Konsberg EM 124 Installation Manual

KongsbergEM124

MultibeamEchoSounder

InstallationManual

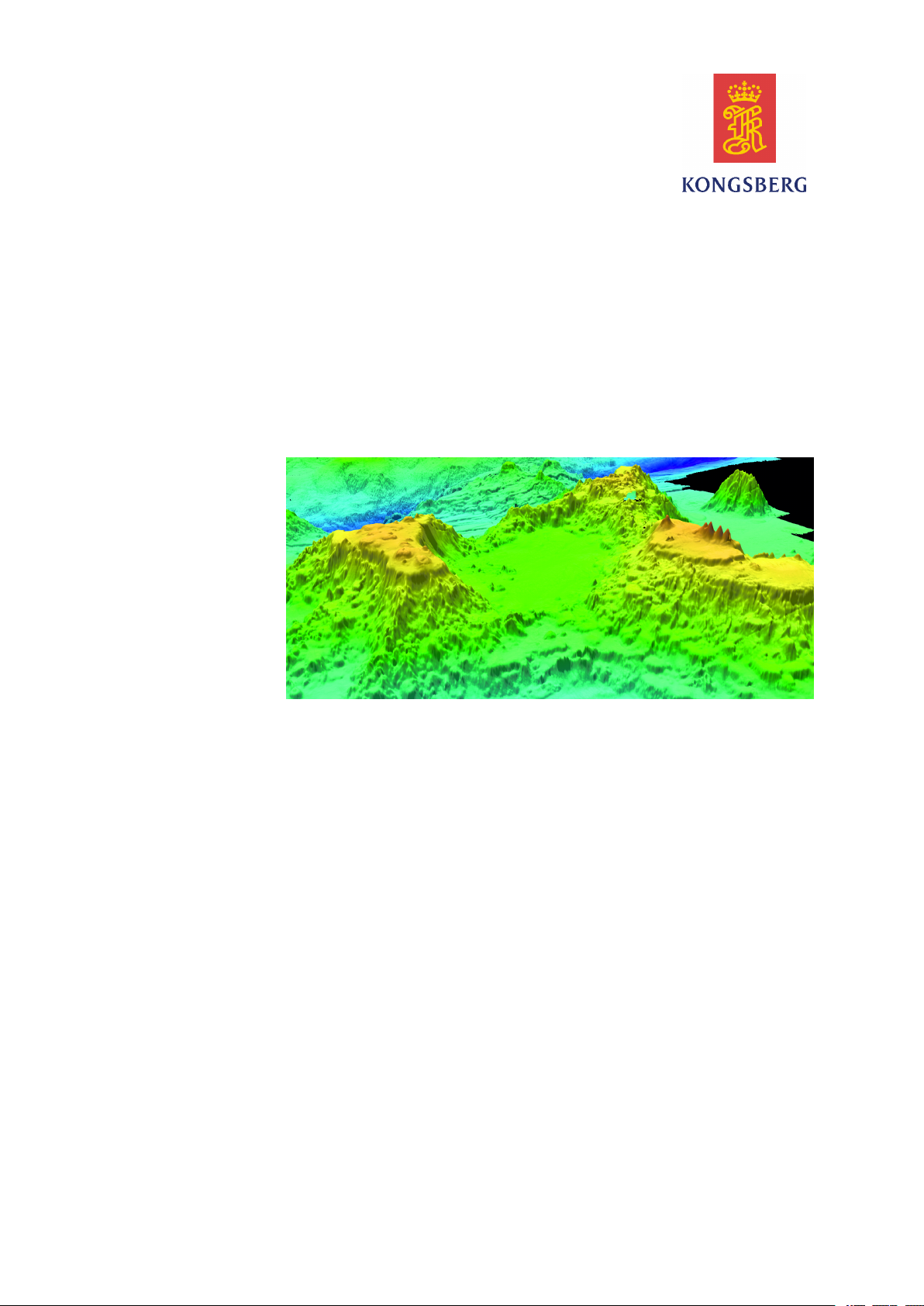

Image:BathymetryoftheNorthernPortionoftheMarianaTrench.

CourtesyofDrJamesV .Gardener ,UniversityofNewHampshire.

443140/A

March2019©KongsbergMaritimeAS

Documentinformation

•Product:KongsbergEM124

•Document:InstallationManual

•Documentpartnumber:443140

•Revision:A

•Dateofissue:11March2019

Copyright

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsberg

MaritimeAS.Nopartofthisdocumentmaybecopiedorreproducedinanyformorby

anymeans,andtheinformationcontainedwithinitisnottobecommunicatedtoathird

party,withoutthepriorwrittenconsentofKongsbergMaritimeAS.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposefor

whichitwasdesigned.Improperuseormaintenancemaycausedamagetothe

equipmentand/orinjurytopersonnel.Y oumustbefamiliarwiththecontentsofthe

appropriatemanualsbeforeattemptingtooperateorworkontheequipment.

KongsbergMaritimedisclaimsanyresponsibilityfordamageorinjurycausedby

improperinstallation,useormaintenanceoftheequipment.

Disclaimer

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentis

correctandfairlystated,butdoesnotacceptliabilityforanyerrorsoromissions.

Supportinformation

Ifyourequiremaintenanceorrepair,contactKongsbergMaritime’s

supportorganisation.Youcanalsocontactususingthefollowingaddress:

km.hydrographic.support@kongsberg.com.Ifyouneedinformationaboutourother

products,visithttps://www.km.kongsberg.com.

KongsbergMaritimeAS

www.kongsberg.com

InstallationManual

Tableofcontents

ABOUTTHISMANUAL..............................................................7

KONGSBERGEM124................................................................9

Systemdescription...........................................................................................................10

Technicaldetails...............................................................................................................11

Systemdiagram................................................................................................................12

Systemunits.....................................................................................................................13

Transducerdescription...........................................................................................13

TransmitterUnitdescription...................................................................................14

ReceiverUnitdescription.......................................................................................14

ProcessingUnitdescription....................................................................................14

HydrographicWorkStationdescription.................................................................15

Supportinformation.........................................................................................................16

PREPARATIONS.....................................................................17

Tools,equipmentandconsumablesrequiredforEM124installation.............................17

Personnelqualications...................................................................................................18

Sonarroomrequirements.................................................................................................19

Environmentalrequirements..................................................................................19

Sizeandaccessrequirements.................................................................................19

Requirementsforinsulation,heatingandventilation.............................................20

Requirementsforelectricalinstallations,cablesandcommunication...................20

Wheretoinstallthetransducer........................................................................................22

Introductiontotransducerlocation.........................................................................22

Mountthetransducerdeep.....................................................................................22

Avoidprotrudingobjectsnearthetransducer.........................................................23

Keepthetransducerfarawayfromthepropellers.................................................24

Mountthetransduceratasafedistancefrombowthruster(s)...............................24

Summaryandgeneralrecommendations...............................................................24

Acousticnoise..................................................................................................................27

Contributingfactors................................................................................................27

Selfnoise................................................................................................................28

Ambientnoise.........................................................................................................31

Electricalselfnoise................................................................................................31

Somemeanstoreduceacousticnoise....................................................................31

INSTALLINGTHETRANSDUCER.............................................34

Transducerdescription.....................................................................................................35

Transducerinstallationprinciples....................................................................................37

Introduction............................................................................................................37

443140/A

3

KongsbergEM124

Gondola..................................................................................................................39

Blister.....................................................................................................................40

Flushmounted........................................................................................................41

Externalmountedwithfairings..............................................................................41

Transducerinstallationsummary.....................................................................................43

Manufacturingandinstallingthecasings........................................................................46

Designing,manufacturingandmountingthesteelconduits............................................48

InstallingtheRXmountingframe...................................................................................52

InstallingtheTXmountingframes..................................................................................55

InstallingtheRXTransducersintothemountingframes................................................57

InstallingtheTXTransducersintothemountingframes................................................60

Rulesfortransducerhandling..........................................................................................63

