Page 1

www.koolance.com

®

Superior Liquid Cooling Systems

ISO

9001

Printed in Korea

RP-1250

RP-1250

User’s Manual

User’s Manual

English v1.01

Page 2

This User Manual is updated regularly. Please be sure to check our support page for a newer

version of this guide: www.koolance.com/support

GENERAL PRECAUTION

Please read this manual carefully before beginning the installation of your Koolance system.

This manual assumes the user has basic experience in building and configuring computer

systems. Information referring to traditional hardware assembly is intentionally brief.

ABOUT SIGNS

Throughout this document, critical information is highlighted in gray-colored boxes. The

following symbols are intended to help prevent any situation which may cause personal

injury and/or damage to equipment:

WARNING: Indicates a potentially hazardous situation which, if not avoided,

!

!

could result in personal injury or be life-threatening.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in damage to equipment or property.

PROHIBITED: Indicates a prohibited action.

PROHIBITED USE

This product is designed, developed and manufactured as contemplated for general use,

including without limitation: general office use, personal use and household use, but is not

designed, developed and manufactured as contemplated for use accompanying fatal risks or

dangers that, unless extremely high safety is secured, could lead directly to death, personal

injury, severe physical damage or other loss, including without limitation: nuclear power core

control, airplane control, air traffic control, mass transport operation control, life support,

or weapon launching control. If these products are used in such hazardous environments,

Koolance Incorporated does not warrant them.

TRADEMARKS

The Koolance name and logo are trademarks or registered trademarks of Koolance, Inc.

Other company and product names used in this publication are for identification purposes

only and may be trademarks or registered trademarks of their respective companies.

COPYRIGHT

All rights reserved. Copyright (C) Koolance Incorporated.

User Manual

i

Page 3

WARNING: The Koolance liquid & coolant pack contain chemicals

!

!

which may be harmful or fatal if swallowed. KEEP THIS AND ALL

DANGEROUS CHEMICALS OUT OF THE REACH OF CHILDREN. If

ingestion has occurred, seek medical attention immediately. Give two

glasses of water. Do not induce vomiting. In the case of eye contact,

flush eyes immediately with water for 15 minutes. Remove contact

lenses. Call a physician if irritation persists. Some individuals may

have an allergic skin reaction with the solution, although generally mild.

Avoid contact as much as possible, and wash exposed area with soap

and water for at least 15 minutes. If irritation persists, or if contact has

been prolonged, get medical help. For further information, please visit

our website at: www.koolance.com

CAUTION: Installation of third-party cooling products is done at the

user’s own risk. Koolance Inc. assumes no responsibility for damage

or loss due to the installation or use of this product. Additionally, adding

liquid coolers and other components to computer hardware may void

the hardware manufacturer’s original warranty. If you have any specific

questions on warranty coverage, please contact your component or

computer manufacturer. If there is any point of installation that you do

not understand, please contact our Technical Support Staff at: tech@

koolance.com, or visit our website at: www.koolance.com/support

System Features 1

Product Diagram ............................................................................................. 2

Display Panel .................................................................................................. 3

Installation 10

Positioning the Unit ....................................................................................... 11

Reservoir & Pump Connections .................................................................... 11

Power Connection .........................................................................................12

Fan Connection .............................................................................................12

Flow Meter Connection ................................................................................. 12

ATX Pass-Through Lead ............................................................................... 13

Temperature Sensor Placement ................................................................... 13

Fittings .......................................................................................................... 14

Cooler & Tubing Configuration ......................................................................15

Disconnecting Hoses .................................................................................... 17

Hose Lengths ................................................................................................ 17

Table of Contents

KOOLANCE CONTACT INFORMATION

Koolance Incorporated (USA)

Address: 2840 W. Valley Hwy. N., Auburn, WA, USA 98001

Telephone: +01-253-893-7551

Fax: +01-253-893-7573

Sales Email: sales@koolance.com

Tech Email: tech@koolance.com

ii

Filling & Maintenance 19

Testing & Filling ............................................................................................. 20

Adding Coolers & Maintenance .................................................................... 22

Troubleshooting ............................................................................................ 23

Limited Warranty ........................................................................................... 26

