Kortek KT-1982F, KT-1982 Series Service Manual

KT-1982F

COLOR MONITOR

SERVICE

MANUAL

1. PRECAUTIONS -------------------------------------------------- 2

2. PRODUCT SPECIFICATION -------------------------------- 5

3. OPERATING INSTRUCTION -------------------------------- 8

4. ADJUSTMENTS ------------------------------------------------- 10

5. TROUBLE SHOOTING GUIDE ---------------------------- 18

6. BLOCK DIAGRAM --------------------------------------------- 28

7. CONNECTING DIAGRAM ----------------------------------- 29

CONTENTS

- 2 -

1-1. Safety precautions

Warnings :

Service should not be attempted by anyone unfamiliar with the

necessary on this Monitor.

The followings are the necessary precautions to be observed before servicing.

1) For continued safety, do not attempt to modify the circuit board.

2) Disconnect the AC power before servicing.

3) When the chassis is operating, semiconductor heat sinks are potential

shock hazards.

1-1-1 Servicing the high voltage volume are CRT Warnings

A High Voltage volum e replaced in the wrong direction may cause excessive

X-Ray emissions.

1) Adjust in order to 26KV with signal at Anode.

2) When the troubleshooting a monitor with excessively High Voltage, avoid

being unnecessarily close to the monitor. Do not operate the monitor for

longer than is necessary to locate the cause of excessive voltage.

3) Excessive High Voltage can produce potentially hazardous X-Ray RADIATION. To avoid such hazards, the high voltage m ust be above the

specified lim it. The nominal value of the High voltage of this Monitor is

26KV±0.3KV at zero beam current(m inimum brightness) under a 120V

AC power source. The High Voltage must not (under any circum stances)

exceed 29KV. Each tim e a monitor requires servicing, the High Voltage

should be checked following the High Voltage check procedure on this

manual. It is recommended the reading of the voltage be recorded as a

part of the service record. It is im portant to use an accurate and reliable

High Voltage meter.

4) When the High Voltage regulator is operating properly, there is no possibility of an X-Ray problem.

5) The CRT is especially designed to prohibit X-ray emission. To ensure

continued X-ray protection, replace the CRT only with one that is the

sam e or equivalent type as the original.

6) Handle the CRT only when wearing shatterproof goggles and after completely.

7) Do not lift the CRT by the neck.

1.Precautions

- 3 -

1-1-2. Fire and Shock Hazard

Before returning the monitor to the user,perform the following safety checks:

1) Inspect each lead dress to make certain that the leads are not pinched or

that hardware is not lodged between the chassis and other metal parts

in the monitor.

2) Inspect all protective devices such as nonm etallic control knobs, insulating

materials, cabinet backs, adjustment and com partment cover or shields

isolation resistor-capacitor networks, m echanical insulations, etc.

