Kop-Flex WALDRON, FLEXALIGN Catalog Page

WALDRON

®

FLEXALIGN

®

Gear Couplings

Size 1 through 7

HIGH STRENGTH 40° TOOTH

SUPERIOR HIGH

MISALIGNMENT SEAL

ECONOMICAL

GEAR COUPLING DESIGN

POWERLIGN® FLANGELESS

COUPLINGS FOR A RUGGED,

COMPACT DESIGN

Index:

Page

HOW TO ORDER ........................................ 161

Technical Advantages.......................... 158 - 159

Service Factors ............................................ 160

Selection Procedure .................................... 161

Fastener Data .............................................. 161

Full Flex Coupling ......................................... 162

Spacer Coupling ........................................... 163

Flex Rigid Coupling ...................................... 164

Floating Shaft Coupling ................................ 164

Limited End Float Coupling .......................... 165

Vertical Coupling .......................................... 165

Short Slide Coupling .................................... 166

Medium Slide Coupling ............................... 166

TAPER-LOCK* Coupling .............................. 167

POWERLIGN® Coupling ............................... 168

* Taper-Lock is believed to be the trademark and/or trade name of Reliance Electric

Company, and is not owned or controlled by Regal Power Transmission Solutions.

157 157

157

WALDRON® ADVANTAGES:

IMPROVED SOFT SEAL offers superior sealing under

misaligned conditions.

UNIQUE TOOTH FORM using a 40° pressure angle,

distributes the load over a larger area than couplings

which use a 20° pressure angle.

FULL TOOTH ENGAGEMENT reduces uneven wear on teeth

that results in longer life plus improved performance.

QUALITY EXPOSED FASTENERS consists of SAE Grade 5

bolts with hex nuts and lock washers. Installation is

simple, without special tools. Shrouded bolts optional.

CLEAR RUST INHIBITIVE AND CORROSION RESISTANT FINISH

protects coupling in normal industrial environments.

AVAILABLE OFF-THE-SHELF in reborables with large bore

capabilities or stock finish bored.

OPTIONAL PILOT RINGS provides positive register between

identical halves. Eliminates selective assembly required

in male, female sleeves.

WALDRON® GEAR COUPLINGS

WALDRON® Size 1-7

INTERCHANGEABLE by half coupling with competitive

coupling designs.

HIGHER MISALIGNMENT CAPABILITY sizes 1-7

compensate for up to ±1 1/2° static angular

misalignment per gear mesh.

