IA

KONTRON

INSTRUMENTS

HPLC

GRADIENT

FORMER

Instruction

manual

-K

Instruction manual

GRADIENT

FORMER

425

HPLC

*-~\4

Checking

TABLE

1.l

OF

CONTENTS

INSTALLATION

Unpacking

1.2

Shipping

1.3

Checking

the

l.5

Installation

1.5.1 Pump

1.5.2

1.5.3

1.5.4

1.5.5

1.5.6

2

list

2

the

serial

mains

Installing

Liquid

Electrical

Gas

Control

supply

4

modification

connections

purge

Computer

number

3

the

gradient former

connection

7

3

4

5

6

6

7

page

2.

INSTRUMENT

General description

2.1

Specifications

2.2

Front

panel

2.2.1 Controls

2.2.2 Status display

DESCRIPTION

2

2

3

3

3

11.86

0

GENERAL INFORMATION

- l -

Instruction

manual

GRADIENT

FORMER

425

HPLC

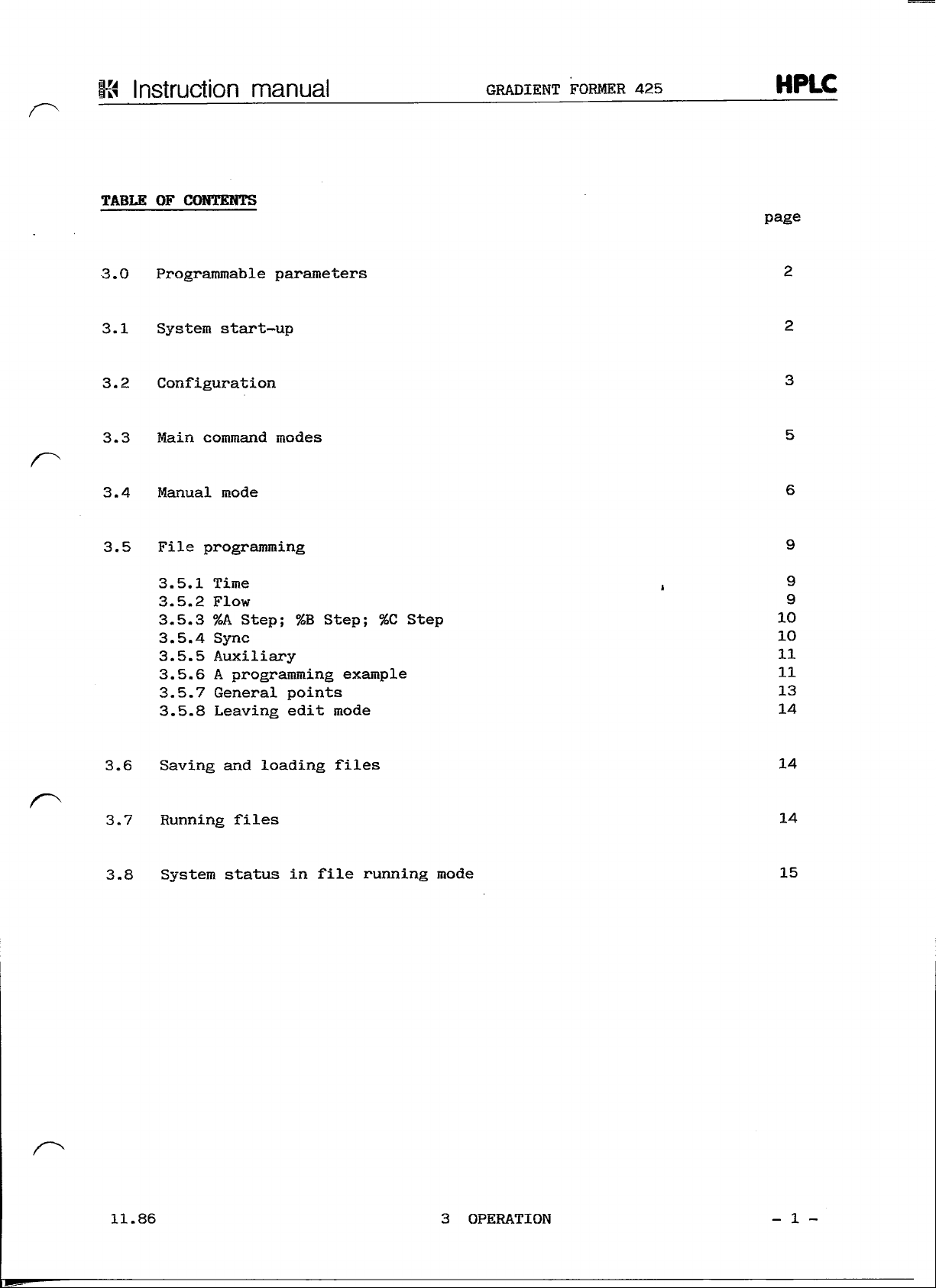

TABLE

3.0

3.1

OF

CONTENTS

OPERATION

Programmable

System

3.2

Configuration

3.3

Main

3.4

Manual

3.5

File

command

programming

3.5.1 Time

3.5.2

3.5.3

3.5.4 Sync

3.5.5

3.5.6 A programming example

3.5.7

3.5.8

(cont.)

parameters

start-up

modes

mode

6

9

Flow

9

%A

Step;

10

Auxiliary

General

Leaving

2

2

3

5

9

%B

Step;

11

points

edit

mode

%C

Step

10

11

13

14

page

3.6

Saving

3.7

Running

3.8

System Status

4.

TROUBLE

4.1

Operation errors

4.2

Software error

5.

MAINTENANCE

5.1

Routine

5.2

Spare

and

files

SHOOTING

maintenance

parts

loading

in

3

files

14

file

2

messages

14

running

3

2

mode

15

11.86

0

GENERAL INFORMATION

- 2 -

13

Instruction

manual

GRADIENT

FORMER

425

HPLC

TABLE

l.

1.l

1.2

1.3

1.4

OF

CONTENTS

INSTALLATION

ünpacking

Shipping

Checking

Checking

1.5

Installation

1.5.1 Pump

2

list

2

the

serial

the

mains supply

4

modification

number

3

3

4

page

1.5.2

1.5.3

1.5.4

1.5.5

1.5.6

Installing

Liquid connections

Electrical

Gas

purge

Control

the

gradient former

connection

7

Computer

7

5

6

6

11.86

l

INSTALLATION

- l -

Ki

Instruction

TL.