Paintingthetransducerface.............................................................................................65

Approvedanti-foulingpaints...........................................................................................67

INSTALLINGTHEEM124HARDWAREUNITS.........................69

TransmitterUnit...............................................................................................................70

InstallingtheTransmitterUnit...............................................................................71

RIO-Pboard-dipswitchsetting............................................................................73

ReceiverUnit...................................................................................................................74

InstallingtheReceiverUnit....................................................................................75

ReceiverUnit-dipswitchsetting..........................................................................77

ProcessingUnit................................................................................................................78

InstallingtheProcessingUnit.................................................................................78

ProcessingUnitrearpaneldescription...................................................................80

ProcessingUnitcircuitboardsandmodules..........................................................81

CBMFboard-dipswitchsetting...........................................................................82

InstallingtheHydrographicW orkStation.......................................................................83

InstallingtheHydrographicW orkStation..............................................................83

HydrographicWorkStationrearconnectors..........................................................86

CABLELAYOUTANDINTERCONNECTIONS.............................88

Cableplans.......................................................................................................................89

Cableplan,ProcessingUnit...................................................................................90

Cableplan,TransmitterUnit..................................................................................91

Cableplan,ReceiverUnit,1degree.......................................................................99

Synchronizationoverview,2TransmitterUnits1ReceiverUnit.........................102

Remoteon/offoverview,2TransmitterUnits1ReceiverUnit............................103

HydrographicWorkStation..................................................................................104

ListofEM124cables....................................................................................................105

Clocksynchronization(1PPS).......................................................................................109

Externalsynchronization...............................................................................................111

4

443140/A

InstallationManual

Cabledrawingsandspecications.................................................................................114

RS-232seriallineusingthreewiresandRJ45connector....................................115

RS-422seriallineusingvewiresandRJ45connector......................................116

Clocksynchronisation(1PPS)usingacoaxcable...............................................117

Externalsynchronisation......................................................................................118

Remotecontrol.....................................................................................................119

RemoteControlusingK-Rem..............................................................................120

Dummyplugfornotusingremotecontrol...........................................................121

RemotecontrolofTransmitterUnit.....................................................................122

RemotecontrolofReceiverUnit..........................................................................124

Remotecontroloverview.....................................................................................126

TransmitTransducercable...................................................................................128

ReceiveTransducercable.....................................................................................129

DIMENSIONALSURVEYINGANDALIGNMENT......................130

Aboutdimensionalsurveyingandalignment................................................................131

Dimensionalsurveying..................................................................................................131

Alignment......................................................................................................................132

Transducerarrayatness...............................................................................................133

Checkingthetransducerarrayatnessandcorrectingdeviations.................................134

Calibration.....................................................................................................................135

Vesselcoordinatesystem...............................................................................................135

TECHNICALSPECIFICATIONS..............................................137

Performancespecications............................................................................................138

Interfacespecications...................................................................................................140

Datagramformats.................................................................................................141

ProcessingUnit.....................................................................................................142

Externalsensorsrequirements..............................................................................145

HydrographicWorkStation..................................................................................146

Weightandoutlinedimensions......................................................................................147

Powerrequirements.......................................................................................................150

Environmentalrequirements..........................................................................................152

Dimensionalsurveyaccuracyrequirements..................................................................155

Alignmentspecications................................................................................................157

DRAWINGFILE....................................................................158

Drawingnumbersreferencedinthisdocument.............................................................158

443140/A

5

KongsbergEM124

6

443140/A

Aboutthismanual

Purposeofmanual

Thepurposeofthismanualistoprovidetheinformation,proceduresandbasicdrawings

requiredforthephysicalinstallationoftheEM124.

Targetaudience

Aboutthismanual

Themanualisintendedfortechnicalpersonnel;suchasskilledshipyardworkers,

electricians,qualiedengineersandnavalarchitects.Itisassumedthatyouunderstand

thegeneralprinciplesofmaritimeelectronicequipment.Y oumustalsobefamiliarwith

computerhardware,interfacetechnologyandinstallationofelectronicandmechanical

products.

Weassumethatyouarefamiliarwiththebasicacousticprinciplesofsoundinwater.

Wealsoexpectthatyouhavesomeexperiencewithmultibeamand/orsinglebeamecho

soundersinhydrographicapplications..

Installationinstructions

Youmustfollowtheinstructionsinthismanualtoensureoptimalperformance.Asa

guide,installationproceduresarepresentedintheordertheymustbedone.

Theequipmentdescribedinthismanualincludesthecompletesystemwithrelevant

cabinets.Unitsprovidedlocallybythecustomer,installationshipyardorlocal

representativearenotdescribed.

Themanualalsodenestheequipmentresponsibility,andprovidesapplicable

instructionsforunpackingandstorageofunits.

Note

Youmustfollowtheinstructionsgiveninthismanual.Ifnotitmayaffectthewarranty.

KongsbergMaritimeASwillacceptnoresponsibilityforanydamageorinjurytothe

system,vesselorpersonnelcausedbyequipmentthathasbeenincorrectlyinstalledor

maintained,orbydrawings,instructionsorproceduresthathavenotbeenprepared

byus.

443140/A

7

KongsbergEM124InstallationManual

Installationdrawings

Theinstallationshipyardmustprovideallnecessaryinstallationdrawingsunless

otherwisespeciedinthedeliverycontract.

KongsbergMaritimeASmay,onspecialorder,provideassistancetothesedrawings.

Note

Ifrequired,alldocumentsprovidedbytheshipyardforthephysicalinstallationof

theEM124mustbeapprovedbythevessel’ snationalregistryandcorresponding

maritimeauthorityand/orclassicationsociety.Suchapprovalmustbeobtainedbefore

theinstallationcanbegin.Theshipownerandshipyarddoingtheinstallationare

responsibleforobtainingandpayingforsuchapproval.

TheoutlinedimensionsoftheEM124unitsarefoundintheDrawinglechapter

inthismanual.

Onlineinformation

ForinformationabouttheEM124andotherproductsfromKongsbergMaritime,visit

ourwebsite.

•https://www.km.kongsberg.com

Registeredtrademarks

Observetheregisteredtrademarksthatapply.

Windows

®

isaregisteredtrademarkofMicrosoftCorporationintheUnitedStatesand

othercountries.

®

EM

isaregisteredtrademarkofKongsbergMaritimeASinNorwayandothercountries.

8

443140/A

Topics

Systemdescription,page10

Technicaldetails,page11

KongsbergEM124

KongsbergEM124

Systemdiagram,page12

Systemunits,page13

Supportinformation,page16

443140/A

9

KongsbergEM124InstallationManual

Systemdescription

EM124multibeamechosounderisahighperformanceechosounderfordeepwater

mapping.

TheEM124isdesignedtoperformseabedmappingtofulloceandepthwithan

unsurpassedresolution,coverageandaccuracy .Thesystemiscosteffective,reliable,

andeasilyoperated.ThedesignoftheEM124isbasedonmorethan50yearsof

hydrographicexperiencewithechosounders,sonarsandunderwaterpositioningfor

civilianandmilitaryuse.Itisthelatestmodelinaseriesofdeepseamultibeamecho

soundersthatstartedwiththeEM12in1990.

TheEM124consistofnewstate-of-the-artelectronicsandseparatetransmitandreceive

transducersinaMillsCrossconguration.Itusesthesameeld-proventransducersas

theEM122,makingiteasytoupgrade.Carehasbeentakentodesignahighly,modular

andexiblesolutionwithcompactelectronicsforeasierandfasterinstallation.Duetoa

exibletransducerdesign,thesystemcanbetailoredtoalmostanyrequiredsize.The

largeststandardsize,0.5x1degrees,givestheultimatesystemperformanceintermsof

resolutionandrange,whileasmaller4x4degreessolutionallowingfulloceandepth

surveysevenonsmallervessels.

TheEM124multibeamechosounderconsistsofthefollowingmainunits.

