USER MANUAL

© Copyright Reserved KONICS Co., Ltd. i

ii © Copyright Reserved KONICS Co., Ltd.

Preface

Preface

Thank you for purchasing KONICS product.

Please familiarize yourself with the information contained in the Safety Precautions section

before using this product.

This user manual contains information about the product and its proper use, and should be kept

in a place where it will be easy to access.

© Copyright Reserved KONICS Co., Ltd. iii

User Manual Guide

User Manual Guide

Please familiarize yourself with the information in this manual before using the product.

This manual provides detailed information on the product's features. It does not offer any

guarantee concerning matters beyond the scope of this manual.

This manual may not be edited or reproduced in either part or whole without permission.

A user manual is not provided as part of the product package.

Visit our web site (www.konics.com) to download a copy.

The manual's content may vary depending on changes to the product's software and other

unforeseen developments within KONICS, and is subject to change without prior notice.

Update notice is provided through out homepage.

We contrived to describe this manual more easily and correctly. However, if there are any

corrections or questions, please notify us these on our homepage.

iv © Copyright Reserved KONICS Co., Ltd.

User Manual Symbols

Symbol

Description

User Manual Symbols

Supplementary information for a particular feature.

Failure to follow instructions can result in serious injury or death.

Failure to follow instructions can lead to a minor injury or product damage.

An example of the concerned feature's use.

※1

Annotation mark.

© Copyright Reserved KONICS Co., Ltd. v

Safety Precautions

Safety Precautions

Following these safety precautions will ensure the safe and proper use of the product and

help prevent accidents, as well as minimizing possible hazards.

Safety precautions are categorized as Warnings and Cautions, as defined below:

Warning

Caution

Failure to follow the instructions may lead to a serious injury

or accident.

Failure to follow the instructions may lead to a minor injury

or accident.

Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical equipment,

ships, vehicles, railways, aircraft, combustion apparatus, safety equipment, crime/disaster

prevention devices, etc.)

Failure to follow this instruction may result in personal injury, fire, or economic loss.

The unit must be installed on a device panel before use.

Failure to follow this instruction may result in electric shock.

Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock.

Check the terminal numbers before connecting the power source.

Failure to follow this instruction may result in fire or burning the unit.

Lithium battery is used in the unit. Do not disassemble or burn the unit.

Failure to follow this instruction may result in explosion.

Do not touch the unit and terminals after cut off the power within 30 sec.

Failure to follow this instruction may result in electric shock.

Ground PE terminal individually and ground cable should be over AWG16 (1.25 mm

Failure to follow this instruction may result in electric shock.

Do not insert any objects at the openings of the unit.

Failure to follow this instruction may result in electric shock or personal injury.

Do not disassemble or modify the unit. Please contact us if necessary.

Failure to follow this instruction may result in personal injury, fire, or economic loss.

Do not use the unit outdoors.

Failure to follow this instruction may result in shortening the life cycle of the unit, or electric

shock.

2

When connecting the power input and relay output cables, use AWG20 (0.05mm

) cables

and make sure to tighten the terminal screw bolt above 0.74N.m to 0.90N.m.

Failure to follow this instruction may result in fire due to contact failure.

Use the unit within the rated specifications.

Failure to follow this instruction may result in shortening the life cycle of the unit, or fire.

2

).

vi © Copyright Reserved KONICS Co., Ltd.

Safety Precautions

Do not use loads beyond the rated switching capacity of the relay contact.

Failure to follow this instruction may result in insulation failure, contact melt, contact failure,

relay broken, or fire.

When connecting magnet contact as relay contact output load, attach a surge absorber at

contact coil.

Failure to follow this instruction may result in product malfunction.

Do not use water or oil-based detergent when cleaning the unit. Use dry cloth to clearn the

unit.

Failure to follow this instruction may result in electric shock, or fire.

Do not use the unit where flammable or explosive gas, humidity, direct sunlight, radiant heat,

vibration, or impact may be present.

Failure to follow this instruction may result in fire or explosion.