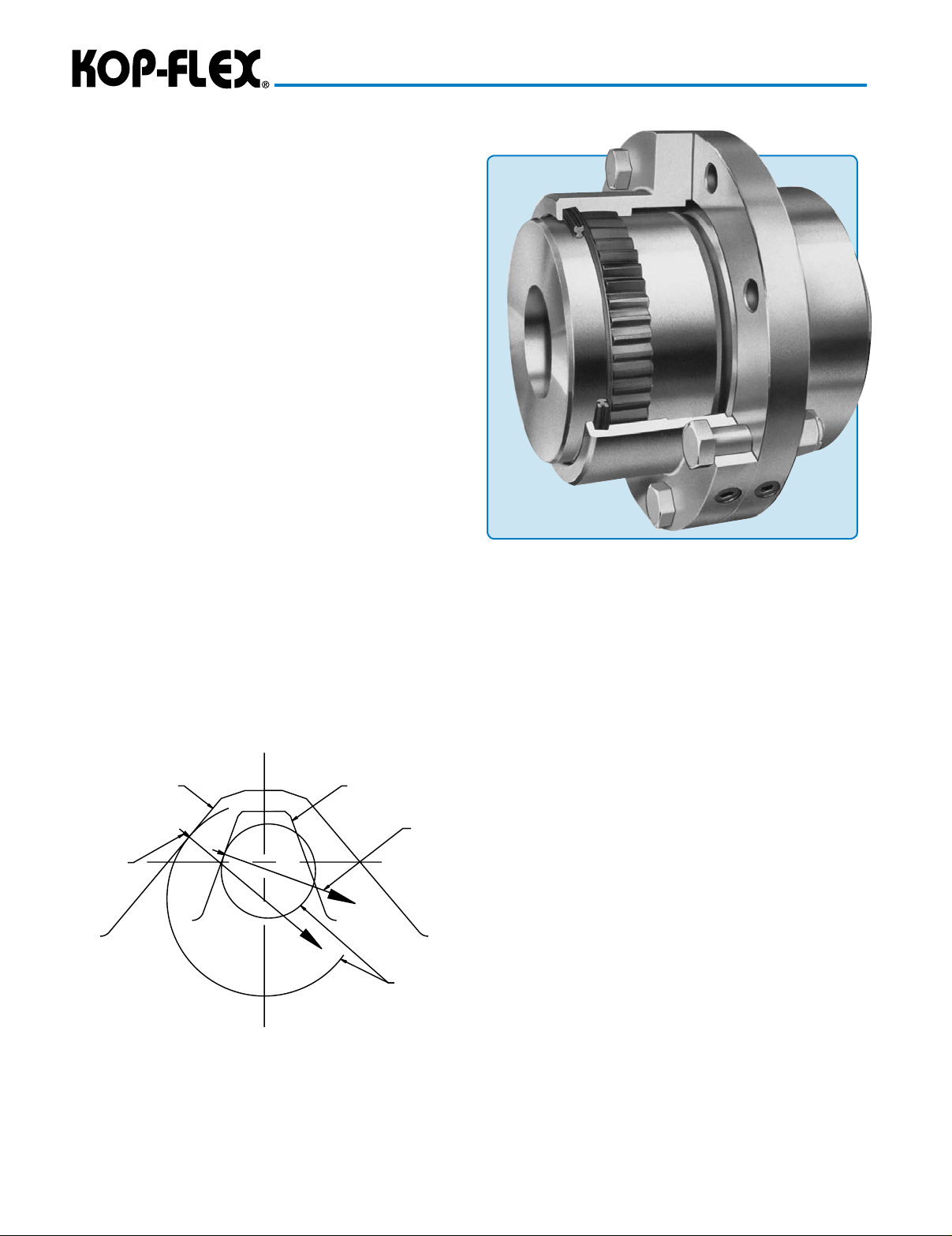

40° LINE

OF ACTION

massive

40° TOOTH

CONVENTIONAL

20° TOOTH

COMPARABLE

INVOLUTE

CURVATURES

20° LINE

OF ACTION

Advantages of the 40° Pressure Angle Tooth

• STRONGER TOOTH

The line of action of the force exerted at the pitch line

of the new Performance Profile crosses the root circle

near the center of the tooth rather than outside the

tooth, as in the case of conventional gear teeth. The

result is an appreciable reduction in root stress which

helps protect against tooth damage.

• GREATER TOOTH CONTACT AREA

The profile of the tooth is significantly flatter due to

the large involute radius of curvature. This causes the

load to be distributed over a larger area. As a result,

compressive stresses, lubricant film pressure and

tooth wear are minimized.

• GREATER SLEEVE CENTERING ABILITY

The 40° pressure angle tooth produces greater radial

forces which helps to maintain sleeve concentricity with

respect to the axis of rotation. As a result, inherent

unbalance and centrifugal forces are minimized and

a smooth and efficient operation is imparted to the

coupling.

• INCREASED ARC OF CONTACT

With the 40° pressure angle tooth there is less

tendency for some of the teeth to lose contact during

misalignment. This prevents a drastic reduction in

torque rating with increased misalignment.

158

20° vs. 40° Tooth Comparison

on the same pitch diameter

• INCREASED STRENGTH AND DURABILITY

Under maximum loading and misaligned conditions,

the stronger tooth, the greater intimacy between the

teeth and the increased arc of contact all combine to

produce a coupling unit that is additionally rugged

and efficiently useful for longer periods of time.