User Manual

iii

Page 4

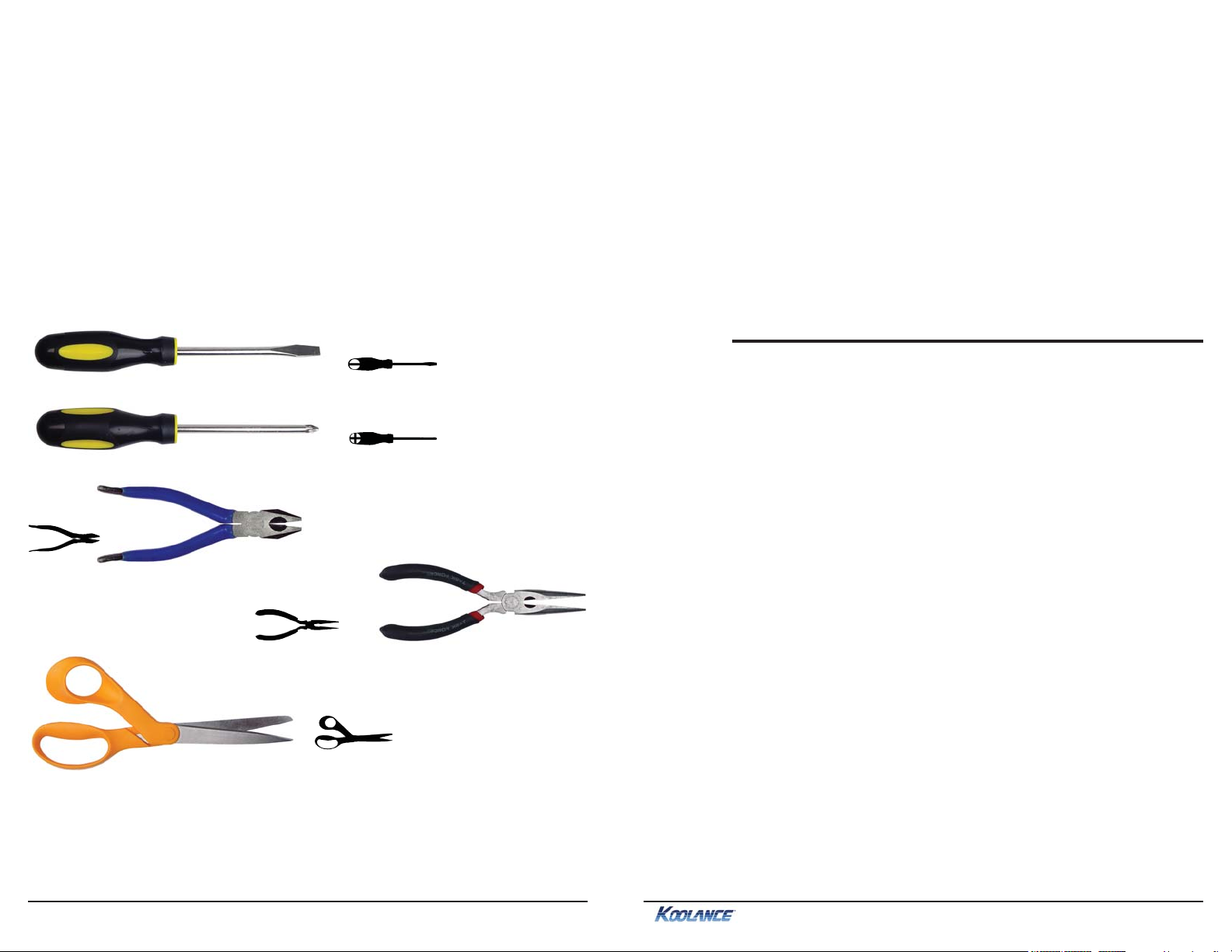

Included Hardware

- Temperature Sensors (x3)

- ATX Pass-Thru Wire

- Mounting screws

- ATX Jumper Wire

- User Manual

Required Tools

During installation, you may need the following tools:

