SERVICE MANUAL

Color Television Receiver

Model: KS21TK305A

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

CONTENTS

I. IMPORTANT SERVICE SAFETY INFORMATION… ……3

II. ALIGNMENT PROCEDURES PLEASE READ BEFORE ATTEMPTING

SERVICE… 5

III. TV SPECIFICATION…………… …………… …… ……...5

IV. TV ADJUSTMENT 7

V. IC INFORMATION………………… ……………………… … ....12

1. PHILIPS UOCIII CHIP (N603) 12

2. SWITCH POWER IC (N901) 41

3. VERTICAL DEFLECTION BOOSTER (N401) 45

4. AUDIO POWER AMPLIFIER (N202) 49

5. EEPROM 24C16 (N602) 52

VI. TV BLOCK DIAGRAM 57

Appendix 1: Schematic Circuit Diagram 58

Appendix 2: PCB Layout Diagram 59

Appendix 3: Exploded Views 63

2

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

IMPORTANT SERVICE SAFETY INFORMATION

Operating the receiver outside of its cabinet or with its back removed involves a shock hazard.

Work on these models should only be performed by those who are thoroughly familiar with

precautions necessary when working on high voltage equipment.

Exercise care when servicing this chassis with power applied. Many B plus and high voltage

RF terminals are exposed which, if carelessly contacted, can cause serious shock or result in damage

to the chassis. Maintain interconnecting ground lead connections between chassis, escutcheon,

picture tube dag and tuner when operating chassis.

These receivers have a “polarized” AC line cord. The AC plug is designed to fit into standard

AC outlets in one direction only. The wide blade connects to the “ground side” and the narrow blade

connects to the hot “side” of the AC line. This assures that the TV receiver is properly grounded to

the house wiring. If an extension cord must be used, make sure it is of the “polarized” type.

Since the chassis of this receive is connected to one side of the AC supply during operation,

service should not be attempted by anyone not familiar with the precautions necessary when

working on these types of equipment.

When it is necessary to make measurements or tests with AC power applied to the receiver

chassis, an Isolation Transformer must be used as a safety precaution and to prevent possible

damage to transistors. The Isolation Transformer should be connected between the TV line cord

plug and the AC power outlet.

Certain High voltage (HV) maybe cause X-ray radiation. Receivers should not be operated with

HV levels exceeding the specified rating for their chassis type. Higher voltage may also increase the

possibility of failure in the HV supply.

It is important to maintain specified values of all components in the horizontal and high voltage

circuits and anywhere else in the receive that could cause a rise in high voltage, or operating supply

voltages. No changes should be made the original design of the receiver.

Components shown in the shaded areas on the schematic diagram and/or identified by in the

replacement parts list should be replaced only with exact factory recommended replacement parts.

The use of unauthorized substitute parts man creats may create shock, fire, X-ray radiation, or other

hazards.

To determine the presence of high voltage, use an accurate high impedance HV meter

connected between the second anode lead and he CRT dag grounding device. When servicing the

3

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

High Voltage System remove static charges from it by connecting a 10K Ohm resistor in series Wan

insulated wire(such as test probe) between the picture tube dag and 2nd anode lead(Have AC line

cord disconnected from AC supply).

The picture tube use in this receiver employ integral implosion protection. Replace with a tube

of the same type number for continued safety. Do not lift picture tube by the neck. Handle the

picture tube only when wearing shatterproof goggles and after discharging the high voltage

completely, Keep others without shatter proof goggles away.

Before returning the receiver to the user, perform the following safety checks:

1. Inspect all lead dress to make certain that leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the receiver.

2. Replace all protective devices such as non-metallic control knobs, insulating fish-papers,

cabinet backs, adjustment and compartment covers of shields, isolation resistor-capacitor networks,

mechanical insulators etc.

3. To be sure that not shock hazard exists, a check for the presence of leakage current should be

made at each exposed metal part having a return path to the chassis (antenna, cabinet metal, screw

heads knobs and/or shafts, escutcheon, etc.) in the following manner.

Plug the AC line cord directly into a 110V/240V (or 180V/240V), AC receptacle. (Do not use

an Isolation Transformer during these checks.) All checks must be repeated with the AC line cord

plug connection reversed. (If necessary, a non-polarized adapter plug must be used only for the

purpose of completing these checks.)

If available, measure the current using an accurate leakage current tester. Any reading of

0.35mA or more is excessive and indicates a potential shock hazard which must be corrected before

returning the receiver to owner.

If a reliable leakage current tester is not available, this alternate method of measurement should

be used. Using two clip leads, connect a 1500 Ohm, 10 watt resistor paralleled by a 0.15MF

capacitor in series with a known earth ground, such as a water pipe or conduit and the metal part to

be checked. Use a VTVM or VOM with 1000 Ohms per Volt, or higher, sensitivity to measure this

AC voltage drop across the resistor,. Any reading of 0.35 volt RMS of more is excessive and

indicates potential shock hazard which must be corrected before returning he receiver to the owner.

4

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

ALIGNMENT PROCEDURES

PLEASE READ BEFORE ATTEMPTING SERVICE

1. Use an Isolation Transformer when performing any service on this chassis.

2. Never disconnect any leads while receiver is in operation.

3. Disconnect all power before attempting an repairs.

4. Do not short any position of the circuit while the power is on.

5. For safety reasons, replacing any components should be according with identical replacement

parts.

6. Before testing, warm up the TV for at least 30 minutes and demagnetize the CRT with an external

degaussing coil.

7. When removing a PCB or related component, after unfastening or changing a wire, be sure to put

the wire back in its original position.

8. Inferior silicon grease can damage IC’s and transistors. When replacing IC’s and transistors, use

only specified silicon grease,. Remove all old silicon when applying new silicon.

9. Before removing the anode cap, discharge drastically because it contains high voltage.

TV SPECIFICATION

1. Ambient Conditions:

1.1 Ambient Temperatures:

a. Operating: -10 ~ +40 ℃

b. Storage: -15 ~ +45 ℃

1.2 Humidity

a. Operation: <80%

b. Storage: <90%

1.3 Air Pressure: 86kpa ~ 106kpa

2. General Specification

2.1 Main IC: PHILIPS UOCIII CHIP (TDA12060 or TDA12062)

2.2 TV Broadcasting System:

5

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

PAL DK/BG/I

SECAM DK/BG

2.3 Scanning Lines & Frequencies

525 lines/60Hz or 625 lines/50Hz

15.75KHz/15.625KHz

2.4 Color Sub-Carrier: 4.433MHz/3.579MHz

2.5 IF: Picture 38.9MHz Sound 5.5/6.5MHz

2.6 Power Consumption: 75W;

2.7 Power Supply: AC 110-240V 50Hz±10%

2.8 Audio Output Power (7%THD): 1.5W X 2;

2.9 Aerial Input Impedance: 75 Ω Unbalanced Din Jack Ant. Input

3. Basic Features of Controller

3.1 Channel Tuning Method: Frequency Synthesizer

3.2 Presettable Program: 240 Programs

3.3 Tuning for VHF and UHF Bands: Auto Tuning/Manual Tuning

3.4 Picture and Sound Adjustment

Bright, Contrast, Color, Sharpness Control and Color Temperature Adjustment

TINT Control (NTSC only)

Volume Control (More controls can do in TV Model 21SL39 and 29F08)

3.5 OSD

General Features (Volume, Brightness, Contrast, Color, Program, Band, Auto Search, Manual

Tune, Muting, AV/TV, Child Lock and Sleep Timer)

AV Stereo

Russia and English Language

3.6 Sleep Timer: 5 -120 Minutes with 5 Minutes Increment

3.7 Auto Standby When No Broadcasting Signal: 5 minutes

3.8 Full Function Infrared Remote Control

3.9 Remote Effective Distance: 8m

4. Construction of Front Panel

6

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Main Power Switch

Remote Sensor

Standby Indicator

Menu Select

TV/AV Select

Program and Volume Up/Down

5. TV’s Terminals

75 Ω Aerial Terminal

3 AV Inputs

1 S-Video Input

1 Y/U/V Input

1 AV Output

SERVICE MANUAL

6. Other Informations

6.1 Magnetic Field: Bv = 0.3~0.65Gs

6.2 Standard Colour Temperature: 9300K (X = 0.284, Y = 0.299)

TV ADJUSTMENT

Test Equipment

1. Oscilloscope

2. Multifunction meter (Internal resistance: DC≥20kΩ/V AC≥5kΩ/V)

3. High voltmeter: 35kV

4. Standard Signal Generator

5. Degaussing coil

Factory menu

Some adjustments must be performed in the Factory menu. You can enter the Factory menu in

the following way:

1. Press the MENU button on the remote control then press the Q.VIEW button on the remote

7

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

control at least 5 times immediately.

2. Press the MENU buttons to select the desired Factory menu pages or press 0-9 number buttons to

enter the Factory menu pages directly and then press the PROG.+/- buttons to select the desired

items.

3. Press the VOL+/- buttons to change the settings.

B+ Adjustment

Test Equipment: Multifunction meter

1. Operate the TV set with AC 110-240V(50/60Hz).

2. Receive Television broadcast signal, set PICTURE to Normal mode.

2. Connect the multifunction meter + lead to C960 and GND. Adjust the RP950 until the meter

reading the proper DC value: B+=115±0.5Vdc.

High voltage check and filament voltage check

Test Equipment: High voltmeter

1. Make sure AC power supply and +B are within pointed range before calibrating high voltage.

2. Connect high voltmeter to anode (G4) of CRT.

3. Turn on the TV, set the BRIGHTNESS and CONTRAST to the minimum (zero beam current),

swap to AV mode (No any signal applied).

4. High voltage please see the related model BOM.

5. Filament voltage measured by virtual value meter please see the related model BOM, usually

within the range of 6.3±0.2Vrms.

Grid voltage adjustment

1. Enter into FAC3 and select VG2, then adjust potentiometer to IN/OUT flash on the screen.

VG2 XX Please see the related model BOM

VSD Brightness XX Please see the related model BOM

VSD XX Please see the related model BOM

2. Receive PHILIPS five circles pattern after settings finishing, set PICTURE to Normal mode.

8

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

RF AGC adjustment

1. Receive a 60dBμV gray scale signal(PAL or SECAM).

2. Enter Factory menu and select AGC TAKE OVER, then adjust it until the picture noise is just

disappeared.

FOCUS adjustment

1. Receive five circles pattern, adjust the pattern to Normal mode.

2. Adjust focus potentiometer (horizontal output transformer) so that the center and four corners of

pattern are the best focus.

Horizontal scanning, vertical scanning and geometry correction adjustment

(adjust with PAL/SECAM and NTSC signal separately)

1. Receive five circles pattern signal, enter into factory menu to call up FAC2.

VERT SLOPE 50(60) XX Adjust it so that horizontal midline of the pattern superpose

with the black edge of the pattern.

VERT SHIFT 50(60) XX Adjust it so that the pattern midline superposes over CRT

geometric center.

VERT AMPLE 50(60) XX Adjust it so that the picture vertical reproduction display ratio

is more than 92%.

