Kop-Flex Series H Catalog Page

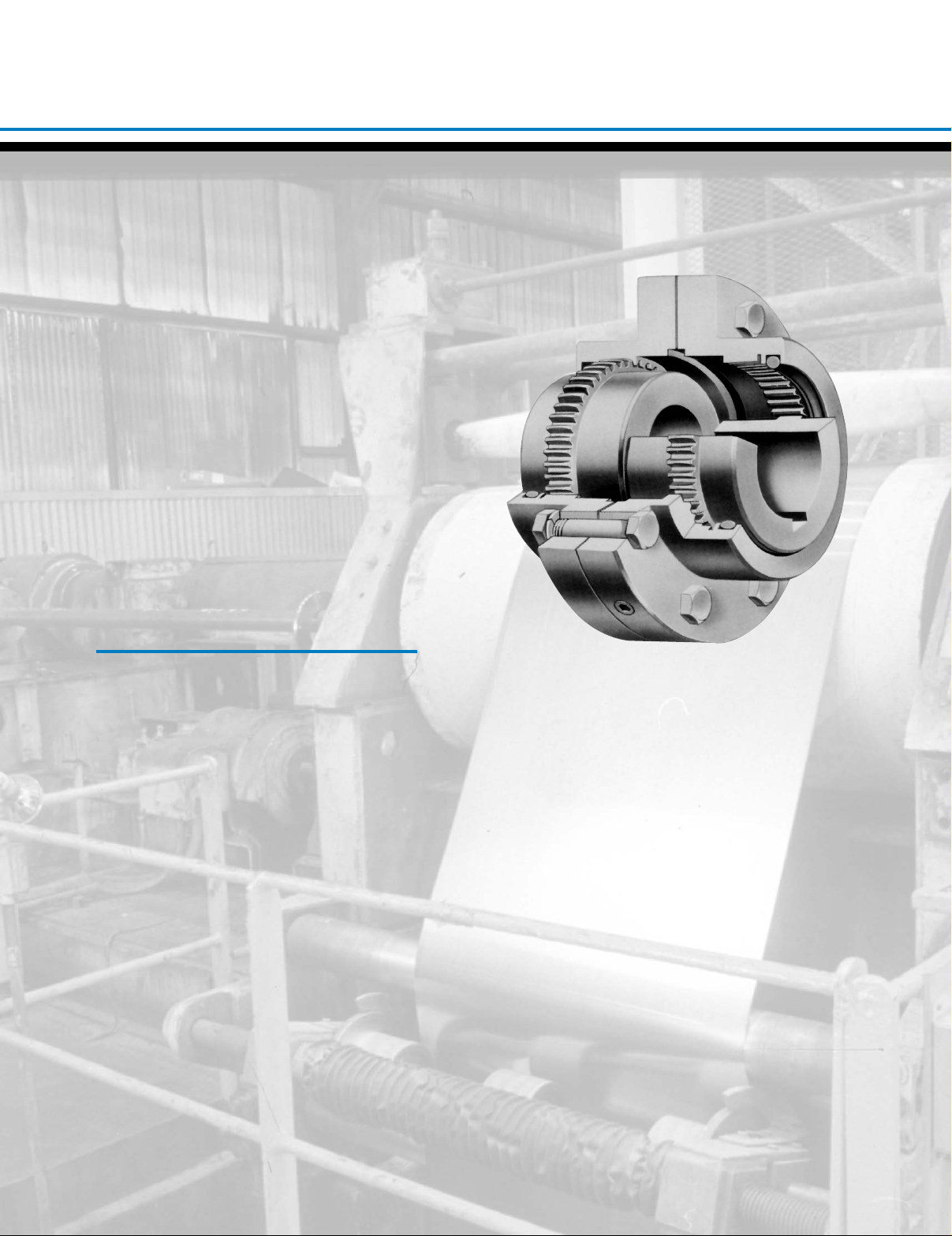

Series H

Gear Couplings

Size 1 through 30

MOST ECONOMICAL

GEAR COUPLING DESIGN

LARGE BORE CAPACITY,

WITH O-RING SEAL

Index:

Page

HOW TO ORDER ........................................ 127

Technical Advantages.......................... 126 - 127

Service Factors ............................................ 128

Selection Procedure .................................... 129

Dynamic Balancing Guide ............................ 129

Full Flex Coupling ................................ 130 - 132

Fastener Data ..................................... 130 - 131

Spacer Coupling ........................................... 133

Flex Rigid Coupling ............................. 134 - 135

Floating Shaft Coupling ....................... 134 - 135

Mill Motor Coupling ............................ 136 - 137

Limited End Float Coupling .......................... 138

Vertical Coupling .......................................... 138

Slide Coupling .............................................. 139

Brake Wheel Coupling ................................. 140

Brake Disc Coupling .................................... 141

Alloy Steel Full Flex ...................................... 142

Alloy Steel Spacer Coupling ......................... 143

125

THE SERIES H ADVANTAGES:

Higher Misalignment Capability

Sizes 1-7 compensate for up to ±1 1/2° static angular

misalignment per gear mesh.

