Manual and Technical Documentation TRANSICORD

as of software revision 6.0

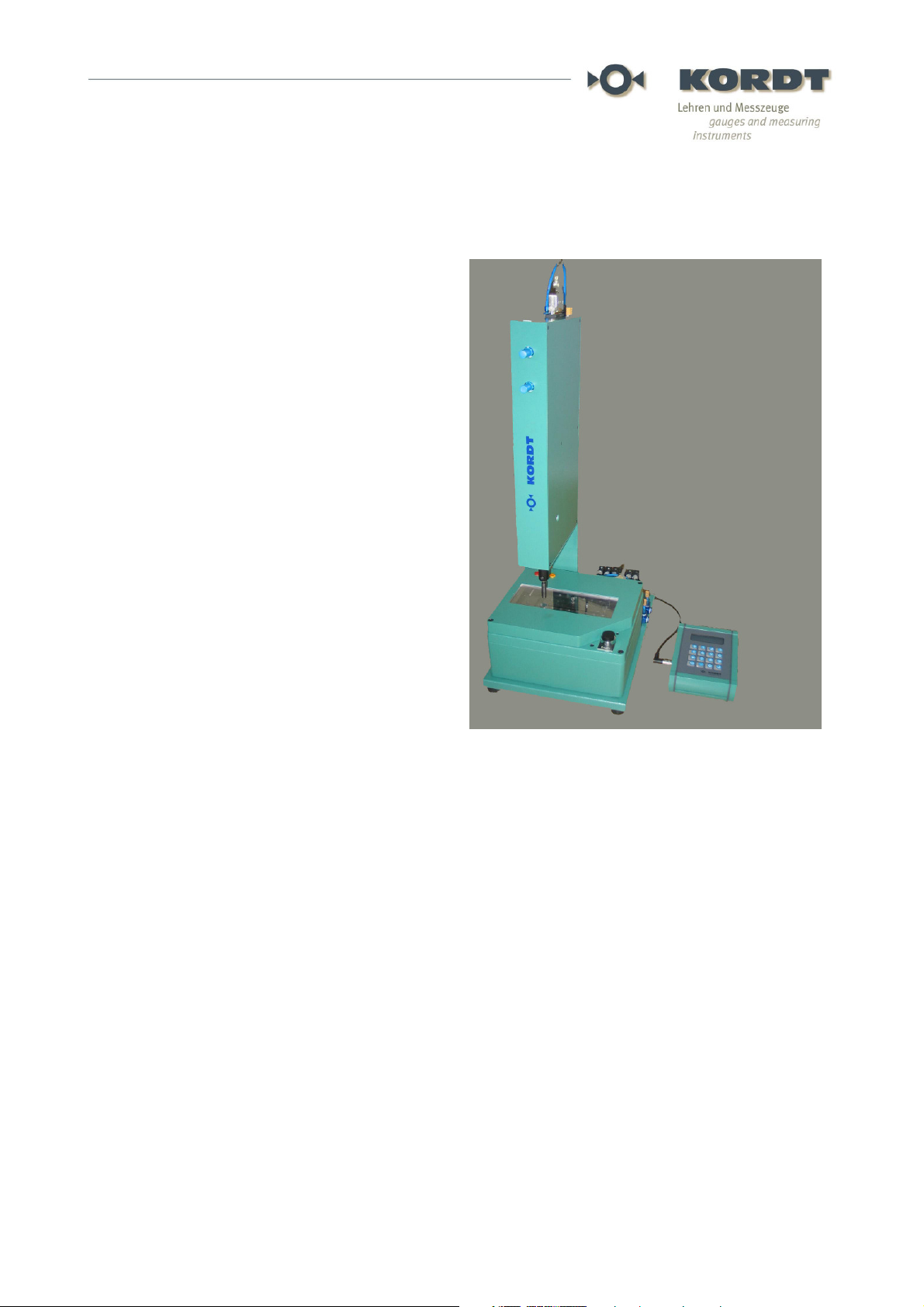

TRANSICORD 10480 V2 is a testing module for

the installation in fully automatic checking and

sorting units or transfer lines as well as for use

in the semi-automatic fixtures.

TRANSICORD 10480 V2 serves for the fast,

standard-compliant and fully automatic gauging

of external and internal threads as well as for

process monitoring in the thread production. Via

opto-isolated interfaces data and parameters are

exchanged with a primary control (SPC) and

serve to process control and documentation.

Strong construction paired with a precise

measuring technology ensure a lowmaintenance use under industry conditions and

provide reliable, reproducible test results.

TRANSICORD 10480 V2 has been developed

for the continuous use.

TRANSICORD 10480 V2 is a self-sufficient,

processor-controlled functional unit. All mobile

axes and the control are integrated. Only the

rack and the component transport with clamping

unit have to be applied according to the specifications. Test sequences are started by an external

start signal and run automatically. All messages and test results are distributed to the interface.

Most metric thread standard thread members are on stock or can be supplied with a short delivery

time. Special thread members can be supplied also: Details on this in chapter 2.

To guarantee a trouble-free operation and exclude damages at the equipment and injuries, please

read this technical documentation carefully before the installation of the device. Follow particularly

the instructions for safety and installation.

®

10480 V2

BA 10480 V2 E 0512/LTA

KORDT GmbH & Co. KG

Fabrik für Lehren und Messzeuge

Preyerstrasse 24 – 26

D - 52249 Eschweiler

Tel.: +49 (0) 2403-7005-0

Fax: +49 (0) 2403-7005-26

email: mail@kordt.de

http//www.kordt.de

1/27

Table of Contents:

1. Extent of supply

2. Gauge members for TRANSICORD 10480 V2

3. Safety instructions

4. General indications for the operation

5. Installation

5.1 Mechanical setup of the testing unit TRANSICORD 10483 V2

5.2 Connection of the control module TRANSICORD 10482

5.3 Connection to SPC

5.4 Power supply

5.5 Adjusting of the compressed air chokes

6. Compensation head TRANSICORD 10002

7. Setting the testing program

7.1 General instructions for the control module

7.2 Description of the menu

7.3 Loading data set

7.4 Starting program

7.5 Statistics

8. Interfaces

9. Running the machine without control module

10. Maintenance

11. Technical specification TRANSICORD 10480 V2

12. Dimensions TRANSICORD 10483 V2

13. Connection plan

14. EU - Installation explanation and EMV - Declaration of Conformity

BA 10480 V2 E 0512/LTA

2/27

1. Extent of supply

TRANSICORD 10480 V2 is delivered with the following components:

