Kop-Flex MAX-C Installation Manual

MAX-C® TYPE “UB” RESILIENT COUPLINGS

F O R M

6007CPE

Revised

November 2015

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and maintenance.

Working on or near energized equipment can result in severe injury or death.

• Do not operate equipment without guards in place. Exposed equipment can

result in severe injury or death.

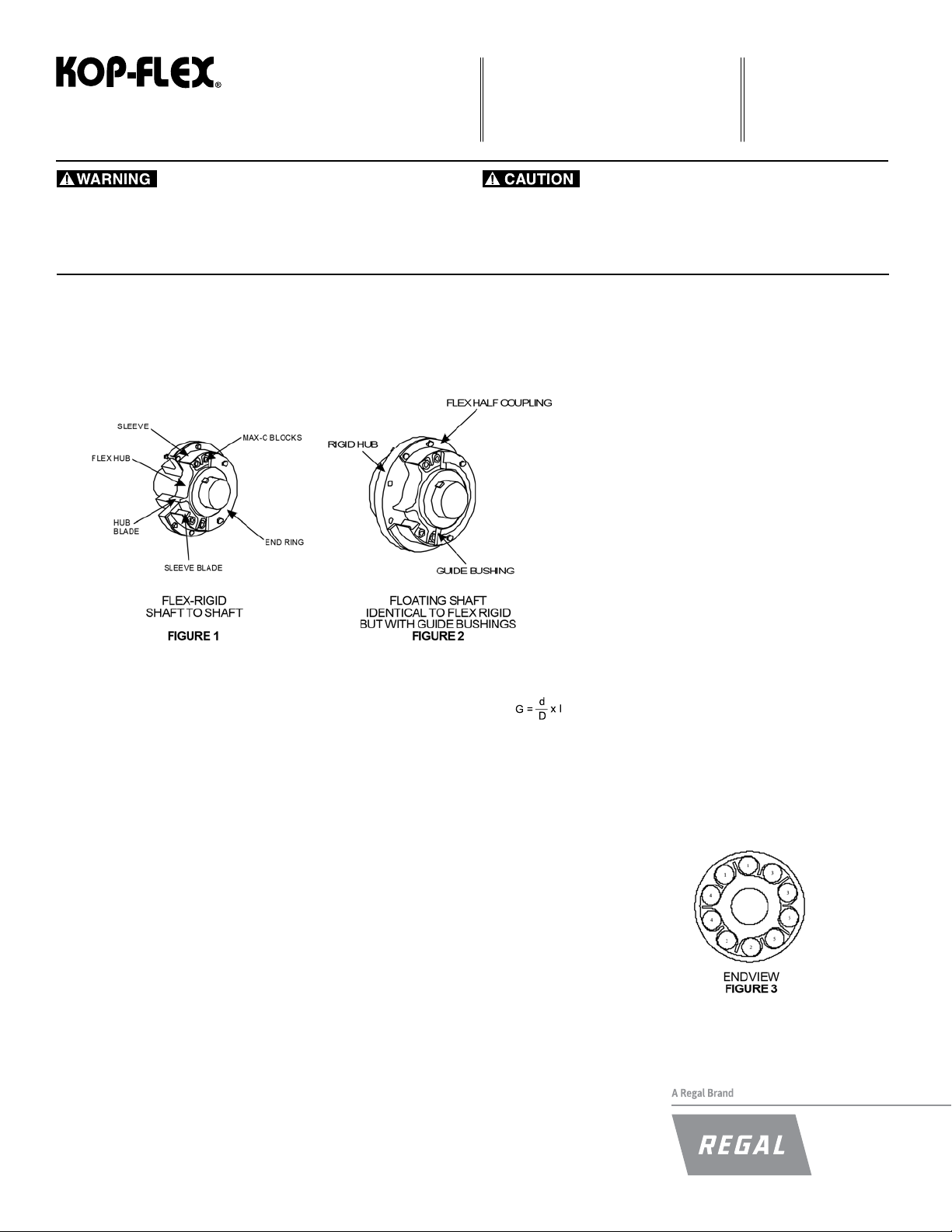

IDENTIFYING FEATURES

ASSEMBLY

These instructions apply specically to Couplings

described in KOP-FLEX Engineering Data Sheet 6015.

1. MOUNT FLEX & RIGID HUBS

a. Place an END RING over the shaft end on which

the ex half coupling is to be mounted. (Floating

shaft cou- plings will have guide bushings

installed in end ring.)

b. Clean the shaft and coat it with a suit- able anti-

galling lubricant, such as ANTI-SEIZE.

c. Expand HUB in oven until bore is substantially

larger than the shaft diameter. Straight bored

hubs are normally bored for an interference t

of approxi- mately 0.0005 in/in of shaft diameter.

(For most values of interference, this will require

a hub temperature of about 300°1). Install KEYS

with a tight t on sides and a slight clearance

over or under the key. Remove HUB from oven

and position quickly on shaft, with hub end ush

with shaft end.