S CORR 50(60) XX Adjust it so that upper pane and bottom pan of the pattern are

the same as the middle pane.

V.LIN.CTRL 50(60) 0

V.LINEARITY 50(60) XX Adjust vertical linear.

VERT ZOOM 50(60) 25 Adjust vertical amplitude(fixed value 25).

2. Call up FAC1

EW WIDTH 50(60) XX Adjust it so that the picture horizontal reproduction display

ratio is more than 92% (H- size adjustment).

9

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

HOR.SHIFT 50(60) XX Adjust it so that the left half is symmetrical with the right

half (H. CEN correction).

EW PARABOLA 50(60) XX Adjust it so that parallelogram will be transformed to

rectangle or trapezium (Receive cross hatch signal)(Parallelogram correction).

TRAPEZIUM 50(60) XX Adjust it so that trapezium distortion is just disappeared

(Receive cross hatch signal)(Trapezium).

UC PARABOLA 50(60) XX Adjust it so that upper corner (left and right) vertical line are

straight line (Receive cross hatch signal)(Upper corner pincushion).

LC PARABOLA 50(60) XX Adjust it so that bottom corner (left and right) vertical line

are straight line (Receive cross hatch signal)(Bottom correction pincushion).

HOR.BOW 50(60) XX Adjust it so that vertical line is the straight line.(Receive

cross hatch signal) (Bow correction).

PARALLEL 50(60) XX Adjust it so that left and right line are straight lines

(Pincushion correction).

White balance adjustment (PAL or SECAM signal)

1. Enter into menu firstly and set COLOR mode to normal.(9300K)

2. Enter into AV mode and receive left black right white signal which with color sync signal.

3. Plug XS805, adjust it automatically with white balance adjustment software, enter into factory

menu when adjustment is OK, then enter into FAC 6、FAC 7、FAC 8 menu to check the following

data are consistent with data in computer.

