Koolspace chillR 100, chillR 900, chillR 300, chillR 600 Operation Manual

Koolspace Wine Cooling System

100 - 300 - 600 - 900

INSTALLATION & OPERATION MANUAL

~3~

READ BEFORE YOU START

Koolspace wine cooling units must be installed precisely as directed in the Manual.

DO NOT attempt to install this unit before reading the Manual!

1.

NEVER Install this unit through an exterior wall, NEVER to OUTDOORS! (Units must ventilate to an adjacent

INTERIOR space, Warm air vents must be completely unobstructed).

2.

DO NOT modify or handle the digital Sensor (incased in vinyl cap on back of unit). The Sensor will read and

respond to changes in AIR temperature in the enclosure. DO NOT attempt to modify the sensor to read liquid

temperature.

3.

Install the unit in an enclosure where ALL surfaces (walls, oor and ceiling) are insulated to R-20 and protected

by vapor barrier on both sides.

4.

Uninsulated concrete oors will radiate heat and humidity during summer months, forcing the unit to work

harder than necessary, the life of unit will be shortened, and will produce EXCESS CONDENSATION.

5.

Install the unit in a location where the condenser (warm side) coil is accessible for periodic vacuuming of the

condensor coil. (See troubleshooting for details.)

6.

Outlet power must be a DEDICATED separately fused and grounded 15-Amp 115 Volt line. Line must not be

shared with any other outlet or appliance. (Insufcient voltage will cause the unit not to run, compressor may

not start, and the LED display may be corrupted).

7.

Extension cord must be must be rated for at least 15 Amps if one is required.

8.

Electronic controller must also be protected against sudden power surges. Koolspace wine cooling systems may

be damaged by power surges or spikes, sudden interruptions or prolonged low-voltage conditions.

9.

You must monitor your unit DAILY. If unit is in “Alarm”, unplug the unit immediately. Always check for any water (condensate) leaks. (Check troubleshooting section)

10.

Koolspace TM will not be liable or responsible for incidental or consequential damages. (See Warranty).

11.

This unit is not designed for COMMERCIAL USE. Such usage will void any warranty. In addition, Third party servicing of these units during the warranty period will void the warranty.

12.

Select a suitable area, sized appropriate to the model’s capacity, in a location where ambient temperature will

not exceed the desired storage temperature by more than 25ºF (14ºC).

13.

This appliance is for INDOOR USE ONLY, and must not be vented into a laundry closet or similar room which traps

warm air.

14.

The unit must vent to an adjacent INTERIOR VENTILATED SPACE CLOSE TO THE CEILING. Exhaust air must not be

obstructed in any way.

15.

The temperature of the air in the immediate area where the unit vents its warm air must never exceed 80ºF

with 70% R.H. (non-condensing). Operating temperatures are: Outside of wine cellar: min. 65ºF (18ºC) Max. 80ºF

(26ºC) / Inside of wine cellar: min. 52ºF (11ºC) Max. 70ºF (21ºC)

WARNING: Lower SET TEMPERATURE FROM DEFAULT 57ºF (14ºC) only if ambient conditions allow. A lower set temp

can cause water overow in high humidity conditions.

SPECIAL NOTE: THIS COOLING UNIT IS CONSTRUCTED FOR INSTALLATION IN WALLS UP TO 7 1/2” INCHES

THICK. IF YOU INSTALL IT IN A THICKER WALL YOU WILL HAVE TO CUT OUT AN AREA AROUND THE AIR VENTS

IN ORDER NOT TO BLOCK THE AIRFLOW.