flat-head screw driver

phillips-head screw driver

pliers

Chapter1

System Features

long-nose pliers

scissors

iv

User Manual

1

Page 5

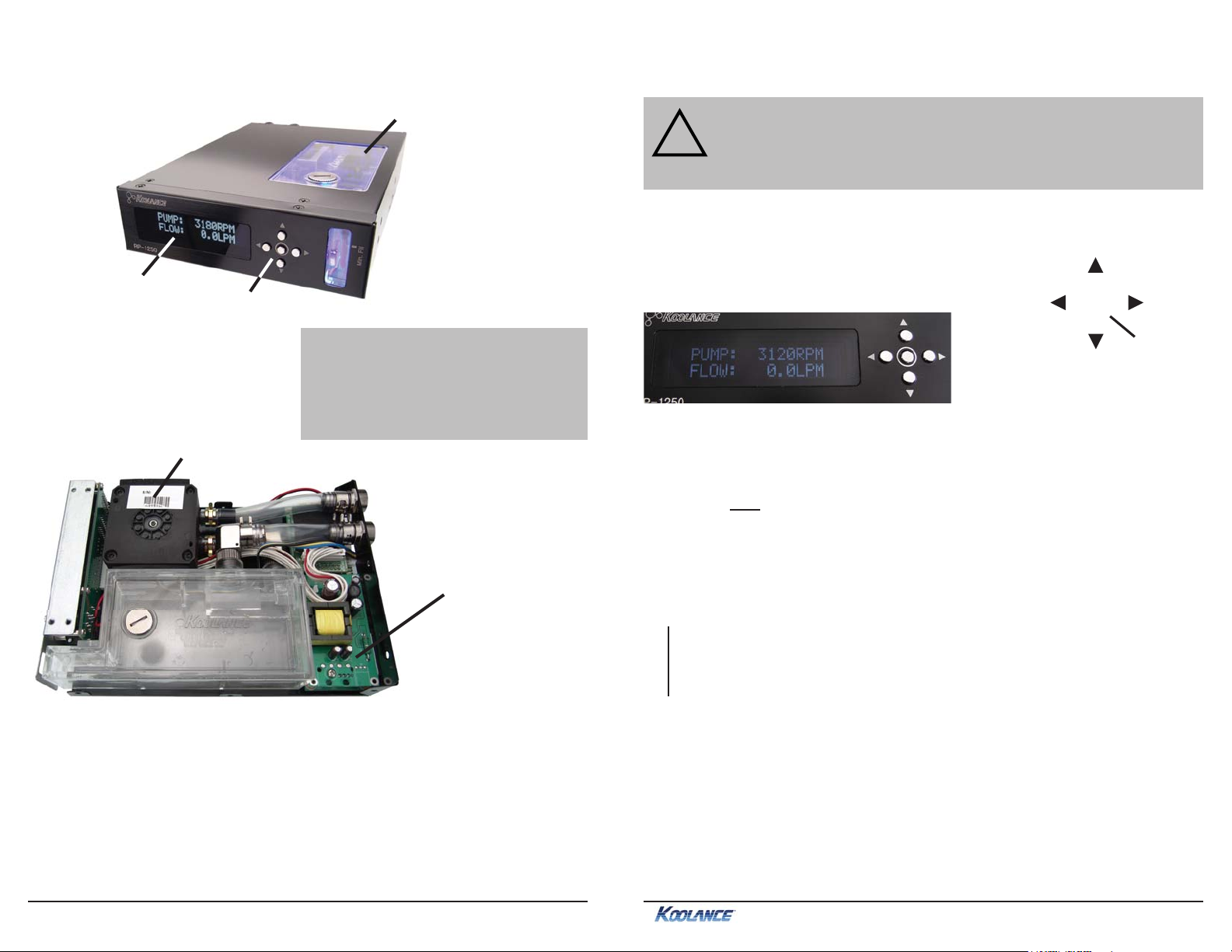

Product Diagram

Display Panel

Display

Control Buttons

Pump

Reservoir

NOTE: After powering on this unit, wait

5 seconds before powering it off again.

Otherwise, the display may lock-up

and require reset (hold ▼ + ▲ for 5

seconds.)

CAUTION: This cooling system allows full user control of hardware

!

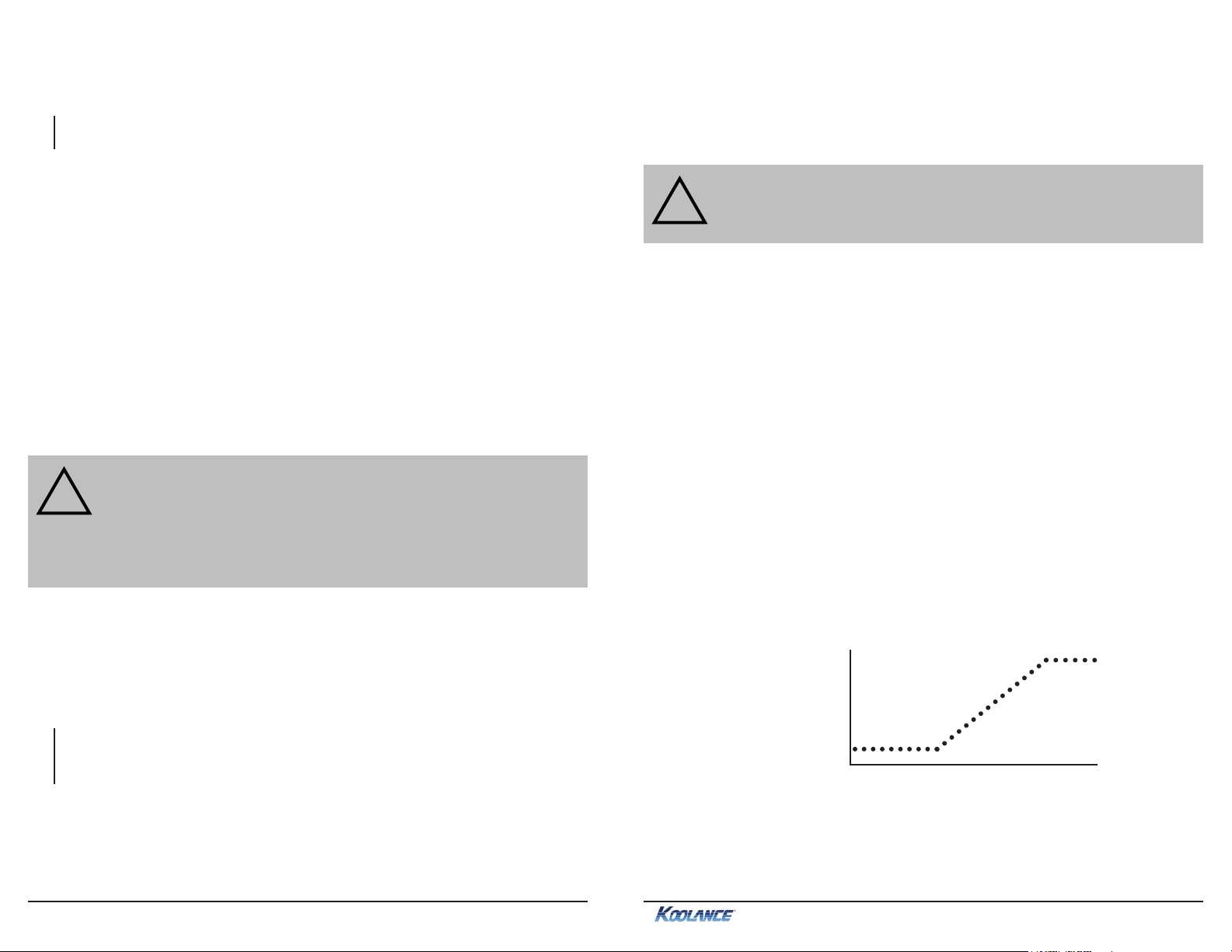

The Koolance display panel allows control and

monitoring of various aspects of the cooling

unit. 4 buttons are used, with directional

arrows to navigate or change settings, and a

center button to enter/exit.

• On the main screen, hold ◙ for 3 seconds to change display units between

ºC/ºF and LPM/GPM.

