Page 1

CP390

Active PMC Carrier Board

for CompactPCI Applications

Manual ID 19976, Rev. Index 0200

Jan 00

The product described in this manual is

in compliance with all applied CE standards.

Page 2

Preface CP390

Chapter

Preface

Preface Table of Contents.............................................0 - 4

Chapt

Chapter

1. Introduction

1.1 Overview .................................................................1 - 2

1.2 Board Interfaces .....................................................1 - 3

1.3 Block Diagram ........................................................1 - 4

1.4 Board Layout ..........................................................1 - 4

1.5 Front Panels ...........................................................1 - 5

0

1

1

1.6 Technical Specifications .........................................1 - 6

1.7 Applied Standards ..................................................1 - 7

1.8 Related Publications ...............................................1 - 7

Chapter

2. Installation

2.1 Board Installation ....................................................2 - 2

2

ID 19976, Rev. 0200Page 0 - 2 ® PEP Modular Computers GmbH

Page 3

CP390 Preface

Chapter

3. Configuration

3.1 Pinouts ....................................................................3 - 2

Chapter

4. Hotswap

4.1 Technical Background of CompactPCI Hotswap ....4 - 2

4.2 Design Implementation on the CP390 ....................4 - 4

Appendix

CompactPCI System Notes

3

4

A

A System Overview ....................................................A - 2

B System Components ..............................................A - 3

ID 19976, Rev. 0200 Page 0 - 3® PEP Modular Computers GmbH

Page 4

CP390 Preface

Preface

Table of Contents......................................................... 0 - 2

Revision History........................................................... 0 - 5

Trademarks.................................................................. 0 - 5

Explanation of Symbols ............................................... 0 - 6

For Your Safety............................................................ 0 - 7

High Voltage Safety Instructions.............................. 0 - 7

Chapt

Chapter

1

0

Special Handling and Unpacking Instructions.......... 0 - 7

General Instructions on Usage................................. 0 - 8

Two Years Warranty .................................................... 0 - 9

ID 19976, Rev. 0200 Page 0 - 4® PEP Modular Computers GmbH

Page 5

Preface CP390

Revision History

Revision History

Manual/Product Title: CP390

Manual ID Number: 19976

Rev.

Index

0100 Initial Issue 1000 Apr. 99

0200 Hotswap chapter added, description of

This document contains information proprietary of PEP Modular Computers. It may not be

copied or transmitted by any means, disclosed to others or stored in any retrieval system or

media, without the prior written consent of PEP Modular Computers GmbH or one of its authorized agents.

The information contained in this document is, to the best of our knowledge, entirely correct.

However, PEP Modular Computers cannot accept liability for any inaccuracies, or the consequences thereof, nor for any liability arising from the use or application of any circuit, product,

or example shown in this document.

Brief Description of Changes Board Index

2000 Jan. 00

CompactPCI and PMC connectors added,

deletion of I/O voltage switching description

Date of

Issue

PEP Modular Computers reserve the right to change, modify, or improve this document or the

product described herein, as seen fit by PEP Modular Computers without further notice.

Trademarks

PEP Modular Computers and the PEP logo are trademarks owned by PEP Modular Computers GmbH, Kaufbeuren, Germany. In addition, this document may include names, company

logos and trademarks which are registered trademarks and are, therefore, proprietary of their

respective owners.

ID 19976, Rev. 0200Page 0 - 5 ® PEP Modular Computers GmbH

Page 6

Explanation of Symbols

!

$

CE Conformity

This symbol indicates that the item described in this manual

is in compliance with all applied CE standards. See also the

section “Applied standards” of this manual.

Caution!

This symbol and title warn you of hazards due to electrical

shocks (> 60 V) when touching products or parts of them.

The non-observance of the measures indicated and/or prescribed by the law may cause harm to your product and/or

life/health.

See also the section “High Voltage Safety Instructions”.

PrefaceCP390

ESD-Sensitive Device!

This symbol and title inform you that electronic boards and

their components are sensitive to static electricity. Therefore, care must be taken during all handling operations and

inspections of this product, in order to ensure product integrity at all times.

Please read also the section “Special Handling and Unpacking Instructions” of this manual.

Attention!

This symbol and title emphasize aspects which, if not read

through carefully by the reader, might cause hazards to

health and/or damages to material.

Note:

This symbol and title emphasize aspects the reader should

read through carefully for his or her own advantage.

PEP Advantage

This symbol and title emphasize advantages or positive

aspects of a product and/or procedure.

Troubleshooting

This symbol and title characterize a message containing

useful information on troubleshooting and problem solving.

ID 19976, Rev. 0200 Page 0 - 6® PEP Modular Computers GmbH

Page 7

CP390Preface

For your safety

Your new PEP product has been developed and carefully tested in order to provide all the features necessary to ensure full compliance with all electrical safety requirements. It has also

been designed for a long fault-free life. However, the life expectancy of your product will be

drastically reduced by improper treatment during unpacking and installation. Therefore, in the

interests of your own safety and of the correct operation of your new PEP product, you are

requested to conform with the following guidelines.

High Voltage Safety Instructions

Warning!

!

All operations on this device must be carried out by sufficiently

skilled personnel.

Caution!

The power supply must always be disconnected before installation, repair and maintenance operations are carried out on this

product. Failure to comply with this basic precaution will subject

the operator to serious electrical shock hazards. Always unplug

the power cable before such operations.

Before installing your new PEP product into a system always

ensure that your mains power is switched off. This applies also to

the installation of piggybacks.

Special Handling and Unpacking Instructions

ESD Sensitive Device!

Electronic boards and their components are sensitive to static

electricity. Therefore, care must be taken during all handling operations and inspections of this product, in order to ensure product

integrity at all times.

$ Do not handle this product while it is outside its protective enclosure while it is not used

for operational purposes, unless it is otherwise protected.