•Transducerarrays

•TransmitterUnit(s)

•ReceiverUnit(s)

•ProcessingUnit

•HydrographicW orkStation

Toformacompletesystemitisalsorequiredtohavesensorsprovidingvesselattitude,

velocity,position,soundspeedproleofthewatercolumnandspeedofsoundatthe

transducerdepth.

10

443140/A

KongsbergEM124

Technicaldetails

TheEM124operatesatsonarfrequenciesinthe10.5-13.5kHzrange.Thetransmitfan

isdividedinto4sectorsinshallowmodes(8sectorsindeepmodes)tomaximizerange

capabilitybutalsotosuppressinterferencefrommultiplesofstrongbottomechoes.

Thesectorsaretransmittedsequentiallywithineachping,andusesdistinctfrequencies

orwaveforms.

Thenominalsonarfrequencyis12kHzwithanangularcoveragesectorofupto150

degreesand1600beamsperping.Achievableswathwidthonaatbottomwillnormally

beupto6times(143degrees)thewaterdepth.Theangularcoveragesectorisoperator

controllableormaybesettoaxedrange.Itmayalsobesettovaryautomaticallywith

depthaccordingtoachievablecoverage.Thismaximizesthenumberofusablebeams.

Thebeamspacingisnormallyhighdensityequidistantwithequiangleavailable.

Thetransmitfanissplitinseveralindividualsectorswithindependentactivesteering

accordingtovesselroll,pitchandyaw.Thisplaceallbeamsona“bestt”toaline

perpendiculartothesurveyline,thusensuringauniformsamplingofthebottomand

100%coverage.

Indualswathmodethetransmitfanisduplicatedandtransmittedwithasmalldifference

inalongtracktilt.Theappliedtilttakesintoaccountdepth,coverageandvesselspeedto

giveaconstantbeamseparationalongtrack.

ThesectorsarefrequencycodedorhaveFMchirps,andtheyaretransmittedsequentially

ateachping.Thesectorsteeringisfullytakenintoaccountwhenthepositionanddepth

ofeachbeamiscalculated,asistherefractionduetothesoundspeedprole,vessel

attitudeandinstallationangles.Thepulselengthandrangesamplingratearevariable

withdepth(autoormanual)forbestresolution.

Inshallowwatersduecareistakentotheneareldeffectsthroughneareldfocusing

individuallyappliedinthedifferentsectors.

EM124appliesonefocusrangeforeachofthetransmitsectorswhichareusedfor

shallowwaterenvironment.Dynamicbeamfocusingisusedforthereceptionbeams.

Thepingrateismainlylimitedbytheroundtriptraveltimeinthewateruptoaping

rateofmorethan5Hz.

ThenumberofindividualTXandRXmodulesinthetwoarraysdependsonthechosen

conguration.Thestandardtypesidentiedby"transmissionxreception"beamwidth

are:

•0.5x1degreesystem:96transmittransducermodulesand16receivetransducer

modules

•1x1degreesystem:48transmittransducermodulesand16receivetransducermodules

•1x2degreessystem:48transmittransducermodulesand8receivetransducermodules

•2x2degreessystem:24transmittransducermodulesand8receivetransducermodules

•2x4degreessystem:24transmittransducermodulesand4receivetransducermodules

•4x4degreessystem:12transmittransducermodulesand4receivetransducermodules

443140/A

11

KongsbergEM124InstallationManual

Systemdiagram

ThesystemdiagramidentiesthemaincomponentsofabasicEM124system.Only

themainconnectionsbetweentheunitsareshown.Detailedinterfacecapabilitiesand

powercablesarenotshown.

AHydrographicW ork

Station

BInterfaces:

•Soundspeed

sensors

•Tide

•Centredepth

output

CProcessingUnit

DInterfaces:

•Positioning

systems

•Attitude(roll,

pitchandheave)

•Soundspeed

sensor

•Velocity

•Clock

•Trigger

input/output

•Clocksynchronisation(1PPS)

ETransmitterUnit(TXU)

FReceiverUnit(RXU)

GTransmittransducermodules

HReceivetransducermodules

12

443140/A

Systemunits

Topics

Transducerdescription,page13

TransmitterUnitdescription,page14

ReceiverUnitdescription,page14

ProcessingUnitdescription,page14

HydrographicWorkStationdescription,page15

Transducerdescription

KongsbergEM124

Atransducerisadevicethatconvertsoneformofenergytoanother.Inanechosounder

systemthetransducerconvertsbetweenelectricenergyandsound.

TheEM124usesseparatetransducerarraysfor

transmittingandreceivingsoundpulses.Both

transducerarrayshaveseveralmoduleswhichare

assembledinmountingframes.

Thetwotransducerarraysarenormallymountedas

“T”or“L”congurationsunderthevessel’shull(Mills

Crossconguration).Thetransmittransducerarray

Receivetransducermodule

shouldbealignedparalleltothevessel’skeel.The

receivertransducerarrayshouldbealigned90degreesonthekeel.Bothtransducer

arraysshouldbehorizontalonaplaneonthekeel.

Thetransmittransducerarraycontainsupto96modulesinaccordancewiththechosen

beamwidth.Eachmodulecontains18elementsarrangedinrowsof6elements.Each

elementisindividuallyconnectedtoitscorrespondingtransmitterintheTransmitter

Unit(s).Itcanthusbedrivenwithanuniqueamplitudelevelandphasetoallowforming

oftherequiredtransmitsectorswithindividualsteering.