• You can exit any menu and return to the main screen by holding ◙ for 2

seconds.

• To reset ALL settings to default, hold ▼ + ▲ for 5 seconds.

Main Menu

safety settings, such as audio alarm, shutdown, and pump speed.

Please be sure to configure your Display Panel properly, or damage

to your computer, data, and/or equipment could result.

Navigate Up,

Increase Setting

Navigate

Left

◙

Navigate Down,

Decrease Setting

Navigate

Right

Enter/Exit

Control Board

Reservoir & Pump - The coolant tank is transparent for easy liquid-level monitoring

through the front window. It is filled through a metal fill port on top. The reservoir

is illuminated by internal blue LEDs.

Control Board - Behind the reservoir, the Control Board is responsible for a number

of tasks, including: powering the pump, display, radiator fans (if attached), and

operating the audio alarm and shutdown modes.

2

System Features

To enter the main menu, briefly press ◙. The selected option will begin flashing.

Use ▼ and ▲ to navigate this menu.

▲

TEMP SET: Temperature, alarm, and shutdown settings

FAN SET: Fan settings

PUMP SET: Pump settings

FLOW SET: Flow meter settings

▼

DISPLAY SET: Display settings

When in the top menu, press ◙ to enter one of the above categories. To exit from

here, press ◄.

TEMP SET

The temperature menu allows configuration of the alarm and safety shutdown

options. This cooling system can monitor up to 3 (included) temperature sensors.

An audio alarm will sound if any sensor reaches its set alarm point. The offending

sensor will also flash in the display, and the radiator fans and pump will increase

User Manual

3

Page 6

to 100% power. If any sensor reaches its set shutdown point, the system will

shutdown power to the computer via relay using the “ATX pass-through” wire.

▲

TEMP1 55C 56C : Sensor #1, Alarm Point, Shutdown Point

TEMP2 51C 54C : Sensor #2, Alarm Point, Shutdown Point

▼

TEMP3 60C 70C : Sensor #3, Alarm Point, Shutdown Point

The speed value will flash. Press ▼ or ▲ to adjust this value. Press ◙ to confirm

the setting.

Higher fan speeds can improve performance, but will produce more noise. Fan

speeds can be adjusted manually from 0-100%.

When in the “Temperature Settings” menu, the selected temperature sensor will

flash. Press

TEMP1 SET

AL: 55C PW: 56C : AL = Alarm, PW = Power (Shutdown)

The alarm value will flash. Press ▼ or ▲ to adjust a value. Press ◙ to change

to the shutdown temperature. Press ◙ again to exit configuration of this sensor.

Press ◄ to return to the previous menu.

NOTE: The shutdown temperature must be at least 1ºC (1-2ºF) higher than the

alarm temperature. If an alarm temperature can not be increased, increase the

shutdown temperature first. The minimum and maximum temperature range

allowable is 0-99ºC (32-210ºF).

!

FAN SET

▼ and ▲ to navigate, or press ◙ to select a sensor to configure:

CAUTION: Generally, sensors report liquid temperature at the water

block, which is typically 5-10°C (9-18°F) lower than the actual heat

source. This difference must be considered if adjusting alarm/shutdown

temperatures. Setting alarm/shutdown modes at too high of temperature can eliminate this feature’s effectiveness. The default Koolance

settings are designed to help compensate for differences in temp.

CAUTION: Fan percentages are based on PWM duty. Fans will not

!

Instead of manual speeds, fans can also be set to automatic. This is highly

recommended, since speeds will change based on temperature sensor feedback.

This is a good way to keep noise levels to a minimum while allowing the cooling

system to respond to temperature. To set a fan channel to automatic, press ▲ past

100% until “AUTO” is shown:

ALL FANS AUTO

From here, press ◙ to configure the automatic mode:

ALL FANS AUTO

T1 L45C H80C : Temp Sensor, Low Point, High Point

The number following “T” designates the temperature sensor this fan channel will

follow. When flashing, press ▼ or ▲ to change sensors (1-3). Press ◙ to move

to the next option.

The number following “L” is the temperature low point. The number following “H”

is the temperature high point. Automatic fan control will adjust fans on a dynamic

ramp between these two points:

operate if set too low. Some types of fans may also not be compatible

with the PWM program and will only operate reliably at 100%.

This unit has three fan channels which can be independently adjusted.

Alternatively, use the master fan channel (“ALL FANS”) to adjust all fan channels

simultaneously.

ALL FANS 50% : All Fans (Master), Speed Setting %

▲

FAN1 SET 84% : Fan Channel #1, Speed Setting %

FAN2 SET 47% : Fan Channel #2, Speed Setting %

FAN3 SET 30% : Fan Channel #3, Speed Setting %

▼

The selected fan channel will flash. Press ▼ and ▲ to navigate, press ◄ to return

to the previous menu, or press ◙ to configure this fan channel:

ALL FANS 50%

4

System Features

100%

Automatic

Fan Power

20%

42ºC

(Low Point)

When the temperature low point is flashing, press ▼ or ▲ to adjust it. Press ◙ to

move to the temperature high point, and press ▼ or ▲ to adjust it. Press ◙ again

to return to the previous menu.

User Manual

60ºC

(High Point)

5

Page 7

PUMP SET

The first line will flash. Press

▼ or ▲ to change what this line will display:

The pump speed can be manually set from 1-10:

PUMP(1-10) 7LV : Pump Speed Level

The pump speed level will flash. Press

previous menu.