$ Whenever possible, unpack or pack this product only at EOS/ESD safe work stations.

Where safe work stations are not guaranteed, it is important for the user to be electrically discharged before touching the product with his/her hands or tools. This is most

easily done by touching a metal part of your system housing.

$ It is particularly important to observe standard anti-static precautions when changing

piggybacks, ROM devices, jumper settings etc. If the product contains batteries for RTC

or memory backup, ensure that the board is not placed on conductive surfaces, including anti-static plastics or sponges. They can cause short circuits and damage the batteries or tracks on the board.

ID 16566, Rev. 0200Page 0 - 7 ® PEP Modular Computers GmbH

Page 8

PrefaceCP390

General Instructions on Usage

$ In order to maintain PEP’s product warranty, this product must not be altered or modi-

fied in any way. Changes or modifications to the device, which are not explicitly

approved by PEP Modular Computers and described in this manual or received from

PEP Technical Support as a special handling instruction, will void your warranty.

$ This device should only be installed in or connected to systems that fulfill all necessary

technical and specific environmental requirements. This applies also to the operational

temperature range of the specific board version, which must not be exceeded. If batteries are present, their temperature restrictions must be taken into account.

$ When performing all necessary installation and application operations please follow only

the instructions supplied by the present manual.

$ Keep all the original packaging material for future storage or warranty shipments. If it is

necessary to store or ship the board please re-pack it as nearly as possible in the manner in which it was delivered.

$ Special care is necessary when handling or unpacking the product. Please consult the

special handling and unpacking instructions on the preceding page of this manual.

ID 19976, Rev. 0200 Page 0 - 8® PEP Modular Computers GmbH

Page 9

CP390Preface

Two Years Warranty

PEP Modular Computers grants the original purchaser of a PEP product a TWO YEAR LIMITED

HARDWARE WARRANTY as described in the following. However, no other warranties that may be

granted or implied by anyone on behalf of PEP are valid unless the customer has the express

written consent of PEP Modular Computers.

PEP Modular Computers warrants their own products, excluding software, to be free from

manufacturing and material defects for a period of 24 consecutive months from the date of

purchase. This warranty is not transferable nor extendible to cover any other users or longterm storage of the product. It does not cover products which have been modified, altered or

repaired by any other party than PEP Modular Computers or their authorized agents. Furthermore, any product which has been, or is suspected of being damaged as a result of negligence, improper use, incorrect handling, servicing or maintenance, or which has been

damaged as a result of excessive current/voltage or temperature, or which has had its serial

number(s), any other markings or parts thereof altered, defaced or removed will also be

excluded from this warranty.

If the customer’s eligibility for warranty has not been voided he should, in the event of any

claim, return the product at the earliest possible convenience to the original place of purchase,

together with a copy of the original document of purchase, a full description of the application

in which the product has been used and a description of the defect. Please pack the product in

such a way as to ensure safe transportation (see our safety instructions).

PEP provides for repair or replacement of any part, assembly or sub-assembly at the company’s own discretion, or to refund the original cost of purchase, if appropriate. In the event of

repair, refunding or replacement of any part, the ownership of the removed or replaced parts

reverts to PEP Modular Computers, and the remaining portion of the original guarantee, or

any new guarantee to cover the repaired or replaced items, will be transferred to cover the

new or repaired items. Any extensions to the original guarantee are considered gestures of

goodwill, and will be defined in the “Repair Report” issued by PEP with the repaired or

replaced item.

PEP Modular Computers will not accept liability for any further claims resulting directly or indirectly from any warranty claim, other than the above specified repair, replacement or refund.

In particular, all claims for damage to any system or process in which the product was

employed, or any loss incurred as a result of the product not functioning at any given time, are

excluded. The extent of PEP Modular Computers liability to the customer shall not exceed the

original purchase price of the item for which the claim exists.

PEP Modular Computers issues no warranty or representation, either explicit or implicit, with

respect to its products’ reliability, fitness, quality, marketability or ability to fulfil any particular

application or purpose. As a result, the products are sold “as is,” and the responsibility to

ensure their suitability for any given task remains that of the purchaser. In no event will PEP

be liable for direct, indirect or consequential damages resulting from the use of our hardware

or software products, or documentation, even if PEP were advised of the possibility of such

claims prior to the purchase of the product or during any period since the date of its purchase.

Please remember that no PEP Modular Computers employee, dealer or agent is authorized to

make any modification or addition to the above specified terms, either verbally or in any other

form, written or electronically transmitted, without the company’s prior consent.

ID 19976, Rev. 0200Page 0 - 9 ® PEP Modular Computers GmbH

Page 10

CP390

Introduction

Introduction

1.1 Overview ............................................................................. 1 - 2

1.2 Board Interfaces .................................................................. 1 - 3

1.3 Block Diagram ..................................................................... 1 - 4

1.4 Board Layout ....................................................................... 1 - 4

1.5 Front Panels ........................................................................ 1 - 5

1.6 Technical Specifications ...................................................... 1 - 6

1.7 Applied Standards ............................................................... 1 - 7

Chapter

1

1.7.1 CE Compliance ........................................................... 1 - 7

1.7.2 Mechanical Compliance ..............................................1 - 7

1.7.3 Environmental Tests ................................................... 1 - 7

1.8 Related Publications ............................................................ 1 - 7

1.8.1 CompactPCI Systems/Boards .................................... 1 - 7

1.8.2 PMC Add-on Modules/Carriers ................................... 1 - 7

ID 19976, Rev. 0200

Page 1 - 1® PEP Modular Computers GmbH

Page 11

CP390 Introduction

1. Introduction

1.1 Overview

PMC modules are renowned for their flexibility and versatility of use. They afford the

user wide ranging system independent solutions by means of easily interchanged or

upgraded mezzanine add-on modules. The PEP CP390 has been designed to maximize the advantages provided by PMC modules in a 3U environment. Flexibility, versatility, convenience and ease of use have been keynotes throughout the design process.

