KONICS KRN1000 SERIES User Manual

USER MANUAL

© Copyright Reserved KONICS Co., Ltd. i

ii © Copyright Reserved KONICS Co., Ltd.

Preface

Preface

Thank you for purchasing KONICS product.

Please familiarize yourself with the information contained in the Safety Precautions section

before using this product.

This user manual contains information about the product and its proper use, and should be kept

in a place where it will be easy to access.

© Copyright Reserved KONICS Co., Ltd. iii

User Manual Guide

User Manual Guide

Please familiarize yourself with the information in this manual before using the product.

This manual provides detailed information on the product's features. It does not offer any

guarantee concerning matters beyond the scope of this manual.

This manual may not be edited or reproduced in either part or whole without permission.

A user manual is not provided as part of the product package.

Visit our web site (www.konics.com) to download a copy.

The manual's content may vary depending on changes to the product's software and other

unforeseen developments within KONICS, and is subject to change without prior notice.

Update notice is provided through out homepage.

We contrived to describe this manual more easily and correctly. However, if there are any

corrections or questions, please notify us these on our homepage.

iv © Copyright Reserved KONICS Co., Ltd.

User Manual Symbols

Symbol

Description

User Manual Symbols

Supplementary information for a particular feature.

Failure to follow instructions can result in serious injury or death.

Failure to follow instructions can lead to a minor injury or product damage.

An example of the concerned feature's use.

※1

Annotation mark.

© Copyright Reserved KONICS Co., Ltd. v

Safety Precautions

Safety Precautions

Following these safety precautions will ensure the safe and proper use of the product and

help prevent accidents, as well as minimizing possible hazards.

Safety precautions are categorized as Warnings and Cautions, as defined below:

Warning

Caution

Failure to follow the instructions may lead to a serious injury

or accident.

Failure to follow the instructions may lead to a minor injury

or accident.

Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in personal injury, fire, or economic loss.

The unit must be installed on a device panel before use.

Failure to follow this instruction may result in electric shock.

Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock.

Check the terminal numbers before connecting the power source.

Failure to follow this instruction may result in fire or burning the unit.

Lithium battery is used in the unit. Do not disassemble or burn the unit.

Failure to follow this instruction may result in explosion.

Do not touch the unit and terminals after cut off the power within 30 sec.

Failure to follow this instruction may result in electric shock.

Ground PE terminal individually and ground cable should be over AWG16 (1.25 mm

Failure to follow this instruction may result in electric shock.

Do not insert any objects at the openings of the unit.

Failure to follow this instruction may result in electric shock or personal injury.

Do not disassemble or modify the unit. Please contact us if necessary.

Failure to follow this instruction may result in personal injury, fire, or economic loss.

Do not use the unit outdoors.

Failure to follow this instruction may result in shortening the life cycle of the unit, or electric

shock.

2

When connecting the power input and relay output cables, use AWG20 (0.05mm

) cables

and make sure to tighten the terminal screw bolt above 0.74N.m to 0.90N.m.

Failure to follow this instruction may result in fire due to contact failure.

Use the unit within the rated specifications.

Failure to follow this instruction may result in shortening the life cycle of the unit, or fire.

2

).

vi © Copyright Reserved KONICS Co., Ltd.

Safety Precautions

Do not use loads beyond the rated switching capacity of the relay contact.

Failure to follow this instruction may result in insulation failure, contact melt, contact failure,

relay broken, or fire.

When connecting magnet contact as relay contact output load, attach a surge absorber at

contact coil.

Failure to follow this instruction may result in product malfunction.

Do not use water or oil-based detergent when cleaning the unit. Use dry cloth to clearn the

unit.

Failure to follow this instruction may result in electric shock, or fire.

Do not use the unit where flammable or explosive gas, humidity, direct sunlight, radiant heat,

vibration, or impact may be present.

Failure to follow this instruction may result in fire or explosion.

Keep dust and wire residue from flowing into the unit.

Failure to follow this instruction may result in fire or product damage.

Check the polarity before connecting cables.

Failure to follow this instruction may result in fire or explosion.

Check the polarity of the measurement input contact before wiring the temperature sensor.

Failure to follow this instruction may result in fire or explosion.

Check the connection diagram of this manual before supplying power.

Failure to follow this instruction may result in fire.

Do not touch terminal during dielectric or insulation resistance test.

Failure to follow this instruction may result in electric shock.

Use insulation transformer and noise filter power for too much noise from the power. Attach

noise filter on the grounded panel, etc. Use short cables for noise filter output part and

power terminal of the unit.

Failure to follow this instruction may result in product damage, malfunction by surge.

If power line and input signal line are close each other, install line filter for noise protection

at power line and use shielded input signal line.

Do not control the alarm output or measure the data during firmware update. Failure to

follow this instruction may result in malfunction. Alarm output, contact input, data

measurement do not operate normally.

After completing firmware update, check the complete message and turn OFF to ON the

power.

All parameter setting values are reset after firmware update. It may not operate as same

way with before updating operation.

Use voltage output of transmitter power output only for transmitter power. Failure to follow

this instruction may result in output module damage.

Do not press the touch screen by sharp or hard objects with excessive force.

To prevent inductive noise, separate cables of the unit from high-voltage line, power line.

Do not install inductive noise or power line closely. It may cause measurement error.

Install the unit at well-ventilated place to prevent over-heat and give space over 30mm

against wall.

Install the unit vertically.

© Copyright Reserved KONICS Co., Ltd. vii

Safety Precautions

viii © Copyright Reserved KONICS Co., Ltd.

Table of Contents

Table of Contents

Preface .............................................................................................................................iii

User Manual Guide ......................................................................................................... iv

User Manual Symbols ...................................................................................................... v

Safety Precautions .......................................................................................................... vi

Table of Contents ............................................................................................................ ix

1 Product Introduction................................................................................. 11

1.1 Features ............................................................................................................. 11

1.2 Components and accessories ........................................................................... 12

1.2.1 Components ............................................................................................... 12

1.2.2 Accessories ................................................................................................ 12

1.3 Ordering information .......................................................................................... 13

1.4 Unit description .................................................................................................. 14

1.4.1 Front part .................................................................................................... 14

1.4.2 Rear part .................................................................................................... 15

2 Specifications ............................................................................................ 17

2.1 KRN1000 ........................................................................................................... 17

2.2 Input/Output ....................................................................................................... 18

2.3 Input type and range .......................................................................................... 20

3 Dimensions ................................................................................................ 21

3.1 KRN1000 ........................................................................................................... 21

3.2 Panel cut-out ...................................................................................................... 21

4 Connections .............................................................................................. 23

4.1 KRN1000 ........................................................................................................... 23

4.2 Input/Output circuit ............................................................................................. 24

5 Installations ............................................................................................... 25

5.1 Environment ....................................................................................................... 25

5.2 Installation Method ............................................................................................. 26

5.3 USB to Serial driver ........................................................................................... 27

5.3.1 Driver installation ........................................................................................ 27

5.3.2 Check the driver ......................................................................................... 28

6 Screen ........................................................................................................ 29

6.1 Initial booting screen .......................................................................................... 29

6.2 Screen description ............................................................................................. 30

6.2.1 Status display part ...................................................................................... 30

6.2.2 Measurement value display part ................................................................ 32

6.2.3 Graph ......................................................................................................... 33

6.2.4 Pop-up menu .............................................................................................. 37

6.2.5 Virtual keyboard ......................................................................................... 38

6.2.6 Color ........................................................................................................... 40

© Copyright Reserved KONICS Co., Ltd. ix

Table of Contents

7 Menu ........................................................................................................... 41

7.1 Display ............................................................................................................... 42

7.1.1 History ........................................................................................................ 42

7.1.2 File History ................................................................................................. 44

7.1.3 Group Setting ............................................................................................. 45

7.1.4 Touch Calibration ........................................................................................ 46

7.2 Status ................................................................................................................. 47