Keep dust and wire residue from flowing into the unit.

Failure to follow this instruction may result in fire or product damage.

Check the polarity before connecting cables.

Failure to follow this instruction may result in fire or explosion.

Check the polarity of the measurement input contact before wiring the temperature sensor.

Failure to follow this instruction may result in fire or explosion.

Check the connection diagram of this manual before supplying power.

Failure to follow this instruction may result in fire.

Do not touch terminal during dielectric or insulation resistance test.

Failure to follow this instruction may result in electric shock.

Use insulation transformer and noise filter power for too much noise from the power. Attach

noise filter on the grounded panel, etc. Use short cables for noise filter output part and

power terminal of the unit.

Failure to follow this instruction may result in product damage, malfunction by surge.

If power line and input signal line are close each other, install line filter for noise protection

at power line and use shielded input signal line.

Do not control the alarm output or measure the data during firmware update. Failure to

follow this instruction may result in malfunction. Alarm output, contact input, data

measurement do not operate normally.

After completing firmware update, check the complete message and turn OFF to ON the

power.

All parameter setting values are reset after firmware update. It may not operate as same

way with before updating operation.

Use voltage output of transmitter power output only for transmitter power. Failure to follow

this instruction may result in output module damage.

Do not press the touch screen by sharp or hard objects with excessive force.

To prevent inductive noise, separate cables of the unit from high-voltage line, power line.

Do not install inductive noise or power line closely. It may cause measurement error.

Install the unit at well-ventilated place to prevent over-heat and give space over 30mm

against wall.

Install the unit vertically.

© Copyright Reserved KONICS Co., Ltd. vii

Safety Precautions

viii © Copyright Reserved KONICS Co., Ltd.

Table of Contents

Table of Contents

Preface .............................................................................................................................iii

User Manual Guide ......................................................................................................... iv

User Manual Symbols ...................................................................................................... v

Safety Precautions .......................................................................................................... vi

Table of Contents ............................................................................................................ ix

1 Product Introduction................................................................................. 11

1.1 Features ............................................................................................................. 11

1.2 Components and accessories ........................................................................... 12

1.2.1 Components ............................................................................................... 12

1.2.2 Accessories ................................................................................................ 12

1.3 Ordering information .......................................................................................... 13

1.4 Unit description .................................................................................................. 14

1.4.1 Front part .................................................................................................... 14

1.4.2 Rear part .................................................................................................... 15

2 Specifications ............................................................................................ 17

2.1 KRN1000 ........................................................................................................... 17

2.2 Input/Output ....................................................................................................... 18

2.3 Input type and range .......................................................................................... 20

3 Dimensions ................................................................................................ 21

3.1 KRN1000 ........................................................................................................... 21

3.2 Panel cut-out ...................................................................................................... 21

4 Connections .............................................................................................. 23

4.1 KRN1000 ........................................................................................................... 23

4.2 Input/Output circuit ............................................................................................. 24

5 Installations ............................................................................................... 25

5.1 Environment ....................................................................................................... 25

5.2 Installation Method ............................................................................................. 26

5.3 USB to Serial driver ........................................................................................... 27

5.3.1 Driver installation ........................................................................................ 27

5.3.2 Check the driver ......................................................................................... 28

6 Screen ........................................................................................................ 29

6.1 Initial booting screen .......................................................................................... 29

6.2 Screen description ............................................................................................. 30

6.2.1 Status display part ...................................................................................... 30

6.2.2 Measurement value display part ................................................................ 32

6.2.3 Graph ......................................................................................................... 33

6.2.4 Pop-up menu .............................................................................................. 37

6.2.5 Virtual keyboard ......................................................................................... 38

6.2.6 Color ........................................................................................................... 40

© Copyright Reserved KONICS Co., Ltd. ix

Table of Contents

7 Menu ........................................................................................................... 41

7.1 Display ............................................................................................................... 42

7.1.1 History ........................................................................................................ 42