INSTALLATION

1.1

UNPACKING

manual

GRADIENT

FORMER

425

HPLC

Compare

main

following

immediately

1.2

SHIPPING

The

1

2 m

1

2

2

3

l

6

l

l

l

l

l

l

l

the

consignment

unit

following

91-00553

07-89023

55-65601

62-13001

62-13002

66-00452

91-00560

92-00910

92-00904

93-00667

93-00668

95-00196

91-00568

52-69103

52-69104

are

packed

shipping l ist and

should

LIST

items

any

with

in a

parts

are

included

Gradient Former

Gas

Mains

Fuse

Fuse 0.63 A (220V)

Solvent bottle

Outlet tube

Inlet

Inlet

Computer cable

Pump

Instruction manual including Software

Conversion

Connector,

Connector,

the

delivery

single box. Check

inform

be

missing.

your

äs

Standard

supply

cable

1.0 A

filter

valve

420

note.

local

accessories:

tube

(110V)

connection

cartridge

cable

kit,

4 way

6 way

Both

the

KONTRON

425

pump

accessories

contents

representative

(titanium)

420

against

and

the

03.87

l

INSTALLATION

- 2 -

Instruction

1.3

CHECK

The

This

note.

THE

plate

number

manual

SERIAL

with

the

must

HUMBER

be

GRADIENT

number

identical with

is

mounted

FORMER

on the

the

rear

serial number

425

side

of the

on the

HPLC

Instrument.

delivery

1.4

CHECKING

The

with

selector (see

Possible

The

the

Frequency

Voltage

THE

MAINS

Gradient Former

other

fuses

mains supply voltage.

mains

operating

on the

adjustment

selector

SUPPLY

425 is

voltages

below)

situated

voltages:

voltage selector have

is not

factory

the

correct voltage must

at the

100, 120, 220,

necessary.

set for

rear

to be

-

Unplug mains

-

Open

screw driver

-

Pull marker

to

the

-

Push

-

Pull

insert

220V

of the

the

(B)

out

50/60Hz.

be set on the

Instrument.

240

VAG

changed

snap-cover

required position.

back into position.

fuse

the

to

cable

at the

wheel

holders

correct fuse.

For

correspond with

(B) and

(A)

top.

Operation

voltage

using

turn

(G)

a

it

and

11.86

-

Push holders

tion,

-

Close

-

Check

displayed.

l

INSTALLATION

(C)

back into posi-

obey arrows.

snap-cover (A).

if the

correct voltage

is

- 3 -

Instruction

1.5

INSTALLATION

The

Gradient Former

It

has

(head

A

conversion

convert a normal pump

The

Installation

not

exposed

be

between

Allow

manual

been developed

part

at

no.

kit is

to

10°C

least

91-00504).

site

dust

and

2 cm

GRADIENT FORMER

425 is an

to

included

420 for

of the

or

corrosive vapors.

35°C.

space

around

accessory

operate

in the

Operation with

gradient

the

for the

with

the

accessory

system

The

System.

425

KONTRON HPLC pump

medium

kit.

the

should

ambient

head

This

gradient former.

be

such that

temperature should

for

this pump

kit is

HPLC

420.

used

it is

to

1.5.1 Pump

The

tion

The

91-00504).

The

with

the

Modification

pump

pump

connection between

420

must

84-00261

pressure-proof

inlet

enclosed with

420

must also

valve

cartridge

be

modified

connections.

be

the

äs

described

the

conversion

fitted

gradient former

in the

with a medium pump head (part

It is

pump head.

in the

kit.

and the

therefore necessary

Installation

pump must

instruc-

no.

be

to

replace

made

11.86

Fig.

1.5.1

l

INSTALLATION

Pump

42O

-

4 -

Ki

Instruction

1.5.1

Pump

The

cartridge

manual

Modification

is

GRADIENT FORMER

(cont.)

replaced

äs

follows:

425

HPLC

NOTE:

1.5.2 Installing

pump

Remove

at

(A) in

Remove

Insert

retaining nut.

IMPORTANT:

Screw

Using a Spanner tighten

420

91-00554,

valve

the

original fitting

fig.

the

original cartridge.

the

cartridge supplied with

The

the

retaining

the

Gradient

fitted

have already been fitted with

cartridge.

1.5.1.

black

pump

head.

with

plastic

nut

Former

the

inert pump

by

unscrewing

sealing

back into

one

füll

the

the

turn

surface

pump head, finger

(approx.

kit

Option article

the

the

retaining

gradient

must

80

correct

nut

former

face into

tight.

cmkp).

inlet

shown

into

no.

the

the

Prior

to the

be

made.

-

Remove

the

-

Check

tightness.

-

Check

äs

—

Replace

The

Gradient Former

solvent bottles should

NOTE:

It

System

no.

initial

the top

unit).

all

all gas

far

äs

possible into

the top

is

recommended

organiser accessory

91-00530).

cover (remove

connections

connections,

425

Installation

to the

ensure

the

cover.

should

be

that

be

placed

the

on top of the

for

the

following

the

four fixing

3-way solenoid valve manifold

that

fitting.

installed

solvent bottles

safer

below

storage (not supplied, part

Instrument

the

supply

the 420

pump.

are

screws

tubes

placed

on the

HPLC pump.

checks

are

in the 420

must

base

for

pushed

The

of

l»

11.86

l

INSTALLATION

- 5 -

Instruction manual

GRADIENT FORMER

425

HPLC

1.5.3 Liquid

Gradient Former - Solvent Reservoir

Push each solvent supply

hole

in the

three

together.

Push

one of the

tube

in the

The

connecting tubes

button

Gradient

The

outlet tube

gradient

the

gradient former

CAUTION:

Gonnections

solvent bottle cap. Note

pairs,

and a

l and 11, 2 and 22, 3 and 33.

appropriate sample bottle.

syringe

Former - Pump

former should

The

Spanner

and gas

filters supplied into

can

be

primed

attached

420

connection

be

and the

fittings

to

hold

(part

connected

pump

must

the

purging

initially using

to the end of the

no.

inlet

not be

retaining nut.

tube

that

the end of each

91-00560)

between

fitting.

over-tightened.

through

the

tubes

These

pump

the 420

the

appropriate

are

organised

should

tube

the

connection

supplied1

pump connection

and

appropriate

Use a

be

place

purge

tube.

with

second

äs

kept

the

the

on

1.5.4 Electrical

Connect

and

Gas

Inlet

both

switch

Purge

Connections

pump

on

both

and

units.

Connect

gradient

pump

gradient former

ion

former

420

to a

suitable

Connection

gradient

IBM-compatible

mains

former

power

-

PC

supply

11.86

Fig.

1.5.4

Electrical Connection - Gradient

l

INSTALLATION

Former

-

6 -

Instruction

1.5.4

Electrical

manual

Connections

GRADIENT

(cont.)