7.2.1 Alarm List.................................................................................................... 47

7.2.2 Event List .................................................................................................... 48

7.2.3 AO/DI Status ............................................................................................... 48

7.3 Input CH Info. ..................................................................................................... 49

7.3.1 Input/Display ............................................................................................... 49

7.3.2 Input Option ................................................................................................ 53

7.3.3 Alarm .......................................................................................................... 58

7.3.4 User Unit..................................................................................................... 60

7.4 Option Info. ........................................................................................................ 61

7.4.1 Alarm Output .............................................................................................. 61

7.4.2 Digital Input................................................................................................. 62

7.4.3 RS422/485 ................................................................................................. 63

7.4.4 Ethernet/USB ............................................................................................. 64

7.5 System Info. ....................................................................................................... 66

7.5.1 Date/Time ................................................................................................... 66

7.5.2 Reservation ................................................................................................ 67

7.5.3 Device......................................................................................................... 69

7.5.4 File .............................................................................................................. 70

7.5.5 Log In.......................................................................................................... 71

7.5.6 System Info. ............................................................................................... 72

7.6 Memory Info. ...................................................................................................... 73

7.6.1 Memory Management ................................................................................ 73

7.6.2 Internal Memory ......................................................................................... 74

7.7 Screen Capture .................................................................................................. 75

7.8 Log OFF/Power OFF ......................................................................................... 76

8 Integrated device management program (DAQMaster) ......................... 77

8.1 Overview ............................................................................................................ 77

8.2 Features ............................................................................................................. 78

8.3 Dedicated features for KRN1000 ...................................................................... 79

8.3.1 Record Backup ........................................................................................... 80

8.3.2 Check backup data ..................................................................................... 81

9 Troubleshooting ........................................................................................ 83

9.1 Error message ................................................................................................... 84

x © Copyright Reserved KONICS Co., Ltd.

1 Product Introduction

1 Product Introduction

1.1 Features

KRN1000 is paperless recorder with LCD method to save recording data at SD / USB memory.

It displays trend graph, bar graph, or digital figures at TFT Color LCD.

Via RS422/485, Ethernet or USB device communication, it is available to set parameters,

transfer data as data logger functions for user convienent.

It supports several communication method and various input/output functions. It also provides

easy and convient graphic user interface (GUI) applying graphic display.

5.6-inch color TFT LCD (640×480) touchscreen display with excellent readability and

intuitive control interface

Supports 27 input types (thermocouple, RTD, analog voltage and current[shunt])

4 / 8 / 12 / 16 input channel models available

Various communication methods (RS422/485, Ethernet, USB) standard

25 to 250 ms high-speed sampling, 1 to 3600 s recording cycle

200 MB internal memory and external memory support (SD/USB up to 32 GB)

Store and backup internal data to external memory (SD/USB)

9 different graph types available

Various option input/output available: digital input (contact/non-contact), alarm output,

transmitter power output

Compact, space-saving design (rear length: 69.2 mm)

© Copyright Reserved KONICS Co., Ltd. 11

1 Product Introduction

1.2 Components and accessories

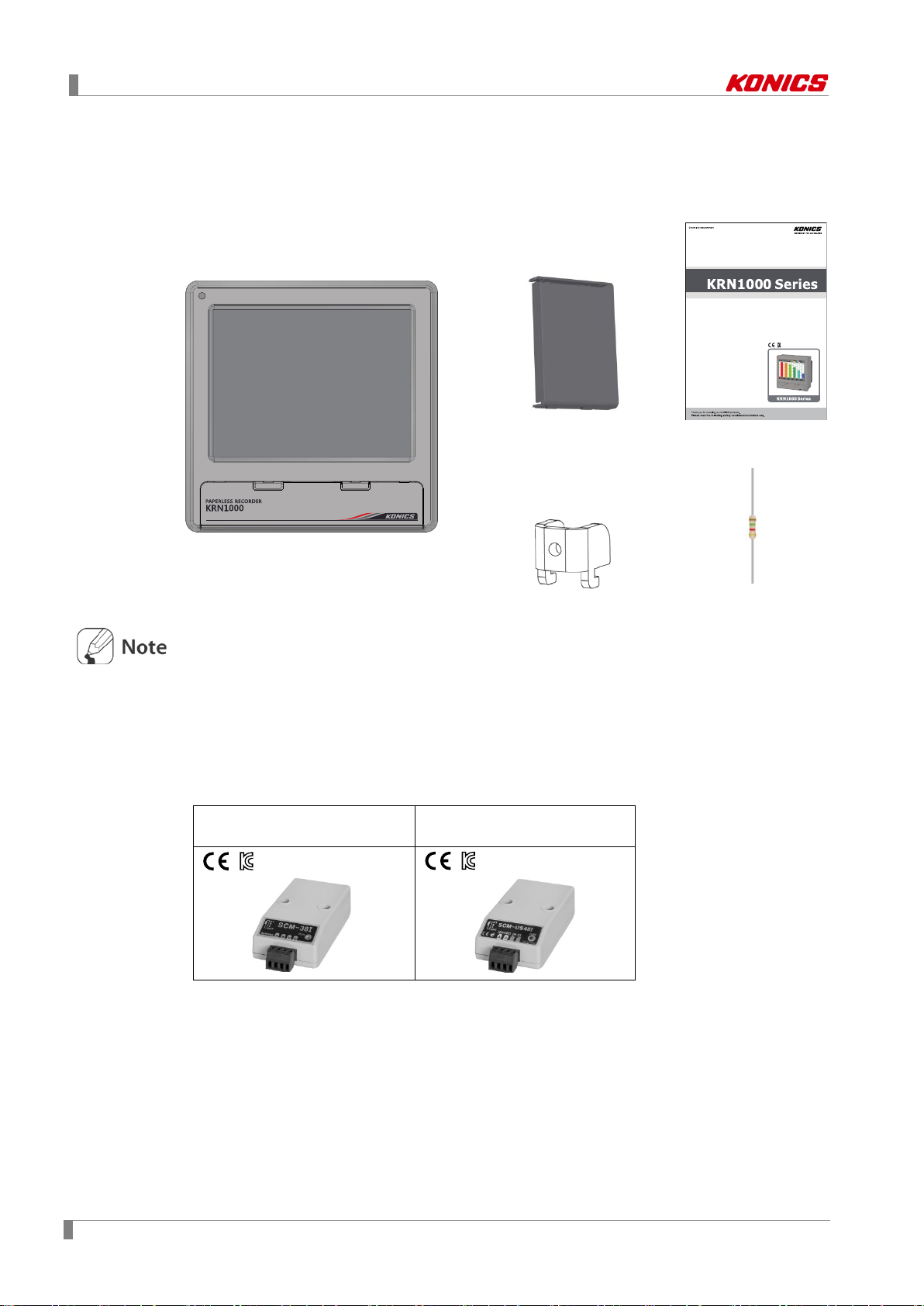

1.2.1 Components

LCD Touchscreen Paperless Recorder

Rear cover User manual

KRN

Before using KRN1000, check the components.

If any component is left out or damaged, contact our company or seller.

KONICS service center: +82-32-820-2356 to 7

1.2.2 Accessories

Communication converter

SCM-38I

(RS232C to RS485 converter)

Use Autonics SCM-38I or SCM-US48I as communication converter.

SCM-38I (RS232C/RS485 converter) and SCM-US48I (USB/RS485 converter) are same

appearance.

1000

Brackets: 4

SCM-US48I

(USB to RS485 converter)

Resistance (250Ω)

12 © Copyright Reserved KONICS Co., Ltd.

