Page 1

1

VID-NXTTN Installation Guide v 1.0

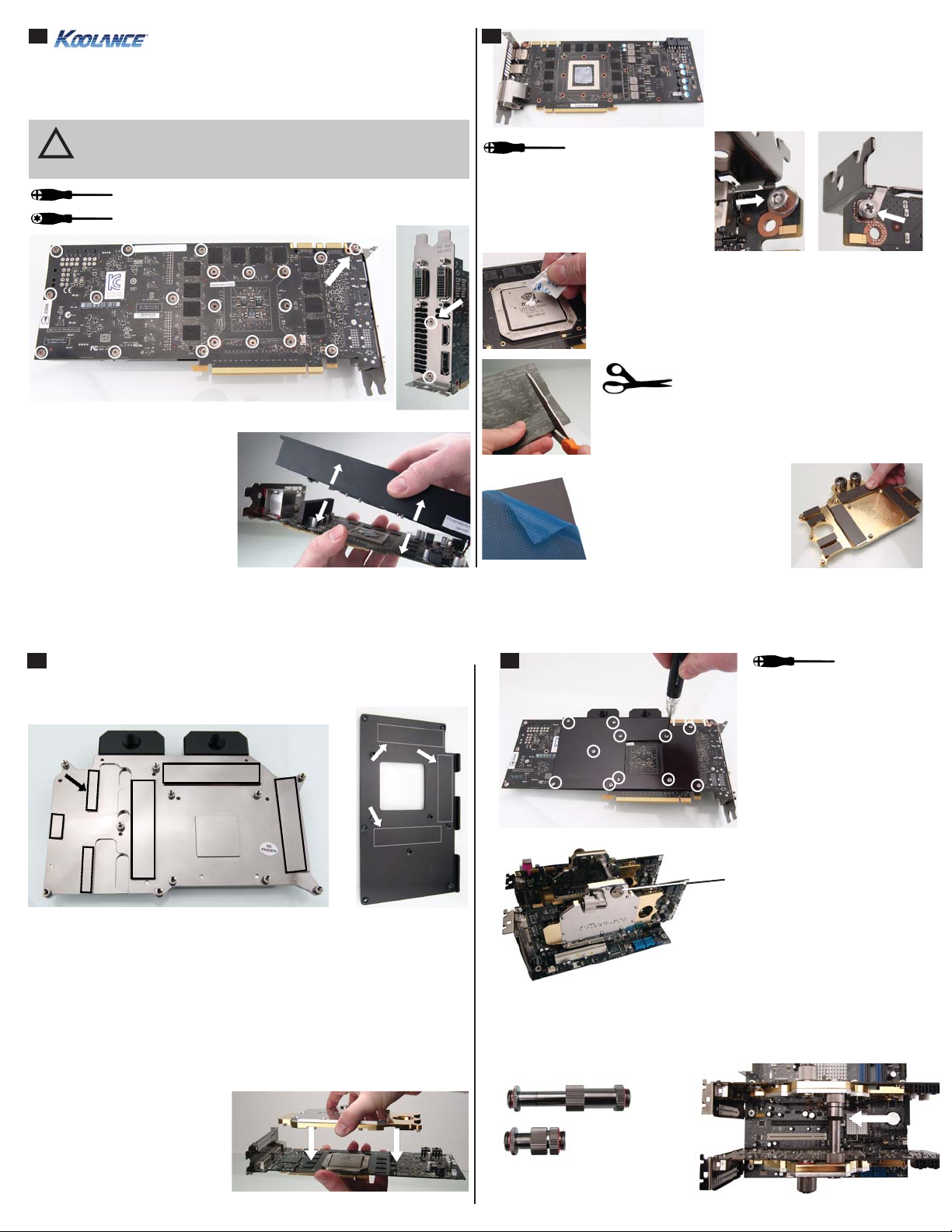

NOTE: The video card should be removed from the chassis in order to install this

cooling device. Most cards using the VID-series blocks are disassembled the same

way, although heat sink assemblies of any given model can vary.

CAUTION: Removal of the original heat sink or liquid cooling may void

your manufacturer’s hardware warranty. Please consult the manufac-

!

turer if unsure, and keep all original parts in case of a return/RMA.

All heat sink assembly screws should be removed. There are

multiple screws on the rear of the video card, and 2 more on

the L-bracket.

GTX TITAN Disassembly Screws (Bottom and Rear L-Bracket)

With all screws removed,

carefully remove the GPU heat

sink, followed by the card heat sink.

Original thermal paste may present

resistance during removal.

2

Use the shortest provided screw with

a nut and washer to secure the PCI

bracket to the top corner of the video

card. The bracket will be loose after

removing the original heat sink.

Thermal paste is only required on the main GPU. The other

areas will utilize the included heat transfer pads.

Spread thermal compound on the GPU thinly and evenly

using the included paste packet, or a piece of thick paper

(such as a business card).

The thermal pad sheet should be cut into

pieces required for your video block contact

areas. Please use the diagram included

with your water block to determine the approximate sizes

needed. Koolance heat transfer pads can have different

thicknesses (0.5mm, 0.7mm, and 1.0mm).

After cutting the proper shapes for

your block, peel the protective film

from each pad.

Apply each thermal pad to the

water block as illustrated in the

provided thermal pad diagram.

Unplug the heat sink fan wire. Remove

the original RAM thermal transfer

material, and wipe any residual thermal

material from the main GPU chipset.

Basically, any area of the video card in contact with the original heat sink will

3

need new heat transfer material. Place thermal pads on the corresponding

areas of the Koolance water block. Additionally, the VID-NXTTN aluminum

back plate will also require thermal pads.

VID-NXTTN Water Block and Back Plate Thermal Pad Locations

Multiple types of heat transfer pads are included with some Koolance blocks.

You might not require both (check the pad diagram). This is done because card

manufactures change the component height tolerance from time to time. After

completing video block assembly, it’ s recommended to remove the block temporarily

to check thermal paste and pad impressions for good component contact:

• If the GPU area paste is not evenly disrupted, thinner thermal pads may be

needed in corresponding areas to improve GPU contact.

• If thermal pads have no chip indentations but the GPU paste looks good,

thicker thermal pads may be needed to improve contact in those areas.

4

Place the aluminum back plate

on the reverse side of the video

card. Using the Koolance-supplied

screws, tighten each location

on the Koolance back plate to

assemble the video card and water

block. Plastic insulating washers

can optionally be used on the back

plate to help prevent scratching.

Socket plugs are included with the VID

coolers which must be placed opposite

the desired nozzle locations.

G 1/4 BSP inlet/outlet nozzles can be

screwed into the top or bottom side of the

cooler, as long as coolant flows from one half

to the other (left to right or right to left).

Connecting Multiple VID Coolers

When connecting multiple VID coolers, Koolance offers an optional direct-connect

nozzle. This minimizes liquid routing while avoiding potential conflicts with hardware

in between the video cards.

Place the Koolance block onto the

video card so the mounting screws

will align.

Optional Two-Three Slot (CNT-VDA34) and

One Slot (CNT-VDA2) Video Connectors

Loading...

Loading...