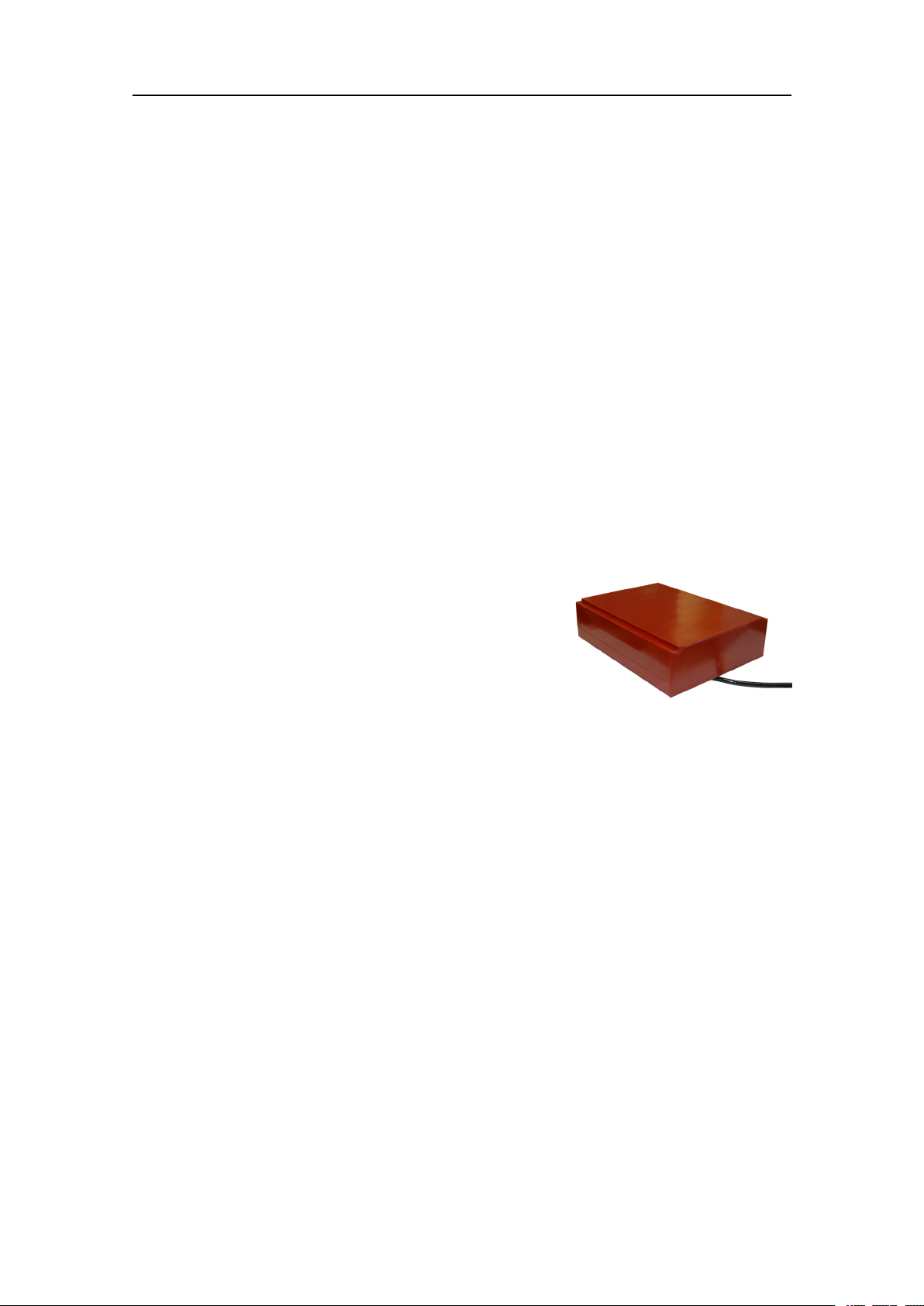

Thereceivetransducercontainsupto16modulesinaccordancewiththechosen

beamwidth.Eachmodulecontains8transducerstaves,andthesehaveindividual

electricalconnectionstotheircorrespondingpreampliersintheReceiverUnit(s).Each

stavecanthusbegivenuniqueamplitudeandphasecontroltoallowformingofthe

requiredreceivebeams.

443140/A

13

KongsbergEM124InstallationManual

TransmitterUnitdescription

TheEM124TransmitterUnithasalltransmitelectronics,likecontrolprocessors,power

ampliers,powersupply,capacitorbatteryandEthernetinterface.

TheTransmitterUnitisawall-mountedsteelcabinetwithintegratedshockandvibration

absorbers,designedforbulkheadmounting.One19inchsub-rackiscontainedinthe

cabinet.Thenumberofcircuitboardsinthesub-rackwilldependuponthechosen

transducerconguration.

TwistedpairEthernetisusedfordatacommunicationwiththeProcessingUnit.

TheTransmitterUnitisnormallylocatedina"sonarroom"closetothetransducerarrays.

ReceiverUnitdescription

TheEM124ReceiverUnithasallreceiveelectronics,likecontrolprocessor,ampliers,

Analog-to-DigitalConverters,powersupplyandEthernetinterface.

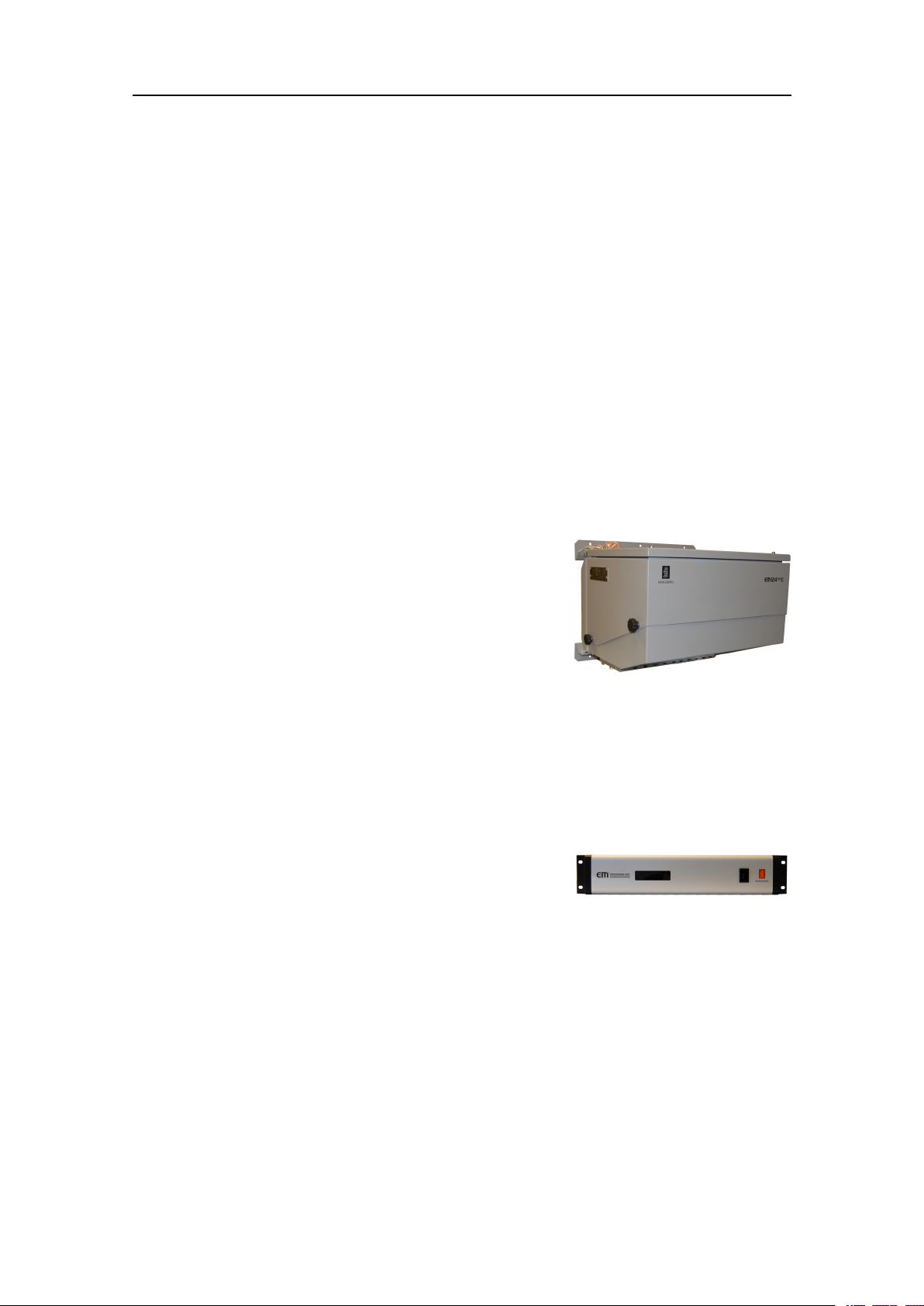

TheReceiverUnitisasmallwall-mountedsteelcabinet

withintegratedshockandvibrationabsorbers,designed

forbulkheadmounting.Thenumberofcircuitboards

willdependuponthechosentransducerconguration.

TwistedpairEthernetisusedfordatacommunication

withtheProcessingUnit.

TheReceiverUnitisnormallylocatedina"sonar

room"closetothetransducerarrays.

ProcessingUnitdescription

TheEM124ProcessingUnitisprovidedtoprocessthesignalstoandfromthe

TransmitterandReceiverUnits.

