Page 1

Post-Flight Inspection and Cleaning

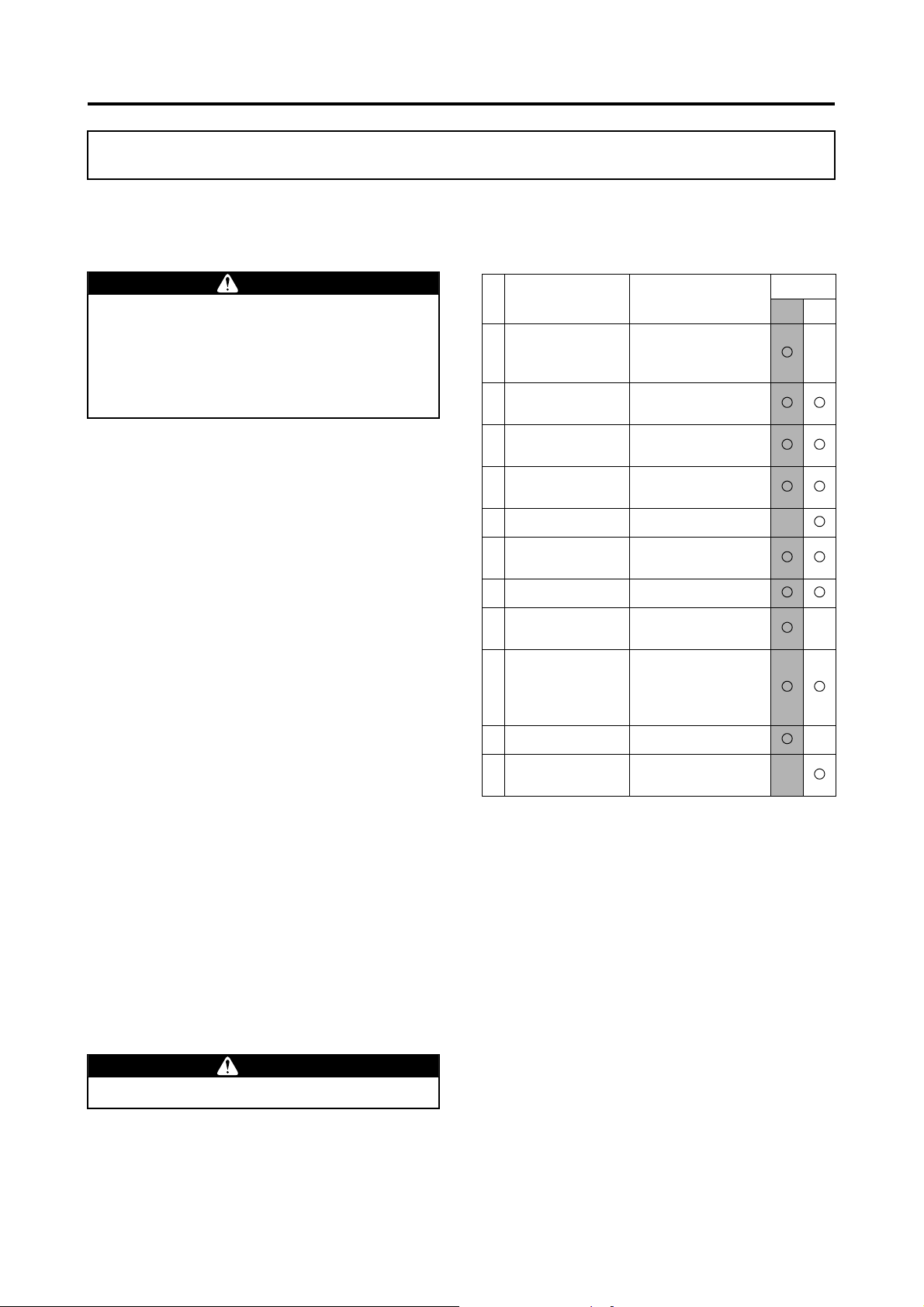

Post-flight Inspection ................................................................ 6-1

Fuel Inspection ...................................................................................6-1

Coolant and Oil Inspections ..............................................................6-2

Rotor Blade Inspection ......................................................................6-2

Air Cleaner Inspection .......................................................................6-3

Servo and Linkage Inspection ...........................................................6-3

Self Monitor Inspection ......................................................................6-4

Tail Rotor Drive Belt Inspection ........................................................6-4

Antenna Inspection ............................................................................6-4

Post-Flight Cleaning and Servicing ......................................... 6-5

Washable Areas ..................................................................................6-6

Non-Washable Areas ..........................................................................6-7

6

Page 2

Post-Flight Inspection and Cleaning

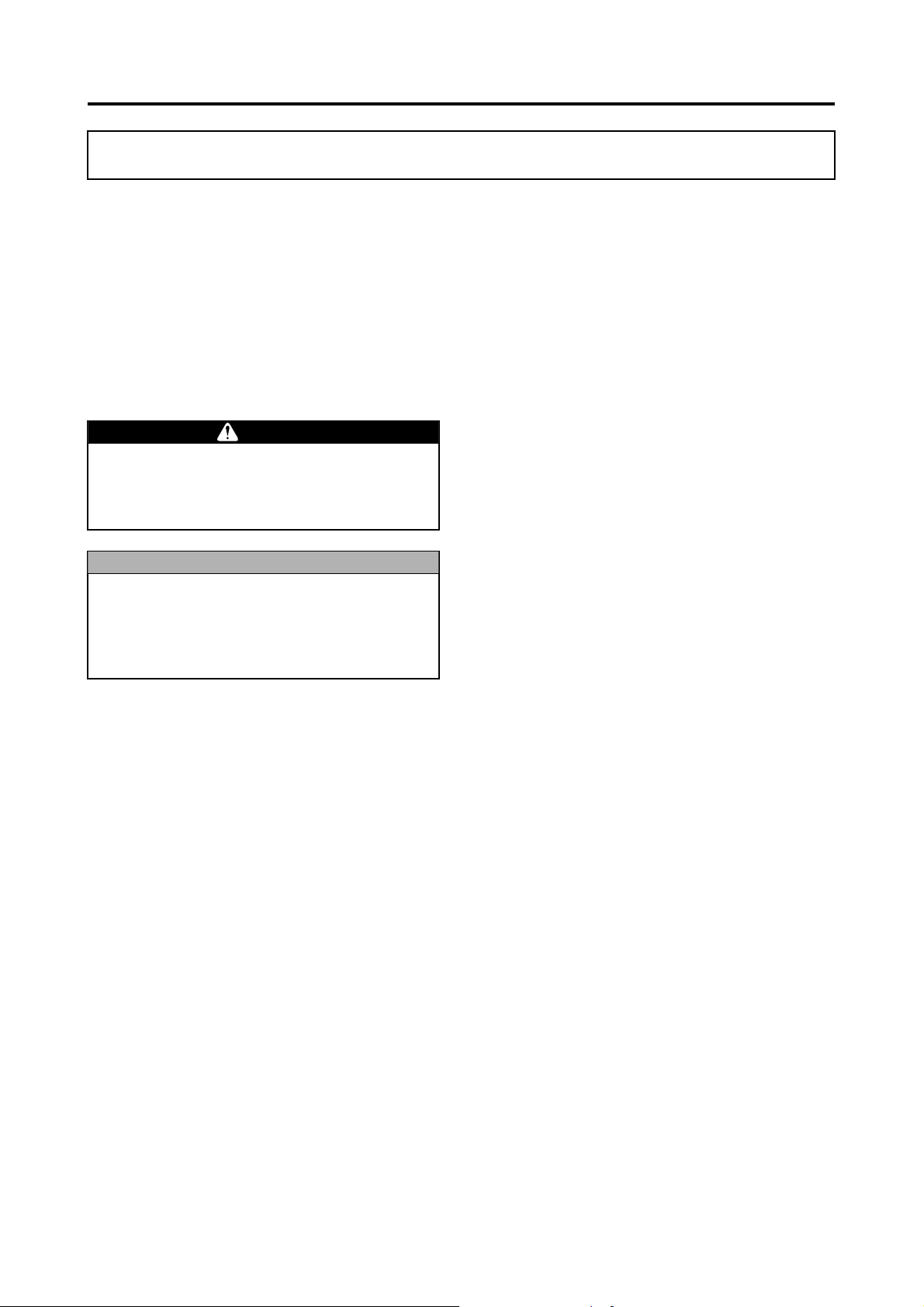

Post-flight Inspection

In preparation for the next flight, inspect the helicopter and make sure each area is free of problems. In addition, enter the results in the flight

inspection log.

WARNING

● To prevent injury, make sure the engine is

stopped before performing an inspection.

● The helicopter is very hot immediately

after a flight. To prevent burns, allow the

temperature of the helicopter to lower sufficiently before performing an inspection.

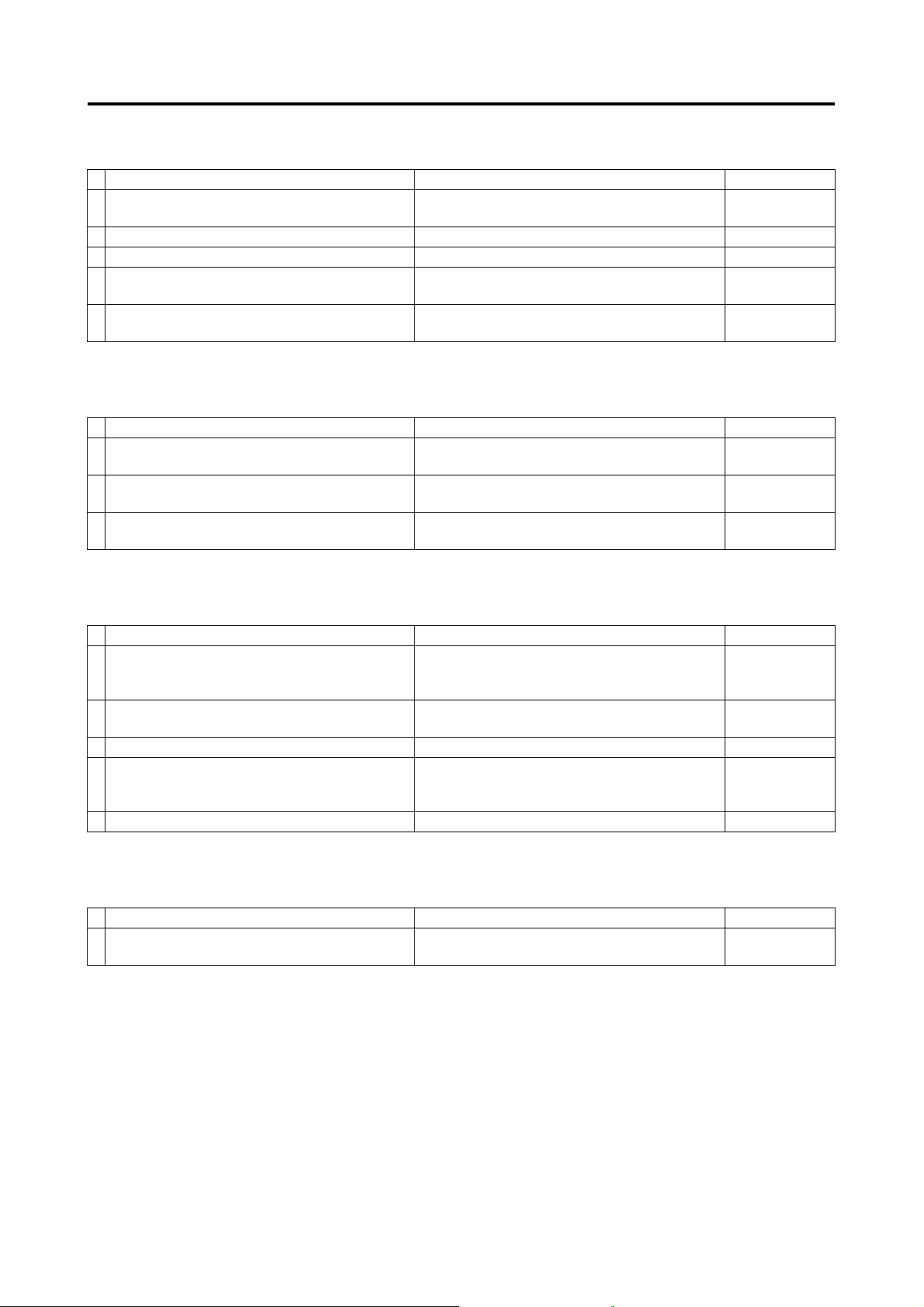

Inspection Point Inspection Items

• Battery Level

Transmitter

1 Fuel

2 Coolant, oil

3 Rotor blades

4 Air cleaner

• Operation

• Antenna installation

• Level

• Leakage

• Level

• Leakage

• Dirtiness, damage

• Movement

• Dirtiness

Flight

Pre Post

Fuel Inspection

Inspect for fuel leakage.