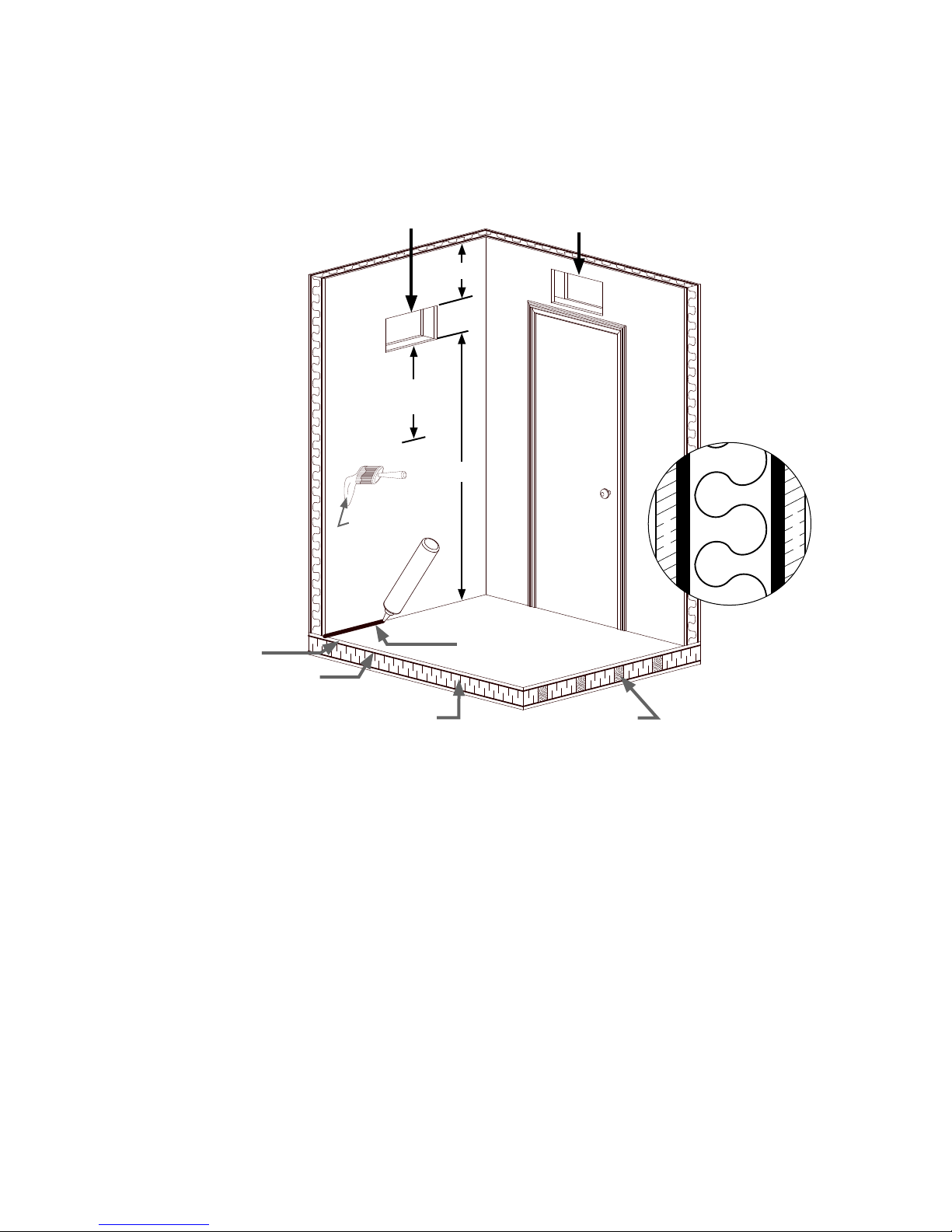

SILICONE CAULKING

PREPARING FOR INSTALLATION

Koolspace chillR is the only unit that allows for isolating the studs against noise and vibration when installed as directed.

RECOMMENDED

OVER THE DOOR

SEAL

Seal corners, joints, gaps,

vents, electrical outlets and

switches, and especially

around door and frame.

Pack larger gaps with insulation. Seal all with silicone

caulking.

ALTERNATIVE

WALL CUTOUT (B)

Min 5”

Min 2’

space

lear

c

Min 6’

CUTOUT (A)

DOOR

WITH

AIRTIGHT

SEAL

Seal drywall with odorless

waterproof paint.

PLYWOOD

FLOOR

BARRIER

VAPOR BARRIER

All surfaces of the enclosure

must be protected by a proper

vapor barrier, ideally on both

inside and outside of wine cellar.

VAPOR

ODORLESS

WATERPROOF

PAINT

INSULATION

(MIN R-20)

INSULATION

( MINIMUM R-20 )

DRYWALL

VAPOR BARRIER

SEAL ALL

JOINTS

SUB-FLOOR

(STUD LUMBER)

INSULATION

Floor, ceiling and all walls of the enclosure must be

insulated to minimum R-20 rating, although R-30 is

recommended.

Best material is foil-backed urethane foam, sealed at

all joints with thermal tape.

Build a proper sub-oor with vapor barrier, and insulate

to at least R-20, especially if oor is concrete.

DRYWALL

VAPOR BARRIER

POWER SUPPLY:

This appliance must be installed in accordance with national wiring regulations.

Do not use if power cord is damaged; it must be replaced by the manufacturer or its service agent or by a qualied

person to avoid a hazard. Plug must remain accessible after installation.

Electrical service must be a dedicated, separately fused and grounded 15 Amp, 115V line.

Do not share the circuit with any other appliance. If extension cord must be used, it must be rated for 15 Amps. Test line

voltage BEFORE operating, and do not use if line voltage is less than 105V. The unit must be protected against power surges

and spikes: use a good quality surge suppressor.