FLOW SET

If a Koolance flow meter (sold separately) has been connected to the slot interface

adapter, configuration is needed to properly display its values. Only one flow meter

can be displayed by the cooling system.

FLOW METER SET

FM-17 ID: 10mm : Flow Meter Model, Tubing Internal Diameter

The Koolance flow meter model number (SKU) will flash. Press ▼ or ▲ to adjust

this based on the following:

• INS-FM16: change to “FM-16”

• INS-FM17, INS-FM17N, INS-FM18: change to “FM-17”

Press ◙ to move to the next option. The tubing internal diameter (ID) size will

flash. This refers to the hose size attached to the flow meter itself. Press ▼ or ▲

to adjust this based on the following:

• 6mm (1/4 inch): change to “ID: 6mm”

• 10mm (3/8 inch): change to “ID: 10mm”

• 13mm (1/2 inch): change to “ID: 13mm”

▼ or ▲ to adjust. Press ◙ to return to the

▲

TEMP1 21.7C : Show temperature sensor #1

TEMP2 21.2C : Show temperature sensor #2

TEMP3 20.8C : Show temperature sensor #3

FAN1 1770RPM : Show fan channel #1

FAN2 1640RPM : Show fan channel #2

FAN3 1820RPM : Show fan channel #3

PUMP 5730RPM : Show pump speed

▼

FLOW 4.1LPM: Show flow rate

◙ to confirm. The second line will flash. Press ▼ or ▲ to adjust this line.

Press

Press ◄ to return to the previous menu, or press ◙ to return to the main screen.

When “FIXED” is the chosen display option, line 1 and 2 can be changed quickly

without reentering the DISPLAY SET menu. To do this, briefly press ▲ from the

main screen. The first line will flash:

TEMP1 21.7C : First line display option

PUMP 5400RPM : Second line display option

Press ▼ or ▲ to change what this line will display among the options described

earlier. Press ◙ to move to line 2, and similarly use ▼ or ▲. Press ◙ again to

exit.

If “CYCLIC” is chosen from the DISPLAY SET menu, multiple values will be rotated

through the front display. The first option is whether these values will cycle vertically

or horizontally through the display:

CYCLIC

VERT HORI: Rotate values vertically or horizontally

Press ◙ to return to the previous menu.

DISPLAY SET

The display settings configure which values you wish to appear on the front display

and how they are shown:

DISPLAY

FIXED CYCLIC : Show 2 values or cycle multiple values

The first option, “FIXED”, will flash. Press ◄ or ► to change between these

options. Press ◙ to configure one of the selections, or press ▲ to exit. If “FIXED”

is selected, two lines will be shown:

TEMP1 21.7C : First line display option

TEMP1 21.7C : Second line display option

6

System Features

The first option, “VERT”, will flash. Press ◄ or ► to change between these options,

press ◙ to configure a selection, or press ▲ to exit. Choosing either option with

◙ will list all available values:

▲

*TEMP1 21.7C : Show temperature sensor #1

*TEMP2 21.2C : Show temperature sensor #2

*TEMP3 20.8C : Show temperature sensor #3

*FAN1 1770RPM : Show fan channel #1

*FAN2 1640RPM : Show fan channel #2

*FAN3 1820RPM : Show fan channel #3

*PUMP 5730RPM : Show pump speed

▼

*FLOW 4.1LPM: Show flow rate

User Manual

7

Page 8

The selected line will flash. Use

enable or disable each value. This will remove the asterisk, thereby hiding that line

from being shown on the main screen:

▲

*TEMP1 21.7C : (shown)

*TEMP2 21.2C : (shown)

*TEMP3 20.8C : (not shown)

*FAN1 1770RPM : (shown)

*FAN2 1640RPM : (not shown)

*FAN3 1820RPM : (not shown)

*PUMP 5730RPM : (shown)

▼

*FLOW 4.1LPM: (shown)

◄ to return to the previous menu, or press ► to exit DISPLAY SET.

Press

▼ and ▲ to navigate to other lines. Press ◙ to

This page is intentionally left blank.

8

System Features

User Manual

9

Page 9

Chapter2

Installation

Positioning the Unit

The cooling unit is designed to operate in one orientation. In other directions, the

pump and reservoir may not bleed properly and could lead to cavitation.

YES

NO

Reservoir & Pump Connections

The rear of the unit accepts various connections to integrate with your cooling

system.

FAN: Radiator fan connections

(2.0A max per plug, 4.5A total)

IN/OUT: Liquid fitting sockets

10

Installation

POWER: Connection from

power supply, 12VDC

TEMP: Temperature sensors

shown on the front display

ATX: Wire lead for safety shutdown relay. For computer use,

leave the 2-pin wire connected to “NO” (Normally Open) pins.

If this unit’s relay feature (see: “Alarm and Shutdown Settings”,

pg.4) will be used for an application requiring a Normally Closed

circuit, move wire lead to “NC”.

User Manual

PUMP:

Internal

pump

ON/SYNC/OFF:

Adjusts LED lighting

of INS-FM16 flow

meter

INS-FM17/INS-FM16:

Connect an optional

flow meter to display

flow rate

11

Page 10

Power Connection

ATX Pass-Through Lead

To Motherboard

The temperature sensors and ATX

lead may come pre-connected to

your unit. If not, connect them per

the diagram on page 11.

Attach the included power harness

to the location on the rear of the

unit marked “Power”. To this,

connect a 12 Volt 4-pin Molex

plug from your power supply.

Fan Connection

This unit has three connections to

power radiator fans. Multiple fans

can be combined into a single plug.