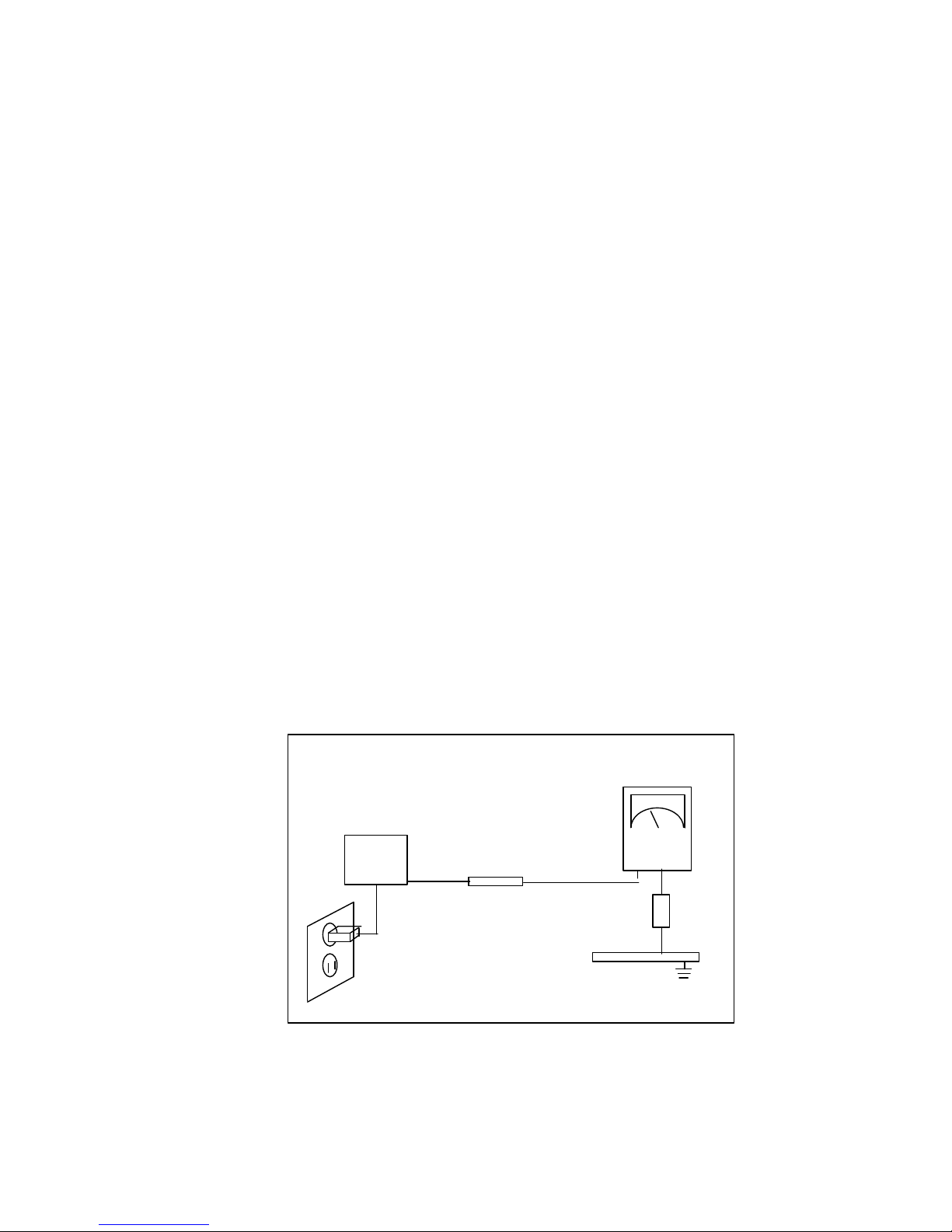

3) To be sure that no shock hazard exists, check for leakage current in the

following manner.

a. Plug the AC line cord directly into a 120 or 230 Volt AC outlet.

(Do not use an isolation transformer for this test)

b. Using two clip leads, connect a 1.5KΩ, 10Watt resistor paralleled by a

0.15Uf capacitor in serial with an exposed metal chassis part and a

known earth ground, such as an electrical conductor and electrical

ground connected to a earth ground.

c. Use a SSVM or VOM with 1000 ohms per-volt or sensitivity to measure

the AC voltage drop across the resistor.

d. Connect the resistor to an exposed metal part having a return path to

the chassis(m etal cabinet, screw heads, knobs, shafts, escutcheon,etc)

and measure the AC voltage drop across the resistor.

e. Any reading of 5.25 volt RMS(this corresponds to 3.5 milliampere AC)

or more is excessive and indicates a potential shock hazard. Correct

the shock hazard before returning the monitor to the user.

LEAKAGE

CURRENT

TESTER

(READING SHOULD)

NOT BE ABOVE

0.5m A

TEST AL L

EXPOSED METAL

SURFACES

DEVICE

UNDER

TEST

2-WIRE

CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

Earth

ground

Figure 1-1. Leakage Current Test Circuit

- 4 -

1-1-3. Product safety notices:

Some electrical and mechanical parts have special safety related characteristics

which are often not evident from visual inspection. The protection they give

may not be obtained by replacing them with components rated for higher voltage,wattage,etc. Parts that have special safety characteristics are identified by

△

on schematics and parts lists.

A substitute replacement that does not have the sam e safety characteristics

as the recommended replacement part might create shock, fire and or other

hazards. Product safety is under review continuously and new instructions

whenever appropriate.

1-2. Servicing Precautions

WARNING 1 : First read the "Safety Precaution" section of this manual. if

unforeseen circumstances create conflict between the servicing

precautions and safety precautions,always follow the safety

precautions.

WARNING 2 : A High Voltage volume replaced in the wrong direction may

cause excessive X-ray emissions.

WARNING 3 : An electrolytic capacitor installed with the wrong polarity might

explode.

