SERVICE MANUAL

Color Television Receiver

Model: TK-A/Q Series

SERVICE MANUAL TK-A/Q

CONTENTS

I. IMPORTANT SERVICE SAFETY INFORMATION…………………… 3

II. ALIGNMENT PROCEDURES PLEASE READ BEFORE

ATTEMPTING SERVICE…………………………………………………… 5

III. TV SPECIFICATION……………………………………………………. 6

IV. TV ADJUSTMENT……………………………………………………….. 9

V. IC INFORMATION……………………………………………………….. 13

1. PHILIPS UOCIII CHIP (N603)……………………………………………………….. 13

2. EEPROM 24C16 (N602)……………………………………………………………….. 53

3. SWITCH POWER IC (N901)…………………………………………………………. 57

4. VERTICAL DEFLECTION BOOSTER (N401)…………………………………….. 61

5. AUDIO POWER AMPLIFIER (N202)……………………………………………….. 66

VI. TV BLOCK DIAGRAM………………………………………………….. 74

IMPORTANT SERVICE SAFETY INFORMATION

Operating the receiver outside of its cabinet or with its back removed involves a shock hazard.

Work on these models should only be performed by those who are thoroughly familiar with

2

SERVICE MANUAL TK-A/Q

precautions necessary when working on high voltage equipment.

Exercise care when servicing this chassis with power applied. Many B plus and high voltage

RF terminals are exposed which, if carelessly contacted, can cause serious shock or result in damage

to the chassis. Maintain interconnecting ground lead connections between chassis, escutcheon,

picture tube dag and tuner when operating chassis.

These receivers have a “polarized” AC line cord. The AC plug is designed to fit into standard

AC outlets in one direction only. The wide blade connects to the “ground side” and the narrow blade

connects to the hot “side” of the AC line. This assures that the TV receiver is properly grounded to

the house wiring. If an extension cord must be used, make sure it is of the “polarized” type.

Since the chassis of this receive is connected to one side of the AC supply during operation,

service should not be attempted by anyone not familiar with the precautions necessary when

working on these types of equipment.

When it is necessary to make measurements or tests with AC power applied to the receiver

chassis, an Isolation Transformer must be used as a safety precaution and to prevent possible

damage to transistors. The Isolation Transformer should be connected between the TV line cord

plug and the AC power outlet.

Certain High voltage (HV) maybe cause X-ray radiation. Receivers should not be operated with

HV levels exceeding the specified rating for their chassis type. Higher voltage may also increase the

possibility of failure in the HV supply.

It is important to maintain specified values of all components in the horizontal and high voltage

circuits and anywhere else in the receive that could cause a rise in high voltage, or operating supply

voltages. No changes should be made the original design of the receiver.

Components shown in the shaded areas on the schematic diagram and/or identified by in the

replacement parts list should be replaced only with exact factory recommended replacement parts.

The use of unauthorized substitute parts man creates may create shock, fire, X-ray radiation, or other

hazards.

To determine the presence of high voltage, use an accurate high impedance HV meter

connected between the second anode lead and he CRT dag grounding device. When servicing the

High Voltage System remove static charges from it by connecting a 10K Ohm resistor in series Wan

insulated wire(such as test probe) between the picture tube dag and 2nd anode lead(Have AC line

cord disconnected from AC supply).

3

SERVICE MANUAL TK-A/Q

The picture tube use in this receiver employ integral implosion protection. Replace with a tube

of the same type number for continued safety. Do not lift picture tube by the neck. Handle the

picture tube only when wearing shatterproof goggles and after discharging the high voltage

completely, Keep others without shatter proof goggles away.

Before returning the receiver to the user, perform the following safety checks:

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the receiver.

2. Replace all protective devices such as non-metallic control knobs, insulating fish-papers,

cabinet backs, adjustment and compartment covers of shields, isolation resistor-capacitor networks,

mechanical insulators etc.

3. To be sure that not shock hazard exists, a check for the presence of leakage current should be

made at each exposed metal part having a return path to the chassis (antenna, cabinet metal, screw

heads knobs and/or shafts, escutcheon, etc.) in the following manner.

Plug the AC line cord directly into a 110V/220V/240V AC receptacle. (Do not use an Isolation

Transformer during these checks.) All checks must be repeated with the AC line cord plug

connection reversed. (If necessary, a non-polarized adapter plug must be used only for the purpose

of completing these checks.)

If available, measure the current using an accurate leakage current tester. Any reading of

0.35mA or more is excessive and indicates a potential shock hazard which must be corrected before

returning the receiver to owner.

If a reliable leakage current tester is not available, this alternate method of measurement should

be used. Using two clip leads, connect a 1500 Ohm, 10 watt resistor paralleled by a 0.15MF

capacitor in series with a known earth ground, such as a water pipe or conduit and the metal part to

be checked. Use a VTVM or VOM with 1000 Ohms per Volt, or higher, sensitivity to measure this

AC voltage drop across the resistor,. Any reading of 0.35 volt RMS of more is excessive and

indicates potential shock hazard which must be corrected before returning he receiver to the owner.

ALIGNMENT PROCEDURES

PLEASE READ BEFORE ATTEMPTING SERVICE

1. Use an Isolation Transformer when performing any service on this chassis.

4

SERVICE MANUAL TK-A/Q

2. Never disconnect any leads while receiver is in operation.

3. Disconnect all power before attempting an repairs.

4. Do not short any position of the circuit while the power is on.

5. For safety reasons, replacing any components should be according with identical replacement

parts.

6. Before testing, warm up the TV for at least 30 minutes and demagnetize the CRT with an external

degaussing coil.

7. When removing a PCB or related component, after unfastening or changing a wire, be sure to put

the wire back in its original position.

8. Inferior silicon grease can damage IC’s and transistors. When replacing IC’s and transistors, use

only specified silicon grease,. Remove all old silicon when applying new silicon.