(A fan wiring harness is optionally

available from Koolance).

CAUTION: The total

combined amperage

!

of all fans connected to

the unit can not exceed

4.5A. The maximum

load on a single fan

header is 2.0A.

The ATX pass-through lead

is responsible for sending the

shut-down signal if any sensor

reaches the preset shutdown

temperature (See Display Panel

for configuration).

There is no polarity direction with

the ATX lead. Connect the male

ATX power lead from the cooling

unit to your computer’s main

chassis power button.

CAUTION: The auto shutdown safety feature of this product will not

function without properly connecting the ATX pass-through lead.

!

From Cooling

Chassis Power

Unit

Connect the female ATX power lead from

the Slot Adapter to the motherboard’s

power switch connection (often marked

“PWRSW”, “PWSW”, or “PWBT”).

This is the connection that would normally

receive the chassis power button

directly.

Button

Flow Meter Connection

The cooling system can show

values for one Koolance INSFM16, INS-FM17/N, or INS-FM18

flow meter (sold separately). The

use of a flow meter is optional.

Connect a flow meter to the

appropriately labeled plug. (Note:

INS-FM18 should connect to the

plug labeled “INS-FM17”.)

12

Installation

Temperature Sensor Placement

Three surface temperature sensors are

included with this product for monitoring.

Generally, sensors are affixed to water

blocks with metal tape. (Liquid temperature

sensors are also available optionally from

Koolance.)

Sensors should never be placed directly

between a heat source and its water block.

This will interfere with contact and can

damage the sensor or heat source.

User Manual

Chip contact

area

(keep out)

13

Page 11

Fittings

Cooler & Tubing Configuration

Install the G 1/4 BSP threaded fittings you

purchased for your unit. It’s recommended

to hand-tighten all fittings to avoid

damaging the unit.

Each hose connection will use a threaded compression

ring or hose clamp to keep it secure. Be sure to thread

the compression ring or hose clamp onto the hose

before attaching it.

Cut tubing into two segments. You

will need to connect each to the rear

fittings.

Squeeze the tube while pushing it

firmly over the fitting. Tubing should

completely cover the fitting.

There are a vast number of methods for configuring a liquid cooling system

(serial, parallel, combinations, alternating components, etc.). There is no single

“correct” way! As long as coolant is flowing and you are satisfied with your device

temperatures, it’s an acceptable configuration.

Similarly, the maximum number of water blocks allowed in a system will depend

upon your own configuration and thermal requirements. It’s common to see five or

more coolers in a Koolance system, but the limit is at what temperature you are

comfortable with.

Serial Loops

A basic serial loop is recommended for *almost* every situation. Provided your

cooling system has a radiator of sufficient size for your total heat load, expect only

a minor difference between outlet and inlet temperatures. In computer cooling,

a delta of less than 1 to 3ºC (1.8 to 5.4ºF) is typical for the heat exchanger. This

means for most loops, you don’t need to worry about “hot water” moving from

one block to the next. It gets only a little warmer throughout the entire loop.

Generally, series is the simplest and most effective configuration. Each device is

daisy-chained to the next, usually starting with the most temperature-critical:

Chipset

Block

Tighten the connection by sliding the

compression fitting down over the fitting

and screwing securely. For hose barbs,

use pliers to move it into the proper

position.

14

Wetting the end of the hose with warm

water can make installation much

easier.

Installation

Cooling System

(Radiator, Pump, Reservoir)

User Manual

CPU

Block

Video

Block

Video

Block

15

Page 12

Parallel Loops

Disconnecting Hoses

Parallel loops are normally used to help accommodate water blocks with

significantly disproportionate flow restriction. They can become quite complicated

and if not well-planned, may lower performance through added bottlenecks and

pressure drop.

One suggestion for parallel loops is to reduce tubing size when splitting. Ideally,

the hose area going into the splitter will be roughly equal to (or slightly lower than)

the combined hose area coming out. For example, 3/8” (10mm) tubing split into

two 3/8” (10mm) paths would lose more pressure than splitting from 3/8” (10mm)

into two or three 1/4” (6mm) paths.

If you are considering a parallel flow path, we would encourage you to experiment

with different setups. There may be more optimal configurations than the example

shown below.

Cooling System

10mm

CPU

Block

10mm

(Radiator, Pump, Reservoir)

Nozzles are designed to attach tightly. If you need to remove a hose for any reason,

it may not pull off easily, even after unscrewing the compression fitting.

Usually, a connection will come free by squeezing the hose on top of the fitting and

twisting/pulling away. If this fails, cutting a small incision lengthwise (parallel) along

the fitting will free it.

When a hose has been removed, it may be distorted. This last portion (about 1cm,

7/16”) should be trimmed to ensure a perfect fit with the next connection. The tip

should always be re-cut if you needed to remove the tubing with an incision.

16

10mm

Splitter

6mm

6mm

Chipset

Block

6mm

RAM

Block

RAM

Block

HD

Block

HD

Block

Chipset

Block

6mm

6mm

6mm

Splitter

Installation

Hose Lengths

Before installing your liquid coolers,

appropriate lengths of tubing must be cut

to connect each device. For computer

cooling, it’s generally easier to estimate

the required amounts with hardware

already mounted.

On the rear of the unit, the inlet and outlet

locations will be labeled. Generally, the

outlet will connect first with your CPU

Cooler or the most temperature-sensitive

device.

