Page 1

i

JetBox 8100 User Manual

Modbus Gatewa y

Copyright@2007

Korenix Technology Co., Ltd.

All rights reserved.

Reproduction without permission is prohibited.

Customer Service: KoreCARE@korenix.com

V1.0

Page 2

ii

Copyright Notice

Copyright© 2007 Korenix Technology Co., Ltd.

All rights reserved.

Reproduction without permission is prohibited.

Information provided in this manual is intended to be accurate and reliable.

However, the original manufacturer assumes no r esponsibility for i t s use, or for

any infringements upon the rights of third parties that may result from its use.

The material in this document is for product information only and is subject to

change without notice. Whil e re asonable effort s have been made in the

preparation of this document to assure its accuracy, Korenix assumes no

liabilities result ing fro m er ror s or omissi ons i n thi s docu ment, or fro m the us e o f

the information contained herein.

Korenix reserves the right to make changes in the product design without

notice to its users.

Acknowledgments

Korenix is a registered trademark of Korenix Technology Co., Ltd.

All other trademarks or registered marks in the manual belong to their

respective manufacturers.

Page 3

iii

Table of Contents

JetBox 8100 User Manual ............................................................................... i

Modbus Gateway ............................................................................................ i

Copyright Notice ........................................................................... ii

Acknowledgments ........................................................................ ii

Chapter 1 Modbus TCP to RTU/ASCII Gateway Application ...................... 1

1.1 Overview ....................................................................................... 1

1.2 Argument s .................................................................................... 2

1.3 Scenarios ...................................................................................... 2

1.4 Limitations .................................................................................... 3

Chapter 2 Appendix ....................................................................................... 5

2.1 Chart Index ................................................................................... 5

2.2 Customer Service ........................................................................ 5

Page 4

Page 5

JetBox 8100 User Manual_Modbus_1.0-r1.doc

Chapter 1 Modbus TCP to RTU/ASCII Gateway Application

1

Chapter 1 Modbus TCP to RTU/ASCII

Gateway Application

1.1 Overview

Modbus is one of the most popular industrial protocols in the world. It is

supported by the traditional RS-232/422/485 devices and recently by the

Ethernet devices. Lots of industrial devices, such as PLCs, DCSs, HMIs,

instruments, and meters, use Modbus as their communication standard.

A Modbus TCP to RTU /ASC II g at eway application is desi gned as a bridge

for the Modbus TCP (Ethernet) masters and Modbus RTU/ASCII (serial)

slaves. It allows the Ethernet-based HMIs or PLCs to control devices over

RS-232/422/485 without additional programming or effort.