Before performing this inspection, turn OFF both

the main switch for the helicopter and the power

switch for the transmitter.

For details, see page 4-19.

Servo, linkage

5

(rudder, throttle)

6 Self monitor

Radio signal

distance test

7 Tail rotor drive belt

GPS system

8 Antenna

• Operation

• Wobble

• States of lighting

• Radio signal reach

• Tension

• Abnormal noise

• Wear, damage

• Refuel

• States of lighting

• Installation state

• Rust

If you discover any fuel leakage, request a repair by

your dealer before the next flight.

WARNING

Fuel leakage could lead to a fire.

6-1

Page 3

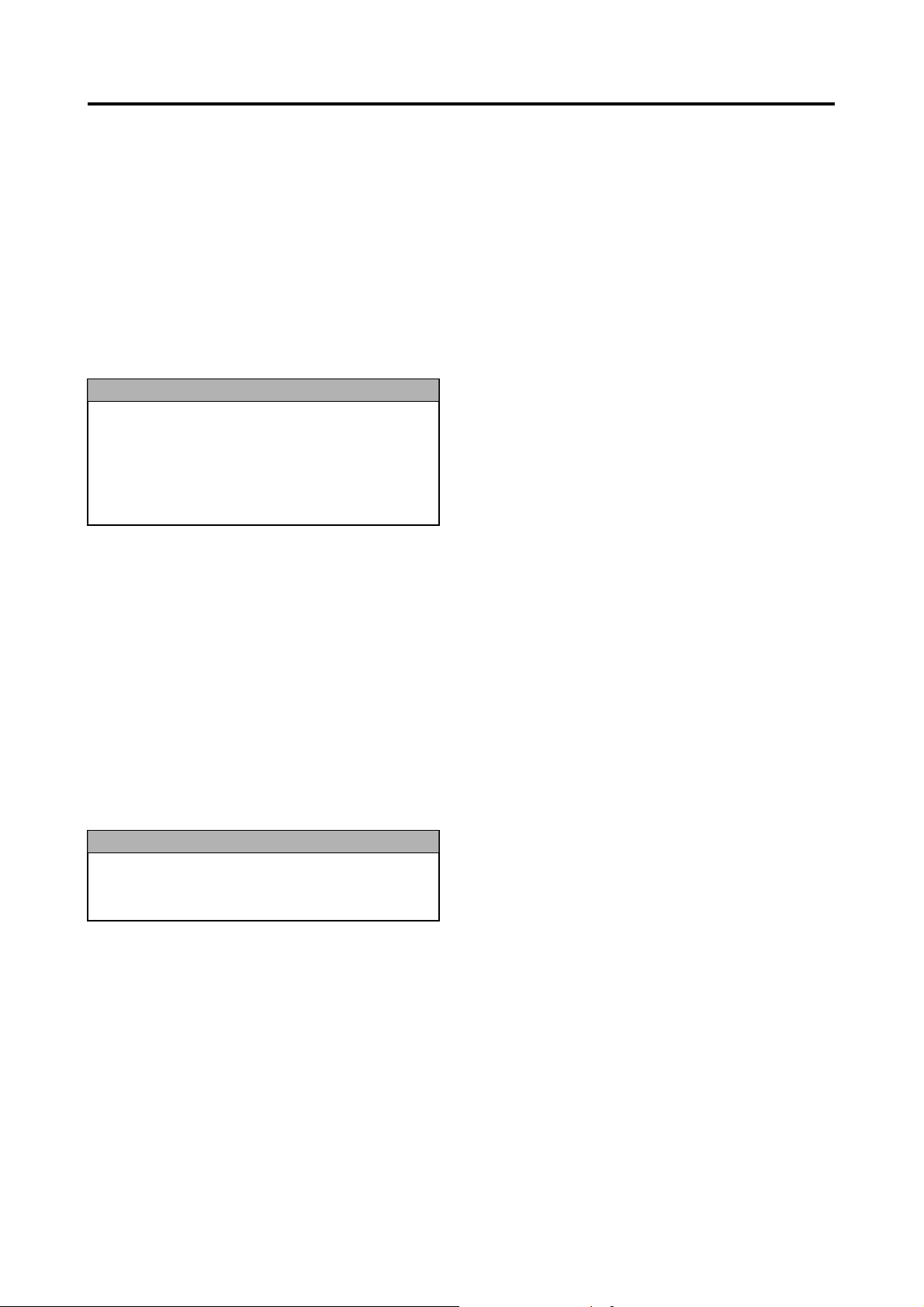

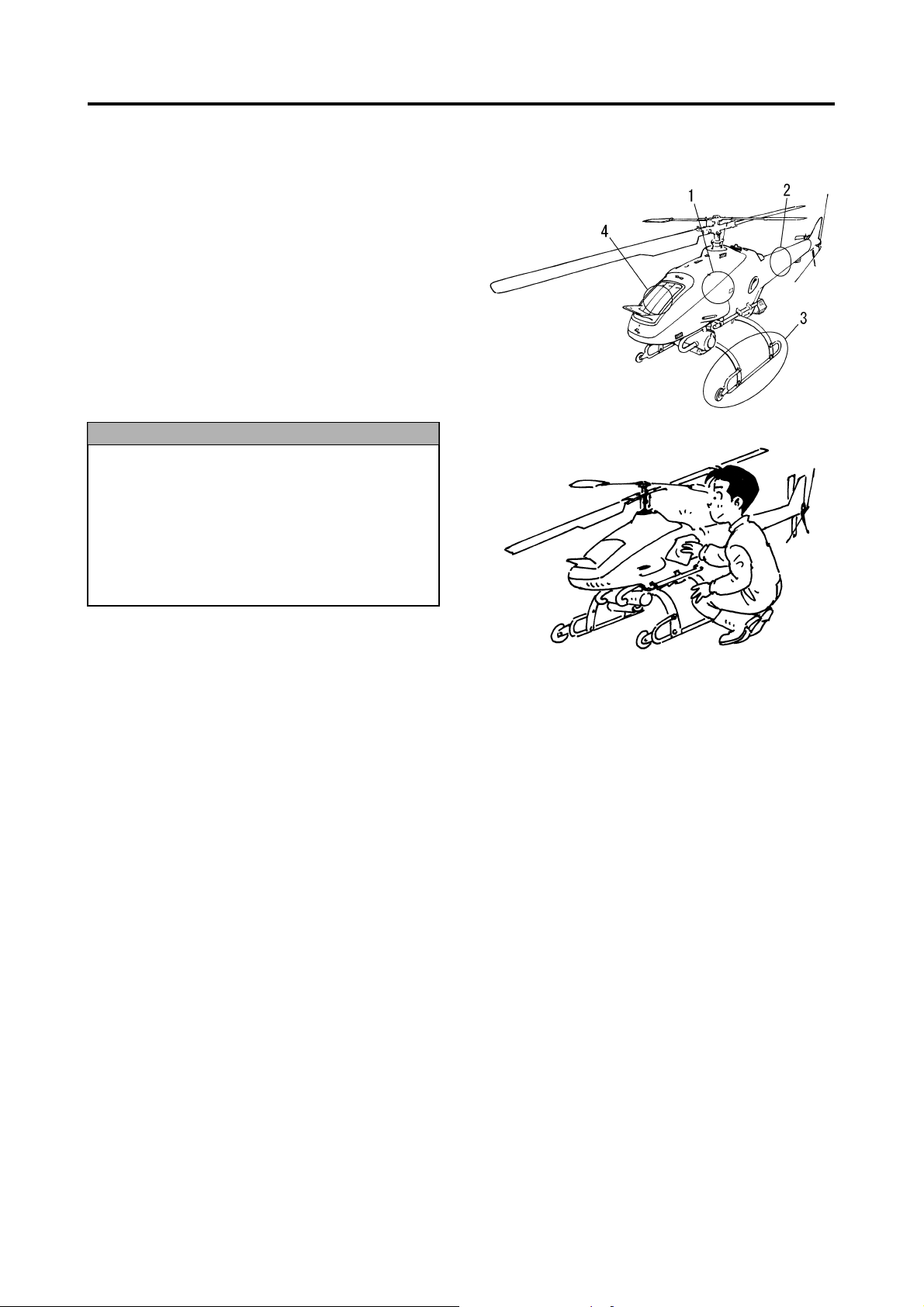

Coolant and Oil Inspections

Inspect the coolant level and check for any coolant

or oil leakage.

Before performing this inspection, turn OFF both

the main switch for the helicopter and the power

switch for the transmitter.

For details, see page 4-20.

A slight stain of coolant or oil does not indicate an

abnormal condition. However, if there are any drops

of coolant or oil leaking, request a repair by your

dealer before the next flight.

NOTICE

● Coolant leakage will adversely affect the

cooling performance of the helicopter and

cause it to overheat.

● Transmission oil leakage will reduce the

internal lubrication of the transmission

and damage the gears and bearings.

Post-Flight Inspection and Cleaning

Rotor Blade Inspection

Inspect the rotor blades for damage, dirtiness, and

movement.

Before performing this inspection, turn OFF both

the main switch for the helicopter and the power

switch for the transmitter.

For details, see page 4-22.

If a rotor blade’s surface is dirty, use household

detergent on a soft cloth, wring out the cloth first,

and use it to wipe the rotor blade’s surface.

If a rotor blade is damaged, request a repair by your

dealer before the next flight.

NOTICE

If a main or tail rotor blade does not move

smoothly or is damaged, it could generate

noise or vibration.