Minimizing operating misalignment will maximize the life of the

coupling. Refer to the Installation and Alignment Instructions

for alignment recommendations.

Larger Bore Capabilities allow the most economical size

selection for shafts up to 10 5/8".

Higher Torque Ratings due to larger tooth pitch diameters than

other couplings.

Versatility in that Series H’s are interchangeable by half coupling

with competitive coupling designs.

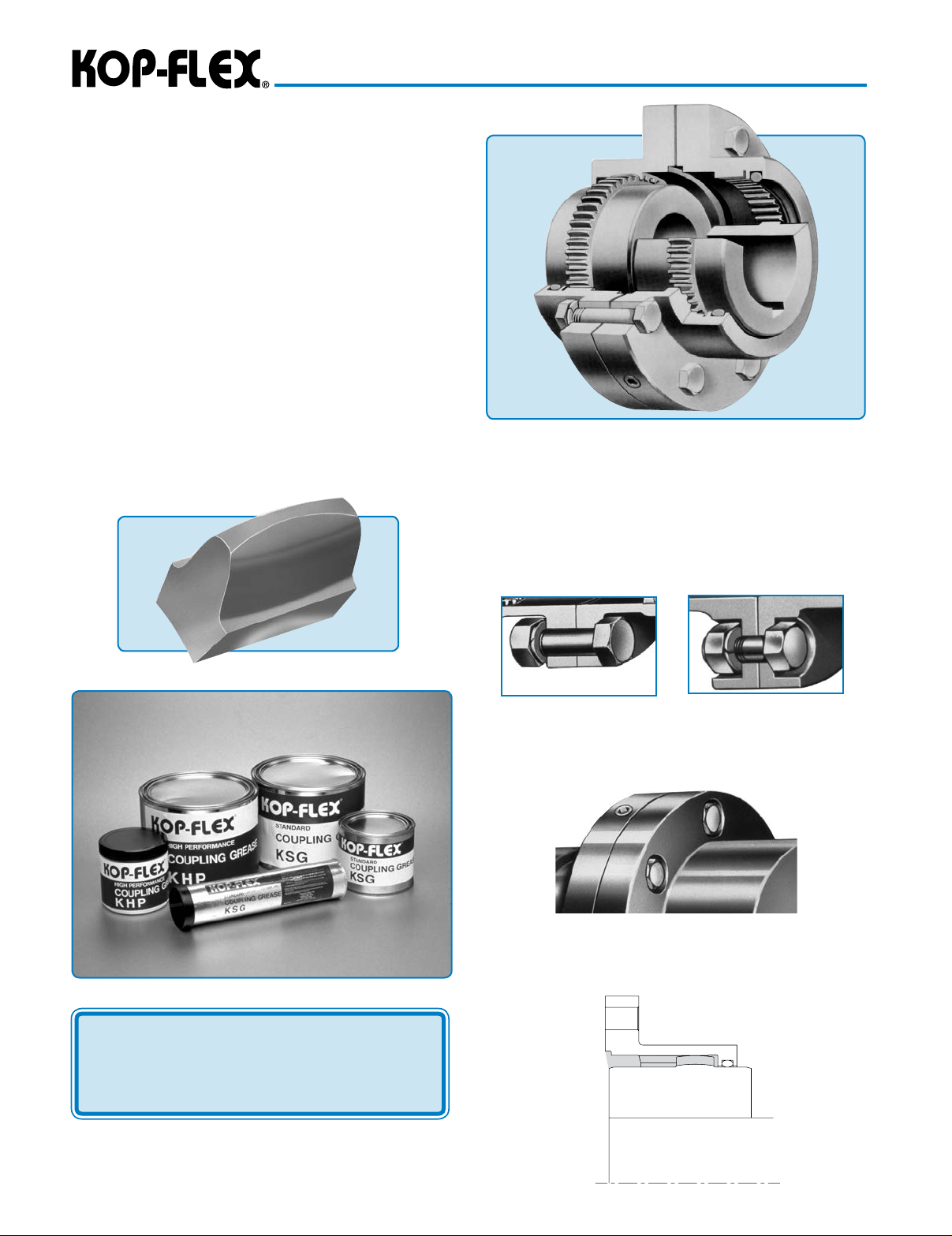

1 1/2° Curved-Face Teeth are a prime feature of the Series H

coupling, sizes 1-7. The crowned hub teeth are a 20° full-depth

involute tooth form with flank, tip, and root curvature. When

used with the straight faced sleeve teeth, these 1 1/2

face hubs offer increased shaft misalignment capability.

° curved

SERIES H GEAR COUPLINGS

Crowned Tooth Sizes 1 - 7

CENTER FLANGE BOLTING:

All couplings feature precision-drilled flange bolt holes, and

tight tolerance Grade 5 flange bolts to assure a long-lasting

flange to flange and fastener fit. Exposed bolt flanges are

standard. Shrouded bolt flanges can be supplied through size

5. Size #5 1/2 and larger couplings are only available with

exposed bolt flanges.