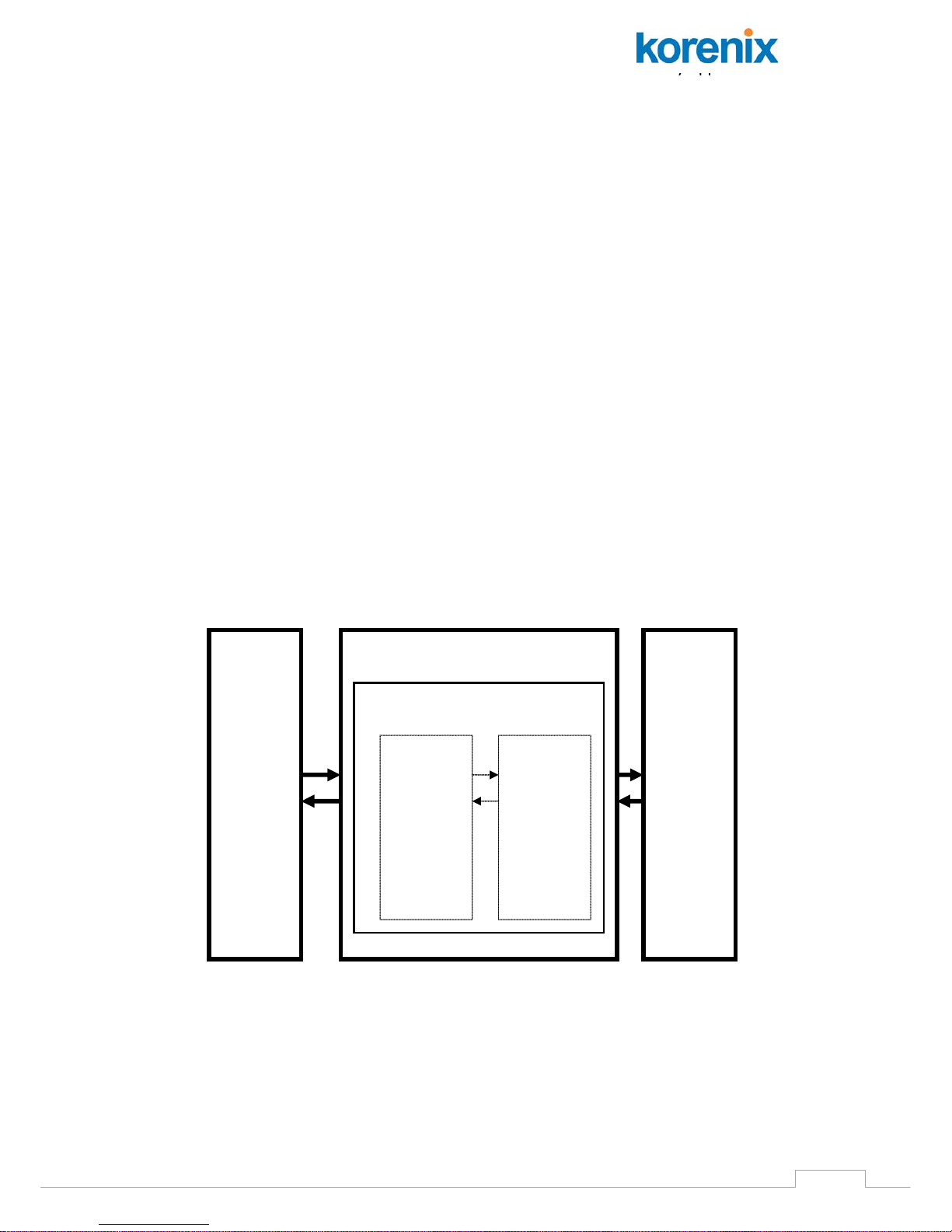

Figure 1-1 shows the block diagrams of Modbus TCP to RTU/ASCII

gateway application.

Figure 1-1 Block Diagrams of Modbus TCP to RTU/ASCII Gateway Application

Modbus

TCP

Master

(HMI or

PLC)

JetBox 8100/8210/8220

ModbusT2R.exe

Modbus

TCP

Slave

Modbus

RTU/

ASCII

Master

Modbus

RTU/

ASCII

Slave

(PLC,

DCS)

Page 6

JetBox 8100 User Manual_Modbus_1.0-r1.doc

2

1.2 Arguments

Table 1-2 is the description of the arguments of the “ModbusT2R.exe”

application. The following command example, “-p 5501 –s COM1: -b

9600 –m RTU –id0 1 –id1 10”, means the g atew ay applicat ion cr eat es on e

Modbus TCP slave service on TCP port 5501 and create one Modbus

RTU master service on “COM1:” with 9600 baud rate and the valid

Modbus RTU slave station ID is from 1 to 10.

Application Name: ModbusT2R.exe

Arguments Description

-help

Lists all the syntax of arguments.

-f [file name]

Specifies an argument file.

-p [TCP port number]

Specifies the TCP port number of Modbus TCP

slave. Default port is 5501.

-s [serial port name]

Specifies the serial port name of Modbus

RTU/ASCII master. Default port is “COM1:”.

-b [baud rate]

Specifies the baud rate of Modbus RTU/ASCII

master. Default baud rate is 9600.