FORMER

425

HPLC

1.5.5

Connect

connection

gradient former with

Connect

signal

"sync"

Connect

HPLC

connections

Gas

The

The

sing

tion

vents

The

for

A

suitable inert

former. Push

into

to

the

pump

on the

the

SYNC input

on the 460

function

the

required auxiliaries

System components

and

Purge

gradient former operates

solvent

during

of the

with inert

gradient former

controlling

the gas

an

inert

mixing

mixing

gas

420

pump

autosampler

is

Programming

System. This

gas

gas

gas

the

supply tube supplied with

purge inlet connection (see fig.

supply

connection

420. Connect

the

COM-1

on the

given

occurs

can

flow

in

if

required. A detailed description

in the

therefore

prior

is

fitted with

to the

connection

at a

on

the

gradient

the

on the

gradient former with

if

section

for

is

given

on the

can

generally

to

starting.

different solvent

must

pressure

IBM-compatible

required. A detailed description

3 of

inlet tube

occur

this

eontrol

is

section

low

pressure

and

be

three

not

independent

therefore

exceeding

former

Computer connection

manual.

of the

3 of

inlet

and

pump

interfere

avoided

reservoirs.

be

made

the

gradient former

1.5.4).

0.5

with

personal

the

remote/continue

autosampler

of

this manual.

to the

head

with

by

itself.

correct

purging

regulating

to the

Connect this tube

bar.

the RS 232

on the

Computer.

of the

or

other

auxiliary

pump

420.

Degas Opera-

the

sol-

valves

gradient

firmly

1.5.6

W

A R N I N G : The

Control

The

Computer.

supplied

The

RS

ching

Computer

gradient System

This Computer must

with

gradient former System requires a single floppy disk

232C

interface

etc is

the

carried

System

solvent

installed

The

exceed

is

Computer.

slot.

storage bottles.

maximum

O.5

controlled

No

out

within

is not

such

inlet pressure

bar.

be

further

designed

that

via an IBM (or

installed

hardware

the

gradient former.

no

pressure

äs

to

operate with

The

for the

described

is

required, auxiliary

pressurized

bottles must

build-up

purge

compatible)

gas

in the

drive

always

can

occur.

must

personal

handbook

and one

be

not

swit-

03.87

m-

—

l

INSTALLATION

- 7

-

S

Instruction

TABLE

OF

CONTENTS

2.

INSTRUMENT DESCRIPTION

manual

GRADIENT

FORMER

425

HPLC

page

General

2.1

Specifications

2.2

Front

panel

2.2.1

2.2.2 Status

Controls

description

2

3

3

display

2

3

11.86

2

INSTRUMENT

DESCRIPTION

- l -

2.

GENERAL

/~\1

SPECIFICATIONS

Instruction

DESCRIPTIQN

The

Gradient Former

allows

side

in

The

troller

System

formation

of the

the

gradient System.

unit

and is

and

manual

425 is an

of

binary

pump

and

thus

is

designed

supplied

solvent reservoirs.

to

operate

complete

GRADIENT

accessory

and

ternary

requires

with a personal Computer

with

FORMER

to the

gradients

only a single high pressure HPLC

connection

425

KONTRON

on the

cables,

HPLC

äs

a gas

pump 420.

low

pressure

System Con-

purging

HPLC

It

pump

Solvent

Gas

Gradient

Gradient

Compositional

Compositional

storage:

purge:

capability:

increment:

accuracy:

precision:

3x11

3

independent regulating valves

control

inlet

Linear

2 or 3

Typically

water/water + 0.5%

and

ml/min.

Typically

runs

50%B,

glass

of

pressure

or

step gradients from either

solvents.

H-

10%B

for a

step gradients

HH

conditions

bottles

inert

0.4% measured over

step gradient from

gas

0.5,bar.

1.5%

acetone

and

purge,

measured

mixtures

at 1.5

flow

äs

above.

for

max.

with

10

0% to

11.86

2

INSTRUMENT DESCRIPTION

-

2 -

K<

Instruction

2.2

FRONT

manual

PANEL

GRADIENT FORMER

425

to

pump

HPLC

420

Power

ON/OFF

2.2.1 Controls

Gradient control

Computer.

ments

Purge Button

Pressing

noid

äs

valve

long

äs

Gas

Purge Regulation

The

three

ging

gas

Fig.

and

The

described

one of the

the

into

gradient

to be

gas

switched

purge button

purge regulating valves control

the

Purge button

Valve

2.2

Gradient

parameter

former

below:

three purge buttons

corresponding solvent reservoir.

Status

input

therefore

to

its

open

is

kept pressed.

LED

Former 425, Front

is

carried

contains

causes

position.

out by the

the

It

the

Gas

purge

regulating

valve

panel

only

two

control

corresponding

remains

rate

open only

of

flow

controlling

ele-

sole-

äs

of

pur-

2.2.2 Status Display

Three

LEDs indicate

valves. A valve

11.86

the

is

switched

current Status

to

open

2

INSTRUMENT DESCRIPTION

when

of

the

each

of the

corresponding

three solenoid

LED is

lit.

- 3 -

-S

Instruction

manual

GRADIENT FORMER

425

HPLC

TABLE

3.0

OF

CONTENTS

Programmable

3.1

System

3.2

Configuration

3.3

Main

3.4

Manual

3.5

File

command

programming

3.5.1 Time

3.5.2

Flow

3.5.3

3.5.4 Sync

3.5.5

3.5.6 A programming example

3.5.7

3.5.8

parameters

start-up

mode

%A

Step;

Auxiliary

General points

Leaving

2

3

modes

6

9

, 9

9

%B

Step;

10

11

edit

2

5

%C

Step

13

mode

14

10

11

page

3.6

Saving

3.7

Running files

3.8

System status

and

loading

14

in

files

file

running mode

14

15

11.86

3

OPERATION

- l -

K4

Instruction

3.0

PROGRAMMÄßIG

The

Gradient Former

lowing

-

Total

-

Percentage composition

solvents.

-

Synchron!zation

HPLC

-

Switching

Gradient

manual

PARAMETERS

functions:

flow.

Autosampler

of up to

Former 425.

GRADIENT

425

of

gradient

460).

four

Software

of

potential-free

allows

mixtures

start

with

Computer control

containing

an

relay

FORMER

autosampler

425

HPLC

up to 3

contact closures

of the

different

(e.g.

fol-

KONTRON

in the

Control

which

for

3.1

SYSTEM

The

section

pump

connected

PC.

CAUTION:

"

Never

Make

cribed

Using

such

load

in

of

these

contains

each instruction.