7.1.2 File History ................................................................................................. 44

7.1.3 Group Setting ............................................................................................. 45

7.1.4 Touch Calibration ........................................................................................ 46

7.2 Status ................................................................................................................. 47

7.2.1 Alarm List.................................................................................................... 47

7.2.2 Event List .................................................................................................... 48

7.2.3 AO/DI Status ............................................................................................... 48

7.3 Input CH Info. ..................................................................................................... 49

7.3.1 Input/Display ............................................................................................... 49

7.3.2 Input Option ................................................................................................ 53

7.3.3 Alarm .......................................................................................................... 58

7.3.4 User Unit..................................................................................................... 60

7.4 Option Info. ........................................................................................................ 61

7.4.1 Alarm Output .............................................................................................. 61

7.4.2 Digital Input................................................................................................. 62

7.4.3 RS422/485 ................................................................................................. 63

7.4.4 Ethernet/USB ............................................................................................. 64

7.5 System Info. ....................................................................................................... 66

7.5.1 Date/Time ................................................................................................... 66

7.5.2 Reservation ................................................................................................ 67

7.5.3 Device......................................................................................................... 69

7.5.4 File .............................................................................................................. 70

7.5.5 Log In.......................................................................................................... 71

7.5.6 System Info. ............................................................................................... 72

7.6 Memory Info. ...................................................................................................... 73

7.6.1 Memory Management ................................................................................ 73

7.6.2 Internal Memory ......................................................................................... 74

7.7 Screen Capture .................................................................................................. 75

7.8 Log OFF/Power OFF ......................................................................................... 76

8 Integrated device management program (DAQMaster) ......................... 77

8.1 Overview ............................................................................................................ 77

8.2 Features ............................................................................................................. 78

8.3 Dedicated features for KRN1000 ...................................................................... 79

8.3.1 Record Backup ........................................................................................... 80

8.3.2 Check backup data ..................................................................................... 81

9 Troubleshooting ........................................................................................ 83

9.1 Error message ................................................................................................... 84

x © Copyright Reserved KONICS Co., Ltd.

1 Product Introduction

1 Product Introduction

1.1 Features

KRN1000 is paperless recorder with LCD method to save recording data at SD / USB memory.

It displays trend graph, bar graph, or digital figures at TFT Color LCD.

Via RS422/485, Ethernet or USB device communication, it is available to set parameters,

transfer data as data logger functions for user convienent.

It supports several communication method and various input/output functions. It also provides

easy and convient graphic user interface (GUI) applying graphic display.

5.6-inch color TFT LCD (640×480) touchscreen display with excellent readability and

intuitive control interface

Supports 27 input types (thermocouple, RTD, analog voltage and current[shunt])

4 / 8 / 12 / 16 input channel models available

Various communication methods (RS422/485, Ethernet, USB) standard

25 to 250 ms high-speed sampling, 1 to 3600 s recording cycle

200 MB internal memory and external memory support (SD/USB up to 32 GB)

Store and backup internal data to external memory (SD/USB)

9 different graph types available

Various option input/output available: digital input (contact/non-contact), alarm output,

transmitter power output

Compact, space-saving design (rear length: 69.2 mm)