-m [“rtu”|“ascii”]

Specifies the protocol of Modbus RTU/ASCII

master. Default protocol is RTU.

-id0 [begin ID]

Specifies the begin ID of a range of Modbus slave

ID. Default begin ID is 0.

-id1 [end ID]

Specifies the end ID of a range of Modbus slave

ID. Default end ID is 247.

Table 1-2 Description of the Arguments of the “ModbusT2R.exe” Application

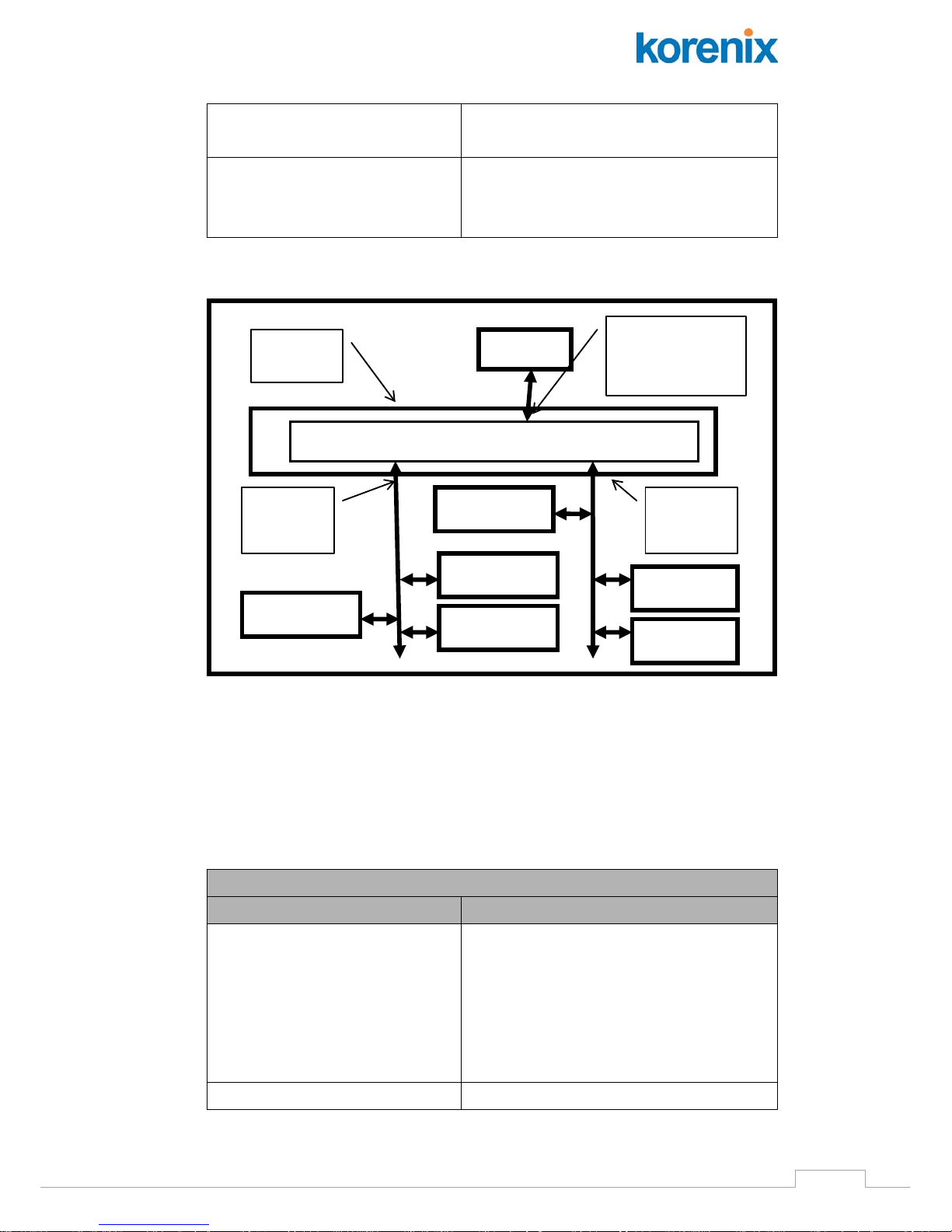

1.3 Scenarios

The following script file, “demo.ini”, specifies one Modbus TCP slave

service and one Modbus RTU master service and one Modbus ASCII

master service. Table 1-3 shows the contents of the script file “demo.ini”.