• Testing unit TRANSICORD 10483 V2

• Compensation head TRANSICORD 10002. The compensation head of TRANSICORD

10002 LH is used for left-hand threads. Please indicate at the order.

• Control module TRANSICORD 10482 with wall mount

• Interconnecting cable TRANSICORD 10484 to connect the testing unit with the control

module (2 m)

• Connector TRANSICORD 10485 to receive the power supply cable

• this technical documentation

Optional accessories:

Unregulated mains adapter/power supply TRANSICORD 10486 V2, 48 VDC – 12.5 A,

for control cubicle installation

BA 10480 V2 E 0512/LTA

3/27

2. Gauge members for TRANSICORD 10480

TRANSICORD 10480 is build for reception of the following CORD gauge members listed

below. CORD Go gauge members are designed that the first full flank is exact ½ pitch from

the face of the member. The special design of the CORD thread members supply a long

live time and reliability and so secure a repeatable test result. The CORD NoGo gauge

members have a guiding thread of two pitch length.. Hence the first full thread is at 2,5xP

from the face of the gauge member.

Most standard metric gauge members are deliverable from stock or can be delivered with a

short delivery time. On request we supply special design gauge members according to your

workpiece drawing.

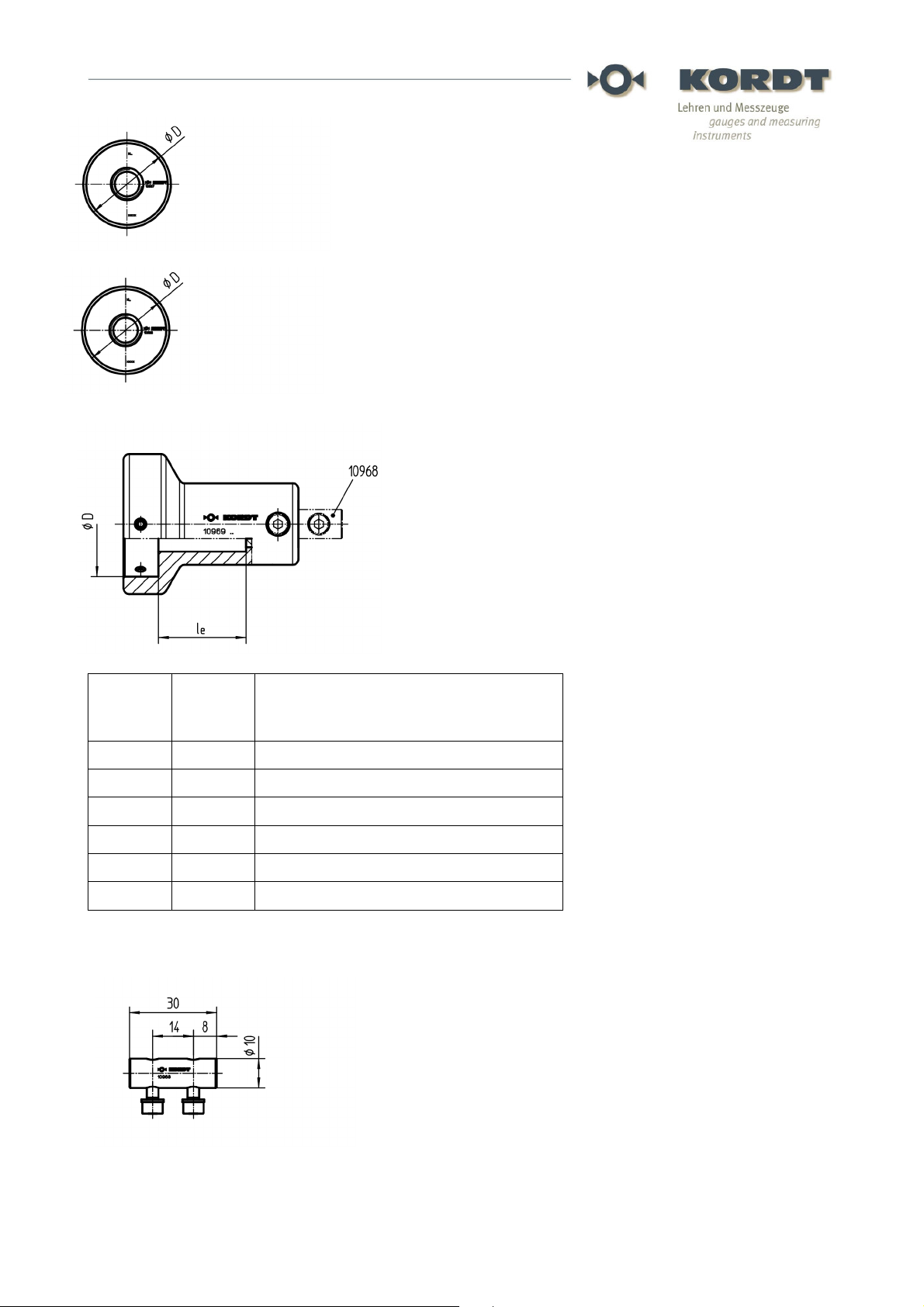

Thread Go gauge member TRANSICORD 10960

l2: according DIN 2282

le: max. screw in length

l: total length

Thread limit gauge member TRANSICORD 10961

le: screw in length

l2: according DIN 2282 and DIN 2284

l3: length of intermediate thread

le: max. screw in length

l: total length

Limit gauge thread member TRANSICORD 10963

l2: according DIN 2284

le: max. screw in length

l: total length

BA 10480 V2 E 0512/LTA

4/27

Ø D

Ie

Nominal diameter of

Thread Go gauge ring TRANSICORD 10967

Thread NoGo gauge ring TRANSICORD 10966

Reception TRANSICORD 10969

for thread gauge ring TRANSICORD 10967 and

10966.

