Page 1

CPCI

Backplane

Manual

PRODUCT DOCUMENTATION

PD18

CP6-BP4-PB-RIO

Reference ID: 24229 PD18

Revision: 01

Issued: August 29, 2003

The product described in this manual

is in compliance with all applied CE

standards.

Page 2

PD18: CP6-BP4-PB-RIO CPCI Backplane

Revision History

CPCI Backplane Manual:

Manual/Product Title:

Reference ID: 24229 PD18

Product Documentation:

CP6-BP4-PB-RIO

Rev.

Index

01 Initial Issue Aug. 29, 2003

Brief Description of Changes Date of Issue

Imprint

Copyright © 2003 PEP Modular Computers GmbH. All rights

reserved. This manual may not be copied, photocopied,

reproduced, translated or converted to any electronic or machinereadable form in whole or in part without prior written approval of

PEP Modular Computers GmbH.

DISCLAIMER:

PEP Modular Computers GmbH rejects any liability for the correctness

and completeness of this manual as well as its suitability for any particular purpose.

This manual was realized by: TPD/Engineering, PEP Modular Computers GmbH.

Page 2 © 2003 PEP Modular Computers GmbH RID 24229 PD18, Rev. 01

Page 3

CPCI Backplane PD18: CP6-BP4-PB-RIO

1. Introduction

The specific product description provided with this product documentation is part of the PEP’s

CPCI Backplane manual. For further information, in particular regarding general details as well

as safety and warranty statements, refer to the CPCI Backplane Manual, ID 24229.