Coupling Greases

KOP-FLEX offers greases specifically designed for use in coupling

applications. For proper lubrication and long service life, use KSG

Standard Coupling Grease, or KHP High Performance Coupling

Grease. See pages 170-172 for detailed specifications.

LUBRICATION:

Each sleeve flange is supplied with two pipe plugs 180° apart.

This permits assembly of a full flex coupling with four lube

plugs positioned every 90°, facilitating lubrication.

The lube seal is a Buna-N O-ring to help retain grease and

exclude contaminants. KHP or KSG coupling greases are

recommended in order to obtain maximum operating life.

126

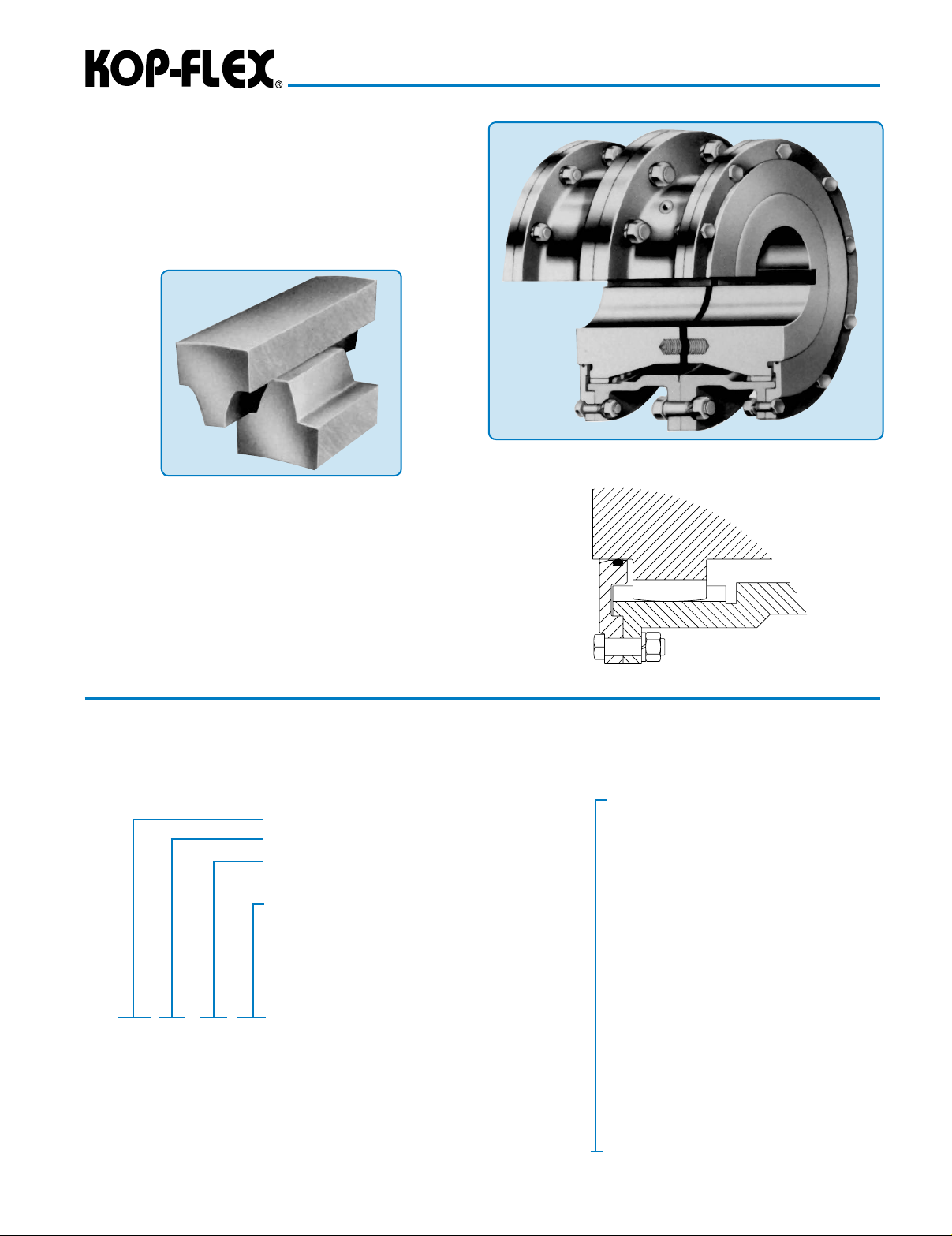

Series H couplings of Size 8 to 30 are designed for ±1/2°

misalignment per flex half coupling, to compensate for

misalignment between the shafts in a full-flex coupling.

Series H couplings can be supplied in full-flex, flex-rigid,

floating shaft and spacer arrangements as well as custom

designs. Only exposed bolt flanges are available in sizes 8

to 30.

The straight-faced, involute stub tooth form is used in the Series

H coupling, sizes 8 to 30. This tooth form distributes contact

pressures across the full length of the hub tooth, to best develop the needed lubricating film, minimizing tooth wear and

extending coupling service life for years of operation.