WALDRON® GEAR COUPLINGS

16

19

22

21

35

35

48

41

52

55

69

7

79

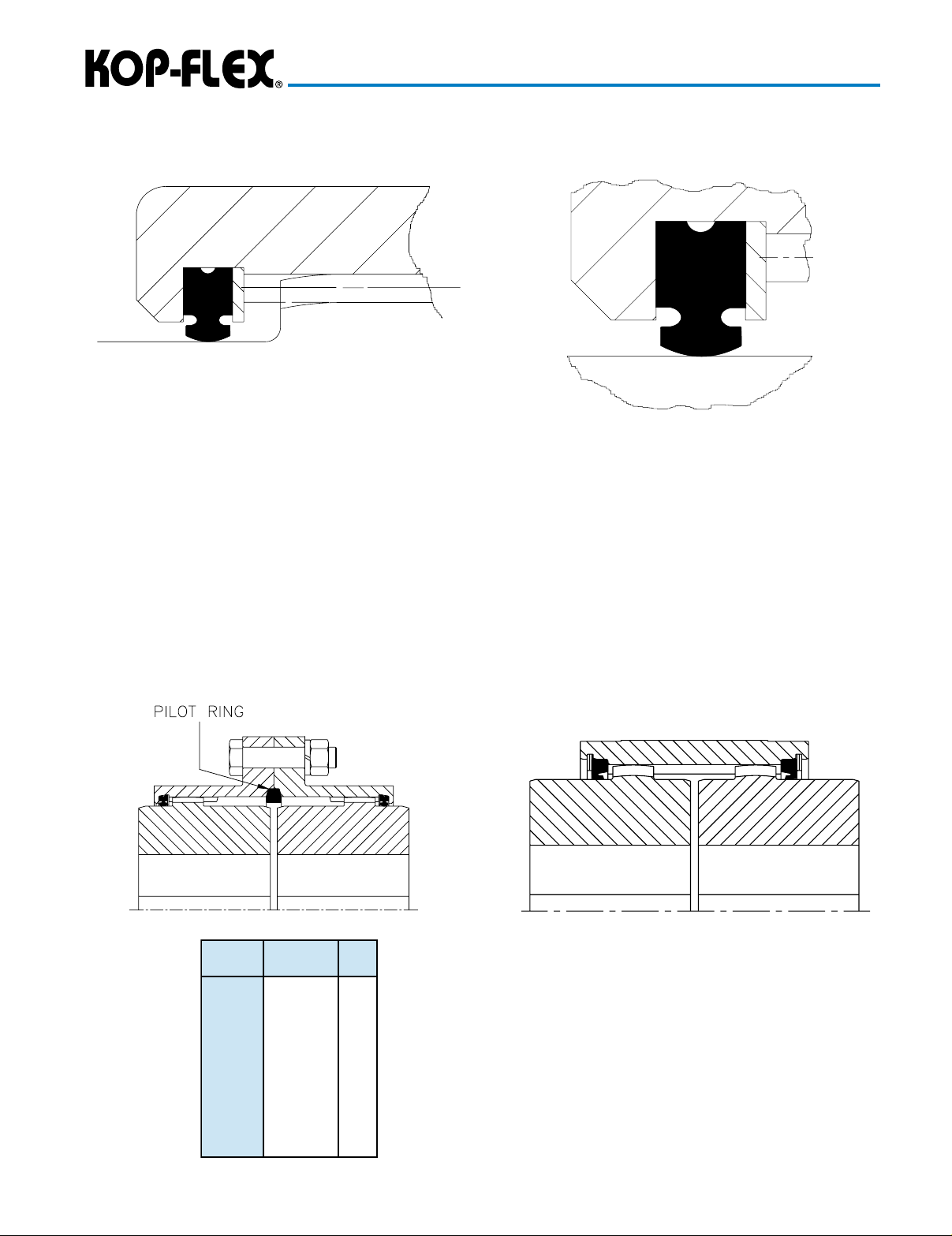

FULL ENGAGEMENT TEETH

The WALDRON® gear coupling has been designed

with full length tooth engagement with the inherent

result of longer life and improved performance.

OPTIONAL PILOT RINGS

HIGH MISALIGNMENT SEAL

Competitive gear couplings incorporate an O-ring seal.

In order to conform with today’s high misalignment

capacities, this O-ring must fit into a groove that is

larger than the ring. WALDRON® couplings use a truly

high misalignment seal that seals remarkably under

misaligned conditions.

WALDRON POWERLIGN

The standard WALDRON® coupling consists of two

identical half couplings. Optional precision steel pilot

rings are available when more accurate centering of the

two sleeves is required.

This flangeless design transmits identical torques as

the standard WALDRON® Coupling. Having a smaller

outside diameter, however, it is more compact, lighter,

and can run at greater speeds.

This alternative may be selected for applications where

space is limited.

cisaB

gnilpuoC

eziS

1

2/11

2

2/12

3

2/13

4

2/14

5

2/15

6

gniRtoliP

.tW

.oNtraP

).bl(

0.

RPW

RPW2/1

0.

1.

RPW

RPW2/1

2.

RPW

2.

2.

RPW2/1

9.

RPW

RPW2/1

.1

RPW

.1

.1

RPW2/1

.1

RPW

RPW

.2

159

Values listed are intended only as a general

guide, and are typical of usual service

requirements. For systems which frequently

utilize the peak torque capability of the power

source, verify that the magnitude of this peak

torque does not exceed the 1.0 Service Factor

Rating of the coupling selected. Applications

which involve extreme repetitive shock or

high-energy load absorption characteristics

should be referred — with full particulars —

to KOP-FLEX.

Values contained in the table are to be

applied to smooth power sources such as

electric motors and steam turbines. For drives

involving internal combustion engines of four

or five cylinders, add 1.0 to the values listed;

for six or more cylinders, add 0.5 to the values

listed. For systems utilizing AC or DC Mill

Motors as the prime mover, refer to Note (1)

CAUTION: All people moving plus overhead

crane applications must be referred to

engineering..