START-UP

gradient

l of

should

copies

in

the

that

the

the

operating instructions

former

this

be

between gradient former

Before using

you

of

your Computer handbook.

format/s

an

autoexec batch file

GF425

functions

a set of

and

manual.

connected

must

your control Software using

Software

make

work with

command

is

exercised

instructions with a corresponding execution

pump

the

at

420

The

Signal

and the

Software

at

least

the

master disk supplied with

in

MS-DOS

system

for

should

control cable

and

one

can be

start-up.

your Computer.

via a

cable

COM1

supplied

back-up copy

you can

created which will automatically

program

be

installed

between gradient former

to the

on an IBM or

with

the

diskcopy

format

This procedure

file

the

for

your duplicate disk

of

äs

described

gradient former

IBM-compatible

gradient former

your

own

the

command

is

type .PRG

time

in

and

use.

unit.

äs

des-

described

11.86

3

OPERATION

- 2 -

Instruction

3.2

CONFIGURATION

manual

GRADIENT

FORMER

425

HPLC

Insert

GF425

the

Fig.

the

followed

following

KONTRON

File

name:

l

ime

[min]

3.2.1

copy

of

by

your

(CR)

mask will

HPLC

Flow

[ml]

A

Step

m m

Configuration

Continue,

Start

menu

master

or

enter.

be

TERNARY

Repeats

cannot

without

disk

The

displayed.

GRADIENT CONTROLLER

l of l l

B

Step

m

i%]

be

C

[*)

INFORMATION

read,

please

Configuration

in the

control

Pressure.

Step

re-configure

appropriate

Software

will

425

Upper-.

Syn

Auxiliary

1234

drive

be

300

Lower:

and

loaded

Vers.

[sec]

type

and

1.11

The

configuration

cannot

working disk. This will

ration.

Press

"C" to

starting mask

KONTRON

File

name:

Time

[min]

SELECTED

MODES:

Flow

[ml]

MODE:

Run.

continue.

shown

Manual.

below:

HPLC

A

Step

W

(%]

MAIN

OPTION

Edit.

The

be

read because

be

automatically created

no

CONFHPLC

screen will then change

TERNARY GRADIENT CONTROLLER

Repeats

B

Step

(*]

MENU

Load.

l of l

(%]

Save.

Dir,

Pressure,

Step

Syn

Config.

file

at the

to

425

Upper:

1234

Quit.

exists

first configu-

display

200

Lower:

Auxiliary

the

Vers.

[sec]

on the

normal

1.11

3.2.2 Normal Starting Menu

11.86

3

OPERATION

- 3 -

Instruction

3.2

CONFIGURATIQN

The

system

the

configuration

limits

end

of a

the

configuration

KONTRON

File

manual

must

for

file

name:

(cont.)

the

batch

PUMP

HE

be

configured

file

pump

420,

and the cam

menu

HPLC

TYPE

AD

is

used

whether

shown

below.

TERNARY

GRADIENT

before

proceeding.

to

define

the

correction

GRADIENT

pump

FORMER

For the

the

upper

should

factor.

CONTROLLER

Medium

425

and

be

switched

Select

425

420

HPLC

gradient

lower pressure

"C"

Vers.

former

off at the

to

obtain

1.11

PRESSURE

PUMP

CAM

SELECTED

MODES:

Set

Fig.

3.2.3 Configuration Menu

The

cam

make

ned.

It

no

effect

factor

NOTE:

MODE:

ESC

pressure

CONFIGURATION

limit

correction factor

small

corrections

is

strongly

on

reproducibility

for

service use.

You

should

LIMITS

OFF AT END OF

CORRECTION Factor:

(0 - 400

recommended

definition

Set

the

required pressure limits

ponding

together

in

leaving

all

field

with

cases.

the

and

the

ränge

The

entry field using

entering

entry

Upper:

Lower:

BATCH

bar):

is set to a

to the

linearity

and is

only

of

therefore

system pressure limits.

the

of

permitted

can be

the

(Y/N)?

200

default

of the

that

this

primarily

use the

by

moving

value required.

entries

completed

Cursor

keys.

200

0

Y

5

value

of 5 and is

gradient profile

factor

the

by

is not

intended

configuration

cursor

The

is

shown

changed.

äs a correction

module

into

the

value entered

on the

either pressing RETURN

used

obtai-

It

corres-

last

to

has

for

line

or

11.86

e.g.

to

-

-

- The

"Pump

off at end of

should

Enter

be

Y if the

continue

Once

you

enter

Move

Enter

at the

have

an

upper

the

cursor

250 and

value

of 250

switched

pump

last

set the

configuration menu.

on

your working copy.

limit

to

of 250 bar

upper limit.

proceed

äs

follows:

press RETURN.

will

batch

off at the end of a

should

set

flowrate.

be

displayed

(Y/N)"

be

switched

is

äs

the

upper limit.

used

to

batch

define whether

of

program

off and N if the

required pressure limits press ESCape

The

CONFHPLC.DAT

3

OPERATION

file will

be

automatically

the

files

pump

to

leave

pump

or

not.

should

the

created

-

4 -

K

Instruction manual

3.3

MAIN

COMMAND

A

brief

starting

RUN:

MQDES

description

menu

is

is

given

used

of the

below.

to

main

start a program

GRADIENT

command

file

FORMER

modes

or a

425

available from

batch

of the

the

same

HPLC

main

file.

MANUAL:

EDIT:

LOAD:

SAVE:

DIR:

CONFIG: selects

QUIT:

Selection

name,

e.g.

allows

is

used

is

used

is

used

disk.

gives a directory listing

stored

returns

of any

R for

command

RUN.

execution

to

create

to

load a previously created program file from disk.

to

störe a previously created

on the

the

you to

of

manually

or

modify

working

configuration

MS-DOS

is

made

disk.

by

entered

program

of all

menu.

entering

instructions.

files.

or

modified file

program (PRG) type files

the

first letter

on

of its

11.86

3

OPERATION

- 5 -

Instruction

3.4

MANUAL

manual

MODE

GRADIENT FORMER

425

HPLC

Select

following

Fig.

"M"

KONTRON

File

neune:

Time

[min]

0,0

Duration

SELECTED

COMMANDS:

Duration

3.4.1

from

menu will

Flow

[ml]

[min]

0.0

0.0

MODE:

ESC.

(0..9999

Manual Operation Menu

0.0

the

Starter

be

HPLC

A

Step

0

Flow

[ml ] [%]

0.0

100 0 0

0.0

100 0 0

MANUAL

Execute.

min):

menu

offered:

TERNARY

Repeats

B

Step

0

ABC

[%] [%]

Aux

only.