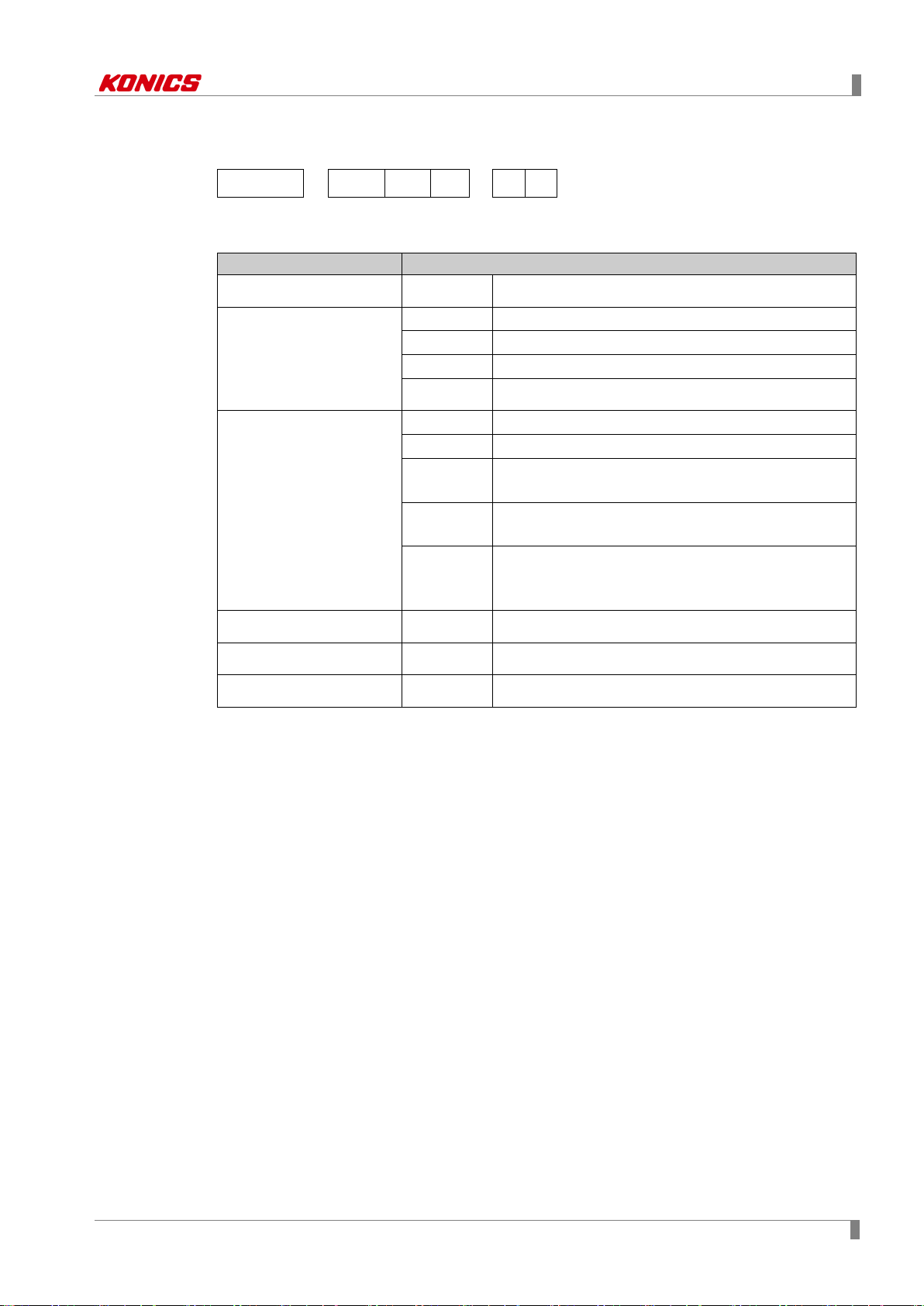

1 Product Introduction

Category

Description

1.3 Ordering information

KRN1000 - 04 0 1

① ② ③ ④

⑤ ⑥

0 S

①Item

②Input channels

③Option input/output

④Communication output

KRN1000 Paperless recorder

04 4 channels

08 8 channels

12 12 channels

16 16 channels

0 None

1 Alarm relay output 8 channels

2

3

4

1 RS422/485 + Ethernet + USB Device

Alarm relay output 6 channels

+ Digital input 2 channels

Alarm relay output 6 channels

+ 24VDC power output for transmitter

Alarm relay output 4 channels

+ Digital input 2 channels

+ 24VDC power output for transmitter

⑤Power supply

⑥Case

0 100-240VAC 50/60Hz

S Standard panel installation type

© Copyright Reserved KONICS Co., Ltd. 13

1 Product Introduction

1 3 2

4

6

7

5

8

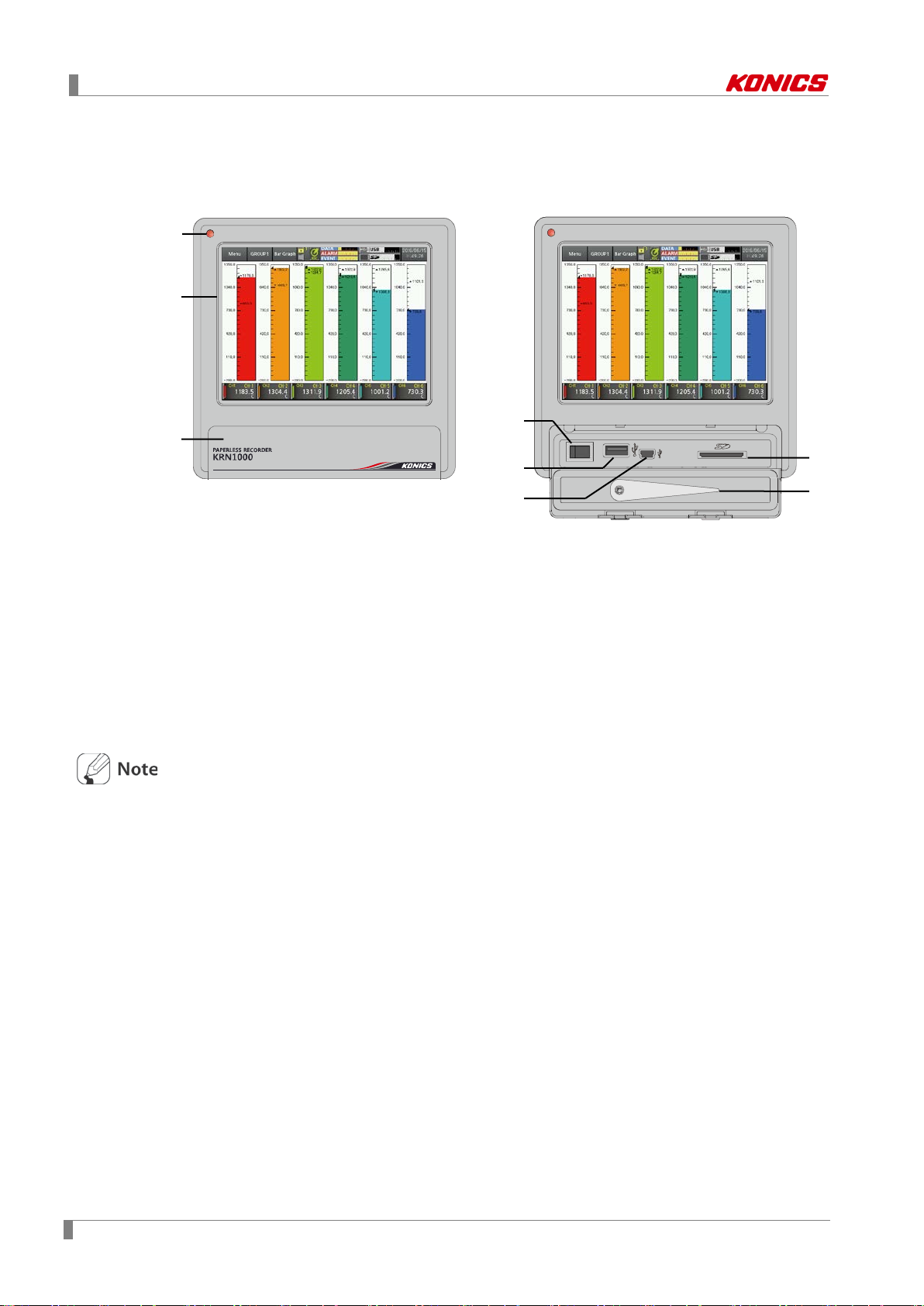

1.4 Unit description

1.4.1 Front part

1. Power indicator: Power turns ON and the red LED turns ON.

2. Screen: Measrued value is displayed as trand graph, bar bar graph, digital figures. (Refer to

‘6 Screen’)

3. Front cover: Open the front cover. There are power switch and, USB Host/Device, SD card

slot.