1) Servicing precautions are printed on the chassis, and should be followed

closely

2) Always unplug the units AC power cord from the AC power source before

attempting to :(a) remove or reinstall any component or assem bly, (b)

disconnect PCB plugs or connectors,(c) connect all test com ponents in

parallel with an electrolytic capacitor.

3) after servicing, always check that the screws, components and wiring have

been correctly reinstalled. Make sure that the area around the serviced

part has not been dam aged.

4) Check the insulation between the blades of the AC plug and accessible

conductive parts(examples:m etal panels,input terminals and earphone jacks).

5) Never defeat any of the +B voltage interlocks. Do not apply AC power to

the unit(or any of its assemblies) unless all solid-state heat sinks are

correctly installed.

6) Always connect a test instruments ground lead to the instrum ent chassis

ground before connecting the lead; always remove the instruments lead last.

- 5 -

2-1 SPECIFICATION

2. Product Specifications

CDT

Tube

Size

Viewable Image Size

Dot Pitch

Deflection Angle

Focusing Method

FST, Dyna flat (option)

48㎝(19") diagonal

45.7㎝(18")

0.26㎜(H)

90

°

Double Focusing(static & dynam ic)

Bandwidth Maximum 140MHz

Scanning Frequency

(Auto Scanning)

Horizontal

Vertical

30-82KHz

50-120Hz

Display Area Norm al

Maximum

350×262.5

㎜

366×275

㎜

Microprocessor User Saving Mode 7 Modes

User Control Display

Digital

Language

Position,Size,Pincushion,T rapezoid,H/Vcorner,

Pin-B,Trapezoid,Parallel,Tilt,Moire,Zoom

Color T emperature,Recall,Manual Degauss

Eng/Ger/F ra/Esp/Port

Display color Color T emperature 9300°K, 6500°K, User Color

Resolution Maximum M ode 1280 X 1024 @ 75Hz

Signal Input Connect 15 pin D-sub(Fem ale) or Option

Safety & EMC

Safety

EMC

UL,CSA,TUV,CB,DHHS

FCC,CE

Power Voltage AC 90-264V, 60 / 50±3Hz

Power Consumption Nomal Operation

Input Current at 120V

Input Current at 240V

≤

100 Watts

Operating :≤1.5Amps rms.

Turn on :≤30Amps Peak.

Operating :≤0.8Amps rms.

Turn on :≤60Amps Peak.