9. Before removing the anode cap, discharge drastically because it contains high voltage.

TV SPECIFICATION

1. Ambient Conditions:

1.1 Ambient Temperatures:

5

SERVICE MANUAL TK-A/Q

a. Operating: -10 ~ +40 ℃

b. Storage: -15 ~ +45 ℃

1.2 Humidity

a. Operation: <80%

b. Storage: <90%

1.3 Air Pressure: 86kpa ~ 106kpa

2. General Specification

2.1 Main IC: Philips UOCIII chip

2.2 System: TV PAL DK/BG/I

SECAM DK/BG/L(L’)

NTSC M

AV PAL

SECAM

NTSC 4.43/3.58

2.3 Channel: VHF-LOW 46.25~140.25MHz

VHF-HIGH 147.25~423.25MHz

UHF 431.25~855.25MHz

CATV 112.25~464.25MHz

2.4 Scanning Lines & Frequencies

525 lines/60Hz or 625 lines/50Hz

15.75KHz/15.625KHz

2.5 Color Sub-Carrier Frequency: 4.433MHz/3.579MHz

2.6 IF: Picture 38.9MHz/38.0MHz/45.75MHz

Sound 4.5MHz/5.5MHz/6.0MHz/6.5MHz

2.7 Power Consumption: 14” and 15” TV 70W

21” TV 75W

29” TV 150W

6

SERVICE MANUAL TK-A/Q

34” TV 180W

2.7 Power Supply:

AC 110/220/240V 50/60 Hz

2.8 Max Audio Output Power (7% THD): 14” and 15” ≥1W X 2

21” ≥1.5W X 2

29” and 34” ≥4W X 2

2.9 Antenna Impedance: 75Ω

3. Basic Features of Controller

3.1 Channel Tuning Method: Frequency Synthesizer

3.2 Preset table Program: 240 Programs or 100 Programs

3.3 Tuning for VHF and UHF Bands: Auto Tuning/Manual Tuning

3.4 Picture and Sound Adjustment:

Bright, Contrast, Color, Sharpness control and Color Temperature adjustment

TINT control (NTSC only)

Volume, Balance, Bass, Treble control

3.5 OSD:

General Features (Volume, Balance, Bass, Treble, Brightness, Contrast, Color, Sharpness,

Program, Auto Search, Manual Tune, Muting, AV/TV, Child Lock and Sleep Timer)

Multi-Language (including English)

3.6 Sleep Timer: 5 -120 Minutes with 5 Minutes Increment

3.7 Auto Standby When No Signal in 5 minutes

3.8 Full Function Infrared Remote Control

8m

3.9 Remote Effective Distance:

4. Construction of Front Panel

Main Power Switch

Remote Sensor

Standby Indicator

Menu Select Button

TV/AV Select Button

Program and Volume Up/Down Button

7

SERVICE MANUAL TK-A/Q

5. TV’s Terminals

75 Ω Aerial Terminal

AV Input and AV Output (TK-A Series)

S-Video Input

Y/U/V Input

SCART Input and Output (TK-Q Series)

6. Other Informations

6.1 Magnetic Field:

Bv = 0.3~0.65Gs

6.2 Standard Color Temperature: 9300K (X = 0.284, Y = 0.299)

TV ADJUSTMENT

Test equipment

8

SERVICE MANUAL TK-A/Q

1. Oscilloscope

2. Multifunction meter (Internal resistance: DC≥20kΩ/V AC≥5kΩ/V)

3. High voltmeter: 35kV

4. Standard Signal Generator

5. Degaussing coil

Factory menu

Some adjustments must be performed in the Factory menu. You can enter the Factory menu in

the following way:

1. Press the MENU button on the remote control then press the Q.VIEW button on the remote

control at least 5 times immediately.

2. Press the MENU buttons to select the desired Factory menu pages or press 0-9 number buttons to

enter the Factory menu pages directly and then press the PROG.+/- buttons to select the desired

items.

3. Press the VOL+/- buttons to change the settings.

B+ adjustment

Test Equipment: Multifunction meter

1. Operate the TV set with AC 110/220/240V(50/60Hz).

2. Receive Television broadcast signal, set PICTURE to Normal mode.

2. Connect the multifunction meter + lead to C960 and GND. Adjust the RP950 until the meter

reading the proper DC value (More details please refer to the TV’s BOM ).

High voltage check and filament voltage check

Test Equipment: High voltmeter

1. Make sure AC power supply and +B are within pointed range before calibrating high voltage.

2. Connect high voltmeter to anode (G4) of CRT and GND.

3. Turn on the TV, set the BRIGHTNESS and CONTRAST to the minimum (zero beam current),

swap to AV mode (No any signal applied).

9

SERVICE MANUAL TK-A/Q

4. High voltage please refer to different CRT

5. Filament voltage measured by virtual value meter please see the related model BOM, usually

within the range of 6.3±0.2Vrms.

Grid voltage adjustment

1. Enter into Factory menu, set VG2, VSD, then adjust potentiometer to IN/OUT flash on the screen.

VG2 XX Please see the related model’s BOM

VSD Brightness XX Please see the related model’s BOM

VSD XX Please see the related model’s BOM

2. Receive PHILIPS five circles pattern after settings finishing, set PICTURE to Normal mode.

RF AGC adjustment

1. Receive a 60dBμV gray scale signal(PAL or SECAM).

2. Enter Factory menu and select AGC TAKE OVER, then adjust it until the picture noise is just

disappeared.

Focus adjustment

1. Receive five circles pattern, adjust the pattern to Normal mode.

2. Adjust focus potentiometer (horizontal output transformer) so that the center and four corners of

pattern are the best focus.