4. Power switch: Turn ON/OFF the power of KRN1000.

5. USB host port: Connect the USB memory.

It recognizes up to 32GB. When using extension cable, cable length should be up to 1.5m.

6. USB device port: Used for parameter settings.

7. SD card slot: SD card memory slot. It supports up to 32GB.

8. Stylus pen: Used for touching screen.

Do not connect the other USB devices except USB memory at USB host port.

14 © Copyright Reserved KONICS Co., Ltd.

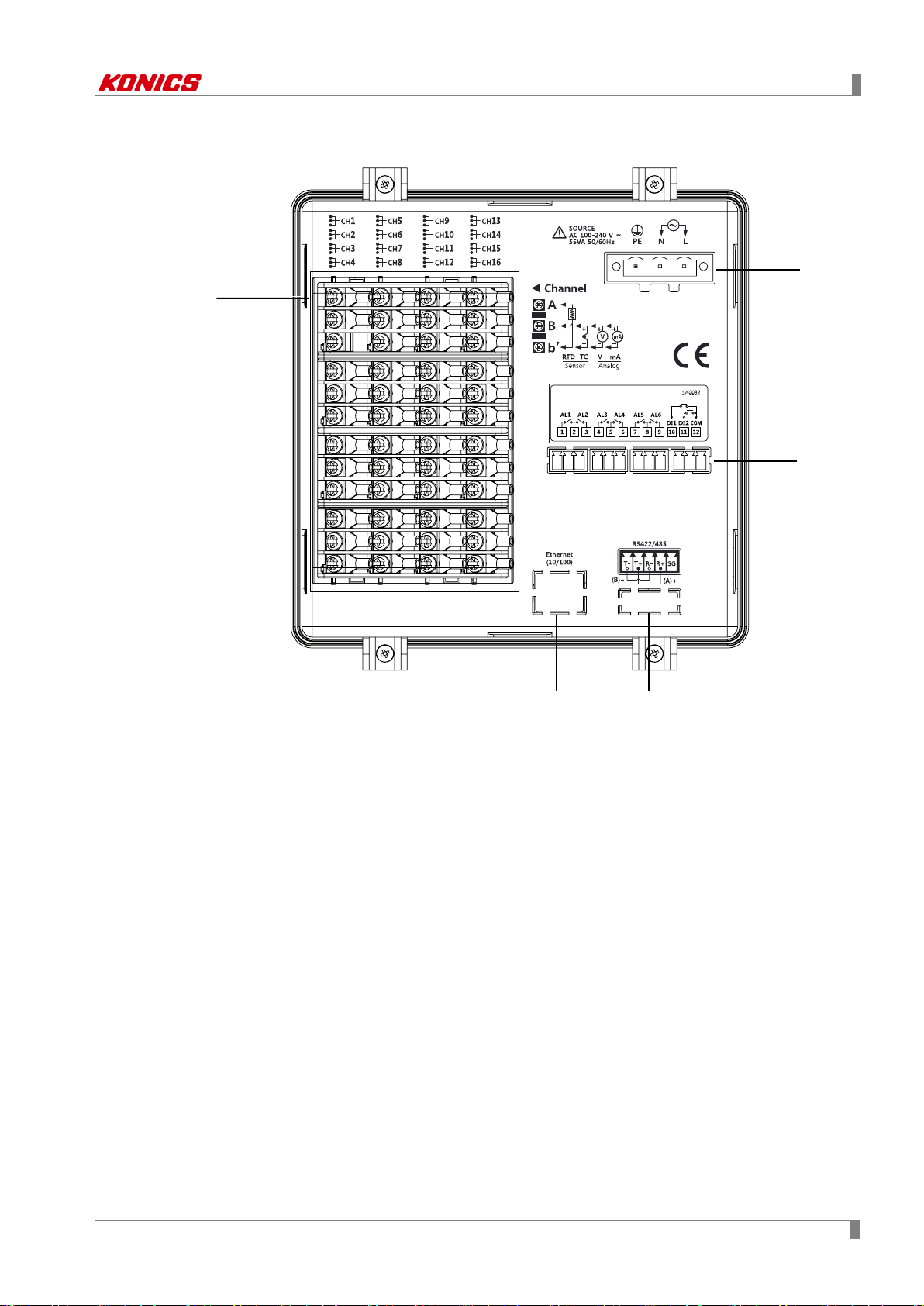

1 Product Introduction

1

2 3 4

5

1.4.2 Rear part

1. Sensor input terminal: Connects universal input.

2. Ethernet port: Connector for ethernet cable. It communicates Modbus TCP.

3. RS422/485 port: Connects RS422/485 for Modbus RTU communication.

4. Option input/output port: Connects for option input/output (digita l in pu t (non-contact/ contact),

alarm output, power for transmitter).

5. Power input: Power connection (100-240VAC 50/60Hz)

© Copyright Reserved KONICS Co., Ltd. 15

1 Product Introduction

16 © Copyright Reserved KONICS Co., Ltd.