0.0

to

enter manual

GRADIENT

l of l

Stop

flow,

CONTROLLER

Pressure.

Step

Syn

Auxiliary

1

0

0

Interrupt,

mode

Upper:

2

0

0

Operation,

425

200

Lower;

Auxiliary

1234

[sec]

4

3

0

0

0

0

Vers.

[sec]

The

1.11

All

entries

the

window.

The

top

values

e.g.

CAUTION:

for the

the

instruction

been

made

line

of

duration

completed.

The

is

correct solvent composition

ted

in

manual Operation

this

various

status line

first

äs

window

parameter.

field

or the

It

selected. Before

described

is the

always

last

is

shows

set

updated every

is set to

in the

are

status

the

value

of

1009SA

starting

for

following

entered

line

and

elapsed

duration

0.1

minutes.

äs

default

your

your

example.

on the

displays

time

if the

pump

column

bottom

since

gradient

when

ensure

has

line

the

current

the

manual

that

been

of

last

has

mode

the

selec—

03.87

3

OPERATION

-

6 -

Instruction

3.4

MANUAL

manual

MODE

(cont.)

GRADIENT

FORMER

425

HPLC

Example

Assuming

flow

-

Move

-

Enter a time

-

Enter a flow

-

Enter

-

Enter

-

Press

The

Example

Using

linear

time

l,

Manual Mode Operation

you

of l

Status

of 10

ml/min.

the

Cursor

80 for

20 for

"E" to

line

2,

Manual Mode Operation

example l äs

gradient

minutes.

wish

to set

(if

of 0,

of

l,

%A,

press RETURN.

%B,

press RETURN.

execute this

will

starting conditions

from

your

starting

necessary)

press RETURN

press RETURN.

instruction.

change

0%C

to

to

display a flow

80%C

conditions

to

duration.

(or

move

Cursor

of

1.0,

and

assuming

with a constant

to

80%A

right).

80%A

you

20%B

and

20%B

and

20%B.

wish

component

to run a

at a

in a

-

Move

-

Enter a time

~

Press RETURN

-

Enter

-

Press RETURN

-

Enter

-

Enter

the

Cursor

0 for

80 for

"E" to

(if

necessary)

of 10

to

%A,

to

%C,

execute this instruction

minutes, press RETURN.

enter

press RETURN.

enter

press RETURN.

the

default

the

default value

to

duration.

value

of l for the

of 20 for

and

start

%B.

the

gradient.

flow.

11.86

3

OPERATION

- 7 -

InstfUCtion

3.4

MANUAL MODE

Step

Step

the

duration.

Aux

only

Each

period

and

gradient instructions

the

contact closure

flow data.

It

is

associated flow data,

The

auxiliary

tions even

manual

(cont.)

Gradients

gradients

of the

of up to 99

however

Cursor

in the

switching

if a

GRADIENT

can

be

carried

four

auxiliary

seconds.

in the

also possible

if

bottom

times

gradient

out by

contacts

This

by

simply entering

appropriate auxiliary

to

enter auxiliary contact

this

is

line

is

will spring

and

then

running.

simply entering a value

can be

can be

required press

press

entered

"E" to

FORMER

switched

the

to Aux 1. You can

425

HPLC

on

manually

in the

field

"A" to

execute these

same

required duration

when

commands

way

entering

select

of 0 for

for a

äs

flow

of

the

without

Aux

only.

now

enter

instruc-

Stop

flow

Pressing

"Continue"

set

at

the

stopped.

Interrupt

Pressing

is

pressed.

time

NOTE:

Leaving

"S"

value.

time

"I"

of

Interruption

After both "Stop flow"

Manual Mode

will

set the

and you

The

time

of

restarting

will cause

The

gradient will continue

the

choice

gradient

operating

pump flow

must

press

will continue

the

i.e.

of

and

mode.

"C"

will

time

isocratically.

"Abort"

return

to 0.

to

restart

to

run

be the

you to the

to be

and

which

same

stopped

at

"Interrupt"

will

Stop flow

the

internally. Gradient conditions

äs

if the

until

those values

immediately

starter

is

flow

you

menu

then replaced

at the

flow

"C"

are

originally

had

not

(for Continue)

current

also

stop a running

for the

by

been

at the

offered

current

-^

main

11.86

To

leave

3

manual

starter menu.

mode

Operation press ESCape which will return

OPERATION

you to the

- 8 -

l

nstruction manual

3.5

FILE

PROGRAMMING

Files

are

list

in the

äs

shown

KONTRON

File

name:

created

below.

main

and

edited

Starter

HPLC

Repeats

in

menu.

TERNARY

edit

The

l of

GRADIENT

mode.

FORMER

Select

425

"E"

edit mode menu will

GRADIENT

CONTROLLER

Pressure,

Upper:

425

from

now

200

the

be

displayed

Vers.

1.11

Lower:

HPLC

command

3.5.1

Time

[min]

0.0

SELECTED

COMMANDS:

Auxl

On

(0..999

MODE:

Flow

[ml]

EDIT

ESC. * ,

sec):

A

Step

«

Fig. 3.5.1 Edit Mode Menu

A

program

execution

columns

file

time

is

consists

for

each

described below:

Time

B

Step

,

t- - Clear

0

screen,

of a set of

instruction.

C

Step

Syn

Delete

instructions

The

significance

Auxiliary

1234

line,

Sort,

Aux

[sec]

only.

with a corresponding

of the

various

This

line.

3.5.2 Flow

Defines

gradients

11.86

is the

the

are not

execution time

total

flow

from

possible with

for the

the

pump 420. Note

the

3

OPERATION

instruction

GF425

Software.

set

contained

that

linear

on

that

flow

- 9 -

K<

Instruction manual

3.5.3

%A

Step;

These

%B

Step;

columns

define

tively.

An

entry

nents.

consistency.

is

not

An

entry

red

if a

again,

consistency check

A

step gradient

e.g.

in the A, B and C

The

100%.

entry

For the

line

to

line.

GF425

A

in the

gradient

of

example

entry

25%

immediately regardless

GRADIENT

%C

Step

the

percentage

columns

makes a check,

eorresponding

eorresponding step

step

is

for B is %B 0

at a

values

is

made

always

shown

certain time

for all

when

given priority over linear

in

when

warning

column

three

the

line

fig.

3.5.6/1

Step

25.

FORMER

composition

is

obligatory

the

line

is

given

is

is

components

is

completed.