Standard:Color temperature 9300K (X=0.284 Y=0.299) FAC 6

Cold color:Color temperature 12000K(X=0.272 Y=0.279) FAC 8

Warm color:Color temperature 6500K (X=0.313 Y=0.329) FAC 7

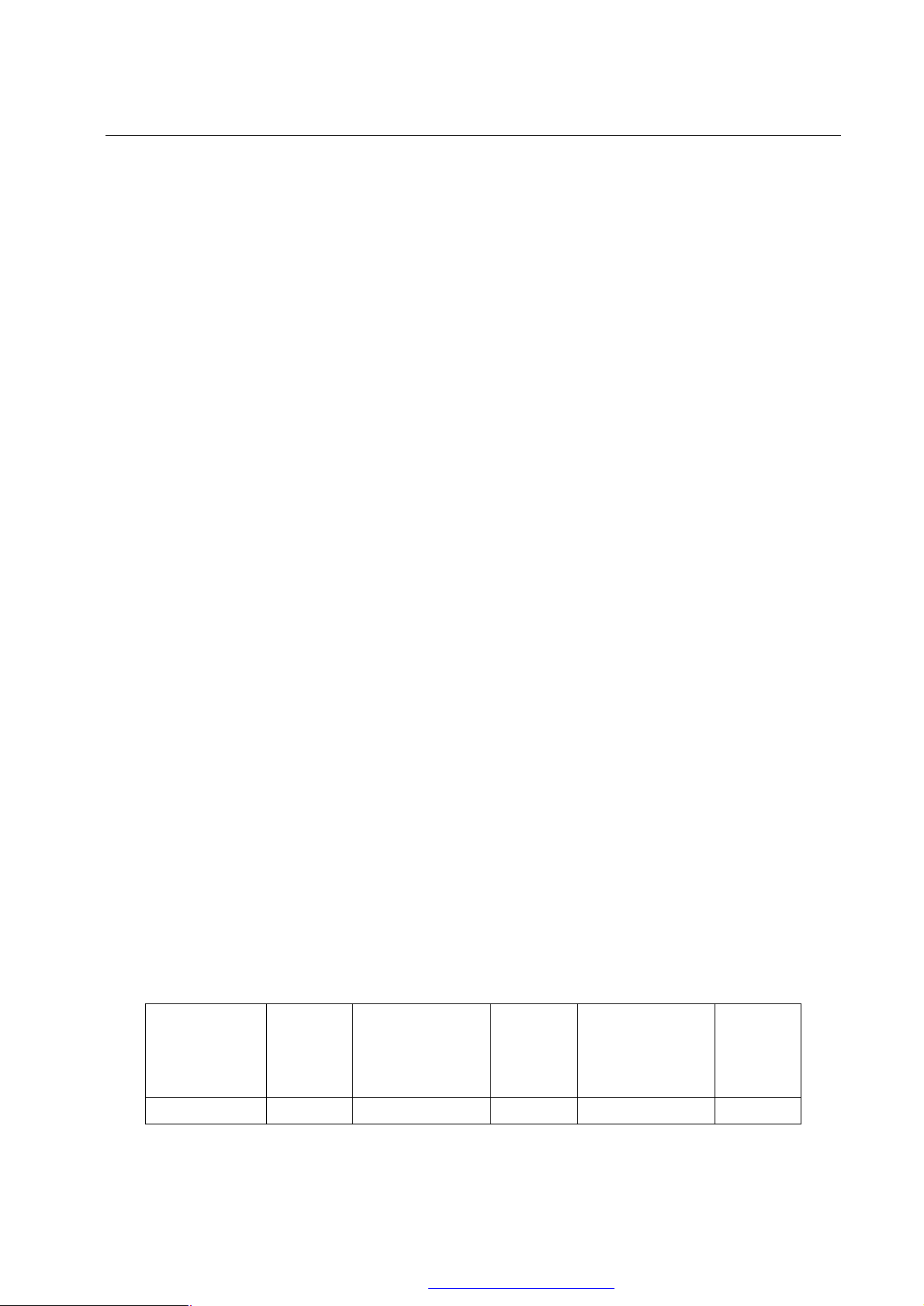

FAC 6

ADJ content

X=0.284

Y=0.299

value

FAC 7

ADJ Content

X=0.313

Y=0.329

value

FAC 8

ADJ Content

X=0.272

Y=0.279

value

BLOR-N xx BLOR-W xx BLOR-C xx

10

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

BLOG-N xx BLOG-W xx BLOG-C xx

WPR-N xx WPR-W xx WPR-C xx

WPR-N xx WPG-W xx WPG-C xx

WPR-N xx WPB-W xx WPB-C xx

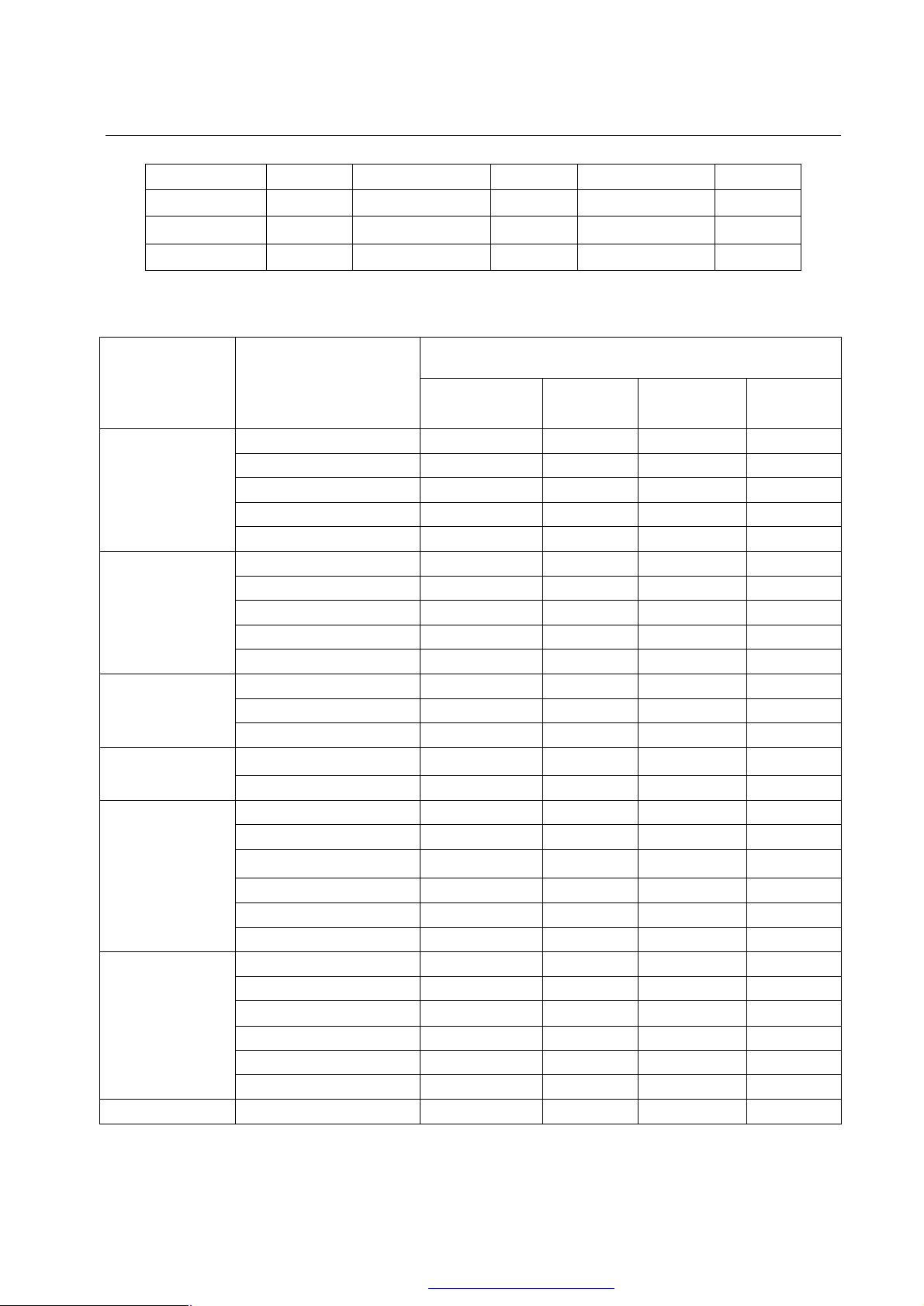

Factory menu

Item

SERVICE MANUAL

Other factory menu data

2108

21F08

1402 21SL39 29F08

TV Model

Factory

adjustment4

Factory

adjustment5

Factory

adjustment6

Factory

adjustment7

Factory

adjustment9

Factory

adjustment10

Factory

TXT-ON

Teletext lang

Teletext E/W

Track. Mode

Sub Brightness

Main YVolume1

Main YVolume2

Main YVolume3

Main XVolume1

Main XVolume2

Max Brightness

Max Contrast

Max Colour

RGB

CL

RGB-IN

DVD1-IN

AV2-IN

AV3-IN

AV1S-IN

CBVS-OUT

IF

TUNER

HIGH GAIN

QSS

SECAM L

NTSC M

French Frequency

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

25 25 25 25

22 22 22 22

44 44 44 44

58 58 58 58

22 22 22 22

44 44 44 44

47 47 47 47

63 63 63 63

47 47 47 47

10 10 10 10

4 2 4 8

0 0 0 0

0 0 1 1

0 0 1 1

1 1 1 1

0 0 1 1

1 1 1 1

3 3 3 3

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

11

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

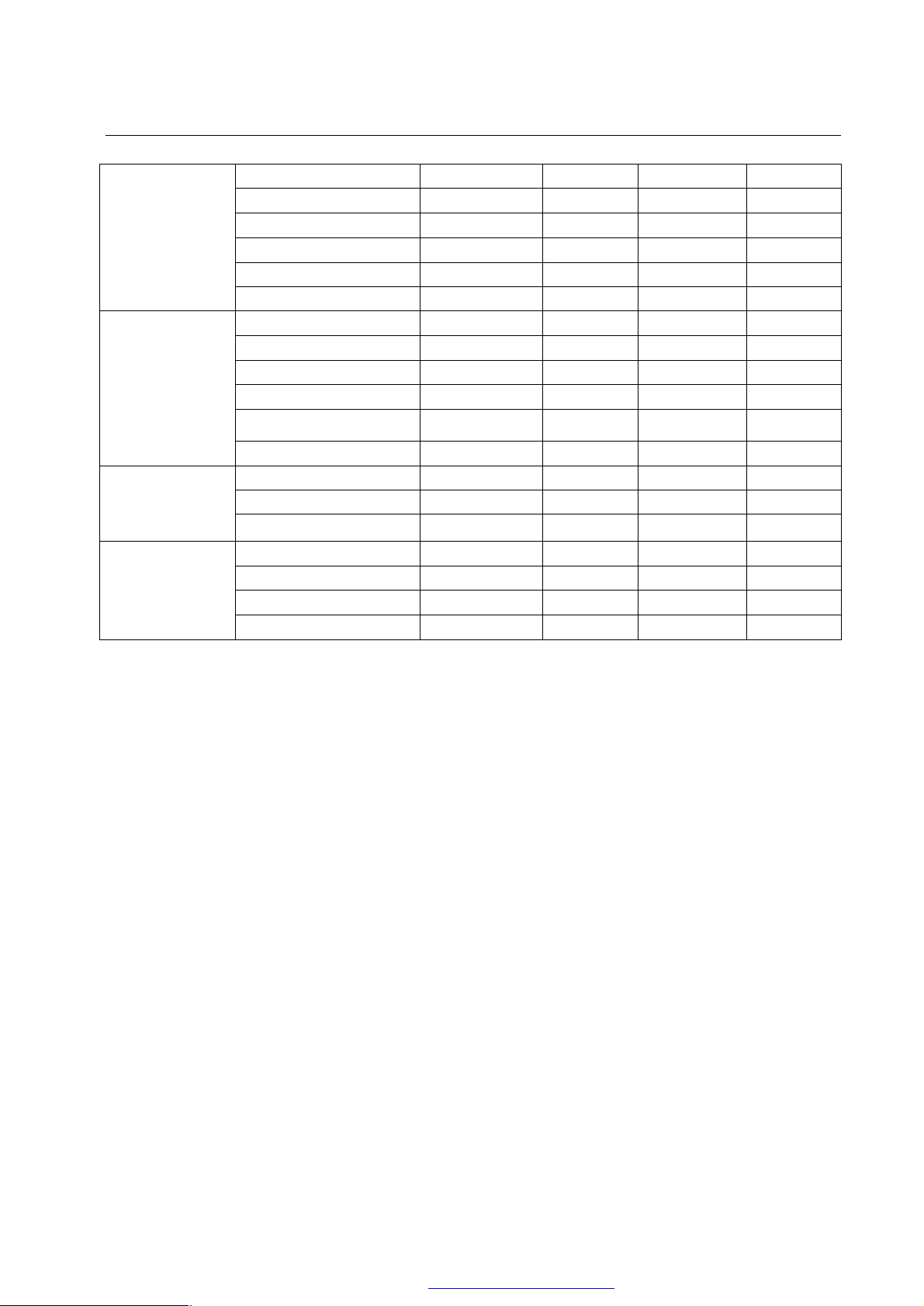

SERVICE MANUAL

adjustment11

Factory

adjustment12

Factory

adjustment13

Factory

adjustment14

Russia Frequency

Italy Frequency

Spain Frequency

Turkey Frequency

German Frequency

Poland Frequency

OP Dyn.skin tone

OP TRUSUR

OP Rotation

OP EQUAL

OP AUDIO CONFIG 0 0 1 1

OP BILING

Blackstretch

Bluestretch

HORIZOTAL OFFSET

TIM-REM

TIM-SLP

PWR-REST

PWR-ONKEY

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 1 1

0 0 0 0

0 0 0 0

0 0 0 0

12 12 12 12

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

IC INFORMATION

1. PHILIPS UOCIII CHIP (N603)

In this section mainly describe two ICs: TDA12060 and TDA12062. the TDA12060 is a AV

Stereo without audio DSP chip, but the TDA12062 is a AV Stereo with audio DSP chip.

1.1 General description

The UOCIII series combines the functions of a Video Signal Processor (VSP) together with a

FLASH embedded TEXT/Control/Graphics -Controller (TCG -Controller) and US Closed

Caption decoder. In addition the following functions can be added:

• Adaptive digital (4H/2H) PAL/NTSC comb filter

• Teletext decoder with 10 or 100 page text memory

• Multi-standard stereo decoder

• BTSC stereo decoder

12

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

• Digital sound processing circuit

• Digital video processing circuit

The UOCIII series consists of the following 3 basic concepts:

• Stereo versions. These versions contain the TV processor with a stereo audio selector, the TCG

-Controller, the multi-standard stereo or BTSC decoder, the digital sound processing circuit and

the digital video processing circuit. Options are the adaptive digital PAL/NTSC comb filter and a

teletext decoder with 10 or 100 page text memory.

• AV stereo versions. These versions contain the TV processor with stereo audio selector and the

TCG -Controller. Options are the digital sound processing circuit, the digital video processing

circuit, the adaptive digital PAL/NTSC comb filter and a teletext decoder with a 10 page text

memory.

• Mono sound versions. These versions contain the TV processor with a selector for mono audio

signals and the TCG -Controller. Options are the adaptive digital PAL/NTSC combfilter and a

teletext decoder with 10 page text memory.

The ICs are mounted in a QFP-128 package and can be used in economy television receivers

with 90 and 110 picture tubes. The package is according to the ROHS legislation, which also

means that the package is lead-free. The ICs have supply voltages of 5V, 3.3V. Also an 1.8V supply

is needed, but this can be simply derived by adding an emitter follower at a reference voltage from

the device.

1.2 Features

1.2.1 Analogue Video Processing

* Multi-standard vision IF circuit with alignment-free PLL demodulator

* Internal (switchable) time-constant for the IF-AGC circuit

* Switchable group delay correction and sound trap (with switchable centre frequency) for the

demodulated CVBS signal

* DVB/VSB IF circuit for preprocessing of digital TV signals.

* Video switch with 3 external CVBS inputs and a CVBS output. All CVBS inputs can be used as

Y-input for Y/C signals. However, only 2 Y/C sources can be selected because the circuit has 2

chroma inputs. It is possible to add an additional CVBS(Y)/C input (CVBS/YX and CX) when the

YUV interface and the RGB/YPBPR input are not needed. It is also possible to insert a CVBS/Y

13

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

signal at the SVO/IFVOUT output.

* Automatic Y/C signal detector

* Integrated luminance delay line with adjustable delay time

* Picture improvement features with peaking (with switchable centre frequency, depeaking, variable

positive/negative peak ratio, variable pre-/overshoot ratio and video dependent coring), dynamic

skin tone control, gamma control and blue- and black stretching. All features are available for CVBS,

Y/C and RGB/YPBPR signals.

* The effect of the various features can de demonstrated by means of a ‘split screen’ mode in which

the features are activated in one half of the picture and switched off in the other half

* Switchable DC transfer ratio for the luminance signal

* Only one reference (24.576 MHz) crystal required for the TCG -Controller, and the colour

decoder

* Multi-standard colour decoder with automatic search system and various “forced mode”

possibilities

* Internal base-band delay line

* Indication of the Signal-to-Noise ratio of the incoming CVBS signal

* Linear RGB/YPBPR input with fast insertion.

* YUV interface. When this feature is not required some pins can be used as additional

RGB/YPBPR input. It is also possible to use these pins for additional CVBS (or Y/C) input

(CVBS/YX and CX).

* Tint control for external RGB/YPBPR signals

* Scan Velocity Modulation output. The SVM circuit is active for all the incoming CVBS, Y/C and

RGB/YPBPR signals.

* RGB control circuit with ‘Continuous Cathode Calibration’, white point and black level off-set

adjustment so that the colour temperature of the dark and the light parts of the screen can be chosen

independently.

* Contrast reduction possibility during mixed-mode of OSD

* Adjustable ‘wide blanking’ of the RGB outputs

* Horizontal synchronization with two control loops and alignment-free horizontal oscillator

* Vertical count-down circuit

* Vertical driver optimized for DC-coupled vertical output stages

14

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

* Horizontal and vertical geometry processing with horizontal parallelogram and bow correction and

horizontal and vertical zoom

* Low-power start-up of the horizontal drive circuit

1.2.2 Sound Demodulation

* Separate SIF (Sound IF) input for single reference QSS (Quasi Split Sound) demodulation.

* AM demodulator without extra reference circuit

* The mono intercarrier sound circuit has a selective FM-PLL demodulator which can be switched

to the different FM sound frequencies (4.5/5.5/6.0/6.5 MHz). The quality of this system is such that

the external band-pass filters can be omitted. I

* The FM-PLL demodulator can be set to centre frequencies of 4.72/5.74 MHz so that a second

sound channel can be demodulated. In such an application it is necessary that an external bandpass

filter is inserted.

* The vision IF and mono intercarrier sound circuit can be used for the demodulation of FM radio

signals. With an external FM tuner also signals with an IF frequency of 10.7 MHz can be

demodulated.

* Switch to select between 2nd SIF from QSS demodulation or external FM (SSIF).

1.2.3 Audio Interfaces and switching

* Audio switch circuit with 4 stereo inputs, a stereo output for SCART/CINCH and a stereo

SPEAKER output with independent L&R analogue volume control.

* Analogue mono AVL circuit at left audio channel

1.2.4 -Controller

* 80C51 -controller core standard instruction set and timing

* 0.4883 s machine cycle

* maximum of 256k x 8-bit flash programmable ROM

* maximum of 8k x 8-bit Auxiliary RAM

* 12-level Interrupt controller for individual enable/disable with two level priority

* Two 16-bit Timer/Counter registers

* One 24-bit Timer (16-bit timer with 8-bit Pre-scaler)

* Watch Dog timer

15

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

* Auxiliary RAM page pointer

* 16-bit Data pointer

* Stand-by, Idle and Power Down modes

* 24 general-purpose I/O pins

* 14 bits PWM for Voltage Synthesis Tuning

* 8-bit A/D converter with 4 multiplexed inputs

* 5 PWM (6-bits) outputs for analogue control functions

* I2C byte level bus interface.