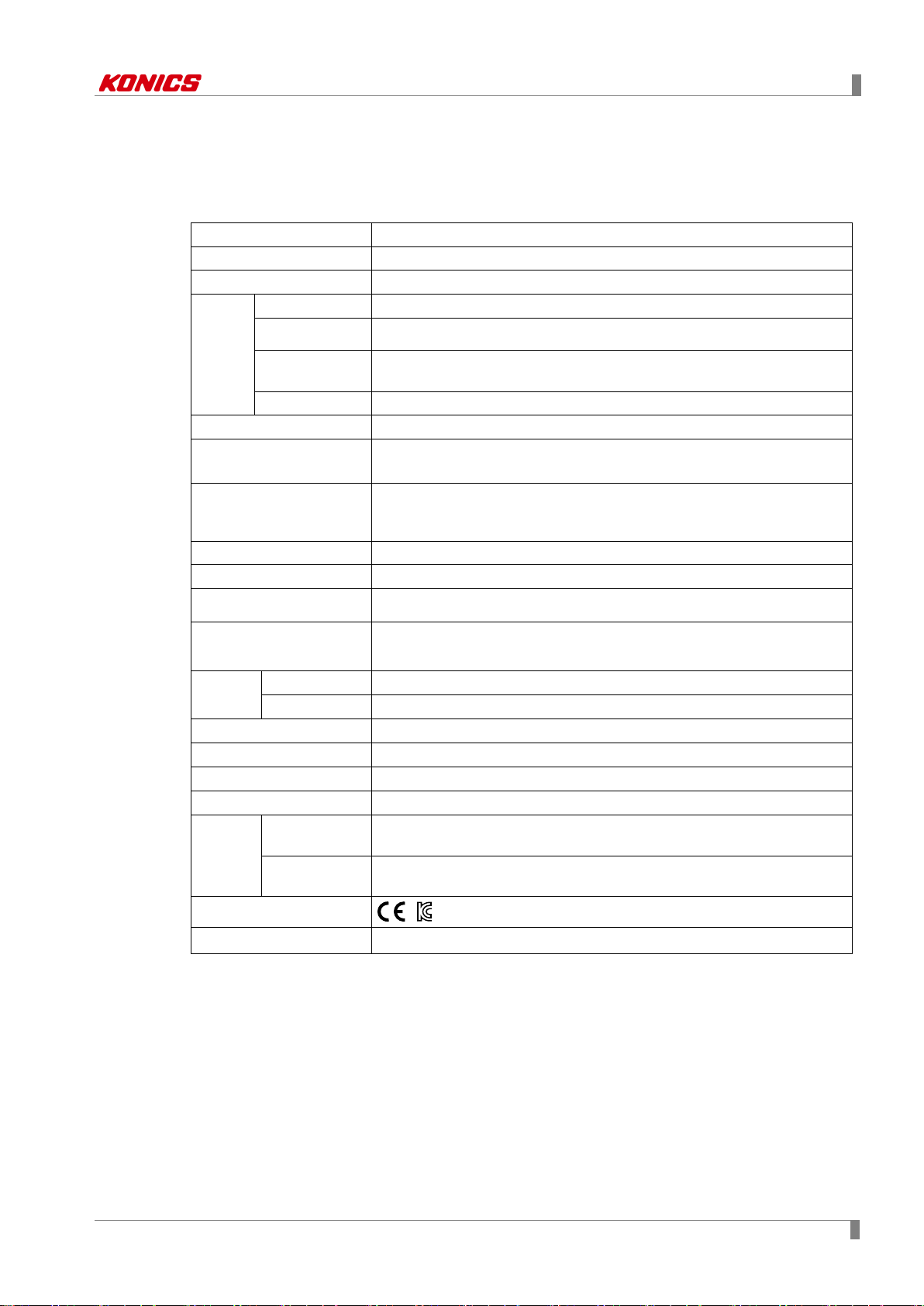

2 Specifications

2

2 Specifications

2.1 KRN1000

Power supply 100-240VAC 50/60Hz

Allowable voltage range 85 to 110% of rated voltage

Power consumption Max. 23VA

Display method 5.6 inch TFT Color LCD

Resolution

Screen

Number of input channels 4 / 8 / 12 / 16 channels

Universal input※1

Sampling period

Recording period 1 to 3600 sec

Internal memory Approx. 200MB

External memory SD / USB memory max. 32GB

Dielectric strength

Vibration

Insulation resistance Over 20MΩ (at 500VDC megger)

Noise immunity Square shaped noise by noise simulator (pulse width 1µs) ±2kV

Time accuracy Within ±2 min/year (available up to 2099)

Protection structure IP50 (front part)

Environm

ent

Adjusting

brightness

Input method Touch screen (Pressure sensitive type)

Mechanical 10 to 60Hz 4.9m/s

Malfunction 10 to 60Hz 1m/s2 in each X, Y, Z direction for 10 min

Ambient

※2

temperature

Ambient

humidity

640×480 pixels

3-level (Min/Standard/Max)

Temperature sensors (thermocouple, RTD),

Analog (voltage, current (shunt))

1 to 4-CH: 25ms/125ms/250ms, 5 to 16-CH: 125ms/250ms

(internal sampling period is average movement filter and alarm output

operation unit time)

2300VAC 50/60Hz for 1 min (between power terminals and case)

※Except ethernet and USB device

in each X, Y, Z direction for 1 hour

0 to 50℃, storage: -20 to 60℃

35 to 85%RH, storage: 35 to 85%RH

Approval

Weight※3 Approx. 1290 to 1400g (approx. 590 to 700g)

※1. For more information of universal input, refer to ‘2.2 Input/Output’.

※2. Environment resistance is rated at no freezing or condensation.

※3. The weight includes packaing. The weight in parenthesis is for unit only.

© Copyright Reserved KONICS Co., Ltd. 17

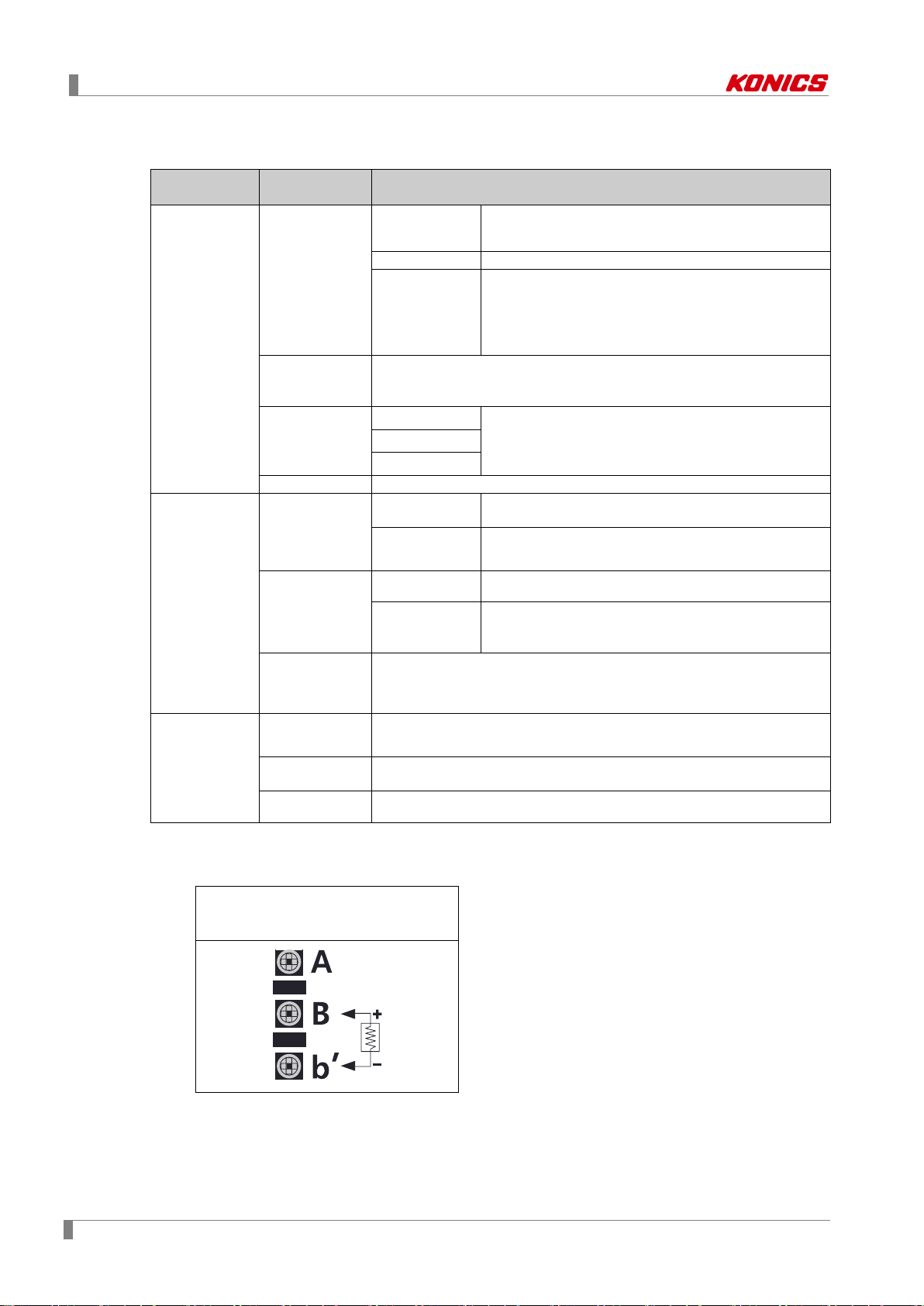

2 Specifications

Input/Output

type

(supplied current: approx. 190µA)

Thermocouple

B, C (W5), E, G, J, K, L, L (Russia), N, P, R, S, T, U

RTD

Warm-up time: Max. 30 min

Thermocouple

Resolution

16-bit

No-contact

input

ON: Residual voltage max. 1V

OFF: Leakage current max. 0.1mA

Short-circuit: Approx. 4mA

Mechanical: Min. 20,000,000 operations

(3A 250V AC, 3A 30V DC)

Power output

Modbus RTU

IEEE802.3 10 BASE-T /

IEEE802.3U 100 BASE-TX (Modbus TCP)

Universal input

method

2.2 Input/Output

Type

Universal input

Option

3

input/output

※

Input type

Input

impedance

Display

accuracy

Digital input

Alarm relay

output

Description

RTD

JPt100Ω, DPt100Ω, DPt50Ω, Cu100Ω, Cu50Ω

Voltage: ±60mV, ±200mV, ±2V, 1-5V, ±5V,

Analog

Current: 0-20mA, 4-20mA (measureable when

using 250Ω shunt resistance)

-1V-10V

1

※

Voltage (V): Approx. 205kΩ

RTD, Thermocouple, Voltage (mV): Min. 200kΩ

2

※

Analog

Contact input

Capacity

Life cycle

At room temperature (25±5℃): ±0.1% F.S.±1-digit

Out of room temperature: ±0.2% F.S.±1-digit

ON: Max. 1kΩ, OFF: Min. 100kΩ,

250VAC 3A, 30VDC 3A, 1 Form A (resistive load)

Electrical: 100,000 operations

24±2VDC, Max. 60mA

4

Built-in over current protection circuit

※

※It is recommended to use shielded cable over AWG 24.