User Manual

Coolant

Inlet

Coolant

Outlet

17

Page 13

With the connected outlet

hose, roughly estimate the

length you will need to your

first cooler, and cut it.

Cut the second hose with

enough length to reach the

last water block that will be in

your system.

Liquid Coolers

You should now install the liquid coolers (CPU, GPU, Hard

Drive, etc.) to your hardware before continuing this User Manual.

Please refer to your cooler kit’s individual installation instructions,

then continue on to the next section.

Using the leftover tubing, cut

shorter pieces to link between

each individual cooler.

NOTE: When filling the reservoir later, it will need to be pulled out from the front

chassis drive bay by about 2.75” (7cm). Be sure to leave enough tubing between

the reservoir unit and connected components to do this.

Continue connecting all of

your coolers in the system

until there are no longer

any open tube ends.

Chapter3

Filling & Maintenance

WARNING: The cooling system’s pump can not be run dry for any

!

period of time. Never power-on the computer or cooling system without

sufficient liquid in the reservoir. Dry-running (and thereby damaging

the pump) is not covered under the Koolance product warranty.

18

Installation

User Manual

19

Page 14

Testing & Filling

Once all the water blocks have

been connected, the system can

be filled with coolant. The fill port is located on top

of the reservoir. Free this component by removing

its side drive screws. Slowly pull it out just enough

to expose the refill plug (about 2.75”, 7cm).

The cooling system should be powered on to assist in the filling process. This also

allows you to check hose connections and make sure there are no tubing folds,

leaks, or blockages. If cooling a computer, this can be done without powering on

other hardware for extra safety (see below).

CAUTION: Jumping the incorrect ATX power supply pins can cause

permanent damage to the power supply.

!

WARNING: Most coolants are electrically conductive. Use caution

when filling the system, and keep all liquids away from electronics and

!

power cables. In case of emergency during installation, immediately

unplug the primary AC power cable. Dry the system thoroughly before

proceeding.

Slowly fill the system. To maintain the product

warranty, use only Koolance approved coolant.

Many alternative liquids and additives can cause

permanent damage to the cooling unit (through

chemical reaction, corrosion, biological growth,

thermal expansion, viscosity, etc.).

Replace the fill port on the reservoir. Do not overtighten the fill port.

Make sure the AC power cord is attached to the power supply. If the power supply

has a rear switch, it must be set to the ON (-) position. Using the included green

Jumper Wire, insert the metal prongs into the fourth and sixth holes on the 20-24

pin ATX motherboard power supply plug as labeled below (usually green and a

black ground wire; See diagram).

If your pump has a speed control option, set it to the lowest level during

this time. Allow the pump to run until the liquid noise subsides.

During this process, cooling systems often need to be tilted gently

to allow air to escape from the pump and radiator. Until the pump

is “burped” in this manner, it can cavitate and there will be no

circulation. (This does NOT indicate a problem with the pump.)

The reservoir level will decrease during this procedure. Remove the

fill port cap and add more liquid when needed. If you frequently hear

this rushing noise in the future, it usually indicates the need for more

coolant.

20

Filling & Maintenance

That’s it! Replace the ATX motherboard connection and boot-up the computer.

User Manual

21

Page 15

Adding Coolers & Maintenance

Troubleshooting

With normal use, Koolance’s liquid coolant should be replaced every 2-3 years. If

it ever becomes contaminated, unclear, or significantly changes color, it should be

replaced immediately. A Koolance “drain valve” (sold separately) is recommended

to make that process easier.

If you are upgrading or removing a cooling block in your system, please follow the

instructions below.

CAUTION: Any time a hose is disconnected with coolant still inside,

!

Working on a liquid cooling system is much easier and safer when liquid coolant is

removed beforehand. However, certain procedures can be done without removing

the coolant.

A binder clamp (available at office supply stores) is helpful for keeping a hose folded

while removing or adding coolers. Even so, pressure within the cooling system is

such that liquid will not easily flow out unless relieved elsewhere-- for example, by

opening the reservoir fill port.

Bend the hose directly before and after the section to be worked on. Place a binder

clamp on both bends, or tie them in this position to help avoid fluid loss. There will

be some liquid exposed; do not operate on the cooling system in this manner near

or above electronic hardware.

leaking will occur. It is highly recommended to empty your cooling

system of coolant before disconnecting any hoses.

We hope your Koolance system will provide you with years of reliable cooling

performance. To help avoid unnecessary RMA issues, we have prepared this list

of possible operational problems, and their most common solutions.

1. The pump does not appear to be operating properly...

Pumps need to be “burped” during the initial bleeding process to avoid this

situation. Reduce pump speed (but not low enough to stop the pump).

While the pump is running, gently tilt the system in various directions until

coolant begins moving. Open the fill port to relieve excess air.

2. My temperatures seem too high...

Verify that the liquid coolers are making sufficient contact with each

component. Ensure thermal paste has been applied (but not excessively),

that the block’s protective bottom film has been removed, and that the water

block is positioned correctly (see the cooler’s manual). Also check there are

no blocks, twists, or crimps in the tubing.

Finally, a dusty Radiator can result in higher temperatures. Please see

Draining and Maintenance for more information.

3. When I adjust the temperature alarm settings, it skips number increments...

This is normal operation if your display is set to display in Fahrenheit, because

the temperature program is based on units Celsius. Some ºC values convert

to decimal temperatures in ºF, or skip over them, and these can not be set by

the program.

