KONKA KLC-2611QS Schematic

LCD TV SERVICE MANUAL

Model list

KLC-2611QS

KLC-2621QS

KLC-3211QS

KLC-3221QS

KLC-2718QS

KONKA GROUP CO,LTD.

Digital Flat Display Division

IMPORTANT SERVICE SAFETY INFORMATION

Operating the receiver outside of its cabinet or with its back removed involves a shock hazard.

Those who are thoroughly familiar with precautions necessary when working on high voltage

equipment should only perform work on these models.

Exercise care when servicing this chassis with power applied. if carelessly contacted, can cause

serious shock or result in damage to the chassis. Maintain interconnecting ground lead connections

between chassis, escutcheon, picture tube dag and tuner when operating chassis.

When it is necessary to make measurements or tests with AC power applied to the receiver

chassis, an Isolation Transformer must be used as a safety precaution and to prevent possible damage

to transistors. The Isolation Transformer should be connected between the TV line cord plug and the

AC power outlet.

It is important to maintain specified values of all components and anywhere else in the received

that could cause a rise in operating supply voltages. No changes should be made to the original design

of the receiver.

Components shown in the shaded areas on the schematic diagram and/or identified by in the

replacement parts list should be replaced only with exact factory recommended replacement parts. The

use of unauthorized substitute parts man creates may create shock, fire, or other hazards.

Before returning the receiver to the user, perform the following safety checks:

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not lodged

between the chassis and other metal parts in the receiver.

2. Replace all protective devices such as non-metallic control knobs, insulating fish papers, cabinet

backs, adjustment and compartment covers of shields, isolation resistor-capacitor networks,

mechanical insulators etc.

3. To be sure that not shock hazard exists, a check for the presence of leakage current should be made

at each exposed metal part having a return path to the chassis (antenna, cabinet metal, screw heads

knobs and/or shafts, escutcheon, etc.) in the following manner.

Plug the AC line cord directly into a 220V/240V, AC receptacle. (Do not use an Isolation

Transformer during these checks.) All checks must be repeated with the AC line cord plug connection

reversed. (If necessary, a non-polari zed adapter plug must be used only for the purpose of completing

these checks.)

PLEASE READ BEFORE ATTEMPTING SERVICE

1. Use an Isolation Transformer when performing any service on this chassis.

2. Never disconnect any leads while receiver is in operation.

3. Disconnect all power before attempting any repairs.

4. Do not short any position of the circuit while the power is on.

5. For safety reasons, replace components any with identical replacement parts (SEE PARTS LIST).

6. Before alignment, warm up the TV for at least 30 minutes.

7. When removing a PCB or related component, after unfastening or changing a wire, be sure to put

the wire back in its original position.

8. Inferior silicon grease can damage IC's and transistors. When replacing IC's and transistor s, use

only specified silicon grease. Remove all old silicon when applying new silicon.

9. Before removing the anode cap, discharge electricity because it contains high voltage.

A. SPECIFICATION

Color System : PAL、SECAM

Sound System : I、D/K、B/G、L/L’

Frequency range: 45M~855.25M

IF Frenquency Video: 38.9MHz

Sound: 33.4MHz

Chroma: 34.47MHz

Audio output power 10%THD 4W X 2

Antenna Impedance 75Ω(Unbalance)

Power Consumption 160W(26’’ and 27’’) , 180W(32’’)

Power Supply : AC~110-240V,50/60Hz

item

1

3

4

5

6

7

8

9

RF Cable

Scart RGB & Composite

Scart Y/C & Composite

Y(CVBS)、Cb/Pb、Cr/Pr

VGA

DVI

Headphone audio output

AC Input

Port list

ADJUSTMENT MANUAL

Ⅰ. TEST NOTE

1

Please follow the pointed test steps and choose the right test equipment to

.

conduct adjustment, otherwise good effect of Unit could not be obtained. The

unit should be warmed up for 30 minutes before adjustment and every

parameter should be adjusted repeatedly till the optimum value obtained, the

pointed voltage value should be ensured during test to get satisfied test result.

2. Test environment

1) Temperature : 15°C-35°C

2) Relative Humidity: 45-75%

3) Air pressure: 86-106Kpa

3 Test equipments(The following equipment should be calibrated before testing)

1) Computer 1 set

2) Multi-meter (VICTOR VC9801) 1 set

3) Video Signal Generator (Chroma Model 2227/2327) 1 set

4) Color Analyzer (Chroma Model 7120 ) 1 set

5) DDC card (DYNACOLOR, INC D8330) 1 slice

6) TV Video Signal Generator (FLUKE PM54200) 1 set

4 Factory mode adjustment

4.1 Enter factory mode adjustment

Using the remote control, press Menu button once first , then press

RECALL (or named PRE.CH) button five times, and you can see manufacture

menu on the LCD panel.