Typical

Application Service

Factor

AGITATORS

Pure Liquids ...........................................................1.0

Liquids & Solids ......................................................1.25

Liquids — Variable Density .....................................1.25

BLOWERS

Centrifugal ..............................................................1. 0

Lobe .......................................................................1.5

Vane .......................................................................1.25

BRIQUETTE MACHINES .................................................2.0

CAR PULLERS — Intermittent Duty................................1.5

COMPRESSORS

Centrifugal ..............................................................1. 0

Centriaxial ...............................................................1.25

Lobe .......................................................................1.5

Reciprocating — Multi-Cylinder ..............................2.0

CONVEYORS — LIGHT DUTY

UNIFORMLY FED

Apron, Bucket, Chain, Flight, Screw .......................1.25

Assembly, Belt .......................................................1. 0

Oven .......................................................................1.5

CONVEYORS — HEAVY DUTY

NOT UNIFORMLY FED

Apron, Bucket, Chain, Flight, Oven ........................1.5

Assembly, Belt .......................................................1.25

Reciprocating, Shaker ............................................2.5

CRANES AND HOISTS (NOTE 1 and 2)

Main hoists, Reversing ...........................................2.5

Skip Hoists, Trolley & Bridge Drives .......................2.0

Slope ......................................................................2.0

CRUSHERS

Ore, Stone ..............................................................3.0

DREDGES

Cable Reels ............................................................1.75

Conveyors ..............................................................1. 5

Cutter Head Jig Drives ...........................................2.5

Maneuvering Winches ............................................1.75

Pumps ....................................................................1.75

Screen Drives .........................................................1.75

Stackers..................................................................1.75

Utility Winches .......................................................1.5

ELEVATORS (NOTE 2)

Bucket ....................................................................1.75

Centrifugal & Gravity Discharge .............................1.5

Escalators ...............................................................1. 5

Freight ....................................................................2.5

FANS

Centrifugal ..............................................................1. 0

Cooling Towers .......................................................1. 5

Forced Draft............................................................1.5

Induced Draft without Damper

Control ................................................................2.0

FEEDERS

Apron, Belt, Disc, Screw ........................................1.25

Reciprocating .........................................................2.5

Typical

Application Service

Factor

GENERATORS —

(Not Welding) ............................................................1.0

HAMMER MILLS ...........................................................2.0

LAUNDRY WASHERS —

Reversing ..............................................................2.0

LAUNDRY TUMBLERS ....................................................2.0

LINE SHAFT ..................................................................1. 5

LUMBER INDUSTRY

Barkers — Drum Type ...............................................2.0

Edger Feed ................................................................2.0

Live Rolls ...................................................................2.0

Log Haul — Incline ....................................................2.0

Log Haul — Well type ...............................................2.0

Off Bearing Rolls .......................................................2.0

Planer Feed Chains ...................................................1.75

Planer Floor Chains ...................................................1.75

Planer Tilting Hoist ....................................................1.75

Slab Conveyor ...........................................................1.5

Sorting Table ..............................................................1.5

Trimmer Feed ............................................................1.75

MARINE PROPULSION

Main Drives ...............................................................2.0

MACHINE TOOLS

Bending Roll ..............................................................2.0

Plate Planer ...............................................................1. 5

Punch Press — Gear Driven ......................................2.0

Tapping Machines .....................................................2.5

Other Machine Tools

Main Drives ...........................................................1.5

Auxiliary Drives .....................................................1.25

METAL MILLS

Draw Bench — Carriage ............................................2.0

Draw Bench — Main Drive .......................................2.0

Forming Machines ....................................................2.0

Slitters .......................................................................1.5

Table Conveyors

Non-Reversing ......................................................2.25

Reversing .............................................................2.5

Wire Drawing & Flattening Machine .........................2.0

Wire Winding Machine ..............................................1.75

METAL ROLLING MILLS (NOTE 1)

Blooming Mills ..........................................................*

Coilers, hot mill .........................................................2.0

Coilers, cold mill ........................................................1.25

Cold Mills ..................................................................2.0

Cooling Beds .............................................................1.75

Door Openers ...........................................................2.0

Draw Benches ...........................................................2.0

Edger Drives .............................................................1.75

Feed Rolls, Reversing Mills .......................................3.5

Furnace Pushers .......................................................2.5

Hot Mills ...................................................................3.0

Ingot Cars .................................................................2.5

Kick-outs ...................................................................2.5

Manipulators .............................................................3.0

Merchant Mills ..........................................................3.0

Piercers .....................................................................3.0