6-2

Page 4

Post-Flight Inspection and Cleaning

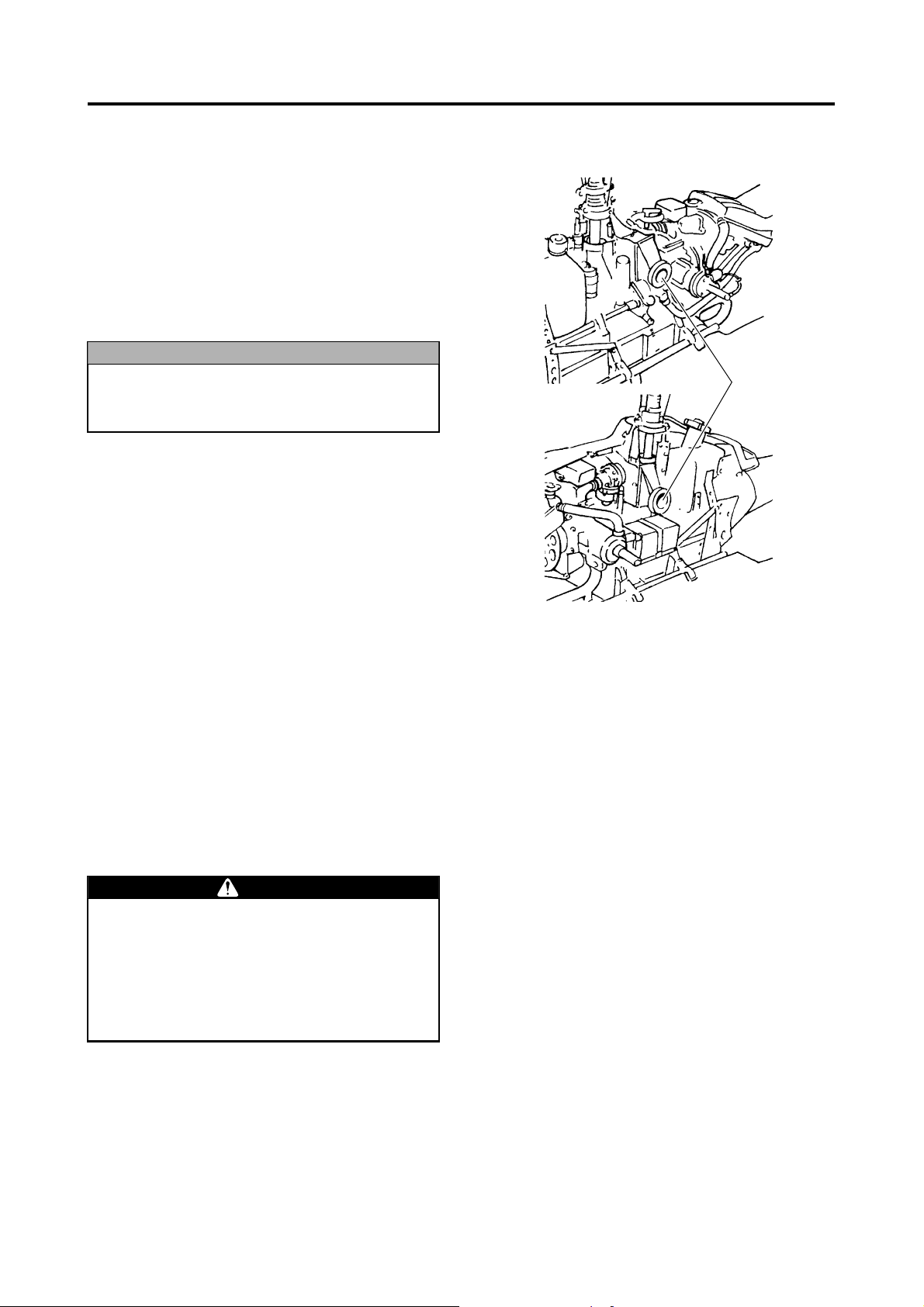

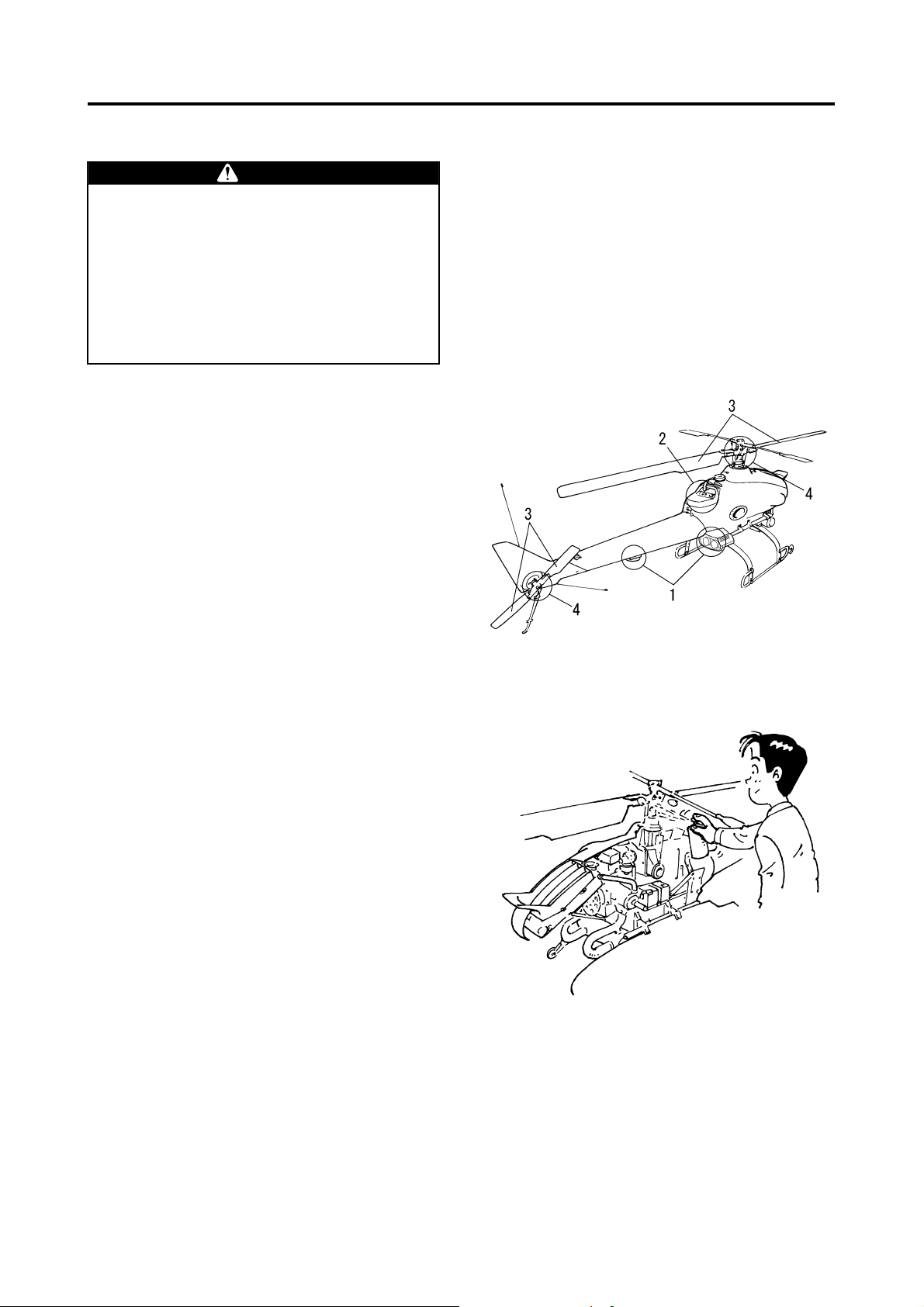

Air Cleaner Inspection

Inspect the air cleaner element for dirtiness.

Before performing this inspection, turn OFF both

the main switch for the helicopter and the power

switch for the transmitter.

Make sure the air cleaner element is free of debris,

dust, pollen, etc.

However, if the air cleaner element is dirty, replace

air cleaner with new ones before the next flight.

NOTICE

A dirty or clogged air cleaner element will

adversely affect the performance of the

engine.

Air cleaner

Servo and Linkage Inspection

Inspect the servos and linkages for proper operation.

Before performing this inspection, turn the power

switch for the transmitter to ON and the main switch

for the helicopter to START.

For details, see page 4-23.

If the servos operate abnormally or the linkages

wobble, request a repair by your dealer before the

next flight.

WARNING

● If the servos operate abnormally or the

linkages wobble, they could adversely

affect the control of the helicopter.

● If the throttle operates abnormally, it could

adversely affect engine control, which

could cause the helicopter to go out of

control.

6-3

Page 5

Self Monitor Inspection

Inspect the illumination of the indicator lights on the

self monitor for proper operation.

Before performing this inspection, turn the power

switch for the transmitter to ON and the main switch

for the helicopter to START.

For details, see the table on page 3-5.

If the lights illuminate abnormally, request a repair

by your dealer before the next flight.

WARNING

Take the appropriate actions in accordance

with the indicator lights. By ignoring the

lights and continuing to fly, you will lose control of the helicopter and cause a serious

accident.

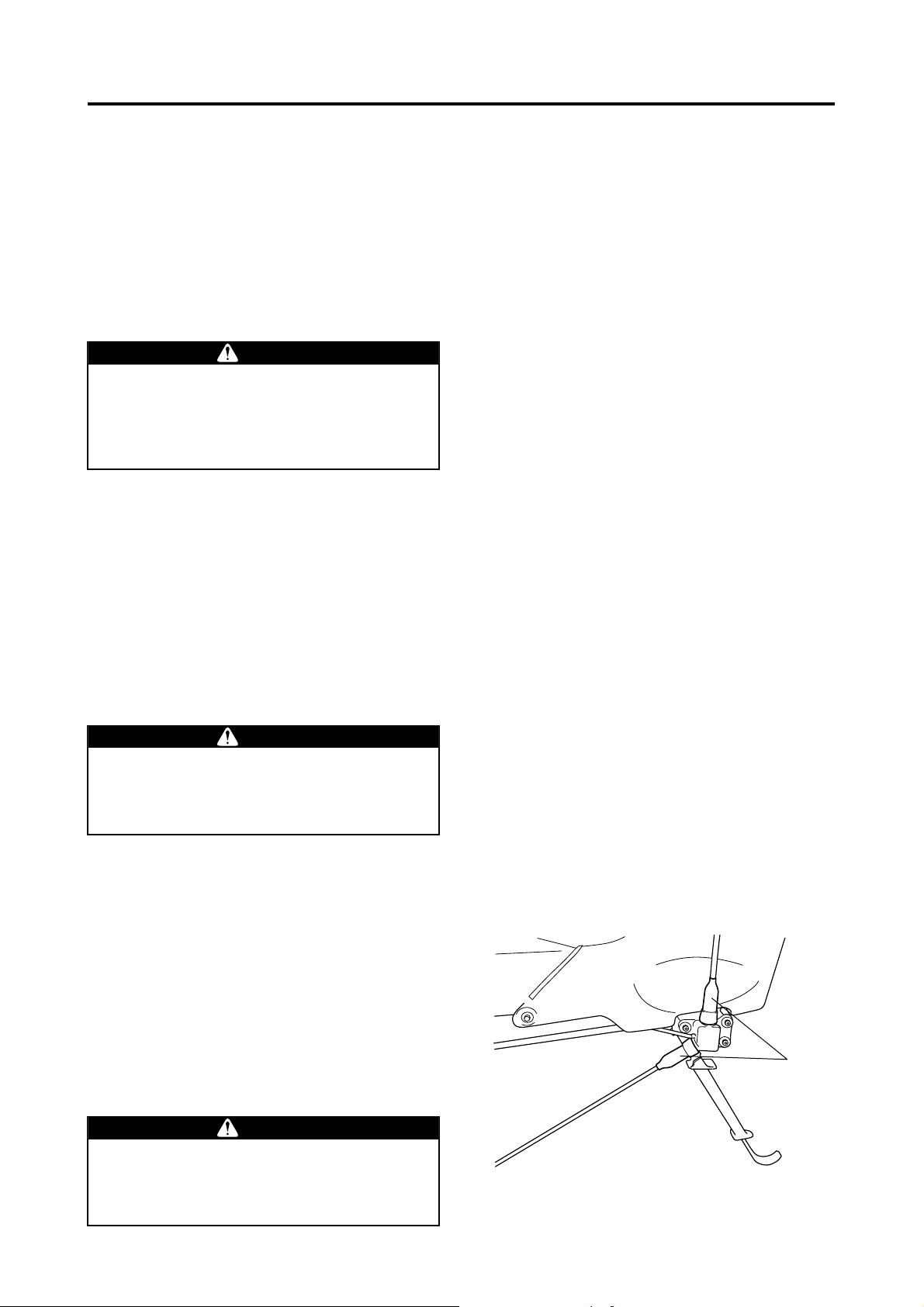

Tail Rotor Drive Belt Inspection

Post-Flight Inspection and Cleaning

Inspect the condition of the tail rotor drive belt and

apply lubricant to the belt.

Before performing this inspection, turn OFF both

the main switch for the helicopter and the power

switch for the transmitter.

For details, see page 4-25.

If there is a problem with the belt, request a repair

by your dealer before the next flight.

WARNING

If there is a problem with the tail rotor drive

belt, it could adversely affect the actuation of

the tail rotor, which could cause the helicopter to go out of control.

Antenna Inspection

Inspect the antenna to make sure it is not loose or

rusted at the area where it is mounted to the helicopter.

Before performing this inspection, turn OFF both

the main switch for the helicopter and the power

switch for the transmitter.

Peel the dust cover from the base of each antenna

pole and make sure the antenna poles are not

loose or rusted.

If they are loose or rusted, request a repair by your

dealer before the next flight.

WARNING

If the antenna is loose or rusted, it will affect

the reception of control signals, which could

cause the helicopter to go out of control during flight.

Dust Covers

6-4

Page 6

Post-Flight Inspection and Cleaning

Post-Flight Cleaning and Servicing

Agricultural chemicals, dust, dead bugs, and pollen

could adhere to the helicopter after an aerial application.

If they remain stuck to the helicopter, they will

cause a chemical reaction, which will lead to rust,

insufficient lubrication, sealant deterioration, and

discoloring.

To prevent these problems, use the methods

described below to clean and service the helicopter

after a flight, in preparation for the next flight. While

cleaning, check all areas of the helicopter for any

damage, abnormal wear, loose fasteners, etc.

WARNING

The helicopter is very hot immediately after a

flight. Therefore, to prevent burns, clean it

only after its temperature has lowered sufficiently.

NOTICE

Washing the helicopter with water will cause

a sudden change in temperature, which

could create problems in electrical parts.

Therefore, clean it only after its temperature

has lowered sufficiently.

6-5

Page 7

Washable Areas

1 Side covers

They may be washed only after they have been

removed from the helicopter.

Do not wash them in the installed state because

the water could splash on other parts.

2 Tail body

Clean it carefully while making sure to prevent

the GPS system and the gyro sensor from direct

contact with water.

3 Leaves and runners

4Radiator

Clean it by using caution not to damage the fins.

NOTICE

Do not use a high-temperature, high-pressure cleaner to clean areas 1 to 4 above, as it

could damage the film and paint on the surface.

After cleaning the washable areas of the helicopter with water, ensure to wring out your

cloth before you wipe the moisture off the

surface.

Post-Flight Inspection and Cleaning

6-6

Page 8

Post-Flight Inspection and Cleaning

Non-Washable Areas

WARNING

The helicopter and the transmitter have a

drip-proof construction and not a water-proof

construction. Therefore, do not use water

directly on areas other than those indicated

in the previous section.