~3~

~5~

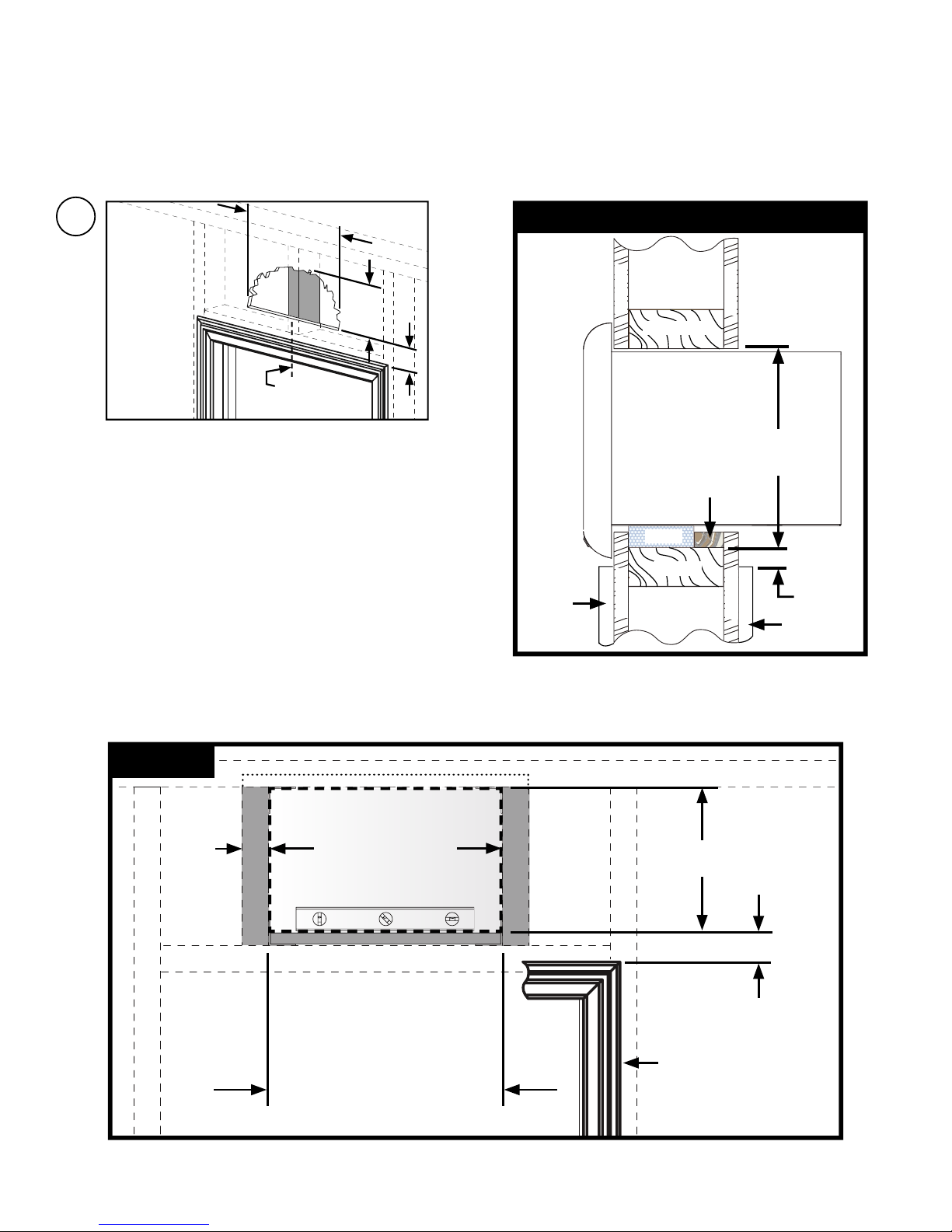

PREPARE FOR OVER THE DOOR CUTOUT (A)

This manual is only a guide, house structure may vary. (For high ceilings install an upper horizontal brace)

START ON THE WARM SIDE

1

HEADER

Open drywall on warm side. Measure distance

from HEADER to TOP PLATE and MOLDING. Follow

the typical installation described in STEPS 2-6 if

clearance is 10” and the HEADER is at least 3/8”

higher than the molding. (SEE PROFILE)

THE FOLLOWING STEPS ARE COMMON FOR 8’ FOOT CEILINGS

max 14”

TOP PLATE

DOOR

CENTER

6”

2”

PROFILE OF INSTALLED UNIT

WARM

SIDE

Drywall

TOP PLATE

Drywall

COOL

SIDE

10”

1/2” WOOD SPACER

FOAM

ONLY if clearance conditions are not met, customize the installation, assure the required dimensions indicated in the DETAIL.

TIP: - Replace FOAM isolator with Shim (plywood).

- Increase headroom (cut TOP PLATE with

utility saw)

DETAIL

11/2”

Cripple Stud

King Stud

DRYWALL CUT-OUT

MUST BE LEVELED!

SHIM

HEADER

Door

Molding

TOP PLATE

Cripple Stud

HEADER

Drywall

Drywall

Molding

H = 9 3/8”

King Stud

Min.1”from molding

3/8”

Door

W =

100-300 Series use :

W = 16”

600-900 Series use :

19 3/8”

DOOR FRAME MOLDING

~4~

Loading...

Loading...