Pusher Rams .............................................................2.5

Reel Drives ................................................................1.75

Reel Drums ...............................................................2.0

Reelers ......................................................................3.0

Rod and Bar Mills ......................................................1.5

Roughing Mill Delivery Table .....................................3.0

Runout Tables

Reversing ..............................................................3.0

Non-Reversing ......................................................2.0

Saws, hot & cold .......................................................2.5

Screwdown Drives ....................................................3.0

Skelp Mills.................................................................3.0

Slitters .......................................................................3.0

Slabbing Mills ............................................................3.0

Soaking Pit Cover Drives ...........................................3.0

Straighteners ............................................................2.5

Tables, transfer & runout ...........................................2.0

Thrust Block ..............................................................3.0

Traction Drive ............................................................3.0

Tube Conveyor Rolls ..................................................2.5

Unscramblers ............................................................2.5

Wire Drawing ............................................................1.5

MILLS, ROTARY TYPE

Ball ............................................................................2.25

Dryers & Coolers ......................................................2.0

Hammer ....................................................................1.75

Kilns ..........................................................................2.0

WALDRON® GEAR COUPLINGS

SERVICE FACTORS

Typical

Application Service

Factor

Pebble & Rod ............................................................2.0

Pug ............................................................................1.75

Tumbling Barrels .......................................................2.0

MIXERS

Concrete Mixers .......................................................1.75

Drum Type .................................................................1. 5

OIL INDUSTRY

Chillers ......................................................................1.25

Paraffin Filter Press ...................................................1.75

PAPER MILLS

Barker Auxiliaries, Hydraulic ......................................2.0

Barker, Mechanical ....................................................2.0

Barking Drum Spur Gear Only ...................................2.25

Beater & Pulper .........................................................1.75

Bleacher ....................................................................1.0

Calenders ..................................................................2.0

Chippers ....................................................................2.5

Coaters .....................................................................1. 0

Converting Machines,

except Cutters, Platers ...........................................1.5

Couch Roll .................................................................1.75

Cutters, Platers .........................................................2.0

Cylinders ...................................................................1.75

Disc Refiners.............................................................1.75

Dryers .......................................................................1.75

Felt Stretcher ............................................................1.25

Felt Whipper ..............................................................2.0

Jordans .....................................................................1.75

Line Shaft ..................................................................1.5

Log Haul ....................................................................2.0

Pulp Grinder ..............................................................1.75

Press Roll ..................................................................2.0

Reel ...........................................................................1.5

Stock Chests .............................................................1.5

Suction Roll ...............................................................1.75

Washers & Thickeners ...............................................1. 5

Winders ....................................................................1. 5

PRINTING PRESSES ......................................................1. 5

PULLERS — Barge Haul ................................................2.0

PUMPS

Centrifugal ................................................................1. 0

Boiler Feed ................................................................1.5

Reciprocating

Single Acting

1 or 2 Cylinders ....................................................2.25

3 or more Cylinders ..............................................1.75

Double Acting ...........................................................2.0

Rotary, Gear, Lobe, Vane ...........................................1. 5

RUBBER INDUSTRY

Mixer — Banbury ......................................................2.5

Rubber Calendar .......................................................2.0

Rubber Mill (2 or more) .............................................2.25

Sheeter .....................................................................2.0

Tire Building Machines ..............................................2.5

Tire & Tube Press Openers .......................................1.0

Tubers & Strainers ....................................................2.0

SCREENS

Air Washing ...............................................................1.0

Grizzly .......................................................................2.0

Rotary — Stone or Gravel .........................................1. 5

Traveling Water Intake ...............................................1.25

Vibrating ....................................................................2.5

SEWAGE DISPOSAL EQUIPMENT

Bar Screens...............................................................1.25

Chemical Feeders .....................................................1.25

Collectors, Circuline or Straightline ...........................1.25

Dewatering Screens .................................................1.25

Grit Collectors ...........................................................1.25

Scum Breakers..........................................................1.25

Slow or Rapid Mixers ................................................1.25

Sludge Collectors ......................................................1.25

Thickeners .................................................................1.25

Vacuum Filters ..........................................................1.25

STEERING GEAR .............................................................1. 0

STOKERS .......................................................................1. 0

WINCH ..........................................................................1. 5

WINDLASS ....................................................................1.75

* Refer to KOP-FLEX

NOTES

(1) Maximum Torque at the coupling must not exceed

Rated Torque of the coupling.

(2) Check local and industrial safety codes.

160

Loading...

Loading...