The End Rings are removable for ease of assembly and to

allow inspection of the gear sets. A Buna-N O-ring seal is

incorporated to help exclude contaminants and retain the

lubricant. Designed for grease lubrication, our KSG or KHP

coupling greases are recommended to obtain maximum

operating life.

SERIES H GEAR COUPLINGS

Straight Tooth Sizes 8 - 30

PART NUMBER EXPLANATION

Complete Rough Bore Coupling

Coupling Size (1 to 30)

Coupling Style (H = Series H)

Bolt Type (EB = Exposed Bolt)

(SB = Shrouded Bolt)

Coupling Type (FF = Full Flex

FR = Flex Rigid

MMFF = Mill Motor Full Flex

SSFF = Slide Full Flex

SSFR = Slide Flex Rigid)

1 1/2 H EB FF

1 1/2H FHUB FB

HOW TO ORDER

COUPLING PARTS

Description

*FHUB = Flex Hub

*RHUB = Rigid Hub

*MMHUB = Mill Motor Hub

SLEEVE = Standard Sleeve

SSLEEVE = Slide Sleeve

FS = Fastener Set (w/gasket)

ERFS = End Ring Fastener Set

VSFS = Vertical/Slide Fastener Set (w/gasket)

LEFD = LEF Disk

SPRxxx = Spacer for x.xx shaft separation

SP = Stop Plate for Slide Couplings

VP = Vertical Plate

* For finish bored hubs, add FB and bore size.

All finish bores and keyways per

AGMA/ASNSI 9002 (Imperial) and

AGMA/ANSI 9112 (Metric).

Clearance bores are available on request

with one setscrew over keyway.

127

Values listed are intended only as a general

guide, and are typical of usual service

requirements. For systems which frequently

utilize the peak torque capability of the power

source, verify that the magnitude of this peak

torque does not exceed the 1.0 Service Factor

Rating of the coupling selected. Applications

which involve extreme repetitive shock or

high-energy load absorption characteristics

should be referred — with full particulars —

to KOP-FLEX.

Values contained in the table are to be

applied to smooth power sources such as

electric motors and steam turbines. For drives

involving internal combustion engines of four

or five cylinders, add 1.0 to the values listed;

for six or more cylinders, add 0.5 to the values

listed. For systems utilizing AC or DC Mill

Motors as the prime mover, refer to Note (1).

CAUTION: All people moving plus overhead

crane applications must be referred to

engineering.

Typical

Application Service

Factor

AGITATORS

Pure Liquids ...........................................................1.0

Liquids & Solids ......................................................1.25

Liquids — Variable Density .....................................1.25

BLOWERS

Centrifugal ..............................................................1. 0

Lobe .......................................................................1.5

Vane .......................................................................1.25

BRIQUETTE MACHINES .................................................2.0

CAR PULLERS — Intermittent Duty................................1.5

COMPRESSORS

Centrifugal ..............................................................1. 0

Centriaxial ...............................................................1.25

Lobe .......................................................................1.5

Reciprocating — Multi-Cylinder ..............................2.0

CONVEYORS — LIGHT DUTY

UNIFORMLY FED

Apron, Bucket, Chain, Flight, Screw .......................1.25

Assembly, Belt .......................................................1. 0

Oven .......................................................................1.5

CONVEYORS — HEAVY DUTY

NOT UNIFORMLY FED

Apron, Bucket, Chain, Flight, Oven ........................1.5

Assembly, Belt .......................................................1.25

Reciprocating, Shaker ............................................2.5

CRANES AND HOISTS (NOTE 1 and 2)

Main hoists, Reversing ...........................................2.5

Skip Hoists, Trolley & Bridge Drives .......................2.0

Slope ......................................................................2.0

CRUSHERS

Ore, Stone ..............................................................3.0

DREDGES

Cable Reels ............................................................1.75

Conveyors ..............................................................1. 5

Cutter Head Jig Drives ...........................................2.5

Maneuvering Winches ............................................1.75

Pumps ....................................................................1.75

Screen Drives .........................................................1.75

Stackers..................................................................1.75

Utility Winches .......................................................1.5

ELEVATORS (NOTE 2)

Bucket ....................................................................1.75

Centrifugal & Gravity Discharge .............................1.5

Escalators ...............................................................1. 5

Freight ....................................................................2.5

FANS

Centrifugal ..............................................................1. 0

Cooling Towers .......................................................1. 5

Forced Draft............................................................1.5

Induced Draft without Damper

Control ................................................................2.0

FEEDERS

Apron, Belt, Disc, Screw ........................................1.25

Reciprocating .........................................................2.5

Typical

Application Service

Factor

GENERATORS —

(Not Welding) ............................................................1.0

HAMMER MILLS ...........................................................2.0

LAUNDRY WASHERS —

Reversing ..............................................................2.0

LAUNDRY TUMBLERS ....................................................2.0

LINE SHAFT ..................................................................1. 5

LUMBER INDUSTRY

Barkers — Drum Type ...............................................2.0

Edger Feed ................................................................2.0

Live Rolls ...................................................................2.0