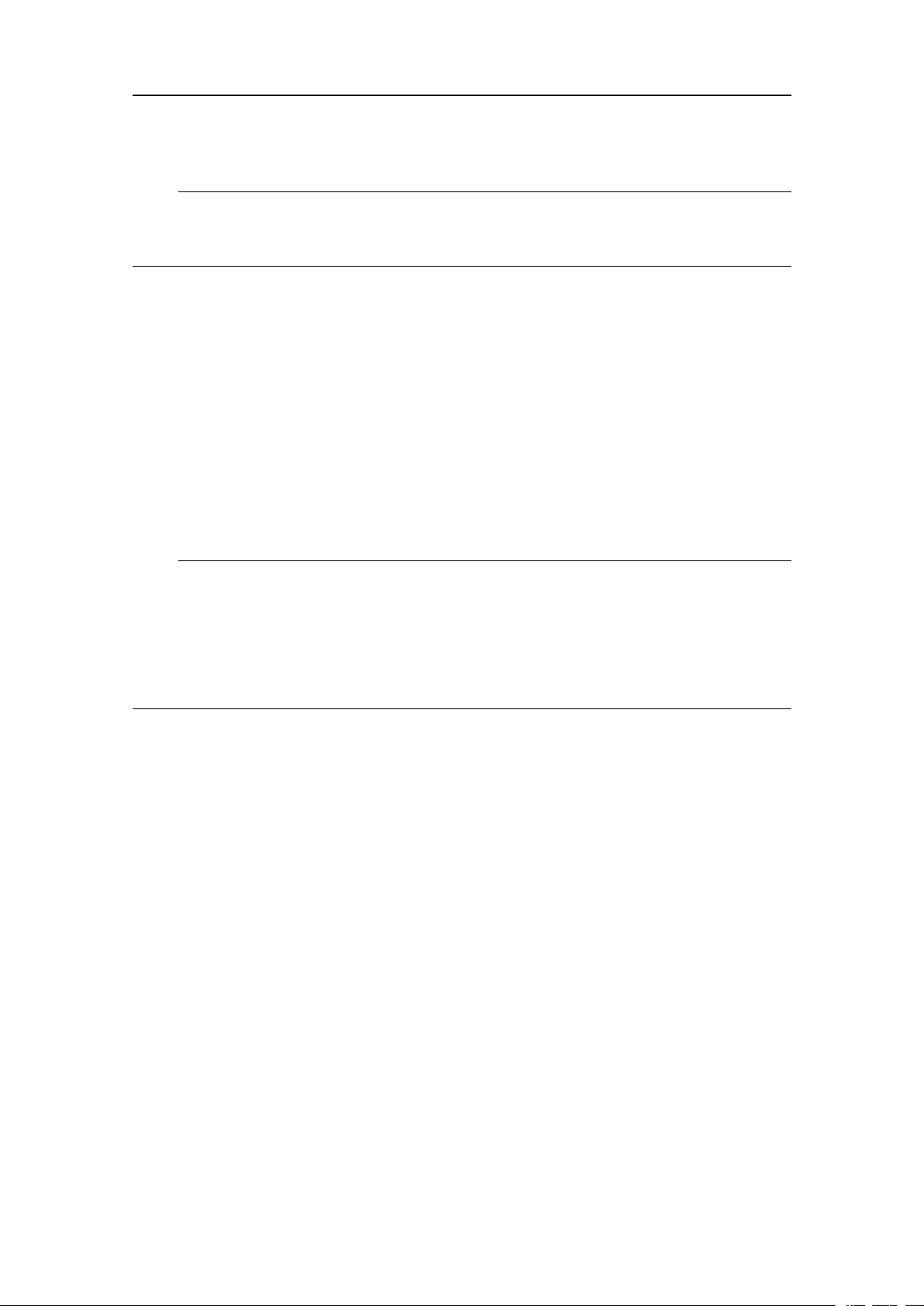

TheEM124ProcessingUnitisanindustrial

computerusingbothCOTS(commercialoff-the-shelf)

componentsandcustommadecomponents.Theunitis

designedandtestedforruggeduse.

TheProcessingUnitperformsthereceiverbeamforming,bottomdetection,andmotion

andsoundspeedcorrections.Itcontainsallinterfacesfortime-criticalexternalsensors

suchasvesselattitude(roll,pitch,headingandheave),vesselpositionandexternal

clock.Morethanonesensorofeachtypemaybeconnectedsimultaneously,withonein

useandallofthemlogged.

TheProcessingUnitcontrolstheTransmitterandReceiverunitsviaEthernet

communication,andisalsointerfacedtotheOperatorstationviaEthernet.

The48VoutputfromtheProcessingUnitcanbeusedforremoteon/offcontrolofthe

TransmitterandReceiverUnits.

14

443140/A

KongsbergEM124

TheProcessingUnitisnormallylocatedina"sonarroom"closetothetransducerarrays.

Theunitcanalsobeplacedinthe"surveyroom"oronthebridge.

HydrographicWorkStationdescription

TheHydrographicWorkStationistheoperatorstationfortheEM124.

Adedicatedmaritimecomputerisprovidedwiththe

EM124MultibeamEchoSounder.Itissetupwith

allnecessarysoftware.

TheHydrographicWorkStationisbasedonthe

Microsoft

TheHydrographicWorkStationisnormallymounted

neartheoperatorworkspace.

®

Windows10operatingsystem.

443140/A

15

KongsbergEM124InstallationManual

Supportinformation

ShouldyouneedtechnicalsupportforyourEM124youmustcontactaKongsberg

Maritimeofce.Alistofallourofcesisprovidedonourwebsite.Youcanalsocontact

ourmainsupportofceinNorway.

A24hourtelephonesupportservicemayalsobeavailabledependingofthelevelof

SLA(ServiceLevelAgreement).

•Companyname:KongsbergMaritimeAS

•Address:Strandpromenaden50,3190Horten,Norway

•Website:https://www.km.kongsberg.com

•E-mailaddress:km.hydrographic.support@kongsberg.com

16

443140/A

Preparations

Topics

Tools,equipmentandconsumablesrequiredforEM124installation,page17

Personnelqualications,page18

Preparations

Sonarroomrequirements,page19

Wheretoinstallthetransducer,page22

Acousticnoise,page27

Tools,equipmentandconsumablesrequired forEM124installation

InordertodotheEM124installation,allnecessarytoolsandequipmentformechanical

work,cabinetinstallationandelectricalwiringmustbeavailable.

Itisnotpracticaltoprovideadetailedlistofallnecessarytoolsandequipment.Y oumust

beequippedwithastandardsetoftools.Thistoolsetmustcomprisethenormaltoolsfor

electronicandelectromechanicaltasks.Thisincludesdifferentscrewdrivertypes,pliers,

spanners,acablestripper,asolderingiron,etc.Eachtoolmustbeprovidedinvarious

sizes.W erecommendthatalltoolsaredemagnetizedtoprotectyourequipment.

However,youmustmakesurethatthefollowingspecializedtoolsareavailable.

•Allnecessarytoolsandconsumablesrequiredforwelding

•Allnecessarytoolsandconsumablesrequiredforphysicalinstallationoftransducer

framesandtransducermodules

•Allnecessarytoolsandconsumablesrequiredforelectricalinstallations

•AnarticulatedjackorsimilararrangementcapableofliftingtheindividualEM124

units

•Torquewrench

443140/A

17

KongsbergEM124InstallationManual

Note

Ifyouneedspecicconsumables,orifspecialtoolsand/ortestinstrumentsarerequired,

theseareidentiedintherelevantprocedure(s).

Personnelqualications

TheinstallationoftheEM124isademandingtask.Itisveryimportantthatthe

personnelinvolvedintheinstallationtasksarecompetentandexperiencedcraftsmen.

Asaminimum,thefollowingcertiedcraftsmenmustbeavailable.

•ServiceengineerfromKongsbergMaritime

•Welders

•Electricians

Note

Thequalityoftheweldingiscriticaltothesafetyofthevessel.Weldingmustonlybe

donebyacertiedwelder .

Ifapplicable,thenalinstallationweldsmustbeapprovedbythevessel’ snational

registry,thecorrespondingmaritimeauthorityand/orclassicationsociety.Observethe

relevantrulesandregulationsrelatedtowelding.

18

443140/A

Preparations

Sonarroomrequirements

Topics

Environmentalrequirements,page19

Sizeandaccessrequirements,page19

Requirementsforinsulation,heatingandventilation,page20

Requirementsforelectricalinstallations,cablesandcommunication,page20

Environmentalrequirements

TheEM124unitsmustbeinstalledinadryanddust-freeenvironment.Theunitsarenot

fullyprotectedagainsthumidity,dustorwater.