Horizontal scanning, vertical scanning and geometry correction adjustment

(adjust with PAL and NTSC signal separately)

1. Enter into factory menu to call up FAC1

EW WIDTH 50(60) XX Adjust it so that the picture horizontal reproduction display

ratio is more than 92% (H- size adjustment).

HOR.SHIFT 50(60) XX Adjust it so that the left half is symmetrical with the right

half (H. CEN correction).

10

SERVICE MANUAL TK-A/Q

EW PARABOLA 50(60) XX Adjust it so that parallelogram will be transformed to

rectangle or trapezium (Receive cross hatch signal)(Parallelogram correction).

TRAPEZIUM

(Receive cross hatch signal)(Trapezium).

UC PARABOLA 50(60) XX Adjust it so that upper corner (left and right) vertical line are

straight line (Receive cross hatch signal)(Upper corner pincushion).

LC PARABOLA 50(60) XX Adjust it so that bottom corner (left and right) vertical line

are straight line (Receive cross hatch signal)(Bottom correction pincushion).

HOR.BOW 50(60) XX Adjust it so that vertical line is the straight line.(Receive

cross hatch signal) (Bow correction).

PARALLEL 50(60) XX Adjust it so that left and right line are straight lines

(Pincushion correction).

2. Receive five circles pattern signal, enter into factory menu to call up FAC2.

VERT SLOPE 50(60) XX Adjust it so that horizontal midline of the pattern superpose

with the black edge of the pattern.

50(60) XX Adjust it so that trapezium distortion is just disappeared

VERT SHIFT 50(60) XX Adjust it so that the pattern midline superposes over CRT

geometric center.

VERT AMPLE 50(60) XX Adjust it so that the picture vertical reproduction display ratio

is more than 92%.

S CORR 50(60) XX Adjust it so that upper pane and bottom pan of the pattern are

the same as the middle pane.

V.LIN.CTRL 50(60) 0

V.LINEARITY 50(60) XX Adjust vertical linear.

VERT ZOOM 50(60) 25 Adjust vertical amplitude(fixed value 25).

White balance adjustment (PAL or SECAM signal)

1. Enter into menu firstly and set PICTURE to Normal mode. (9300K)

11

SERVICE MANUAL TK-A/Q

2. Enter into AV mode and receive left black right white signal which with color sync signal.

3. Plug XS805, adjust it automatically with white balance adjustment software, enter into factory

menu when adjustment is OK, then enter into FAC 6、FAC 7、FAC 8 menu to check the following

data are consistent with data in computer.

Standard: Color temperature 9300K (X=0.284 Y=0.299) FAC 6

Warm color: Color temperature 6500K (X=0.313 Y=0.329) FAC 7

Cold color: Color temperature 12000K(X=0.272 Y=0.279) FAC 8

FAC 6

ADJ content

X=0.284

Y=0.299

BLOR-N xx BLOR-W xx BLOR-C xx

BLOG-N xx BLOG-W xx BLOG-C xx

WPR-N xx WPR-W xx WPR-C xx

WPR-N xx WPG-W xx WPG-C xx

WPR-N xx WPB-W xx WPB-C xx

value

FAC 7

ADJ Content

X=0.313

Y=0.329

value

FAC 8

ADJ Content

X=0.272

Y=0.279

value

Other factory menu data

Each TV model has different factory menu, more details please refer to the TV’s adjustment

Engineering Illumination.

IC INFORMATION

1. PHILIPS UOCIII CHIP – TDA110XXH1/TDA120XXH1 (N603)

12

SERVICE MANUAL TK-A/Q

1.1 General description

The UOCIII series combines the functions of a Video Signal Processor (VSP) together with a

FLASH embedded TEXT/Control/Graphics µ-Controller (TCG µ-Controller) and US Closed

Caption decoder. In addition the following functions can be added:

Adaptive digital (4H/2H) PAL/NTSC comb filter

•

• Teletext decoder with 10 or 100 page text memory

Multi-standard stereo decoder

•

• BTSC stereo decoder

Digital sound processing circuit

•

• Digital video processing circuit

The UOCIII series consists of the following 3 basic concepts:

• Stereo versions. These versions contain the TV processor with a stereo audio selector, the TCG

µ-Controller, the multi-standard stereo or BTSC decoder, the digital sound processing circuit and

the digital video processing circuit. Options are the adaptive digital PAL/NTSC comb filter and a

teletext decoder with 10 or 100 page text memory.

• AV stereo versions. These versions contain the TV processor with stereo audio selector and the

TCG µ-Controller. Options are the digital sound processing circuit, the digital video processing

circuit, the adaptive digital PAL/NTSC comb filter and a teletext decoder with a 10 page text

memory.

• Mono sound versions. These versions contain the TV processor with a selector for mono audio

signals and the TCG µ-Controller. Options are the adaptive digital PAL/NTSC combfilter and a

teletext decoder with 10 page text memory.

The ICs are mounted in a QFP-128 package and can be used in economy television receivers

with 90 and 110 picture tubes. The package is according to the ROHS legislation, which also

means that the package is lead-free. The ICs have supply voltages of 5V, 3.3V. Also an 1.8V supply

is needed, but this can be simply derived by adding an emitter follower at a reference voltage from

the device.

1.2 Features

1.2.1 Analogue Video Processing (all versions)

13

SERVICE MANUAL TK-A/Q

* Multi-standard vision IF circuit with alignment-free PLL demodulator

* Internal (switchable) time-constant for the IF-AGC circuit

* Switchable group delay correction and sound trap (with switchable centre frequency) for the

demodulated CVBS signal

* DVB/VSB IF circuit for preprocessing of digital TV signals.

* Video switch with 3 external CVBS inputs and a CVBS output. All CVBS inputs can be used as

Y-input for Y/C signals. However, only 2 Y/C sources can be selected because the circuit has 2

chroma inputs. It is possible to add an additional CVBS(Y)/C input (CVBS/YX and CX) when the

YUV interface and the RGB/YPBPR input are not needed. It is also possible to insert a CVBS/Y

signal at the SVO/IFVOUT output.

