Installation and Alignment Instructions

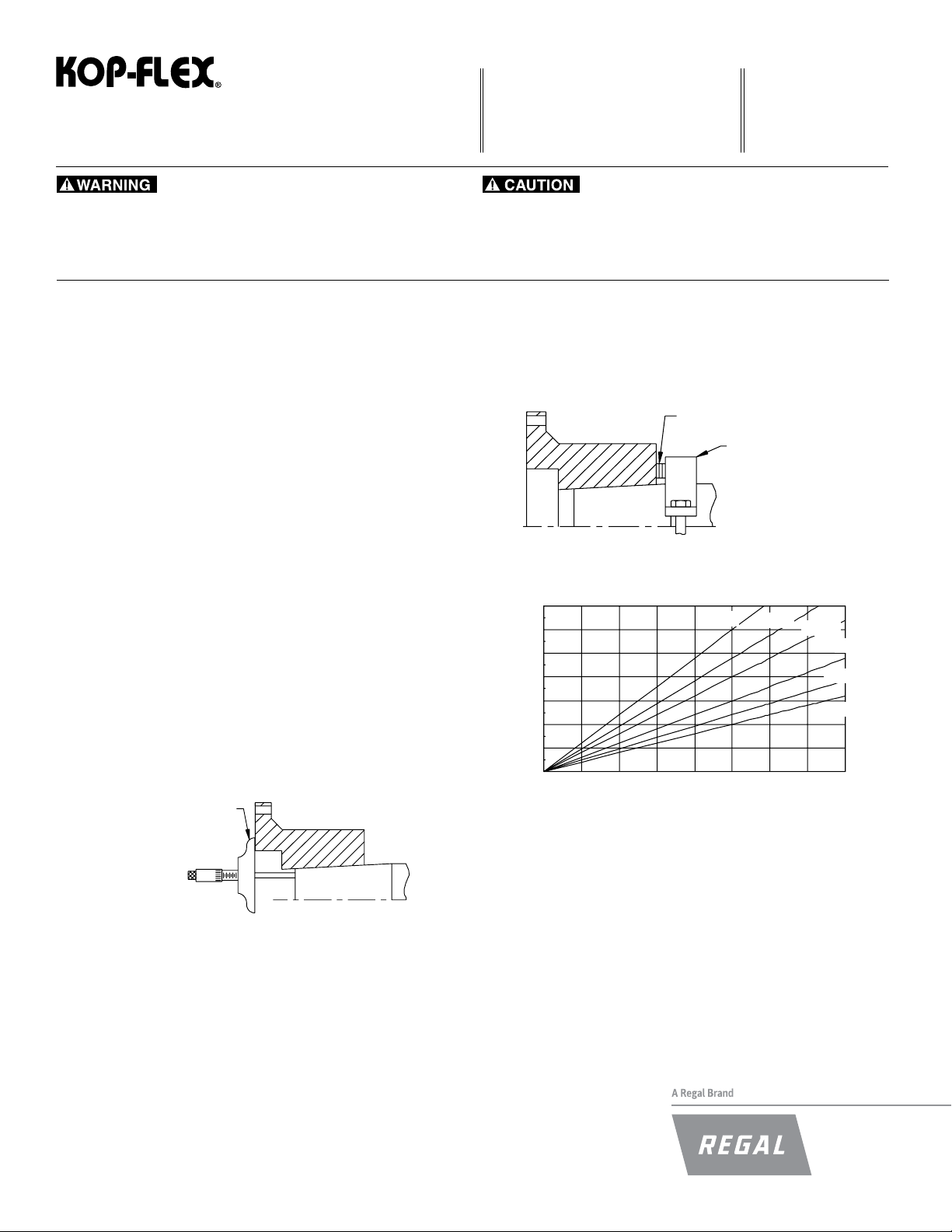

Figure 3. Hub Advance vs. Interference Chart

KD11 Disc Coupling

F O R M

22-002E

Revised

November 2015

• Read and follow all instructions carefully.

• Disconnect and lock-out power before installation and maintenance.

Working on or near energized equipment can result in severe injury or death.

• Do not operate equipment without guards in place. Exposed equipment can

result in severe injury or death.