[mm]

[mm]

TRANSICORD thread gauge rings

[mm]

20 23 2 – 5,5

30 26 5,5 – 10

36 30 10 - 15

43 31 16 – 20

51 31 21 – 25

61 39 26 - 30

Connection piece TRANSICORD 10968

to connect compensation head TRANSICORD

10002 and reception TRANSICORD 10969

BA 10480 V2 E 0512/LTA

5/27

3. Safety instructions

Caution! For the use of equipment driven electrically are the following fundamental

security procedures for protection against blow, injury and danger of fire to be taken

into account.

Read and follow these notes before you use the device.

Keep the safety instructions well.

3.1 Keep your area of work tidy. Disorder in the field of work yields causing danger of

accident.

3.2 Take into account surroundings influences. Do not expose the equipment to damp

or wet environment. Do not use the equipment in the near of combustible liquids,

liquids or gas. Provide a good illumination.

3.3 Protect yourself from an electric blow. Avoid to touch not earthed parts.

3.4 Keep third persons away! Keep other persons away from your field of work.

3.5 Do not overload your device. You work better and saver in the described performance

area.

3.6 Use the right tool. Do not use a too weak equipment, clamping devices or feeding

units. Do not use equipment for purposes and work for which it is not intended.

3.7 Wear a suitable working clothes. Wear no far clothes or jewellery. You can be

included or captured by moving parts.

3.8 Do not misuse the cables. Do not carry the device at the cable and do not use it to

unplug the plug from the electrical outlet. Protect the cable from heat and sharp edges.

3.9 Secure the component. Use clamping devices and feeding units or vice around the

component to hold the component tight. It is kept thus safer than with your hand and makes

the operation of the device possible with both hands.

3.10 Do not bend your stand. Avoid an abnormal posture. Provide a safe state and keep

the balance any time.

3.11 You keep your equipment in good condition and handle with care.

Pay attention to cleanness and rust protection to work for certain and well. . Follow the

maintenance regulations and the notes for tool changes and accessories.

Check the plug and the cable regularly and let these damages replaced by an expert . Keep

grips dry and free of oil and grease.

3.12 Unplug the mains plug if you are not using it, before the maintenance and other work

on the device.

3.13 Do not leave a tool key. Before switching on, check that the keys and setting tools

are removed.

3.14 Avoid an unintentional start. Do not carry an equipment connected to the power

supply system or with a finger at the switch. Make sure that the switch is turned off at the

terminal connection to the power supply system.

3.15 Be always attentive. Watch your work. Proceed sensibly. Follow the notes of the

operator. Do not use the device if you are lacking in concentration.

3.16 Check your device on damages. All parts must be put together correctly and satisfy

all conditions to ensure the faultless operation of the device. Damaged safety devices or

parts should be repaired by our customer services or are repaired or replaced according to

the instructions as far as nothing else is indicated in the operating instructions. Faulty parts

only may be in working order put or replaced by suitable specialist staff. Do not use an

equipment if the switch on/off is broken. Only use KORDT original parts.

3.17 Accessories

You use only accessories and options for your safety which are indicated in this technical

documentation. The use of others than this one in the technical documentation or use tools

or accessories not recommended in the catalogue can mean a personal injury danger for

BA 10480 V2 E 0512/LTA

6/27

you.

3.18 Installation

Have particularly the electrical installation of the device executed only of specialist staff. A

faulty connection of the device represents a danger for persons. Disturbances and

damages cannot be excluded at a faulty installation. Use our offer of putting into operation.

3.19 General

Not authorized changes, mishandling or -setting as well as not attention of the manual a

liability of the manufacturer for all damages excludes.

3.20 Care

The testing machine with its accessories should be cleaned in fixed cycle and protected

against corrosion at the shiny areas. The used gauge member (thread gauge) must be oiled

regularly in the operation. Gauge members should be managed and brought to the

recalibration in the context of a general control of measuring and testing equipment.

3.21 Control of measuring and testing equipment

For your control of measuring and testing equipment to ISO 9000 pp. we offer you our

KORDT-Calibrating Service (KKS).

4. General notes for operation

TRANSICORD 10480 V2 consists of 2 devices: The testing unit TRANSICORD 10483 V2

and the control module TRANSICORD 10482.

The testing unit TRANSICORD 10483 V2 has an axially mobile turning spindle which is

driven with a very dynamic, brushless servomotor. The axial movement of the turning

spindle is steered with compressed air. On the end of this spindle the compensation head

TRANSICORD 10002 is fastened. The compensation head compensates small position and

angular errors of the tested work-piece. The compensation head is also used for receiving

the thread gauge member. Before the testing sequence starts the thread to be checked

must be placed aligned to the turning spindle and fixed against rotation. The examining

process is started by an electrical start signal.

The handy control module TRANSICORD 10482 is connected to the testing unit with a

signal cable and serves for the manual setting of the examining process as well as

displaying results and reports. The control module can mounted user friendly at an

accessible place.

TRANSICORD 10480 V2 screws in the thread gauge member after receiving an external

start signal. It controls the testing procedure with the measurement of the length of the

screw in and the torque used.

TRANSICORD 10480 V2 tests external and internal thread attributive. With other words the

result of the tests will be „Go“, „NoGo“ and „Rework“.

The result is shown on the display when the testing procedure has finished. It will be

distributed via an optocoupler interface (see chapter 8). The display will freeze till the next

result is received. Alternatively the result can also be read out via optocoupler isolated TTY

interface. The TTY has the benefit that the thread depth and the torque can be read out in

addition. Furthermore all parameters can be transferred through this interface in two

directions. Statistics about the test results are shown at the display.

The following tests can be carried out:

• Go gauging

• Go gauging with thread depth measurement

• NoGo gauging

BA 10480 V2 E 0512/LTA

7/27

• Limit / Go-NoGo gauging (for through taped internal thread only)

On one hand the test result depends whether the set, maximum torque of screw in is

reached (see chapter. 7.2.5). On the other hand, it is dependent how far the gauge member

can be screwed in.

For the screw in procedure different testing levels control the behaviour of the testing unit:

T0 = Base level of the spindle (not turning of the spindle)

T1 = Start of the thread according to the component drawing.