* Remote Control Pre-processor (RCP)

* Universal Asynchronous Receiver Transmitter (UART)

1.2.5 Display

* 50Hz/60Hz display timing modes

* Two page operation for 16:9 screens

* Serial and Parallel Display Attributes

* Single/Double/Quadruple Width and Height for characters

* Smoothing capability of both Double Size, Double Width & Double Height characters

* Scrolling of display region

* Variable flash rate controlled by software

* Soft colours using CLUT with 4096 colour palette

* Globally selectable scan lines per row (9/10/13/16/) and character matrix [12x9, 12x13, 12x16,

16x18, (VxH)]

* Fringing (Shadow) selectable from N-S-E-W direction

* Fringe colour selectable

* Contrast reduction of defined area

* Cursor

* Special Graphics Characters with two planes, allowing four colours per character

* 64 software redefinable On-Screen display characters

* 4 WST Character sets (G0/G2) in single device (e.g. Latin, Cyrillic, Greek, Arabic)

* G1 Mosaic graphics, Limited G3 Line drawing characters

* WST Character sets and Closed Caption Character set in single device

16

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

* Curtaining effect via software

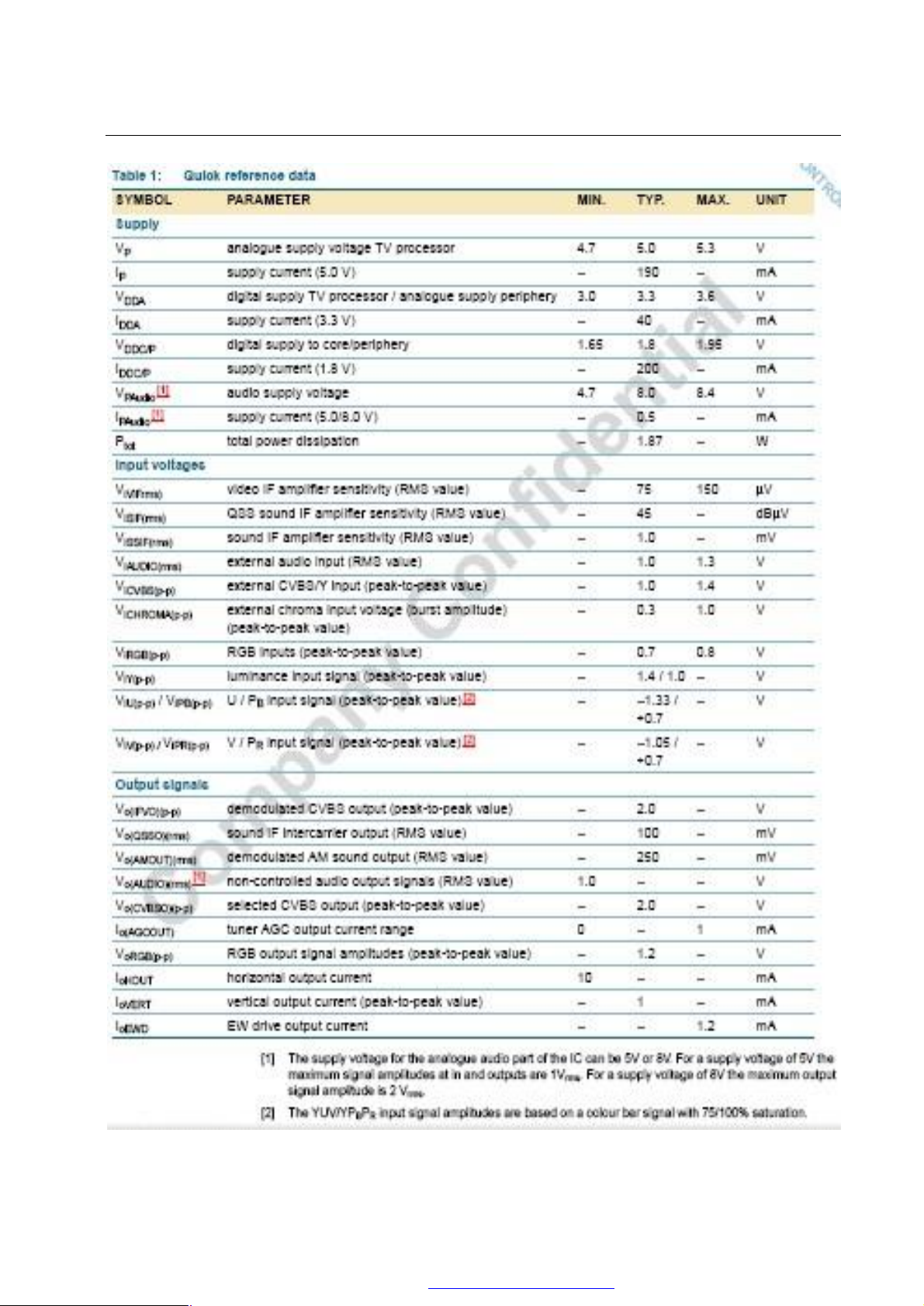

1.3 Quick reference data

SERVICE MANUAL

17

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

18

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

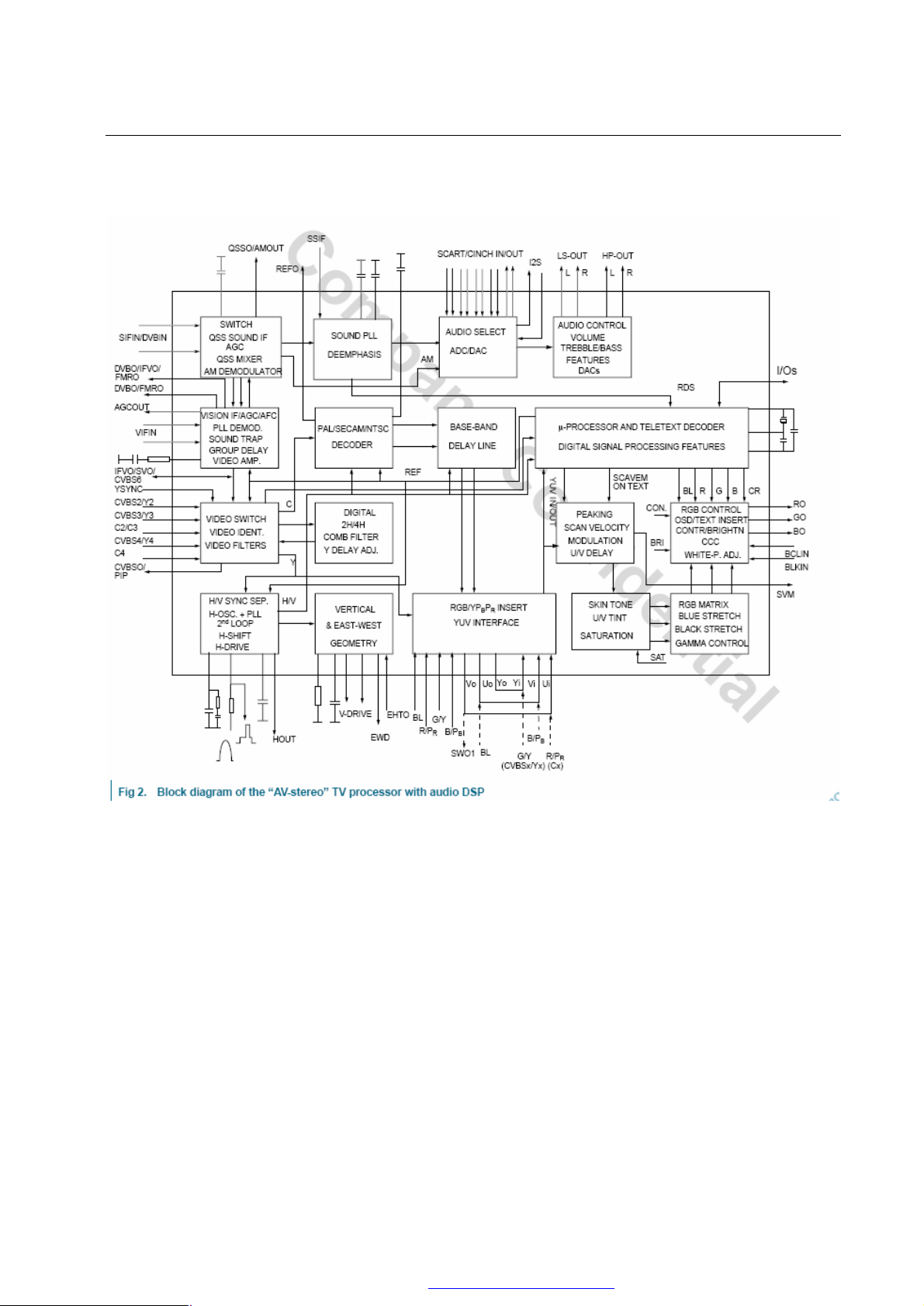

1.4 Block diagram

SERVICE MANUAL

Note: TDA12062block diagram

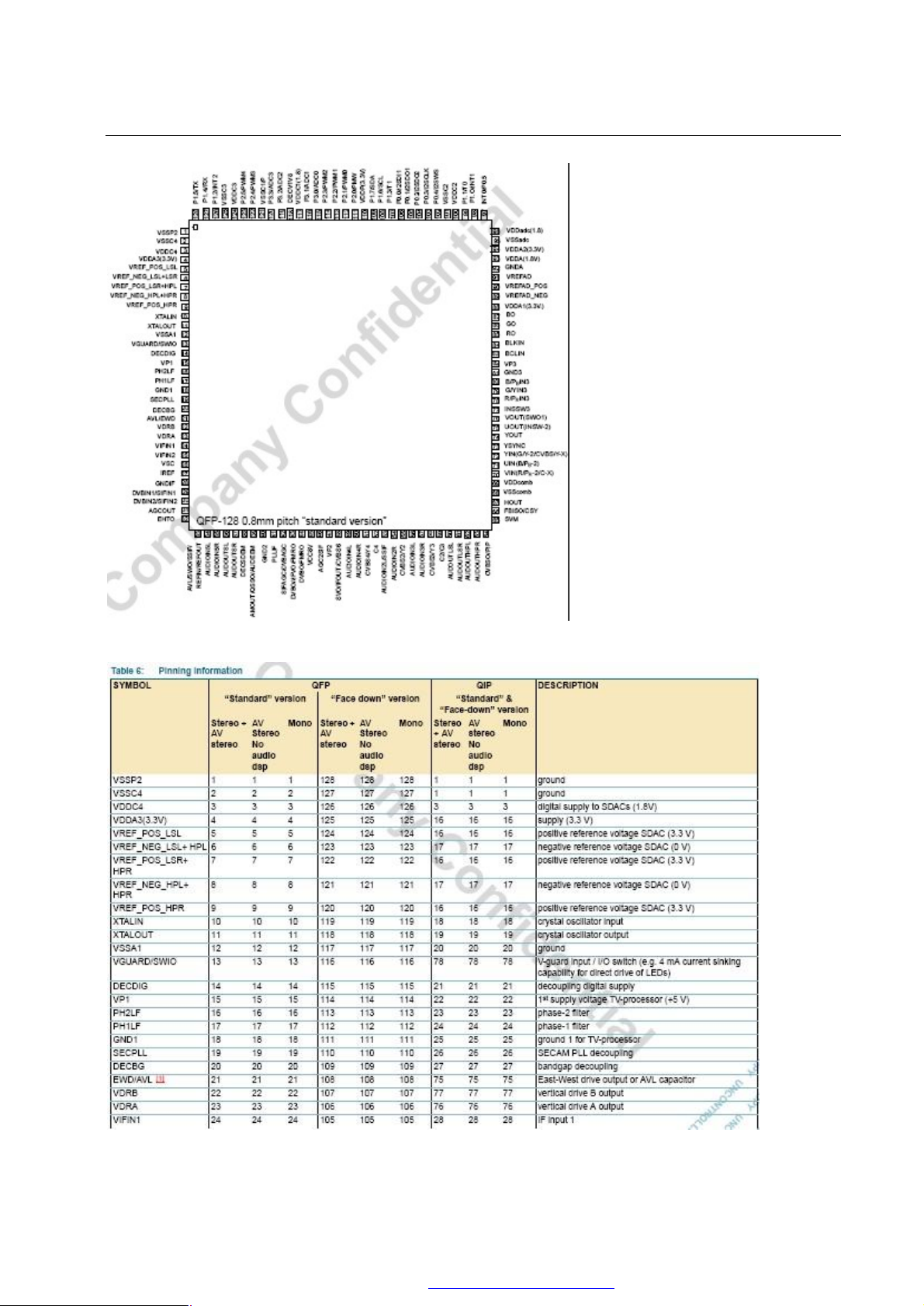

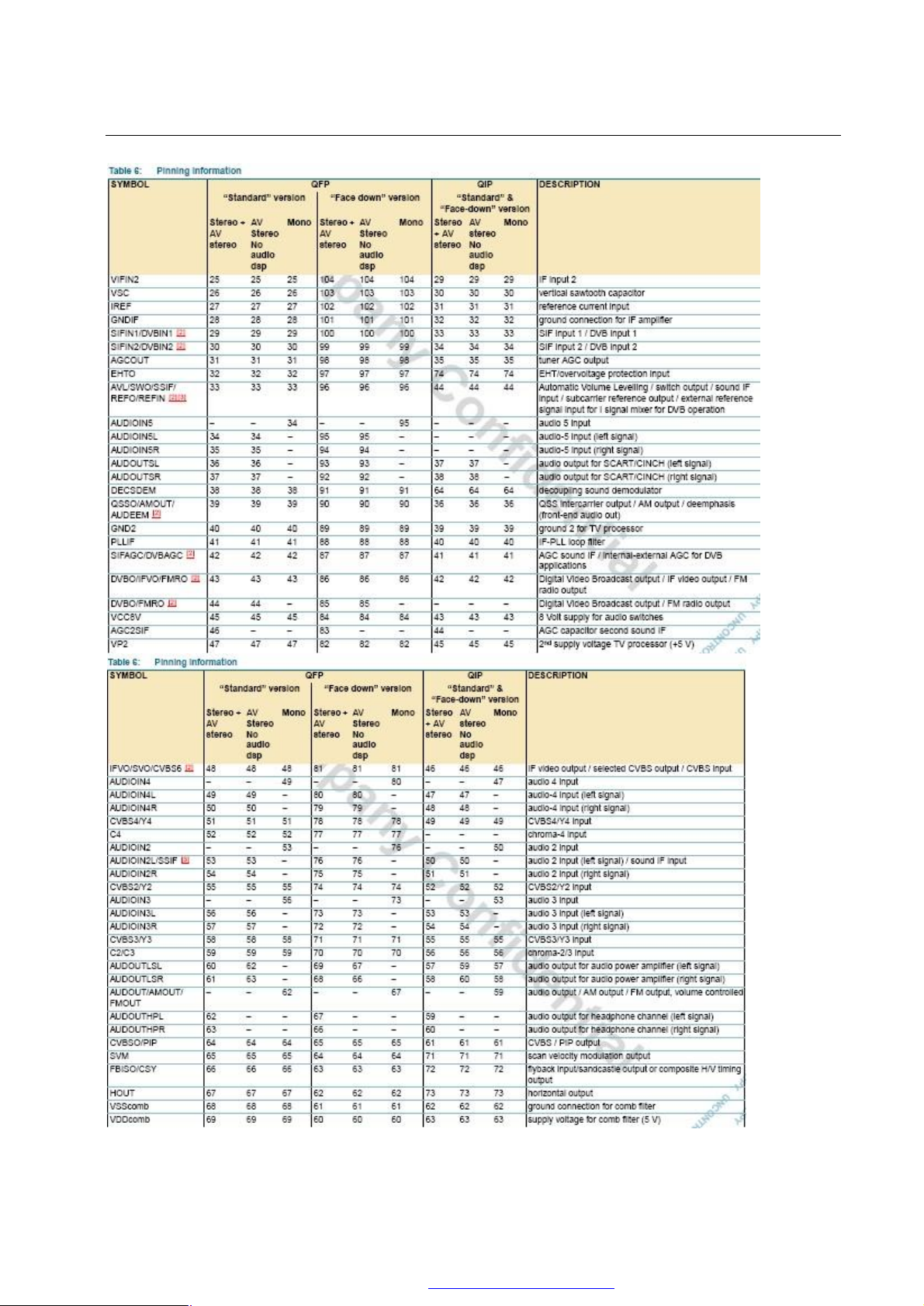

1.5 Pinning information

19

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

Note: TDA12062’s pinning

20

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

21

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

22

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

1.6 Power & Reset Management

There are three Power Saving modes, Stand-by, Idle and Power Down, incorporated into the

TCG -Controller die. When utilizing either mode, the 3.3V power to the device (VDDP & VDDA)

should be maintained, the 1.8V power to digital core except 80c51 and pads will be switched-off

internally to minimize the leakage current. The internally generated 1.8V will be maintained to

supply the power of 80c51 and pads.

1.6.1 Reset Capabilities

The TCG -Controller global power on reset is generated internally hence no external reset

circuitry is required.

Furthermore two additional user reset possibilities are offered:

• a hardware reset via pin P_TMSEL

• a software reset via pin P_TMSEL

The pin P_TMSEL is in two different ways: for test mode and FLASH/ISP programming

control and as a global reset pin to the TCG -Controller. The reset capability is an active high

reset incorporating an internal pull-down. Thus it can be left unconnected in the application. In

UOCIII this pin is connected to the VSP die but the VSP is capable to serve this functionality in a

kind of bypass mode.

The software reset capability is performed using a reset bit inside a SFR register called

ROMBK. This bit is used by the micro-controller to reset the following functions / blocks: stereo

23

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

sound decoder, RDS, ISP, acquisition, display, display RAM and digital video interface. The

software reset is executed by initially setting the corresponding bit to ‘1’ followed by clearing the bit

to ‘0’. The reset is launched after the falling edge of this process. It takes approximately 200 ms to

complete the internal reset sequence. Please note that of course the micro controller, its peripherals

(e.g. timers) and the program flash are not affected by this reset.

1.6.2 Power Modes

1.6.2.1 Stand-by mode

During Stand-by mode, the Acquisition, Display, RDS, and SSD sections of the device are

disabled. The following functions remain active:

• 80c51 CPU Core

• I2C

• RCP (Remote Control Pre-processor)

• Timer/Counters

• WatchDog Timer

• UART, SAD and PWMs

To enter Stand-by mode, the STANDBY bit in the ROMBANK register must be set. The status

of all SFRs, internal RAM contents are maintained, as are the device output pin values, but the