Execute the “ModbusT2R.exe” with arguments “-f demo.ini” to start the

gateway application with script file. Figure 1-4 shows this demo scenario.

Script File Name: demo.ini

Contents Description

-p 5501 –s COM1: -b 9600 –m

One Modbus TCP master on TCP port 5501

Page 7

JetBox 8100 User Manual_Modbus_1.0-r1.doc

-p 5501 –s COM1: -b 9600 –m RTU –id0 1 –id1 10

3

RTU –id0 1 –id1 10

and One Modbus RTU master on serial

“COM1:”. Valid station ID range from 1 to 10.

-p 5501 –s COM2: -b 9600 –m

ASCII –id0 11 –id1 20

One Modbus TCP master on TCP port 5501

and One Modbus ASCII master on serial

“COM2:”. Valid station ID range from 11 to 20.

Table 1-3 Contents of the Script File “demo.ini”

Table 1-4 Scenario of Running “ModbusT2R.exe” with “demo.ini” Script File

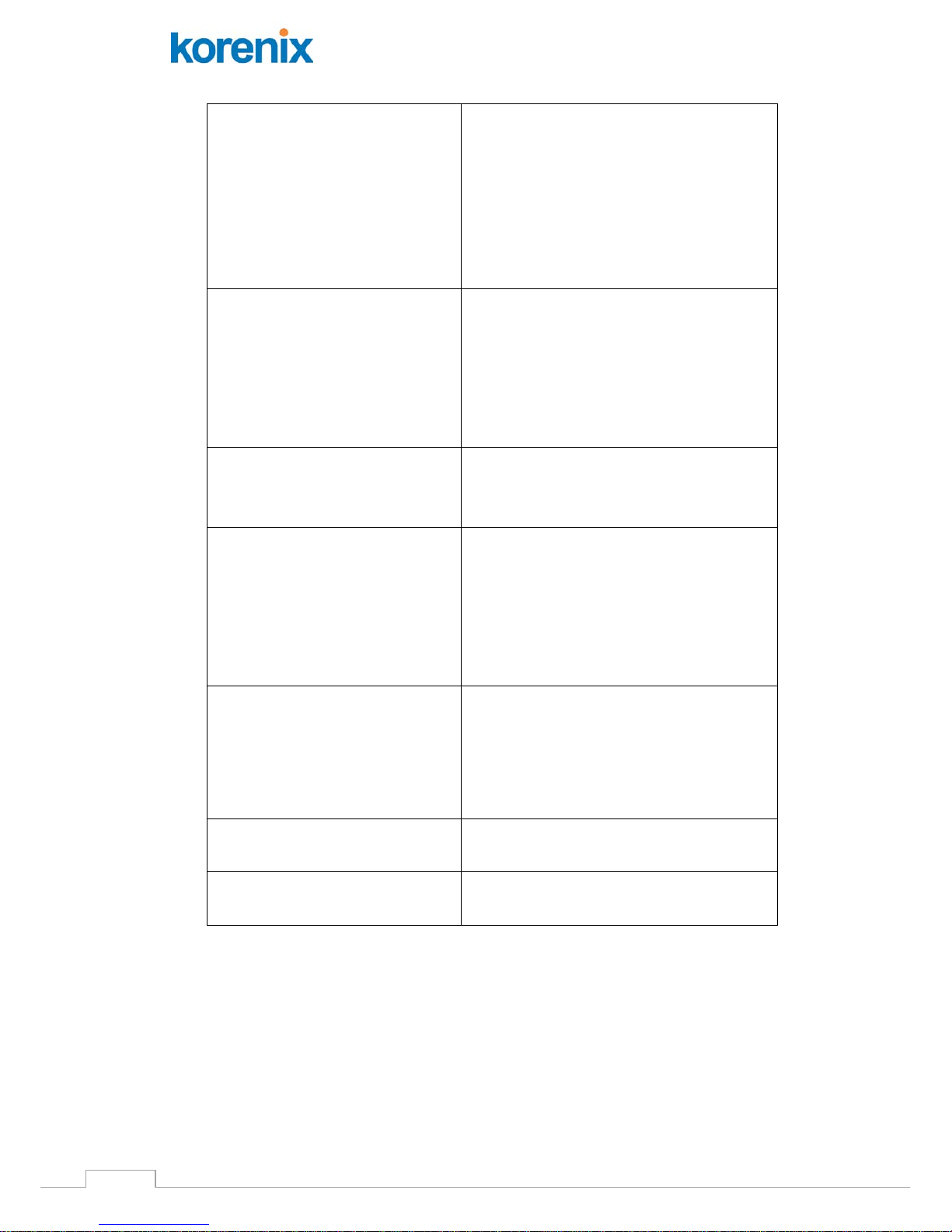

1.4 Limitations

Some limitations while running “ModbusT2R.exe” are detailed in the Table

1-5.

Application Name: ModbusT2R.exe

Limitations Description

No same station ID

Modbus station ID is used as an index

for the gateway application in the

current design, so Modbus RTU/ASCII

slave device with the same station ID

is not allowed to join the gateway

network.

No TCP request buffering

Modbus TCP master is not allowed to

SCADA

Ethernet

TCP port 5501

PLC ID=2

COM1:

RS 485

DCS ID=3

Meter ID=1

PLC ID=12

COM2:

RS 485

DCS ID=13

Meter

JetBox

Modbus TCP to RTU/ASCII Gateway Application

Page 8

JetBox 8100 User Manual_Modbus_1.0-r1.doc

4

send multiple requests to slaves

located in the Modbus RTU/ASCII

network. Because no request buffering

is supported, the request will be

redirected to the specific serial port

immediately. If it is a RS-485 serial

