Page 1

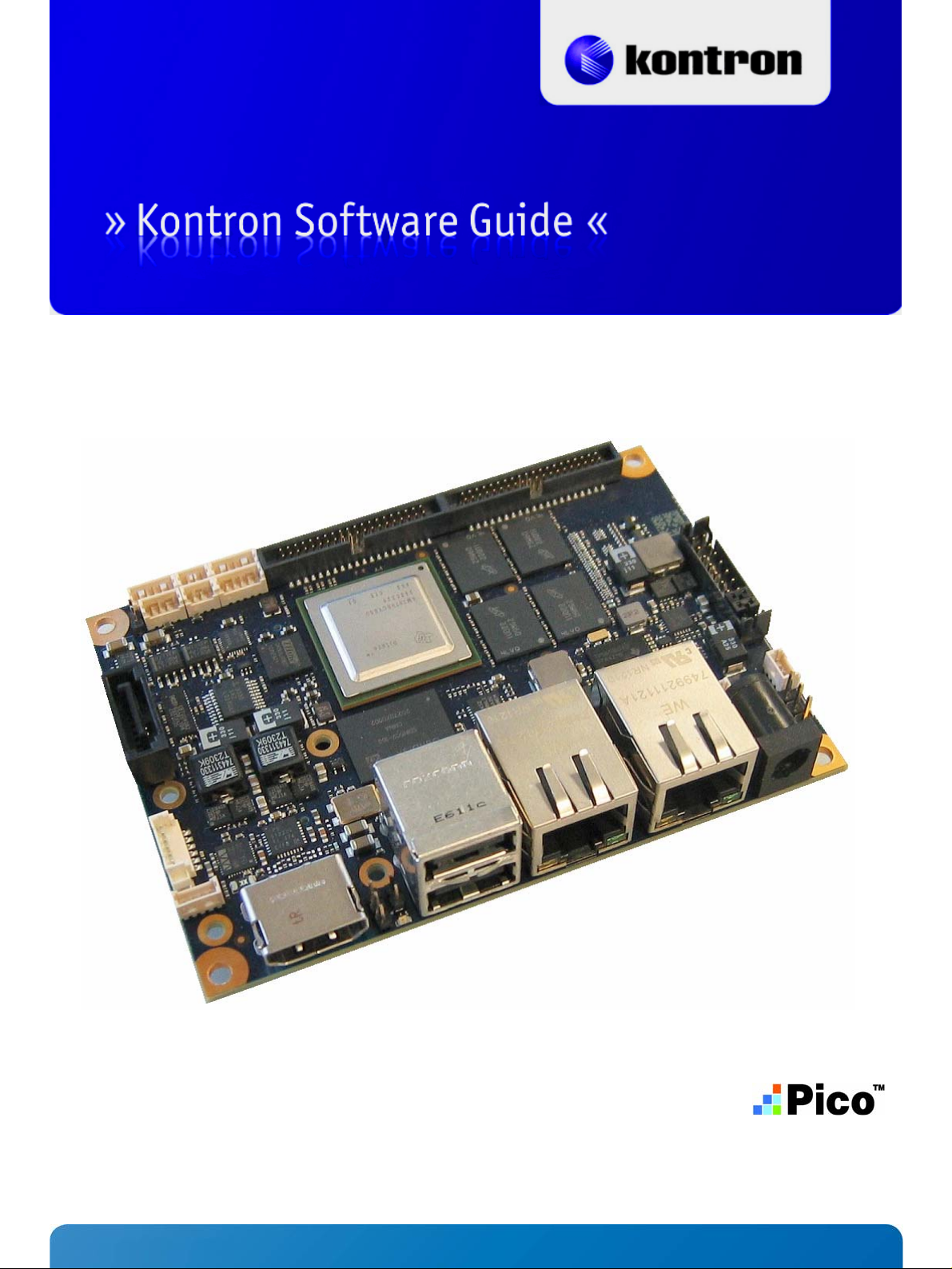

KTAM3874/pITX

KTD-S0057-I

The pulse of innovation

Page 2

User Information

Table of Contents

» Table of Contents «

1 User Information .............................................................................1

1.1 About This Document.................................................................................................... 1

1.2 Copyright Notice.......................................................................................................... 1

1.3 Trademarks................................................................................................................. 1

1.4 Standards................................................................................................................... 1

1.5 Warranty .................................................................................................................... 1

1.6 Life Support Policy ....................................................................................................... 2

1.7 Technical Support ........................................................................................................ 2

2 U-Boot Setup ..................................................................................3

2.1 Setup Command .......................................................................................................... 3

2.2 Setup Usage................................................................................................................ 3

2.3 Display Menu .............................................................................................................. 4

2.3.1 Boot Display .............................................................................................................................4

2.3.2 Mirror Mode.............................................................................................................................. 4

2.3.3 LCD Panel Resolution.................................................................................................................. 5

2.3.4 LCD Panel Mapping ....................................................................................................................5

2.3.5 Backlight Output Control............................................................................................................. 5

2.3.6 Backlight Output Level ...............................................................................................................5

2.3.7 Backlight Brightness.................................................................................................................. 5

2.4 Devices Menu .............................................................................................................. 6

2.4.1 mPCI Express® Port .................................................................................................................... 6

2.4.2 Audio Device............................................................................................................................. 6

2.4.3 LAN Devices.............................................................................................................................. 6

2.4.4 S-ATA® Device........................................................................................................................... 6

2.4.5 CAN Port 0................................................................................................................................ 7

2.4.6 CAN Port 1................................................................................................................................ 7

2.4.7 UART Port 5 ..............................................................................................................................7

2.4.8 First GPIO Port .......................................................................................................................... 7

2.4.9 Second GPIO Port....................................................................................................................... 7

2.5 Password Command...................................................................................................... 8

2.6 Defaults Command ....................................................................................................... 8

2.7 Save Command ............................................................................................................ 9

2.8 Summary Command...................................................................................................... 9

2.9 ShowDID Command ...................................................................................................... 9

3 U-Boot Environment....................................................................... 10

KTAM3874/pITX Software Guide

Page 3

User Information

Table of Contents

4 VESA® DisplayIDTM.......................................................................... 12

4.1 LCD/LVDS Technology Overview .....................................................................................12

4.1.1 Detailed Timing Descriptor ........................................................................................................ 12

4.1.2 24 Bit Color Mapping Tips.......................................................................................................... 14

4.2 EDID 1.3 Specification (VESA®) ......................................................................................15

4.3 DisplayID

4.3.1 DisplayIDTM Parameter Summary ................................................................................................. 15

4.3.2 DisplayIDTM Restrictions ............................................................................................................ 16

4.3.3 LCD Panel Selection ................................................................................................................. 16

4.3.4 DisplayID

4.3.5 Building DisplayIDTM File ........................................................................................................... 18

4.3.6 Erasing DisplayIDTM Record ........................................................................................................ 18

4.3.7 U-Boot EEPROM Update Tool ...................................................................................................... 18

TM

Specification (VESA

TM

Windows

®

Tool ........................................................................................................ 17

®

)...................................................................................15

5 U-Boot Bootloader ......................................................................... 20

5.1 UART Bootloader ........................................................................................................20

5.2 Ethernet Bootloader....................................................................................................22

5.3 SPITM Bootloader.........................................................................................................23

5.4 MMC Bootloader .........................................................................................................25

6 DebianTM Linux® BSP ....................................................................... 26

6.1 User Login Arguments..................................................................................................26

6.2 Video Decoding ..........................................................................................................26

6.3 Audio Support ............................................................................................................26

6.4 KEAPI Interface ..........................................................................................................26

6.5 CAN Bus Utilities (SocketCAN) .......................................................................................27

6.6 S-ATA® Interface.........................................................................................................27

6.7 Suspend Mode............................................................................................................27

6.8 Screensaver ...............................................................................................................27

6.9 Sysfs Support .............................................................................................................28

7 Ethernet Switch ............................................................................. 29

8 Kernel Boot from SPITM Flash ............................................................ 30

9 Root File System Boot from S-ATA® Drive............................................. 31

10 Linux® Programming Examples (DebianTM) .......................................... 32

10.1 TI® AM3874 Register Access ..........................................................................................32

10.1.1 Register Access Restrictions....................................................................................................... 34

10.2 SPITM Interface Examples ..............................................................................................35

10.2.1 SPITM Loopback Test Utility ........................................................................................................ 35

10.2.2 SPITM Display Interface.............................................................................................................. 39

KTAM3874/pITX Software Guide

Page 4

User Information

Table of Contents

10.3 I

10.3.1 I

10.3.2 I

2CTM

Interface Examples...............................................................................................42

2CTM

Detection Utility............................................................................................................... 42

2CTM

Display Interface .............................................................................................................. 48

10.4 UART Interface Examples ..............................................................................................51

10.4.1 UART Loopback Test Utility ........................................................................................................ 51

10.4.2 UART Display Interface ............................................................................................................. 53

10.5 Timer Example............................................................................................................55

10.6 GPIO Example.............................................................................................................60

10.7 Watchdog Example ......................................................................................................69

10.8 CAN Bus Examples .......................................................................................................71

10.8.1 CAN Loopback Test Utility.......................................................................................................... 71

10.8.2 Single CAN Controller Usage ...................................................................................................... 78

10.8.3 CAN Wiring ............................................................................................................................. 79

10.9 Backlight Example ......................................................................................................80

10.10 RS485 Interface Example..............................................................................................83

10.11 Sound Programming with ALSA......................................................................................88

10.12 Graphic Programming ................................................................................................116

10.12.1 X11TM ................................................................................................................................116

10.12.2 Cairo ................................................................................................................................140

10.12.3 GTK+ 3.x ...............................................................................................................................156

10.12.4 QtTM 4.8 ................................................................................................................................170

10.12.5 QtTM Quick 1.x / QML................................................................................................................211

10.13 Interprocess Communication (Root/User)...................................................................... 259

Appendix A: Linux® on microSDTM Card ....................................................... 273

A.1 UbuntuTM 12.04 LTS ...................................................................................................273

A.2 UbuntuTM 14.04 LTS ...................................................................................................277

Appendix B: User Space on Onboard Flash .................................................. 283

Appendix C: Reference Documents ............................................................ 288

Appendix D: Document Revision History ..................................................... 289

KTAM3874/pITX Software Guide

Page 5

KTD-S0057-I Page 1 User Information

1 User Information

1.1 About This Document

This document provides information about products from KONTRON Technology A/S and/or its subsidiaries.

No warranty of suitability, purpose or fitness is implied. While every attempt has been made to ensure that

the information in this document is accurate the information contained within is supplied “as-is” - no

liability is taken for any inaccuracies. Manual is subject to change without prior notice.

KONTRON assumes no responsibility for the circuits, descriptions and tables indicated as far as patents or

other rights of third parties are concerned.

1.2 Copyright Notice

Copyright © 2013-2014, KONTRON Technology A/S, ALL RIGHTS RESERVED.

No part of this document may be reproduced or transmitted in any form or by any means, electronically or

mechanically, for any purpose without the express written permission of KONTRON Technology A/S.

1.3 Trademarks

Brand and product names are trademarks or registered trademarks of their respective owners.

1.4 Standards

KONTRON Technology A/S is certified to ISO 9000 standards.

1.5 Warranty

This product is warranted against defects in material and workmanship for the warranty period from the

date of shipment. During the warranty period KONTRON Technology A/S will at its discretion decide to

repair or replace defective products.

Within the warranty period the repair of products is free of charge as long as warranty conditions are

observed.

The warranty does not apply to defects resulting from improper or inadequate maintenance or handling by

the buyer, unauthorized modification or misuse, operation outside of the product’s environmental specifications or improper installation or maintenance.

KONTRON Technology A/S will not be responsible for any defects or damages to third party products that

are caused by a faulty KONTRON Technology A/S product.

KTAM3874/pITX Software Guide

Page 6

KTD-S0057-I Page 2 User Information

1.6 Life Support Policy

KONTRON Technology's products are not for use as critical components in life support devices or systems

without express written approval of the general manager of KONTRON Technology A/S.

As used herein:

Life support devices or systems are devices or systems which

a) are intended for surgical implant into body or

b) support or sustain life and whose failure to perform, when properly used in accordance with instructions

for use provided in the labelling, can be reasonably expected to result in significant injury to the user.

A critical component is any component of a life support device or system whose failure to perform can be

reasonably expected to cause the failure of the life support device or system or to affect its safety or

effectiveness.

1.7 Technical Support

Please consult our web site at http://www.kontron.com/support for the latest product documentation,

utilities, drivers and support contacts

or use the special e-mail address sbc-support@kontron.com for a

technical problem. In any case you can always contact your board supplier for technical support.