contents of Display memory are lost. Since the output values on RGB and VDS are maintained the

display output must be disabled before entering this mode. This mode should be used in conjunction

with both Idle and Power-Down modes.

It is not recommended to enter either the Idle mode or Power-Down mode directly from the

application mode. During Standby mode execution the necessary provisions are executed to safely

enter the subsequent modes and re-cover from them.

1.6.2.2 Idle mode

During Idle mode, Acquisition, Display, RDS, SSD and the CPU sections of the device are

disabled. The following functions remain active:

• I2C

• RCP

• Timer/Counters

24

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

• WatchDog Timer

• UART, SAD and PWMs

To enter Idle mode the IDL bit in the PCON register must be set. The WatchDog timer must be

disabled prior to entering Idle to prevent the device being reset. It is advice to use the RCP (Remote

Control Pre-processor) during the Idle mode to reduce the false interrupt wake-up of 80c51 in order

to achieve the low power saving mode. The CPU state is frozen along with the status of all SFRs,

internal RAM contents are maintained, as are the device output pin values, but the contents of

Display memory are lost. Since the output values on RGB and VDS are maintained the Display

output must be disabled before entering this mode.

There are three methods available to recover from Idle:

• Assertion of any enabled interrupt will cause the IDL bit to be cleared by hardware, thus

terminating Idle mode. The interrupt is serviced, and following the instruction RETI, the next

instruction to be executed will be the one after the instruction that put the device into Idle mode.

• A second method of exiting Idle is via an Interrupt generated by the SAD DC Compare circuit.

When TCG -Controller is configured in this mode, detection of an analogue threshold at the input

to the SAD may be used to trigger wake-up of the device i.e. TV Front Panel Key-press. As above,

the interrupt is serviced, and following the instruction RETI, the next instruction to be executed will

be the one following the

instruction that put the device into Idle.

• The third method of terminating idle mode is with a power on reset. Reset defines all SFRs and

Display memory to a pre-defined state, but maintains all other RAM values. Code execution

commences with the program counter set to “0000”.

1.6.2.3 Power down mode

In Power Down mode the XTAL oscillator is running still. The contents of all SFRs and Data

memory are maintained, however, the contents of the Display memory are lost. The port pins

maintain the values defined by their associated SFRs. Since the output values on RGB and VDS are

maintained the Display output must be made inactive before entering Power Down mode.

The power down mode is activated by setting the PD bit in the PCON register. It is advised to

disable the WatchDog timer prior to entering Power down. Recovery from Power-Down takes

several milli-seconds as the oscillator must be given time to stabilize.

25

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

There are three methods of exiting power down:

• The first method to wake up from Power-Down is to use one of these two external interrupts: EX0

and EX1. The interrupt EX2 cannot be used to wake up the system. Since the clock is stopped, these

external interrupts needs to be set level sensitive before entering Power-Down. The interrupt is

serviced, and following the instruction RETI, the next instruction to be executed will be the one

after the instruction that put the device into Power-Down mode.

• A second method to exit Power-Down is via an interrupt triggered by the SAD DC comparator.

This can be used e.g. to trigger a wake-up of the device by TV Front Panel key-press. As above, the

interrupt is serviced, and following the instruction RETI, the next instruction to be executed will be

the one following the instruction that put the device into Power-Down

• The third method of terminating the Power-Down mode is with a Power On reset. Reset defines all

SFRs and Display memory, but maintains all other RAM values. Code execution commences with

the Program Counter set to “0000”.