Log Haul — Incline ....................................................2.0

Log Haul — Well type ...............................................2.0

Off Bearing Rolls .......................................................2.0

Planer Feed Chains ...................................................1.75

Planer Floor Chains ...................................................1.75

Planer Tilting Hoist ....................................................1.75

Slab Conveyor ...........................................................1.5

Sorting Table ..............................................................1.5

Trimmer Feed ............................................................1.75

MARINE PROPULSION

Main Drives ...............................................................2.0

MACHINE TOOLS

Bending Roll ..............................................................2.0

Plate Planer ...............................................................1. 5

Punch Press — Gear Driven ......................................2.0

Tapping Machines .....................................................2.5

Other Machine Tools

Main Drives ...........................................................1.5

Auxiliary Drives .....................................................1.25

METAL MILLS

Draw Bench — Carriage ............................................2.0

Draw Bench — Main Drive .......................................2.0

Forming Machines ....................................................2.0

Slitters .......................................................................1.5

Table Conveyors

Non-Reversing ......................................................2.25

Reversing .............................................................2.5

Wire Drawing & Flattening Machine .........................2.0

Wire Winding Machine ..............................................1.75

METAL ROLLING MILLS (NOTE 1)

Blooming Mills ..........................................................*

Coilers, hot mill .........................................................2.0

Coilers, cold mill ........................................................1.25

Cold Mills ..................................................................2.0

Cooling Beds .............................................................1.75

Door Openers ...........................................................2.0

Draw Benches ...........................................................2.0

Edger Drives .............................................................1.75

Feed Rolls, Reversing Mills .......................................3.5

Furnace Pushers .......................................................2.5

Hot Mills ...................................................................3.0

Ingot Cars .................................................................2.5

Kick-outs ...................................................................2.5

Manipulators .............................................................3.0

Merchant Mills ..........................................................3.0

Piercers .....................................................................3.0

Pusher Rams .............................................................2.5

Reel Drives ................................................................1.75

Reel Drums ...............................................................2.0

Reelers ......................................................................3.0

Rod and Bar Mills ......................................................1.5

Roughing Mill Delivery Table .....................................3.0

Runout Tables

Reversing ..............................................................3.0

Non-Reversing ......................................................2.0

Saws, hot & cold .......................................................2.5

Screwdown Drives ....................................................3.0

Skelp Mills.................................................................3.0

Slitters .......................................................................3.0

Slabbing Mills ............................................................3.0

Soaking Pit Cover Drives ...........................................3.0

Straighteners ............................................................2.5

Tables, transfer & runout ...........................................2.0

Thrust Block ..............................................................3.0

Traction Drive ............................................................3.0

Tube Conveyor Rolls ..................................................2.5

Unscramblers ............................................................2.5

Wire Drawing ............................................................1.5

MILLS, ROTARY TYPE

Ball ............................................................................2.25

Dryers & Coolers ......................................................2.0

Hammer ....................................................................1.75

Kilns ..........................................................................2.0

SERIES H GEAR COUPLINGS

SERVICE FACTORS

Typical

Application Service

Factor

Pebble & Rod ............................................................2.0

Pug ............................................................................1.75

Tumbling Barrels .......................................................2.0

MIXERS

Concrete Mixers

Drum Type .................................................................1. 5

OIL INDUSTRY

Chillers ......................................................................1.25

Paraffin Filter Press ...................................................1.75

PAPER MILLS

Barker Auxiliaries, Hydraulic ......................................2.0

Barker, Mechanical ....................................................2.0

Barking Drum Spur Gear Only ...................................2.25

Beater & Pulper .........................................................1.75

Bleacher ....................................................................1.0

Calenders ..................................................................2.0

Chippers ....................................................................2.5

Coaters .....................................................................1. 0

Converting Machines,

except Cutters, Platers ...........................................1.5

Couch Roll .................................................................1.75

Cutters, Platers .........................................................2.0

Cylinders ...................................................................1.75

Disc Refiners.............................................................1.75

Dryers .......................................................................1.75

Felt Stretcher ............................................................1.25

Felt Whipper ..............................................................2.0

Jordans .....................................................................1.75

Line Shaft ..................................................................1.5

Log Haul ....................................................................2.0

Pulp Grinder ..............................................................1.75

Press Roll ..................................................................2.0

Reel ...........................................................................1.5

Stock Chests .............................................................1.5

Suction Roll ...............................................................1.75

Washers & Thickeners ...............................................1. 5

Winders ....................................................................1. 5

PRINTING PRESSES ......................................................1. 5

PULLERS — Barge Haul ................................................2.0

PUMPS

Centrifugal ................................................................1. 0

Boiler Feed ................................................................1.5

Reciprocating

Single Acting

1 or 2 Cylinders ....................................................2.25

3 or more Cylinders ..............................................1.75

Double Acting ...........................................................2.0

Rotary, Gear, Lobe, Vane ...........................................1.5

RUBBER INDUSTRY

Mixer — Banbury ......................................................2.5

Rubber Calendar .......................................................2.0

Rubber Mill (2 or more) .............................................2.25

Sheeter .....................................................................2.0

Tire Building Machines ..............................................2.5

Tire & Tube Press Openers .......................................1.0

Tubers & Strainers ....................................................2.0

SCREENS

Air Washing ...............................................................1.0

Grizzly .......................................................................2.0