Before contacting support please be prepared to provide as much information as possible:

Board identification:

System environment:

Type

Part number (find PN on label)

Serial number (find SN on label)

O/S type and version

Driver origin and version

Attached hardware (drives, USB devices, LCD panels ...)

KTAM3874/pITX Software Guide

Page 7

KTD-S0057-I Page 3 U-Boot Setup

2 U-Boot Setup

The sense of a special Setup part is to avoid expendable changes in the proper operating systems. The

®

Setup entries are valid for all supported operating systems (e.g. Linux

®

bedded Compact). For example if you switch from Linux

to AndroidTM or vice versa in the ideal case no

changes will be necessary. The Setup data records are stored in a non-volatile memory (EEPROM) and not in

an erasable script. A possible password input protects from unauthorized access.

The KONTRON Setup provides two configurable main menus:

display

devices

The display menu allows to define one or more boot displays, resolution and mapping of a LCD panel and

backlight parameters. The

devices part involves some hardware device settings, e.g. audio controller

enabled or disabled.

ATTENTION

Only the original KONTRON BSPs guarantee the realization of the U-Boot Setup features.

, AndroidTM and Windows® Em-

2.1 Setup Command

For a help screen type the command without an argument

setup

Now you can see all the supported sub-commands (menus). Normally the following entries are displayed

display display settings

devices onboard device configuration

password password input

defaults reset all settings to the default values

summary show all actual settings

save save all settings to EEPROM

showdid show the DisplayIDTM settings

Syntax example: setup display <Enter>

2.2 Setup Usage

After the execution of a sub-command (e.g. setup devices) the selection of a submenu only requires a

numeric value. Thereafter the real settings are visible. Now you can choose between an alphanumeric

(default) or a numeric input. The alphanumeric presentation illustrates intuitive the right choice. If you

favor the numeric input delete all chars with the <Backspace> key, type the number and then press the

<Enter> key.

After the completion of all changes it is reasonable to control the settings with the summary command.

Syntax:

setup summary <Enter>

KTAM3874/pITX Software Guide

Page 8

KTD-S0057-I Page 4 U-Boot Setup

2.3 Display Menu

This menu part includes several display settings:

First boot display

Second boot display

Boot display mirror mode

LCD panel resolution

LCD panel mapping

Backlight output control

Backlight enable level

Backlight brightness

2.3.1 Boot Display

The TI® AM3874 implies a graphics subsystem with two independent HD display controllers. Without a

restriction (except duplicate usage but 'none' on both settings is possible) each controller interface can be

configured as:

none switch off the display controller

lcd

hdmi

Examples:

First boot display hdmi

Second boot display none

or

First boot display none

Second boot display lcd

or

First boot display hdmi

Second boot display lcd

or

First boot display lcd

Second boot display hdmi

2.3.2 Mirror Mode

This feature is only meaningful if both boot displays are active. In enabled state always the first boot

display determines the real resolution. In this case it would be advisable to use the LCD panel (setting

'lcd') as first boot display. If mirror mode is disabled the second boot display remains black but it can be

used with custom programs.

KTAM3874/pITX Software Guide

Page 9

KTD-S0057-I Page 5 U-Boot Setup

2.3.3 LCD Panel Resolution

You have the choice to select a panel resolution with a fixed timing or a special setting 'auto' for a free

®

definable timing based on the VESA

®

chapter 'VESA

DisplayIDTM'. The KTAM3874/pITX supports following resolutions:

auto free timing based on VESA® DisplayIDTM

vga fixed timing 640x480 pixel, 18 bit color depth, single channel

wvga fixed timing 800x480 pixel, 18 bit color depth, single channel

svga fixed timing 800x600 pixel, 18 bit color depth, single channel

xga fixed timing 1024x768 pixel, 24 bit color depth, single channel

sxga fixed timing 1280x1024 pixel, 24 bit color depth, dual channel

uxga fixed timing 1600x1200 pixel, 24 bit color depth, dual channel

fullhd fixed timing 1920x1080 pixel, 24 bit color depth, dual channel

DisplayIDTM specification. For further details about DisplayIDTM see the

2.3.4 LCD Panel Mapping

There are two interface modes existing at 24-bit color depth: FPDI (Flat Panel Display Interface) or LDI

VDS Display Interface). For 18-bit color depth this setting has no validity. More information can be found

(L

®

in chapter ' VESA

DisplayIDTM/24 Bit Color Mapping Tips'.

fpdi

ldi

2.3.5 Backlight Output Control

Almost all LCD panels support either analog or PWM backlight brightness, therefore two options are available.

analog

pwm frequency approx. 600 Hz

2.3.6 Backlight Output Level

Some backlight inverters need a low level for the enable signal, other inverters a high level. Use this

submenu to configure the right enable output level.

low voltage = 0V

high voltage = +3.3V

2.3.7 Backlight Brightness

This submenu allows the definition of the analog backlight brightness (voltage range: 0V to +5V). The input

format is represented by a decimal number with maximal three digits.

KTAM3874/pITX Software Guide

Page 10

KTD-S0057-I Page 6 U-Boot Setup

Examples:

Brightness: 0 minimal value = 0V

or

Brightness: 255 maximal value = +5V

2.4 Devices Menu

This menu part defines several hardware device settings:

mPCIe port settings

Audio settings

LAN ports settings

SATA settings

CAN port 0 settings

CAN port 1 settings

UART port 5 settings

First GPIO port settings

Second GPIO port settings

2.4.1 mPCI Express® Port

The selection is limited to the enable respectively disable feature.

disabled

enabled

2.4.2 Audio Device

The selection is limited to the enable respectively disable feature.

This setting only concerns the audio codec and not the HDMI® audio part.

Note:

disabled

enabled

2.4.3 LAN Devices

The selection is limited to the enable respectively disable feature.

This setting affects both LAN controllers.

Note:

disabled

enabled

2.4.4 S-ATA® Device

The selection is limited to the enable respectively disable feature.

disabled

enabled

KTAM3874/pITX Software Guide

Page 11

KTD-S0057-I Page 7 U-Boot Setup

2.4.5 CAN Port 0

The selection is limited to the enable respectively disable feature.

disabled

enabled

2.4.6 CAN Port 1

The selection is limited to the enable respectively disable feature.

disabled

enabled

2.4.7 UART Port 5

You can choose between three modes:

rs232

rs422

rs485

2.4.8 First GPIO Port

All interface signals can be defined as GPIOs (General Purpose Input Output) or some special signals have

another function (Timer 4 to 7). For a detailed overview about these signals see the KTAM3874/pITX User's

Guide chapter 'Digital I/O Interface'. The signals are named GPIO21 to 24.

the operating systems do not support these special functions because the possible applications can

Note:

be too different.

The main menu shows following options:

Multiplexed GPIO/TIMER4+6 part

The submenu allows the selection between:

Multiplexed GPIO/TIMER5+7 part

gpio

timer

2.4.9 Second GPIO Port

All interface signals can be defined as GPIOs (General Purpose Input Output) or some special signals have

another function (UART2, UART4 or SPI3). For a detailed overview about these signals see the KTAM3874/

pITX User's Guide chapter 'Digital I/O Interface'. The signals are named GPIO12 to 18 resp. GPIO4 to 7.

The main menu shows following options:

Multiplexed GPIO/UART2 part

Multiplexed GPIO/UART4 part

Multiplexed GPIO/SPI3 part

KTAM3874/pITX Software Guide

Page 12

KTD-S0057-I Page 8 U-Boot Setup

The submenu for UART2 and UART4 allows the selection between:

gpio

uart

and the submenu for SPI3:

gpio

spi

2.5 Password Command

If you want to control the access to the Setup settings it is possible to use a password protection. Maximal

eight alphanumeric chars, numbers or special characters are admissible. You can delete an old password

respectively cancel the password protection with the input of an empty string.

Syntax:

Example:

New password: ******** e.g. 12%&fgWQ

Verify password: ******** the same input

setup password <Enter>

2.6 Defaults Command

In some cases it can be useful to reset quickly the Setup settings. For an example there is a problem with

driving of a single

Syntax:

First boot display hdmi

Second boot display none

Boot display mirror mode enabled

LCD panel resolution auto

LCD panel mapping fpdi

Backlight output control pwm

Backlight enable level high

Backlight brightness 128

mPCI Express interface enabled

Audio interface enabled

LAN interfaces enabled

SATA interface enabled

CAN interface 0 enabled

CAN interface 1 enabled

UART interface 5 rs232

GPIO/TIMER4+6 interface gpio

GPIO/TIMER5+7 interface gpio

GPIO/UART2 interface gpio

GPIO/UART4 interface gpio

GPIO/SPI3 interface gpio

setup defaults <Enter>

display - preferably a LCD panel - and the connection of a HDMI® monitor is possible.

KTAM3874/pITX Software Guide

Page 13

KTD-S0057-I Page 9 U-Boot Setup

2.7 Save Command

This is one of the most important sub-commands. Without this calling all Setup changes are lost after

power off. The save instruction writes the temporary Setup settings into the non-volatile memory device

(EEPROM).

Syntax:

setup save <Enter>

2.8 Summary Command

This Setup command gives a quick overview about all actual settings.

Syntax:

Example:

DISPLAY PART:

First boot display : hdmi

Second boot display : lcd

Boot display mirror mode : enabled

LCD panel resolution : sxga

LCD panel mapping : ldi

Backlight output control : pwm

Backlight enable level : high

Backlight brightness : 255

DEVICES PART:

mPCI Express interface : enabled

Audio interface : disabled

LAN interfaces : enabled

SATA interface : disabled

CAN interface 0 : enabled

CAN interface 1 : enabled

UART interface 5 : rs485

GPIO/TIMER4+6 interface : gpio

GPIO/TIMER5+7 interface : gpio

GPIO/UART2 interface : uart

GPIO/UART4 interface : gpio

GPIO/SPI3 interface : gpio

setup summary <Enter>

2.9 ShowDID Command

The showdid command provides the necessary information for checking the DisplayIDTM values. Some additional messages are possible, for example:

No DisplayID record present !

ATTENTION: DisplayID record is not activated !

Syntax: setup showdid <Enter>

KTAM3874/pITX Software Guide

Page 14

KTD-S0057-I Page 10 U-Boot Environment

Example:

DisplayID data:

----------------------------

Type I Timing Data Block

Pixel clock : 83500000 Hz

Horizontal active : 1280 clocks

Horizontal sync start : 1430 clocks

Horizontal sync end : 1530 clocks

Horizontal total : 1680 clocks

Horizontal sync pol. : positive

Vertical active : 800 lines

Vertical sync start : 815 lines

Vertical sync end : 816 lines

Vertical total : 831 lines

Vertical sync pol. : positive

Display Device Data Block

Color depth : 24 bit

Display Interface Data Block

Number of channels : 1

Color mapping : FPDI

3 U-Boot Environment

You can use the U-Boot environment to configure the behavior of U-Boot as you like. Default settings:

autoload=yes

baudrate=115200

bootcmd=run sdboot;run mmcboot;run spiboot;ru n nfsboot

bootdelay=3

bootfile=uImage

bootmmc=setenv root_bootargs root=/dev/mmcblk${device}p${rootpart} rw rootwait;setenv interface mmc;

mmc rescan ${device} && run fsdetect

cpuspeed=cpu_maxfreq=800

cputype=AM3874

debug_bootargs=earlyprink

default_bootargs=console=ttyO0,115200n8 vram=50M notifyk.vpssm3_sva=0xBF900000 ti814xfb.vram=0:16M,1:16M

noinitrd --no-log

doboot=run setmemarg;run loadscript;run setbootarg;run loadkernel;

ethaddr=xx:xx:xx:xx:xx:xx

eth1addr=xx:xx:xx:xx:xx:xx

ethact=cpsw

extra_bootargs=bootdisp1=hdmi bootdisp2=none mirrordisp=1 pcie=1 audio=1 lan=1 sata=1 can0=1 can1=1

uart5_mode=rs232 tm46_enable=0 tm57_enable=0

uart2_enable=0 uart4_enable=0 spi3_enable=0

fsdetect=setenv fsloader ext2load ${interface} ${device};fatinfo ${interface} ${device} && setenv fsloader fatload ${interface}

${device};run doboot

lcdmode=0,0,0,0,0,0,0

loadaddr=0x80009000

loadkernel=${fsloader} ${loadaddr} ${bootfile} && bootm ${loadaddr}

loadscript=${fsloader} ${scriptaddr} ${scriptfile} && source ${scriptaddr}

mmcboot=setenv device 1; setenv rootpart 1; run bootmmc

memsize=2048

nfsboot=setenv autoload no; dhcp;sete nv root_bootargs root=/dev/nfs ${nfsroot} ip=${ipaddr}:${serverip}:${gatewayip}:

${netmask}:${hostname}:eth0:off;setenv f sl oader tftp;run doboot;

nfsroot=nfsroot=192.168.1.1:/nfsroot

KTAM3874/pITX Software Guide

Page 15

KTD-S0057-I Page 11 U-Boot Environment

ramdisk_file=ramdisk.gz

rootpart=2

scriptaddr=0x80900000

scriptfile=boot.scr

sdboot=setenv device 0; setenv rootpart 2; run bootmmc

setbootarg=setenv lcd_bootargs lcdmode=${lcdmode} videomode=${videomode};setenv bootargs ${default_bootargs}

${lowmem} ${highmem} ${debug_bootargs} ${root_bootargs}

${lcd_bootargs} ${extra_bootargs} ${cpuspeed}

eth0=${ethaddr} eth1=${eth1addr}

setmemarg=setenv lowmem mem=417M;test ${cputype} = DM8148 && setenv lowmem mem=364M;setenv highmem

mem=320M@0x9FC00000;test ${memsize} = 2048 &&

setenv highmem ${highmem} mem=1023M@0xC0000000;

setenv highmem ${highmem} vmalloc=512M

spiboot=setenv root_bootargs root=/dev/mmcbl k0p${rootpart} rw rootwait;run setbootarg;sf probe 0 && sf read ${load ad d r }

0xE2000 0x31E000 && bootm ${loadaddr}

verify=yes

videomode=25180000,640,656,752,800,480,490,492,525,0,1,1

ATTENTION

Do not change the arguments in red color because U-Boot generates these parameters itself.