Comm.

※

output

for

transmitter

RS422/485

5

Ethernet

USB Device USB V2.0 Full Speed (Modbus RTU)

※1. Current measurement and connecti on examples

Connect 250Ω shunt resistance and set analog input type 0-20mA (shunt) / 4-20mA (shunt).

It is available to measure 0-20mA / 4-20mA current.

shunt resistance connection

18 © Copyright Reserved KONICS Co., Ltd.

2 Specifications

※2. ◎ At room temperature (23℃ ± 5℃)

RTD Cu50Ω (-200≤T≤200): (±0.1% F.S. or ±1.5℃, select the higher one) ±1-digit

RTD DPt50Ω (-200≤T≤500): (±0.1% F.S. or ±1.5℃, select the higher one) ±1-digit

Thermocouple R, S, C, G type (0≤T≤100): (±0.1% F.S. or ±4.0℃, select the higher one)

±1-digit

Thermocouple U, T type (-100≤T≤400): (±0.1% F.S. or ±2.0℃, select the higher one)

±1-digit

Thermocouple B type, below 400℃: There is no accuracy standards.

All thermocouples, below -100℃: (±0.3% F.S. or ±4.0℃, select the higher one) ±1-digit

◎ Out of room temperature range

RTD Cu50Ω (-200≤T≤200): (±0.2% F.S. or ±3.0℃, select the higher one) ±1-digit

RTD DPt50Ω (-200≤T≤500): (±0.2% F.S. or ±3.0℃, select the higher one) ±1-digit

※3. Input/Output is different by option. Refer to ‘1.3 Ordering information’.

※4. For supplying power for transmitter, it is recommened to use shield cable to reduce noise.

※5. RS422/485, ethernet, USB device communication outputs are not used at the same time.

※If sensor input line is longer, it is recommended to use shield cable to reduce noise.

Before the wiring, turn OFF the unit.

Be sure that the polarity of power for transmitter. If not, it may cause produc t dam age.

When supplying the over voltage at sensor input, it may cause product damage.

© Copyright Reserved KONICS Co., Ltd. 19

2 Specifications

Temperatu re r an ge

K (CA)

TC-K

-200.0 to 1350.0

-328.0 to 2462.0

73.2 to 1623.2

J (IC)

TC-J

-200.0 to 800.0

-328.0 to 1472.0

73.2 to 1073.2

E (CR)

TC-E

-200.0 to 800.0

-328.0 to 1472.0

73.2 to 1073.2

T (CC)

TC-T

-200.0 to 400.0

-328.0 to 752.0

73.2 to 673.2

B (PR)

TC-B

100.0 to 1800.0

212.0 to 3272.0

373.2 to 2073.2

R (PR)

TC-R

0.0 to 1750.0

32.0 to 3182.0

273.2 to 2023.2

S (PR)

TC-S

0.0 to 1750.0

32.0 to 3182.0

273.2 to 2023.2

N (NN)

TC-N

-200.0 to 1300.0

-328.0 to 2372.0

73.2 to 1573.2

C (TT)

1

TC-C

0.0 to 2300.0

32.0 to 4172.0

273.2 to 2573.2

G (TT)

TC-G

0.0 to 2300.0

32.0 to 4172.0

273.2 to 2573.2

L (IC)

TC-L

-200.0 to 900.0

-328.0 to 1652.0

73.2 to 1173.2

L (Russian type)

TC-L_R

0.0 to 600.0

32.0 to 1112.0

273.2 to 873.2

U (CC)

TC-U

-200.0 to 400.0

-328.0 to 752.0

73.2 to 673.2

Platinel Ⅱ

TC-P

0.0 to 1350.0

32.0 to 2462.0

273.2 to 1623.2

Cu50Ω

CU50

-200.0 to 200.0

-328.0 to 392.0

73.2 to 473.2

Cu100Ω

CU100

-200.0 to 200.0

-328.0 to 392.0

73.2 to 473.2

JPt100Ω

JPT100

-200.0 to 600.0

-328.0 to 1112.0

73.2 to 873.2

DPt50Ω

DPT50

-200.0 to 600.0

-328.0 to 1112.0

73.2 to 873.2

DPt100Ω

DPT100

-200.0 to 850.0

-328.0 to 1562.0

73.2 to 1123.2

-60.00-60.00mV

±60mV

Resolution: 10µV

-200.00-200.00mV

±200mV

Resolution: 10µV

-2.000-2.000V

±2V

Resolution: 1mV

1.000-5.000V

1-5V

Resolution: 1mV

-5.000-5.000V

5V

Resolution: 1mV

-1.00-10.00V

-1V-10V

Resolution: 10mV

(shunt)

(shunt)