Itisimportantthatthesonarroomiskeptdry.TheEM124unitsmustnotbeexposed

toexcessivetemperatures,dust,moistureorhumidity.Suchconditionscancause

corrosiveattacksandsubsequentfailurestotheelectroniccircuitry.Visitthesonarroom

atregularintervalstochecktemperatureandhumidity,andtakethenecessaryactions

iftheenvironmentalconditionsarepoor.

Avoidrunninglargepowercablestroughthesonarroom.

ObservetheenvironmentalspecicationsrelatedtotheEM124units.

Sizeandaccessrequirements

Awelldesignedsonarroomwithawellttedsizeandeasyaccessreducestheriskof

corrosion,andsimpliesmaintenance.Thisincreasessystemreliability .

Thesonarroommustbelargeenoughtohouseallthesystemunits.Theroommust

provideenoughspacetoallowefcientmaintenance.Y oumustbeabletokeepallthe

cabinetdoorsfullyopenwithoutunduerestrictiontoyourmovements.

1Theroommustnotbeusedforanyotherheavymachinery.

2Theroommustnotbeunnecessarilyobstructedbygirders,pipesetc,whichmay

causeinstallationproblemsorimpedemaintenance.

3Thesonarroommustbeaccessibleunderallconditionsatseaorataberth.

4Alldoorsorhatchesmustbedesignedsothatthetoolsandequipmentcanbe

removedwithoutbeingdisassembled.

443140/A

19

KongsbergEM124InstallationManual

Requirementsforinsulation,heatingandventilation

Thebulkheadsinthesonarroomshouldbeinsulatedandprovidedwithaninteriorwall

tothedeck.Theroomshouldbeequippedwithheaterandconnectedtothevessel's

ventilationsystem.

Heatingrequirements

Heatingisaneffectivemethodforreducinghumidity.Theheaterinthesonarroommust

dimensionedtomaintaintheequipmentwithinitsenvironmentaltolerances.

ObservetheenvironmentalspecicationsrelatedtotheEM124units.

Ventilationrequirements

Thesonarroomshouldbeconnectedtothevessel'sventilationsystemtoensureasupply

ofcoolingair.Ifaventilationsystemisnotavailable,installtwo3”pipesfromthesonar

roomtoasuitablefreshairlocationondeck.

Thefreshairshouldentertheroomasclosetotheooraspossible,andshouldbe

extractedfromashighaspossible.Afunnelshapeddrip-collectormustbemounted

belowtheventpipestodivertmoisturetothebilge.Onthemaindeck,thebest

ventilationisprovidedwhentheoutletpipeisatleastfourmetershigherthantheinlet

pipe.T okeepoutseawater,rainandspray,theventilationpipesmustbettedwith

goosenecksoranequivalentdesign.

Note

Ifthevesselislikelytooperateintropicalconditions,asuitableairconditioningsystem

mustbeinstalled.Theairconditioningsystemmustbeabletoprovideanambient

temperaturethatdoesnotexceedthemaximumoperatingtemperaturesoftheEM124

unitsthatareinstalledintheroom.

Requirementsforelectricalinstallations,cablesand communication

Theelectricalinstallationsinthesonarroommustmeetminimumrequirementsto

providesuitablelightsandsupplypower.

Lightrequirements

Thesonarroommustbeequippedwithsuitablelightingtosimplifytheinstallation

andtoaidfuturemaintenance.

Communicationrequirements

Thesonarroomshouldbeequippedwithatelephone,anintercomsystem,oranyother

meansoforalcommunicationbetweenthesonarroomandthebridgeand/orcontrol

room(s).

20

443140/A

Preparations

Powerrequirements

Eachunitinthesonarroomshouldbeprovidedwithaseparatecircuitbreakeronthe

mainssupply.

Propervesselgroundmustbeprovided.

Aminimumnumberofadditionalelectricaloutletsmustbeprovidedforotherequipment.

Cablingrequirements

ThesonarroomunitsareconnectedtootherEM124unitslocatedindifferent

compartmentsonthevessel.Theunitsmayalsobeconnectedtoperipheraldevices.If

thesecablespassthroughhatchesorareaswheretheymaybedamaged,theymustbe

runinconduits.Minimum2”conduitisrecommended.

Makesurethatallsystemcablesareproperlyconnectedandsecured,andinstalled

withsomeslack.Theslackisessentialtowithstandvibrations,andtofacilitatefuture

maintenanceandreplacements.

443140/A

21

KongsbergEM124InstallationManual

Wheretoinstallthetransducer

Topics

Introductiontotransducerlocation,page22

Mountthetransducerdeep,page22

Avoidprotrudingobjectsnearthetransducer,page23

Keepthetransducerfarawayfromthepropellers,page24

Mountthetransduceratasafedistancefrombowthruster(s),page24

Summaryandgeneralrecommendations,page24

Introductiontotransducerlocation

Asingleanswertothequestion"wheretoinstallthetransducer"cannotbegiven.

Thephysicallocationofthetransducerdependsonthevessel'sdesignandconstruction,

howthehullisshaped,andhowthewaterrunsalongthehull.Therearehowevera

numberofimportantguidelines,andsomeoftheseareevenconicting.

Note

Theinformationheremustbeconsideredasgeneraladvice.EachEM124installation

mustbehandledseparatelydependingonthehulldesignandtheotherelectricaland

mechanicalsystemsinstalledonthevessel.

Mountthetransducerdeep

InordertoachievethebestpossibleEM124performance,mountthetransduceras

deepaspossibleunderthevessel’shull.

Thereareseveralreasonsforthisrecommendation.

Flownoise

Considerthesituationswhenthevesselisunloaded,andpitchinginheavyseas.The

vesselisridinghigh,andthebowmayevenbeliftedoutofthewater.Thiswillcausea

lotofairtofollowtheshapeofthehull.

Theupperwaterlayersoftheseacontainamyriadofsmallairbubblescreatedbythe

breakingwaves.Inheavyseastheupper5to10metresmaybelledwithair,andthe

highestconcentrationswillbenearthesurface.Airbubblesabsorbandreectthesound

energy,andtheymayinworstcasesblockthesoundtransmissionaltogether.

22

443140/A

Preparations

Cavitation

Cavitationistheformationofsmallairbubblesclosetothetransducerface.Thebubbles

appearbecausethelocalpressurebecomesnegativeduringpartsoftheacousticpressure

cycles.Thecavitationthresholdincreaseswiththehydrostaticpressure.Thenoiseis

madewhenthebubblesimplode.

Transmittinginair

Thetransducermustneverbeliftedfreeofthewatersurface.Ifthetransduceris

activatedwhenoutofthewateritmaybedamagedbeyondrepair.Mountingthe

transduceratadeeppositiononthehullwillinnormallypreventthis.

Slamming

Slamminghappensifthevesselhullclimbsoutofthewaterinheavyseas.Theforceof

thewaterwhenthehullfallsdownmaypushthetransducerup,andmaycausedamage

bothtothetransducerandtoitsmounting.Thisisespeciallyimportantforlowfrequency

Transducerswithlargefaces.Theeffectofslammingcanbereducedbymountingthe

transducerasdeepaspossibleonthehull.

Note

KongsbergMaritimeAStakesnoresponsibilityforanydamagestothetransducer,the

cableorthemountingarrangement,causedbyslamming.

Avoidprotrudingobjectsnearthetransducer

Objectsprotrudingfromthehullwillgenerateturbulenceandownoise.Thiswill

reducetheEM124performance.

Protrudingobjectsmaybezincanodes,transducersoreventhevessel'skeel.Holesand

pipeoutletsarealsoimportantnoisesources,aswellasroughsurfacescausedbybad

welding.Eventracesofsealingcompound,sharpedges,boltsoremptyboltholeswill

createnoise.Alltheseprotrudingobjectsmayactasresonantcavitiesamplifyingthe

ownoiseatcertainfrequencies.

Donotplaceatransducerinthevicinityofprotrudingobjects,andespeciallynotclose

behindthem.Makesurethatthesurfaceofthetransducerface,thehullplatingandputty

aroundthetransducerisasevenandsmoothaspossible.Mountingscrewsorboltsmust

notbeextrudingfromthetransducer,theinstallationhardwareorthehullplating.If

necessary,grindandpolishallsurfaces.