The result is a board which, although essentially a carrier for PMC modules, also

includes a wide range of important features such as a PCI-PCI bridge and (optionally

available) the ability to hotswap. Use of the hotswap version means, of course, that all

PMC modules employed on the board are effectively hotswapable.

The CP390 is a 3U non-intelligent, active CPCI carrier board with one PMC slot.

Some of the Outstanding Features of the CP390:

• active carrier with PCI-to-PCI bridge: the primary and secondary PCI busses are

capable of being operated independently of one another

• 32 Bit / 33MHz PCI Bus on the CPCI and on the PMC side

• it supports the Interrupts INTA, INTB, INTC and INTD

• software transparent: the non-hotswap version does not require a software driver.

• it supports all the signals of the PCI Bus on its connectors Jn1 (CON2),

Jn2 (CON3)

• The connectors which connect the mezzanine board with the carrier include all the

signals of a 33MHz, 32-bit, multi-master PCI bus, the power rails for 5V, 3.3V,

V(I/O) and other specialised signals for Board Detection.

• A PCI-to-PCI bridge provides for coupling of the PMC side to the CompactPCI

side, so that two independent PCI busses exist. The PCI-to-PCI bridge is the

INTEL 21150. It is software transparent and consequently a software driver is not

required to manage data transfer between the PMC module and the CPCI bus.

• The CP390 has been designed to function with all PEP CompactPCI backplanes.

Features of the PEP Modular Computers’ PMC modules

PEP Modular Computers’ PMC modules are operable in both CompactPCI and VME

systems. They offer all the key benefits of PC I/O technology, namely:

• low cost solutions

• high performance

• a processor independent local I/O bus

• a broad range of I/O peripheral devices

PEP Modular Computers’ PMC modules may be installed on a variety of different carrier

boards, including:

• CompactPCI 3U/6U: CPU CP600, CP602, CP610, CP611, CP612

• CompactPCI PMC carrier boards such as the CP390 and CP690

Customers who additionally require the functionality of the CP390 in the 6U Form

Factor are referred to PEP’s new double-height PMC Module carrier board, the

CP690, which holds two PMC modules.

ID 19976, Rev. 0200Page 1 - 2 ® PEP Modular Computers GmbH

Page 12

CP390 Introduction

1.2 Board Interfaces

CompactPCI Interface

The CompactPCI interface connector J1 (CON1) provides all the necessary signals for

data transfer as defined by PCI Specification Rev. 2.1.

The CP390 is routed to the CompactPCI backplane by means of the Intel 21150 PCI-toPCI bridge which interfaces the board with a data path width of 32-bit and a speed up to

33MHz.

PMC Interface

The PMC interface of the CP390 provides an easy way to extend a CompactPCI system

via the wide array of interfaces and functions which are available on PMC modules produced by the entire range of PMC vendors. The secondary side of the PCI-to-PCI

Bridge provides a 32-bit wide PCI data path with a speed of up to 33MHz which is

routed to the onboard connectors Jn1 and Jn2. These connectors also provide the

power supply for the PMC module. The interface has been designed to comply with the

IEEE 1386.1 specification which defines a PCI electrical interface for the CMC (Common Mezzanine Card) form factor.

Additionally, the CP390-HS (Hotswap version) has been designed to comply with the

CPCI Hotswap specification PICMG 2.1 R1.0, which means that the power supply of the

PMC modules will be ramped up and a reset generated whenever the board is plugged

into a running system.

ID 19976, Rev. 0200 Page 1 - 3® PEP Modular Computers GmbH

Page 13

CP390 Introduction

1.3 Block Diagram

Figure 1-1: Block Diagram

Hotswap Control

and

Status Register

PCI - PCI

Bridge

Hotswap

Power Control

Serial

Term

1.4 Board Layout

The CP390 has two connectors onboard which provide all the PCI signals and the

power supply for the PMC-Module.

Figure 1-2: Board Layout (Front View)

Opening for

PMC Module

Hotswap LED

Power

Controller

Hotswap Control

and Status Register

1 2

63 64

PCI - PCI

Bridge

1 2

63 64

ID 19976, Rev. 0200Page 1 - 4 ® PEP Modular Computers GmbH

Page 14

CP390 Introduction

1.5 Front Panels

HotswapStandard

CP 390

CP 390

Hot Swap

HS

The CP390 front panel is provided with a window for the insertion of a PMC module

bezel.