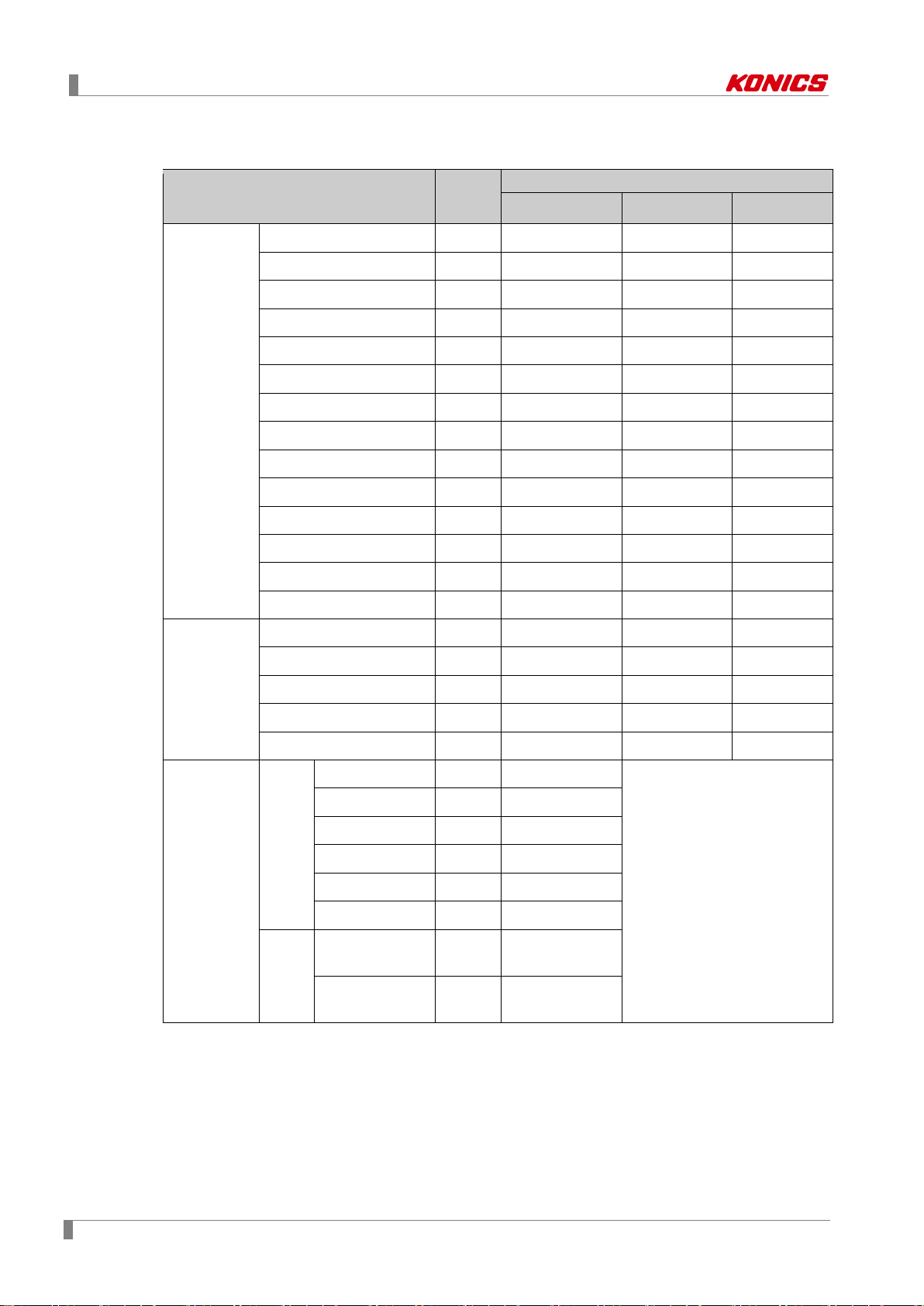

2.3 Input type and range

Input type Display

Thermocouple

※

2

※

3

※

℃ ℉

K

RTD

Voltage

-99999 to 99999

(display range depends on the

Analog

±

decimal point position.)

0-20mA

0-20mA

—

Current

(shunt)

4-20mA

4-20mA

—

※1. C (TT): Same as exisitng W5 (TT) type temperature sensor.

※2. G (TT): Same as existing W (TT) type temperature sensor.

※3. Russian L type temperature sensor is divided from general purpose L type.

20 © Copyright Reserved KONICS Co., Ltd.

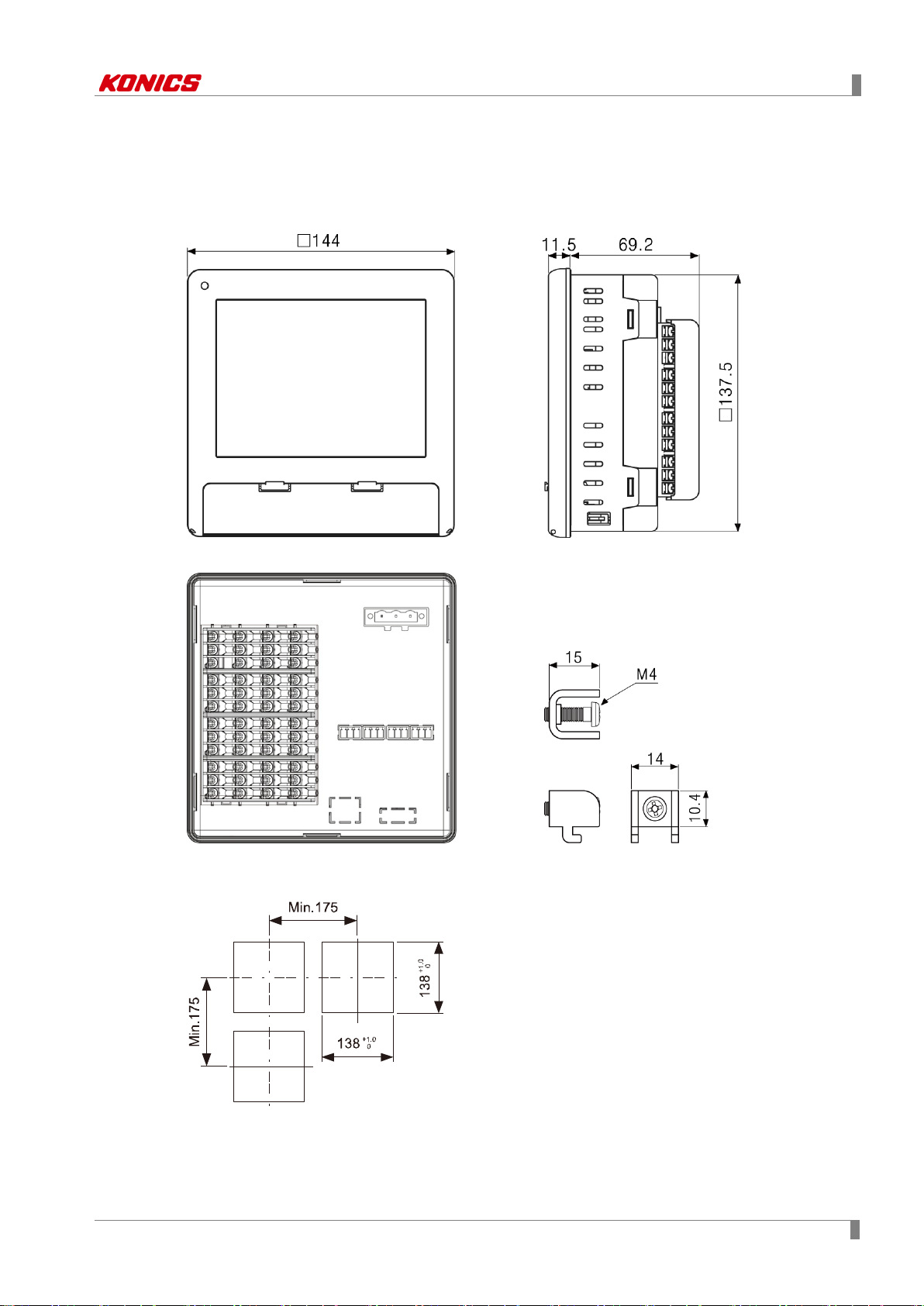

3 Dimensions

(Unit: mm)

3 Dimensions

3.1 KRN1000

3.2 Panel cut-out

※Use panel which is 1 to 5mm thickness.

© Copyright Reserved KONICS Co., Ltd. 21

3 Dimensions

22 © Copyright Reserved KONICS Co., Ltd.