Linearity Cross Pattern

Horizontal : 5%

Vertical : 5%

Environment

Temperature

Humidity

Operating : 0 to +40

℃

Storage : -40 to +60

℃

Operating : 10 to 85%

Storage : 5 to 95%

- 6 -

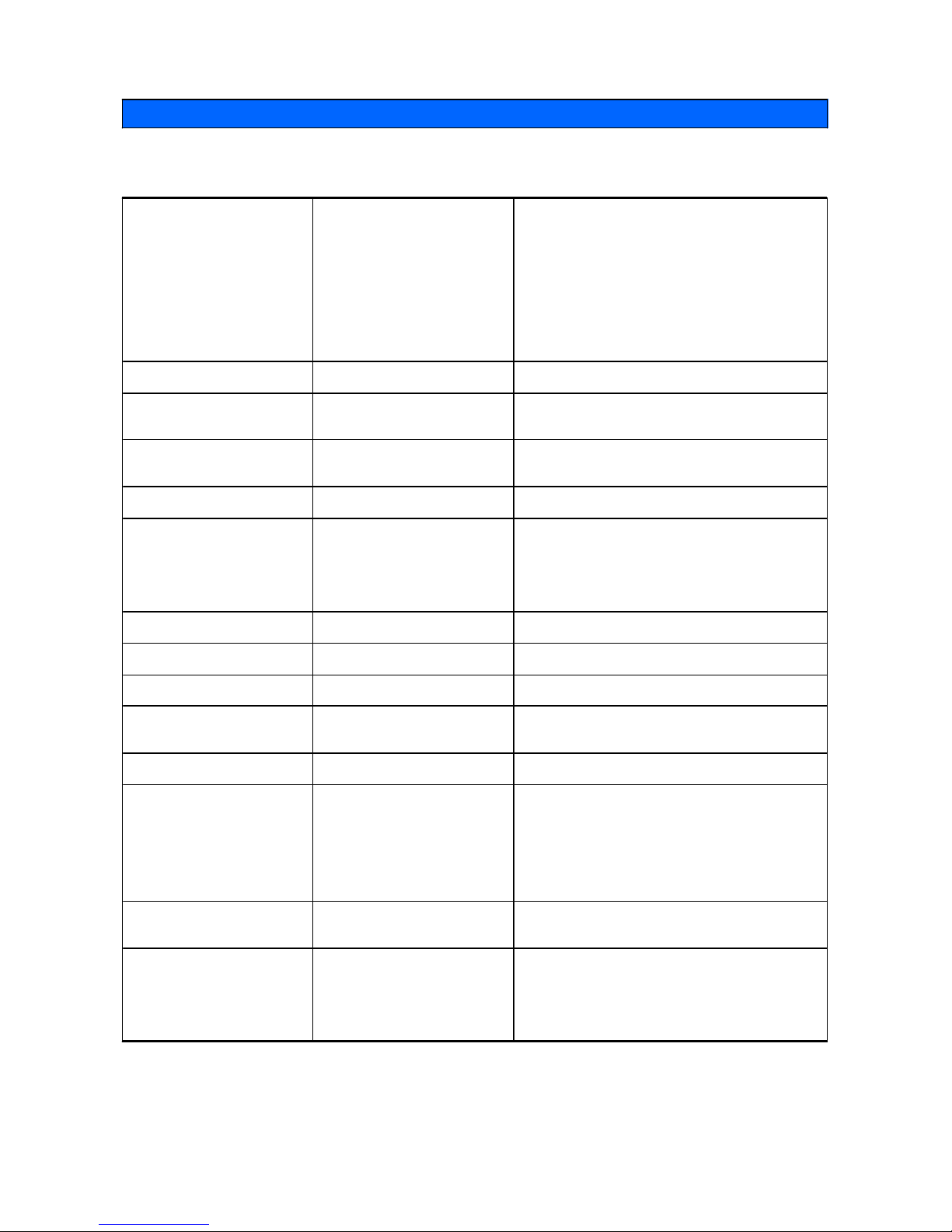

2-2 Monitor Interface Wiring (AMP-25P)