4.2 factory menu operation method

Press the channel +/- button to selection the sub menu of factory menu

(including F、E、UOCⅢ、Temp), and press the vol+ to enter the sub menu and

setting the value.

4.3 exit the factory menu

Press the MUTE button again and again or turn off the TV, it can exit the

factory menu.

4.4 AGC adjustment

In TV mode,Receive 60dB split field signal. Enter factory mode menu

“UOCⅢ” item,press”CHAN▽” to select “AGC” ,then use VOL+/- to adjust

the item until the voltage of Pin 1 of N100 to be about 2.5V±0.2V,or the noise in

the picture disappears.

4.5 White calibration adjustment

1 Receive black or white signal under AV or PC mode, adjusting brightness

and contrast to set the brightness to 15Nit in dark area and 90 Nit in bright area.

2 Adjust white balance. Press“MENU”button once, then press “RECALL”

five times to enter factory menu, select “Temp” Menu,

Adjust Red 0-100

Green 0-100

Blue 0-100

3 Adjusting chromaticity coordinates of black and white to fit the requirement

(X=0.283,Y=0.297), or plug automatic calibration system to adjust white

calibration automatically.

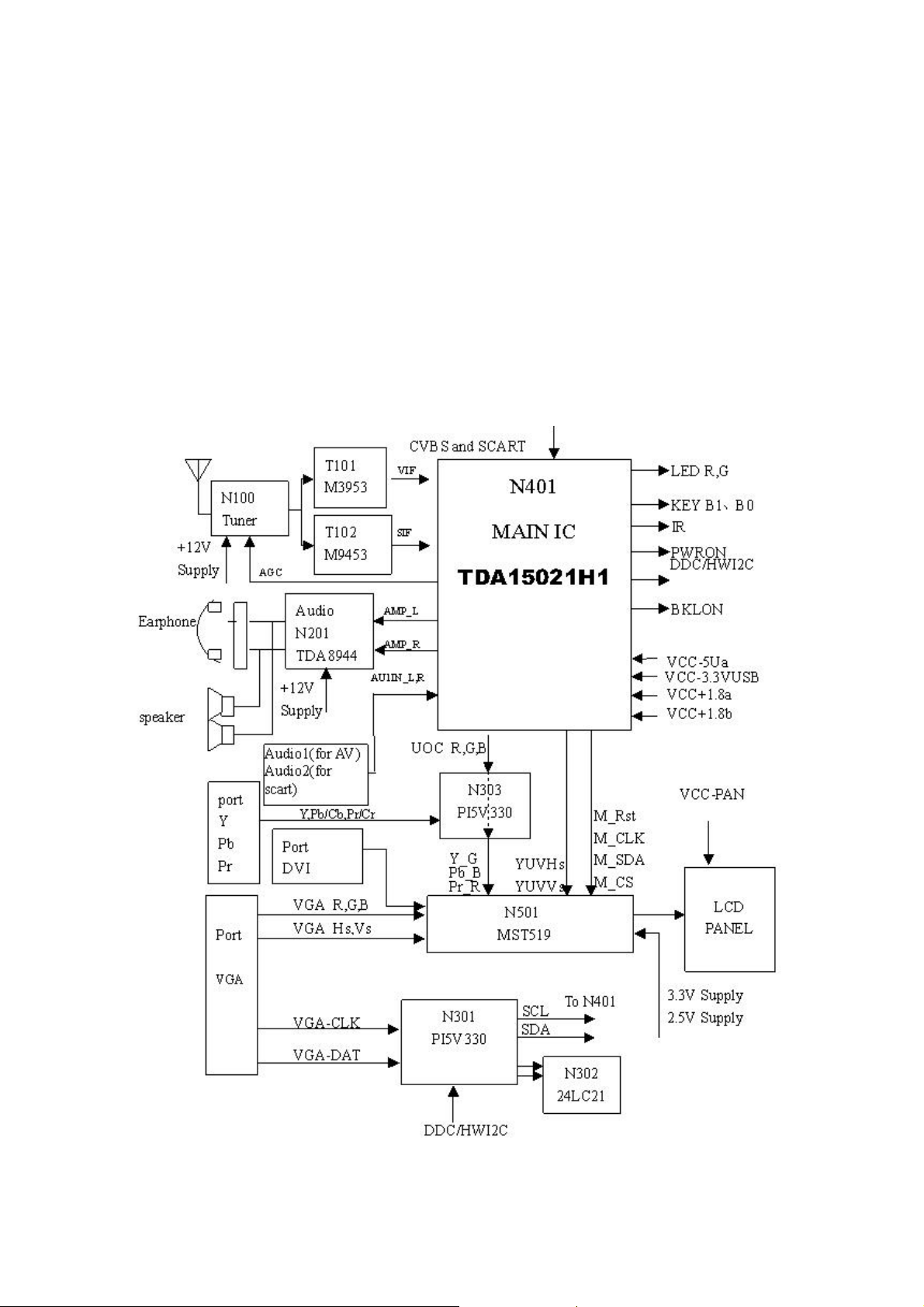

BLOCK DIAGRAM

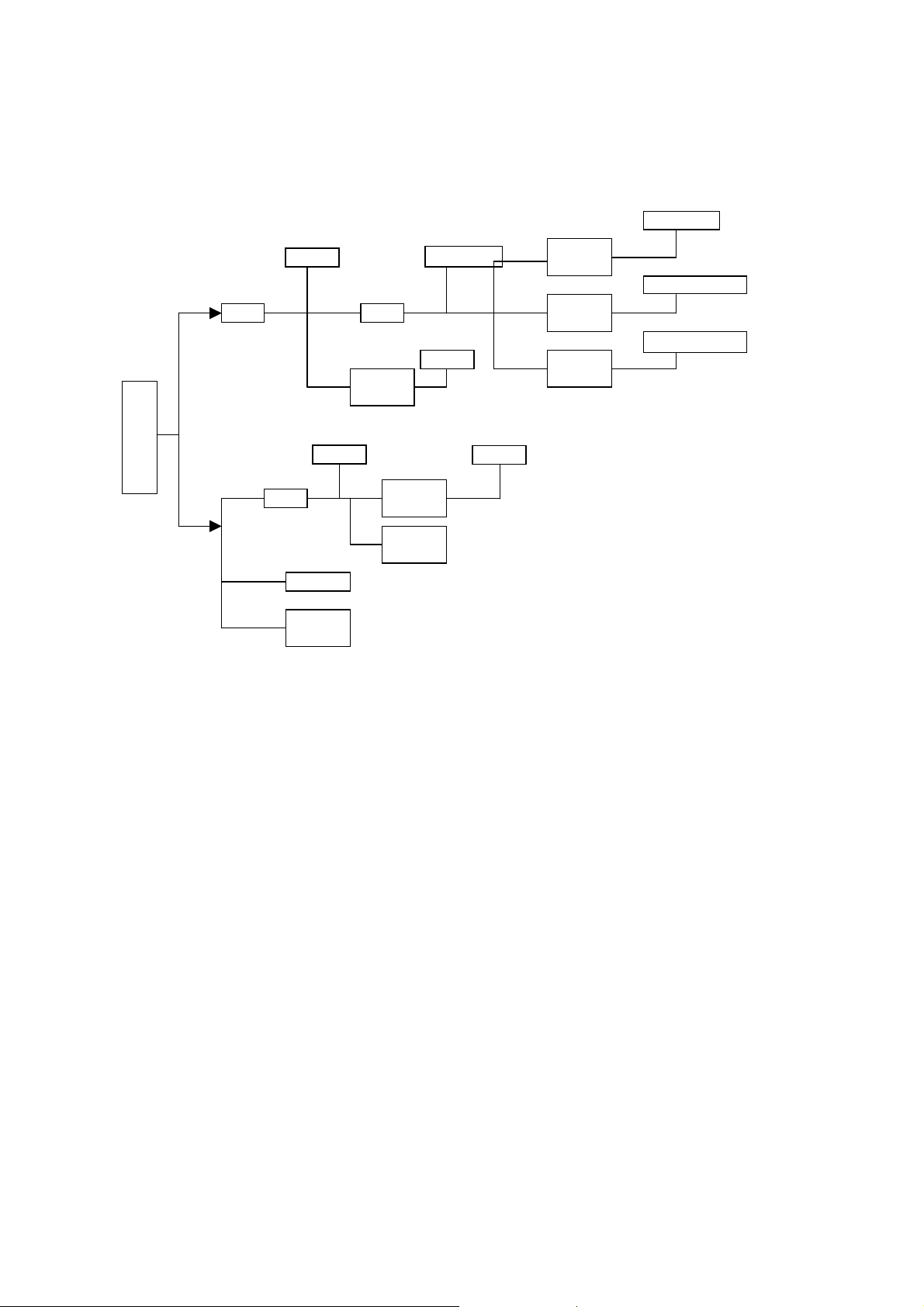

Signal Board Power Diagram

5V

F802

Vcc_5v

For

L809

XS

804

12V

Vcc 12

F801

N803

9435A

N860

9435A

N200

TDA151

INVERT

N201

TDA894

Vcc_USB

Vcc 5v

FOR

N401

Vcc 12

N804

1117-3.3

N805

1117-2.5

N806

1117-3.3

FOR Panel

VCC-3.3

FOR

N501

VCC-CORE

FOR

N501

VCC-3.3USB

FOR

N401

Loading...

Loading...