ID 19976, Rev. 0200 Page 1 - 5® PEP Modular Computers GmbH

Page 15

CP390 Introduction

1.6 Technical Specifications

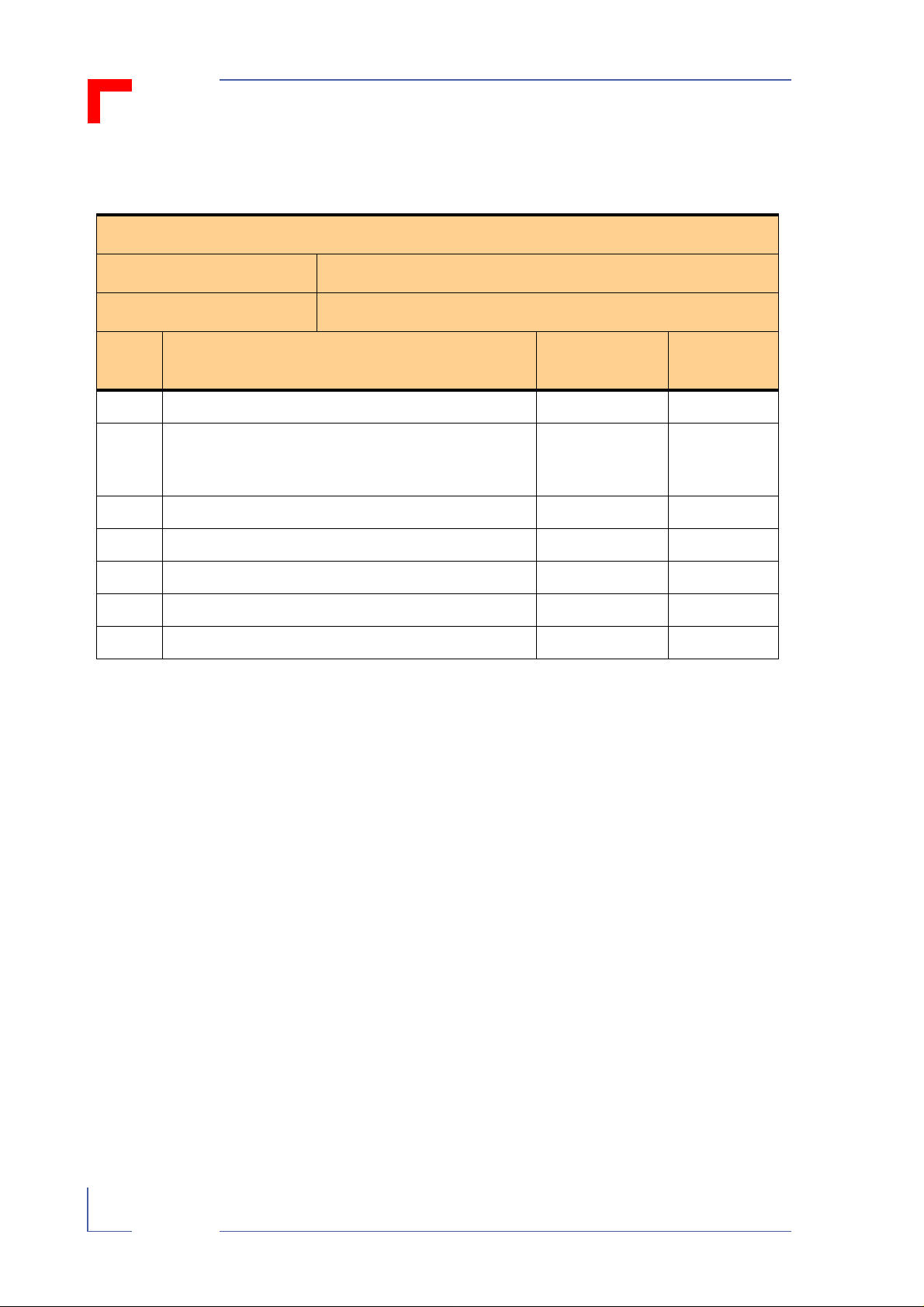

Table 1-1: CP390 Specifications

CP390 Specifications

PCI-Standard Compliant with PCI 2.1

Signaling Voltage

Driver Support A software driver is not required

Connectors PMC Jn1 (CON2) and Jn2 (CON3) connectors

Mechanical Compliance

Power 3.3V / 0.07 A (Core-Supply)

Temperature Range

Operating Humidity 5 – 95% (non condensing)

Vibrations and

Broad-Band Random Vibration

Shocks

Permanent Shocks

Single Shock

CPCI-Side: 3.3V / 5V tolerant

PMC-Side: 5V signaling

IEEE 1101.10

CMC IEEE P1386/Draft 2.0 (with minor

exceptions)

Operation:

• 0° to +60°C (standard)

• -25° to +75°C (extended)

Storage:

• -55° to +85°C

IEC68-2-6 compliant

IEC68-2-64

IEC68-2-29

IEC68-2-27

Single-height Eurocard:

Board Dimensions

Board Weight 122 grams

100 mm x 160 mm

1 x 4 HP slot

ID 19976, Rev. 0200Page 1 - 6 ® PEP Modular Computers GmbH

Page 16

CP390 Introduction

1.7 Applied Standards

1.7.1 CE Compliance

The PEP Modular Computers’ CompactPCI systems comply with the requirements of

the following CE-relevant standards:

• Emission EN50081-1

• Immission EN50082-2

• Electrical Safety EN60950

1.7.2 Mechanical Compliance

• Mechanical Dimensions IEEE 1101.10

1.7.3 Environmental Tests

• Vibration/Broad-Band IEC68-2-6

Random Vibration IEC68-2-64 (3U boards)

• Permanent Shock IEC68-2-29

• Single Shock IEC68-2-27

1.8 Related Publications

1.8.1 CompactPCI Systems/Boards

CompactPCI Specification, V. 2.0, Rev. 2.1

CompactPCI hotswap Specification, PICMG 2.1 R1.0

1.8.2 PMC Add-on Modules/Carriers

• Draft Standard for a Common Mezzanine Card Family, P1386/Draft 2.0

• Draft Standard Physical and Environment Layers for PCI Mezzanine Cards,

P1386.1/Draft 2.0

ID 19976, Rev. 0200 Page 1 - 7® PEP Modular Computers GmbH

Page 17

CP390

Installation

Installation

2.1 Board Installation ................................................................. 2 - 2

2.1.1 CPCI Signaling Voltage .............................................. 2 - 3

Chapter

2

ID 19976, Rev. 0200

Page 2 - 1® PEP Modular Computers GmbH

Page 18

CP390 Installation

$$

2. Installation

2.1 Board Installation

Caution!

If you are using the non-hotswap version of the CP390, please

switch off the target system before installing the board in a free

slot. Failure to do so could endanger your life/health and may

damage your board or system.

ESD Equipment!

Your carrier board and PMC module contain electrostatically sensitive devices. Please observe the necessary precautions to avoid

damage to your board:

• Discharge your clothing before touching the assembly. Tools

must be discharged before use.