M Reset 14

Touch_ TXD 13

13VCD_Net 20

Touch_ RXD 12

Net Ground 15

13VDC 21

A_Grnd 22

Red 1

Red_GND 2

Green 3

Green_GND 4

Blue 5

Blue_GND 6

Shield GND 7

H Sync 8

V Sync 9

I2C CLK 10

I2C SDA 11

AC Line 24

AC Ntrl 25

Frame GND 23

USB Vcc 16

USBD- 17

USBD+ 18

USB GND 19

1

2

3

4

5

1 Red

2 Red_GND

3 Green

4 Green_GND

5 Blue

6 Blue_GND

1

2

1 Shield GND

2 H Sync

3 V Sync

3 I2C CLK

3 I2C SDA

1

2

3

22 AWG

22 AWG

22 AWG

22 AWG

22 AWG

22 AWG

22 AWG

Shield

Shield

Shield

22 AWG

22 AWG

22 AWG

22 AWG

22 AWG

18 AWG

18 AWG

Touch Screen

Controller

CRT Neck Board

Video Connector

Main Board Sync Connector

#8 Ring Lug Chassis Ground

- 7 -

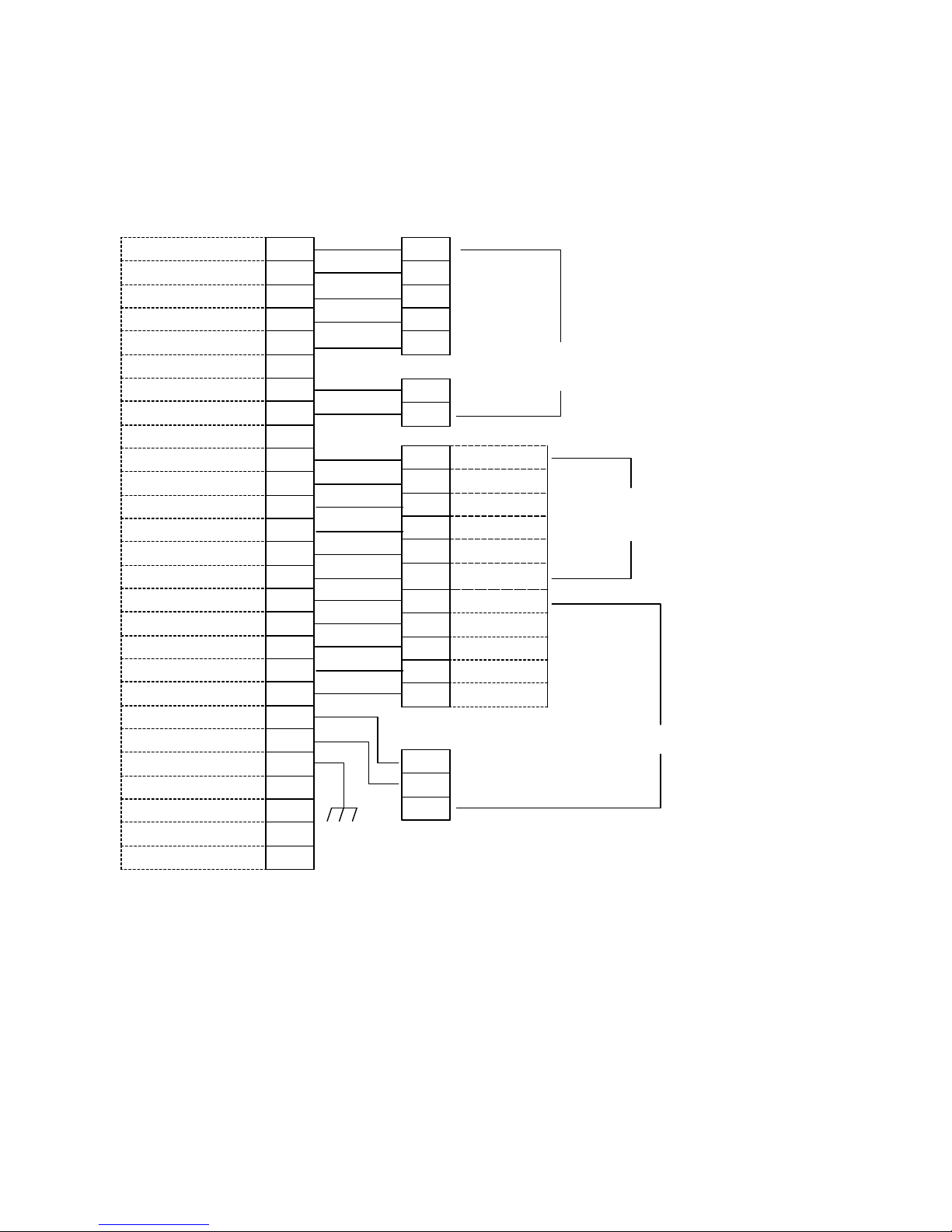

2-3 TIMING CHART

DESCRPTION

IGT VESA

640*480 640*480 640*480 640*480 1024*768 800*600 1024*768

H

f KHz

31.469 31.469 31.469 37.860 48.363 53.674 60.24

A uS

31.8 31.8 31.77 26.413 20.677 18.631 16.60

B uS

2.4 2.4 3.813 1.270 2.092 1.138 1.200

C uS

3.0 3.0 1.906 4.603 2.262 2.702 2.20

D uS

24.0 24.0 25.42 20.317 15.754 14.222 12.80

E uS

2.4 2.4 0.636 0.762 0.369 0.569 0.4

POL.

POS POS NEG POS NEG POS NEG

V

f Hz

50.0 59.940 59.94 72.809 60.00 8 5.0 61 74. 93

O mS

20.000 16.663 16.683 13.735 16.667 11.756 13.346

P mS

0.509 0.254 0.064 0.079 0.124 0.056 0.05

Q mS

0.372 0.890 1.048 0.740 0.60 0.503 0.497

R mS

15.26 15.26 15.253 12.678 15.88 11.179 12.749

S mS

0.509 0.890 0.318 0.238 0.062 0.019 0.050

POL.