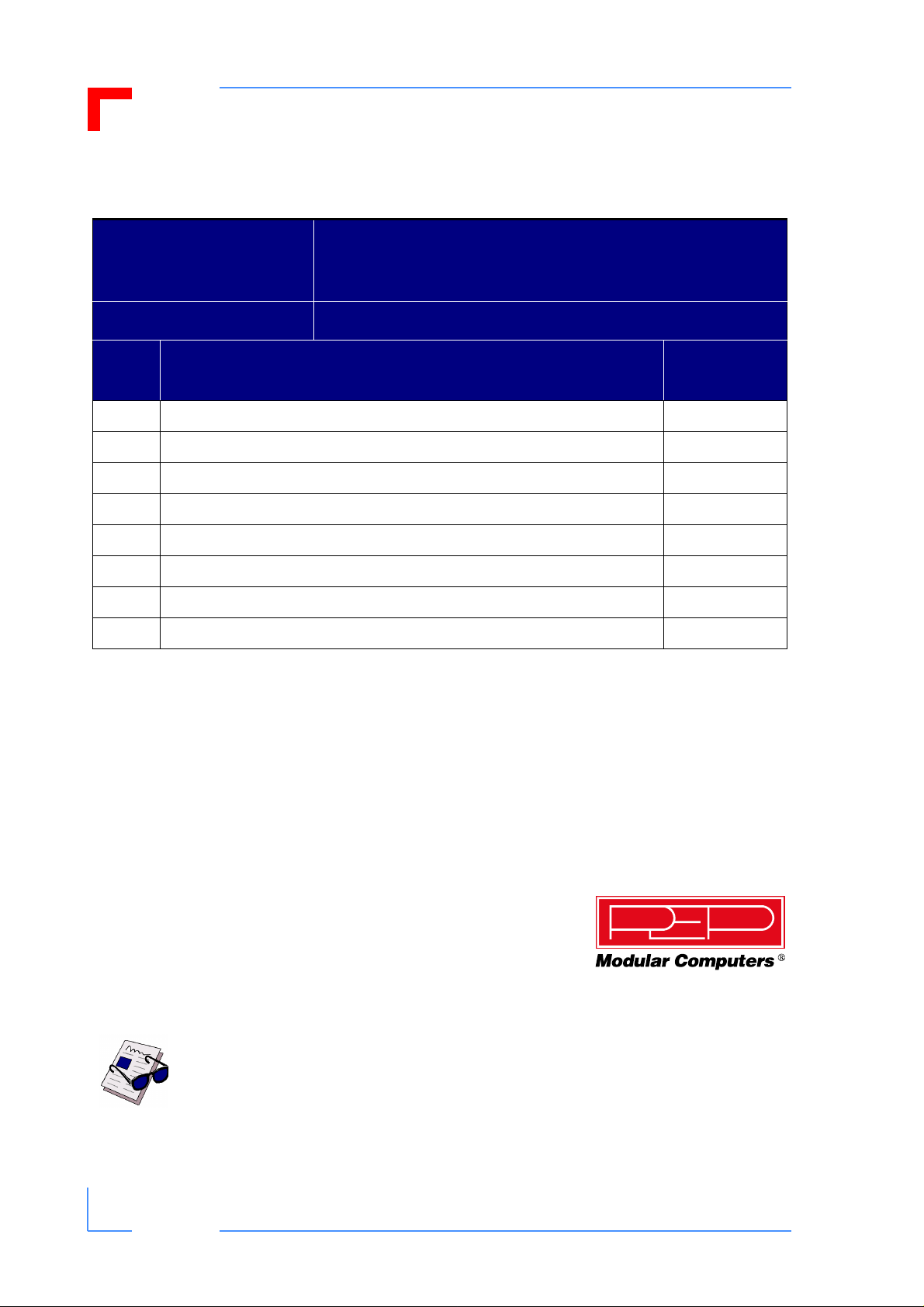

2. CP6-BP4-PB-RIO Power Bar Backplane

The main features of the 6U, 4-slot, power bar backplane CP6-BP4-PB-RIO are described in

the following table:

Table 1: Distinctive Features of Backplane CP6-BP4-PB-RIO

Feature Specification

Form Factor

Size

Number of Slots

Bus Resolution

Bus Frequency

Rear I/O Connectivity

Hot-Swap Capability

Power Supply Connector

Redundant Power Supply

System Management

Flexible Grounding Option

Fan Connector

MSD Connector

6U

95.5*262.05 mm

4

64 bits

33 or 66MHz

P3 to P5 on all slots

Yes

11 power bar terminals, M3 lugs

–

Optional

Yes

Optional

Optional

Power LED

PS-ON Connector

System MON-CTRL Connector

RID 24229 PD18, Rev. 01 © 2003 PEP Modular Computers GmbH Page 3

–

Yes

Yes

Page 4

PD18: CP6-BP4-PB-RIO CPCI Backplane

3. Board Layout

Figure 1: CP6-BP4-PB-RIO Board Layout (Front)

234

34

2

Page 4 © 2003 PEP Modular Computers GmbH RID 24229 PD18, Rev. 01

= logical slot

1

1

numbering

Page 5

CPCI Backplane PD18: CP6-BP4-PB-RIO

Figure 2: CP6-BP4-PB-RIO Board Layout (Reverse)

JP15

BRIDGE

)

I/O

(

V

POWER TERMINALS

JP12 JP11

RID 24229 PD18, Rev. 01 © 2003 PEP Modular Computers GmbH Page 5

POWER TERMINALS

Page 6

PD18: CP6-BP4-PB-RIO CPCI Backplane

4. Signalling Environment

4.1 V(I/O) Setting

There is one block of three high-current terminals (designated as V(I/O)) for connecting V(I/O)

to either the +5V or +3.3V power supply. V(I/O) must be connected either to the +5V or the

+3.3V input power. It is the responsibility of the system integrator to ensure that the required

signalling voltage is implemented and that the backplane P1 connector coding corresponds to

the implemented signalling voltage.

Warning!

Using both 3.3V and 5V boards within the same backplane segment

may result in damage to your equipment. Please note that the presence of only one 5V board determines a 5V signalling environment.

The default setting is 5V.

4.2 P1 Connector Coding for V(I/O)

The CompactPCI Specification foresees coding of the P1 connector to correspond to the signalling environment of the PCI bus. For this reason, only boards with universal or the corresponding coding can be physically inserted into the backplane. PEP’s factory default setting

for V(I/O) is +5V and male, 1567 code, brilliant blue coding keys are used.

Warning!

Using boards with an inadequate signalling voltage may result in damage to your equipment. Therefore, when changing the signalling environment from 5V to 3.3V or vice versa, it is mandatory that proper

coding keys are used (refer to chapter 3 of the CPCI Backplane Manual, ID 24229, for details).

5. Interfaces

5.1 Power

Bolt type terminals are provided for inputting DC power to this backplane. These terminals are

primarily designed for extending the DC power busses, but they can also be used with nonpluggable power supplies for providing primary DC power input. Refer to Figure 2 for termina l

locations.

Page 6 © 2003 PEP Modular Computers GmbH RID 24229 PD18, Rev. 01

Page 7

CPCI Backplane PD18: CP6-BP4-PB-RIO

5.2 Fan Connectors

The backplane can be optionally equipped with two connectors for supplying power for fans

and for connecting a fan speed control device. JP21 (FAN1), is a 3-contact male connector

which supplys +12V for fan operation as well as the possibility to connect to a speed control

device for regulating air flow within the system sub-rack. JP22 (NTC1), is a 2-contact male

connector which provides a separate connection for a speed control device and is designed to

be used in conjunction with JP21.

For fans that have their own speed control or where no control is required, pins 1 and 2 of

JP21 can be used. For external speed control of fans, pins 2 and 3 of JP21 and pins 1 and 2

of JP22 are used. Pin 3 of JP21 and pin 2 of JP22 are connected internally on the board side

to each other.