1.6.2.4 General recommendations

In power saving application modes where all three external interrupts are required the Idle

mode must be used. The difference between the Power Down mode and the Idle mode in terms of

power is quite small since they only differ in the amount of peripherals kept operational. The

purpose of these peripherals is to provide the interrupt request signals to wake up the micro

controller.

1.7 Display Engine

The display section reads the contents of the Display memory and interprets the

control/character codes. From this information and other global settings, the display produces the

required RGB signals and Video/Data (Fast Blanking) signal for a TV signal processing device.

The display is synchronized to the TV signal processing device by way of Horizontal and

Vertical sync signals generated in UOCIII. From these signals the display timing is derived.

Display Block Diagram

26

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿ www.fineprint.com.cn

SERVICE MANUAL

1.8 Functional Description Video Processor

1.8.1 Vision IF amplifier

The vision IF amplifier can demodulate signals with positive and negative modulation. The

PLL demodulator is completely alignment-free.

The VCO of the PLL circuit is internal and the frequency is fixed to the required value by using

the clock frequency of the TCG m-Controller as a reference. The setting of the various frequencies

(e.g. 38, 38.9, 45.75 and 58.75 MHz) can be made via the control bits IFA-IFC in subaddress 2FH.

Because of the internal VCO the IF circuit has a high immunity to EMC interferences.

The output of the AFC detector can be read from output byte 04H and has a resolution of 7 bits

(25 kHz per step). By means of this information a fast tuning algorithm can be designed.

The IC contains a group delay correction circuit which can be switched between the BG and a

uncompensated group delay response characteristic. This has the advantage that in multi-standard

receivers no compromise has to be made for the choice of the SAWfilter. This group delay

correction is realised for the demodulated CVBS output signal. The IC contains in addition a sound

trap circuit with a switchable centre frequency.

1.8.2 Digital Broadcast reception

Apart from processing analogue TV signals, the IF circuit can also preprocess digital TV

27

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

signals before they are sent to a digital signal processor. These signals have to be supplied to the

sound IF inputs. In this mode the IF reference frequency is fixed at 43.008 or 49.152 MHz. It is also

possible to supply an external reference signal to demodulator. The demodulator multiplies the

incoming signal with the fixed oscillator frequency. The mixed down signal is low pass filtered to

obtain a I-signal. The “Stereo” and “AV Stereo” versions have a differential output, however, it is

possible to use a single-ended output. The various output signal conditions can be set by means of

the IFO2-IFO0 bits in subaddress 31H (see also Table 128). The “Mono” versions have a

single-ended output.

The AGC has two modes of operation: the internal mode in which the IC sets the gain with its

own reference and an external mode in which the gain can be controlled with an external circuit. In

the second case the SIFAGC pin is used as an input to control the IF gain with an external circuit.

1.8.3 QSS Sound circuit

The sound IF amplifier is similar to the vision IF amplifier and has an external AGC

decoupling capacitor.

The single reference QSS mixer is realised by a multiplier. In this multiplier the SIF signal is

converted to the intercarrier frequency by mixing it with the regenerated picture carrier from the

VCO. The mixer output signal is supplied to the output via a high-pass filter for attenuation of the

residual video signals. With this system a high performance hi-fi stereo sound processing can be

achieved.

The AM sound demodulator is realised by a multiplier. The modulated sound IF signal is

multiplied in phase with the limited SIF signal. The demodulator output signal is supplied to the

output via a low-pass filter for attenuation of the carrier harmonics.

Switching between the QSS output and AM output is made by means of the AM bit in

subaddress 33H.

1.8.4 FM demodulator

The FM demodulator is realised as narrow-band PLL with internal loop filter, which provides

the necessary selectivity without using an external band-pass filter. To obtain a good selectivity a

28

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

linear phase detector and a constant input signal amplitude are required. For this reason the

intercarrier signal is internally supplied to the demodulator via a gain controlled amplifier and AGC

circuit. To improve the selectivity an internal bandpass filter is connected in front of the PLL circuit.

The nominal frequency of the demodulator is tuned to the required frequency (4.5/5.5/6.0/6.5

MHz) by means of a calibration circuit which uses the clock frequency of the TCG11 m-Controller

as a reference. It is also possible to frequencies of 4.72 and 5.74 MHz so that a second sound

channel can be demodulated. In the latter application an external bandpass filter has to be applied to

obtain sufficient selectivity (the sound input can be activated by means of the setting of

CMB2-CMB0 bits in subaddress 4AH). The setting to the wanted frequency is realised by means of

the control bits FMA, FMB and FMC in the control bit 33H.

From the output status bytes it can be read whether the PLL frequency is inside or outside the

window and whether the PLL is in lock or not. With this information it is possible to make an

automatic search system for the incoming sound frequency. This can be realized by means of a

software loop which switches the demodulator to the various frequencies and then select the

frequency on which a lock condition has been found.

The amplitude deemphasis output signal changed with 6 dB by means of the AGN bit. In this

way output signal differences between the 4.5 MHz standard (frequency deviation ±25 kHz) and the

other standards (frequency deviation ±50 kHz) can be compensated.

1.8.5 FM radio mode

The internal FM demodulator can also be used for the demodulation of FM radio signals. This

mode is activated by the FMR bit (subaddress 34H). Depending on the UOCIII version, the mono

demodulator as well as the stereo demodulator can be used for FM radio. Both demodulators can

also be used simultaneously, so switching between the demodulators is an option and RDS

demodulation can also be carried out.

There are two FM-radio options, depending on the tuner. The first one uses an optimized tuner

with 10.7 MHz output. The tuner output signal can be filtered and applied to the SSIF input. The

SSIF frequency of the mono demodulator can be set by the FMD bit. In case of using the stereo

demodulator one have to set the ‘STDSEL’ register. The second option is the FM radio eco(nomy)

using a normal multistandard tuner + an extra Radio I.F. SAW filter. In this case the I.F.

29

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

demodulator has to be set to one of the fixed frequencies (43.008 MHz or 49.152 MHz) by the IFA

-IFE bits in subaddress 31H. The I.F. centre frequency depends on the I.F. downmix frequency and

the FM demodulator settings. The bandwidth of the RIF filter should be between 200 and 300 KHz

for proper channel selectivity. A common QSS sound SAW filter with 800 KHz bandwidth is too

wide. In the FM radio eco mode the SSIF output signal can be supplied to the output pins (FMRO)

for external filtering by setting the IFO2- IFO0 bits in subaddress 31H.

The SS IF bit can be either pin 33 or pin 53 (pins 96 or 76 respectively for the “face down”

version). The selection is made by means of the CMB2-CMB0, SSIFS and SSIFM bits.

1.8.6 CVBS and Y/C input signal selection

The ICs have 3 inputs for external CVBS signals. All CVBS inputs can be used as Y input for

the insertion of Y/C signals. However, the CVBS(Y)2 input has to be combined with the C3 input. It

is possible to add and extra CVBS(Y/C) input via the pins which are intended to be used for YUV

interface (or RGB/YPBPR input). The selection of this additional CVBS(Y/C) input is made via the

YC bit. The CVBS selector has one independently switchable output. The switch configuration is

given in Figure 72. The choice of the various modes can be made via the INA-IND bits in

subaddress 38H.

The function of the IFVO/SVO/CVBS6 pin is determined by the SVO1/SVO0 bits. When used

as output a selection can be made between the IF video output signal or the selected CVBS signal

(monitor out). This pin can also be used as additional CVBS input. In the input selector this signal is

indicated as CVBS/Y-6 (see Figure 72). The CVBS/Y-6 input has to be combined with the C4 input.

The selection of the CVBS/Y-6 signal is valid only at the SVO1/SVO0 setting 1/0.

It is possible to use the group delay and sound trap circuit for the CVBS2 signal (via the CV2

bit).

For the CVBS(Y/C) inputs the circuit can detect whether a CVBS or Y/C signal is present on

the input. The result can be read from the status register (YCD bit in subaddress 03H) and this

information can be used to put the input switch in the right position (by means of the INA-IND bits

in subaddress 38H). The Y/C detector is only active for the CVBS(Y)3/C3, CVBS(Y)4/C4 and

CVBS(Y)x/Cx inputs. It is not active for the CVBS(Y)2/C3 and CVBS(Y)6/C4 inputs.

The video ident circuit can be connected to all video input signals. This ident circuit is

30

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

independent of the synchronisation and can be used to switch the time-constant of the horizontal

PLL depending on the presence of a video signal (via the VID bit). In this way a very stable OSD

can be realised. The result of the video ident circuit can be read from the output bit SID (subaddress

00).

1.8.7 Synchronisation circuit

The IC contains separator circuits for the horizontal and vertical sync pulses. To obtain an

accurate timing of the displayed picture the input signal of the sync separator is not derived from the

various CVBS/Y or RGB/YPBPR inputs but from the YOUT pin. For this reason the YOUT pin

must be capacitively coupled to the YSYNC pin. The delay between the various inputs and the

YOUT signal can have rather large differences (e.g. comb filter active or not). By choosing the

YOUT signal as input signal for the sync separator these delays have no effect on the picture

position. Only for RGB signals without sync on green the input of the sync separator has to be

connected to one of the CVBS inputs. This selection is made by means of the SYS bit.

The horizontal drive signal is obtained from an internal VCO which is running at a frequency

of 25 MHz. This oscillator is stabilised to this frequency by using the clock signal coming from the

31

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

reference oscillator of the TCG m-Controller.

To obtain a stable On-Screen-Display (OSD) under all conditions it is important that the first

control loop is switched off or set to low gain when no signal is available at the input. The input

signal condition is detected by the video identification circuit. The video identification circuit can

automatically switch first control loop to a low gain when no input signal is available. This mode is

obtained when the VID bit is set to “0”. When the VID bit is “1” the mode of the first control loop

can be switched by means of the FOA/FOB or POC bits.

For a good performance during normal TV reception (display of the front-end signal) various

connections are active between the vision IF amplifier and the synchronization circuit (e.g. gating

pulses for the AGC detector and noise gating of the sync separator). These connections are not

allowed when external video signals are displayed. The switching of these connections can be

coupled to the input signal selection bits (INA-IND). This mode is obtained when the VDXEN bit is

“0”. Due to the input signal selector configuration it is possible that the internal CVBS signal is

available on one of the other CVBS inputs. In this condition the connections between the vision IF

amplifier and the synchronisation circuit can be switched on and off by means of the VDX bit. The

VDXEN bit must be set to “1” for this mode.

The vertical synchronisation is realised by means of a divider circuit.

1.8.8 Horizontal and vertical drive

The horizontal drive is switched on and off via the soft start/stop procedure. The soft start

function is realised by means of variation of the TON of the horizontal drive pulses. During the

soft-stop period the horizontal output frequency is doubled resulting in a reduction of the EHT so

that the picture tube capacitance can easily be discharged. In addition the horizontal drive circuit has

a ‘low-power start-up’ function.

The vertical ramp generator needs an external resistor and capacitor. For the vertical drive a

differential output current is available. The outputs must be DC coupled to the vertical output stage.