443140/A

23

KongsbergEM124InstallationManual

Keepthetransducerfarawayfromthepropellers

Thepropulsionpropellersisthedominantnoisesourceonmostvessels.Thenoise

iseasilytransmittedthroughthewater.Thisnoisemayoftenreducetheoverall

performanceofyourEM124.

Thetransducermustbeinstalledasfarawayfromthepropellersaspossible.Thebest

positionsarethereforeontheforepartofthehull.Positionsoutsidethedirectlineof

sightfromthepropellersarebest.

Onsmallvesselswerecommendmountingthetransduceronthatsideofthekeelwhere

thepropellerbladesmoveupwards.Thisisbecausethepropellercavitationisweakest

onthatside.Thecavitationstartswhenthewaterowsinthesamedirectionasthe

propellerblades.Thisiswherethepropellerbladesmovedownwards.

Mountthetransduceratasafedistancefrombowthruster(s)

Bowthrusterpropellersareextremelynoisy.Whenyoudecidewheretoplacethe

transducer,youmustconsiderthenoisecreatedbymostbowthrusters.

Wheninoperation,thenoiseandcavitationbubblescreatedbythethrustermaymake

yourEM124MultibeamEchoSounderuseless,almostnomatterwherethetransduceris

installed.Whenthebowthrustersarenotinoperation,thetunnelcreatesturbulence.If

yourvesselispitching,thetunnelmaybelledwithairoraeratedwaterintheupper

positionandreleasethisinthelowerposition.

Ingeneral,thetransducershouldthereforebeplacedwellawayfromthebowthruster(s).

However,thisisnotaninvariablerule.Certainthrusterdesigns-combinedwiththeir

physicallocationsonthehull-maystillofferasuitablelocationforthetransducer,even

closetothethruster.Ifyouareindoubt,consultanavalarchitect.

Summaryandgeneralrecommendations

Someoftheinstallationguidelinesprovidedfortransducerlocationmaybeconicting.

Forthisreason,eachvesselmustbetreatedindividuallyinordertondthebest

compromise.

Ingeneral,themostimportantfactoristoavoidairbubblesinfrontofthetransducer

face.Forthisreason,therecommendedtransducerlocationisnormallyintheforepartof

thehull,wellaheadofthenoisecreatedbythebowwave.

Themaximumdistancefromthebowisnormallyequaltoonethirdofthetotalwater

linelengthofthehull.

Note

Mountingthetransducermorethan10–15metersfromthebowmaycauseproblems

withtheturbulentow.

24

443140/A

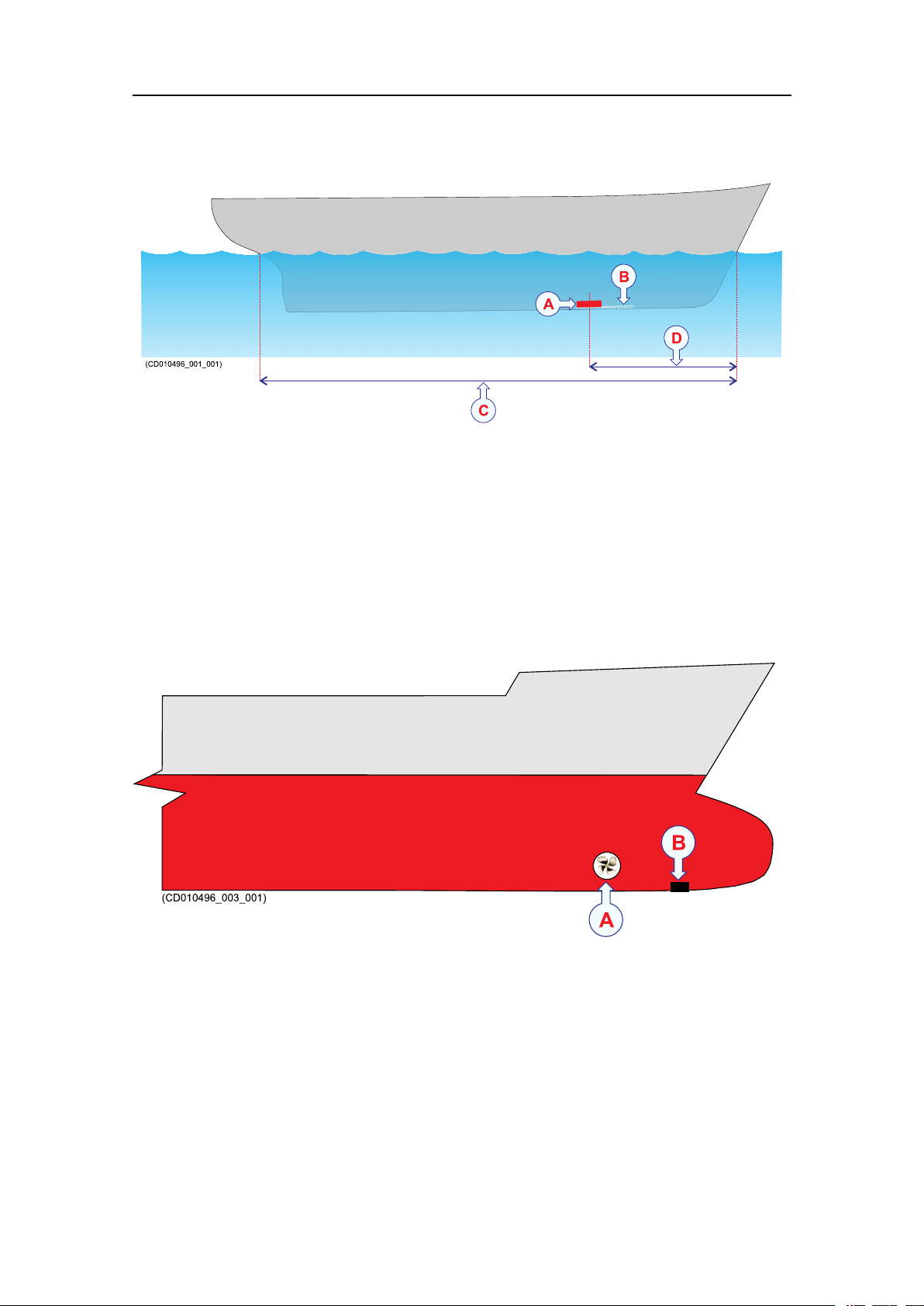

ATransducer

BInclinationangle

CHulllengthatwaterline

Preparations

DMaximum1/3ofthehulllengthatwaterline(C)

Ifthevesselhullhasabulbousbow,thismaywellbeagoodtransducerlocation,but

alsointhiscasetheowpatternoftheaeratedwatermustbetakenintoconsideration.

Theforemostpartofthebulbisoftenagoodlocation.

AThruster

BTransducerlocation

Thisappliestothevesselinnormaltrimandspeed.

443140/A

25

KongsbergEM124InstallationManual

Important

Thetransducermustnothaveanegativeinclinationanglecomparedtowaterow.

Donotplaceatransducerinthevicinityofprotrudingobjects,andespeciallynotclose

behindthem.

Makesurethatthesurfaceoftheresultinginstallationisassmoothandstreamlinedas

possible.

26

443140/A

Acousticnoise

Aswithanyotherhydroacousticsystems,thequalityoftheEM124echodataand

presentationsaresubjecttounwantedacousticnoise.Theechoesfromanylargeand

smalltargetmustbedetectedinsidethenoise.

Itisimportantthatwekeepthenoiselevelaslowaspossible.Theisnecessarytoobtain

longrangeanddependableinterpretationsoftheechoes.Evenwiththeadvancednoise

lteringofferedbytheEM124,wemustaddressthenoisechallenge.Thisisimportant

duringtheplanningandpreparationsfortheEM124installation.