T2 = Minimum depth at the Go gauging. T2 must be reached before the result „GUT“

(Go) can be generated. If T2 is not reached, the result will be „NA“ for Rework.

T3 = Maximal depth for the NoGo gauging. If T3 is reached the result will be „AUS“

for NoGo.

TR = From this level the rotation speed will be reduced to the inserting speed. The

rotation speed should be reduced before the level T2, resp. T3 is reached. At T2 or

T3 the gauge normally will run tight. To save gauges and avoid blocking of the

machine due to tightening at high speed and torque the speed should be reduced

before running tight usually.

5 Installation

5.1 Mechanical setup of the testing unit TRANSICORD 10483 V2

In principle, the testing unit can be put in all orientations. Take special care, however, when

checking below up that no dirt and liquid can penetrate into the spindle case. These can cause

disturbances in the long run. Please gather the necessary connection measures to the fastening

from the drawing in chapter 11. An adjustable connection console is recommended in order to align

the spindle to the component in the fixture.

The compensation head allows wrong position of the thread axis of the component to the spindle

axis of maximal 0.6 mm and 0.6 degrees. The more exactly the component is placed the less

friction you have at the testing procedure.

Fasten the thread gauge member on the compensation head. Before you can alternatively screw in

the gauge member into the component and pull the spindle at the gauge to check the alignment of

the spindle to component (only permitted without power supply and compressed air connection!).

Take care that the most possible, mechanical lift of the spindle is never exceeded. Take also in

account that faulty parts may require longer lift. We recommend a distance of approx. 5 mm

between the gauge and the component surface when the spindle is fully lifted (base level T0.) Pay

attention to the possible collision risks in automatic and setting mode!

As the component mostly is dimensioned form its face make sure that the thread start is always

fixed in the same position and will not be influenced of tolerances of other measures of the

component. Otherwise the component tolerances have influence on the thread depth measuring

and influence the test result. Pay attention to a good clamping so it will not break out by stress

during the testing process. A good clamping will guarantee a good test result of the thread depth

measurement.

Take care that it can never come to collisions at the work-piece transport. Heavy damages are

inevitably the consequence. Therefore the work-piece only may be moved when the spindle is fully

back and in base level (T0) and the "Ready" signal is shown(see chapter 5-3-1 and chapter 8).

Take possible errors also into you calculation (e.g. compressed air, power supply, failure of

components).

BA 10480 V2 E 0512/LTA

8/27

Connect the testing unit via an air maintenance unity to the compressed air supply when the unit is

mounted and fixed in position. Please adjust 4 to 6 bar. Do not oil the compressed air.

Ensure a regular lubrication of the gauge member. The wear on the gauge is reduced

considerably and extends its life time with that.

5.2 Connection of the Control Module TRANSICORD 10482

Fasten the control module with the enclosed wall mountings to a well accessible place and

connect the testing with the delivered Interconnecting Cable 10484. This has a length of 2

metres. Extend the cable under no circumstances. The proper operation of TRANSICORD

10480 V2 can be ensured only with the original cable.

The control module should remain connected to the testing unit permanently.

Avoid to align the Interconnecting Cable 10484 parallel to high-power cables. Protect

the interconnecting cable against damages by installing it in a cable channel.

5.3 Connection to SPC

Attach the SPC to the testing unit TRANSICORD 10483 V2 according to the appending

terminal connection plan (see chapter 12). Use a shielded cable and apply the screen onesided! Take into account that the optocoupler interface needs a power supply of its own. To

avoid ground loops use two additional wires to connect the optocoupler supply to the SPC

power supply.

Program your SPC so that a trouble-free operation is ensured. Follow the following

instruction in any case:

5.3.1 Testing sequence can only be started when the spindle is in base level (T0), the

„READY“-Signal is supplied and no error occurs.

5.3.2 Power supply faults are detected by TRANSICORD.

5.3.3 Errors are distributed over output "/FEHLER" and shown as a text at on the display.

Follow the announced instructions. Errors can be collected via the TTY interface.

5.3.4 Move the component only when the spindle is in base level (T0), the „READY“ signal is supplied and no error occurs. While the testing sequence is running the

component must be fixed tight.

5.3.5 The result of the test is distributed when the testing sequence is completed and the

spindle is at base level (T0) again. Until the distribution of the next result the present

test results can be collected. In this time period the communication via the TTY

interface also can take place. For safety reasons the TTY interface is only active,

when the testing program is running see chapter 2.4) or the "READY" signal is

displayed (NO IN THE SETTING MODE).

5.3.6 The advices are also important for the setting mode! Draw you attention especially

to a possible collision and a correct clamping and positioning of the components.

Further description you find at chapter 8.

5.4 Power supply

Connect the testing unit to the unregulated power supply TRANSICORD 10486 V2 when you

have finished the pre-work. Use for this the delivered cable connection socket

TRANSICORD 10485 and a three-wire cable with a wire diameter of at least 1.5 mm ², better

2.5 mm ². The line should not be long any more than 5 metres. Also protection ground has to

BA 10480 V2 E 0512/LTA

9/27

be connected.

At use of another power supply this must certainly have a low intrinsic resistance ("stiff output

voltage") to guarantee a trouble-free operation. As a rule, power supplies with toroidal mains

transformer have this quality. Switched power supplies should not be used. Do not attach

other consumers to the power supply. A isolation must be between mains and secondary

side.

5.5 Setting of compressed air throttle

Adjust the speed and damping of the axial spindle movement for the two directions

separately at the compressed air chokes at the testing unit. The air pressure should be 4 to 6

bar. Use the function "spindle" as in chapter 7.2.9.1 described. Set the throttle for the two

directions separately so that the spindle moves speedily but not too fast and well cushioned.

Caution: Injury danger! Keep away from the area of the spindle.

BA 10480 V2 E 0512/LTA

10/27

6 Compensation head TRANSICORD 10002

The compensation head TRANSICORD 10002

evens small position and angle offsets and

reduces the load to the spindle.

Ordering note: If you require the compensation

head for left-hand thread, please indicate at the

order absolutely! The TRANSICORD

compensation head for left-hand threads has the

type number 10002 LH.