Failure to observe this precaution could

cause the electric parts or the sliding areas

to malfunction, which could lead to a serious

accident.

1 GPS System and Azimuth sensor

Washing these areas with water will cause them

to malfunction as a result of exposure of the

internal components to water.

Therefore, use a soft, moist cloth that has been

wrung out to wipe the dirty areas.

2 Control Panel

Washing these areas with water will cause the

hour meter, GPS antenna, switches, and the

monitor lights to malfunction as a result of exposure of the internal components to water.

Therefore, use a soft, moist cloth that has been

wrung to wipe the dirty areas.

3 Main and Tail Rotor Blades

Washing these areas with water will cause the

rotors to lose their balance and create vibrations

as a result of exposure of the internal components to water.

If the rotor surface is dirty, use household detergent on a soft cloth, wring the cloth, and use it to

wipe the rotor surface.

4 Main and Tail Rotor Head Areas

Washing these areas with water will adversely

affect the lubrication of the bearings and slides,

which could damage or wear those parts.

Therefore, use a soft, moist cloth that has been

wrung out to wipe the dirty areas.

Apply a small amount of the dealer-specified

anti-rust lubricant to the bearings, rod ends, and

sliding portions of parts, and then wipe them with

a dry cloth.

6-7

Page 9

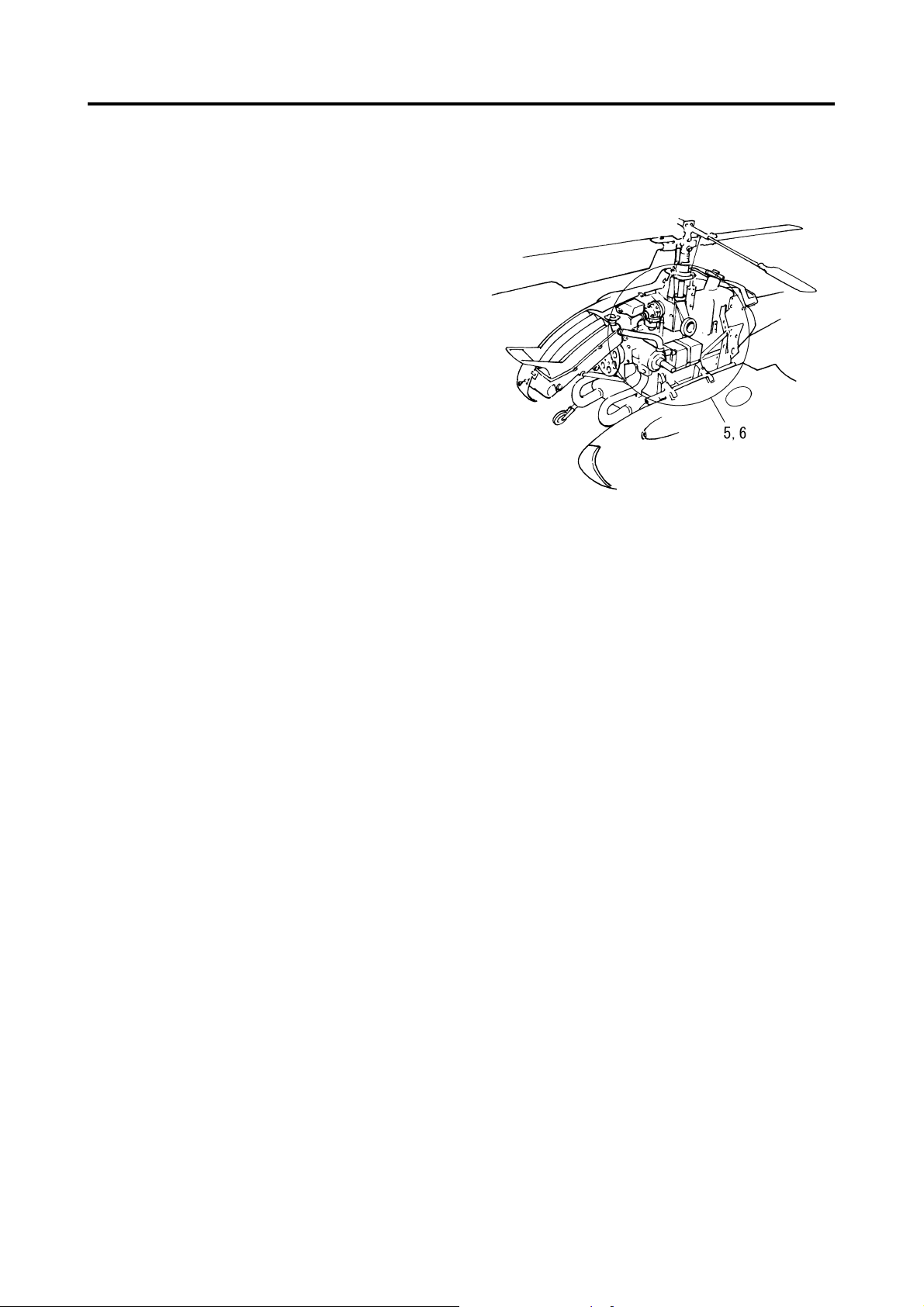

5 Servos and Electrical Parts

Washing these areas with water will cause them

to malfunction as a result of exposure of the

internal components to water.

6 Frame

Washing this area with water will cause the

YACS control to malfunction as a result of exposure of the internal electric components to water.

Therefore, use a soft, moist cloth that has been

wrung out to wipe the dirty areas.

7 Flight Transmitter

Washing this area with water will cause the

transmitter to malfunction as a result of exposure

of the internal switches and electric components

to water. Therefore, use a soft, moist cloth that

has been wrung out to wipe the dirty areas.

Post-Flight Inspection and Cleaning

6-8

Page 10

Post-Flight Inspection and Cleaning

6-9

Page 11

Simple Maintenance

Battery Recharging Procedure ................................................. 7-1

7

Page 12

Simple Maintenance

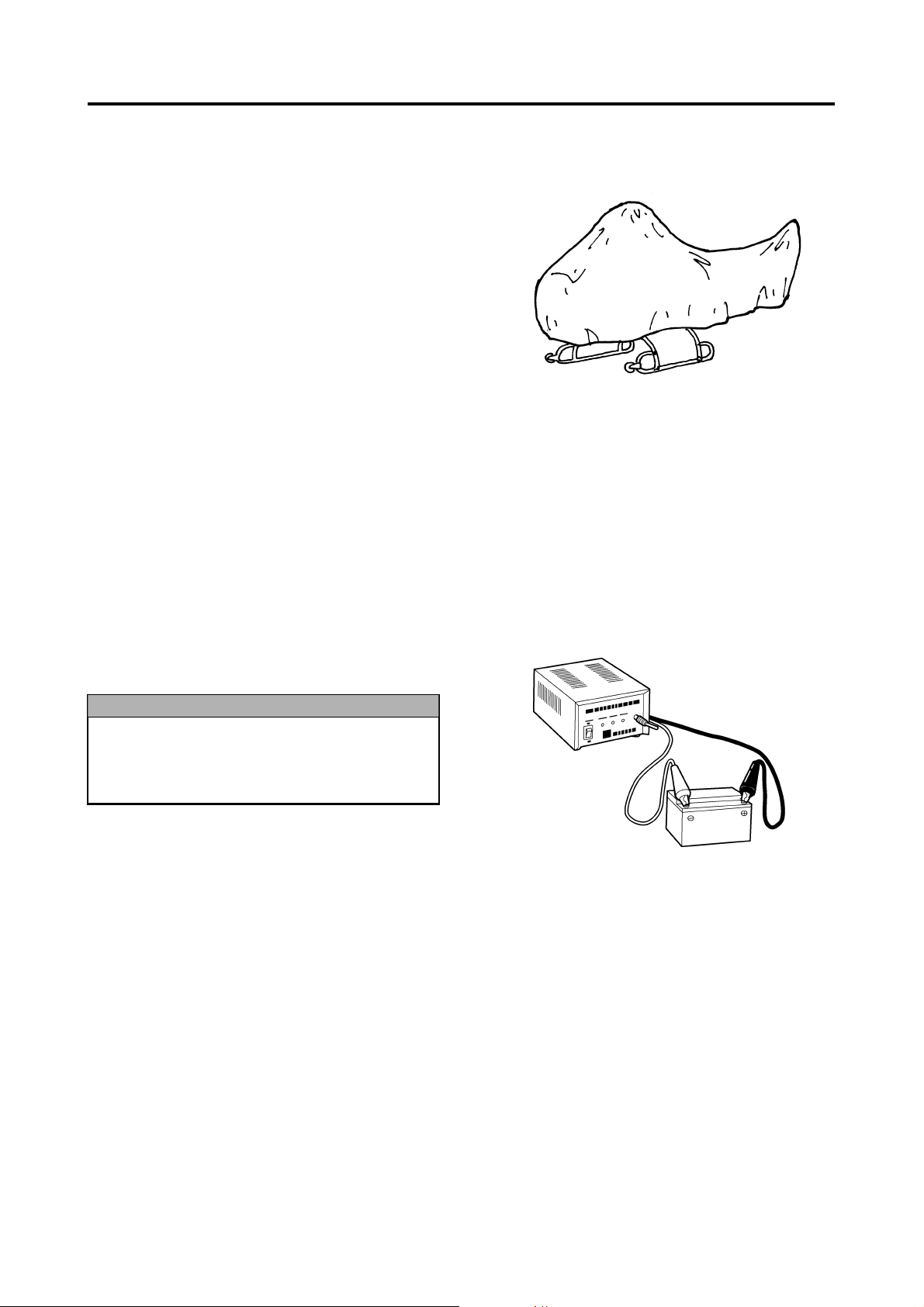

Battery Recharging Procedure

This helicopter uses a sealed battery.

It is not necessary to refill or inspect the battery

fluid.

If there is any abnormality in the battery, request a

repair by your dealer.

WARNING

The battery produces flammable gas (hydrogen gas). Mishandling it could lead to an

explosion resulting in injuries. Make sure to

observe the following:

● Fire is strictly prohibited. Do not short a

circuit, cause a spark, or let any fire such

as cigarettes come near. This could cause

an explosion.

● Do not connect to the battery terminals in

the wrong order. Doing so could cause a

fire.

● Recharge in a well ventilated place.

● Keep gasoline, oil, or organic solvent from

getting on the battery, as this could cause

the battery case to crack.

● Do not drop it or apply any other strong

impact.

● The battery fluid is diluted sulfuric acid.

Contact with the skin, eye, or clothing

could lead to a serious injury.

● Keep out of reach of children.

First Aid

● In the unlikely event that the battery fluid

gets on the skin, clothing, etc., immediately rinse with copious amounts of water.

● If it enters the eye, immediately rinse it

with copious amounts of water, and seek

medical attention.

+Terminal (red cap) -Terminal (black cap)

Battery Battery Support Strap

7-1

NOTICE

● This is a sealed 12V battery.

● This battery has been filled with fluid and

charged. No fluid level inspection or refilling is necessary.

● For recharging, use the dedicated sealed

battery recharger. Contact your dealer for

details.

● If the battery is to be left unused for a long

time, remove the battery from the helicopter, and recharge every 3 months.

● When replacing the battery, make sure to

use a genuine battery.

Page 13

Removing the Battery

1 Make sure to turn OFF the main switch on the

control panel.

2 Disconnect the negative - and positive + termi-

nals of the battery, in that order.

3 Remove the battery support strap and take the

battery out of the helicopter.

Reinstalling the Battery

Reinstall the battery in reverse order of removal.

TIP

● Batteries are consumables.

● The battery should be replaced every year.

Simple Maintenance

7-2

Page 14

Simple Maintenance

7-3

Page 15

Proper Management

Storage Precautions .................................................................. 8-1

Daily Storage Procedure ....................................................................8-2

Long-Term Storage Procedure ..........................................................8-2

Operating the Helicopter After Long-Term Storage ........................8-3

Other Types of Management .................................................... 8-5

8

Page 16

Proper Management

This unmanned helicopter for industrial applications

has been manufactured for the purpose of aerial

application of agricultural chemicals, fertilizers, and

seeds.

Secure a storage location for the helicopter and its

auxiliary devices, to prevent theft and illegal use

outside of its intended purpose, such as criminal

acts.

As a measure to prevent illegal use, this product is

equipped with the following features:

• Areas of use are limited

• Specified operation period

• Specified total operation time

Storage Precautions

To select a storage site, consider factors such as

sources of fire or spark, temperature, humidity,

dust, theft, and the presence of any stacked loads

in the area.

We recommend that you provide a dedicated cabinet for storing the auxiliary devices.

In addition to protecting the helicopter from damage

and theft, or the auxiliary devices from loss, these

measures will facilitate the monitoring of their maintenance conditions and ensure efficient preparation

for the next flight.