This will result

of the

of

is

if the

optional

required.

and

3.5.6/2

value

425

HPLC

A,

B and G respec-

for all

completed,

sum

and is

In

is

entries.

for

three

for

of A, B and C

only

this case, once

required

below,

in B

%B

the

being

on the

compo-

100%

requi-

and a

first

set

next

3.5.4

From

linear

The

Step

treated

Sync

"Sync"

sample

actual

phase

time

suction

NOTE:

For

the

lines

corresponding step entries

a

period

this

start

ABC

of

example

gradient must

value

value.

äs

is a

injection

start

after sending

sample

phase.

Many

of 5 min

for a

In

the

start value

synchronizatlon

of a

injection

zation described below

In

these

phase

starting

SYNC

suction

shown

(7-2)

it can be

be

made

linear gradient

cases where a step value

and

gradient

gradient occurs

the

first gradient

autosamplers

cases

is

possible

the

autosampler

parameter.

phase

at 2 and 7 min

and in

between

seen that entries

in the %A, %B and %C

for a

must

In

will

linear gradient.

parameter

start.

at the

be

are not

partial

by

short-circuiting

this

at

least

this case a linear gradient over

25%B

can

however

which

For

start

parameters.

synchronized

capable

for the

synchronization

on the

way

starting

be

respectively

and

75%B

is

given this will always

can be

low

of the

of the

KONTRON HPLC

next program line after

synchronized.

will

for the end

columns respectively.

be

used

pressure

In

with

the

of the

there

be

generated.

values

either a %ABC

to

co-ordinate

gradients

first

the

type

with

pump

this case actual

start

of

synchroni-

Autosampler

the

suction

sync input

autosampler

are

no

of a

or a

be

the

suction

of the

460.

and

the

and

11.86

3

OPERATION

- 10 -

[i

InstrüCtion

manualGRADIENT

FORMER

425HPLC

3.5.4

Sync

(

cont . )

Synchronization with

Using

cribed

of

-

-

- The

the

GF425

in the

injection

äs f ollows

Connect

input

Connect

sampler

gradient former

min

and

below.

The

System

Setting

soon

on

until

contact

The

transmits a "continue" Signal

released.

is

continue

of the

äs

this

and

starts

the

is

gradient former

once again closed

autosampler

and

:

the

on the

Aux l on the

and Aux 2 to the

2.1

then

sample

The

with

functions

sync

line

the

closed.

Controller goes

its

the

Autosampler

Software

start

"remote

gradient

min

respectively

parameter

is

autosampler routine.

is in the

now

injection routine.

to

manual

suction

continue"

former.

gradient former

should

äs f ollows:

reached.

waits until

for l

460

control

phase

STEP input.

be

causes

Aux l,

sample

to the

immediately

second, which causes

the

START

it is

in the

possible

completely.

Output

programmed

on the

to the

example

the

Controller

programmed

The

loop

and

the

next suction phase start

master Computer.

to the

and

to

This

autosampler

START input

äs

shown

shown

for l

autosampler then proceeds

then

next line, where

STEP

synchronize

to be

the

the

functions

can

be

carried

to the

on the

for the

in

fig.

interrupted

second,

remote continue

The

hold

autosampler

des-

both

lines

time

out

sync

auto-

at 2

3.5.6/2

Switches

and

is

then

Aux l

äs

to

3.5.5

Auxiliary

Up

to 4

determined

time

3.5.6 A Programming

An

example

with

shown

section

11.86

3

potential-free contact closures

time

for

which

the

resulting control program.

start

3.5.4

within a program

the

Example

of a

and

is

relay

program

synchronization

included

contact should

is

shown below

(see instruction

can be

file.

of an

OPERATION

It is

In

be

äs a gradient profile together

addition

autosampler

switched

only

necessary

closed.

to the

at 2.1

- 11 -

minutes).

on for a

to

gradient profile

äs

described

pre-

enter

the

in

Instruction

manual

GRADIENT

FORMER

425

HPLC

3.5.6 A Programming

100%

75%

50%

25%

0%

0'

T

Fig.

3.5.6/1

Example

2'

3'

Gradient

(cont.)

U

5'

Profile

61

T

Example

9'

10'

100%

••

75%

50%

25%

-»-Time

0%

Programming

defined

by the

Comparison

shown

below

GF425

solvent

points

Software.

at 9

in

total

KONTRON

File

nome-.

Time

[min]

0.0

2.0

2.1

7.0

9.0

10.0

of

such a gradient

corner points

of the

in

above gradient profile with

fig.

3.5.6/2

Note

minutes

EXAMPLE

Flow

[ml]

1.0

1.0

1.0

l .0

1.0

due to the

which

are

HPLC

A

Step

m

(%]

100

25

25

25

25

is

of the

will

that there

step required, this results

realized using

TERNARY

Repeats

25

25

l of

0

25

75

75

25

Step

[*]

25

carried

out by

gradient profile.

show

25

how

this

are

effectively 2 corners

the

step instruction.

GRADIENT CONTROLLER

Pressure.

C

Step

0

50

0

0

50

Syn

50

50

entering

the

resulting program

is

realized within

the

in 6

200

Vers.

Lower:

425

Upper:

Auxiliary

1234

values

for

corner

1.11

[sec]

the

each

SELECTED

MODES:

Fig.

3.5.6/2

11.86

^

MODE:

Run.

MAIN

Manual.

OPTION

Program

MENÜ

Edit.

Load.

Example

Save.

3

OPERATION

Dir,

Config. Quit.

- 12 -

Instruction

3.5.7 General Points

When

programming

the

required

required.

files.

manual

gradient profile

The

GRADIENT

it is

following

recommended that

which

points should help

you

will

FORMER

first

help

you in

425

sketch

to

HPLC

in

graph form

define

the

corners

creating program

- The

- The

-

Starting a file

-

Maintenance

eurrent

screen together

meter.

The

the

You

values. A value

check

you

minutes,

values

stency check similar

consistency.

out

set

Note

the

case,

program

programming

lines

The

parameter

data entry

must enter values

for

leave

step values

for

easily

the

that

linear entry

never operate

äs

value

100% consistency

that instruction line.

produce gradient

each

äs

System

the

file,

the

shown

parameter

with

entry

field

for

are

parameter

with a defined

shown above

to

100%A- entry

column

of

isocratic composition over longer periods

e.g.

same

in the

is

always

the

permitted ränge

entered

is

using

each parameter must

optional

run,

at

above between

via the

completed

the

for %A, %B and

only

steps.

if

to

that

at 0

in the

is

must total 100%.

100%A.

values

above example.

displayed

cursor

after entry

and,

step entries

for

composition

minutes.

above example,

only necessary because

in the

on the

of

values

keyboard

with either RETURN

keys.