* Automatic Y/C signal detector

* Integrated luminance delay line with adjustable delay time

* Picture improvement features with peaking (with switchable centre frequency, depeaking, variable

positive/negative peak ratio, variable pre-/overshoot ratio and video dependent coring), dynamic

skin tone control, gamma control and blue- and black stretching. All features are available for CVBS,

Y/C and RGB/YPBPR signals.

* The effect of the various features can de demonstrated by means of a ‘split screen’ mode in which

the features are activated in one half of the picture and switched off in the other half

* Switchable DC transfer ratio for the luminance signal

* Only one reference (24.576 MHz) crystal required for the TCG µ-Controller, and the colour

decoder

* Multi-standard colour decoder with automatic search system and various “forced mode”

possibilities

* Internal base-band delay line

* Indication of the Signal-to-Noise ratio of the incoming CVBS signal

* Linear RGB/YPBPR input with fast insertion.

* YUV interface. When this feature is not required some pins can be used as additional

RGB/YPBPR input. It is also possible to use these pins for additional CVBS (or Y/C) input

(CVBS/YX and CX).

* Tint control for external RGB/YPBPR signals

* Scan Velocity Modulation output. The SVM circuit is active for all the incoming CVBS, Y/C and

14

SERVICE MANUAL TK-A/Q

RGB/YPBPR signals.

* RGB control circuit with ‘Continuous Cathode Calibration’, white point and black level off-set

adjustment so that the colour temperature of the dark and the light parts of the screen can be chosen

independently.

* Contrast reduction possibility during mixed-mode of OSD

* Adjustable ‘wide blanking’ of the RGB outputs

* Horizontal synchronization with two control loops and alignment-free horizontal oscillator

* Vertical count-down circuit

* Vertical driver optimized for DC-coupled vertical output stages

* Horizontal and vertical geometry processing with horizontal parallelogram and bow correction and

horizontal and vertical zoom

* Low-power start-up of the horizontal drive circuit

1.2.2 Analogue Sound Processing

1.2.2.1 Mono versions

* The low-pass filtered ‘mixed down’ I signal is available via a single ended output stage

1.2.2.2 Stereo versions

* The low-pass filtered ‘mixed down’ I signal is available via a single ended or balanced output

stage.

1.2.3 Sound Demodulation (all versions)

* Separate SIF (Sound IF) input for single reference QSS (Quasi Split Sound) demodulation.

* AM demodulator without extra reference circuit

* The mono intercarrier sound circuit has a selective FM-PLL demodulator which can be switched

to the different FM sound frequencies (4.5/5.5/6.0/6.5 MHz). The quality of this system is such that

the external band-pass filters can be omitted.

* The FM-PLL demodulator can be set to centre frequencies of 4.72/5.74 MHz so that a second

sound channel can be demodulated. In such an application it is necessary that an external bandpass

filter is inserted.

* The vision IF and mono intercarrier sound circuit can be used for the demodulation of FM radio

signals. With an external FM tuner also signals with an IF frequency of 10.7 MHz can be

15

demodulated.

SERVICE MANUAL TK-A/Q

* Switch to select between 2nd SIF from QSS demodulation or external FM (SSIF).

1.2.4 Audio Interfaces and Switching

1.2.4.1 Mono versions

* Audio switch circuit with 4 external audio (mono) inputs and a volume controlled output

* AVL circuit

1.2.4.2 AV stereo versions without audio DSP

* Audio switch circuit with 4 stereo inputs, a stereo output for SCART/CINCH and a stereo

SPEAKER output with independent L&R analogue volume control.

* Analogue mono AVL circuit at left audio channel

1.2.4.3 Stereo versions with audio DSP

* Audio switch circuit with 4 stereo inputs, a stereo output for SCART/CINCH, 1 stereo output for

HEADPHONE. The headphone channel has an analogue volume control circuit for the L and R

channel. Finally 1 stereo SPEAKER output with digital controls.

* AVL (Automatic Volume Levelling) circuit for the headphone channel.

* Digital input crossbar switch for all digital signal sources and destinations

* Digital output crossbar for exchange of channel processing functionality

* Digital audio input interface (stereo I2S input interface)

* Digital audio output interface (stereo I2S output interface)

1.2.5 Stereo Demodulator and Decoder (full stereo versions)

* Demodulator and Decoder Easy Programming (DDEP)

* Auto standard detection (ASD)

* Static Standard Selection (SSS)

* DQPSK demodulation for different standards, simultaneously with 1-channel FM demodulation

* NICAM decoding (B/G, I, D/K and L standard)

* Two-carrier multistandard FM demodulation (B/G, D/K and M standard)

* Decoding for three analog multi-channel systems (A2, A2+ and A2*) and satellite sound

* Adaptive de-emphasis for satellite FM

16

SERVICE MANUAL TK-A/Q

* Optional AM demodulation for system L, simultaneously with NICAM

* Identification A2 systems (B/G, D/K and M standard) with different identification time constants

* FM pilot carrier present detector

* Monitor selection for FM/AM DC values and signals, with peak and quasi peak detection option

* BTSC MPX decoder

* SAP decoder

* digital dbx® noise reduction 3 4

* Japan (EIAJ) decoder

* FM radio decoder

* Soft-mute for DEMDEC outputs DEC, MONO and SAP

* FM overmodulation adaptation option to avoid clipping and distortion

1.2.6 Audio Multi Channel Decoder (versions with audio DSP)

* Dolby® Pro Logic® (DPL) 5 4

* Virtual Dolby® Surround (VDS) 6

* Five channel processing for Main Left and Right, Subwoofer, Centre and Surround. To exploit this

feature an external DAC is required.