© Copyright Reserved KONICS Co., Ltd. 11

1 Product Introduction

1.2 Components and accessories

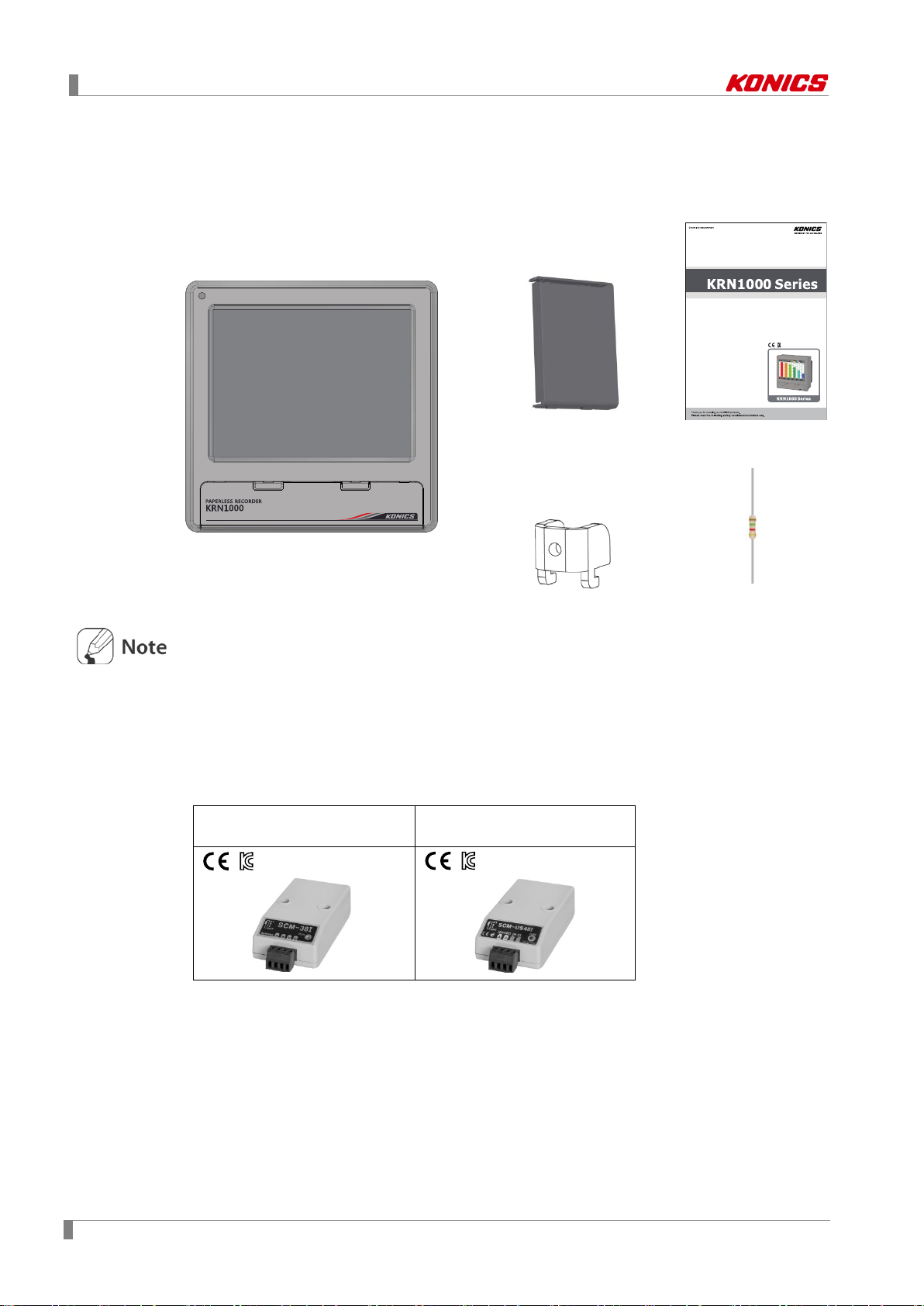

1.2.1 Components

LCD Touchscreen Paperless Recorder

Rear cover User manual

KRN

Before using KRN1000, check the components.

If any component is left out or damaged, contact our company or seller.

KONICS service center: +82-32-820-2356 to 7

1.2.2 Accessories

Communication converter

SCM-38I

(RS232C to RS485 converter)

Use Autonics SCM-38I or SCM-US48I as communication converter.

SCM-38I (RS232C/RS485 converter) and SCM-US48I (USB/RS485 converter) are same

appearance.

1000

Brackets: 4

SCM-US48I

(USB to RS485 converter)

Resistance (250Ω)

12 © Copyright Reserved KONICS Co., Ltd.