WARNING! Because of the possible danger to person(s) or property from accidents which may result from the improper use or unapproved modication of the

product, this product must be installed, maintained, and operated in accordance with the procedures, standards and engineering information specied in

the product brochures and illustrations. To assure safe operation, this product should be inspected in accordance with the instructions described in this

form. Proper guards and other suitable safety devices or procedures as may be desirable, or as may be specied in safety codes, should be installed by

the user. Guards and other safety equipment are not provided, nor are they the responsibility of Regal Power Transmission.

• Periodic inspections should be performed. Failure to perform proper maintenance

can result in premature product failure and personal injury.

1. General Instructions

Prior to installation, inspect the coupling for any signs of damage that may have occured during shipping. Check that all parts are on hand and are as ordered.

WARNING! Only bolts and nuts supplied by Kop-Flex are to be used.

Components should be cradled or supported during handling to avoid damage and

should be wrapped for protection. Flanges should be kept free of nicks and burrs.

Read all of the installation instructions and review the procedure before the actual

coupling installation.

Figure 2. Using Split Collar to Set Advance

FEELER GAUGES

SPLIT COLLAR

2.0 Installation of Coupling Hubs - Keyed Mounting

2.1 Check the hub bore and shaft for nicks and burrs, dress if necessary.

Make sure that the bore and shaft are clean.

2.2 For tapered bores, check the t of the bore to the shaft.

2.3 Keys must be precisely tted to the keyway in the shaft and hub. Each

key should be a tight t on the sides with a slight clearance on top. To

maintain dynamic balance, the keys should ll the keyway exactly and

not be too short or too long.

2.4 Clean the hub bore and shaft. For straight bores, proceed to step 2.6.

For tapered bores, mount the hub hand-tight on the shaft and lightly rap

it with a soft mallet to establish the initial line-to-line t. This is the START

position. With a depth gauge, measure the amount the hub overhangs

the shaft end and record this value. See Figure 1.

DEPTH GAUGE

.070

.060

.050

).ni(ecnavdA

.040

.030

.020

.010

.000

.0000 .0005 .0010 .0015 .0020 .0025 .0030 .0035 .0040

Interference (in.)

Diametral Taper Rate

1/2"/ft

5/8"/ft

3/4"/ft

1"/ft

1 1/4"/ft

1 1/2"/ft

Figure 1. Measuring Hub Overhang

2.5 Taper Bores Only: A recommended method to measure the hub advance

is to install a split collar on the shaft, away from the hub by the amount

of the specied advance. Use feeler gauges for accurate spacing. See

Figure 2. The amount of hub advance is dependent upon the desired

interference and taper angle as specied by the machine manufacturer

or as given on the coupling drawing. See Figure 3.

2.6 Heat the hub to expand the bore; DO NOT allow the hub temperature to

exceed 600°F (300°C). DO NOT apply an open ame to any part of the

coupling, an oven is recommended.

WARNING! To avoid the risk of explosion, re, or damage to the cou-

pling and equipment, and/or injury to personel, do not use

an open ame or oil bath to expand the hub. If heat is used

at any time for installation, DO NOT allow the hub temperature to exceed 600°F (300°C).

2.7 Place the hub in the proper position on the shaft. Hold the hub in place

as it cools. For taper bores, verify the hub advance (see Figure 1 and 2)

and install the shaft retaining nut. Remove the split collar from the shaft.