Rotary — Stone or Gravel .........................................1. 5

Traveling Water Intake ...............................................1.25

Vibrating ....................................................................2.5

SEWAGE DISPOSAL EQUIPMENT

Bar Screens...............................................................1.25

Chemical Feeders .....................................................1.25

Collectors, Circuline or Straightline ...........................1.25

Dewatering Screens .................................................1.25

Grit Collectors ...........................................................1.25

Scum Breakers..........................................................1.25

Slow or Rapid Mixers ................................................1.25

Sludge Collectors ......................................................1.25

Thickeners .................................................................1.25

Vacuum Filters ..........................................................1.25

STEERING GEAR .............................................................1. 0

STOKERS .......................................................................1. 0

WINCH ..........................................................................1. 5

WINDLASS ....................................................................1.75

* Refer to KOP-FLEX

NOTES

(1) Maximum Torque at the coupling must not exceed

Rated Torque of the coupling.

(2) Check local and industrial safety codes.

.......................................................1.75

128

1. Select Coupling Based on Bore Capacity.

Select the coupling size that has a maximum bore

capacity equal to or larger than the larger of the

two shafts. For interference fits larger than AGMA

standards, consult KOP-FLEX.

2. Verify Coupling Size Based on Load Rating.

a. Select appropriate Service Factor from the Table

onpage 128.

b. Calculate required HP / 100 RPM:

HP x Service Factor x 100

RPM

c. Verify that the selected coupling has a rating

greater than or equal to the required HP / 100

RPM.