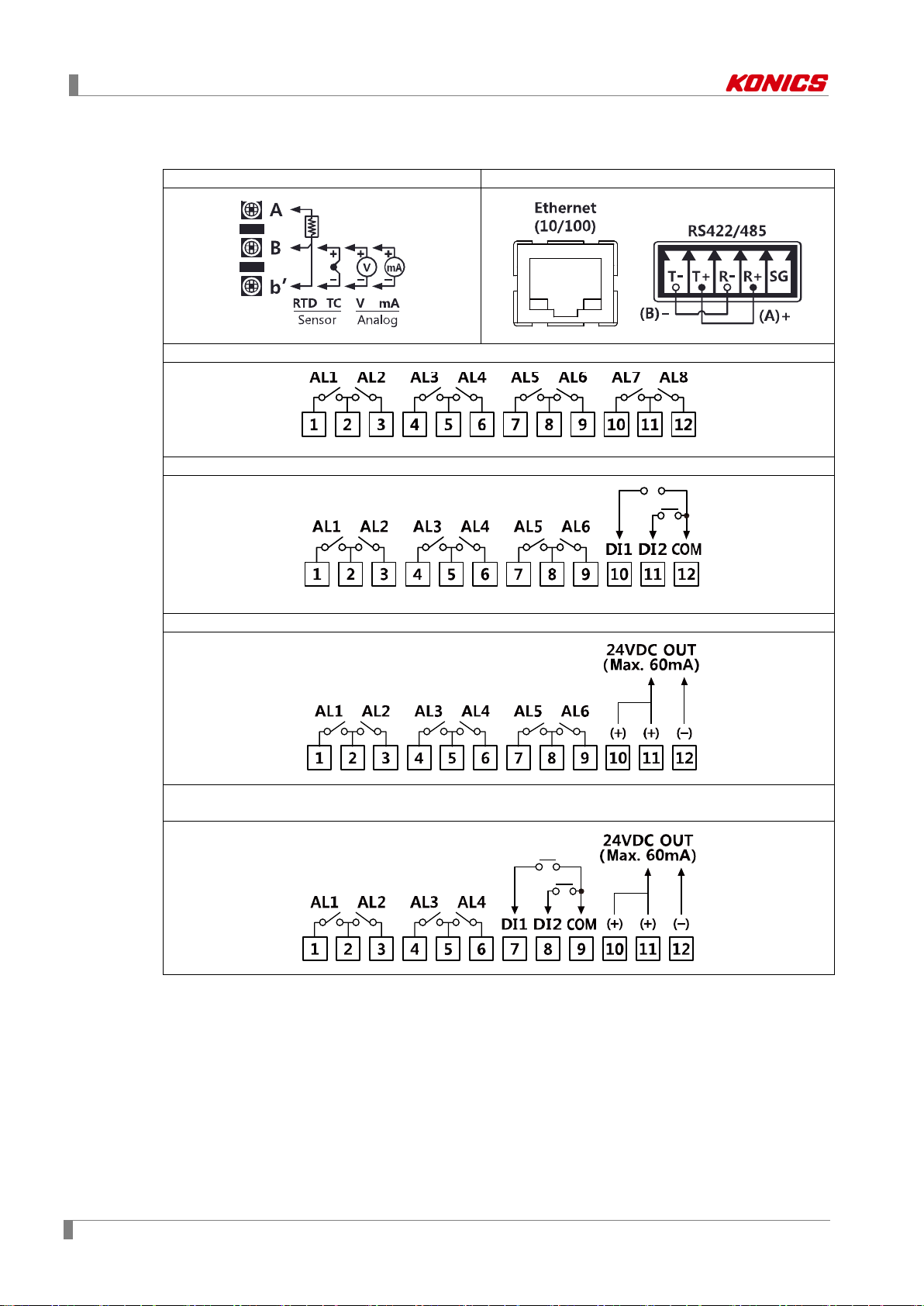

4 Connections

No

Descriptions

1

Connects universal input.

Connects option input/output (digital input (non-contact/contact), alarm output, power for

transmitter).

3

Connects communication output.

1 2 3

4 Connections

4.1 KRN1000

This figure is back side of KRN1000.

2

© Copyright Reserved KONICS Co., Ltd. 23

4 Connections

Universal input

Communication output

Option input/output 1 (alarm output 8 channels)

Option input/output 2 (alarm output 6 channels + digital input 2 channels)

Option input/output 3 (alarm output 6 channels + power for transmitter output)

Option input/output 4

(alarm output 4 channels + digital input 2 channel s + power for transmitter output)

4.2 Input/Output circuit

24 © Copyright Reserved KONICS Co., Ltd.

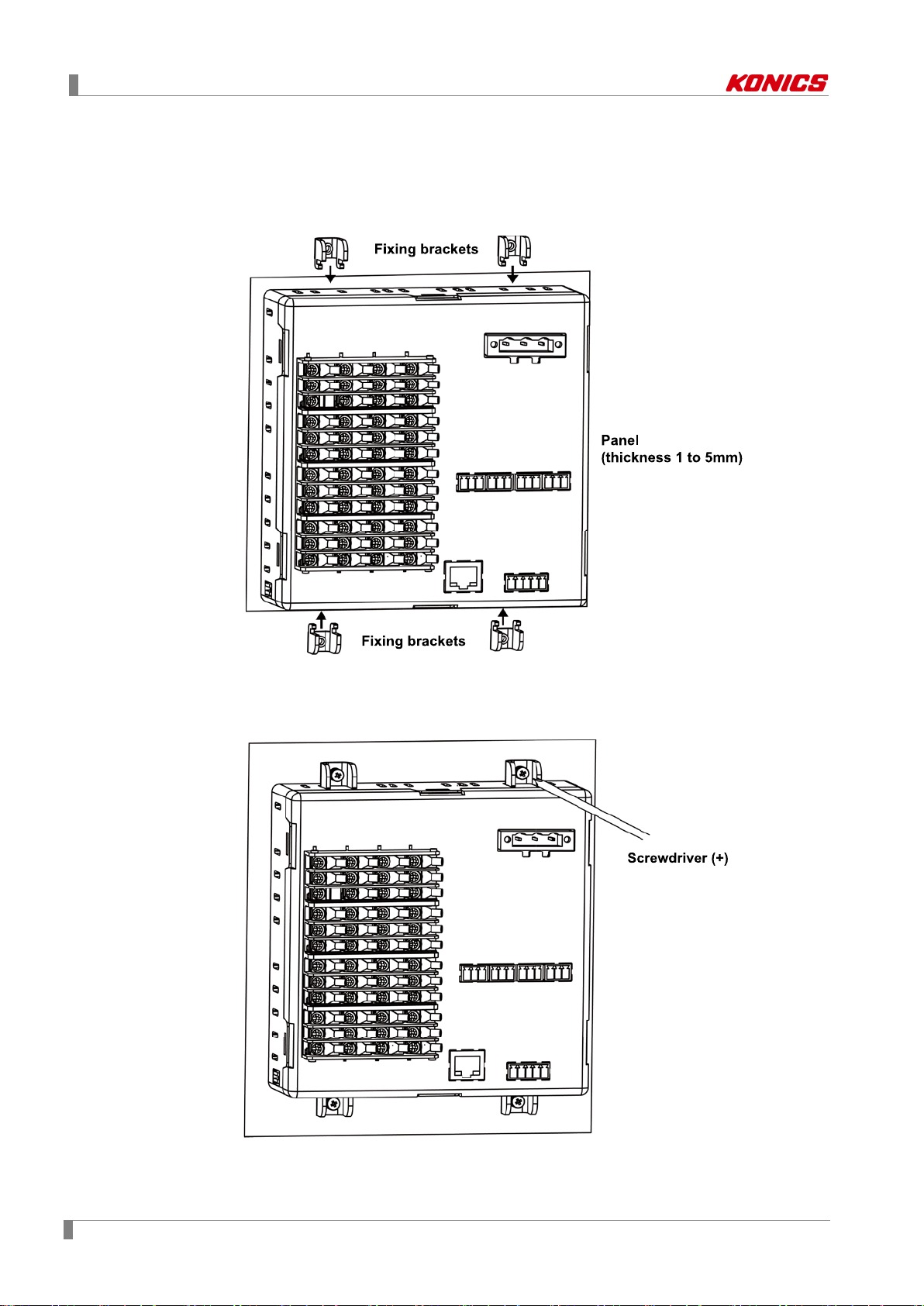

5 Installations

5 Installations

5.1 Environment

Install the unit in place where the below conditions are satisfied.

Place where ventilation is well

To prevent from malfunction and damage by overheating (use temperature range: 0 to

50℃), install this unit where ventilation is well.

In case installing several KRN1000, space each other by panel cut-out.

Place where vibration is not severe

If there is too much vibration, it may cause malfunction such as print error. For more

information about vibration, please refer to ‘2 Specifications’.

In case of temperature measurement with thermocouple temperature sensor at the place

where temperature is fluctuated, data error may occur. You should warm-up this unit over 30

min. to acquire accurate data before using it.

© Copyright Reserved KONICS Co., Ltd. 25

5 Installations

5.2 Installation Method

1st Install KRN1000 on the processed panel as panel cut-out diagram. Mount fixing

brackets on upper/lower parts.

2nd Tighten fixing brackets on upper/lower parts to fix on the panel with screwdriver (+)

with 0.4N•m torque.

26 © Copyright Reserved KONICS Co., Ltd.

Loading...

Loading...