1 Store the helicopter, rotors, and transmitters in

separate, lockable locations so that they will not

be stolen or subject to other criminal acts.

2 If the helicopter is stolen, immediately report the

theft to your dealer. Then, contact your local

police department.

8-1

Page 17

Daily Storage Procedure

1 Perform “Post-flight Inspection” (P6-1) and

record the results in the flight log.

2 Clean the helicopter. (See page 6-5.)

3 Place the helicopter cover (sold separately) and

store it indoors, in an area that is not damp.

4 Clean the flight transmitter and remove its bat-

tery. (See page 4-2.)

Long-Term Storage Procedure

If the helicopter will not be operated for a few

months, follow the storage procedure given below

in preparation for the subsequent operation.

Proper Management

1 Perform “Post-flight Inspection” (P6-1) and

record the results in the flight log.

2 Clean the helicopter. (See page 6-5.)

3 Remove the onboard battery and recharge it with

a dedicated recharger. (See page 7-1.)

After recharging, store the battery in a cool and

dark location, and recharge it every 3 months.

NOTICE

To disconnect the battery, first disconnect its

negative terminal, followed by the positive

terminal. Reversing this order could cause

the battery to short.

4 Fuel must be drained from the fuel tank and the

carburetor. Request the performance of this

operation by your dealer.

5 Place the helicopter cover and store it indoors, in

an area that is not damp.

6 Clean the flight transmitter and remove its bat-

tery. Store the battery in a cool and dark location.

8-2

Page 18

Proper Management

Operating the Helicopter After Long-Term Storage

TIP

● Have a periodic inspection performed on

the helicopter if you will be operating it

after prolonged storage of 1 year or more.

● Contact your dealer for details.

To operate the helicopter after storing it for a few

months, perform the following preparations:

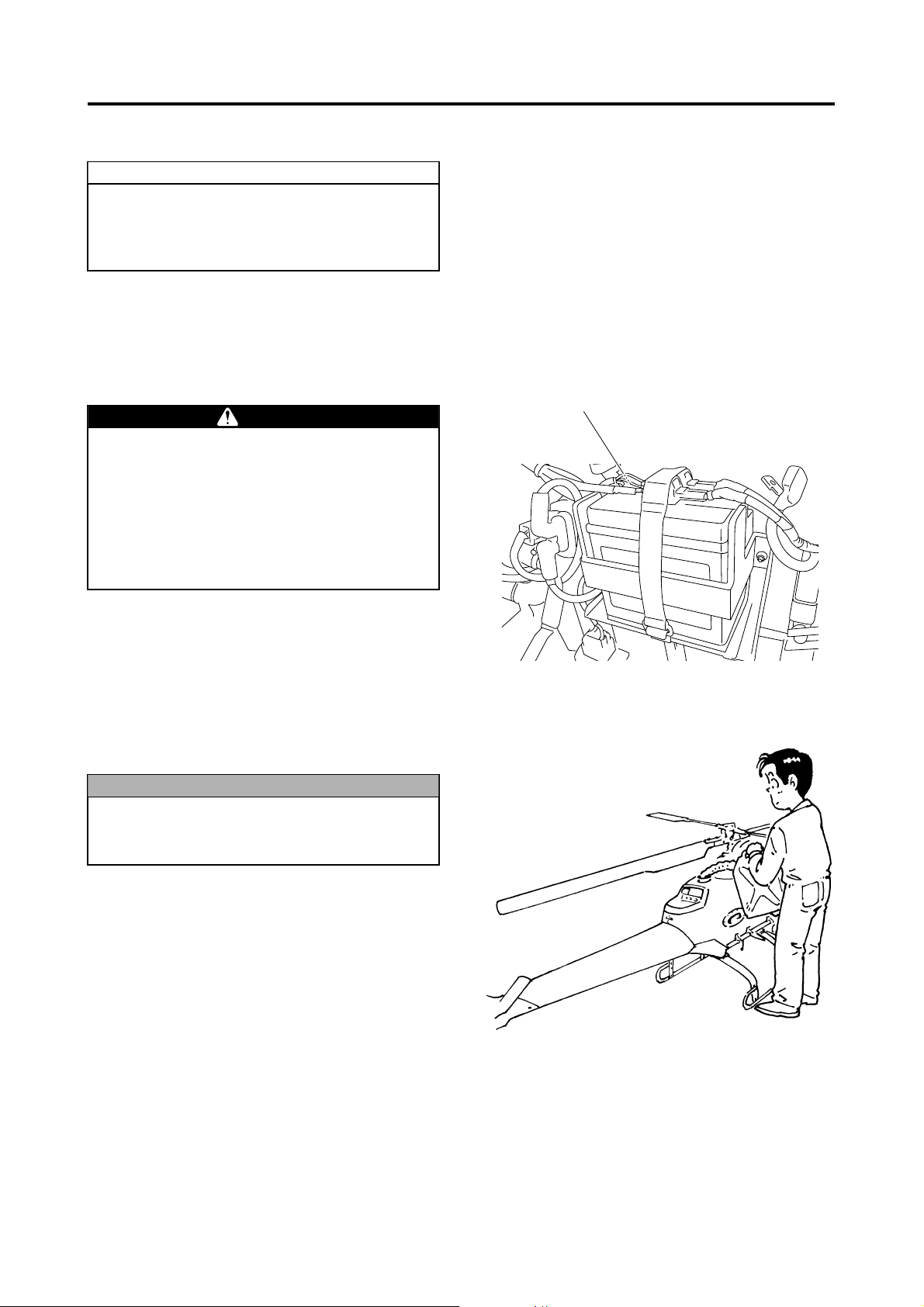

1 Install fully charged batteries in the helicopter

and the flight transmitter, after making sure the

main switch on the helicopter is turned OFF.

WARNING

● Do not interchange the positive and negative poles when connecting the battery terminals, as it could cause a fire or

malfunction.

● To connect the battery, first connect its

positive terminal, followed by the negative

terminal. Reversing this order could cause

the battery to short.

Connect the positive terminal first

2 Prepare fresh fuel and pour it in the fuel tank.

(See page 4-4.)

NOTICE

Never use old leftover fuel.

This could cause the engine to stop or operate poorly

8-3

Page 19

3 Perform pre-flight inspections. (See page 4-17.)

4 Start the engine. After prolonged storage, the

engine will be hard to start because it will take a

while for the fuel to reach the carburetor.

TIP

If the engine does not start within 5 seconds

after you have pressed the starter switch,

wait about 10 seconds to allow the battery

voltage to recover. Then, press the starter

switch again.

Repeat the cycle of operating the starter motor for 5

seconds and waiting 10 seconds, 4 or 5 times. This

will allow the fuel to reach the carburetor and the

engine to start.

Proper Management

8-4

Page 20

Proper Management

Other Types of Management

This helicopter and some parts fall under the listcontrolled items of Japan’s “Foreign Exchange and

Foreign Trade Act”. Use sufficient care to ensure

that the list-controlled items are not stolen or lost.

8-5

Page 21

Troubleshooting

Engine ......................................................................................... 9-1

Helicopter ................................................................................... 9-4

YACS ........................................................................................... 9-6

GPS ............................................................................................. 9-7

Flight Transmitter ...................................................................... 9-8

Sprayer ....................................................................................... 9-9

9

Page 22

Troubleshooting

The problems listed here can be handled primarily

by the user.

Problems or causes that are not listed here are

handled by your dealer. If such problems occur,

cancel the flight and contact your dealer to have the

helicopter inspected and repaired.

● Make sure to follow the instructions given

in the “User Action” column, and do not

take any actions that are not called for.

● If you have any questions, be sure to contact your dealer. If an inspection, adjustment, or part replacement is performed by

a person who does not possess the knowhow and proficiency to service the helicopter, it could lead to a serious accident.

WARNING

Engine

Starter motor does not operate

Main Cause User Action Remarks

Main switch on the helicopter is not turned to

1

START.

2 Power switch of the flight transmitter is not ON. Turn ON the power switch of the flight transmitter. See page 5-3.

Throttle stick on the flight transmitter is not in the

3

SLOWEST position.

4 Decompression is not operating. Operate the decompression lever. See page 5-5.

5 Helicopter battery terminals are loose. Firmly tighten the battery terminals. See page 7-1.

6 Onboard battery is faulty.

Turn the main switch on the helicopter to START. See page 5-3.

Move the throttle stick of the flight transmitter to

the SLOWEST position.

Recharge the battery with a dedicated recharger,

or replace it.

See page 5-5.

See page 7-1.

The starter motor does not operate, and all 3 flight indicator lights,

“”, “”, and “” illuminate simultaneously.

Main Cause User Action Remarks

1 Request your dealer for repair.

Engine does not start

Main Cause User Action Remarks

1 There is no fuel. Pour fresh fuel in the tank. See page 4-4.

2 Poor quality fuel (old fuel) Request your dealer for repair.

3 Carburetor starter does not operate. Operate the starter lever. See page 5-5.

4 Spark plugs are faulty.

5 Spark plug caps are improperly installed. Install the spark plug caps properly.

6 Starter motor spins slowly.

Immediately stop the flight and request a repair

by your dealer.

Recharge the onboard battery with a dedicated

recharger.

See page 7-1.

9-1

Page 23

Troubleshooting

Engine speed does not increase

Main Cause User Action Remarks

Main switch on the helicopter is not turned to

1

FLIGHT.

2 Starter lever has not been returned. Return the starter lever. See page 5-6.

3 Decompression lever has not been returned. Return the decompression lever. See page 5-6.

4 Air cleaner element is dirty or clogged.

5 Spark plugs are faulty.

Turn the main switch on the helicopter to FLIGHT. See page 5-7.

Immediately stop the flight and replace air cleaner

with new ones.

Immediately stop the flight and request a repair

by your dealer.

Engine has no power

Main Cause User Action Remarks

1 Engine overheats.

2 Spark plugs are faulty.

3 Air cleaner element is dirty or clogged.

Immediately stop the flight, and check the contents in the next section “Engine overheats”.

Immediately stop the flight and request a repair

by your dealer.

Immediately stop the flight and replace air cleaner

with new ones.

Engine overheats

Main Cause User Action Remarks

Replenish coolant.

1 Coolant is leaking or insufficient.

2 Specified coolant is not used.

3 Radiator is dirty or its fins are clogged. Clean the radiator. See page 6-6.

4 Radiator fan motor is not operating.

5 Engine load is excessive. Reduce the payload. See page 4-10.

If coolant is leaking, request a repair by your

dealer.

Use the dealer-specified coolant and tap water

with the proper mixing ratio.

If the motor does not operate when the main

switch on the helicopter is turned to FLIGHT,

request a repair by your dealer.

See page 4-20.

See page 4-20.

Coolant gushed out of recovery tank

Main Cause User Action Remarks

1 Engine overheats.

Immediately stop the flight, and check the contents in the previous section “Engine overheats”.

9-2

Page 24

Troubleshooting

Helicopter emits a burning smell

Main Cause User Action Remarks

1 Engine overheats.

2 Oil is leaking.

3 Wires are burned.

Immediately stop the flight, and check the contents in “Engine overheats” on page 9-2.

Immediately stop the flight and request a repair

by your dealer.

Immediately stop the flight and request a repair

by your dealer.

Engine idle is unstable

Main Cause User Action Remarks

1 Spark plugs are faulty.

2 Spark plug caps are improperly installed. Install the spark plug caps properly.

3 Starter lever has not been returned. Return the starter lever. See page 5-6.

4 Idle speed is too low.

Immediately stop the flight and request a repair

by your dealer.

Slightly raise the throttle trim lever on the flight

transmitter.

Engine idle is too high

Main Cause User Action Remarks

1 Throttle trim lever is improperly adjusted. Lower the throttle trim lever.

Carburetor throttle valve is not in contact with stop

2

screw.

Check the operation of the carburetor.

If it does not close fully, request a repair by your

dealer.

See page 4-23.

Engine speed does not decrease after landing

Main Cause User Action Remarks

Sensor operates abnormally due to a large shock

1

sustained during landing.

Land the helicopter more gently.

Turn OFF the YACS control switch.

See page 5-11.

Exhaust emits excessive smoke

Main Cause User Action Remarks

1 Gasoline and oil mixing ratio is improper. Replace the fuel. See page 4-4.

2 Specified oil is not used. Use the Yamaha-specified oil. See page 4-4.

Engine makes noise

9-3

Main Cause User Action Remarks

Engine is damaged internally or lubricated insuffi-

1

ciently.

Immediately stop the flight and request a repair

by your dealer.

Page 25

Helicopter

Helicopter vibrates

Main Cause User Action Remarks

1 Main rotor blades are positioned improperly.

Main rotor or tail rotor retaining bolts are tightened

2

improperly.