Topics

Contributingfactors,page27

Selfnoise,page28

Ambientnoise,page31

Preparations

Electricalselfnoise,page31

Somemeanstoreduceacousticnoise,page31

Contributingfactors

Severalfactorsarecontributingtotheperformanceofthehydroacousticequipment

usedonboardavessel.

Factorscontributingtotheperformanceofthehydroacousticequipmentusedonboarda

vesselare:

•Thequalityandpropertiesofthetransmittedsignal

•Thequalityofthereceivingsystem

•Theoperationalsettingsmadeduringoperation

•Thepropertiesofthetarget(s)

•Thesignal-to-noiseratio

Themajorityofthesefactorscanneitherbecontrollednorimprovedbymeans

ofinstallationmethodsortransducerlocations.Thequalityandpropertiesofthe

transmittingandreceivingsystemsarekeyfactorsduringourproductdevelopment,while

ourenduserdocumentationaimstohelptheusertomaketherightltersettingsduring

operation.Asforthetargetproperties,thereisnothinganyofuscandowiththose.

Thesignal-to-noiseratio,however,canbeimprovedbymakingthecorrectchoices

duringinstallation.

Signal-to-noiseratio(oftenabbreviatedSNRorS/N)isameasureusedin

scienceandengineeringthatcomparesthelevelofadesiredsignaltothelevelof

backgroundnoise.Itisdenedastheratioofsignalpowertothenoisepower,often

expressedindecibels.Aratiohigherthan1:1(greaterthan0dB)indicatesmore

443140/A

27

KongsbergEM124InstallationManual

signalthannoise.WhileSNRiscommonlyquotedforelectricalsignals,itcan

beappliedtoanyformofsignal[...].

http://en.wikipedia.org/wiki/Signal_to_noise_ratio(September2013)

Thesignalistheechothatwewanttoknowsomethingabout,whilethenoiseisany

unwantedsignalsordisturbances.Theechomustbedetectedinthenoiseandthereforeit

isnecessarytokeepthenoiselevelisaslowaspossibleinordertoobtainlongrange

anddependableinterpretation.

Thenoisethatcontributestothesignaltonoiseratiomaybedividedintothefollowing

typesofnoise:

•Selfnoise

•Ambientnoise

•Electricalnoise

•Reverberation

AThetransducercanpickupnoisefrom

•Biologicaldisturbances

•Interference

•Cavitation

•Propellernoise

•Flownoise

•Acousticnoisefromotherhydroacousticsystems

BThetransducercableislong,andmaypickupelectricnoisefromgenerators,

pumps,coolingsystemsandotherelectricorelectromechanicaldevices.

CThepreampliersareverysensitive,andtheycaneasilypickupelectricalnoise

frominternalandexternalpowersupplies.Thepreampliersarealsovulnerablefor

analoguenoisecreatedbytheirownelectroniccircuitry .Digitalnoisecreatedby

theconverterandprocessingcircuitrycanalsocreateproblems.

DConverterstransformtheanalogueechoestodigitalformat.

ESignalprocessingcircuitrycancreatedigitalnoise.

Selfnoise

Anyvesselequippedwithahydroacousticsystem(forexampleechosounderorsonar)

willproducemoreorlessselfnoise.

Therearemanysourcesofsuchselfnoise.W ewillheregointosomedetailsinorderto

analysethedifferentsourcesofselfnoiseonavesselandhowtheymayinuenceupon

thenoiselevelofthehydroacousticinstruments.

28

443140/A

Preparations

Machinerynoise

Themaincontributortomachinerynoiseisusuallythemainengineonboardthevessel.

Thecontributionfromauxiliarymachinerymay,however,beconsiderable,especiallyif

itisinpoorshape.Themachinerynoisecanbetransmittedtothetransduceras:

•Structure-bornenoisethroughtheshipstructureandthetransducermountings

•Water-bornenoisethroughthehullintothewatertothetransducer

Electricalnoise

Modernvesselsarenormallyequippedwithalotofelectricinstrumentssuchas

hydroacousticsystems,radars,navigationsystems,andcommunicationequipment.

Anyelectricinstrumentsmayinsomecasescauseelectricalinterferenceandnoise.

Internationalregulationsandcerticationsareusedtocontrolandreducethis,buteven

thesearelimitediftheelectricalsystemsarepoorlyinstalledand/ormaintained.

Propellernoise

Propellernoiseisoftenthemainsourceofnoiseathighervesselspeeds.V ariablepitch

propellersorfastmovingpropellersusuallymakemorenoisethanxedpropellersor

slowmovingpropellers.

Propellernoiseisusuallywater-borne.Insomecases,however,shaftvibrationsor

vibrationsinthehullnearthepropellermaybestructure-bornetothetransducer.Ifa

propellerbladeisdamaged,thismayincreasethenoiseconsiderably.

Propellercavitationisaseveresourceofnoise."Singing"propellersmightbeasourceof

noise,whichinterferesatdiscretefrequencies.Insomecasesstaticdischargefromthe

rotatingpropellershaftmaybequitedisturbing.

Cavitation

Cavitationistheformationofsmallairbubbles

closetothetransducerface.Thebubblesappear

becausethelocalpressurebecomesnegative

duringpartsoftheacousticpressurecycles.

Thecavitationthresholdincreaseswiththe

hydrostaticpressure.Thenoiseismadewhen

thebubblesimplode.

Cavitationnoisemayappearnearextruding

objectsathigherspeeds,butmoreoftenitis

causedbythepropellers.Propellercavitationisaseveresourceofnoise.Thecavitation

startswhenthewaterowsinthesamedirectionasthepropellerblades.Thisiswhere

thepropellerbladesmovedownwards.

Insomecasesaresonantphenomenonissetupinaholenearthehull.Thissoundwill

haveadiscretefrequency,whileallotherownoisewillhaveawidefrequencyspectrum.

(ImagefromU.S.Navyinthepublicdomain.)

443140/A

29

KongsbergEM124InstallationManual

Flownoise

Theupperwaterlayersoftheseacontainamyriadofsmallairbubblescreatedbythe

breakingwaves.Whenthehullmovesthroughwateritwillcauseadisturbance,andthis

willgeneratefriction.Thefrictionzoneiscalledtheowboundarylayer.Theowin

thisboundarylayermaybelaminarorturbulent.

•Thelaminarowisanicelyordered,parallelmovementofthewater.

•Theturbulentowisadisorderlyowpattern,fullofeddies.

ATurbulentow

BLaminarow

CAirbubbles

Airbubblesabsorbandreectthesoundenergy,andtheymayinworstcasesblockthe

soundtransmissionaltogether.

Theboundarylayerincreasesinthicknesswhenitbecomesturbulent.Theboundary

layeristhinintheforwardpartofthevesselhull,andincreasesasitmovesaft.The

thicknessdependsonshipsspeedandontheroughnessofthehull.Allobjectssticking

outfromthehull,ordentsinthehull,willdisturbtheowandwillincreasethethickness

oftheboundarylayer.Whentheowspeedishigh,theturbulencecanbeviolentenough

todestroytheintegrityofthewater.Smallvoidsorcavitiesinthewaterwilloccurand

thisiscalledcavitation.

Rattlenoise

Rattlenoisemaybecausedbylooseobjectsinthevicinityofthetransducer,likexing

bolts.Therattlemayalsocomefromlooseobjectsinsidethehull.

Interference

Interferencefromotherhydroacousticequipmentonboardthesamevesselmaybean

annoyingsourceofdisturbance.Unlessthesamefrequencyisusedformorethanone

pieceofequipmentonlythetransmittedpulsewillcontributetotheinterference.

Inphysics,interferenceisthephenomenoninwhichtwowavessuperposeeach

othertoformaresultantwaveofgreaterorloweramplitude.Interferenceusually

referstotheinteractionofwavesthatarecorrelatedorcoherentwitheachother,

eitherbecausetheycomefromthesamesourceorbecausetheyhavethesameor

30

443140/A

Loading...

Loading...