External air flow regulation can be accomplished using a negative thermal coefficient (NTC)

device connected to JP22.

Figure 3: Orientation and Pinouts of Connectors JP21 and JP22

JP21

JP22

3

2

1

2

1

Table 2: Pinout of JP21 Connector

Pin Function

1GND

2 +12V

3NTC1/2

Table 3: Pinout of JP22 Connector

Pin Function

1GND

2NTC1/2

RID 24229 PD18, Rev. 01 © 2003 PEP Modular Computers GmbH Page 7

Page 8

PD18: CP6-BP4-PB-RIO CPCI Backplane

5.3 System Management Connectors JP19 and JP20

Two five-contact male system management bus (IPMB0/1) connectors, JP19/20, can be

optionally provided for external interfacing to this bus.

Figure 4: Orientation and Pinout of the IMPB0/1 Connectors JP19/20

Table 4: Pinout of IMPB0/1

Connectors JP19/20

Pin Function

5

1

1 IMPB0_SCL / IMPB1_SCL

2GND

3 IMPB0_SDA / IMPB1_SDA

4 IMPB_PWR / V

5SMB_Alert *

* JP20 only

5.4 MSD Connector

One 4-pole Molex male connector, JP4, can be optionally equipped on the backplane for the

connection of mass storage devices (drives) to the +5V/+12V power supply of the bus.

Figure 5: Orientation and Pinout of Connector JP4

Table 5: Pinout of Connector JP4

1

Pin Function

2

3

1 +12V

2GND

3GND

4+5V

4

Page 8 © 2003 PEP Modular Computers GmbH RID 24229 PD18, Rev. 01

Page 9

CPCI Backplane PD18: CP6-BP4-PB-RIO

5.5 System Monitor and Control Connectors JP11 and JP12

This backplane is provided with two connectors for system monitor and control signal interfacing to external devices. Both are 26-contact, male, double pin-row connectors, and have the

same signal pinout configuration. The system management bus (IPMB0), the power supply

monitor and control signals, and push button reset (PRST#) signal are all implemented on

these connectors.

Figure 6: Orientation and Pinout of the SMC Connectors JP1 1 and JP12

Table 6: Pinout of SMC Connectors

JP11 and JP12

Function

Pin

Pin Row A Pin Row B

JP11

b

a

113

1 IMPB0_SCL GND

2 IMPB0_SDA IMPB0_PWR

3N/C GND

4N/C GND

5N/C GND

6 INH# GND

JP12

b

a

113

Note...

The signal pinout assignment is a function of the power supply actually utilized

with this backplane. Refer to the corresponding power supply documentation for

the applicable signal pinout.

7 FAL# DEG#

8PRST# GND

9 GND V1 SENSE (+5V)

10 V2 SENSE (+3.3V) SENSE RTN

11 V3 SENSE (+12V) GND

12 V1 SHARE (+5V) V2 SHARE (+3.3V)

13 V3 SHARE (+12V) GND

RID 24229 PD18, Rev. 01 © 2003 PEP Modular Computers GmbH Page 9

Page 10

PD18: CP6-BP4-PB-RIO CPCI Backplane

5.6 Auxiliary Signal Connector JP15

One five-contact male auxiliary signal connector , JP15, can be optionally provided for external

interfacing.

Figure 7: Orientation and Pinout of Connector JP15

Table 7: Pinout of Connector JP15

Pin Function

4

1

1GND

2P5VStby

3PRST#

4PSON

6. Optional System Configurations

6.1 Power Supply Options

The design of this backplane allows for several different power supply options:

1. The default configuration of a single compatible pluggable power supply.

2. Addition of compatible pluggable power supplies installed either to the left or right of the

backplane.

Option 1 is the standard configuration which requires the integr ation of a single CP-ADAP-P47PB (3U or 6U) power bar adapter.

Option 2 can be achieved through the use of power bar adapter boards which can be mounted

either to the left or right of the backplane. These boards which accommodate pluggable power

supplies are connected to the backplane terminals through the use of power bars. In addition,

the system monitor and control signals can be extended via JP11 or JP12 to the power supply

adapter boards using appropriate cabling. This configuration allows for additional power supplies to be added which satisfy system requirements such as redundancy, power sharing, or

simply increasing available power.

6.2 System Addon Options

The CP6-BP4-PB-RIO backplane is designed to allow the installation of backplane(s) to the left

or right of it in a sub-rack and at the same time maintaining the slot raster. This feature makes

it possible to add (an) additional backplane(s) using appropriate hardware for accommodating

multiple system configurations in one sub-rack.

Page 10 © 2003 PEP Modular Computers GmbH RID 24229 PD18, Rev. 01

Loading...

Loading...