3 Main rotor or tail rotor is damaged.

Cushion tape has peeled from the main rotor or

4

tail rotor.

5 Tracking of the main rotor or tail rotor is faulty.

6 Main rotor or tail rotor is imbalanced.

7 Chemical tank is improperly installed. Securely install the chemical tank.

Install the rotor blades by matching their color

marks.

Follow the specified tightening procedure to

tighten the bolts.

Immediately stop the flight and request a repair

by your dealer.

Immediately stop the flight and request a repair

by your dealer.

Immediately stop the flight and request a repair

by your dealer.

Immediately stop the flight and request a repair

by your dealer.

Troubleshooting

See page 4-15.

See page 4-15.

See page 4-22.

See page 4-22.

See the operation manual for

the sprayer.

Helicopter cannot take off

Main Cause User Action Remarks

Immediately stop the flight, and check the con-

1 Engine speed does not increase.

2 Engine lacks power.

3 Payload is excessive. Reduce the payload. See page 4-10.

tents in “Engine speed does not increase” on

page 9-2.

Immediately stop the flight, and check the contents in “Engine has no power” on page 9-2.

Helicopter makes noise during takeoff

Main Cause User Action Remarks

1 Tail belt is loose.

2 Bolts of parts are loose. Check all parts for loose bolts.

Immediately stop the flight and request a repair

by your dealer.

See page 4-25.

Helicopter descends after takeoff

Main Cause User Action Remarks

1 Engine lacks power.

2 Payload is excessive. Reduce the payload. See page 4-10.

3 Throttle stick is operated improperly.

Immediately stop the flight, and check the contents in “Engine has no power” on page 9-2.

Operate the throttle stick by making sure the

amount of its movement does not decrease drastically.

9-4

Page 26

Troubleshooting

Helicopter moves considerably in rudder direction after takeoff

Main Cause User Action Remarks

1 Rudder was operated excessively before takeoff.

Do not operate the rudder excessively when taking off with the YACS control ON.

See page 5-8.

Helicopter drifts in one direction

Main Cause User Action Remarks

1 Trim is adjusted improperly. Adjust the trims on the flight transmitter. See page 5-9.

Helicopter descends when flare (brake) is applied

Main Cause User Action Remarks

Rotor lift decreased due to an abrupt flare opera-

1

tion.

2 Payload is excessive. Reduce the payload. See page 4-10.

Do not operate the flare abruptly. See page 5-8.

Helicopter moves considerably in rudder direction when flare

(brake) is applied

Main Cause User Action Remarks

Helicopter lost its balance due to an abrupt flare

1

operation.

Do not operate the flare abruptly. See page 5-8.

9-5

Page 27

YAC S

YACS warning light illuminates or flashes

Main Cause User Action Remarks

Identifiable through the illumination or flashing

1

pattern.

Self monitor light other than “” illuminates

Main Cause User Action Remarks

1 Identifiable through the illumination location.

YACS control configuration takes time

Immediately stop the flight and take appropriate

actions accordance to the information on page 3-7.See page 3-7.

Immediately stop the flight and take appropriate

actions accordance to the information on page 3-5.See page 3-5.

Troubleshooting

Main Cause User Action Remarks

Allow the YACS control to configure itself on a flat

1 Helicopter is not still.

surface. (Configuration will not complete if the

helicopter is tilted or moving.)

“” indicator light remains ON even after refueling

Main Cause User Action Remarks

Keep the refueling tank in a shade because the

1 Fuel temperature is too high.

fuel in it will reach a high temperature if the tank is

left under a scorching sun.

See page 5-4.

9-6

Page 28

Troubleshooting

GPS

GPS control configuration takes time (outer lights flashing)

Main Cause User Action Remarks

Wait until reception is restored or move to another

location and redo the configuration.

1 GPS radio signal reception is poor.

If the symptom does not improve after waiting or

changing the location, request an inspection of

the system by your dealer.

GPS indicator outer lights do not flash (with engine stopped)

Main Cause User Action Remarks

1 Power switch of the flight transmitter is not ON. Turn ON the power switch of the flight transmitter.

2 GPS system failure

Request your dealer for repair. (The helicopter

can continue to fly under YACS control only.)

See page 3-9.

See page 3-10.

Not all indicators illuminate even when GPS control switch is turned

ON

Main Cause User Action Remarks

Wait until reception is restored or move to another

GPS radio signal reception is poor (outer lights do

1

not illuminate).

2 Transmitter’s GPS control switch is faulty.

location and redo the configuration.

If the symptom does not improve after waiting or

changing the location, request an inspection of

the system by your dealer.

Request your dealer for repair. (The helicopter

can continue to fly under YACS control only.)

See page 3-9.

See page 3-10.

9-7

Page 29

Troubleshooting

Flight Transmitter

Output light does not illuminate

Main Cause User Action Remarks

1 Transmitter has an internal failure.

Battery monitor light illuminates

Main Cause User Action Remarks

1Battery’s state of charge is low. Replace with a fully charged battery. See page 3-11.

Battery use duration is too short

Main Cause User Action Remarks

1 Battery failure Replace the battery. See page 3-11.

2Battery’s memory effect

Immediately stop the flight and request a repair

by your dealer.

Use a battery discharger to eliminate the memory

effect. (Contact your dealer on how to eliminate

the memory effect.)

See page 4-18.

Battery monitor light illuminates suddenly

Main Cause User Action Remarks

If the light illuminates when the battery lead wire

1 Battery lead wire is damaged.

is shaken by hand, the battery lead wire is damaged. Immediately stop the flight and request a

repair by your dealer.

Dropped transmitter on ground

Main Cause User Action Remarks

1 Transmitter may be damaged internally.

Immediately stop the flight and request an inspection of the transmitter by your dealer.

Dropped transmitter into water

Main Cause User Action Remarks

1 Transmitter may be damaged internally.

Immediately stop the flight and request an inspection of the transmitter by your dealer.

Buzzer sounds a 3-3-7 pattern

See page 4-2.

Main Cause User Action Remarks

1 Transmitter has an internal failure.

Immediately stop the flight and request an inspection of the transmitter by your dealer.

See page 3-11.

9-8

Page 30

Troubleshooting

Sprayer

Chemical remains in right chemical tank

Main Cause User Action Remarks

This normal condition occurs because the heli-

1 Helicopter is tilting.

Sprayer does not operate

Main Cause User Action Remarks

1 Sprayer selector switch was operated improperly.

Other problems with liquid sprayer

copter tilts 5 degrees to the right during the flight.

(Ultimately, the sprayer will discharge all the

chemical in the tank.)

Select the switch position in accordance with the

type of sprayer that is being used.

See page 5-3.

See the operation manual for the liquid sprayer.

9-9

Page 31

Specifications

Specifications Data .................................................................. 10-1

Data List ............................................................................................10-1

Dimensions .......................................................................................10-2

10

Page 32

Specifications

Specifications Data

Data List

Product Name RMAX TypeII G UNIT,

Manufacturer Model L25

Performance Chemical Load Capacity* 16 kg

Practical Range (visual range) 150 m

Engine Type 2-cycle, horizontally opposed 2-cylinder

Cylinder Displacement 246 cc

Maximum Output 15.4 kW

System Water-Cooled

Electrical

Helicopter

Dimensions

Cooling

Starting System Electric Starter

Fuel

Control

System

Radiowave Frequencies for

Flying

Battery

Spark Plug

Main Rotor Diameter 3130 mm

Tail Rotor Diameter 535 mm

Overall Length / Overall Length

with Rotor

Overall Width 720 mm

Overall Height 1080 mm

Specified Coolant Mixture of dealer-specified coolant and water

Mixing ratio Dealer-specified ratio

Type Regular gasoline mixed with 2-cycle engine oil

Mixing ratio 50 parts gasoline to 1 part oil

Specified Oil Dealer-specified oil

Tank Capacity 6 liters

Name YACS-G

Warning Device Self Monitor, YACS Warning Light, GPS Indicator Light

Warnin gs

Onboard 12 V, 6.0 Ah, VRLA, leaded battery

Transmitter 9.6 V, 1.0 Ah, Ni-MH battery

Low Fuel Level, Excess Load, Radio Signal Interference, Low Voltage, GPS

Control Condition, Velocity Display, etc.

72.690, 72.730, 72.810, 72.850, 72.910, 72.950 MHz

Unmanned helicopter spark plug (Yamaha P/N 94702-00271)

(NGK P/N BR7HS-10)

2750 mm/3630 mm

* The performance may vary with atmospheric temperature, humidity, and altitude.

10-1

Page 33

Dimensions

Specifications

Unit: mm

10-2

Page 34

Specifications

10-3

Page 35

Inspection

Inspection Types and Descriptions ....................................... 11-1

Pre-Flight Inspection ........................................................................11-1

Post-flight Inspection .......................................................................11-2

30-Hour Inspection ...........................................................................11-2

Periodic Inspection ..........................................................................11-2

General Inspection ...........................................................................11-2

11

Page 36

Inspection

Inspection Types and Descriptions

The prescribed types of inspections are described

below.

• Pre-flight and post-flight inspections are to be

performed by the operator.

• For the 30-hour inspection, periodic inspection,

and general inspection, contact your dealer

(authorized service facility for Yamaha unmanned

helicopters for industrial applications).

WARNING

Have your dealer perform the 30-hour inspection, periodic inspection, general inspection,

and repairs. The performance of these

inspections by a person who is not a certified

unmanned helicopter service technician

could cause the helicopter to malfunction or

result in an accident.

TIP

Do not fly or perform an aerial application

without having a periodic inspection performed every 100 hours of operation.

What are Yamaha-authorized service facilities for

unmanned helicopters for industrial applications?

It is a service facility staffed by certified service

technicians for Yamaha industrial unmanned helicopters and equipped with the prescribed service

equipment.

Pre-Flight Inspection

Ensures that the helicopter and the auxiliary equipment are free of problems before a flight.

See page 4-17 for details on the inspection.

11-1

Page 37

Post-flight Inspection

Ensures that the helicopter and the auxiliary equipment are free of problems after a flight.

See page 6-1 for details on the inspection.

If a problem is detected, cancel the flight and

promptly contact your dealer.

Record the results of the inspection on the flight

log.

30-Hour Inspection

An inspection service performed after the delivery

of a new helicopter, when the hour meter indicates

a total of 30 hours of operation.

Inspection

Periodic Inspection

An inspection service performed at a Yamahaspecified dealer once for every 100 hours of operation indicated by the hour meter. The service

includes testing for durability and performance of

the helicopter and sprayer.

General Inspection

An inspection service to ensure the safety of the

helicopter when the hour meter shows a total of

500 or more hours of operation.