Note: Ensure that the end ring end of the hub is

mounted away from the shaft end.

d. Taper Bored Hubs—

Micrometer Method: Calculate

where, G = Diametral Growth of hub body diameter

d = Diameter at small end of the bore

D = Hub body diameter.

(Actual measurement with an external

micrometer.)

I = Total Diametral Interference required.

Set micrometer to D + G. Draw hub onto shaft until

hub body diameter equals D + G, as checked with the

micrometer at 90° to keyway(s).

Draw Method: Mount the cold hub hand tight on the

shaft and tap lightly with a soft mallet to establish

initial snug t. Draw hub up an additional distance to

obtain the desired interference t for the connection.

(The required amount of axial movement is dependent

upon the bore diameter and taper angle.)

• Periodic inspections should be performed. Failure to perform proper maintenance

can result in premature product failure and personal injury.

Install the hub retention means provided with the shaft

and secure.

NOTE: Interference t requirements in excess of 0.0005

in/in of bore diameter should be referred to KOP- FLEX

for approval.

2. PLACE EQUIPMET IN POSITION Place SLEEVE

into position over FLEX HUB and move equipment

into place. Separate hubs by dimension ‘C’, Table A.

(For ywheel mounted assemblies, carefully guide

SLEEVE into rabbet in ywheel or adapter plate

and attach.) Install ange bolts and tighten to proper

installation torque.

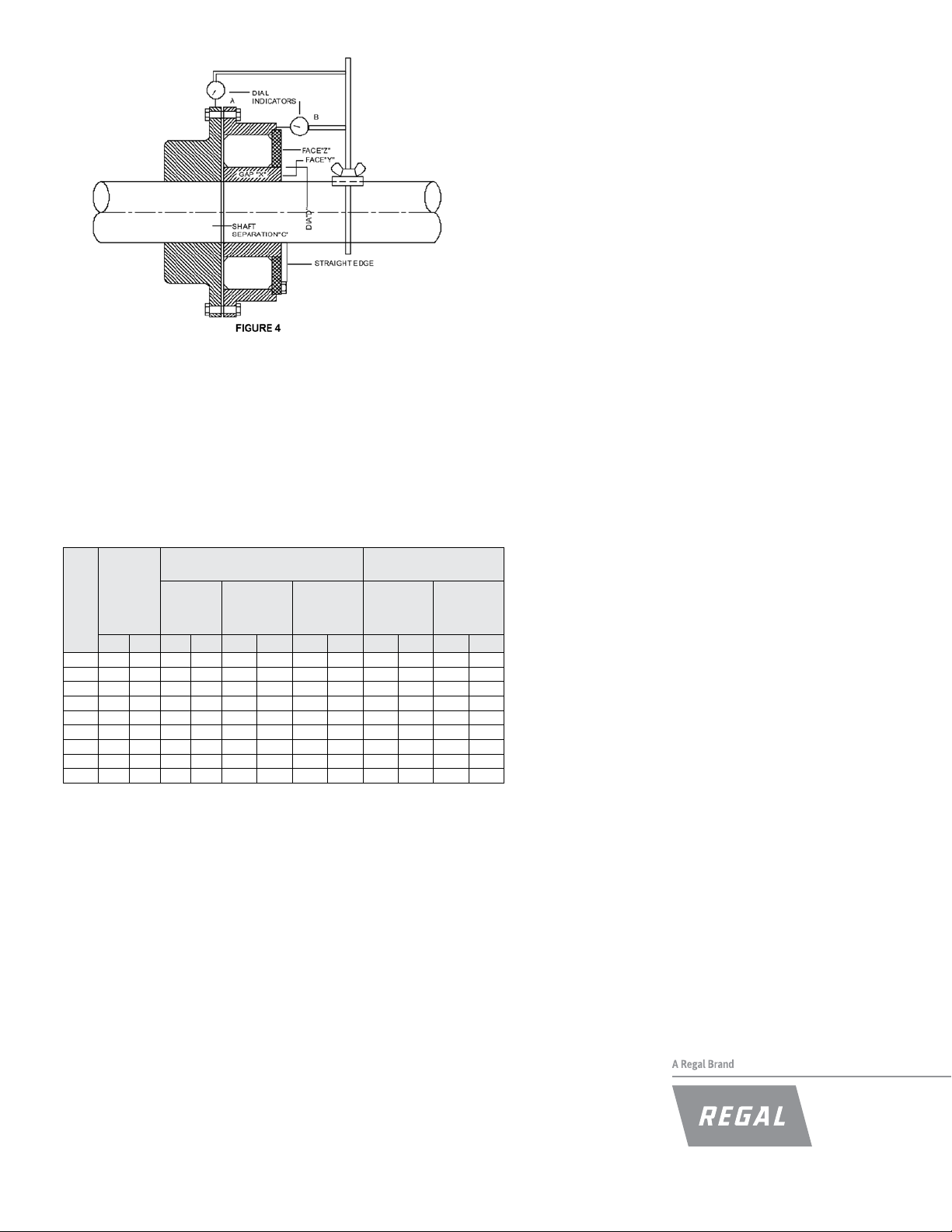

3. ALIGN EQUIPMENT (See Fig. 4.) Attach END RING

to SLEEVE using caution in guiding rabbeted

diameter into place. Move equipment laterally and

jack or shim vertically until gap ‘X’ between the END

RING and the FLEX HUB is of uniform dimension

when measured with a feeler gage, and until surface

‘Y’ is ush with surface ‘Z’ when a straight edge is

placed across the two surfaces. (Where electric

motors, generators or thrust bearings are involved,

axial position of the rotor or bearing should be

controlled while positioning equipment.)