The U-Boot command 'printenv' lists all variables, 'setenv' modifies the values and 'saveenv' stores the

new environment.

KTAM3874/pITX Software Guide

Page 16

KTD-S0057-I Page 12 VESA® DisplayIDTM

4 VESA

®

DisplayIDTM

4.1 LCD/LVDS Technology Overview

4.1.1 Detailed Timing Descriptor

The input fields Pixel Clock, Horizontal Active, Horizontal Blank, Horizontal Sync Offset, Horizontal Sync

Width, Vertical Active, Vertical Blank, Vertical Sync Offset and Vertical Sync Width must be filled in with the

correct values according to the panel’s data sheet. In many cases the value for Horizontal/Vertical Blank

cannot be read directly from the data sheet. Instead terms such as Display Period (active pixels/lines) or

Horizontal/Vertical Total appear.

In this case the following calculation can be made:

⇒ Blank Value = Total Value – Active Value.

Sometimes the datasheet does not specify Sync Offset and/or Sync Width. In this case the permissible

values can only be determined through testing. However the rule is:

⇒ The sum of Sync Offset and Sync Width must not exceed the value for Horizontal/Vertical Blank.

Also datasheets are often different for displays with double pixel clock. If Pixel Clock and Horizontal Values

seem to be halved this must be corrected for input:

⇒ The values must always be entered as though it were a panel with single pixel clock.

Example 1:

PRIMEVIEW PM070WL4 (single pixel clock)

Data sheet specifications:

Clock Frequency [typ.] 32 MHz

HSync Period [typ.] 1056 Clocks (equivalent to Horizontal Total)

HSync Display Period [typ.] 800 Clocks (equivalent to Horizontal Active)

HSync Pulse Width [typ.] 128 Clocks

HSync Front Porch [typ.] 42 Clocks

HSync Back Porch [typ.] 86 Clocks

VSync Period [typ.] 525 Lines (equivalent to Vertical Total)

VSync Display Period 480 Lines (equivalent to Vertical Active)

VSync Pulse Width [typ.] 2 Lines

VSync Front Porch [typ.] 10 Lines

VSync Back Porch [typ.] 33 Lines

Result:

Pixel Clock 32

Horizontal Active 800

Horizontal Blank 256 ((128 + 42 + 86) → H. Pulse Width + H. Front Porch + H.

Back Porch)

Horizontal Sync Offset 42 (H. Front Porch)

Horizontal Sync Width 128 (H. Pulse Width)

Vertical Active 480

Vertical Blank 45 ((2 + 10 + 33) → V. Pulse Width + V. Front Porch + V. Back

Porch)

Vertical Sync Offset 10 (V. Front Porch)

Vertical Sync Width 3 (V. Pulse Width)

KTAM3874/pITX Software Guide

Page 17

KTD-S0057-I Page 13 VESA® DisplayIDTM

Example 2:

SHARP LQ190E1LW01 (double pixel clock)

Data sheet specifications (no definition of Sync Offset and Sync Width):

Clock Frequency [typ.] 54 MHz

Horizontal Period (1) [typ.] 844 Clocks (equivalent to Horizontal Total)

Horizontal Display Period 640 Clocks (equivalent to Horizontal Active)

Vertical Period [typ.] 1066 Lines (equivalent to Vertical Total)

Vertical Display Period 1024 Lines (equivalent to Vertical Active)

Result:

Pixel Clock 108 (2 x 54 MHz)

Horizontal Active 1280 (2 x 640 Clocks)

Horizontal Blank 408 ((844 – 640) x 2 Clocks)

Horizontal Sync Offset 45 (normally approx. 10 – 15 % of Horizontal Blank)

Horizontal Sync Width 140 (normally approx. 30 – 70 % of Horizontal Blank)

Vertical Active 1024

Vertical Blank 42 (1066 – 1024 Lines)

Vertical Sync Offset 1 (normally approx. 1 – 3 Lines)

Vertical Sync Width 3 (normally approx. 1 – 15 Lines)

Example 3:

LG-PHILIPS LM170E01-TLA1 (double pixel clock)

Data sheet specifications:

Clock Frequency [typ.] 54 MHz

Hsync Period [typ.] 844 Clocks

Horiz. Valid [typ.] 640 Clocks

Horiz. Back Porch [typ.] 124 Clocks

Horiz. Front Porch [typ.] 24 Clocks

Vsync Period [typ.] 1066 Lines

Vert. Valid [typ.] 1024 Lines

Vert. Back Porch [typ.] 38 Lines

Vert. Front Porch [typ.] 1 Line

Result:

Pixel Clock 108 (2 x 54 MHz)

Horizontal Active 1280 (2 x 640 Clocks → Horizontal Addr. Time)

Horizontal Blank 408 ((844 – 640) x 2 Clocks)

Horizontal Sync Offset 48 (2 x 24 Clocks → Horizontal Front Porch)

Horizontal Sync Width 112 (((408/2 – 124 – 24) x 2) → H. Blank – H. Back Porch – H.

Front Porch)

Vertical Active 1024 (Vertical Addr. Time)

Vertical Blank 42 (1066 – 1024 Lines)

Vertical Sync Offset 1 (Vertical Front Porch)

Vertical Sync Width 3 (Vertical Blank – Vertical Back Porch – Vertical Front Porch)

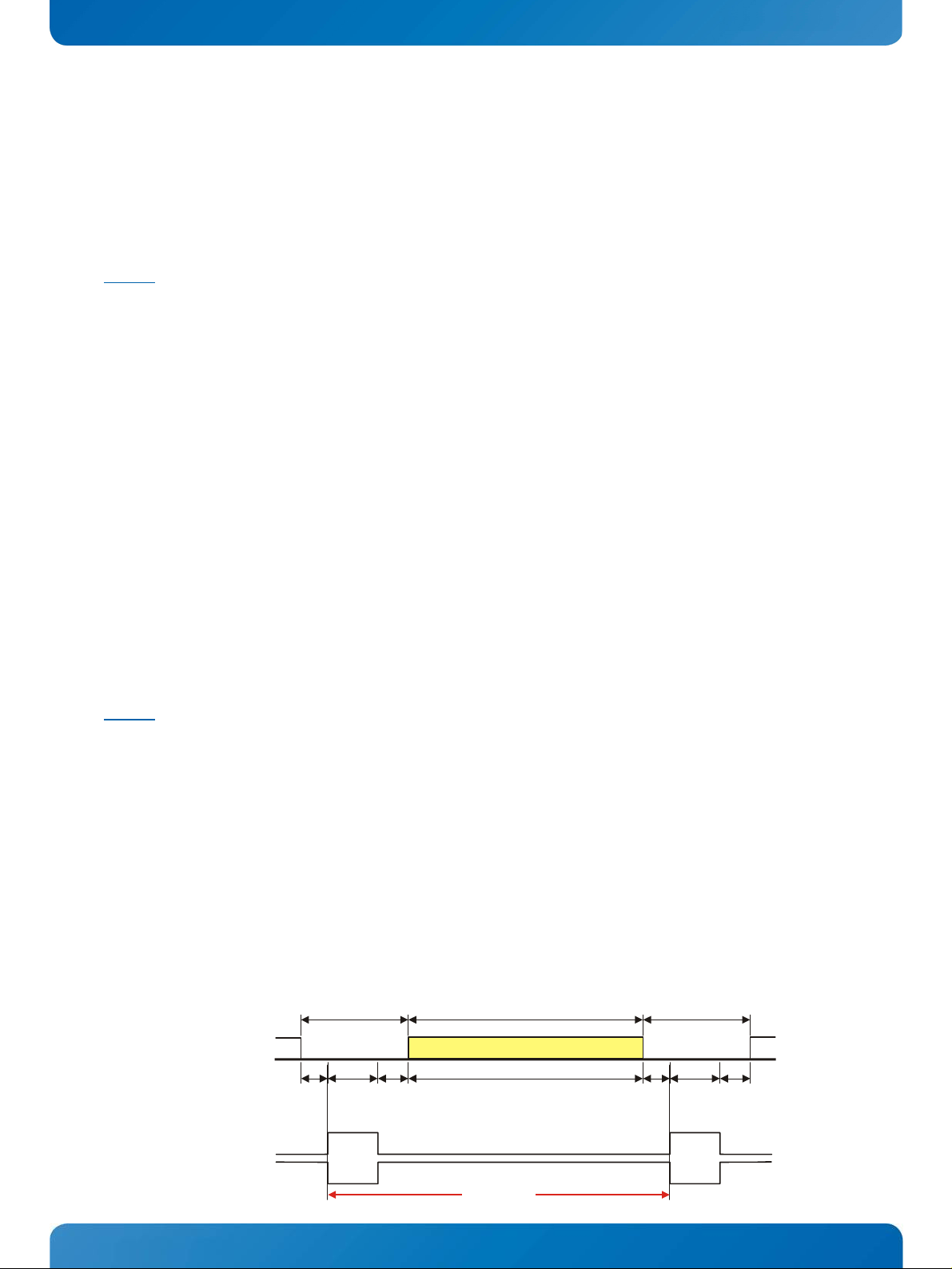

The following picture shows the typical video timing.

Timing Parameter Definitions

Blanking

Active Part

Blanking

H-/V-Video

Front

Porch

H-/V-Sync

Sync

Pulse

Width

pos.

Sync

neg.

Sync

Back

Porch

Address Time

Total

KTAM3874/pITX Software Guide

Front

Porch

Sync

Pulse

Width

pos.

Sync

neg.