• Do not touch components, connector-pins or traces.

• If working at an anti-static workbench with professional discharging equipment, please do not omit to use it.

PMC Module Installation

1. Place the EMC gasket on the bezel of your PMC-Module

2. Unscrew the stand-off, which is positioned at the PCI-Bridge

Note:

In order to support an active PMC carrier and, therefore, to

comply with the CPCI specification, it was necessary to

place the PCI-to-PCI bridge in the position where a socket

for mounting a stand-off would normally be (PMC specification). As a result, the second stand-off has been omitted.

3. Push the PMC bezel into the window of the front-panel of the CP390 and plug the

connectors together.

4. Use three screws (M2.5 x 6mm) to fix the board

ID 19976, Rev. 0200Page 2 - 2 ® PEP Modular Computers GmbH

Page 19

CP390 Installation

Figure 2-1: Installation Diagrams

PMC module

CP390 Front Panel

1

PMC bezel

10mm stand-off

2

CP390

3

3 *M2.5 *6mm

screws

2.1.1 CPCI Signaling Voltage

The primary side of the PCI-to-PCI bridge, i.e. the CPCI side, has buffers for 3.3V signaling but works equally well in a 5V signaling environment.

ID 19976, Rev. 0200 Page 2 - 3® PEP Modular Computers GmbH

Page 20

CP390

Configuration

Configuration

3.1 Pinouts ................................................................................ 3 - 2

3.1.1 Jn1 (CON2) Pin Assignment .......................................3 - 2

3.1.2 Jn2 (CON3) Pin Assignment .......................................3 - 3

Chapter

3

ID 19976, Rev. 0200

Page 3 - 1® PEP Modular Computers GmbH

Page 21

CP390 Configuration

3. Configuration

3.1 Pinouts

3.1.1 Jn1 (CON2) Pin Assignment

Table 3-1: Jn1, 32-bit PCI

Pin Number Signal Name Signal Name Pin Number

1 TCK -12V 2

3 Ground INTA# 4

5 INTB# INTC# 6

7 BUSMODE1# +5V 8

9 INTD# PCI-RSVD* 10

11 Ground PCI-RSVD* 12

13 CLK Ground 14

15 Ground GNT# 16

17 REQ# +5V 18

19 V(I/O) AD[31] 20

21 AD[28] AD[27] 22

23 AD[25] Ground 24

25 Ground C/BE[3]# 26

27 AD[22] AD[21] 28

29 AD[19] +5V 30

31 V(I/O) AD[17] 32

33 FRAME# Ground 34

35 Ground IRDY# 36

37 DEVSEL# +5V 38

39 Ground LOCK# 40

41 SDONE# SBO# 42

43 PAR Ground 44

45 V(I/O) AD[15] 46

47 AD[12] AD[11] 48

49 AD[09] +5V 50

51 Ground C/BE[0]# 52

53 AD[06] AD[05] 54

55 AD[04] Ground 56

57 V(I/O) AD[03] 58

59 AD[02] AD[01] 60

61 AD[00] +5V 62

63 Ground REQ64# 64

ID 19976, Rev. 0200Page 3 - 2 ® PEP Modular Computers GmbH

Page 22

CP390 Configuration

3.1.2 Jn2 (CON3) Pin Assignment

Table 3-2: Jn2, 32-bit PCI

Pin Number Signal Name Signal Name Pin Number

1 +12V TRST# 2

3 TMS TDO 4

5 TDI Ground 6

7 Ground PCI-RSVD* 8

9 PCI-RSVD* PCI-RSVD* 10

11 BUSMODE2# +3.3V 12

13 RST# BUSMODE3# 14

15 3.3V BUSMODE4# 16

17 PCI-RSVD* Ground 18

19 AD[30] AD[29] 20

21 Ground AD[26] 22

23 AD[24] +3.3V 24

25 IDSEL AD[23] 26

27 +3.3V AD[20] 28

29 AD[18] Ground 30

31 AD[16] C/BE[2]# 32

33 Ground PMC-RSVD 34

35 TRDY# +3.3V 36

37 Ground STOP# 38

39 PERR# Ground 40

41 +3.3V SERR# 42

43 C/BE[1]# Ground 44

45 AD[14] AD[13] 46

47 Ground AD[10] 48

49 AD[08] +3.3V 50

51 AD[07] PMC-RSVD 52

53 +3.3V PMC-RSVD 54

55 PMC-RSVD Ground 56

57 PMC-RSVD PMC-RSVD 58

59 Ground PMC-RSVD 60

61 ACK64# +3.3V 62

63 Ground PMC-RSVD 64

ID 19976, Rev. 0200 Page 3 - 3® PEP Modular Computers GmbH

Page 23

CP390

Hotswap

Hotswap

4.1 Technical Background of CompactPCI Hotswap ................. 4 - 2

4.1.1 Hotswap System ......................................................... 4 - 2

4.1.1.1 The Hotswap Backplane .........................................4 - 3

4.1.1.2 The System Host (System Controller) .................... 4 - 3

4.1.1.3 The Hotswap Board ................................................ 4 - 4

4.1.1.4 Software and Operating System .............................4 - 4

4.2 Design Implementation on the CP390 .................................4 - 4

Chapter

4

4.2.1 Power Ramping .......................................................... 4 - 4

4.2.2 Precharge ................................................................... 4 - 4

4.2.3 Handle Switch ............................................................. 4 - 4

4.2.4 ENUM# Interrupt ......................................................... 4 - 5

4.2.5 Hotswap Control and Status Register / Statemachine 4 - 5

4.2.6 Programming the GPIO’s ............................................4 - 7

4.1.1.1 GPIO: Output Enable Control Register - Offset 66h 4 - 7

4.1.1.2 GPIO Input Data Register - Offset 67h ................... 4 - 7

4.1.1.3 GPIO Output Data Register - Offset 65h ................ 4 - 8

ID 19976, Rev. 0200

Page 4 - 1® PEP Modular Computers GmbH

Page 24

CP390 Hotswap

4. Hotswap

4.1 Technical Background of CompactPCI Hotswap

In many modern application systems downtime is costly and/or unacceptable. Server

applications, telecommunications networks and automated systems requiring continuous monitoring call for a system design in which a single card can be inserted or

extracted without affecting the rest of the system. The ease with which a board may be

removed and replaced is dependent on the mechanical design (form factor), the possibility of deactivating the software drivers for the board (operating system) and the ability

to remove and insert the board without disturbing the signal quality on the bus.