äs

shown

It is

linear entries

7 and 9

linear entry

is

%C,

the

be

entered.

is

in the

also

necessary

are

of A, B, C can be

The

GF425

at

The

minutes,

last

also displayed here.

so-called

completed, i.e.

above

required.

is

will

25%A, 25%B

System will,

columns

for

The

is

line

that

or by

here

made

the

leaving

GF425

example

to

A

for

carried

immediately

and

values

in

achieved

on

on the

para-

linear

will

when

at 9

enter

consi-

100%

50%C.

in

this

in a

by

both

-

After a line

keys

to

leave

copied

been

-

Auxiliaries

using

e.g.

- A

to

correction

least

11.86

3

from

made.

the Aux

In the

program

the

desired parameter

one

is

the

These values

can be

only

"A".

The

jump

to the Aux

required

can be

of a

other % entry.

completed

the

line. Values

last line once

switched

command.

above example enter

flow

using

modified

single % value will always require correction

you can use

for

the

can be

entries

entry field.

the

simply

in the

will

cursor

at any

and

correcting

OPERATION

either RETURN

flow

time

overwritten

middle

the

time

be

deleted

A

left

time

key.

in

- 13 -

etc. will

entry

sync entry

edit

the

in the new

if

of a

of 2.1 and

and the

mode

old

value. Note that

or the

be

automatically

required.

gradient profile

can be

simply

cursor

line

then press

cursor

by

will

made

moving

of at

has

if

{<

Instruction

manual

GRADIENT FORMER

425HPLC

3.5.8

3.6

SAVING

Leaving

To

leave

starter menu.

A

file

by

pressing

the

stops.

NOTE:

Should

prompt

write

enter

Edit

edit

AND

which

file

name.

The

A

the

will

the

existing file enter

N and a new

Mode

mode

LOADING

has

"S"

The

extension

file saved

necessary

within

the

be

used.

file name given with

be

given before

press ESCape

FILES

just

when

GF425

been

in the

name

GF425.

file name.

may

PRG is

to use the

will require that

created

main

contain

added automatically.

äs

TEST will

Use of

the

Y; if you do not

which

or

starter

up to 8

name TEST when loading

MS-DOS

the

existing file

will return

modified

menu.

be

stored

commands

the

save instruction already

in

edit mode

You

will

characters

äs

TEST.PRG.

such

complete name, i.e. TEST.PRG

is

overwritten.

wish

you

to the

can

be

be

prompted

without spaces

It

is

or

re-saving

äs

COPY outside

exist

To

to

overwrite

main

saved

for

or

only

of

a

over-

then

3.7

RUNNING

A

stored file

enter

the

file name

NOTE:

Pressing

FILES

Pressing

following

—

You

The

be

switched

"R"

sequence.

will

Press

RETURN

number

configuration

NOTE:

"R"

can be

to

be

(for Run) when

be

of

repeats followed

off at the end of the

i.e.

reloaded using

of the

"L"

displayed.

promted

if

only l cycle

program

always uses

the set

file required

also causes a directory

for the

can be

displayed

in the

the

the

load

command. Press

and

press RETURN.

of

existing

main

number

is

by

RETURN.

used

batch

currently activated instruction set,

on the

starter

of

repeats required.

required

to

define

or

not,

screen.

menu will initiate

or

whether

see

enter

section 3.2.

"L" and

PRG

the

required

the

pump should

then

files

the

11.86

3

OPERATION

- 14 -

S

Instruction

3.7

RUNNING

Example:

manual

FILES (cont.)

GRADIENT

FORMER

425

HPLC

Assuming

off the

- Use "L" to

-

Press

-

Enter

- The

EXAMPLE

3.8

SYSTEM STATUS

The

second

running

FILE

NAME:

REPEATS: defines

you

wish

to run the

pump.

load

"R"

10 for the

System will

file.

IN

FILE

line

of

files.

defines

of the

file

the

file EXAMPLE

number

now

RUHNING

repeats required

the

current repeat

start

main

the

the

of

repeats

running

MODE

menu

displays

name

current repeat

named

followed

of the

is

status

EXAMPLE

the

first

three

currently

shown

is

10

times

by

RETURN.

of ten

important

status.

on the

displayed.

and

then

repeats

parameters

running file.

The

total number

right.

On the

switch

of the

for

of

left

X~N

'

PRESSURE: defines

the

The

bottom

graph

of

The

next

11.86

3

line displays

elapsed

instruction step

time

the

pressure

PRG

file

against total time

to be

the

now

elapsed

executed

OPERATION

limits

being run.

time

configured

in a

äs a visual aid.

is

always highlighted.

- 15 -

file

and

and

saved

shows

a bar

with

<

Instruction manual

TABLE

OF

CONTENTS

4.

TROÜBLE SHOOTING

4.1

Operation

4.2

Software error

errors

GRADIENT

2

messages

3

FORMER

425HPLC

page

11.86

4

TROÜBLE SHOOTING

- l

Instruction

manual

GRADIENT

FORMER

425

HPLC

4.

4.1

TROÜBLE

This

errors

former. Part 2 deals with error

Software.

OPERATIONAL

ERROR

Poor

retention

SHOOTING

section

which

reproducibility

is

can

ERRORS

time.

divided

be

into

encountered

of

two

parts.

during

messages

POSSIBLE

System

Certain solvent

require permanent purging with

helium

degassing

Part l deals

normal Operation

encountered

SOLUTIONS

not

adequately degassed.

for

reliable Operation

can

in

combinations

occur upon

with

of the

using

possible

gradient

the

GF425

may

if

mixing.

Poor

reproducibility

time

during

only.

Continued

despite

High

purging.

purge

lack

gas

the

first

of

reproducibility

consumption.

of

retention

analyses

System

standing.

suitable solvent

ensure that

are

free

Check

possible

Reduce

0.5

including cylinder

tightness.

not

adequately

Flush

all

füll

bar. Check

of

degassed solvent

of

entrapped air.

all

system

leaks.

supply

the

connecting tubes

connections

See

pressure

all

purged

System with

combination

section

to

connections

connection

after

for

5.