Sync

Back

Porch

Page 18

KTD-S0057-I Page 14 VESA® DisplayIDTM

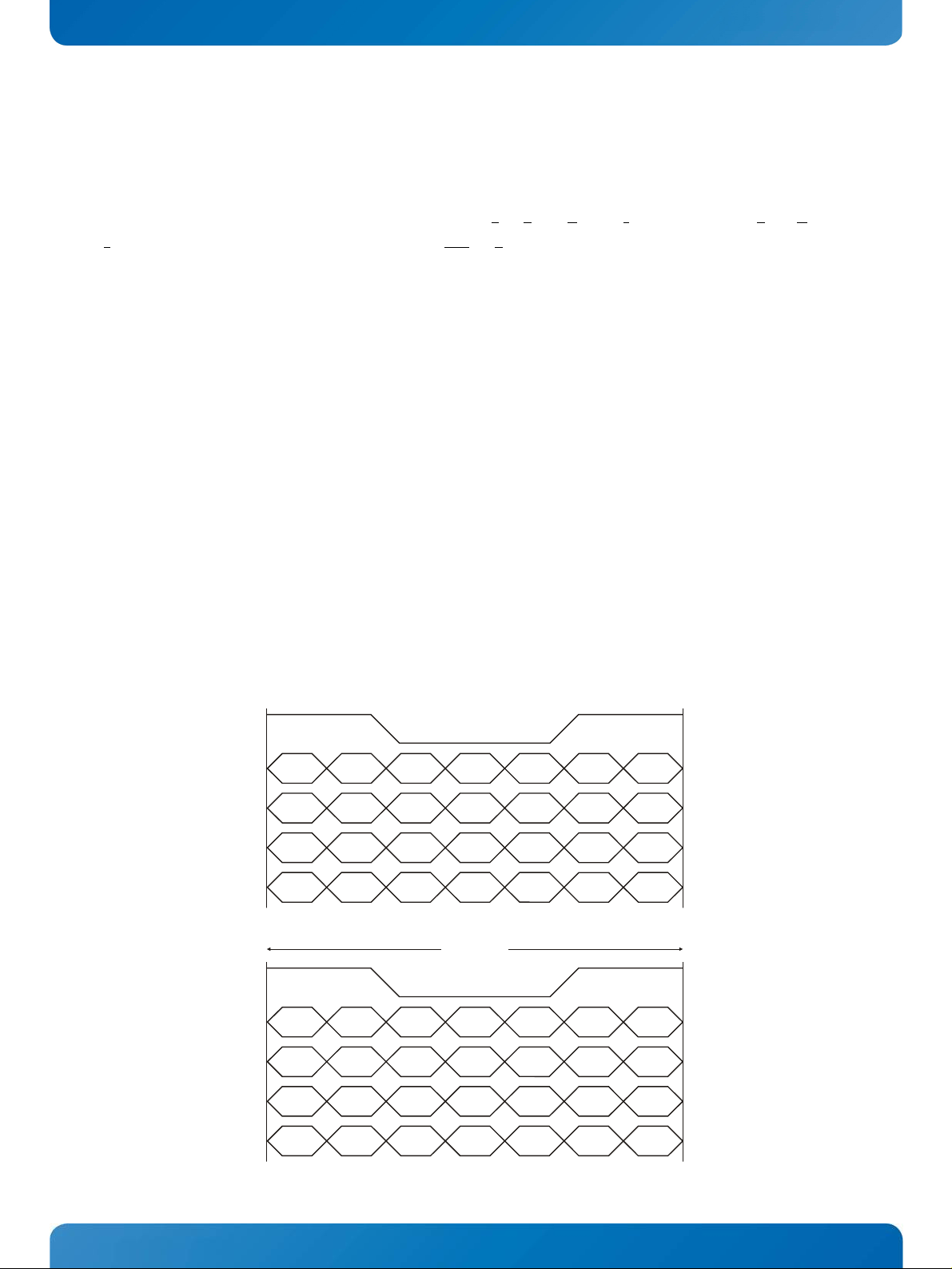

4.1.2 24 Bit Color Mapping Tips

The double pixel clock or 24-bit color depth can generally be taken from the datasheet. There are two

interface modes existing at 24-bit color depth: FPDI (F

nterface). Some panels use the line SELL LVDS (SELect Lvds data order). The LVDS data assignment in the

I

lat Panel Display Interface) or LDI (LVDS Display

datasheet can give you an indication by the last channel (e.g. RX3/TX3 – SELL LVDS = low) wether it is a LDI

panel (contains the lowest bits).

Example:

FPDI data assignment (LVDS channel 3 even or odd):

Tx/Rx27 Red 6 (e.g. even: RE6 or ER6)

Tx/Rx5 Red 7

Tx/Rx10 Green 6 (e.g. even: GE6 or EG6)

Tx/Rx11 Green 7

Tx/Rx16 Blue 6 (e.g. even: BE6 or EB6)

Tx/Rx17 Blue 7

Tx/Rx23 not used

LDI data assignment (LVDS channel 3 even or odd):

Tx/Rx27 Red 0 (e.g. even: RE0 or ER0)

Tx/Rx5 Red 1

Tx/Rx10 Green 0 (e.g. even: GE0 or EG0)

Tx/Rx11 Green 1

Tx/Rx16 Blue 0 (e.g. even: BE0 or EB0)

Tx/Rx17 Blue 1

Tx/Rx23 not used

TxClk

TxOut0

G0

R5

R4

R3

R2 R1

R0

FPDI

TxOut1

TxOut2

B1

DE

B0

VS

G5 G4 G3 G2 G1

HS

B5

B4

B3

B2

TxOut3

B7

B6

G7 G6 R7

R6

t

cycle

LDI

TxClk

TxOut0

TxOut1

G2 R7 R6 R5

B3

R4

R3

R2

G3G4G5G6G7B2

TxOut2

TxOut3

DE VS HS B7 B6 B5

B1

B0 G1 G0

R1

B4

R0

KTAM3874/pITX Software Guide

Page 19

KTD-S0057-I Page 15 VESA® DisplayIDTM

4.2 EDID 1.3 Specification (VESA

®

)

The EDID (Extended Display Identification Data) record has a fixed structure. The first 8 bytes contain the

distinctive identification 0x00, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0x00. The end of the record is marked by

the checksum (1 byte). The result of the addition of all bytes including the checksum has to be zero.

For a comprehensive support of the majority of available panels you don't need all fields of the EDID

record. The Detailed Timing Descriptor (18 bytes) is the most important field. No 24bit panels (FPDI/LDI)

are supported though. This means EDID should only be used for 18bit panels.

®

For further information please consult the official EDID specification from the VESA

comitee which has to

be payed.

4.3 DisplayID

TM

Specification (VESA®)

Intended as a replacement for all previous EDID versions DisplayIDTM contains many new features. It's a

structure with several well defined elements (tags). Not every element that is listed in the specification has

to be part of the resulting data set (basic section).

KONTRON has decided to use this selection of tags (mandatory presence).

Tag Description

0x00 Product Identification Data Block (Vendor ID, Product Code, Manufacturing Date ...)

0x03 Type I Detailed Timing Data Block (Pixel Clock, Horizontal/Vertical Data ...)

0x0C Display Device Data Block (Device Technology, Operating Mode, Color Depth ...)

0x0D Interface Power Sequencing Data Block (Power On/Off Timing)

0x0F Display Interface Data Block (Interface Type, Interface Attribute ...)

4.3.1 DisplayIDTM Parameter Summary

Only a part of the parameters used in the DisplayIDTM Windows® tool are interpreted by a specific board. The

following table shows a summary of the used parameters (valid for KTAM3874/pITX).

Group Parameter Comment

Type I Timing Pixel Clock

Type I Timing Horizontal Active

Type I Timing Horizontal Blank

Type I Timing Horizontal Sync Offset Front porch

Type I Timing Horizontal Sync Width

Type I Timing Vertical Active

Type I Timing Vertical Blank

Type I Timing Vertical Sync Offset Front porch

Type I Timing Vertical Sync Width

Display Interface 1 Bits per Pixel Color depth (18 or 24bit)

Display Interface 1 Pixel per Clock Single or dual channel

Display Interface 1 24 Bit Color Mapping FPDI or LDI

KTAM3874/pITX Software Guide

Page 20

KTD-S0057-I Page 16 VESA® DisplayIDTM

4.3.2 DisplayIDTM Restrictions

Depending on the graphic controller not all features can be used. The following table shows the most important restrictions.

Restrictions for KTAM3874/pITX

Variable power sequencing not supported

4.3.3 LCD Panel Selection

The choice of a LCD display is basically defined by two parameters.

Parameter Value

Pixel per Clock (Channels) 1 or 2

Pixel Clock Range 165 MHz

Currently this leads to a maximum resolution of

With TIs® graphic driver it is not guaranteed that every resolution can be achieved. KONTRON does not

guarantee the correct function of the board for untypical resolution. In principal the use of DisplayID

allows realizing every special display resolution. For this a valid DisplayID

onboard EEPROM. Additionally the U-Boot Setup entry

setup display x submenu [3] x Set LCD panel resolution

must be set to auto.

1920 x 1080 Pixel

TM

dataset must be written to the

TM

KTAM3874/pITX Software Guide

Page 21

KTD-S0057-I Page 17 VESA® DisplayIDTM

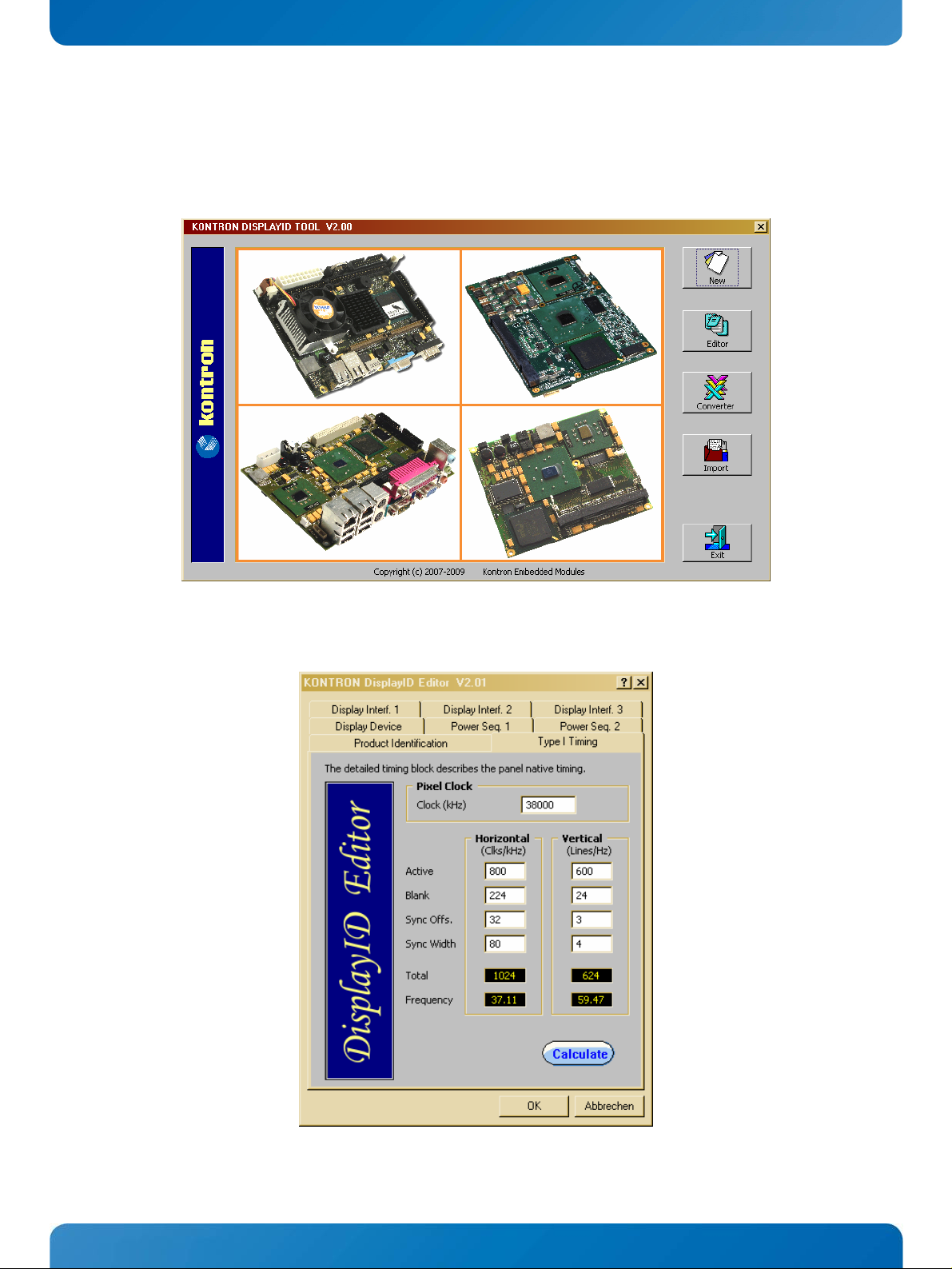

4.3.4 DisplayIDTM Windows® Tool

The DisplayIDTM parameter can be modified with the DisplayIDTM Windows® tool.

For an example the following picture shows the input fields for the Detailed Timing parameters.

For more information see the documentation of the DisplayID

kontron.com).

KTAM3874/pITX Software Guide

TM

tool (software can be downloaded from

Page 22

KTD-S0057-I Page 18 VESA® DisplayIDTM

TM

The DisplayID

isplayIDTM Data). This file format cannot be used to program the onboard EEPROM.

tron D

Editor saves the parameters in a intermediate file format. The file extension is 'KDD' (Kon-

For transferring this file format into the binary file format for the EEPROM apply the Converter.

4.3.5 Building DisplayIDTM File

Start the Windows® tool DisplayID.exe.

Use the Editor if you want to modify an existing DisplayIDTM file or select New to create a

complete new record.

Change respectively enter new parameters.

Save the parameters in a file with the extension 'KDD'.

Open the saved 'KDD'-file using the Converter.

Save the binary file with the extension 'KDB' (Kontron DisplayIDTM Binary).

Program the onboard EEPROM using the board specific update tool.

4.3.6 Erasing DisplayIDTM Record

Create a dummy file with a size of 128 bytes filled with the value 0xFFh and program this file using the U-

TM

Boot update tool. This treatment deletes a valid DisplayID

record.

4.3.7 U-Boot EEPROM Update Tool

The update tool is a new component of the U-Boot bootloader. You need two commands to program a

TM

DisplayID

file into the EEPROM:

ext2load, fatload, loadb or loady

writedid

File Operation

The following example gives an overview:

TM

The storage medium is a microSD

is located in the root directory. The file size of wvga.kdb amounts 81 bytes.