POS POS NEG POS NEG POS NEG

VIDEO

SYNC

HORIZONTAL VERTICAL

A

B

C D

E

O

P

Q R

S

A : LINE TIME TOTAL B :HORIZONTAL SYNC WIDTH

C : BACK PORCH D : ACTIVE TIME

E : FRONT PORCH

O : F RAME TIME TOTAL P : VERTICAL SYNC WIDTH

Q : BACK PORCH R : ACTIVE TIME

S : FRONT PORCH

- 8 -

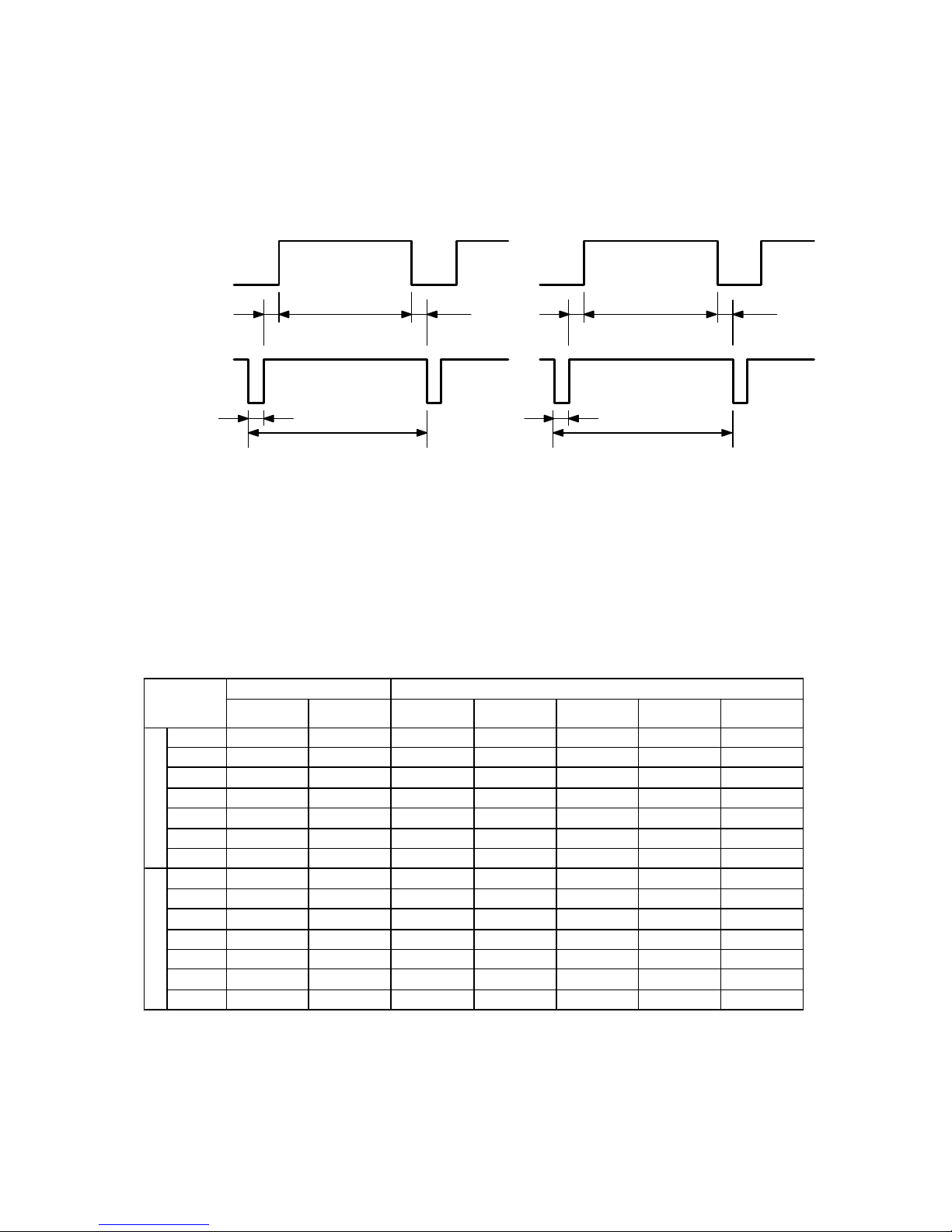

3-1 FRAME-UR (GK+)

3.2 MAIN PCB ASS'Y

3. Operating Instruction

Touch Screen

Main Board

Socket Board

(T he GK+ is without shield

cover)