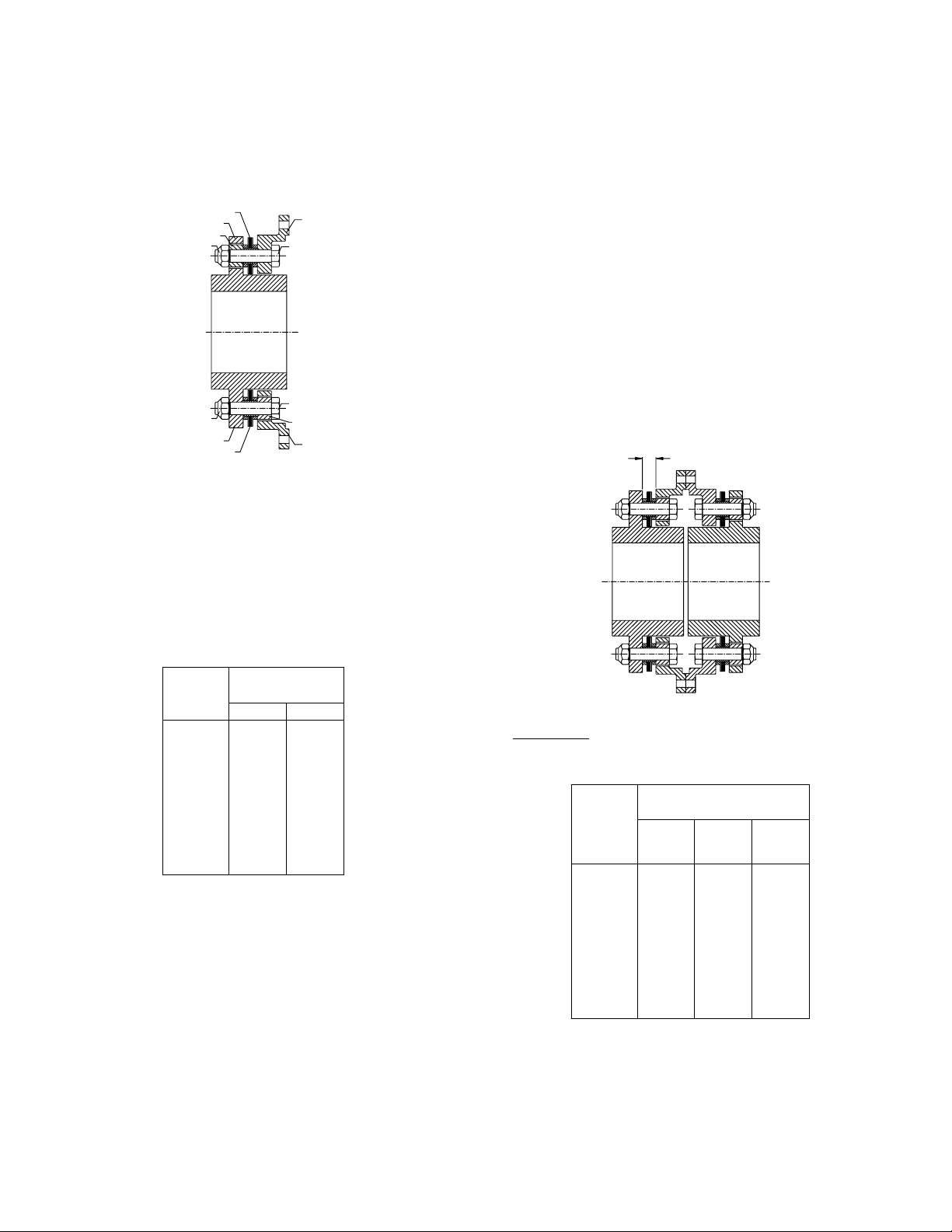

3.0 Initial Assembly

3.1 Place the disc pack and adapter in position over the hub body diameter

as shown in Figure 4. The reamed holes in the adapter should be

aligned with the large clearance holes in the hub as in the upper portion

of Figure 4. The large clearance holes in the adapter should be aligned

with the reamed holes in the hub as in the lower portion of Figure 4.

DISC PACK

SPACING WASHER

DISC PACK NUT

DISC PACK NUT

HUB

HUB

DISC PACK

Figure 4. Bolt Adapter and Disc Pack to Hub

3.2 Insert disc pack bolts through the reamed bolt holes in the adapter,

through the disc pack holes and through the clearance holes in the hub.

Install a spacing washer and nut over each disc pack bolt (See Figure

4., upper half). Place spacing washers on the remaining disc pack bolts

and insert them from the adapter side through the adapter clearance

holes, through the disc pack holes and through the reamed bolt holes in

the hub (See Figure 4., lower half).

ADAPTER

DISC PACK BOLT

DISC PACK BOLT

SPACING WASHER

ADAPTER

4.0 Alignment

Note: Exact values and procedures for aligning equipment are normally

specied by the equipment manufacturers.

The amounts given below represent values that would provide excel-

lent coupling performance in operation.