4. INSTALL MAX-C RESILIENT BLOCKS After the

equipment has been aligned as described above,

and with the end ring supported over the shaft, insert

the blocks in pairs using a nonmetallic hammer. See

end view of Figure 3 for proper installation sequences.

5. CHECK FINAL ALIGNMENT

Mount a dial indicator bracket on the ex half shaft with two dial indicators positioned

as shown in Figure 4. Rotating the drive slowly, take readings at four points 90°

apart and align as accurately as possible.

The two machines must be aligned within the tabulated values as shown in Table A.

Initial alignment should be as accurate as possible.

When alignment is completed, a nal check with a straight edge should be made

across the end ring and ex hub surfaces. If the difference exceeds the tabulated

value, adjustment should be made by moving one of the machines axially.

6. ATTACH END RING

Carefully guide END RING into rabbet in SLEEVE, install bolts and tighten to

proper installation torque. (END RING bolts to normally provided with Nylok

inserts. Bolts should be inspected to ensure that these inserts are intact prior

to attaching END RING.)

Maintenance

It is recommended that, during normal maintenance periods, the END

RING be removed and the MAX-C BLOCKS be examined for evidence of

cracking or splitting. The BLOCKS may also show some signs of permanent

deformation, but unless there are signs of deterioration or destruction of

the BLOCKS, this should not be considered cause for replacement. When

replacement of the BLOCKS becomes necessary, the procedure for removal

is the reverse of that described above for installation.

After removing the END RING, the BLOCKS can be levered out individually,

or the SLEEVE can be jacked away from the RIGID HUB after ange bolts

are removed, freeing all of the BLOCKS at once.

Once the BLOCKS have been removed, clean inner surfaces, insert new

BLOCKS if required, and re-install END RING in accordance with installation

instructions.

On oating shaft assemblies, the guide bushings can be replaced without

moving connected equipment — instructions are furnished with the

replacement bushings.

User Notice: The ratings of Kop-Flex’s Type ‘UB’ coupling were established

using the exceptional properties of the Kop-Flex MC elastomer. The use

of any other material can severely alter the coupling performance. If

replacement is ever necessary, the elastomer blocks must be replaced with

Kop-Flex MC elastomer blocks. Kop-Flex also manufacturesotherrubber

blocks for resilient couplings which are not intended for and should not be

used in Type ‘UB’ couplings.

TABLE A

ALLOWABLE INSTALLATION*

MISALIGNIMENT LIMITS

SHAFT

CPLG

SEP. “C”

SIZE

INCH MM INCH MM INCH MM INCH MM LB-FT N-m LB-FT N-m

1.5 3/32 2.381 .010 .254 .006 .152 .006 .152 13 17.6 6 8.13

2.0 3/32 2.381 .010 .254 .006 .152 .007 .178 23 31.2 13 17.63

2.5 1/8 3.175 .015 .381 .008 .203 .008 .203 23 31.2 23 31.20

3.0 1/8 3.175 .015 .381 .008 .203 .010 .254 23 31.2 35 47.50

3.5 1/8 3.175 .015 .381 .008 .203 .012 .305 55 74.6 55 74.60

4.0 1/8 3.175 .015 .381 .010 .254 .014 .356 55 74.6 110 149.20

5.0 1/8 3.175 .015 .381 .010 .254 .016 .406 11 0 149.2 200 271.20

6.0 3/16 4.763 .020 .508 .015 .381 .020 .508 200 271.2 320 433.90

7.0 3/16 4.763 .020 .508 .015 .381 .020 .508 200 271.2 320 433.90

* INITIAL INSTALLATION SHOULD BE ALIGNED AS ACCURATELY AS POSSIBLE

** MISMATCH BETWEEN END RING FACE “Z” AND FLEX HUB FACE “Y”

NOTE: CENTER FLANGE BOLTS HAVE SPECIAL BODY DIAMETERS FOR TIGHT

FIT IN THE JIG-REAMED BOLT HOLES— USE ONLY KOP-FLEX FURNISHED

BOLTS FOR REPLACEMENT

AXIAL**

±

RADIAL

(INDICATOR

“A”)FIGURE

4

ANGULAR

(INDICATOR

“B”)

±

BOLT TIGHTENING

TORQUE VALUES

CENTER

FLANGE

BOLTS

(SEE NOTE)

END RING

BOLTS

Kop-Flex, MAX-C are trademarks of Regal Beloit Corporation or one of its afliated companies.

©2015 Regal Beloit Corporation, All Rights Reserved. MCIM15129E • Form 6007CPE • Printed in USA

Loading...

Loading...