= HP / 100 RPM

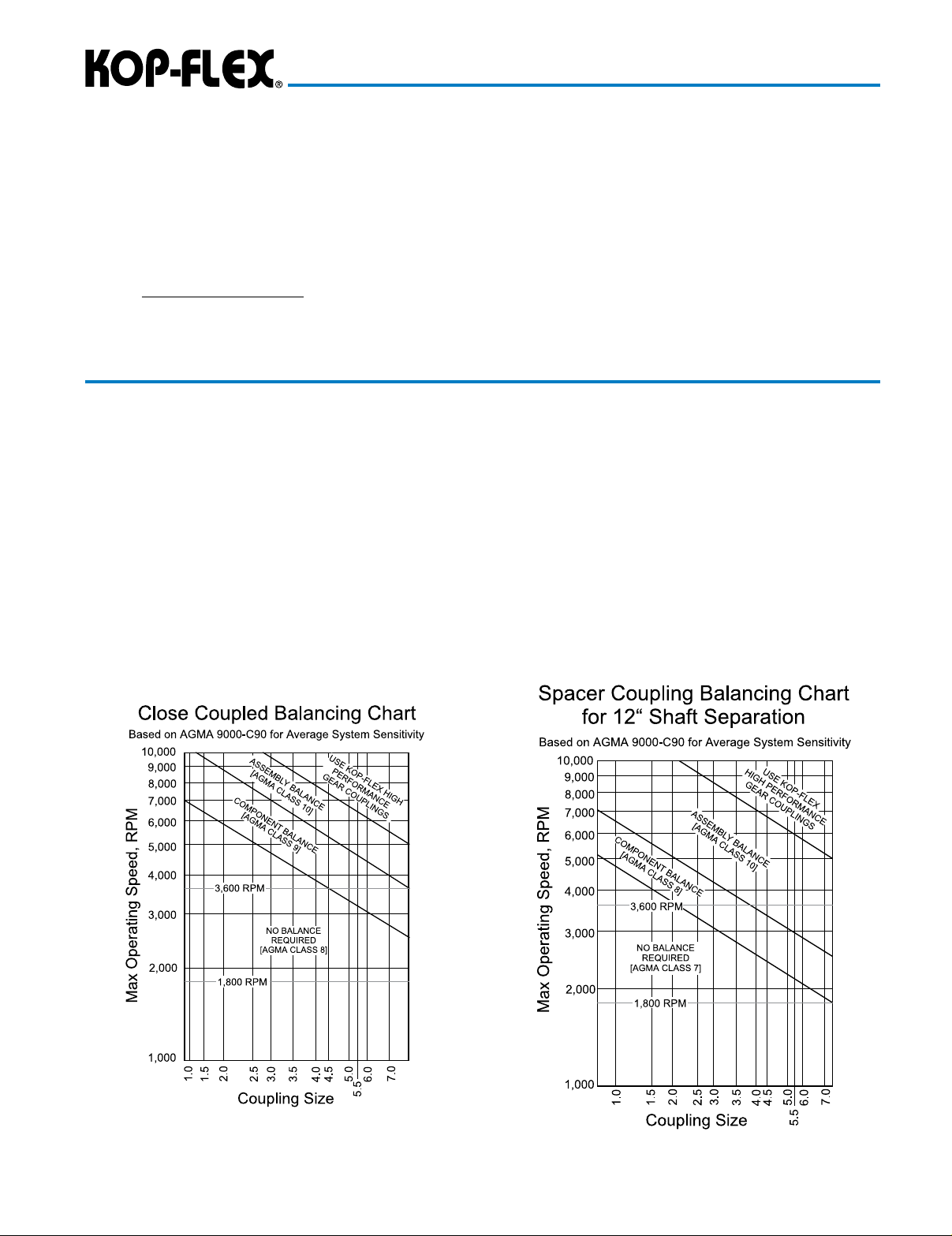

DYNAMIC BALANCING GUIDE

SERIES H GEAR COUPLINGS

SELECTION PROCEDURE

3. Check Balance Requirements.

Consult the Dynamic Balancing Guide to help determine if

balancing is required. Verify that the maximum operating

speed does not exceed the maximum speed rating of the

coupling. The maximum speed rating does not consider

lateral critical speed considerations for floating shaft

applications.

Note: Care must be exercised on proper selection of any

shaft coupling. The Users must assure themselves

that the design of the shaft to coupling hub

connection is adequate for the duty intended.

Balancing requirements for a coupling are dependent on

factors determined by the characteristics of the connected

equipment. For this reason, the Balancing Charts should be

used as a GUIDE ONLY to assist in determining whether or

not balancing is required.

The Balancing Charts shown are based on AGMA 9000-C90

suggested balance classes for systems with “Average”

sensitivity to unbalance. For systems with higher sensitivity

to unbalance, balancing of the coupling may be required at

lower speeds. For systems which are less sensitive to unbalance, couplings may be able to operate at higher speeds

than those shown at lower balance levels. Therefore, in the

absence of either a thorough system analysis or past user

experience with a similar installation, these charts should

be used as a GUIDE ONLY.

FAST’S® and Series H gear couplings may be component

balanced, or assembly balanced with fitted components

(Type FB and Type HB, respectively).

WALDRON® gear couplings are available component balanced

only.

Model B gear couplings are not designed to be balanced.

These charts apply to sizes 1 through 7 only. Dynamic

balance of size 8 through 30 must be considered on a caseby-case basis. Consult KOP-FLEX for assistance.

129

A conventional 4-bearing system has two bearings on the

14

36

36

17

18

52

58

54

36

--

--

*7

--

mumixaM

thgieW

98

72

18

52

14

28

18

18

12

12

14

12

26

22

28

22

26

22

18

32

driving shaft and two bearings on the driven shaft. Both

angular and offset shaft misalignment will be present to

some degree and a full flex coupling is mandatory. The

full flex coupling is the standard coupling having two

gear ring sets, one set per half coupling. For selection

procedure see page 129.

Coupling Greases

KOP-FLEX offers greases specifically designed for use in coupling

applications. For proper lubrication and long service life, use KSG

Standard Coupling Grease, or KHP High Performance Coupling

Grease. See pages 170-172 for detailed specifications.