Good initial alignment to the minimum possible values will promote optimum machinery performance and eliminate potential operating problems. After securely tightening the foundation bolts, the hub separation

and alignment should be rechecked and adjusted if necessary. The

coupling alignment should be checked periodically. Even when a coupling is well aligned at installation, subsequent settling of foundations,

shifting of equipment, etc., may cause the alignment to deteriorate.

Axial Alignment

4.1 Measure the thickness of the disc pack before bringing the equipment

together. (See Figure 5 dimension P). The axial separation is set after

the adapters and disc packs are bolted to the hubs. Bring the driving

and driven equipment together until the anges of the adapters touch.

Measure the gap between the disc pack anges and adjust the axial

separation of the equipment until this measurement equals the thickness of the disc pack.

P

3.3 Tighten all nuts evenly and in an alternating fashion to the torque specied in Table 1.

Coupling

Size

103 10 14

153 27 37

204 55 75

254 55 75

304 115 160

354 175 240

404 280 380

454 280 380

504 420 570

554 730 1000

604 1020 1400

705 1800 2450

805 2300 3100

905 2300 3100

Disc Pack Bolt Tightening Torques

Tightening Torque

(Lightly Oiled)

ft-lb Nm

Table 1.

Figure 5. Axial Alignment Measurements

Reference only: The design hub separation for various hub arrangements

(Figure 6) is shown in Table 2.

Hub Separation (Inches)

Size

Standard

103 .12 1.31 2.50

153 .12 1.58 3.03

204 .12 1.62 3.12

254 .19 1.22 2.25

304 .19 1.41 2.62

354 .25 1.75 3.25

404 .25 2.25 4.25

454 .31 2.19 4.06

504 .31 2.20 4.09

554 .31 2.48 4.64

604 .31 2.70 5.09

705 .38 3.00 5.62

805 .38 3.53 6.68

905 .50 3.59 6.68

Design Hub Separations (Reference Only)

Reversed

Table 2.

One Hub

Two Hubs

Reversed

MCIM15114E • Form 22-002E • Printed in USA

2

HUB

SEPARATION

STANDARD

HUB

SEPARATION

ONE HUB REVERSED

5.0 Final Assembly

5.1 Bring the driving and driven equipment together until the anges of the

adapters just begin to touch. Measure the gap between the disc pack

anges and adjust the axial position of the equipment until the amount

of gap equals the disc pack thickness measured in step 4.1.

5.2 Rotate the equipment shafts until the ange holes are aligned.

5.3 Bolt the anges together using the ange bolts and nuts. See Figure 7.

Tighten all ange nuts evenly and in an alternating fashion to the torque

specied in Table 4.

HUB

SEPARATION

TWO HUBS REVERSED

Figure 6. Design Hub Separations

4.2 For some applications, initial set-up of the equipment may be simplied

by collapsing the disc packs slightly before bringing the equipment

together. KD11 couplings have been designed with collapsing holes for

this purpose. Collapsing screws are not supplied with the couplings.

See Table 3 for collapsing screw sizes.

Coupling Size

Collapsing Screw

Screw Size Length

103 1/4-20 UNC 1.00

153 1/4-20 UNC 1.25

204 1/4-20 UNC 1.50

254 1/4-20 UNC 1.50

304 1/4-20 UNC 1.75

354 3/8-16 UNC 2.25

404 3/8-16 UNC 2.50

454 3/8-16 UNC 2.50

504 1/2-13 UNC 3.00

554 1/2-13 UNC 3.25

604 5/8-11 UNC 3.50

705 1/2-13 UNC 4.00

805 5/8-11 UNC 4.50

905 5/8-11 UNC 4.50

Table 3. Collapsing Screw Sizes (not provided with coupling)

To collapse the disc packs, insert collapsing screws through the

clearance holes in the hub ange into the tapped holes in the adapter.

Tighten evenly to collapse the disc packs just enough to be able to position the equipment; usually .03” (sizes 103 through 404) and .06” (sizes

454 through 905) is sufcient. DO NOT OVERTIGHTEN.

Important: Remove collapsing screws and set axial alignment accord-

ing to 4.1. Do not operate coupling with collapsing screws installed.