1 Product Introduction

Category

Description

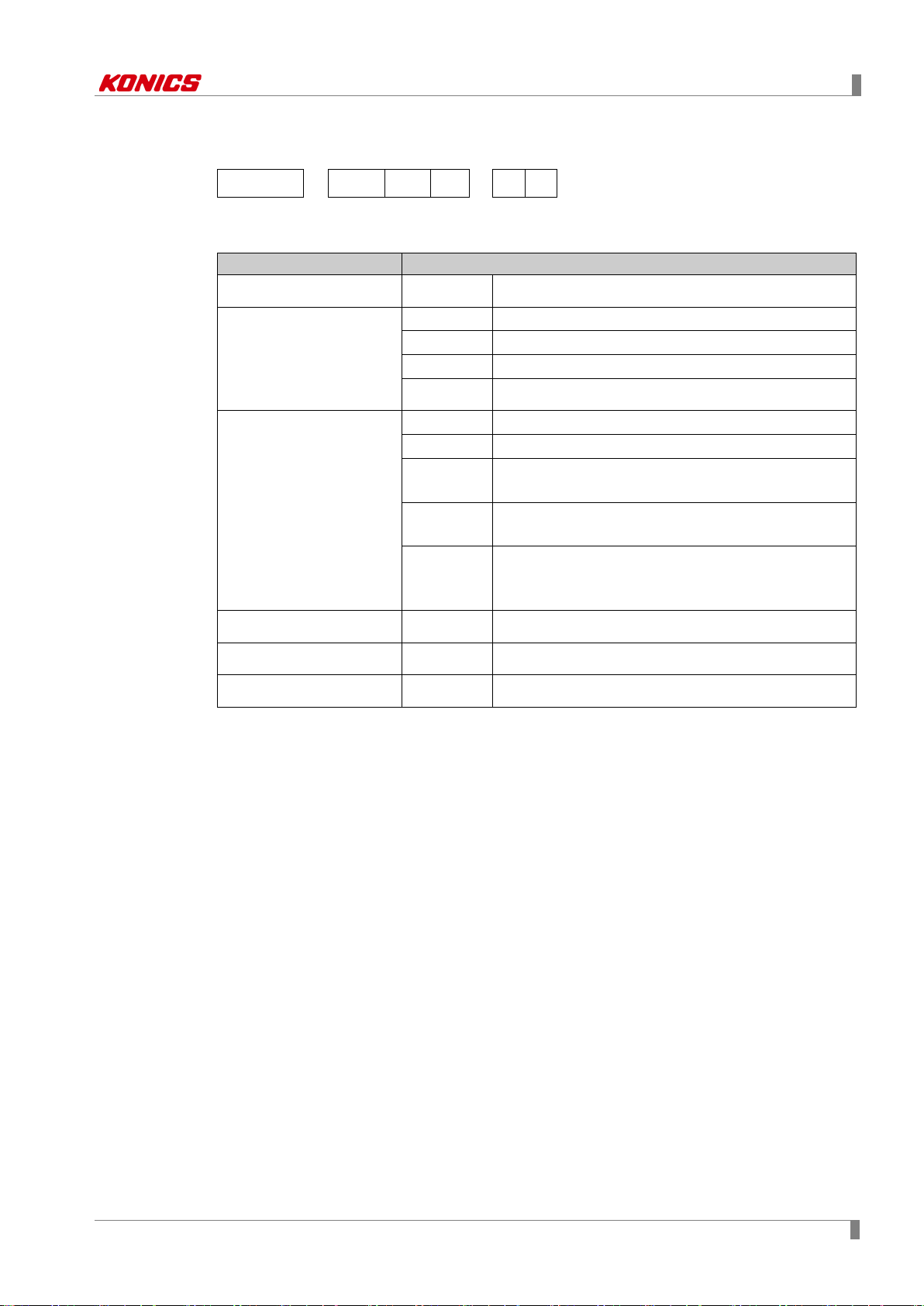

1.3 Ordering information

KRN1000 - 04 0 1

① ② ③ ④

⑤ ⑥

0 S

①Item

②Input channels

③Option input/output

④Communication output

KRN1000 Paperless recorder

04 4 channels

08 8 channels

12 12 channels

16 16 channels

0 None

1 Alarm relay output 8 channels

2

3

4

1 RS422/485 + Ethernet + USB Device

Alarm relay output 6 channels

+ Digital input 2 channels

Alarm relay output 6 channels

+ 24VDC power output for transmitter

Alarm relay output 4 channels

+ Digital input 2 channels

+ 24VDC power output for transmitter

⑤Power supply

⑥Case

0 100-240VAC 50/60Hz

S Standard panel installation type

© Copyright Reserved KONICS Co., Ltd. 13

1 Product Introduction

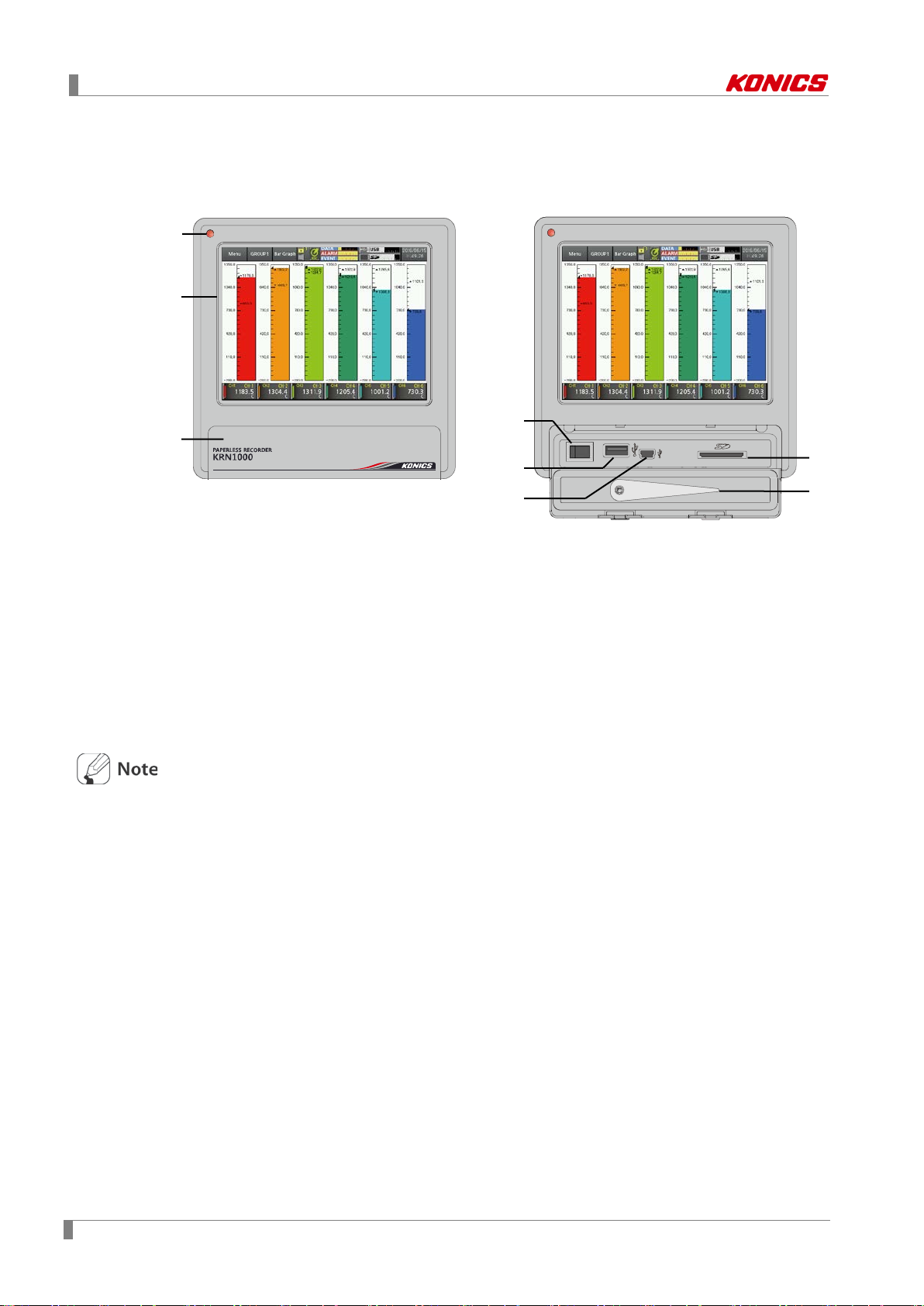

1 3 2

4

6

7

5

8

1.4 Unit description

1.4.1 Front part

1. Power indicator: Power turns ON and the red LED turns ON.

2. Screen: Measrued value is displayed as trand graph, bar bar graph, digital figures. (Refer to

‘6 Screen’)

3. Front cover: Open the front cover. There are power switch and, USB Host/Device, SD card

slot.

4. Power switch: Turn ON/OFF the power of KRN1000.

5. USB host port: Connect the USB memory.

It recognizes up to 32GB. When using extension cable, cable length should be up to 1.5m.