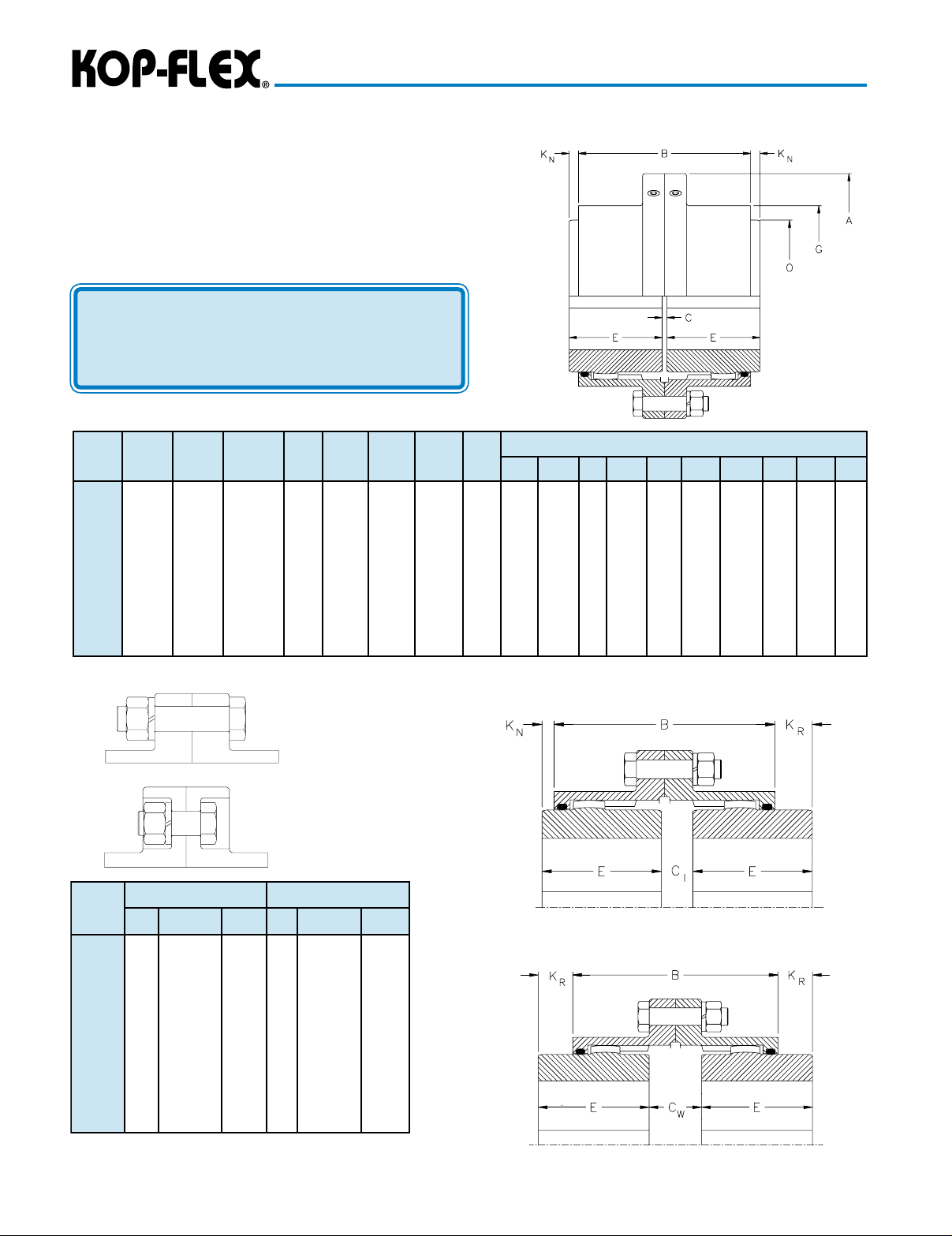

SERIES H GEAR COUPLINGS

FULL FLEX COUPLING SIZE 1-7

gnilpuoC

eziS

1

2/11

2

2/12

3

2/13

4

2/14

5

*2/15

*6

*7

mumixaM

htiweroB

dradnatS

yawyeK

8/514/318/1x8/321005700051005410161/9461/138/161/34/161/11161/1323/723/

4/128/3223/7x8/572000710004300021816 61/938/161/52/161/51161/51323/

8/723 4/1x4/30500513000360039337 61/1148/161/91 61/7261/51423/

2/134/3361/5x8/709007650043110097758/388/3561/323/514/323/138/7561/723/3

48/348/3x106100010100020200865861/7961/9661/323/928/5123/9138/7623/3

8/545 61/7x4/1153200084100069200060311161/1174/161/118/7161/3423/92723/5

2/158/162/1x2/1157300063200027406252912/1214/384/14/114/124/344/192/12/1

4/168/762/1x4/3150500081300063607741628/53161/11961/561/7161/9261/558/3018/54/3

8/178/372/1x4/31007000144000288003467361/55161/11161/523/1318/5323/1661/91123/1

84/182/1x2029000085000061108834744/36161/72161/523/328/7323/92661/112123/7

8/784/198/5x2/125021000957000815100634068161/53161/523/1128/3423/3178/73123/9

8/3014/3014/3x2/1204810000611000023200032094/3028/3518/361/3124/1561/11861/16161/3

htiweroB

decudeR

htpeD

yawyeK

htpeD

gnitaR

decudeR

/PH

001

yawyeK

MPR

kaeP

euqroT

gnitaR

euqroT

gnitaR

).ni-.bl(

).ni-.bl(

mumixaM

htiw

deepS

diloS

)MPR(

sbuH

ABC

).bl(

* Sizes 5 1/2, 6 and 7 are only available with exposed bolt sleeves. Type EB exposed bolt sleeves are standard.

TYPE EB EXPOSED BOLTS

TYPE SB SHROUDED BOLTS

FASTENER DATA

gnilpuoC

eziS

.ytQ

62/11x4/14/336 8/7x4/

1

82x8/361/3148 1x8/

2/11

62/12x2/18/75011x8/

2

64/32x8/58/170161/51x2/

2/12

84/32x8/58/182161/51x2/

3

88/33x4/32/19218/51x8/

2/13

88/33x4/311418/51x8/

4

018/33x4/321418/51x8/

2/14

84/14x8/72/131418/12x4/

5

414/13x8/72/141-

*2/15

414/13x8/74/351-

*6

618/53x14/181-

Sizes #5 1/2 and larger are available in exposed bolts only.

BEepyT

tloBdesopxE

&eziS

htgneL

tloB

elcriC

130

.ytQ

BSepyT

tloBdeduorhS

&eziS

htgneL

tloB

elcriC

/33

1/314

1/315

3/99

/501

/311

1/331

snoisnemiD

EG

C

C

I

W

ONE HUB REVERSED

TWO HUBS REVERSED

K

NKR

O

/32

3/3

/13

3/9

/74

/1

/55

3/9

/16

/37

/18

1/5

/19

/5

/101

1/51

/111

/5

/131

Loading...

Loading...