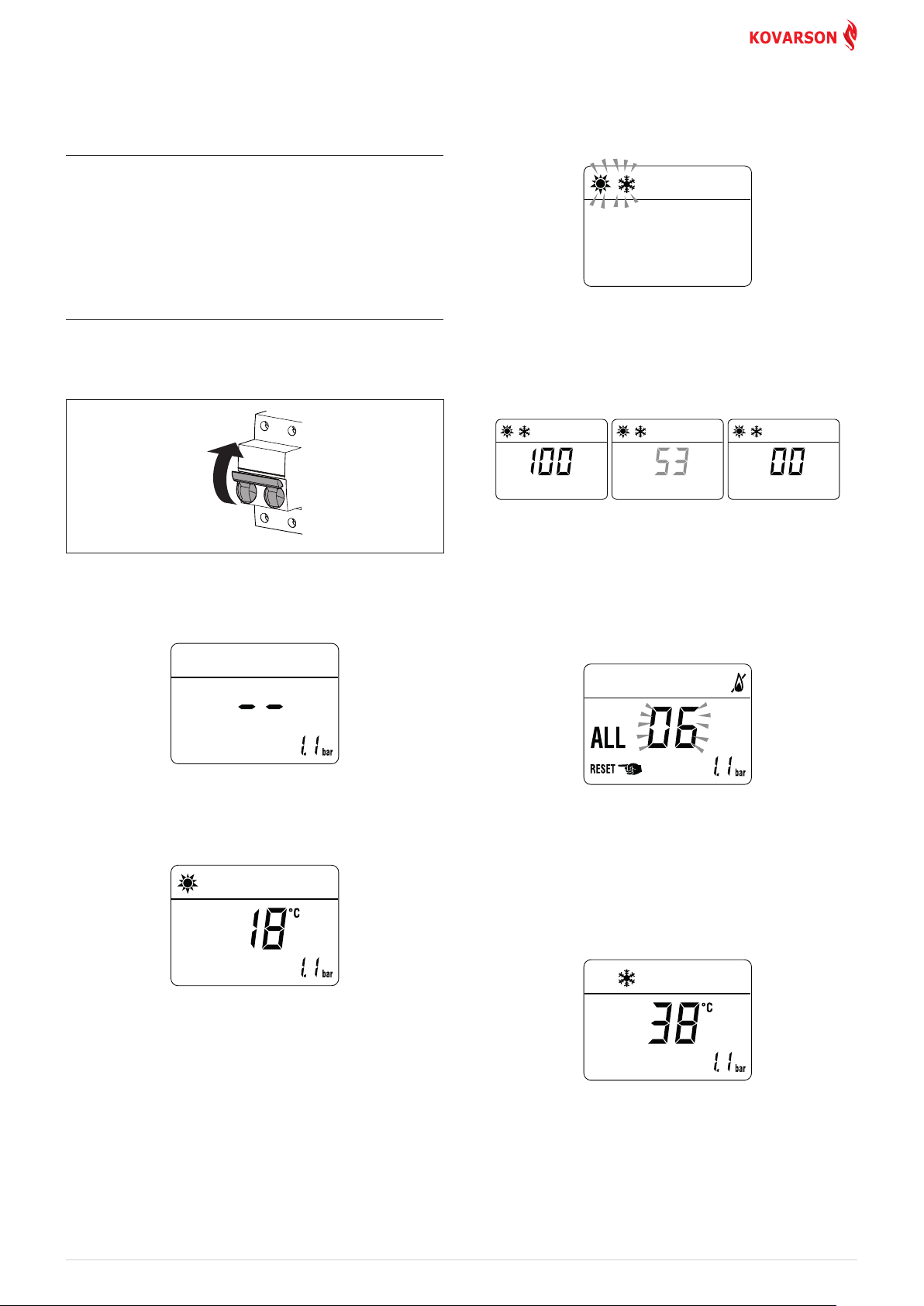

To access the internal parts of the boiler:

– remove the two screws (1), pull the front panel (2) forwards

and release it from the top by lifting it

2

4.2 External cleaning

4.2.1 Cleaning the cladding

When cleaning the cladding, use a cloth dampened with soap

and water or alcohol for stubborn marks.

d

IT IS FORBIDDEN

to use abrasive products.

1

Fig. 38

– remove the screws (3) securing the control panel (4)

– move the panel (4) upwards (a) but keeping it in the side

guides (5) to the end of travel

– bring it forwards and down (b) until it is horizontal

4

b

3

a

5

Fig. 39

27

Page 28

– loosen the clips (6) and extract the air inlet pipe (7)

6

10

6

7

8

– unscrew the swivel joint (8)

– extract the connectors (9) from the fan and disconnect the

electrode cable (10)

m

CAUTION

Work carefully when removing the assembly (13) to

prevent any damage occurring to the internal insulation

of the combustion chamber and the door seal.

4.3.2 Cleaning the burner and the combustion

chamber

The combustion chamber and the burner do not require any

particular maintenance. Simply brush them with a soft brush.

4.3.3 Checking the ignition/detection electrode

Check the state of the ignition/detection electrode and replace

if necessary. Check the measurements as per the drawing

whether the ignition/detection electrode is replaced or not.

+0,5

6

+0,5

-0,5

4,5

-0,5

9

Fig. 40