1.2.7 Volume and tone control for loudspeakers (versions with Audio DSP)

* Automatic Volume Level (AVL) control

* Smooth volume control

* Master volume control

* Soft-mute

* Loudness

* Bass, Treble

* Five band graphic equalizer

* Dynamic Bass Boost (DBB) 7

* Dynamic Virtual Bass (DVB) 8

* BBE® Sound processing 3 4

* Processed or non processed subwoofer output

* Programmable beeper

17

SERVICE MANUAL TK-A/Q

1.2.8 µ-Controller

* 80C51 µ-Controller core standard instruction set and timing

* 0.4883 µs machine cycle

* maximum of 256k x 8-bit flash programmable ROM

* maximum of 8k x 8-bit Auxiliary RAM

* 12-level Interrupt controller for individual enable/disable with two level priority

* Two 16-bit Timer/Counter registers

* One 24-bit Timer (16-bit timer with 8-bit Pre-scaler)

* Watch Dog timer

* Auxiliary RAM page pointer

* 16-bit Data pointer

* Stand-by, Idle and Power Down modes

* 24 general-purpose I/O pins

* 14 bits PWM for Voltage Synthesis Tuning

* 8-bit A/D converter with 4 multiplexed inputs

* 5 PWM (6-bits) outputs for analogue control functions

* I2C byte level bus interface.

* Remote Control Pre-processor (RCP)

* Universal Asynchronous Receiver Transmitter (UART)

1.2.9 Data Capture

* Text memory max up to 100 pages

* Inventory of transmitted Teletext pages stored in the Transmitted Page Table (TPT) and Subtitle

Page Table (SPT)

* Data Capture for US Closed Caption

* Data Capture for 525/625 line WST, VPS (PDC system A) and 625 line Wide Screen Signalling

(WSS) bit decoding

* Automatic selection between 525 WST/625 WST

* Automatic selection between 625 WST/VPS on line 16 of VBI

* Real-time capture and decoding for WST Teletext in Hardware, to enable optimized m-processor

throughput

18

SERVICE MANUAL TK-A/Q

* Automatic detection of FASTEXT transmission

* Real-time packet 26 engine in Hardware for processing accented, G2 and G3 characters

* Signal quality detector for video and WST/VPS data types

* Comprehensive teletext language coverage

* Vertical Blanking Interval (VBI) data capture of WST data

1.2.10 Display

* 50Hz/60Hz display timing modes

* Two page operation for 16:9 screens

* Serial and Parallel Display Attributes

* Single/Double/Quadruple Width and Height for characters

* Smoothing capability of both Double Size, Double Width & Double Height characters

* Scrolling of display region

* Variable flash rate controlled by software

* Soft colours using CLUT with 4096 colour palette

* Globally selectable scan lines per row (9/10/13/16/) and character matrix [12x9, 12x13, 12x16,

16x18, (VxH)]

* Fringing (Shadow) selectable from N-S-E-W direction

* Fringe colour selectable

* Contrast reduction of defined area

* Cursor

* Special Graphics Characters with two planes, allowing four colours per character

* 64 software redefinable On-Screen display characters

* 4 WST Character sets (G0/G2) in single device (e.g. Latin, Cyrillic, Greek, Arabic)