less

to

and

than

for

11.86

4

TROÜBLE SHOOTING

-

2 -

K8

Instruction

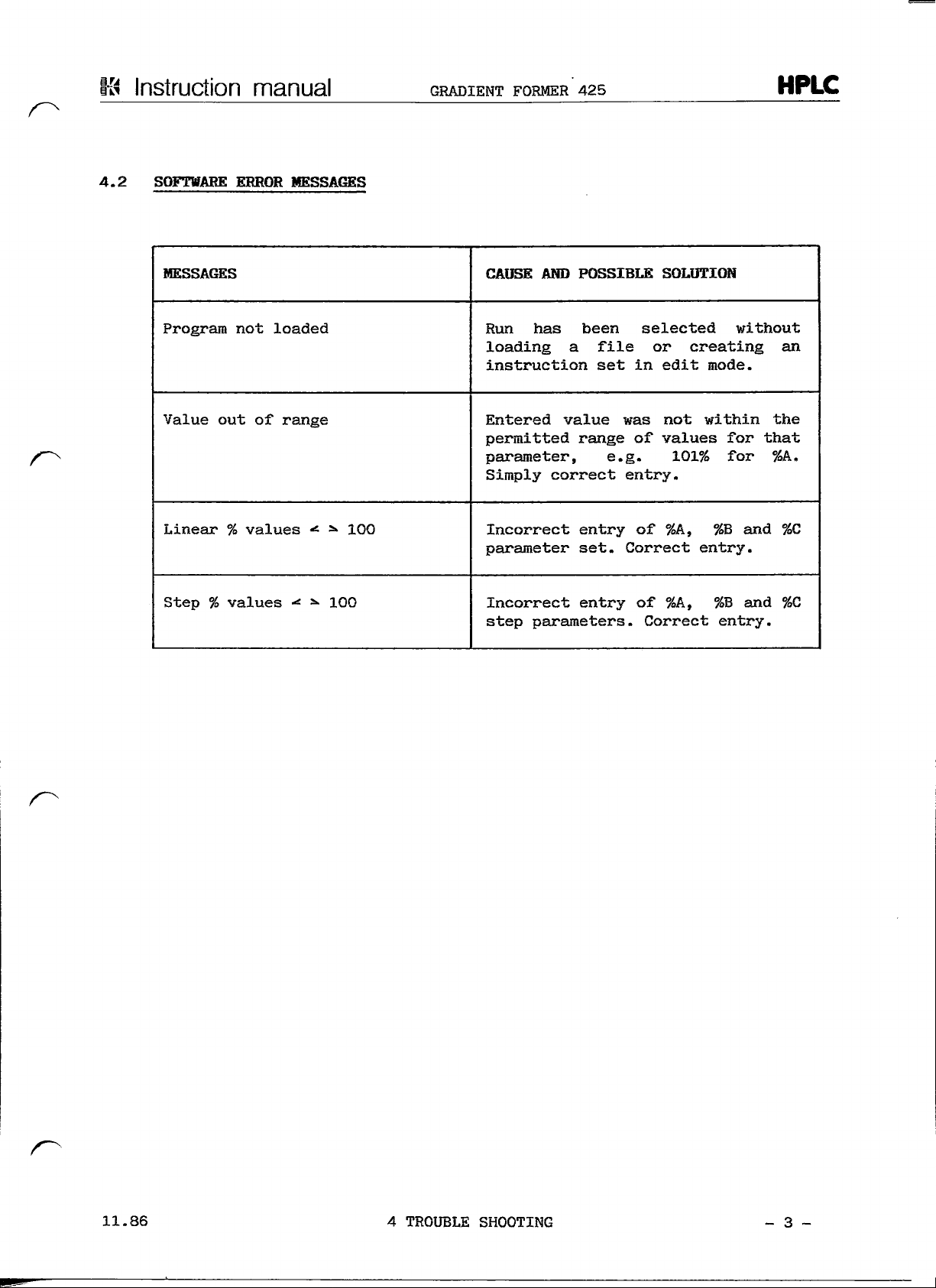

4.2

SOFTWARE

manual

EREOR

MESSAGES

GRADIENT

FORMER

425

HPLC

MESSAGES

Program

Value

Linear % values

Step % values

not

out of

loaded

ränge

•*• •*•

*•

*>

100

100

CAUSE

Run

AND

has

POSSIBLE

been

loading a file

instruction

Entered

permitted

Parameter,

Simply

Incorrect

Parameter

set in

value

was not

ränge

e.g.

correct entry.

entry

set.

Incorrect entry

step

parameters.

SOLÜTION

selected

or

edit

without

creating

mode.

within

of

values

101%

of

%A,

for

for

%B

and

Correct entry.

of

%A,

%B

and

Correct entry.

an

the

that

%A„

%C

%C

»•

11.86

4

TROUBLE

SHOOTING

- 3 -

13

Instruction

manual

GRADIENT

FORMER

425

HPLC

TABLE

5.

5.1

OF

CONTENTS

MAINTENANCE

Routine

5.2

Spare

parts

maintenance

3

2

page

11

„86

5

MAINENTANCE

- l -

4

Instruction

MAINTENANCE

5.1

ROUTINE

The

HPLC Gradient Former

considered

system

at

least

following

-

Check

manual

MAINTENANCE

äs

"consumables".

for

signs

on a monthly

components

inernally

of the

the

unit

of

liquid

and

GRADIENT FORMER

425

contains very

The

user

should

leakage.

or

connections

externally.

äs

follows.

It

is

recommended

basis. This

connections.

to the

To do

monthly

this

425

HPLC

few

parts

however

that

regulärly

this

which

is

check should cover

solenoid

you

must

valve

remove

manifold both

can

check

carried

the top

be

the

out

the

cover

CAÜTION:

Remove

the

Check

the

top

the

Tighten

Check

that

seated.

Replace

Check

the

of

leakage.

Check

electrical connections between gradient former,

Computer

Check

that

purging

The

unit

supply

befbre

four fixing

cover.

connections

the

tube connections

all

connections

the top

cover.

connections

Remedy

before

an

of

solvents

äs

each

adequate supply

nnist

be

removing

screws

to the

disconnected

at the

valve manifold

if

necessary.

to the gas

between

gradient

necessary.

run if

possible.

of gas is

is

being practised.

the top

base

regulating

former

from

cover.

of the

for

the raains

unit

signs

valves

and

available

and

of

are

pump

for

pump

if

continuous

power

remove

leakage.

firmly

signs

and

11.86

5

MAINENTANCE

- 2 -

Kä

Instruction manual

5.2

SPARE

PARTS

The

following

spare

representative.

Part

Number

parts

Please

always

Description

can

quote

GRADIENT

be

ordered

the

FORMER

425

through

corresponding

your

part

local

number.

HPLC

KONTRON

91-00560

71-00921

93-00667

93-00668

93-00665

96-00200

94-00983

07-89023

92-00627

87-00794

Outlet

Inlet

Gable,

Gable,

Solenoid

Gas

Gradient Controller printed circuit

Tubing

Inlet

Solvent

tube

connection

valve

purge

for gas

filter

for

Pump

gradient

gradient former - pump

valve

valve

former - Computer

assy

assy,

purge

420

coniplete

feed tube

(GF425 - PÜ420)

faoard

07.90

5

MAINENTANCE

- 3 -

Loading...

Loading...