PFC Board

AMP Connector

- 9 -

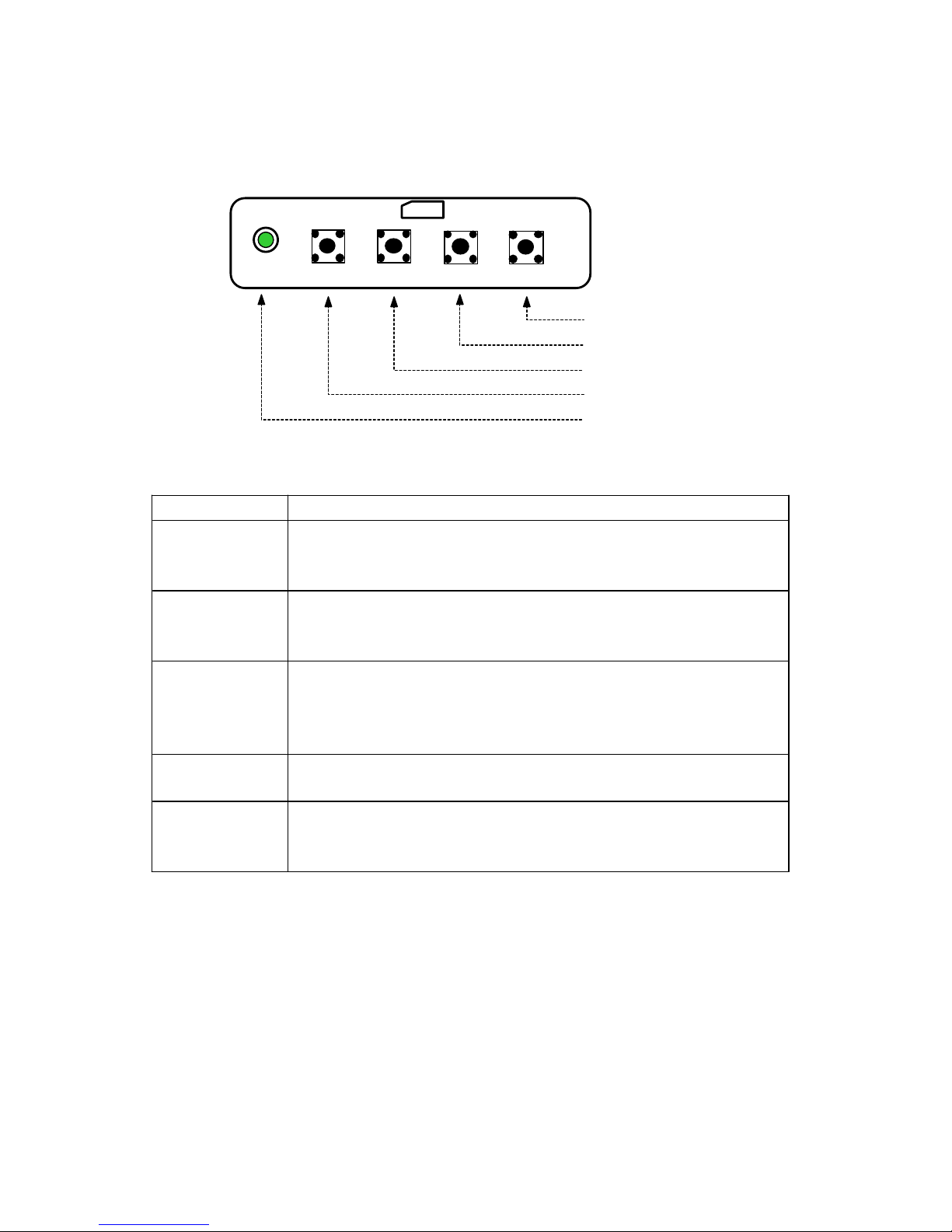

3-3. Function of Control

Control Function

LED

(Power Indicator)

The light of power LED changes according to each state.

◎

on mode : Green LED.

◎

power saving mode : green LED blinking.

SELECT (DEG)

This button is used to select the control item on the MENU.

In M ENU, the control item could be selected and unselected by

this button.

MOD

When you press this button, the MENU appears.The MENU will

disappear in 10 seconds if you don't operate any button.

When you press MOD button again, the MENU disappears.

This button is used to exit the value of any selected control.

UP

This button is used to increase the value of any selected control.

This button is used to locate to the next control item for select.

DOWN

This button is used to decrease the value of any selected control.

This button is used to locate to the previous control item for

select.

UP

DOWN

SELECT(DEG)

MOD

LED

Loading...

Loading...