* G1 Mosaic graphics, Limited G3 Line drawing characters

* WST Character sets and Closed Caption Character set in single device

* Curtaining effect via software

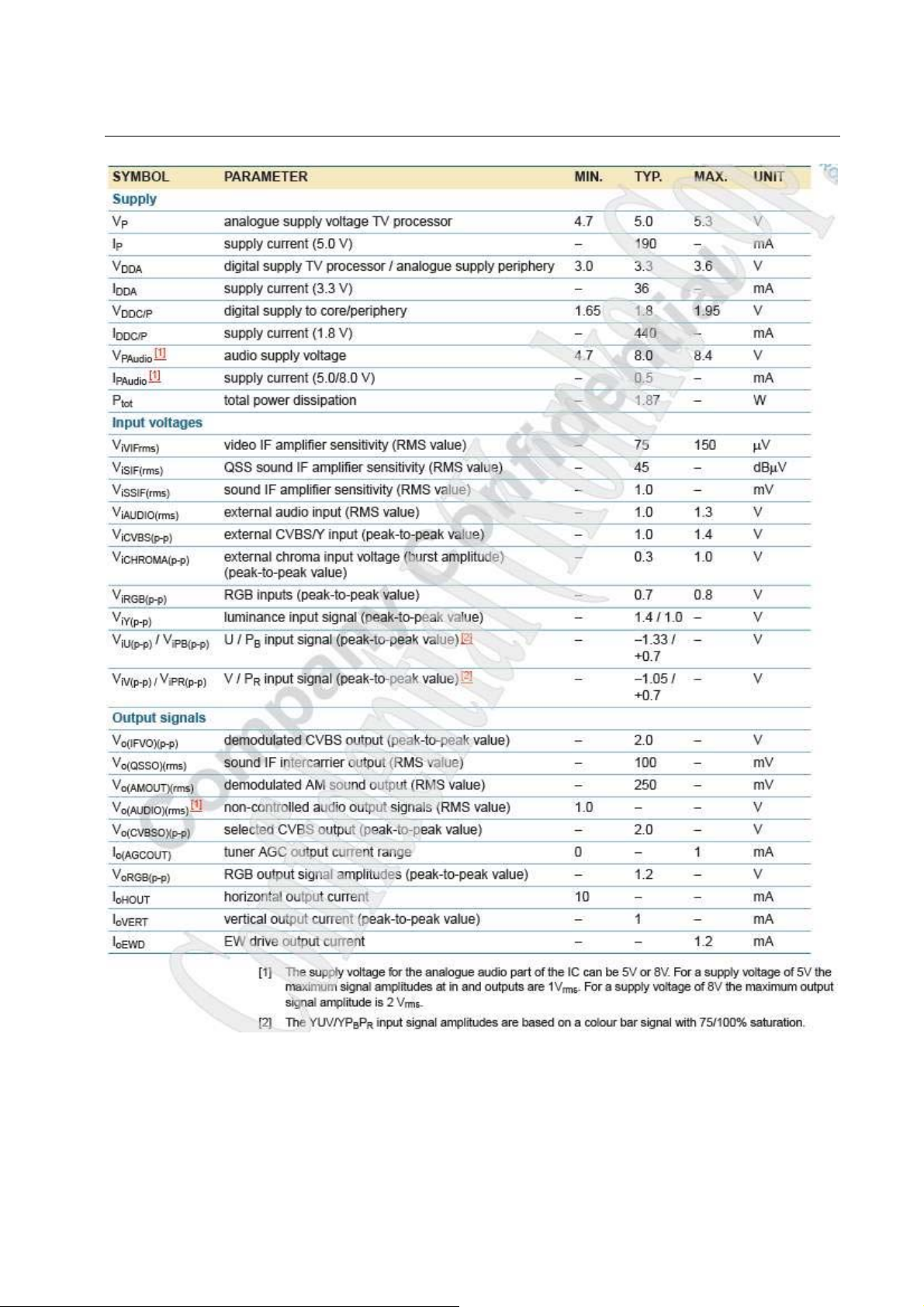