The IC has the following geometry control functions:

• Vertical amplitude

• Vertical slope

• S-correction

32

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

• Vertical shift

• Vertical zoom

• Vertical scroll

• Vertical linearity correction. When required the linearity setting for the upper and lower part of the

screen can have a different setting.

• Horizontal shift

• EW width

• EW parabola width

• EW upper and lower corner parabola correction

• EW trapezium correction

• Horizontal parallelogram and bow correction.

When the vertical amplitude is compressed (zoom factor <1) it is still possible to display the

black current measuring lines in the overscan. This function is activated by means of the bit OSVE

in subaddress 40H.

The vertical guard input is combined with an I/O function. The following functions can be

realised with this pin:

• Just vertical guard input.

• Combination of vertical guard and LED drive output. In this condition the output is high-ohmic

during the vertical retrace (1 ms) so that the vertical guard pulse can be detected.

• Single ended output switch

• Input port

The functionality of this pin is controlled by the VGM1/0 and LED bits.

When the East-West geometry function is not required (e.g. for 90° picture tubes) the EW

output pin can be used for the connection of the AVL capacitor. This function is chosen by means of

the AVLE bit.

The UOCIII devices can also be used as input processor for 100 Hz or LCD TV receivers. In

that case the deflection drive signals are not required. For these applications, H/V timing signal can

be obtained from the H-drive and VDRB output pins. The polarity of these pulses is negative. For

the H-output a pull-up resistor is required. The sandcastle signal will be available on the FBISO pin.

This mode is activated by means of the LCD bit (subaddress 4AH). A change of the LCD bit is

possible only in the stand-by mode (STB = 0).

33

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

1.8.9 Chroma, luminance and feature processing

Some versions contain a 4H/2H (2D) adaptive PAL/NTSC comb filter. The comb filter is

automatically activated when standard CVBS signals are received. A signal is considered as

“standard signal” when a PAL or NTSC signal is identified and when the vertical divider is in the

modes ‘standard narrow window’ or ‘standard TV norm’.For non-standard signals and for SECAM

signals the comb filter is bypassed and the signal is filtered by means of bandpass and trap filters.

The chroma band-pass and trap circuits (including the SECAM cloche filter) are realized by

means of internal filters and are tuned to the right frequency by comparing the tuning frequency

with the reference frequency of the colour decoder.

The circuit contains the following picture improvement features:

• Peaking control circuit. The peaking function can be activated for all incoming CVBS, Y/C and

RGB/YPBPR signals. Various parameters of the peaking circuit can be adapted by means of the

I2C-bus. The main parameters are:

– Peaking centre frequency (via the PF1/PF0 bits in subaddress 19H).

– Ratio of positive and negative peaks (via the RPO1/RPO0 bits in subaddress 47H). The peaks in

the direction “white” are the positive peaks.

– Ratio of pre- and aftershoots (via the RPA1/RPA0 bits in subaddress 47H).

• Video dependent coring in the peaking circuit. The coring can be activated only in the low-light

parts of the screen. This effectively reduces noise while having maximum peaking in the bright parts

of the picture.

• Black stretch. This function corrects the black level for incoming signals which have a difference

between the black level and the blanking level. The amount of stretching (A-A in Fig. 105) and the

minimum required back ground to activate the stretching can be set by means of the I2C-bus

(BSD/AAS in subaddress 45H).

• Gamma control. When this function is active the transfer characteristic of the luminance amplifier

is made non-linear. The control curve can be adapted by means of I2C-bus settings (see Fig. 107). It

is possible to make the gamma control function dependent on the picture content (Average Picture

Level, APL). The effect is illustrated in Fig. 108. Previously this function was mentioned under the

name “white stretch function”.

34

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

• Blue-stretch. This circuit is intended to shift colour near ‘white’ with sufficient contrast values

towards more blue to obtain a brighter impression of the picture.

• Dynamic skin tone (flesh) control. This function is realised in the YUV domain by detecting the

colours near to the skin tone.

• Scan-Velocity modulation output. Also the SVM function can be activated for all incoming CVBS,

Y/C and RGB/YPBPR signals. The delay between the RGB output signals and the SVM output

signal can be adjusted (by means of the SVM2-SVM0 bits in subaddress 48H) so that an optimum

picture performance can be obtained. Furthermore a coring function can be activated. It is possible

to generate Scan Velocity Modulation drive signals during the display of ‘full screen’ teletext (not in

mixed mode). Another feature is that the SVM output signal can be made dependent on the

horizontal position on the screen (parabola on the SVM output).

The effect of the various features can de demonstrated by means of the ‘split-screen’ mode.

When the TV receiver is switched to this mode the features are switched on in the left half of the

picture and switched off in the right half of the picture or vice versa. It is possible to add a signal

blanking in the middle of the screen. The features that are switched on and off are: peaking, scan

velocity modulation, black stretch, gamma control, DC transfer ratio, blue stretch, dynamic skin

tone control, tint on U/V and soft clipping.

1.8.10 Colour decoder

The ICs decode PAL, NTSC and SECAM signals. The PAL/NTSC decoder does not need

external reference crystals but has an internal clock generator which is stabilised to the required

frequency by using the clock signal from the reference oscillator of the TCG m-Controller.

Under bad-signal conditions (e.g. VCR-playback in feature mode), it may occur that the colour

killer is activated although the colour PLL is still in lock. When this killing action is not wanted it is

possible to overrule the colour killer by forcing the colour decoder to the required standard and to

activate the FCO-bit (Forced Colour On) in subaddress 3CH. The sensitivity of the colour decoder

for PAL and NTSC can be increased by means of the setting of the CHSE1/CHSE0 bits in

subaddress 3CH.

The Automatic Colour Limiting (ACL) circuit (switchable via the ACL bit in subaddress 3BH)

prevents that oversaturation occurs when signals with a high chroma-to-burst ratio are received. The

35

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

ACL circuit is designed such that it only reduces the chroma signal and not the burst signal. This has

the advantage that the colour sensitivity is not affected by this function.

The SECAM decoder contains an auto-calibrating PLL demodulator which has two references,

viz: the divided reference frequency (obtained from the m-Controller) which is used to tune the PLL

to the desired free-running frequency and the bandgap reference to obtain the correct absolute value

of the output signal. The VCO of the PLL is calibrated during each vertical blanking period, when

the IC is in search or SECAM mode. The frequency offset of the B-Y demodulator can be reduced

by means of the SBO1/SBO0 bits in subaddress 3CH.

The base-band delay line is integrated. In devices without CVBS comb filter this delay line is

also active during NTSC to obtain a good suppression of cross colour effects. The demodulated

colour difference signals are internally supplied to the delay line. The baseband comb filter can be

switched off by means of the BPS bit (subaddress 3CH).

The subcarrier output is combined with a 3-level output switch (0 V, 2.1 V and 4.5 V). The

output level and the availability of the subcarrier signal is controlled by the CMB2-CMB0 bits.

1.8.11 RGB output circuit

In the RGB control circuit the signal is controlled on contrast, brightness and saturation. The IC

has a YUV interface so that additional picture improvement ICs can be applied. To compensate

signal delays in the external YUV path the clamp pulse in the control circuit can be shifted by means

of the CLD bit in subaddress 44H. When the YUV interface is not required some of the pins can be

used for the insertion of RGB/YPBPR signals or as additional CVBS(Y)/C input. When the YUV

interface is not used one of the pins (VOUT) is transferred to general purpose output switch (SWO1).

The IC has also a YUV interface to the digital die. Via this loop digital features like “double

window” are added.

A tint control is available for the base-band U/V signals. For this reason this tint control can be

activated for all colour standards. The signals for OSD and text are internally supplied to the control

circuit. The output signal has an amplitude of about 1.2 V black-to-white at nominal input signals

and nominal settings of the various controls.

To obtain an accurate biasing of the picture tube the ‘Continuous Cathode Calibration’ system

has been included in these ICs. The system is slightly adapted compared with the previous circuits.

36

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

In the new configuration the cut-off level of the picture tube is controlled with a continuous loop

whereas the correction of the amplitude of the output signals is realised by means of a digital loop.

As a consequence the current measurement can be controlled from the m-Processor. The value of

the “high current” in the CCC loop can be chosen via the SLG0 and SLG1 bits (subaddresses 42H

and 46H). The gain control in the 3 RGB channels is realised by means of 7-bit DACs. The total

gain control range is ±6 dB. The change in amplitude at the cathodes of the picture tube for one LSB

is about 1.1 VP-P. The setting of the control DAC is determined by the following registers:

• The white point setting of the R, G and B channel in subaddress 20H to 22H. This register has a

resolution of 6 bits and the control range in output signal amplitude is ±3 dB.

• The cathode drive setting (CL3-CL0 in subaddress 42H). This setting is valid for all channels, the

resolution is 4 bits and the control range is ±3 dB.

• The gain setting of the R, G and B channel. During switch on this register is loaded with the preset

gain setting of subaddress 23H to 25H and when necessary it will be adapted by the CCC control

loop. These registers have a resolution of 7 bits.

The setting of the gain registers of the 3 channels can be stored during switch off and can be

loaded again during switch-on so that the drive conditions are maintained.

When required the operation of the CCC system can be changed into a one-point black current

system. The switching between the 2 possibilities is realised by means of the EGL bit (EGL = 0) in

subaddress 42H. When used as one-point control loop the system will control the black level of the

RGB output signals to the ‘low’ reference current and not on the cut off point of the cathode. In this

way spreads in the picture tube characteristics will not be taken into account. In this condition the

settings of the “white point control registers” (subaddress 20H - 22H) and the “cathode drive level

bits” (CL3 - CL0 in subaddress 42H) are added to the settings of the RGB preset gain registers

(subaddress 23H - 25H).

A black level off-set can be made with respect to the level which is generated by the black

current stabilization system. In this way different colour temperatures can be obtained for the bright

and the dark part of the picture. The black level control is active on the Red and the Green output

signal. It is also possible to control the black level of the Blue and the Green output signal (OFB bit

= 1).

In the Vg2 adjustment mode (AVG = 1) the black current stabilization system checks the

output level of the 3 channels and indicates whether the black level of the highest output is in a

37

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

certain window (WBC-bit) or below or above this window (HBC-bit). This indication can be read

from the status byte 01 and can be used for automatic adjustment of the Vg2 voltage during the

production of the TV receiver. During this test the vertical scan remains active so that the indication

of the 2 bits can be made visible on the TV screen.

The control circuit contains a beam current limiting circuit and a peak white limiting circuit.

The control is realised by means of a reduction of the contrast and brightness control settings. The

way of control (first contrast and then brightness or contrast and brightness in parallel) can be

chosen by means of the CBS bit (subaddress 44H). The peak white level is adjustable via the

I2C-bus.

To prevent that the peak white limiting circuit reacts on the high frequency content of the video

signal a low-pass filter is inserted in front of the peak detector. The circuit also contains a

soft-clipper which prevents that the high frequency peaks in the output signal become too high. The

difference between the peak white limiting level and the soft clipping level is adjustable via the

I2C-bus in a few steps.