Setting:

The compensation head is assembled together

with the bore ø10 lying above on the testing

spindle. It compensates small position and

angular errors and reduces the stress on the

spindle. After screwing out of the hexagon

headed screw ISO 4762-M 4 x 12 -12.9 with

spring washer the compensation head can be

pulled off. By turning the thread pin ISO 4026 - M

5 x6 at the lower tape the centring force of the

compensation head can be adjusted according to

the individual situation. Caution! Fasten the

thread pin not too tight, since otherwise the

centring taper can be damaged.

Maintenance: Check regularly the thread pin

10002-17 for deformation. If this is bent, you

exchange the pin (see drawing). Grease the

connection areas of reception and shaft. Release

the connection whenever it is blocked. Clean and

grease junction points before the assembly.

BA 10480 V2 E 0512/LTA

11/27

7 Setup the test program

7.1 General notes for the control module:

All functions and parameters of TRANSICORD 10480 V2 are executed or changed with the

control module 10482. The control module has a 4-line illuminated LC display and a robust

membrane keyboard with 16 buttons.

The numbered menu lines can be selected directly by pressing the number button. On

available, not visible lines point out to little arrows on the right in the display. A keystroke on

the corresponding arrow button rolls the screen in the desired direction.

Letters and special signs being able to be set also when required in text fields over the

number buttons: Press the button quick several times till the desired sign appears.

Line inputs must always be completely carried out until line end. If the last letter is entered,

the new value is stored with the <Enter> button. The <Esc> button rejects the input. An input

terminated can be at any time with the <Esc> button. The previous value reappears. You also

change to the primary menu with<Esc>. The input is checked on plausibility and rejected at

faults.

Manual and setting of the test program

Switching on TRANSICORD a status is pointed with detail of the software version briefly:

TRANSICORD 10480

KORDT GmbH & Co. KG

GERMANY

Version 4.1

Shortly after that a test is executed after confirmation with <Enter>.

Caution! The spindle is moved at this test. Keep away from the danger area.

While the testing sequence errors are displayed. You will be requested to remove these

errors. Only if the function test is finished without error a test program can be started (see

chapter 7.4). After finishing the test sequence TRANSICORD is running in automatic mode

and is waiting for the start signal.

Please push <ESC> to switch to the main menu. TRANSICORD is now in manual mode.

For safety reasons TRANSICORD reacts to the START signal only in automatic mode.

1) Setup

2) Load Test Record

3) Run Program

4) Statistics

BA 10480 V2 E 0512/LTA

12/27

9) Functional Test ↑

To set the program procedure as follows:

Press <1> for Setup:

7.2 Description of the Setup menu:

You see the following displays:

1) Thread Parameters

2) Repitions _

3) n_test ______rpm

4) n_thread_____rpm↓

5) M_max ___ Ncm ↑

6) T1 scan

7) Edit Levels

8) Save Record ↓

Press <1> for

7.2.1 Thread Parameters

7.2.1.1 Diameter

Press <1> again. The cursor jumps into the petition field. Insert the approx. nominal

diameter of the thread. This value will be used for various suggestion values. Finish our

petition with <ENTER>. (Note: Single digit values have to be start with zero). Value from 01

to 99 mm are applicable.

7.2.1.2 Pitch

Press <2> to set the pitch. Proceed like before. You have to enter the pitch with a resolution

of two digits. Values from 0.10 – 9.99 mm are applicable.

1) Nom.Diameter __ mm

2) Pitch _,__ mm

3) RH Thread

4) Go Gauging+Depth

7.2.1.3 Turning direction

Repeat pressing the <3> and you will change the turning direction. Mainly right hand

threads are used. Keep in mind that you need to replace the compensation head to left-

BA 10480 V2 E 0512/LTA

13/27

hand if you change the turning direction to left hand.

7.2.1.4 Gauging mode

Press <4>. If you repeat to press <4> you toggle between:

1. Go gauging

For Go gauging of internal thread testing. The Go thread gauge member CORD 10960 or

for external thread the Go gauge ring CORD 10965 together with the matching reception

CORD 10969 and intermediate piece CORD 10968 are used.

2. Go gauging + depth (Go gauging with measurement the thread length)

For Go gauging of internal thread testing. The Go thread gauge member CORD 10960 or

for external thread the Go gauge ring CORD 10965 together with the matching reception

CORD 10969 and intermediate piece CORD 10968 are used.

3. Limit gauging

For limit gauging of internal thread. The thread limit gauge member CORD 10961 is used.

Limit gauging is only possible with through taped bores.

4. No Go gauging

For NoGo gauging of internal thread. The thread NoGo member CORD 10963 or for

gauging of external thread the thread NoGo gauge ring CORD 10966 together with the

matching reception CORD 10969 and intermediate piece CORD 10968 are used.

Go back to the main menu with <ESC> when you have finished your setting.

7.2.2 Repetitions

If the thread member does not thread itself into the component there are various reasons

possible:

• Defect of the thread start or a chip blocks the entrance

• Gauge member arrives with a high speed on an unlucky spot of the thread

• Component is not proper aligned, etc.

You can set the repetition up to three times to repeat threading the gauge member into the

thread of the component. The spindle will turn back without lifting and will start the

procedure again. Set the repetitions to 0 – 3 times.

7.2.3 n_test (test speed in rpms)

If required you may change the default test speed. Insert a value in rpm. The speed can be

between 100 and 2000 rpm. For your orientation see the default speed. If you choose a

speed to high the test can get uncertain.

7.2.4 n_thread (threading speed in rpms)

To save gauge and component it is recommended to use a slower speed to thread the

gauge. If required you may change thread rotation speed. The insert rotation speed can be

set between 50 and 1000 rpm. The thread speed will accelerate to the test speed when T1

BA 10480 V2 E 0512/LTA

14/27

plus one lead is reached and will decelerate again when TR is reached.

7.2.5 M_max (maximum torque in Ncm)

The required torque depends of various factors: Diameter, pitch, material, lubrication,

thread length, tolerance, tightness between gauge and component etc. Hence the max.

torque has to be set separately. Keep in mind that the required torque might be higher if the

component is not aligned proper or is less lubrication. If the max. torque is reached the

testing sequence will be stopped. According to the spindle position the result of the test will

be distributed.