1.3 Quick reference data

19

SERVICE MANUAL TK-A/Q

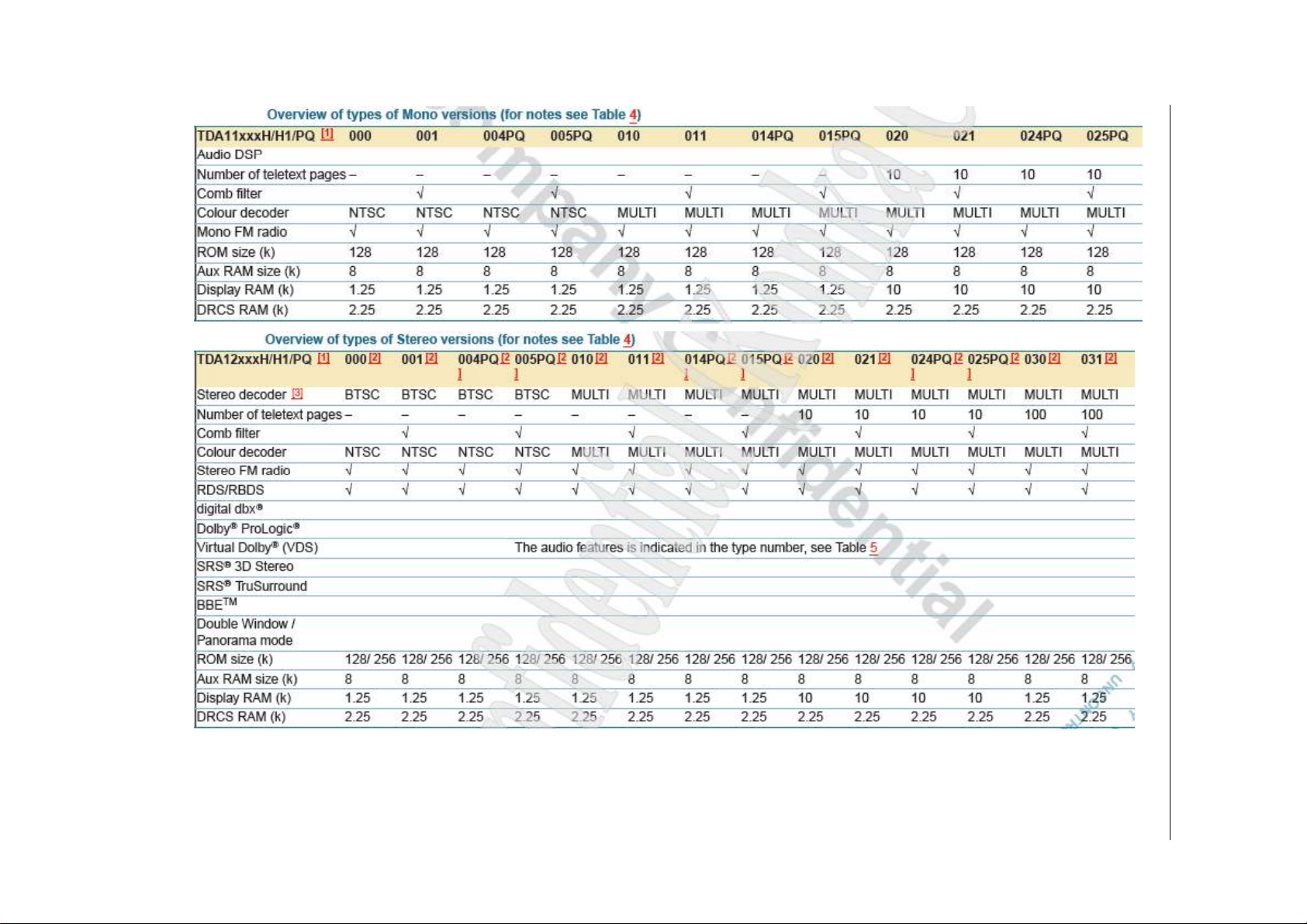

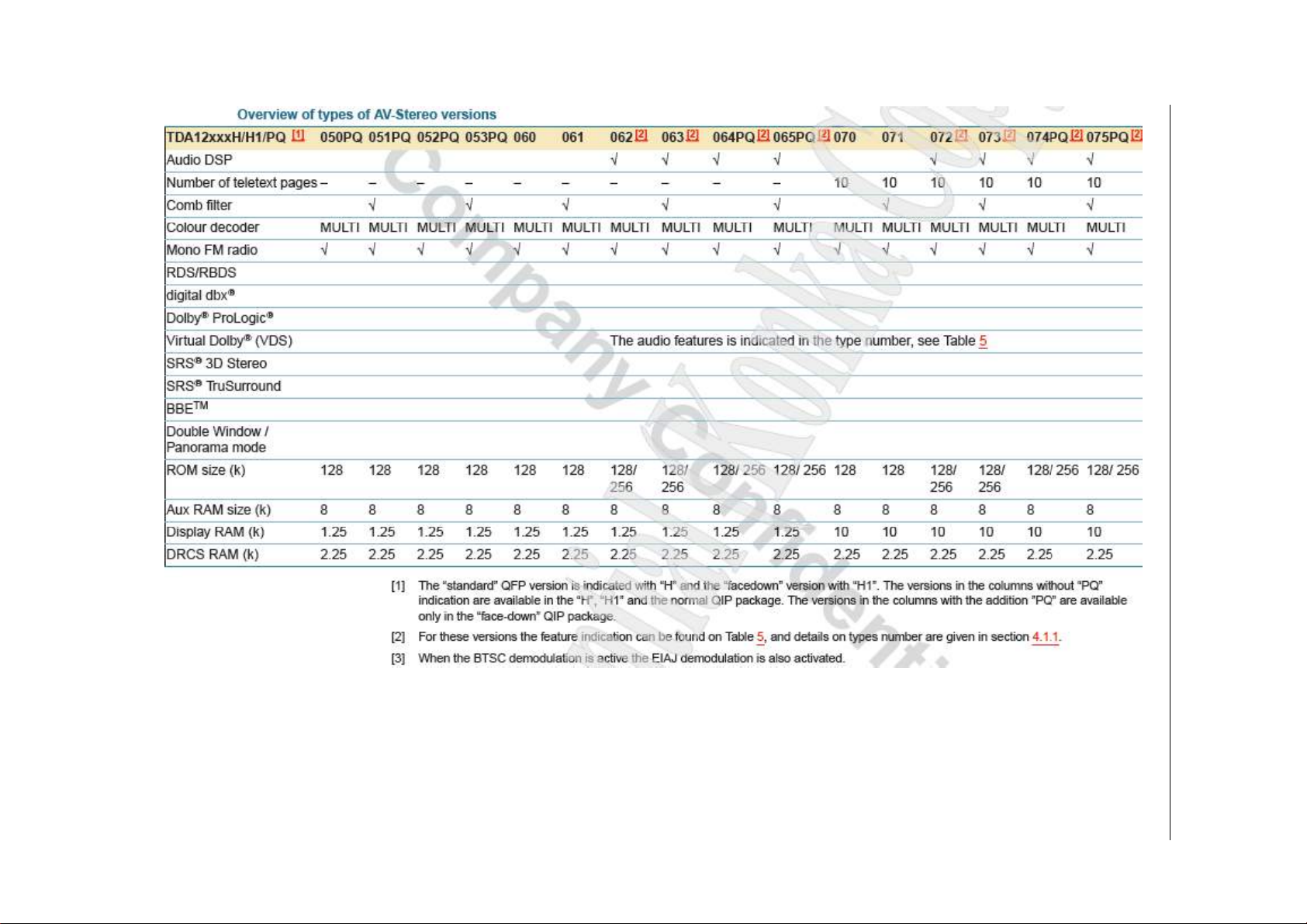

1.4 Ordering Options

20

21

SERVICE MANUAL TK-A/Q

22