Radiator Performance

Over time, dust will accumulate on the radiator. While the cooling system may

continue to operate in this condition, performance can decrease. To keep the

system clean, check the radiator periodically (through the top fan grill) and use

a can of electronics air cleaner if necessary.

22

Filling & Maintenance

4. After the system has been on for awhile, the temperature alarm sounds...

Make sure the temperature is at or above your preset alarm temperature (default is 50ºC, 122ºF). If not, the audio alarm may be emanating from another

location, such as your motherboard’s BIOS alarm or video card. The Koolance

temperature will flash whenever the cooling system alarm sounds.

If the alarm is produced by the Koolance unit and the display temperature

has not reached the alarm preset, please contact our technical department.

Also verify that the fans and pump are operating (see Troubleshooting #1),

and that liquid movement is present in the reservoir.

User Manual

23

Page 16

5. My system has boot-up problems, or does not turn on...

10. The flow meter reads “0”.

Make sure the ATX wire lead is connected to “NO” (Normally Open) on the rear

of the unit. (See: “Reservoir and Pump Connections” for details.)

If this does not solve the issue, it is unrelated to the Koolance unit. In a computer,

a problem with the RAM, motherboard, power supply, video card, processor,

or monitor can cause the system to appear not to boot-up properly.

6. My system appears to be leaking fluid...

It is possible a connection was not properly sealed (however unlikely). If you

can see liquid somewhere on the tubing, or at the bottom of the chassis,

computer components may need to be removed for a system test (see Testing

& Filling).

If liquid should get onto another computer component, shut down the system,

and remove the component. In many cases, the hardware will be fine after

allowing it to dry. However, the system should not be operated until you have

discovered where the leak is coming from and can repair the problem. Should

the leak be situated somewhere where it can not be easily repaired, please

contact our Technical Department for further assistance.

7. My computer’s BIOS gives me errors that there is no cooling fan attached...

Some motherboards will not boot, or may generate an error or alarm if no

cooling fan is attached to the CPU or motherboard chipset power connectors.

There is typically an option to disable this warning in BIOS, but you may

need to boot with a fan attached initially to disable this setting. If the system

is not booting due to this problem, clear the CMOS and try configuring BIOS

again.

Make sure the Koolance flow meter you have purchased is directly connected

to the back of the unit (See Connecting the Unit). Also be sure the correct flow

meter model and tubing ID are selected via the front display (See Display

Panel).

8. The Display Panel shows “OPEN” for a temperature sensor...

This indicates a temperature sensor was not found for the specified channel.

If there is no sensor connected to that channel, this is its normal status.

9. The front display is locked up or not responding.

This can happen if the unit is powered off within 5 seconds of being powered

on. Reset the display to manufacturer defaults by holding ▼ + ▲ for 5 seconds.

Three beeps will be heard to indicate the unit was reset. After a reset, all configuration settings (temperature, alarm, fans, etc.) must be updated again.

24

User Manual

25

Page 17

Limited Warranty

Koolance Incorporated (“Koolance”) warrants each new Koolance liquid-cooled

system (“the system”), against defects in materials or workmanship for a period of

one year from the date of purchase, and agrees to repair or replace any defective

Koolance system without charge. Shipping costs are non-refundable.

This warranty is non-transferable. All warranty claims must be accompanied by the original

proof of purchase.

THIS WARRANTY DOES NOT COVER DAMAGE RESULTING FROM ACCIDENT,

MISUSE OR ABUSE, LACK OF REASONABLE CARE, SHIPPING DAMAGE,

MODIFICATIONS, THE AFFIXING OF ANY ATTACHMENT NOT PROVIDED WITH

THE PRODUCT, LOSS OF PARTS, OR OPERATING COMPONENTS AT SPEEDS OR

FUNCTIONS OTHER THAN THOSE SPECIFIED BY THEIR MANUFACTURERS.

Use of unauthorized replacement parts or liquids will void this warranty. Koolance

Incorporated will not pay for warranty service performed by a non-authorized repair

or diagnostic service and will not reimburse the consumer for damage resulting from

warranty service performed by a non-authorized repair service. No responsibility is

assumed for any special incidental or consequential damages due to a defective Koolance

product.

In order to obtain warranty service, contact our RMA department for information. The

product must be shipped postage prepaid to an authorized Koolance service location. It

is suggested that, for your protection, you return shipments of product by insured mail,

insurance prepaid. Damage occurring during shipment is not covered by this warranty.

Shipping costs are non-refundable. No other warranty, written or oral, is authorized by

Koolance Incorporated.

Disclaimer

IN NO EVENT SHALL KOOLANCE INCORPORATED OR ITS EMPLOYEES, AGENTS,

SUPPLIERS, MANUFACTURERS, OR CONTRACTORS BE LIABLE FOR ANY

DAMAGES OF ANY KIND OR CHARACTER, INCLUDING WITHOUT LIMITATION

ANY COMPENSATORY, INCIDENTAL, DIRECT, INDIRECT, SPECIAL, PUNITIVE, OR

CONSEQUENTIAL DAMAGES, LOSS OF USE, LOSS OF DATA, LOSS OF INCOME OR

PROFIT, LOSS OF OR DAMAGE TO PERSONS OR PROPERTY, CLAIMS OF THIRD

PARTIES, OR OTHER LOSSES OF ANY KIND OR CHARACTER, AND WHETHER

OR NOT THE POSSIBILITY OF SUCH LOSS OR DAMAGE HAS BEEN NOTIFIED TO

KOOLANCE INCORPORATED.

26

Loading...

Loading...