If required you may change the max. torque. The torque can be set between 20 and 100

Ncm. It is advisable to set the max. torque to the lowest possible value. With this you can

minimize the stress and the wear out of component and gauge. Please take into account

that gauges with small diameters and gauges with extra long shafts may be overloaded and

break. On the other head the test result with a torque set to low will be insecure.

7.2.6 Scan for T1

The face of TRANSICORD gauge members are always designed with 0.5 pitch distance

from the first full flank. Therefore the TRANSICORD gauges are applicable for the thread

depth measurement absolutely. NoGo gauges have an alignment cylinder of two pitch

length. To determine the start of thread of the component the thread gauge member will be

touch the face of the component and read out the value. With this procedure the start of the

thread according to the component drawing is known by the control.

T1 will be scanned

Adjust

setting master

and confirm.

Put in a component without a thread or a setting master and clamp it. Accept this message

with <ENTER> and the spindle will move the gauge member to the surface of the

component or setting master. The value 0.5 x pitch will added and stored as test level T1.

CAUTION: If you change the pitch in the setting the start of thread will not fit anymore. In

this case you have to reset the settings again.

Automatically you will be leaded to „Edit test levels“ (see chapter 7.2.7). According to the

way of gauging the levels T1, T2, T3 and TR will be presented. No relevant levels will be

removed from the screen. Level T1 was, as described above, defined new and all other test

levels will be set to the same value. All previous existing lines will be over written.

The test levels T2, T3 and TR have to be edited according to the component drawing. Work

chronologically. Keep in mind that always the actual, absolute spindle stroke is the basis. To

get the correct values for T2, T3 and TR you have to add the value for T1 to the values you

see in the component drawing.

This procedure might be difficult but the advantage is that there will be never confusion

about the level. Accordingly values larger then 61 mm will not be possible.

See the details in the following chapter.

BA 10480 V2 E 0512/LTA

15/27

7.2.7 Edit test levels

After you have set T1 as described above (see chapter 7.2.6) you can edit the other test

levels.

The test levels will be measured from the reference point at the upper back stop of the

spindle. The test levels have to be edited with a 0.01 mm resolution and will be read out

with that accuracy after the testing sequence.

Not relevant examining levels are removed depending on way of gauging. The plausibility of

the petition values is checked and if necessary mixes up the order of the values. Therefore

enter the examining levels chronologically and with rising values.

The following test levels are given:

T0 = Basic level of the spindle; No turning of the spindle. (fixed, not changeable.)

T1 = Start of the thread according to the component drawing. The thread speed (see

chapter 7.2.4) will be used to level T1 plus one pitch. At this position it is sure that the

thread member has found the start of the thread. Form this point on the speed will

accelerate up to the set test speed.

T2 = Minimum level for Go gauging. T2 have to be reached to generate the result „GUT“.

Set T2 to the minimum thread length of the component. If T2 is not reached the result will

be „NA“ for rework.

T3 = Max. level for NoGo. If the level T3 is reached the result „AUS“ for NoGo will be given.

If you are in the mode „Go gauging with thread length“ the rotation will continue max. two

turns to give also the reading for the thread length also if the tap on the component is to

deep.

TR = Level from which on the reduced rotation speed will be effective. At Go and Limited

gauging the rotation speed should be reduced before T2, resp. T3 is reached. This will save

gauge and component wearing because below T2 or at T3 normally the gauge will tighten

at max. torque. Also this will avoid blocking of the machine when checking with larger

gauges running tight at high speed and high torque. TR will be generated by entering T2 at

the Go gauging modus resp. in the modus NoGo or limit gauging modus automatically by

setting of T3.

7.2.8 Save test record

When you have completed the setting you can save these parameters. You can record up

to four sets of parameters. When have chosen the set no. you can enter name, description

and name of the program. By fast repetitive pushing of the buttons you can enter letters and

special characters. 16 characters can be entered each line.

Be aware that TRANSICORD will not save the set of parameters automatically. It will only

save the settings if you record the values. When you start >TRANSICORD the last actual

and saved test record will be shown.

7.2.9 Functional test

With this function you can test all functions of the instrument.

CAUTION! Danger of injury: The spindle will move and turn! Keep away from the area of

the spindle. Use this function only if you are sure that the spindle can move freely and no

risk of injury is present.

BA 10480 V2 E 0512/LTA

16/27

7.2.9.1 Spindle

If you repetitively press <1> the position of the spindle will toggle: Move forward, hold, move

back. The current status will be displayed. After the spindle has moved forward the length

will be displayed.

7.2.9.2 Drive

If toggling <2> the drive will run or stop. On the display you see the next function.

7.2.9.3 Run sequence

1) Spindle

<measured depth>

3) Drive

4) Test Sequence

To test the set of parameters you have to accept with <Enter> the following message:

A single test sequence will be performed. Make sure that the component is aligned and

firmly fixed. After the test sequence is finished the result of the test will be displayed.

CAUTION! Risk of injury: The spindle moves forward and turns!

With this test sequence the setting is finished.

Do not forget to save the parameters whenever you find the setting proper (see

chapter 7.2.8)!

Press <ESC> to return to the main menu.

7.3 Load test record parameters

Select the test record from the menu. This will load this test record into the actual set of

parameters. Only with the actual set of parameters the program can be run. If you program

TRANSICORD the next time the last actual set of parameters will be loaded. If you change

parameters please keep always in mind that you might have to change the gauge member

and the fixture. If you change the direction of rotation you also have to change the

compensation head TRANSICORD 10002 for the other hand.

Please insert

component and

confirm.

7.4 Run program

With this function TRANSICORD switches from setting mode to automatic mode and is

waiting for the START-Signal to start the test sequence. To start a test sequence the

READY-Signal must be displayed („1“) and simultaneously the /FEHLER-Signal must be

„1“ (/FEHLER is at an Error on „0“!). The READY-Signal is supplied („1“), if the spindle is at

the basic level (T0) and no error occurs.

BA 10480 V2 E 0512/LTA

17/27

CAUTION! The component may only be moved if the READY-Signal is high and

/FEHLER is high. The START-Signal may only be given if the component is aligned

and clamped tight. During the whole test sequence the component must be fixed.