SERVICE MANUAL TK-A/Q

23

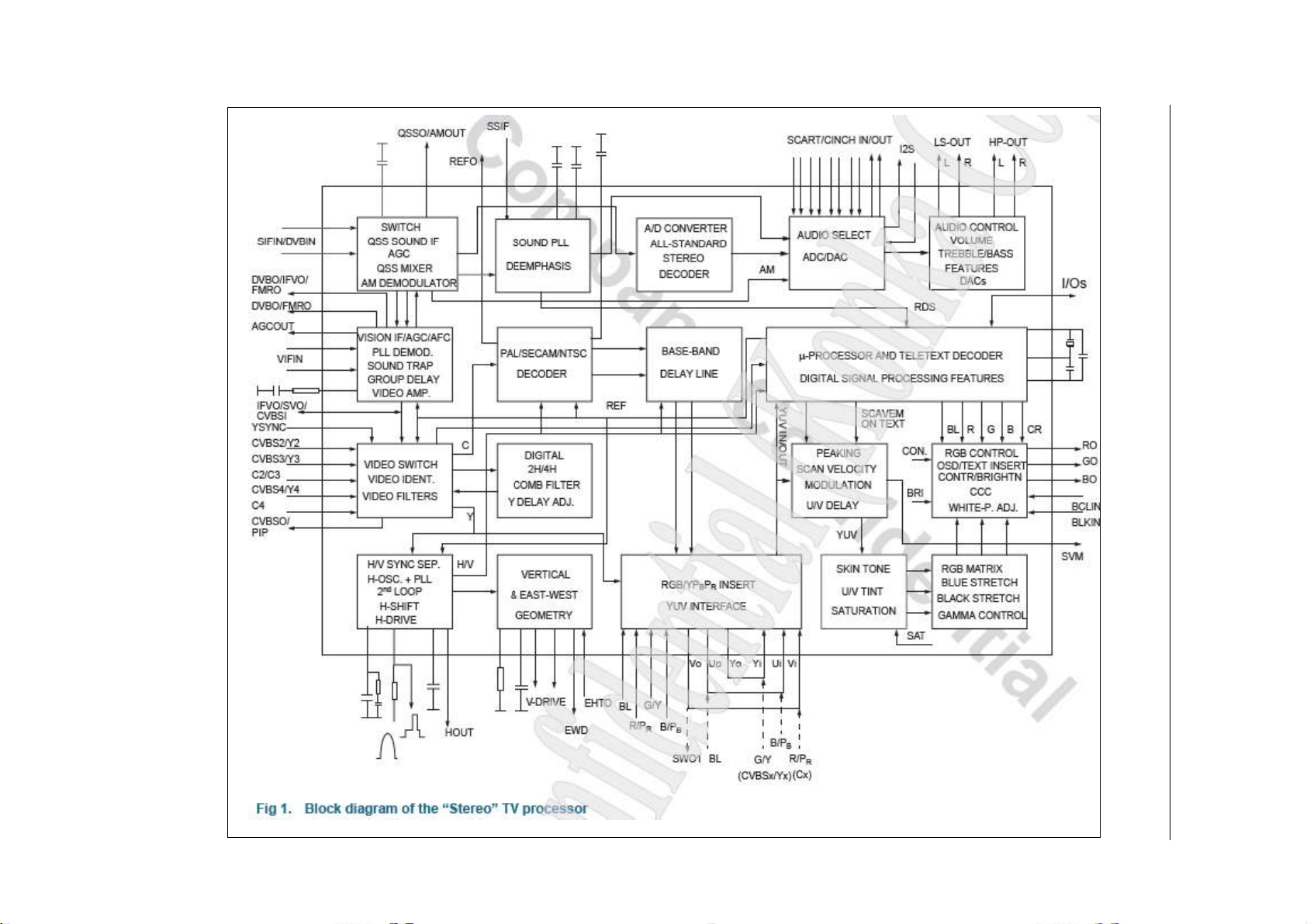

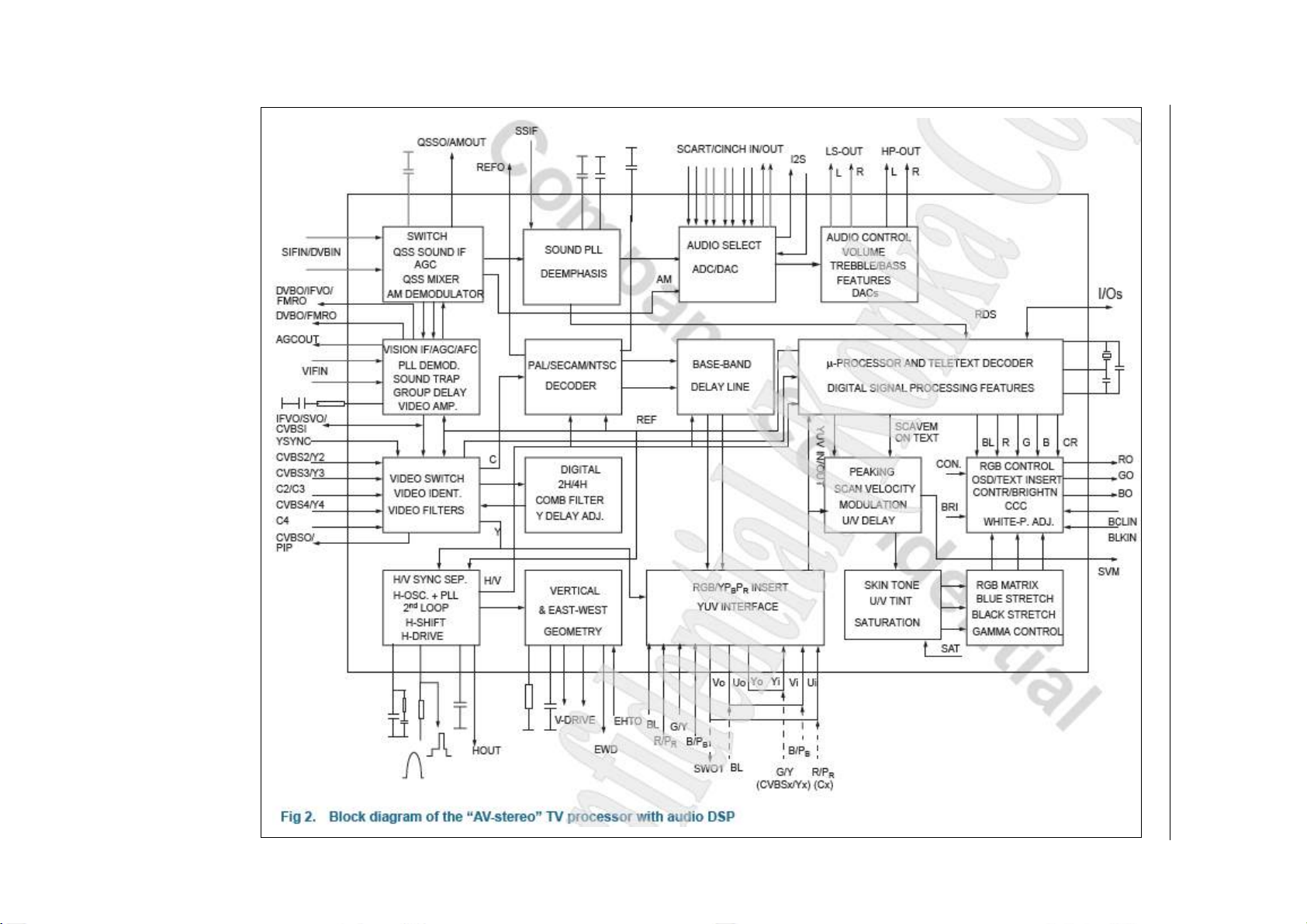

1.5 Block diagram

SERVICE MANUAL TK-A/Q

24

SERVICE MANUAL TK-A/Q

Loading...

Loading...