11-2

Page 38

Inspection

11-3

Page 39

Index

A

Air cleaner ......................................................... 2-3

Inspection ................................................... 6-3

Antenna ............................................................. 2-1

Inspection ................................................... 6-4

Azimuth Sensor ................................................. 2-1

B

Basic requirements ........................................... 1-2

Battery ............................................................... 2-3

Recharge .................................................... 7-1

Boom .......................................................... 4-1, 4-6

C

Carburetor ......................................................... 2-3

Check point indicator .................................. 2-2, 3-5

Chemical requirements ................................... 1-11

Chemical tank ............................................ 4-1, 4-6

Control panel ..................................................... 2-2

Coolant

Inspection ................................................. 4-20

Cushion tape ................................................... 4-22

D

Data list ........................................................... 10-1

Decompression lever ................................. 2-1, 5-5

E

Engine

Start ............................................................ 5-3

Stopping ................................................... 5-11

F

Failsafe actions ............................................... 3-12

Filter net ............................................................ 4-5

Flight indicator ............................................ 2-2, 3-5

Flight mode

Selecting ................................................... 4-13

Selector switch .................................. 2-2, 4-13

Flight requirements ........................................... 1-7

Flight transmitter ............................................... 2-4

Antenna .................................................... 4-18

Basic stick operation and helicopter

movement ............................................. 3-1

Recharging and replacing battery ............... 4-1

Basic trim lever operation and helicopter

movement ............................................. 3-2

Fuel

Inspection ................................................. 4-19

Preparing and refueling .............................. 4-4

Fuel filter ......................................................... 4-19

Fuel line ........................................................... 4-19

Fuel tank ........................................................... 2-3

Fuel tank cap .............................................. 2-1, 4-5

G

GPS

Antenna ...................................................... 2-1

Control switch ............................................. 3-3

Indicator light .......................................2-2, 3-9

Inspection ................................................. 4-26

Safety features and actions during

poor signal reception ........................... 3-15

Unit ............................................................. 2-1

Grip handle ........................................................ 4-7

H

Helicopter requirements .................................... 1-5

Hour meter ............................................... 2-2, 4-14

I

Inspection

30-hour inspection .................................... 11-2

General inspection .................................... 11-2

Periodic inspection .................................... 11-2

Post-flight Inspection ......................... 6-1, 11-2

Pre-flight .......................................... 4-17, 11-1

Intermediate transmission ............................... 4-21

L

Landing ........................................................... 5-11

Leaf ................................................................... 2-1

Linkage

Inspection ................................................. 4-23

M

Main rotor blade ................................................ 2-1

Inspection ................................................. 4-22

Main rotor blades

Installing and removing ............................. 4-15

Main switch ................................................ 2-2, 5-3

Malfunction area indicator .......................... 2-2, 3-6

Muffler ............................................................... 2-1

O

Oil

Inspection ................................................. 4-20

Operator requirements ...................................... 1-3

P

Payload inspection .......................................... 4-10

Plug cap ............................................................ 2-3

Post-Flight Cleaning and Servicing ................... 6-5

Product safety label locations ........................... 1-1

Page 40

R

Radiator ............................................................. 2-1

Radiator cap ............................................. 2-3, 4-21

Radio signal

Distance test ............................................. 4-25

Radio signal monitor ................................... 4-9

Radio signal interference inspection ................. 4-9

Recovery tank .......................................... 2-3, 4-20

Rubber hooks ........................................... 2-1, 4-16

Runner ....................................................... 2-1, 4-7

S

Self monitor ....................................... 2-2, 3-5, 4-24

Shutter pump cleaning switch ........................... 2-2

Side cover ......................................................... 2-1

Installing and removing ............................. 4-16

Slide servo ........................................................ 2-3

Inspection ................................................. 4-23

Slide servo thermo sensor ................................ 3-6

Spinner constant rotation switch ....................... 2-2

Spray

Spray switch ............................................... 3-4

Sprayer

Selector switch .................................... 2-2, 4-3

Spraying

Selecting and setting sprayer ..................... 4-3

Stabilizer blade .................................................. 2-1

Starter lever ................................................ 2-1, 5-5

Starter switch ............................................. 2-2, 5-6

Stone guard ............................................... 2-1, 4-6

Storage ............................................................. 8-1

T

Tail body ............................................................ 2-1

Tail cover ........................................................... 2-1

Tail rotor blade .................................................. 2-1

Inspection ................................................. 4-22

Tail rotor drive belt .......................................... 4-25

Takeoff .............................................................. 5-8

Transmission case .......................................... 4-21

Transmitter

Battery monitor light ......................... 3-11, 4-18

Inspection ................................................. 4-18

Transporting procedure ..................................... 4-6

Trim lever

Aileron ................................................. 2-4, 5-9

Elevator ............................................... 2-4, 5-9

Rudder ................................................. 2-4, 5-9

Throttle ................................................ 2-4, 5-5

Y

YACS

Control switch ............................................. 3-3

Warning light ........................................ 2-2, 3-7

Page 41

Please read this manual before using the product.

UNMANNED HELICOPTER FOR INDUSTRIAL APPLICATIONS

UNMANNED HELICOPTER FOR INDUSTRIAL APPLICATIONS

UNIT,

LIQUID SPRAYER

LIQUID SPRAYER

OPERATION MANUAL

OPERATION MANUAL

Page 42

Foreword

Thank you for using the liquid sprayer for the RMAX TypeII G Unit, unmanned helicopter for

industrial applications.

This operation manual describes the proper operating procedures as well as inspection and

servicing methods for the liquid sprayer for the RMAX TypeII G Unit, helicopter. Before using

this product, please be sure to read this operation manual, along with the separate opera-

tion manual for the RMAX TypeII G Unit, helicopter, and thoroughly understand the informa-

tion contained therein.

In this manual, the warning notes, which are necessary for safe and proper operation of this

product, are categorized and shown as follows. Please make sure to observe these instruc-

tions, as they all contain important information.

DANGER

This indicates that improper operation will

cause imminent danger, which could lead to

serious injury or death.

WARNING

This indicates that improper operation could

lead to minor and serious injuries or death.

NOTICE

Indicates that improper operation could

cause property damage.

TIP

Indicates proper operating procedure and

tips on inspection and maintenance.

Indicates a prohibited action.

The specific prohibited action is illustrated near the symbol.

● After you have read this operation manual, keep it within easy access near the product.

● If you have lost this operation manual, contact your dealer to request another copy.

● Contact your dealer if you have any questions or comments regarding the contents of

this operation manual.

● Some diagrams and contents in this manual may differ from the actual device, due to

specification changes, etc.

Page 43

Table of Contents

Safety Precautions

Product Safety Label Locations ............................................................... 1-1

Requirement ............................................................................................... 1-2

Spraying Precautions ................................................................................1-5

Usage Precautions..................................................................................... 1-9

Part Names

Part Names ................................................................................................. 2-1

Mounting and Removing the Sprayer

Mounting and Removing the Sprayer ...................................................... 3-1

Spraying Method

Relevant Switches ..................................................................................... 4-1

Using the Sprayer ...................................................................................... 4-3

Spray Specifications Settings .................................................................. 4-7

1

2

3

4

Cleaning and Inspections

Cleaning the Sprayer ................................................................................. 5-1

Inspecting and Cleaning Various Parts ................................................... 5-3

Troubleshooting

Troubleshooting......................................................................................... 6-1

Specifications

Specifications Data.................................................................................... 7-1

Product Inspection

About Inspections...................................................................................... 8-2

5

6

7

8

Page 44

Safety Precautions

Product Safety Label Locations

Before using the device, please read and understand the affixed product safety labels thoroughly.

NOTICE

1-1

Page 45

Safety Precautions

Requirement

Basic requirements

WARNING

To ensure safe use, please make sure to read

the operation manual thoroughly before use.

WARNING

This liquid sprayer for the unmanned helicopter for industrial applications has been

manufactured for the purpose of aerial application of agricultural chemicals, fertilizers,

and seeds. Do not use it for other applications. It could also cause unexpected accidents.

1

2

3

4

WARNING

Do not modify the helicopter or the auxiliary

devices. Do not use parts other than genuine

parts. Any modification of the helicopter or

use of non-genuine parts may cause unexpected accidents.

5

6

7

8

1-2

Page 46

Safety Precautions

Operator requirements

WARNING

Flying this helicopter requires a high level of

skill.

The helicopter should be operated only by a

person who possesses an appropriate

license.

WARNING

Make sure to wear a helmet during flight. To

perform an aerial application, make sure to

wear clothing that is appropriate for the operation. Performing a flight and an aerial application in clothing that is not appropriate for

the task could cause loss of visibility, maneuvering error, or cause your foot to slip, resulting in unexpected accidents. Furthermore, it

could harm your health through exposure to

agricultural chemicals.

Certificate of

Authorization

Observe the following clothing requirements:

● Wear a helmet.

● Wear goggles and a particle mask.

● Wear long-sleeved clothing with secure buttons

and fasteners.

● Wear slip-proof shoes that are easy to walk with.

● Do not wear objects that could obstruct vision

when there is wind, or adversely affect operation

(especially towels and gloves).

WARNING

A minimum of 3 people is required for an

aerial application: a navigator who has been

briefed on the aerial application procedure,

an assistant who readies, mixes, and supplies agricultural chemicals, and an operator.

Beware that an understaffed operation could

lead to an accident.

1-3

Page 47

WARNING

The operation of an unmanned helicopter

involves considerable mental fatigue. The

operator should not fly the helicopter continuously for more than one hour, but should

take a rest every hour. Prolonged continuous

flight operation could cause the operator to

lose concentration and could lead to an accident.

WARNING

Do not fly the helicopter after drinking alcohol or taking a cold medicine, or if you are in

poor physical condition. Flying the helicopter

in poor physical condition could cause loss

of concentration, and could lead to an accident.

Safety Precautions

1-4

Page 48

Safety Precautions

Spraying Precautions

When operating an unmanned helicopter for the purpose of spraying agricultural chemicals, ensure safe operation, as well as the safety of humans, animals, agricultural products, and the environment during aerial application.

General Flight Pattern for Aerial Application

Example: Disease and pest control of a rice paddy

• Flight altitude: 3 to 4 m

• Flying speed: 10 to 20 km/h

• Flying interval: 5 or 7.5 m

• Wind velocity: 3 m/s maximum

Just passed 10 meters,

and 5 meters

Flying height between

3 and 4 meters

Wind

DANGER

When performing tasks such as refueling,

never approach (or allow others to approach)

within 20 m of the helicopter until the main

rotor has come to a complete stop and the

engine has stopped. Entering within 20 m of

the helicopter could cause a serious accident.

Flying speed between

10 and 20 km/h

Flying interval 5 or 7.5 meters

Affirmative!

1-5

Page 49

Using Registered Agricultural Chemicals

Use nationally registered agricultural chemicals,

and use them properly by reading the usage

instructions and precautions included in the manual

for each respective chemical.

WARNING

Do not use agricultural chemicals other than

those registered. Failure to do so could

expose animals, plants, or people to agricultural chemicals for which the operator will be

held socially responsible.

WARNING

Control and handle agricultural chemicals

strictly in accordance with their manuals.

Negligent control and improper handling of

agricultural chemicals could lead to chemical

pollution or health hazards.

Safety Precautions

1-6

Page 50

Safety Precautions

Spray Chemical

Since the agricultural chemical is diluted at a low

dilution rate, make sure to observe the following:

(1) Agricultural Chemical

● Use nationally registered agricultural chemicals.

● In low-volume liquid spraying, the characteristics

of the agricultural chemical can easily change

when mixed with other agricultural chemicals,

and may produce solids or turn to a gum-like

state. When mixing, use agricultural chemicals

that have been checked in advance for physiochemical change, compatibility with the sprayer,

mixture toxicity, etc.

● Spreading agents (surface active agents) cannot

be added.

Label

(2) Dilution Water

For dilution water, make sure to use tap water. Do

not use agricultural water, as this could lead to

debris clogging or characteristic change in the agricultural chemical.

(3) Dilution Rate

For example, to make 8 of spray solution of an

agricultural chemical diluted to 8x, dilute 1 of

agricultural chemical with 7 of tap water (dilution

water). This will make 8 of spray solution.

Agricultural chemical: 8 × 1/8 = 1

Tap water: 8 - 1 (agricultural

chemical) = 7

Since flowable and water-dispersible chemicals can

easily precipitate, combine and mix them well just

before aerial application flight.

Tap Water

Agricultural

Water

Chemical

Tap Water

Spray Solution

1-7

Page 51

Safety Precautions

Pouring the Spray Solution

● Check the inside of the chemical tank (into which

the solution will be poured), the check valve, the

strainer section, and the filter for any debris or

sediments. If you find any debris or sediments,

make sure to remove them before pouring the

solution.

● Keep the chemical tank load to 8 or less per

side (16 combined for left and right tanks).

TIP

● For higher altitudes and temperatures,

decrease the load.

● For information on load capacity, see the

operation manual for the helicopter.

Check Valve

Filter in the

Chemical Tank

Strainer

Chemical Tank

1-8

Page 52

Safety Precautions

Usage Precautions

Stop the engine when replenishing the chemical.

When replenishing the chemical, make sure to stop

the engine. If this task takes longer than one

minute, turn OFF the main switch on the helicopter.

DANGER

Never approach (or allow others to approach)

within 20 m of the helicopter until the main

rotor has come to a complete stop and the

engine has stopped. Entering within 20 m of

the helicopter could cause a serious accident.

Securely mount the chemical tanks.

Prior to the flight, check that both chemical tanks

are securely mounted.

NOTICE

If the chemical tanks are not securely

mounted, they could come off during flight.

Do not apply excessive force on the boom.

When performing tasks such as replenishing the

chemical, use caution not to trip on the boom.

NOTICE

If an excessive force is applied against the

folding direction of the boom, it could

become damaged.

1-9

Page 53

Part Names

Part N ames

1

Chemical Tank

Right and Left Nozzles

Bracket

Chemical Tank Joint

Boom

Center Nozzle

Boom

Joint

Bracket

Handle

Tank Cap

2

3

Chemical Tank

4

Bracket

Chemical Tank Joint

Boom

Three-way Cock

Nozzle Switching Motor

5

Right and Left Nozzles

6

7

8

Filter Cap

2-1

Page 54

Mounting and Removing the Sprayer

Mounting and Removing the Sprayer

1 Position the sprayer under the frame.

TIP

Extend the sprayer boom, and slide horizontally from between the leaves.

2 Of the three connectors running from the frame,

connect the 2-pole connectors to the sprayer

pump’s power connectors, and the 3-pole connector to the power connector of the nozzle

switching motor.

TIP

If necessary, apply the dealer-specified

grease onto the O-rings of the joints on the

bottom of the chemical tanks.