For loading the file into memory type the following standard U-Boot command lines

mmc rescan 0

ext2load mmc 0 81000000 wvga.kdb

The memory address (0x81000000) is free selectable. With the md command you can control the result

md.b 81000000 80

Now you can load the memory content into the EEPROM. Type the new KONTRON U-Boot command

writedid 81000000 51

The 'count' respectively the size argument is a very important parameter. Do not use another value as the

TM

file size of your DisplayID

file.

card formatted with a Linux® partition and the DisplayIDTM file wvga.kdb

KTAM3874/pITX Software Guide

Page 23

KTD-S0057-I Page 19 VESA® DisplayIDTM

Serial Download

The following example demonstrates a serial download via the ymodem protocol:

The KTAM3874/pITX board is connected to a desktop computer with a suitable terminal program (e.g.

Hyper-Terminal or TeraTerm). The file size of wvga.kdb amounts 81 bytes.

For downloading the file into memory type the following standard U-Boot command line

loady

Now U-Boot waits for reply. User input to the desktop terminal program starts the download session. After

the download of wvga.kdb ends you can control the result with the

md.b 80009000 80

Now you can load the memory content into the EEPROM. Type the new KONTRON U-Boot command

writedid 80009000 51

The 'count' respectively the size argument is a very important parameter. Do not use another value as the

TM

file size of your DisplayID

file.

The memory parameter of md.b and writedid depends on the environment entry loadaddr because

Note:

loady uses this definition as base address, for example if loadaddr equals 0x81000000 the new KONTRON U-

Boot command changes to

writedid 81000000 51

md command

KTAM3874/pITX Software Guide

Page 24

KTD-S0057-I Page 20 U-Boot Bootloader

5 U-Boot Bootloader

TI® requires a two-part U-Boot version. The ROM code loads the first part (named U-Boot-MIN) into the onchip prozessor RAM and starts automatically this part. After setting up the clocks and initializing all

necessary peripherals U-Boot-MIN loads the final version. The KTAM3874/pITX board offers four different

TM

load mechanisms: SPI

(default, see chapter 'SPI

For development purposes the UART and Ethernet methods promise some advantages.

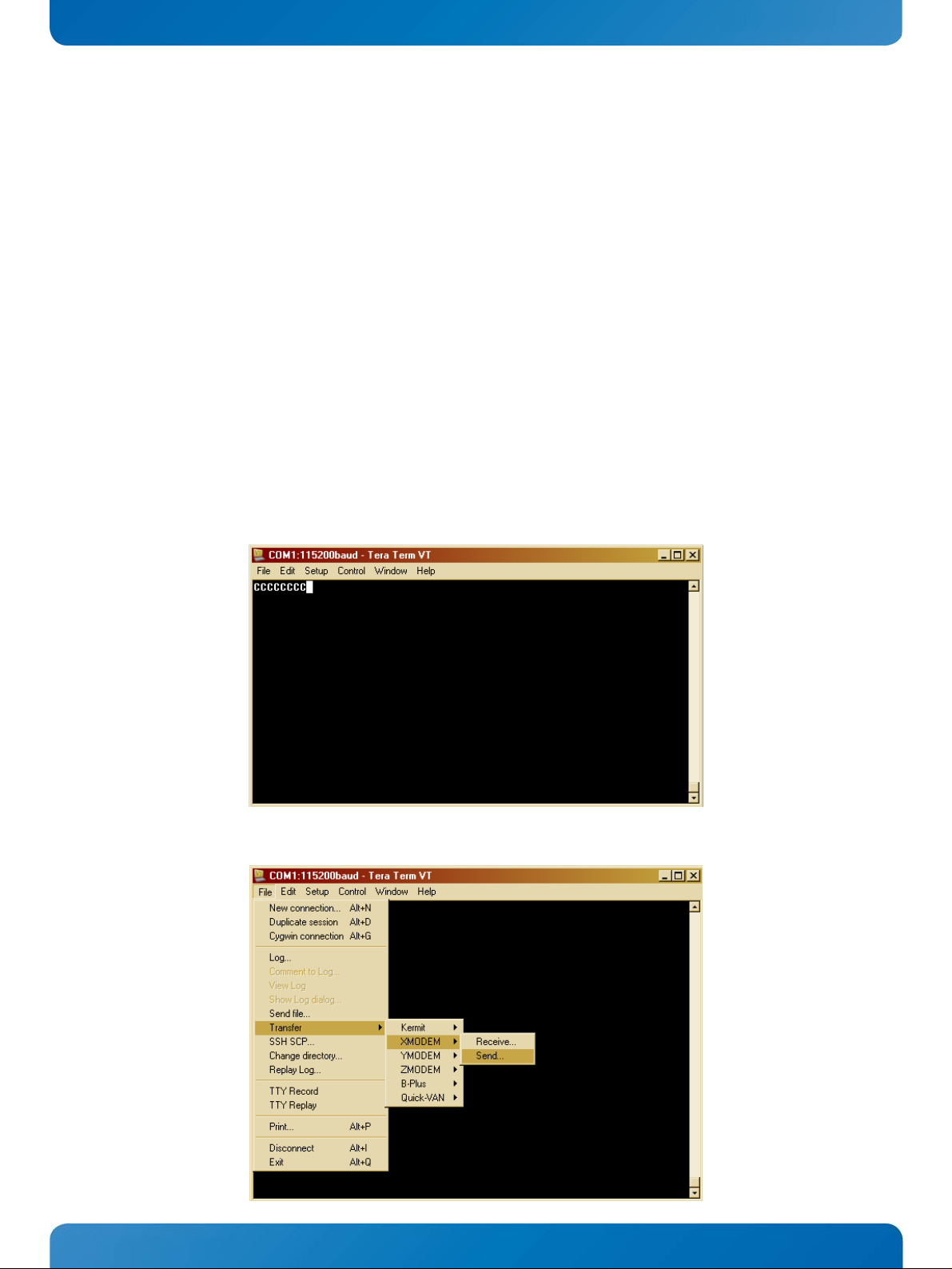

5.1 UART Bootloader

The first serial port (UART0) on connector J1304 provides the serial console interface. For communication

a standard terminal program on a desktop computer is necessary (e.g. TeraTerm). The next line shows the

default serial console settings:

The UART method strictly needs a jumper on pin header J1101 (see User's Guide chapter 'Serial Console').

After power on the following screen appears:

115 kBaud / 8 data bits / 1 stop bit / no parity

TM

Bootloader'), MMC, Ethernet and UART.

Now you have to select the XMODEM transfer mode.

KTAM3874/pITX Software Guide

Page 25

KTD-S0057-I Page 21 U-Boot Bootloader

Note: Do not start the transmission before all eight C's are visible - otherwise the download can be confused.

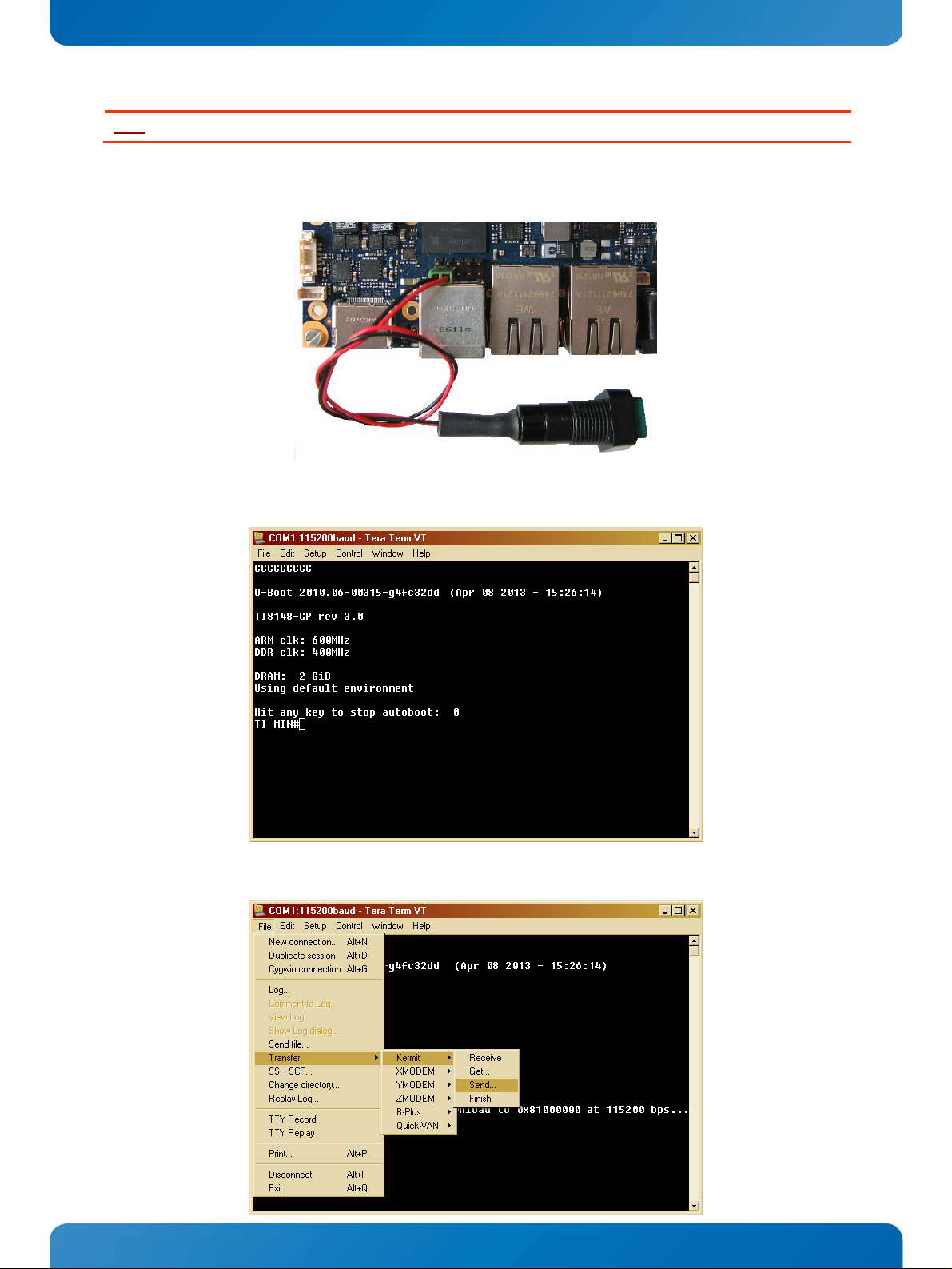

Thereafter select the U-Boot-MIN file (normally named 'u-boot.min.uart') and immediately press the Reset

button to start the download process.

The terminal program shows the following result:

Type 'loadb 81000000' at the 'TI-MIN#' prompt and press 'Enter'. Then choose the Kermit transfer mode.