CompactPCI hotswap is currently the most effective way to meet this need. Staggered

pins on the backplane guarantee controlled power sequencing of the board, while the

signals ENUM, BDSEL, HEALTHY and the hotswap control and status register bits may

be used to control board access from the software side.

4.1.1 Hotswap System

A hotswap system consists of a hotswap platform which comprises a hotswap backplane, the system host (CPU) with hotswap features, cooling, power supplies etc. plus

the boards to be hotswapped. Hotswapping is not possible unless the operating system

has the capability to enable and disable the board specific driver during normal operation.

ID 19976, Rev. 0200Page 4 - 2 ® PEP Modular Computers GmbH

Page 25

CP390 Hotswap

$

$

4.1.1.1 The Hotswap Backplane

The hotswap backplane has staggered pins to ensure defined power sequencing.

Figure 4-1: Illustration of Staggered Pinning on the Hotswap Backplane

BACKPLANE BOARD

Step 3

Step 2

Step 1

EARLY POWER *

BACK END POWER *

PCI SIGNALS

ENUM#

HEALTHY# *

BD_SEL#

*EARLY POWER: a part of VCC, 3.3V, V(I/O) and GND

*BACK END POWER: the main part of VCC,

*HEALTHY: only for high availability

Note:

EXPLANATORY KEY

+3.3V, V(I/O), +/-12V and GND

Some special signals (e.g. ENUM, HEALTHY, BDSEL...) have particular routing requirements.

4.1.1.2 The System Host (System Controller)

The System Controller must have the possibility to utilize the special signals defined by

the CompactPCI hotswap specification. If a high availability system is used it must additionally be able to control the hardware connection with the peripheral boards (Hardware

Connection Control).

ID 19976, Rev. 0200 Page 4 - 3® PEP Modular Computers GmbH

Page 26

CP390 Hotswap

4.1.1.3 The Hotswap Board

To ensure that a board may be removed and replaced in a working bus without

disturbing the system it requires the following additional features.

• precharge

• power ramping

• hotswap Control and status register bits

• automatic interrupt generation whenever a board is about to be removed or

replaced.

• an LED to indicate that the board may be safely removed.

4.1.1.4 Software and Operating System

No hotswap support is currently provided by Intel based operating systems. Windows

2000, which is scheduled to become available in February 2000, is expected to provide

hotswap support. Special software will require to be developed for other proprietary

systems.

In a hotswap environment the software driver and the operating system have the

following additional requirements:

• The OS must provide the possibility to initialize PCI devices during normal

operation whenever required (allocate resources).

• The OS must provide the possibility to load or unload software drivers during

normal operation whenever required.

4.2 Design Implementation on the CP390

4.2.1 Power Ramping

On the CP390, a special hotswap controller is used to ramp up the supply voltage of the

PMC modules (Back End Power). This is done to avoid transients on the 3.3V and the

5V power supplies from the Hotswap system. When the power supply is stable, the

hotswap controller generates a reset on the PMC slots to put the devices into a definite

state.

4.2.2 Precharge

Precharge is provided on the CP390 by a resistor on each signal line (PCI bus),

connected to a 1V reference voltage.

4.2.3 Handle Switch

A microswitch is situated in the extractor handle. Opening the handle initiates the

generation of the ENUM interrupt (produced by the onboard logic).

ID 19976, Rev. 0200Page 4 - 4 ® PEP Modular Computers GmbH

Page 27

CP390 Hotswap

!

4.2.4 ENUM# Interrupt

The onboard logic generates a low active interrupt signal to indicate that the board is

about to be extracted from the system or inserted into the system.

4.2.5 Hotswap Control and Status Register / Statemachine

All hotswap peripheral boards provide a HotSwap Control And Status Register which

provides information on the current state of the board. The defined bits in this register

set are named:

Table 4-1: Hotswap Control and Status Register / Statemachine

Bit Name Function

EXT Indication of extraction process

INS Indication of insertion process

LOO Led on

EIM ENUM mask bit

Due to the fact that no 64-bit transparent PCI-to-PCI bridge currently exists, which

would provide built-in hotswap status registers, another way of implementing these bits

had to be found.

The solution, therefore, is to put this information into the onboard logic.

Since on-chip registers handle read and write accesses in the same way, it is necessary

to exercise care when configuring the PCI-to-PCI GPIOs (general purpose IOs).

Table 4-2: Hotswap Register Bits

Bit Name Signal on 21150

EXT GPIO[2]

INS GPIO[3]

LOO GPIO[0]

EIM GPIO[1]

Attention!

GPIO[2:3] have to be configured as inputs. A different configuration may damage your bridge device.

ID 19976, Rev. 0200 Page 4 - 5® PEP Modular Computers GmbH

Page 28

CP390 Hotswap

Figure 4-2: Hotswap State Machine

Power on Slot empty

EXT: 0

INS: 0

ENUM#: 1

DISCONNECT#: 1

LED#: 1

HANDLE: closed

EIM: 0

LOO: 0

FFs valid: 0

Toggle

EIM and LOO

Toggle

EIM and LOO

EXT: 0

INS: 0

ENUM#: 1

DISCONNECT#: 1

Extraction armed Disconnected

LED#: 1

Handle: closed

EIM: 0

LOO: 0

FFs valid: 1

Open Handle

#: low active signal

FFs valid: PLD-internal Flip-Flops are valid.