Damages otherwise can damage the instrument and flying parts can injure persons.

While the automatic mode the statistics will be shown on the display (see below)., These

are the same values you can call from the menu (see chapter 7.5 statistics). The TTYinterface is only active in automatic mode due to safety reasons.

7.5 Statistics

At the display you see the number of executed tests and the results of the tests. If you scroll

down the display you see the thread depth of the last test and the torque which is used

between T1 and T2. If you press <1> (Reset) the values will set to zero.

8 Interfaces

All TRANSICORD 10480 V2 interfaces are of optocoupler type. (Terminal occupation see plan

in chapter 13):

• Static inputs:

• START - start test sequence

• CONFIRM - confirm

• IN_0 - spare input

• IN_1 - spare input

• Static outputs:

• GUT - result of test: Go

• AUS - result of test: NoGo

• NA - result of test: Not OK., Rework

• READY - ready for test sequence

• /FEHLER - error, (active low)

• OUT0 - spare output

• OUT1 - spare output

• OUT2 - spare output

• Passive TTY-Interface:

The implemented serial, passive TTY interface is optocoupler isolated and compatible

SPCs (e.g. Siemens S5). TRANSICORD 10480 V2 never sends independently through

this interface but only responds to request. Via this interface it is not only possible to

recall the result of the last test. You can also access the parameters of the current

program and change the set of parameters while the machine is running. The TTY

interface is only working in automatic mode due to safety reasons (see chapt. 7.4 Run

program). It is working at 9600 Baud, 8 Data bits and a single stop-bit.

BA 10480 V2 E 0512/LTA

18/27

Go, Limit, NoGo gauging, Go gauging with

Please be aware that TRANSICORD 10480 V2 is performing a limited plausibility test

but will not do a security test. Check the correctness of the parameters before you

transmit them. Errors, accidents and damages and damages which result from

faulty setting values lie in the responsibility of the operator.

After each status request or command the sign 0x0D (Carriage Return, dec. 13) must

be attached so that the command is recognised as finished. On each command there

will be a semicolon as answer, on each faulty command an error code followed by a

semicolon. On each status request the answer will be a status code followed by a

semicolon. All values will be sent in ASCII code. It is not distinguished between capital

and small letters. Each String will be finished with 0x0D.

Status

request

SM xxx (Ncm) torque of test between T1 und T2

ST xx.xx (mm) max. depth of the last test

SG xxxxxx (Stück) number of Go parts

SA xxxxxx (Stück) number of NoGo parts

SN xxxxxx (Stück) number of Rework parts

SP xx GO,NG,NA

SF Exxx Fehler deciaml error code, octal coded

SMM xxx (Ncm) max. torque

SNP xxxx (U/min.) test rotation speed

SNE xxxx (U/min.) threading speed

ST1 xx,xx (mm) test level T1

ST2 xx,xx (mm) test level T2

ST3 xx,xx (mm) test level T3

STR xx,xx (mm) test level TR

SST x,xx (mm) pitch

SDU xx (mm) nominal diameter

SRL x R, L right hand / left hand thread

Format of

transmitted

parameter

(Unit) Description of parameter

Finding of test (GUT = Go, AUS = NoGo,

NA = Rework)

SLE xx GO,LM,NG,GD

SWI x (number) number of retrails of the test

Command

PMM xxx (Ncm) max. torque

PNP xxxx (rpm) n_test

PNE xxxx (rpm) n_thread

PT1 xx.xx (mm) test layer T1

PT2 xx.xx (mm) test layer T2

PT3 xx.xx (mm) test layer T3

PTR xx.xx (mm) test layer TR

PST x.xx (mm) pitch

PDU xx.xx (mm) nominal diameter of the thread

PRL x R, L right hand / left hand thread

PLE xx GO,LM,NG,GD

PWI x 0..3 number of retrials of the test

PSL x 1..4 load Data set no. (x)

BA 10480 V2 E 0512/LTA

Format of

parameter

Parameter (unit) description of command

depth measurement

Go, limit, NoGo gauging, Go gauging with

depth measurement

19/27

Error code

Description of error

Command

Bit

ERR01 n_thread > n_test PNP

ERR02 n_thread > n_test PNE

ERR03 T1 > T2 PT1

ERR04 T1 > T3 PT1

ERR05 T2 < T1 PT2

ERR06 T2 > T3 PT2

ERR07 T3 < T2 PT3

ERR08 parameter missing command

ERR09 parameter invalid command

ERR10 command invalid command

ERR11 range exceeded command

ERR12 parameter to long command

ERR13 parameter to short command

ERR14 parameter missing command

ERR15 status request invalid status request

ERR16 no result available status request

ERR17 format invalid command

ERR18 PT2 invalid in NoGo test PT2

ERR19 PT3 invalid in Go test PT3

ERR20 data set empty PSL

Status request

return value

description of error

0 supply voltage too low xxxxxxx1

1 motor temperatur exceeded xxxxxx1x

2 compressed air missing xxxxx1xx

3 spindle is stucking xxxx1xxx

4 reference missing xxx1xxxx

5 motor test aborted due to error xx1xxxxx

binary code

9 Operation without Control Module

(as of s/w revision 6.0)

TRANSICORD 10480 V2 is also operable without the Control Module TRANSICORD 10482. It

is sometimes useful to disconnect the Control Module if you like to inhibit manual access to the

test program during continuous operation. In this case it is imperative to realise the

communication across the TTY interface.

We advise you to leave the Control Module connected at every time. So messages on

the display can help to give the operator a fast interfering into the process. Also when

changing the gauge member it is necessary to use the Control Module to adapt the test

program.

When operating TRANSICORD 10480 V2 without Control Module 10482 the functional test

has to be confirmed by applying a positive impulse at the static input “CONFIRM” (ca. 100

ms). If an error is signaled with a low output at “/FEHLER the error also has to be confirmed in

the same way. The error code is readable via the TTY interface. Every single error has to be

confirmed.

TRANSICORD 10480 V2 will get ready for the first test if there is no error shown anymore.