During switch-off of the TV receiver a fixed beam current is generated by the black current

control circuit. This current ensures that the picture tube capacitance is discharged. During the

switch-off period the vertical deflection can be placed in an overscan position so that the discharge

is not visible on the screen.

A wide blanking pulse can be activated in the RGB outputs by means of the HBL bit in

subaddress 43H. The timing of this blanking can be adjusted by means of the WBF/R bits in

subaddress 26H. In the LCD mode (AKB = 1 and LCD = 1) the wide blanking can also be activated.

1.9 Functional Description Sound Processor

The TV Sound Processor is a digital TV sound processor for analog multi-channel sound

systems in TV sets. It is based on a 24 bit DSP and designed to support several applications.

A new easy-to-use control concept was implemented for easiest configuration programming of

the very complex functionality of the TV Sound Processor. Pre-defined setups are available for all

implemented sound processing modes. A loudspeaker switching concept allows it to adapt the

pre-defined setups to the specific loudspeaker application.The built-in intelligence for pre-defined

standards and Auto Standard Detection (ASD) allows an easy setup of the demodulator and decoder

part.

38

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

The control concept for the audio processor is based on the following new features:

• Pre-defined setups for the sound processing modes like Dolby® Pro Logic® and Virtual Dolby®

Surround (422, 423)

• Flexible configuration of audio outputs to the loudspeaker configuration with an additional output

crossbar.

• Master volume function

The control concept for the demodulator and decoder (DEMDEC) is based on the following

new features:

• Easy demodulator setup for all implemented standards with Demodulator and Decoder Easy

Programming (DDEP) for a pre-selected standard or combined with Auto Standard Detection (ASD)

for automatic detection of a transmitted standard

• Automatic decoder configuration and signal routing depending on the selected or detected standard

• FM overmodulation adaptation option to avoid clipping and distortion.

1.10 Limitting values

2. SWITCH POWER IC (N901)

2.1 STR-W6753

2.2 Block Diagram

39

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

2.3 Functions of each terminal

40

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

2.4 Example Application Circuit

SERVICE MANUAL

2.5 Pin Configuration

41

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

2.6 Electrical characteristics in MOSFET

42

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

3. VERTICAL DEFLECTION BOOSTER (N401)

3.1 STV9302B (used in TV Model 1402/2108/21F08)

3.1.1 Main Features

■ Power Amplifier

■ Flyback Generator

■ Output Current up to 2.5 App

■ Thermal Protection

■ Stand –by Control

3.1.2 Description

The STV9325 is a vertical deflection booster designed for TV and monitor applications.

This device, supplied with up to 35 V, provides up to 2 .5 App output current to drive the

vertical deflection yoke

The internal flyback generator delivers flyback voltages up to 75 V.

In double supply applications, a stand-by state will be reached by stopping the (+)

supply alone.

3.1.3 Pin Configuration

43

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

3.1.4 Internal Block Diagram

44

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

3.1.5 Absolute Maximum Ratings

45

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

3.1.6 Electrical Characteristics

46

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

3.1.7 DC-coupled Application

When DC coupled , the display vertical position can be adjusted with input bias. On the other

hand, 2 supply sources (VS and -VEE) are required.

A Stand-by state will be reached by switching OFF the positive supply alone, In this

state,where both inputs are the same voltage as pin 2 ro higher, the output will sink negligible

current from the deviation coil.

47

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

3.1.7.1 Centering

3.1.7.2 Peak Current

3.1.7.3 Ripple Rejection

When both ramp signal and bias are provided by the same driver IC, you can gain natural

48

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

rejection of any ripple caused by a voltage drop in the ground, if you manage to apply the same

fraction of ripple voltage to both booster inputs. For that purpose, arrange an intermediate point in

the bias resistor bridge, such that (R8 / R7) = (R3 / R2), and connect the bias filtering capacitor

between the intermediate point and the local driver ground. Of course, R7 should be connected to

the booster reference point, which is the ground side of R1.

4. AUDIO POWER AMPLIFIER (N202)

4.1 TDA2615 (used in TV Model 1402/2108/21F08/21SL39)

TDA2615 is a 2 X 6 W hi-fi audio power amplifier.

4.1.1 Features

Requires very few external components

No switch -on/switch-off clicks

Input mute during switch -on and switch-off

Low offset voltage between output and ground

Excellent gain balance of both amplifiers

Hi -fi in accordance with “IEC 268” and “DIN 45500”

Short -circuit proof and thermal protected

Mute possibility.

4.1.2 General Description

49

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

The TDA2615 is a dual power amplifier in a 9-lead plastic single-in-line (SIL9MPF) medium

power package. It has been especially designed for mains fed applications, such as stereo radio and

stereo TV.

4.1.3 Quick Reference Data

4.1.4 Block Diagram

50

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

4.1.5 Functional Description

The TDA2615 is a hi-fi stereo amplifier designed for mains fed applications, such as stereo

radio and stereo TV. The circuit is optimally designed for symmetrical power supplies, but is also

well-suited to asymmetrical power supply systems.

An output power of 2 6 W (THD = 0.5%) can be delivered into an 8 load with a

symmetrical power supply of 12 V. The gain is internally fixed at 30 dB, thus offering a low gain

spread and a very good gain balance between the two amplifiers (0.2 dB).

A special feature is the input mute circuit. This circuit disconnects the non-inverting inputs

when the supply voltage drops below 6 V, while the amplifier still retains its DC operating

adjustment. The circuit features suppression of unwanted signals at the inputs, during switch-on and

switch-off.

The mute circuit can also be activated via pin 2. When a current of 300 A is present at pin 2,

the circuit is in the mute condition.

The device is provided with two thermal protection circuits. One circuit measures the average

temperature of the crystal and the other measures the momentary temperature of the power

transistors. These control circuits attack at temperatures in excess of +150 C, so a crystal

operating temperature of max. +150 C can be used without extra distortion.

With the derating value of 6 K/W, the heatsink can be calculated as follows:

at RL = 8 and VS = 12 V, the measured maximum dissipation is 7.8 W.

4.1.6 Pin Configuration

51

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

4.1.7 Pinning

SERVICE MANUAL

5. EEPROM 24C16 (N602)

5.1 Features

• Write Protect Pin for Hardware Data Protection

– Utilizes Different Array Protection Compared to the AT24C16A

• Low-voltage and Standard-voltage Operation

– 2.7 (VCC = 2.7V to 5.5V)

52

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

• Internally Organized 2048 x 8 (16K)

• 2-wire Serial Interface

• Schmitt Trigger, Filtered Inputs for Noise Suppression

• Bi-directional Data Transfer Protocol

• 400 kHz (2.7V) Clock Rate for AT24C16A

• 16-byte Page Write Modes

• Partial Page Writes are Allowed

• Self-timed Write Cycle (10 ms Max)

• High Reliability

– Endurance: One Million Write Cycles

– Data Retention: 100 Years

• Automotive Grade, Extended Temperature and Lead-Free Devices Available

• 8-lead PDIP Packages

5.2 Description

The AT24C16A provides 16384 bits of serial electrically erasable and programmable read only

memory (EEPROM) organized as 2048 words of 8 bits each. In the AT24C16A, the 16K is

internally organized with 128 pages of 16 bytes each. Random word addressing requires an 11-bit

data word address.

The device is optimized for use in many industrial and commercial applications where low

power and low voltage operation are essential. The AT24C16A is available in space saving 8-lead

PDIP package and is accessed via a 2-wire serial interface. In addition, the AT24C16A is available

in 2.7V (2.7V to 5.5V) supply.

5.3 Pin Configurations

53

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

5.4 Block Diagram

SERVICE MANUAL

5.5 Pin Description

SERIAL CLOCK (SCL): The SCL input is used to positive edge clock data into each EEPROM

device and negative edge clock data out of each device.

54

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

SERIAL DATA (SDA): The SDA pin is bidirectional for serial data transfer. This pin is open-drain

driven and may be wire-ORed with any number of other open-drain or open collector devices.

DEVICE/PAGE ADDRESSES (A2, A1, A0): The A2, A1 and A0 pins are device address inputs.

The AT24C16A does not use the device address pins, which limits the number of devices on a

single bus to one. The A0, A1 and A2 pins are no-connects.

WRITE PROTECT (WP): The AT24C16A has a Write Protect pin that provides hardware data

protection. The Write Protect pin allows normal read/write operations when connected to ground

(GND). When the Write Protect pin is connected to VCC, the write protection feature is enabled and

operates as shown in the following table.

5.6 Device Operation

Clock and Data Transitions: The SDA pin is normally pulled high with an external device. Data

on the SDA pin may change only during SCL low time periods. Data changes during SCL high

periods will indicate a start or stop condition as defined below.

Start Condition: A high-to-low transition of SDA with SCL high is a start condition which must

precede any other command.

Stop Condition: A low-to-high transition of SDA with SCL high is a stop condition. After a read

sequence, the stop command will place the EEPROM in a standby power mode.

55

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

Acknowledge: All addresses and data words are serially transmitted to and from the EEPROM in 8

bit words. The EEPROM sends a zero to acknowledge that it has received each word. This happens

during the ninth clock cycle.

Standby Mode: The AT24C16A features a low power standby mode which is enabled: (a) upon

power-up and (b) after the receipt of the STOP bit and the completion of any internal operations.

Memory Reset: After an interruption in protocol, power loss or system reset, any 2-wire part can be

reset by following these steps: (a) Clock up to 9 cycles, (b) look for SDA high in each cycle while

SCL is high and then (c) create a start condition as SDA is high.

56

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

POWER IC

Vertical circuit

IF

AV1/SVHS input

5V

+9V +B

+21V

I²C

AV2/YCbCr input

Horizontal

TV BLOCK DIAGRAM

RF

TUNERR

SAW

FILT

ER

AV output

24C16

I²C

UOC III

TDA12062H1/N1F00

TDA2615

R,G,B

+12V -12V

CRT

BOARD

Speaker

CR

T

STV9325A

circuit

+5V

-12V +12V +8V

~220

STR6753

+B

+21V

57

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

Appendix 1: Schematic Circuit Diagram

1. Main Board 35009395

2. CRT Board 35008607

58

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

Appendix 2: PCB Layout Diagram

1. Main Board 35009395

59

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

2. CRT Board 35008607

60

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

61

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

Appendix 3: Exploded Views

62

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SERVICE MANUAL

63

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

PDF 文件以 "PDF 制作工厂" 试用版创建 http://www.fineprint.com

PDF 文件以 "PDF 制作工厂" 试用版创建 http://www.fineprint.com

36033109

36031314

36031315

36033108

KS21TK305AASSEMBLY

CAM350 PRO V 7.0 : Fri Jul 14 14:22:01 2006 - (Untitled)

PDF 文件以 "PDF 制作工厂" 试用版创建 ÿ http://www.fineprint.com

CAM350 PRO V 7.0 : Fri Jul 14 14:22:44 2006 - (Untitled)

PDF 文件以 "PDF 制作工厂" 试用版创建 ÿ http://www.fineprint.com

Loading...

Loading...