EXT: 0

INS: 1

ENUM#: 0

DISCONNECT#: 1

LED#: 1

Handle: closed

EIM: 0

LOO: 0

FFs valid: 1

EXT: 1

INS: 0

ENUM#: 0

DISCONNECT#: 1

LED#: 1

Handle: open

EIM: 0

LOO: 0

FFs valid: 1

Insertion

Extraction

Close Handle

Toggle

EIM and LOO

followed by

Setting LOO

EXT: 0

INS: 0

ENUM#: 1

DISCONNECT#: 1

LED#: 1

Handle: open

EIM: 0

LOO: 0

FFs valid: 0

Physical

Handle

is open

Insertion:

Power

Ramping,

Handle

Physical

Extraction:

is open

EXT: 0

INS: 0

ENUM#: 1

DISCONNECT#: 0

LED#: 0

Handle: open

EIM: 0

LOO: 1

FFs valid: 1

ID 19976, Rev. 0200Page 4 - 6 ® PEP Modular Computers GmbH

Page 29

CP390 Hotswap

4.2.6 Programming the GPIO’s

This sub-chapter provides information for programming the GPIO’s (General Purpose

I/O’s) of the PCI-to-PCI bridge.

4.2.6.1 GPIO: Output Enable Control Register - Offset 66h

This section describes the GPIO for the Output Enable Control Register.

Dword address = 64h

Byte enable p_cbe_1<3:0> = x0xxb

Table 4-3: GPIO Output Enable Control Gegister - Offset 66h

Dword Bit Name R/W Description

The gpio<3:0> output enable control

write-1-to-clear. Writing 1 to any of these bits configures the corresponding gpio<3:0> pin as an input

only; that is, the output driver is tristated.

Writing 0 to this register has no effect.

When read, reflects the last value written.

19:16

GPIO output

enable

write-1-to-clear

R/W1TC

Reset value: 0 (all pins are input only).

The gpio<3:0> output enable control

write-1-to-set. Writing 1 to any of these bits configures the corresponding gpio<3:0> pin as bidirectional, that is,

enables the output driver and drives the value set in

the output data register (65h).

Writing 0 to this register has no effect.

When read, reflects the last value written.

Reset value: 0 (all pins are input only).

23:20

GPIO output

enable

write-1-to-set

R/W1TS

4.2.6.2 GPIO Input Data Register - Offset 67h

This section describes the GPIO input data register.

Dword address = 64h

Byte enable p_cbe_1<3:0> = 0xxxb

Table 4-4: GPIO Input Data Register - Offset 67h

Dword Bit Name R/W Description

27:24 Reserved R Reserved. Returns 0 when read.

This read-only register reads the state of the

31:28 GPIO input R

ID 19976, Rev. 0200 Page 4 - 7® PEP Modular Computers GmbH

gpio<3:0> pins. This state is updated on the

PCI clock cycle following a change in the gpio pins.

Page 30

CP390 Hotswap

4.2.6.3 GPIO Output Data Register - Offset 65h

This section describes the GPIO output data register.

Dword address = 64h

Byte enable p_cbe_1<3:0> = xx0xb

Table 4-5: GPIO Output Data Register - Offset 65h

Dword Bit Name R/W Description

The gpio<3:0> pin output data

write-1-to-clear. Writing 1 to any of these bits drives

the corresponding bit low on the gpio<3:0> bus if it is

programmed as bi-directional. Data is driven on the

PCI clock cycle following completion of the

configuration write to this register. Bit positions corresponding to gpio pins that are programmed as input

only are not driven.

Writing 0 to these bits has no effect.

When read, reflects the last value written.

11:8

GPIO output

enable write1-to-clear

R/W1TC

15:12

GPIO output

enable write1-to-set

R/W1TS

Reset value: 0.

The gpio<3:0> pin output data

write-1- to-set. Writing 1 to any of these bits drives

the corresponding bit high on the gpio<3:0> bus if it

is programmed as bi-directional. Data is driven on the

PCI clock cycle following completion of the

configuration write to this register. Bit positions corresponding to gpio pins that are programmed as input

only are not driven.

Writing 0 to these bits has no effect.

When read, reflects the last value written.

Reset value: 0.

ID 19976, Rev. 0200Page 4 - 8 ® PEP Modular Computers GmbH

Page 31

CP390

CompactPCI System Notes

Appendix

CompactPCI System Notes

A System Overview ..................................................................A - 2

1 Note on CompactPCI ........................................................A - 2

2 Main Features of CompactPCI Systems ...........................A - 2

B System Components .............................................................A - 3

A

ID 19976, Rev. 0200

Page A - 1® PEP Modular Computers GmbH

Page 32

CP390 CompactPCI System Notes

CompactPCI System Notes

A System Overview

The PEP Modular Computers CompactPCI systems described in this chapter operate

with the PCI bus architecture to support additional I/O and memory-mapped devices as

required by various industrial applications. In the following you will find the most important information on all system relevant CompactPCI features. For more detailed information concerning the CompactPCI standard, please consult the complete Peripheral

Component Interconnect (PCI) and CompactPCI Specifications. For further information

regarding these standards and their use, visit the homepage of the PCI Industrial Com-

puter Manufacturers Group (PICMG).

1 Note on CompactPCI

CompactPCI is an extension of the PCI specification. It has been optimized for industrial

and embedded applications that require a more robust mechanical form factor as compared to Desktop PCI. CompactPCI systems use industry standard mechanical components and high performance connector technologies to provide systems that are well

suited for rugged applications. CompactPCI stands for systems that are electrically

compatible with the PCI Specification, allowing low cost PCI components to be used.