KTAM3874/pITX Software Guide

Page 26

KTD-S0057-I Page 22 U-Boot Bootloader

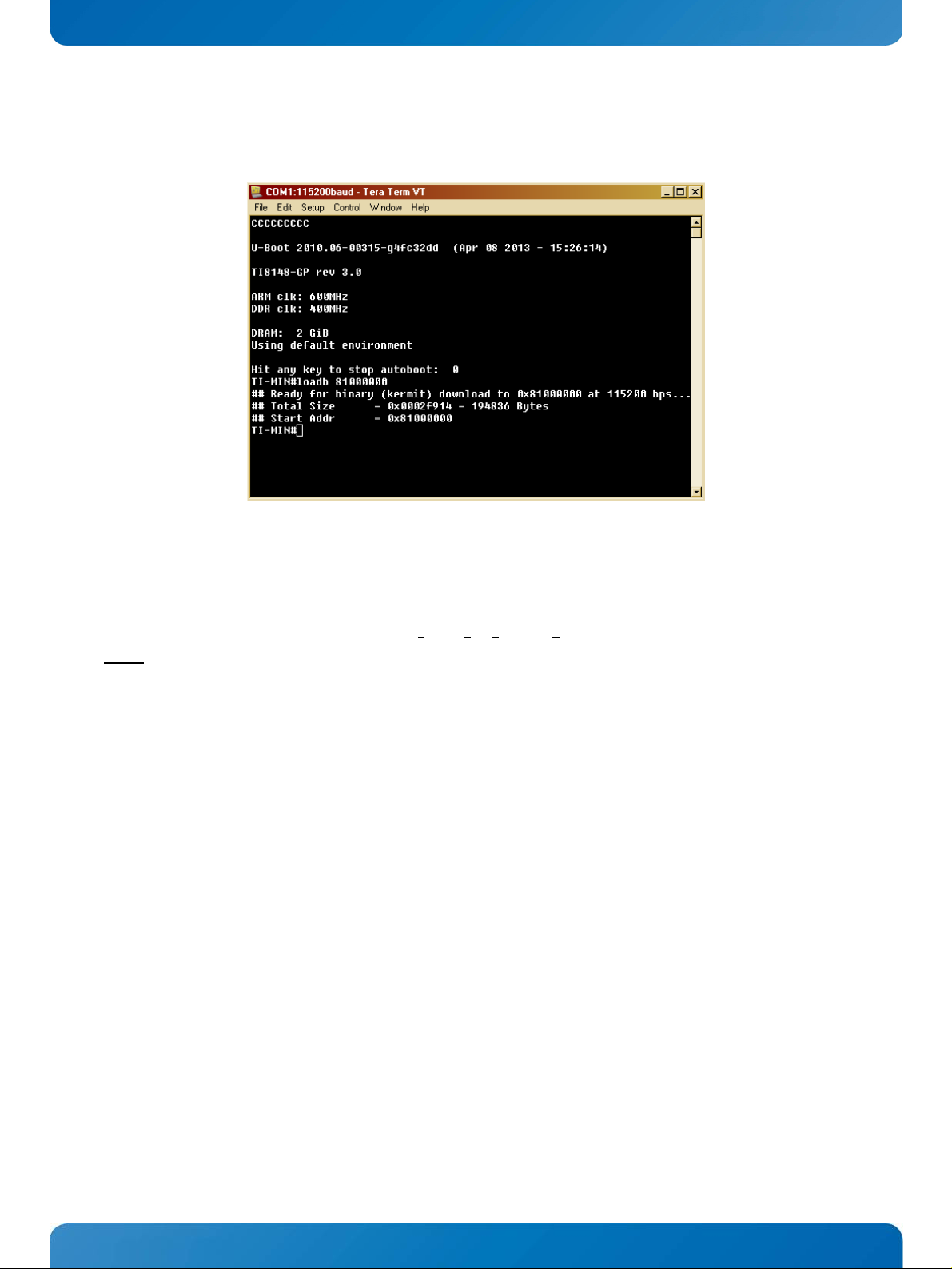

The next step is to load the final U-Boot version (normally named 'u-boot.bin'). This time the transfer

starts automatically. The result looks as follows:

Now you can start the final U-Boot version with 'go 81000000'.

5.2 Ethernet Bootloader

For download over Ethernet you need a TFTP (Trivial File Transfer Protocol) server with DHCP ability.

Use only the first Ethernet port (J1600).

Note:

Some preference changes are necessary:

This method strictly needs a jumper on pin header J1101 (see User's Guide chapter 'Serial

Console').

Rename the U-Boot-MIN file named 'u-boot.min.eth' in 'MLO'.

The ROM code tries first to load the U-Boot-MIN part over the serial interface but this approach fails.

Afterwards the ROM code etablish the Ethernet connection and loads MLO and subsequently the real UBoot version. As a result of the serial interface timeout the network connection is rather slowly.

Copy 'MLO' and u-boot.bin' into the same directory.

KTAM3874/pITX Software Guide

Page 27

KTD-S0057-I Page 23 U-Boot Bootloader

5.3 SPI

TM

Bootloader

This chapter describes the programming of the SPITM flash with the serial interface. Alternative you can load

TM

both U-Boot versions for example from the microSD

Assumption:

the default boot order is active (SPITM flash first boot device).

card.

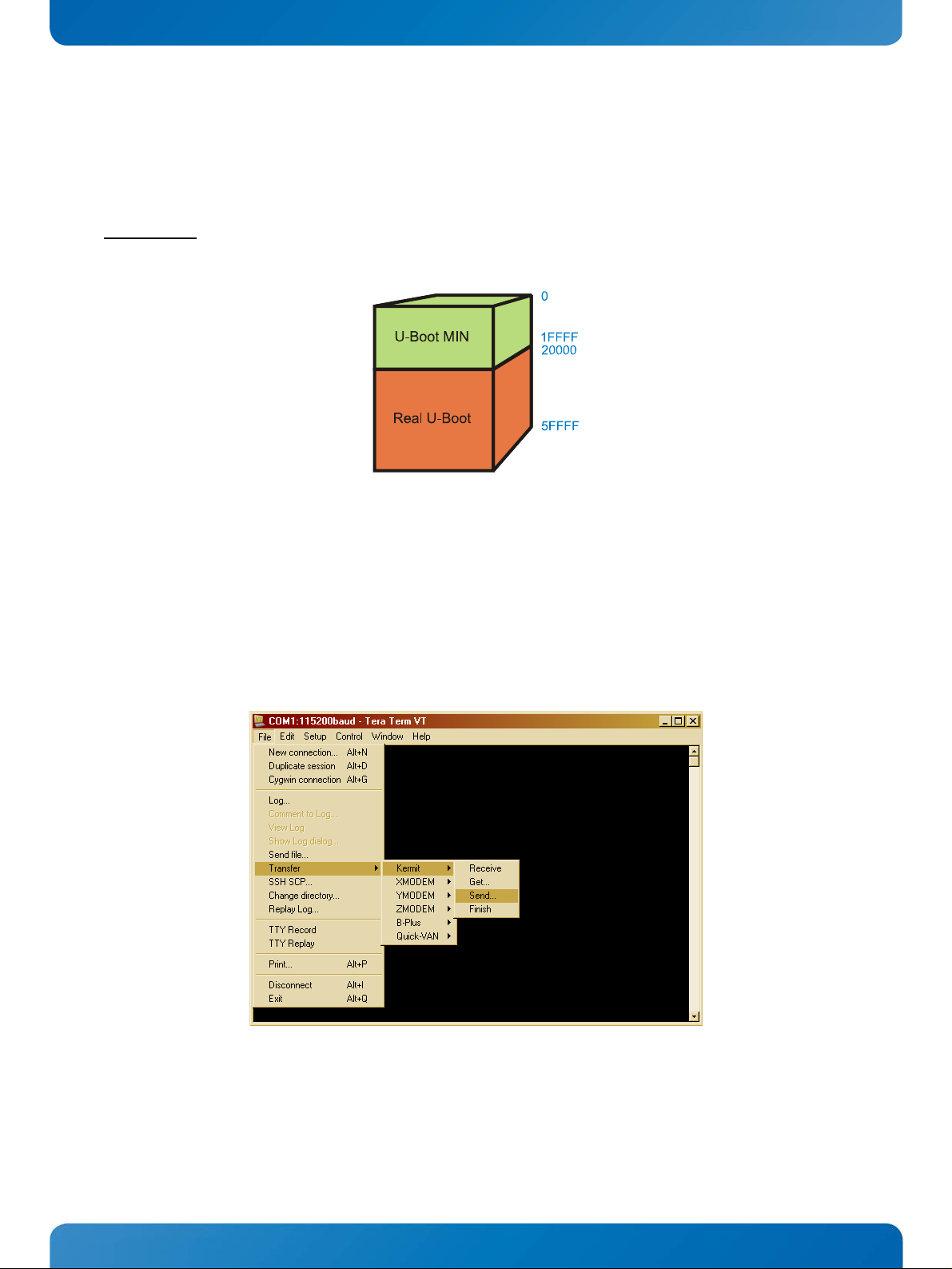

The picture shows the fixed address ranges within the SPITM flash.

After power on U-Boot starts from SPITM. Hit any key to stop the autoboot process. As a first step you should

TM

erase the bootloader part of the SPI

flash with the following commands:

sf probe 0:0

sf erase 0 60000

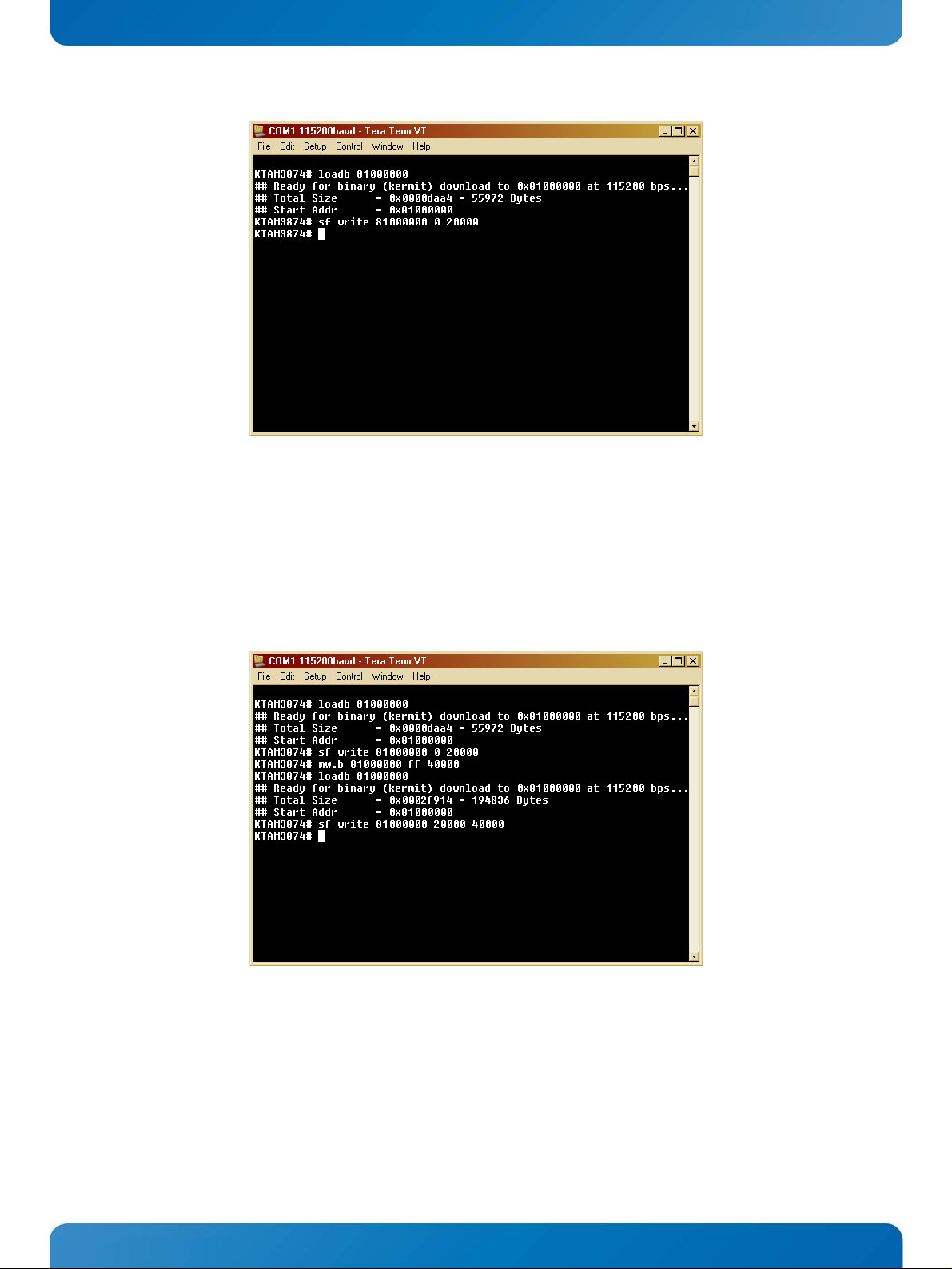

Thereafter type 'loadb 81000000' at the 'KTAM3874#' prompt and press 'Enter'. Then choose the Kermit

transfer mode. Before the download you can clear the memory with

mw.b 81000000 ff 20000

Load the U-Boot-MIN file (normally named 'u-boot.min.spi') and then type

sf write 81000000 0 20000

KTAM3874/pITX Software Guide

Page 28

KTD-S0057-I Page 24 U-Boot Bootloader

Now the first update part is finished. For the second part type again 'loadb 81000000' at the 'KTAM3874#'

prompt and press 'Enter'. Then choose the Kermit transfer mode. Before the download you can clear the

memory with

mw.b 81000000 ff 40000

Load the real U-Boot file (normally named 'u-boot.bin') and then input with another offset and size

sf write 81000000 20000 40000

After power off and power on U-Boot-MIN loads automatically the second part. No additional steps are

necessary.

KTAM3874/pITX Software Guide

Page 29

KTD-S0057-I Page 25 U-Boot Bootloader

5.4 MMC Bootloader

For booting from the microSDTM card you have to change some preferences:

Replug the boot order jumper to MMC x SPI x ... (see User's Guide chapter 'Boot Order').

Rename the U-Boot-MIN file named 'u-boot.min.sd' in 'MLO'.

Format the microSDTM card with FAT16 or FAT32 (Linux® partitions are not accepted). For

®

previous Linux

Disk Storage Format Tool' otherwise the detection can fail.

You need an active FAT partition.