6. USB device port: Used for parameter settings.

7. SD card slot: SD card memory slot. It supports up to 32GB.

8. Stylus pen: Used for touching screen.

Do not connect the other USB devices except USB memory at USB host port.

14 © Copyright Reserved KONICS Co., Ltd.

1 Product Introduction

1

2 3 4

5

1.4.2 Rear part

1. Sensor input terminal: Connects universal input.

2. Ethernet port: Connector for ethernet cable. It communicates Modbus TCP.

3. RS422/485 port: Connects RS422/485 for Modbus RTU communication.

4. Option input/output port: Connects for option input/output (digita l in pu t (non-contact/ contact),

alarm output, power for transmitter).

5. Power input: Power connection (100-240VAC 50/60Hz)

© Copyright Reserved KONICS Co., Ltd. 15

1 Product Introduction

16 © Copyright Reserved KONICS Co., Ltd.

2 Specifications

2

2 Specifications

2.1 KRN1000

Power supply 100-240VAC 50/60Hz

Allowable voltage range 85 to 110% of rated voltage

Power consumption Max. 23VA

Display method 5.6 inch TFT Color LCD

Resolution

Screen

Number of input channels 4 / 8 / 12 / 16 channels

Universal input※1

Sampling period

Recording period 1 to 3600 sec

Internal memory Approx. 200MB

External memory SD / USB memory max. 32GB

Dielectric strength