CompactPCI is an open specification supported by PICMG.

2 Main Features of CompactPCI Systems

Some of the outstanding features of the CompactPCI systems compliant with Specification 2.0, Release 2.1 are:

• PCI signalling

• 32 and 64 bit data transfer at 66 MHz

• up to 16 (2 × 8) PCI slots per backplane

• industry standard software support

• 3U small form factor (100 mm by 160 mm)

• 6U form factor (233 mm by 160 mm)

• Eurocard packaging

• wide variety of available I/O functions

• industry support from over 350 members.

• possibility of PMC modules on some boards

PEP Advantage

PEP Modular Computers’ CompactPCI systems are designed as

open systems, able to be expanded at any time, so that their backplanes can be equipped with precisely the CPCI boards that correspond to a customer’s specific needs. However, in order to supply

you with an appropriate choice of workstations, the PEP basic

equipment is divided into pre-configured sets and custom solutions.

ID 19976, Rev. 0200Page A - 2 ® PEP Modular Computers GmbH

Page 33

CP390 CompactPCI System Notes

B System Components

PEP Modular Computers have devised their CompactPCI systems as a comprehensive

open solution for industrial environments, offering different workstation configurations

which are capable of including all the components necessary to fulfill the requirements

of virtually all existing system functionalities.

CompactPCI Backplane(s)

• 4-slot backplane;

• 6-slot backplane;

• 8-slot backplane;

• 16-slot (2 × 8) backplane.

CPU Function

PEP Modular Computers provides CPU boards corresponding in size and characteristics to the special features of the PEP systems.

Display Related Functions

Display related functions such as frame grabbing are supported by dedicated boards.

Communication

Communication boards are provided for the currently relevant industrial communication

systems such as Fast Ethernet.

Fieldbus Control

Fieldbus control boards provide data exchange with field control and automation subsystems like PEP Modular Computers’ SMART2 or VMEbus systems using up-to-date

transmission standards for example:

• CAN fieldbus control

• PROFIBUS control

Industrial I/O Functions

PEP’s CompactPCI systems support an ever increasing number of industrial I/O functionalities in the fields of:

• Digital I/O

• Analog I/O

• SERCOS

Self-Testing

A special PEP self-testing board provides a trouble-spotting capability within your PEP

system.

ID 19976, Rev. 0200 Page A - 3® PEP Modular Computers GmbH

Page 34

CP390 CompactPCI System Notes

System Hardware

The PEP CompactPCI system hardware includes housings, storage devices, power

supply units, network adapters etc. The most important system hardware elements with

which to configure your CompactPCI system are as follows:

Multiprocessor

In a CompactPCI multiprocessor system, a system controller communicates with other

CPU’s through a non-transparent PCI / PCI bridge. PEP Modular Computers’

CompactPCI system controllers, CP600/CP610, which are designed to work together

with PEP CPU’s, CP611/CP612, provide full multiprocessor solutions.

Housings

• Board cages for 19-inch cabinets or wall mounting, available in 3U/4U/6U/7U

heights and 42HP/84HP width

Mass Storage Devices

• Hard-disk drive

• Floppy-disk drive

• CD-ROM drive

Power Supply Units

Table 1-1: Power Supply Units

Form Factor Input Type

3U AC

DC

6U AC

DC

180W DIN M-Series CP3-SVE-M-180AC

235W ATX CP3-SVE-ATX-235AC

120W DIN M-Series CP3-SVE-M-120DC-V1 (-E1)

150W DIN M-Series CP3-SVE-M-150DC-V2 (-R)

250W DIN M-Series CP6-SVE-M-250AC-R

270W DIN M-Series CP6-SVE-M-270AC

250W DIN M-Series CP6-SVE-M-250DC-R

270W DIN M-Series CP6-SVE-M-270DC

Power

Output

Power

Supply

Connector

Power Supply

Unit

ID 19976, Rev. 0200Page A - 4 ® PEP Modular Computers GmbH

Page 35

CP390 CompactPCI System Notes

Form Factors

PEP Modular Computers CompactPCI boards are available in different form factors,

mainly as 3U (single-height) and 6U (double-height) boards and as 4HP (single-width),

8HP (double-width), and 12HP (triple-width) boards.

Please note that the following units of measurement are used to express the dimensions

of PEP CompactPCI card slots:

• Height: 1 U = 44.45 mm

• Width: 1 HP = 5.08 mm

On certain boards/carriers with PMC connectors, PMC add-on modules can also be

installed. Please note that the form factor currently implemented by PEP Modular Com-

puters for its PMC modules is:

• 149mm x 74mm (single-size standard).

For a detailed description of the PEP Modular Computers CompactPCI modules please

consult the specific component’s manuals or data sheets.

PEP Advantage

As the PEP Modular Computers CompactPCI system provides

comprehensive open solutions, new features and functionalities

may be added to our range. To keep abreast of the latest developments, please contact your local PEP Sales Office or visit the PEP

Web Site.

ID 19976, Rev. 0200 Page A - 5® PEP Modular Computers GmbH

Page 36

CPU

C

W

CP390 CompactPCI System Notes

Figure 1-1: Example of a PEP Modular Computers CompactPCI System

ompactPCI

orkstation

ID 19976, Rev. 0200Page A - 6 ® PEP Modular Computers GmbH

WD Timer

Add-ons

HDD

FDD

CD-ROM

COM

LPT

Keyboard

Host

Computer

Graphics

PanelLink

VGA

LVDS

Fieldbus

SERCOS

PROFIBUS

CAN

Server

Computer

Communic.

F. Ethernet

CPCI Backplane

Fast

Ethernet

Image Control

RGB

SYNC

WWW

Industrial I/O

Digital I/O

Analog I/O

Host

Computer

Multi

Processor

Add-on

Carriers

SMART2

SMART I/O

PEP9300

Loading...

Loading...