Note:

Copy 'MLO' and u-boot.bin' to the microSDTM card.

After power on U-Boot-MIN (MLO) loads automatically the second part.

formatted cards it would be advisable to use for example the 'HP® USB

KTAM3874/pITX Software Guide

Page 30

KTD-S0057-I Page 26 DebianTM Linux® BSP

6 Debian

TM

Linux® BSP

6.1 User Login Arguments

For both, serial remote system or terminal root privileges with 'sudo', the arguments are the same

(necessary input in green color):

ktam3874 login: ktam3874

Password: ktam3874

6.2 Video Decoding

The KTAM3874/pITX is not qualified for video decoding, the major focus lies on industrial applications. If

you still want to apply a video player use

MPlayer ('sudo apt-get install mplayer'). Other deployable

programs (e.g. Totem Movie Player or SMPlayer, VLC does not work with the default settings) show strong

dropouts.

For measuring the graphics performance use the

glmark2-es2 benchmark.

6.3 Audio Support

If you have trouble with audio input/output please check the 'alsamixer' settings.

Examples with the command line tool 'amixer':

First select a card with amixer -c KTAM3874 (WM8903 codec) or use amixer -c HDMI

®

(HDMI

For an overview type amixer contents

To change a value type e.g. amixer cset numid=27 on

You can find some audio files in the directory

example

aplay login.wav.

monitor). Card names are readable in the directory /proc/asound/

/usr/share/sounds/. Play these files with the 'aplay' tool, for

6.4 KEAPI Interface

The menu item 'Applications x System Tools x KEAPI' offers the practical KEAPI GUI tool. A password is

needed (default:

mentation but rather hidden.

The KEAPI GUI includes four important components: SerialBus, GPIO, Perf(ormance) and Misc(ellaneous).

TM

Three I2C

busses are selectable in the SerialBus tab:

For GPIO pin assignment see the KTAM3874/pITX User's Guide (chapter 'Digital I/O Interface'). The Perf

tab only allows the switch between 600 and 800 MHz (all available frequencies are listed in the file '/sys/

devices/system/cpu/cpu0/cpufreq/scaling_available_frequencies'). Finally the Misc tab includes the

Watchdog and System State control (only RESTART possible - TURN OFF and HIBERNATE without function).

Kontron) - this information can also be detected in the 'Kontron EAPI for Linux' docu-

#0 for onboard devices. Normally the access to these devices should be avoided - further

information on request.

#1 for the HDMI

#2 provides free access to the I2C

®

DDC EEPROM. The graphic driver blocks the access.

TM

bus at J2105 (pins 3 and 4).

KTAM3874/pITX Software Guide

Page 31

KTD-S0057-I Page 27 DebianTM Linux® BSP

6.5 CAN Bus Utilities (SocketCAN)

The directory /usr/bin contains all necessary CAN bus utilities you may need. An overview:

Utility Short Description

canbusload statistic tool

can-calc-bit-timing CAN baudrate calculation

candump shows the received message from the CAN bus, e.g. candump can0

canfdtest full-duplex test program (slave and host part)

cangen CAN frames generator for testing purpose

cangw CAN-to-CAN gateway to route (and modify) messages between multiple buses

canlogserver capture data as ASCII logfile format

canplayer send CAN frames from a file to a CAN interface

cansend send CAN-frames via CAN_RAW sockets, e.g. cansend can0 500#1E.10.10 (500 = CAN ID)

cansniffer capture and analyze CAN traffic

Additional information can be retrieved in the directory /proc/net/can. If you want to overwrite the default

baudrate of 500 kbps change the value in the file

mands (example, requires root rights):

sudo ifconfig can0 down

sudo ip link set can0 up type can bitrate 125000

After boot up it is not necessary to enter the command ifconfig can0/can1 up because this is already done.

More information about SocketCAN can be found on following webpage:

http://www.mjmwired.net/kernel/Documentation/networking/can.txt

/etc/default/can0 resp. can1 or use the following com-

6.6 S-ATA

®

Interface

The S-ATA® port supports two interfaces: either the standard L-type connector J903 or the mSATA® inter-

®

face on the mini PCI Express

tically from the connector J903 to J900 and disables the mini PCI Express

connector J900. After plug in a mSATA® card the hardware switches automa-

®

lanes.

6.7 Suspend Mode

Some of TI's® graphics drivers do not support the suspend/resume feature. Due to this limitation the board

cannot be put into suspend mode if graphics output is enabled and active.

To work around this limitation you must stop the X session and unload the graphics driver modules before

entering the suspend mode. When resuming load the modules first and start the X session afterwards.

6.8 Screensaver

The X screensaver overlays the Gnome

mode and press Enter.

TM

screensaver. In order to solve this issue type xset s off in terminal

KTAM3874/pITX Software Guide

Page 32

KTD-S0057-I Page 28 DebianTM Linux® BSP

6.9 Sysfs Support

Alternative to the KEAPI interface you can use Sysfs to manipulate the GPIOs or the backlight. The example

reads the content and direction of GPIO0 (GP0[10]) and sets the direction to 'output' and the content to

'high'.

Comment:

root@ubuntu:# echo 10 > /sys/class/gpio/export enable GP0[10] access

root@ubuntu:# cat /sys/class/gpio/gpio10/value read content

1 value = high

root@ubuntu:# cat /sys/class/gpio/gpio10/direction read direction

in direction = inpu t

root@ubuntu:# echo "out" > /sys/class/gpio/gpio10/direction set direction to output

root@ubuntu:# echo 1 > /sys/class/gpio/gpio10/value set content to high

root@ubuntu:# echo 10 > /sys/class/gpio/unexport disable GP0[10] access

KTAM3874/pITX Software Guide

Page 33

KTD-S0057-I Page 29 Ethernet Switch

7 Ethernet Switch

TI®'s AM3874 SoC knows two different Ethernet operating modes: the normal dual port and the optional

three port switch

brought out externally on connector J1600 respectively J1601. You can choose between both modes with

an additional U-Boot environment variable (default: dual port mode if the variable is absent).

The environment argument default_bootargs represents a good place for attachment with the U-Boot

command

editenv. Do not forget to save this setting using the command saveenv.

The following picture shows an example with three boards which have at least one free port. There is no

difference between the connectors J1600 and J1601.

setting. The switch contains one port with internal connection and two ports which are

dual_emac=0 $ Three port switch mode

dual_emac=1

Dual port mode

$

For detection of the actual mode use the command ifconfig within Linux

see only

eth0 and for dual port mode eth0/eth1.

®

. As a result for switch mode you

There are no restrictions regarding the connection of other computer boards for example an x86 board with

®

the Windows

operating system.

KTAM3874/pITX Software Guide

Page 34

KTD-S0057-I Page 30 Kernel Boot from SPITM Flash

8 Kernel Boot from SPI

TM

Flash

In some cases it is necessary to program the Linux® kernel into the SPITM flash. U-Boot cannot boot the

®

kernel from the S-ATA

or USB interface (for S-ATA® example see next chapter). The most obvious option

insists in the use of the U-Boot flash command 'sf'.

# sf probe 0:0

4096 KiB SST25VF032B at 0:0 is now current device

# mw.b 81000000 ff 320000

# loadb 81000000

Ready for binary (kermit) download to 0x81000000 at 115200 bps...

Total Size = ... = ... Bytes

Start Addr = 0x81000000

# sf write 81000000 e2000 31e000

The following picture shows the SPITM flash structure:

Note:

The SPITM flash boot requires an additional modification in the U-Boot environment.

loadaddr = 0x81000000

Another option represents the programming of the SPITM flash within the Linux® operating system (e.g.

TM

boot from microSD

# cat /proc/partitions

major minor #blocks name

31 0 128 mtdblock0

31 1 256 mtdblock1

31 2 8 mtdblock2

31 3 512 mtdblock3

31 4 3192 mtdblock4

179 0 7761920 mmcblk0

179 1 7757824 mmcblk0p1

.........

card). First check the partition layout with

KTAM3874/pITX Software Guide

Page 35

KTD-S0057-I Page 31 Root File System Boot from S-ATA® Drive

Thereafter type the following line

# sudo dd if=/boot/uImage of=/dev/mtdblock4

4626+1 records in

4626+1 records out

... bytes (... MB) copied, ... s, 46.0 kB/s

9 Root File System Boot from S-ATA

®

Drive

The S-ATA® part (mSATA® or standard S-ATA® connector) offers the fastest board interface. This is the only

way of achieving transfer rates about 150 MB/s, normally only with SSD drives. The kernel does not

automatically mount the drive therefore you have to modify the configuration file

etc/fstab (per default

this file is empty). The example uses a freely chosen drive identifier (sda1) and target directory.

# UNCONFIGURED FSTAB FOR BASE SYSTEM

/dev/sda1 /media/sata ext4 defaults 0 1

After update you should create the new directory /media/sata. But this method has a serious disadvantage:

if you remove the drive the kernel stops with an error message.

Furthermore the U-Boot environment needs an additional modification:

spiboot =setenv root_bootargs root=/dev/sda1 rw rootwait;run setbootarg;sf probe 0 && sf read ${loadaddr}

0xE2000 0x31E000 && bootm ${loadaddr}

KTAM3874/pITX Software Guide

Page 36

KTD-S0057-I Page 32 Linux® Programming Examples (DebianTM)

10 Linux

10.1 TI

®

®

Programming Examples (DebianTM)

AM3874 Register Access

With the simple known program devmem2 you can read and write all registers of TI

following sourcecode for

TM

distribution).

tu

/*

* devmem2.c: Simple program to read/write from/to any location in memory.

* Copyright (C) 2000, Jan-Derk Bakker (J.D.Bakker@its.tudelft.nl)

* This software has been developed for the LART computing board

* (http://www.lart.tudelft.nl/). The development has been sponsored by

* the Mobile MultiMedia Communications (http://www.mmc.tudelft.nl/)

* and Ubiquitous Communications (http://www.ubicom.tudelft.nl/)

* projects.

* The author can be reached at:

* Jan-Derk Bakker

* Information and Communication Theory Group

* Faculty of Information Technology and Systems

* Delft University of Technology

* P.O. Box 5031

* 2600 GA Delft

* The Netherlands

* This program is free software; you can redistribute it and/or modify

* it under the terms of the GNU General Public License as published by

* the Free Software Foundation; either version 2 of the License, or

* (at your option) any later version.

* This program is distributed in the hope that it will be useful,

* but WITHOUT ANY WARRANTY; without even the implied warranty of

* MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

* GNU General Public License for more details.

* You should have received a copy of the GNU General Public License

* along with this program; if not, write to the Free Software

* Foundation, Inc., 59 Temple Place, Suite 330, Boston, MA 02111-1307 USA

*/

#include <stdio.h>

#include <stdlib.h>

#include <string.h>

#include <errno.h>

#include <fcntl.h>

#include <sys/mman.h>

#define FATAL do { fprintf(stderr, "Error at line %d, file %s (%d) [%s]\n", \

__LINE__, __FILE__, errno, strerror(errno)); exit(1); } while(0)

#define MAP_SIZE 4096UL

#define MAP_MASK (MAP_SIZE - 1)

devmem2 contains some differences to the original program (compiled on Ubun-

®

's AM3874 SoC. The

KTAM3874/pITX Software Guide

Page 37

KTD-S0057-I Page 33 Linux® Programming Examples (DebianTM)

int main (int argc, char **argv)

{

int fd;

void *map_base, *virt_addr;

unsigned long read_result, writeval;

off_t target;

int access_type = 'd';

if (argc < 2)

{

fprintf (stderr, "\nUsage:\t%s {address} [type [data]]\n"

"\taddress : memory address to act upon\n"

"\ttype : access operation type : [b]yte, [w]ord, [d]word\n"

"\tdata : data to be written\n\n", argv[0]);

exit (1);

}

target = strtoul (argv[1], NULL, 16);

if (argc > 2)

access_type = tolower (argv[2][0]);

if ((fd = open ("/dev/mem", O_RDWR | O_SYNC)) == -1) FATAL;

map_base = mmap (0, MAP_SIZE, PROT_READ | PROT_WRITE, MAP_SHARED, fd, target & ~MAP_MASK);

if (map_base == (void *) -1) FATAL;

virt_addr = map_base + (target & MAP_MASK);

switch (access_type)

{

case 'b': read_result = *((unsigned char *) virt_addr); break;

case 'w': read_result = *((unsigned short *) virt_addr); break;

case 'd': read_result = *((unsigned long *) virt_addr); break;

default : fprintf (stderr, "Illegal data type '%c'.\n", access_type); exit (2);

}

printf ("Value at address 0x%lX: 0x%lX\n", target, read_result);

fflush (stdout);

if (argc > 3)

{

writeval = strtoul (argv[3], NULL, 16);

switch (access_type)

{

case 'b': *((unsigned char *) virt_addr) = writeval;

read_result = *((unsigned char *) virt_addr);

break;

case 'w': *((unsigned short *) virt_addr) = writeval;

read_result = *((unsigned short *) virt_addr);

break;

case 'd': *((unsigned long *) virt_addr) = writeval;

read_result = *((unsigned long *) virt_addr);

break;

}

printf ("Written: 0x%lX - Readback: 0x%lX\n", writeval, read_result);

fflush (stdout);

}

K

KTAM3874/pITX Software Guide

Page 38

KTD-S0057-I Page 34 Linux® Programming Examples (DebianTM)

if (munmap (map_base, MAP_SIZE) == -1) FATAL;

close (fd);

return 0;

}

The following lines demonstrate the access to an AM3874 register (all values are hexadecimal):

Read the GPIO port 0 debounce register ./devmem2 48032150

Enable debouncing of GP0[10] (write access) ./devmem2 48032150 d 400

You need root rights for use of 'devmem2'.