port, a collision could happen.

No timeout

Modbus TCP to RTU/ASCII gateway

application is desig ned w i thout t im eou t

mechanism. Modbus TCP master

should take care of the response

timeout for individual M odbus

RTU/ASCII slaves.

No broadcast

Request for station ID 0 will not be

broadcast to the Modbus serial

network.

Hardcode serial parameters

The serial port parameters are

hardcode to even parity, 8 data bits, 1

stop bit and none flow control for RTU

protocol and even parity, 7 data bits, 1

stop bit and none flow control for

ASCII protocol

One TCP port per instance

Only one Modbus TCP slave service

will be created on the first specified

TCP port number for one instance.

Multiple instances of gateway

application are allowed.

Executable without UI

A standalone executable and no UI

available.

Not a service

It’s not a service, no start and stop

behaviors are supported.

Table 1-5 Limitations While Running “ModbusT2R.exe” Application

Page 9

JetBox 8100 User Manual_Modbus_1.0-r1.doc

Chapter 2 Appendix

5

Chapter 2 Appendix

2.1 Chart Index

Figure 1-1 Block Diagrams of Modbus TCP to RTU/ASCII Gateway Application…………1

Table 1-2 Description of the Arguments of the “ModbusT2R.exe” Application……………2

Table 1-3 Contents of the Script File “demo.ini”……………………………………………....2

Table 1-4 Scenario of Running “ModbusT2R.exe” with “demo.ini” Script File……………..3

Table 1-5 Limitations While Running “ModbusT2R.exe” Application……………………….3

2.2 Customer Service

Korenix Technologies Co., Ltd.

Business service : sales@korenix.com

Customer service: koreCARE@korenix.com

Web Site: http://www.korenix.com

Loading...

Loading...