Sprayer

Leaf

Leaf

3-pole connector

3 Insert the dampers of the sprayer (2 locations)

into the mounting holes (2 locations) on the

frame.

2-pole connector

Mounting Holes

Dampers

3-1

Page 55

Mounting and Removing the Sprayer

4 Lift the rear of the sprayer, and fasten by insert-

ing bolts and washers through the right and left

bracket holes on the frame.

Tightening

Torque

Use a 4 mm hex wrench.

5 Securely mount the left and right chemical tanks

by fitting the sprayer’s brackets into the mounting

stays on the chemical tanks.

If the chemical tanks are not mounted properly, it could cause the helicopter to shake,

the chemical to leak, or the chemical tank to

fall off the helicopter.

3 to 4.5 N·m (0.3 to 0.45 kg·m)

TIP

NOTICE

Bolts/Washers

Bracket Holes

Chemical Tank

1

2

3

4

TIP

If necessary, apply dedicated grease

(Yamaha Grease B) onto the O-rings on the

bottom of the chemical tanks.

(set in securely)

Guide

Mounting Stay

Bracket

Valve Seal

(set in securely)

5

6

7

6 To remove the sprayer, follow the mounting pro-

cedure in reverse order.

O-Rings

Joint

8

3-2

Page 56

Spraying Method

o

Relevant Switches

Helicopter Control Panel

Shutter Pump Cleaning Switch

Spinner Constant Rotation Switch

Used for cleaning the pump.

See “Cleaning the Sprayer” on

page 5-1.

4-1

Sprayer Selector Switch

To use the speed-dependent

function, switch to “”.

When not using the speeddependent function, switch t

“”.

Page 57

Flight Transmitter

Spraying Method

1

Spray Volume Adjuster

(for Liquid)

This adjusts the amount of liquid discharged.

See “Spray Specifications

Settings” on page 4-7.

Power Swi tch

This is the power switch

for the transmitter.

Spray Switch

This is an ON/OFF switch for the

spray pump.

See “Using the Sprayer” on page 4-3.

Spray Volume Switch

This switches between the left/

right nozzles and the center

nozzle.

See “Using the Sprayer” on

page 4-5.

2

3

4

5

6

7

8

4-2

Page 58

Spraying Method

Using the Sprayer

Spraying with Flight Transmitter

1 Switch the sprayer selector switch on the flight con-

trol panel to “”.

To use the speed-dependent function, switch to

“”.

2 Set the spray volume adjuster and the spray noz-

zle settings according to “Spray Specifications

Settings” on page 4-7.

Sprayer Selector Switch

3 Tur n ON ( “in” position) the spray switch (the ON/

OFF switch) on the flight transmitter to actuate

the spray pump. Press again (“out” position) to

stop.

4 Check the spraying condition. Check if the spray-

ing condition from each nozzle is good.

NOTICE

Do not keep the pump running for more than

10 seconds with nothing spraying out from

the nozzle, or on an empty tank. The pump

could burn out.

Spray Switch

ON (to operate) OFF (to stop)

Push

Illustration of Spraying Conditions

Release

4-3

Good Poor Poor

Page 59

How to Release Air Pockets

When the chemical tanks are plugged/unplugged,

or when the chemical is sprayed until the chemical

tanks are empty, air pockets will get entrained

inside the sprayer piping, causing the spraying condition to deteriorate.

With the chemical tanks set in place, if the air pockets are not completely released by discharging from

the nozzles, turn OFF the sprayer switch, and

release the air pockets as follows:

1 Facing the rear of the helicopter, turn the three-

way cock handle on the rear of the sprayer so

that it points to your left.

2 Turn ON the sprayer switch, and run the spray

pump for 5 to 7 seconds.

3 Point down the three-way cock to the spraying

position, and verify that the discharge condition

from the nozzle is good.

Spraying Method

Three-way Cock Handle

Air Releasing Position (pointing left)

DANGER

When releasing air pockets, do not perform

the task (or allow others to approach the helicopter) until the main rotor has stopped

rotating completely and the engine has

stopped.

TIP

If you are using the speed-dependent function and need to release air after receiving

the GPS signal, set the sprayer selector

switch to “”. After releasing air pockets,

return the sprayer selector switch to “”.

Spraying Position (pointing down)

4-4

Page 60

Spraying Method

Switching Between Nozzles

Set the spray volume switch on the flight transmitter

to “1” (“out” position) to discharge from the right and

left nozzles. Set it to “1/2” (“in” position) to dis-

charge from the center nozzle.

To switch between nozzles, turn OFF the spray

switch, and perform the task after the spray pump

has stopped.

Nozzle

“1”

ON

(to operate)

Release

Sprays from left

and right nozzles

Spray Switch

ON (to operate) OFF (to stop)

Push

Release

Push

“1/2”

Push

Sprays from center nozzle

“1”

OFF

Release

(to stop)

Release

“1/2”

Push

Stops spray pump

TIP

If you switch between nozzles with the spray

volume switch while the spray switch is in

the ON state, the spray pump will stop for

approximately one second, during which the

nozzle switching motor runs.

Spray Volume Switch

“1/2” (Center nozzle) “

Push

1” (Left and right nozzles)

Release

4-5

Page 61

Spraying Method

Using the Speed-Dependent Function

TIP

● The speed-dependent function can be used only when all of the following three conditions are

met:

• Low-volume liquid spraying at 7.5m spray width, 8L/ha

• Left and right nozzles are selected

• The GPS signal reception is good (i.e. the outer GPS indicator lights are ON)

The state of the flight mode selector switch on the helicopter and the GPS control switch on

the flight transmitter are irrelevant.

● When the center nozzle is used, the speed-dependent function does not work, and discharging is

done in proportion to a constant volume set by the spray volume adjuster on the flight transmitter.

1 Switch the sprayer selector switch on the flight

control panel to “ ”.

2 Set the spray volume adjuster and the spray noz-

zle settings according to “Spray Specifications

Settings” on page 4-7.

TIP

If the flight velocity exceeds 20km/h, only the

outer lights of the YACS warning lights illuminate. If this happens, drop the flight velocity

to 20km/h or less.

Sprayer Selector Switch

YACS

Warning Light

GPS

Indicator Light

Only the outer lights

of the YACS warning

lights illuminate

If the GPS signal reception is poor (the outer GPS indicator lights are ON), the speed-dependent function

does not work, and the chemical is discharged at a constant rate set by the spray volume adjuster on the flight

transmitter.

During a GPS-controlled flight, if the GPS signal reception worsens (GPS indicator lights cycles a pattern

“outer lights ON > inner lights ON > OFF”), the speed-dependent function does not work, and the chemical is

discharged at a constant rate set by the spray volume adjuster on the flight transmitter.

In this case, immediately turn OFF the GPS control switch according to the operation manual for the helicopter.

4-6

Page 62

Spraying Method

Spray Specifications Settings

Set the spray volume adjuster and spray nozzles according to the chemical to be used.

Spray Specifications

Low-Volume

Liquid Spraying

Spray

Volu me

(L/ha)

Right and Left

Nozzles

Center Nozzle 8 3.75 Yellow 1 (has groove) Level 24 Standard

8 7.5 Yellow 2 Level 24 Standard

Spray

Width

(m)

Nozzle

Color

Spray Volume Adjuster

Number of

Nozzles

Volu me

Position

Remarks

(b)

0

40

24

32

(a)

TIP

● The adjuster covers a range of volumes, allowing you adjust the spray volume according to the

chemical used.

● When you turn all the way towards the (b) direction, and start turning back towards the (a) direction, the first notch you reach is Level 1.

● Turning in the (a) direction increases the spray volume, and turning in the (b) direction decreases

the spray volume.

● Levels between 32 to 40 use maximum current, therefore, do not use continuously.

● After adjusting the volume, make sure to put the rubber cover back on.

● The spray specifications settings above are only to be used as a guideline. Before the actual

spraying task, make sure to check the spray volume for the chemical you are using.

4-7

Page 63

Cleaning and Inspections

WARNING

Control and handle the agricultural chemicals strictly in accordance with their manuals. Negligent

control and improper handling of agricultural chemicals could lead to chemical pollution or health

hazards.

NOTICE

● Clean the sprayer after every spraying work, as the spraying performance could deteriorate due

chemicals solidifying onto the sprayer.

● Use a drain pipe to collect the leftover chemical and cleaning solutions from cleaning into a container, and dispose it according to the operation manual for the chemical.

● During winter seasons, the pump or the filter cap may become damaged by frozen liquids. Therefore, for long-term storage during winter seasons, drain the leftover chemical and remove the filter cap.

1

2

Cleaning the Sprayer

Cleaning the Spray Pump

1 Turn the sprayer selector switch to “ ”.

2 Mount the chemical tank filled with tap water,

and turn the main switch of the helicopter to

“START”. Press the “ ” switch on the con-

trol panel to clean the inside of the sprayer piping.

3 To switch between the right/left nozzles and the

center nozzle, press the “ ” switch to tem-

porarily stop the pump, then use the “ ”

switch.

4 Drain the chemical inside the spray piping

through the drain pipe, by pointing the three-way

cock handle to the right, thereby actuating the

spray pump.

5 After draining out the chemical, point the three-

way cock handle to the spraying position (down).

Sprayer Selector Switch

3

4

5

6

6 Remove the filter and nozzles, and wash them

with tap water. (See pages 5-3 and 5-4.)

7 If you want to wash the sprayer thoroughly,

remove the sprayer and wash with tap water.

When doing this, use caution to keep the 2-pole

and 3-pole connecters from getting wet. (See

page 3-1.)

7

8

Spinner Constant Rotation Switch

Shutter Pump Cleaning Switch

5-1

Page 64

Cleaning and Inspections

Press once Press again

Switches to right

and left nozzles or

center nozzle

Operates pump Stops pump

Switches to right

and left nozzles or

center nozzle

TIP

● Operating the pump for more than one

minute could drain the battery.

● During cleaning, do not use the flight

transmitter to switch between right/left

nozzles and center nozzle.

Three-way Cock Handle

Drain Pipe

Chemical Draining Position (pointing right)

Spraying Position (pointing down)

5-2

Page 65

Inspecting and Cleaning Various Parts

Filter Inspection and Cleaning

1 Turn OFF the main switch of the helicopter.

2 Remove the left and right chemical tanks.

3 Remove the filter cap, and visually inspect if the

filter inside is clogged.

If clogged, wash it with tap water.

NOTICE

● If a tear exists in the filter, replace it, as it

could cause the spray pump or the nozzles

to become clogged.

● When putting on the filter cap, securely

fasten the O-ring to prevent air entrainment and liquid leakage.

Cleaning and Inspections

Filter

O-Ring

Filter Cap

5-3

Page 66

Cleaning and Inspections

Nozzle Inspection and Cleaning

1 Loosen the nozzle caps and end caps for the

left, right and center nozzles. Remove seat 2,

strainer 2, seat 1, and nozzle, and check them

for damage and wear.

If clogged, wash it with tap water.

2 Reattach the nozzles so that the nozzle spraying

hole and the boom are parallel.

Right and

Left Nozzles

Center Nozzle

Nozzle

Number

XR TEEJET

11002 VS

XR TEEJET

8002 VS

Nozzle

End Cap

Cap Color

Yellow Black

Red Blue

Color

TIP

● When reattaching the nozzles, do not confuse the left/right nozzles and the center

nozzle.

● Only the center nozzle has a groove along

its outer perimeter.

Nozzle

Cap

Right and Left Nozzles

Red Nozzle Cap

Nozzle

Parallel

End Cap

Seat 2

Strainer 2

Seat 1

Nozzle

Black End Cap

Center Nozzle

Parallel

Nozzle

Boom

Red Nozzle Cap

Blue End Cap

Boom

5-4

Only the center nozzle has a groove along its outer perimeter

Page 67

Chemical Tank Inspection and Cleaning

Cleaning and Inspections

1 Inspect the check valve on the chemical tank cap

to check if it is clogged.

2 Remove the strainer and visually check if it is

clogged.

If clogged, wash it with tap water.

Check Valve

Filter in the

Chemical Tank

Strainer

Chemical Tank

3 Remove the filter by turning it counterclockwise,

and visually check if it is clogged.

If clogged, wash it with tap water.

NOTICE

● If a tear exists in the strainer or filter,

replace it, as it could cause the spray

pump or the nozzles to become clogged.

● When using a chemical that precipitates

quickly, frequently remove and clean the

strainer and filter.

● When removing the filter, do not pull it by

the mesh part, as this could damage the

filter.

Chemical Tank Joint Inspection and Cleaning

Visually check if the valve seal part of the chemical

tank joint is clogged.

If clogged, wash it with tap water.

Chemical Tank Joint

5-5

Page 68

Troubleshooting