ATTENTION

10.1.1 Register Access Restrictions

The functionality of the GPIO connectors deserves special interest. You can use the respective device driver

interface or for more flexibility direct register access (e.g. with 'devmem2'). The table shows two cases

where the register access fails.

Function Short Desciption Memory Address Direct Access

I2C2

SPI2

SPI3

UART2

UART4

TIM4

TIM5

TIM6

TIM7

I2CTM - 3rd controller 0x4819C000

SPITM - 3rd controller 0x481A2000

SPITM - 4th controller 0x481A4000

UART - 3rd controller 0x48024000

UART - 5th controller 0x481A8000

Timer 4 0x48044000

Timer 5 0x48046000

Timer 6 0x48048000

Timer 7 0x4804A000

YES

NO

NO

YES

YES

YES

YES

YES

YES

TM

The problem with the SPI

disabled. You can solve this issue with the following register programming (needed root rights):

Enable clock domain in CM_ALWON_SPI_CLKCTRL ./devmem2 48181590 d 30002

interface resides in the fact that outside of the device driver the clock domain is

Now all SPITM registers are fully accessible.

KTAM3874/pITX Software Guide

Page 39

KTD-S0057-I Page 35 Linux® Programming Examples (DebianTM)

10.2 SPI

TM

Interface Examples

10.2.1 SPITM Loopback Test Utility

A simple way to check the SPITM interface consists in shorting of the data lines (MISO, MOSI). After that you

TM

can use the following program with root rights (compiled on Ubuntu

/*

* SPI testing utility (using spidev driver)

* Copyright (c) 2007 MontaVista Software, Inc.

* Copyright (c) 2007 Anton Vorontsov

* This program is free software; you can redistribute it and/or modify

* it under the terms of the GNU General Public License as published by

* the Free Software Foundation; either version 2 of the License.

*/

#include <stdint.h>

#include <stdio.h>

#include <stdlib.h>

#include <getopt.h>

#include <fcntl.h>

#include <sys/ioctl.h>

#include <linux/spi/spidev.h>

#define ARRAY_SIZE(a) (sizeof(a) / sizeof((a)[0]))

static const char *device = "/dev/spidev3.0"; /* Connector J2105 pin 5 to 8 */

/****** Do not forget to enable SPI3 (= spidev4.0) in U-Boot Setup ******/

/*static const char *device = "/dev/spidev4.0";*/ /* Connector J2105 pin 23 to 26 */

static uint8_t mode = 0;

static uint8_t bits = 8;

static uint32_t speed = 1000000;

static uint16_t delay;

static void pabort (const char *s)

{

perror (s);

abort ();

}

static void transfer (int fd)

{

int ret;

uint8_t tx[] = {

0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF,

0x40, 0x00, 0x00, 0x00, 0x00, 0x95,

0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF,

0xFF, 0xFF, 0xFF, 0xFF, 0xFF, 0xFF,

0xFF, 0xFF, 0xFF, 0xFF, 0xDE, 0xAD,

0xBE, 0xEF, 0xBA, 0xAD, 0xF0, 0x0D };

distribution):

KTAM3874/pITX Software Guide

Page 40

KTD-S0057-I Page 36 Linux® Programming Examples (DebianTM)

uint8_t rx[ARRAY_SIZE(tx)] = {0, };

struct spi_ioc_transfer tr = {

.tx_buf = (unsigned long) tx,

.rx_buf = (unsigned long) rx,

.len = ARRAY_SIZE(tx),

.delay_usecs = delay,

.speed_hz = 0,

.bits_per_word = 0 };

ret = ioctl (fd, SPI_IOC_MESSAGE (1), &tr);

if (ret == 1)

pabort ("Cannot send SPI message");

for (ret = 0; ret < ARRAY_SIZE(tx); ret++)

{

if (! (ret % 6))

puts ("");

printf ("%.2X ", rx[ret]);

}

puts ("");

}

void print_usage (const char *prog)

{

printf ("Usage: %s [-DsbdHOC]\n", prog);

puts (" -D --device device to use (default /dev/spidev1.1)\n"

" -s --speed max speed (Hz)\n"

" -d --delay delay (usec)\n"

" -b --bpw bits per word \n"

" -H --cpha clock phase\n"

" -O --cpol clock polarity\n"

" -C --cs-high chip select active high\n");

exit (1);

}

void parse_opts (int argc, char *argv[])

{

while (1)

{

static const struct option lopts[] = {

{ "device", 1, 0, 'D' },

{ "speed", 1, 0, 's' },

{ "delay", 1, 0, 'd' },

{ "bpw", 1, 0, 'b' },

{ "cpha", 0, 0, 'H' },

{ "cpol", 0, 0, 'O' },

{ "cs-high", 0, 0, 'C' },

{ NULL, 0, 0, 0 }};

int c;

c = getopt_long (argc, argv, "D:s:d:b:HOC", lopts, NULL);

if (c == -1) break;

KTAM3874/pITX Software Guide

Page 41

KTD-S0057-I Page 37 Linux® Programming Examples (DebianTM)

switch (c)

{

case 'D': device = optarg; break;

case 's': speed = atoi (optarg); break;

case 'd': delay = atoi (optarg); break;

case 'b': bits = atoi (optarg); break;

case 'H': mode |= SPI_CPHA; break;

case 'O': mode |= SPI_CPOL; break;

case 'C': mode |= SPI_CS_HIGH; break;

default: print_usage (argv[0]); break;

}

}

}

int main (int argc, char *argv[])

{

int ret = 0;

int fd;

parse_opts (argc, argv);

fd = open (device, O_RDWR);

if (fd < 0)

pabort ("Cannot open device");

/* SPI mode */

ret = ioctl (fd, SPI_IOC_WR_MODE, &mode);

if (ret == -1)

pabort ("Cannot set SPI mode");

ret = ioctl (fd, SPI_IOC_RD_MODE, &mode);

if (ret == -1)

pabort ("Cannot get SPI mode");

/* Bits per word */

ret = ioctl (fd, SPI_IOC_WR_BITS_PER_WORD, &bits);

if (ret == -1)

pabort ("Cannot set bits per word");

ret = ioctl (fd, SPI_IOC_RD_BITS_PER_WORD, &bits);

if (ret == -1)

pabort ("Cannot get bits per word");

/* Max speed in Hz */

ret = ioctl (fd, SPI_IOC_WR_MAX_SPEED_HZ, &speed);

if (ret == -1)

pabort ("Cannot set max speed in Hz");

ret = ioctl (fd, SPI_IOC_RD_MAX_SPEED_HZ, &speed);

if (ret == -1)

pabort ("Cannot get max speed in Hz");

printf ("SPI mode: %d\n", mode);

printf ("Bits per word: %d\n", bits);

printf ("Max speed: %d Hz (%d kHz)\n", speed, speed/1000);

KTAM3874/pITX Software Guide

Page 42

KTD-S0057-I Page 38 Linux® Programming Examples (DebianTM)

transfer (fd);

close (fd);

return ret;

}

You should consider following parameter limits:

Parameter MIN MAX Units

Databits (Bits per Word) 4

Transmission Speed 2000

Transmission Mode Only full duplex possible (driver restriction)

Bit Transfer Mode Only MSB first mode possible

The test array of the original sourcecode contains 38 bytes but this number can cause a crash if you

Note:

use 32 data bits (number should be 36 bytes).

Further information is available on

Examples:

Using default values ./spi

Set speed to 10 MHz ./spi -s 10000000

Set mode to 3 ./spi -H -O

https://www.kernel.org/doc/Documentation/spi/spi-summary.

As result you should see this screen output:

32

48000000

Bits

Hz

KTAM3874/pITX Software Guide

Page 43

KTD-S0057-I Page 39 Linux® Programming Examples (DebianTM)

10.2.2 SPITM Display Interface

The SPITM interface is well suited to connect uncomplicated intelligent small graphic modules for example

The schematic below shows the connection to I/O connector J2105 pin 5 to 8 (SPI2). Please notice that this

draft only serves for demonstration purposes but not for real applications.

Electronic Assembly eDIP128-6.

In general the following pinout applies for all SPITM interfaces:

D0 $ MISO (Master In Slave Out = Receive)

D1 $ MOSI (Master Out Slave In = Transmit)

Note: Please perform a RESET before you execute the test program.

KTAM3874/pITX Software Guide

Page 44

KTD-S0057-I Page 40 Linux® Programming Examples (DebianTM)

Now the corresponding test program (needs root rights):

/* SPI test program for

* Electronic Assembly graphic module eDIP128-6

* Copyright (c) 2013 Kontron Technology A/S

* This program is free software; you can redistribute it and/or modify

* it under the terms of the GNU General Public License as published by

* the Free Software Foundation; either version 2 of the License.

*/

#include <stdint.h>

#include <stdio.h>

#include <stdlib.h>

#include <getopt.h>

#include <fcntl.h>

#include <sys/ioctl.h>

#include <linux/spi/spidev.h>

#define ARRAY_SIZE(a) (sizeof(a) / sizeof((a)[0]))

#define SPI_OPEN_ERROR 0x10

#define SPI_MODE_ERROR 0x11

#define SPI_BITS_ERROR 0x12

#define SPI_SPEED_ERROR 0x13

static const char *device = "/dev/spidev3.0";

/****** Do not forget to enable SPI3 (= spidev4.0) in U-Boot Setup ******/

/*static const char *device = "/dev/spidev4.0";*/

static uint8_t mode = 3;

static uint8_t bits = 8;

static uint32_t speed = 100000;

static uint16_t delay = 10;

static int fd;

static int transmit_spi_test_string (void)

{

uint8_t tx[] = {

0x11, /* DC1 */

0x05, /* Data len */

0x48, 0x65, 0x6C, 0x6C, 0x6F, /* Data = 'Hello' */

0x0A /* Checksum */

};

struct spi_ioc_transfer xfer = {

.tx_buf = (unsigned long) tx,

.rx_buf = (unsigned long) NULL,

.len = ARRAY_SIZE(tx),

.delay_usecs = delay,

.speed_hz = 0,

.bits_per_word = 0 };

if (ioctl (fd, SPI_IOC_MESSAGE (1), &xfer) == 1)

return -1;

return 0;

}

KTAM3874/pITX Software Guide

Page 45

KTD-S0057-I Page 41 Linux® Programming Examples (DebianTM)

int init_spi_interface (void)

{

fd = open (device, O_RDWR);

if (fd < 0)

return SPI_OPEN_ERROR;

if (ioctl (fd, SPI_IOC_WR_MODE, &mode) == -1)

return SPI_MODE_ERROR;

if (ioctl (fd, SPI_IOC_WR_BITS_PER_WORD, &bits) == -1)

return SPI_BITS_ERROR;

if (ioctl (fd, SPI_IOC_WR_MAX_SPEED_HZ, &speed) == -1)

return SPI_SPEED_ERROR;

return 0;

}

int main (void)

{

int ret;

printf ("\nSPI Test for eDIP128-6\n");

if ((ret = init_spi_interface ()))

{

close (fd);

printf ("SPI init error: 0x%02X\n\n", ret);

return -1;

}

if (transmit_spi_test_string ())

{

close (fd);

printf ("SPI transmission fails!\n\n");

return -1;

}

close (fd);

printf ("SPI transmission successfully finished.\n\n");

return 0;

}

KTAM3874/pITX Software Guide

Page 46

KTD-S0057-I Page 42 Linux® Programming Examples (DebianTM)

10.3 I

2CTM

Interface Examples

10.3.1 I2CTM Detection Utility

The following sourcecode represents an optimized lean version of the standard I2CTM detection program

TM

without unnecessary overhead (compiled on Ubuntu

/*

i2cdetect.c - a user-space program to scan for I2C devices

Copyright (C) 1999-2004 Frodo Looijaard <frodol@dds.nl>, and