Offset and Angular Alignment

4.3 Reverse dial indication or optical methods of alignment (such as laser)

are recommended. A cold alignment and a hot check (with corrections if

necessary) are required. The hub ange OD can be used to mount the

alignment equipment. The hub ange OD is machined to be concentric

to the coupling bore and can be used as the reference diameter.

4.4 The maximum recommended operating misalignment is:

0.10 degrees per disc pack

(0.0035 in/in TIR equivalent parallel offset)

Important:Total misalignment is the combination of equipment parallel

offset and angular misalignment.

Note that improving the alignment below these values will promote

optimum machinery performance.

Coupling

Size

103 9 12

153 9 12

204 9 12

254 18 24

304 18 24

354 25 34

404 25 34

454 60 81

504 60 81

554 120 160

604 120 160

705 120 160

805 210 285

905 335 450

Table 4. Flange Bolt Tightening Torque

Tightening Torque

(Lightly Oiled)

ft-lb N-m

Figure 7. Bolt Adapter

Flanges Together

6.0 Dynamic Balancing

Balanced parts will be marked with a letter “B”. The couplings may be

component balanced (hubs and adapters) with no match marks, or assembly

balanced as a complete coupling with matchmarks. If it is supplied with

matchmarks, it must be assembled with the matchmarks in line.

Note: For assembly balanced couplings, disconnecting the disc packs from

the hubs and adapters disturbs the balance of the coupling. When disc packs

are removed from assembly balanced couplings, the coupling assembly must

be rebalanced before placing back in operation.

7.0 Finish Boring and Keyways

Coupling hubs are often furnished with a “rough stock bore.” This rough bore

is not necessarily concentric to the other hub diameters. To prepare for boring, set-up and indicate the hub as shown in Figure 8.

8.0 Bore Sizing and Recommended Fits

The nish bore size should be based on the actual measured shaft dimension, regardless of whether it is a straight or tapered shaft. For keyed shafts,

a light interference t based on a nominal interfer- ence rate of 0.0005

inch per inch of shaft diameter is suggested, or refer to published AGMA

standards. Do not exceed an interference t 0.001 inch per inch of shaft

diameter. If other than a light interference t is desired, consult the published

AGMA boring and keyway standards.

For Straight Bores, the hub diameter should be chucked in the boring lathe

and dial indicated as shown in Figure 8.

For Taper Bores, chuck and indicate as shown in Figure 8. Machine the

counterbore and SKIM A REFERENCE DIAMETER on the hub body. Then,

reverse the hub in the chuck, and indicate using the reference diameter

before nal boring.

Run-outs should be as near zero as possible. It is essential that the nished

bores be concentric to the two indicating surfaces.

MCIM15114E • Form 22-002E • Printed in USA

3

9.0 Keyways

Keyways should be cut to give a tight t on the sides and a slight clearance

over the key. Keyways should not have sharp corners. Refer to published

AGMA standards for specic dimensioning of coupling bores and keyways.

OR

Figure 8. Hub Boring

Name (Last, First)

Title:

Company Name:

Location:

Phone:

APPLICATION DATA

10.0 General Recommendations

10.1 KOP-FLEX® KD11 disc couplings are designed to operate for extended

periods without the need for lubrication or maintenance. Visual inspection of the disc packs is sufcient to assess the operating condition of the

coupling.

10.2 All machinery should be monitored to detect unusual or changing vibration levels. The KOP-FLEX KD11 coupling, under normal operation

conditions, has no wearing parts and will retain its original balance quality. Any change in vibration levels should be investigated and remedial

action should be taken immediately.

5 YEAR WARRANTY REGISTRATION CARD

Coupling Type:

HP:

RPM:

Application:

Distance Between Shaft Ends

Send Warranty Card To: Attention Marketing Department

Kop-Flex, Inc.

Mail to: P. O. Box 1696 or Fax to: 410-787-8424

Baltimore, MD 21203-1696

:nevirD:gnivirD:)s(eziS tfahS

# rotoM# pmuP noitacifitnedI tnalP

Kop-Flex is a trademark of Regal Beloit Corporation or one of its afliated companies.

©2015 Regal Beloit Corporation, All Rights Reserved. MCIM15114E • Form 22-002E • Printed in USA

Loading...

Loading...