BA 10480 V2 E 0512/LTA

20/27

10 Maintenance

The construction and all components of TRANSICORD 10480 V2 are selected and developed

for maximum possible life time. Beside the gauge members there are no wearing parts on

TRANSICORD 10480 V2 which have to be exchanged regularly. We recommend the following

maintenance:

• Depending on the load of the drive unit check in regular cycles all moving parts on the

unit and the devices. Clean periodically from dirt.

• Check especially the compensation head TRANSICORD 10002 as described in chapter 6.

• Make sure that the gauge member is periodically lubricated. With this you reduce the

necessary torque and the wear out of the gauge. Synthetic oils are recommended.

• Bring the gauges to the monitoring of testing equipment in regular cycles. Exchange the

gauges before they reach the limits of wearing. Only good test gauges will supply

good results.

• If there are any errors or damages send the whole machine to Kordt GmbH & Co. KG,

Eschweiler, for repair. Never execute unauthorized repairs or changes. Rights to claim

under guarantee will expire from outside intervention or changes.

CAUTION!

Manipulation, faulty usage or setting as well as treatment not according to the manual of the

instrument will exclude all liability of the producer on all damages and losses. Repairs may

be executed by KORDT or KORDT authorized persons. The use of foreign parts will exclude

the warranty. Only original parts of KORDT are allowed. The machine and the accessories

should be cleaned and oiled on the metal surfaces after each use and have to be recalibrated

periodically.

Note: For recalibration please contact us or our local agent.

BA 10480 V2 E 0512/LTA

21/27

11 Technical specification TRANSICORD 10480 V2

•••• Mounting position arbitrary (respect the IP protection class!)

•••• Rotation speed: 50 - 2000 rpm

•••• Torque: 0.2 – 1 Nm

•••• Nominal thread pitch diameter ca. 3 – 30 mm

•••• mechanical spindle stroke: 61 mm

•••• measuring range: >= 60 mm

•••• resolution of thread length measuring: 0,01 mm

•••• repeatability of length measuring: +/-0.01 mm

•••• compressed air: 4 – 6 bar, 1 l/min.

•••• Nominal power supply: 48 V-DC +/- 15% – 10A, fused with 10 A fast

•••• optically isolated inputs: 24V-DC +/-15% – 10mA [START]

•••• optically isolated outputs: 24V-DC +/-15% – 10mA [READY, /FEHLER, GUT, AUS, NA]

•••• serial TTY interface (passive): 20mA, max. 30V, 9600 Baud, 8 data bits, 1 stop bit

•••• protection category: TRANSICORD 10483 V2: IP44 mounted vertically, test direction up to

down; TRANSICORD 10482: IP54

•••• Humidity: Not condensing

•••• Temperature: 0 - 45°C

BA 10480 V2 E 0512/LTA

22/27

12 Dimensions of TRANSICORD 10483 V2

BA 10480 V2 E 0512/LTA

23/27

Pin no.

Signal

Function

Notice

Pin no.

Signal

Function

Notice

13 Connection diagram

10483 V2: -X1 4 pin male Connector Hirschmann CA 3

3 V+_L power supply: +48 V isolated to

2 GND_L power supply: Ground optocoupler interface

PE PE Protective Earth

10483 V2: -X2 D-Sub 25 pin female MIL 24308 / DIN 41652 Teil 1

1 START input start sequence

2 IN0 input spare

3 IN1 input spare

4 CONFIRM input confirm

5 N.C. n.c. not connected

6 GUT output findings Go

7 AUS output findings NoGo

8 NA output findings Rework

9 READY output status

10 /FEHLER output status

11 OUT0 output spare

12 OUT1 output spare

13 OUT2 output spare

14 TTY-RX+ Receive + TTY interface

15 TTY-RX- Receive - TTY interface

16 TTY-TX+ Transmit + TTY interface

17 TTY-TX- Transmit - TTY interface

18 – 21 V+_IO optocoupler interface supply: +24V isolated to power supply at X1

22 – 25 GND_IO optocoupler interface supply: Ground isolated to power supply at X1

BA 10480 V2 E 0512/LTA

24/27

BA 10480 V2 E 0512/LTA

25/27

14 EU – Installation explanation and EMV - Declaration of

Conformity

In accordance with the EC machine guideline 2006/42/EC of May 17th, 2006, appendix II B

and EMV guideline 2004/108/EC to the adjustment of the legal provisions of the member

states about the electromagnetic compatibility.

We hereby explain that the machine described hereinafterly meets the basic safety and health

requirements of the EC guideline 2006/42/EC in its conception and construction as well as in

the execution brought about into traffic by us. The engine component may only then be taken

into operation 2006/42 if the engine into which the engine component shall be installed was

stated that (/EC) the regulation of the guideline corresponds.

Furthermore we explain that the machine described hereinafterly corresponds in the execution

of the EMV-judging line brought about into the traffic by us to the electromagnetic compatibility

2004/108/EC.

Producer: Kordt GmbH & Co. KG

Preyerstraße 24 – 26

D-52249 Eschweiler

Description of the machine:

function: thread testing machine

Type/Model: 10480 V2

build: from 2012

Harmonized standards particularly used:

•••• DIN EN 12100-1 Safety of machinery - Basic concepts, general principles for design

Part 1: Basic terminology, methodology

•••• DIN EN 12100-2 Safety of machinery - Basic concepts, general principles for design

Part 2: Technical principles

•••• DIN EN 60204-1 Safety of machinery - Electrical equipment of machines

Part 1: General requirements

• DIN EN ISO 13849 Safety of machinery - Safety-related parts of control systems

• DIN EN 61000-6-2: Electromagnetic compatibility (EMC)

• DIN EN 61000-6-4: Electromagnetic compatibility (EMC)

Furthermore we declare that the special technical documentation for this uncomplete

machine according appendix VII, part B have been made and make the commitment to

hand over this to the market supervisory authority.

BA 10480 V2 E 0512/LTA

26/27

Assignee for the technical documentation

Heinz Offergeld, Manager QS

Eschweiler, 2.2.2012

Detail on the person of the signatory:

Jantzen, Martin, General Manager

BA 10480 V2 E 0512/LTA

27/27

Loading...

Loading...