Vibration

Insulation resistance Over 20MΩ (at 500VDC megger)

Noise immunity Square shaped noise by noise simulator (pulse width 1µs) ±2kV

Time accuracy Within ±2 min/year (available up to 2099)

Protection structure IP50 (front part)

Environm

ent

Adjusting

brightness

Input method Touch screen (Pressure sensitive type)

Mechanical 10 to 60Hz 4.9m/s

Malfunction 10 to 60Hz 1m/s2 in each X, Y, Z direction for 10 min

Ambient

※2

temperature

Ambient

humidity

640×480 pixels

3-level (Min/Standard/Max)

Temperature sensors (thermocouple, RTD),

Analog (voltage, current (shunt))

1 to 4-CH: 25ms/125ms/250ms, 5 to 16-CH: 125ms/250ms

(internal sampling period is average movement filter and alarm output

operation unit time)

2300VAC 50/60Hz for 1 min (between power terminals and case)

※Except ethernet and USB device

in each X, Y, Z direction for 1 hour

0 to 50℃, storage: -20 to 60℃

35 to 85%RH, storage: 35 to 85%RH

Approval

Weight※3 Approx. 1290 to 1400g (approx. 590 to 700g)

※1. For more information of universal input, refer to ‘2.2 Input/Output’.

※2. Environment resistance is rated at no freezing or condensation.

※3. The weight includes packaing. The weight in parenthesis is for unit only.

© Copyright Reserved KONICS Co., Ltd. 17

2 Specifications

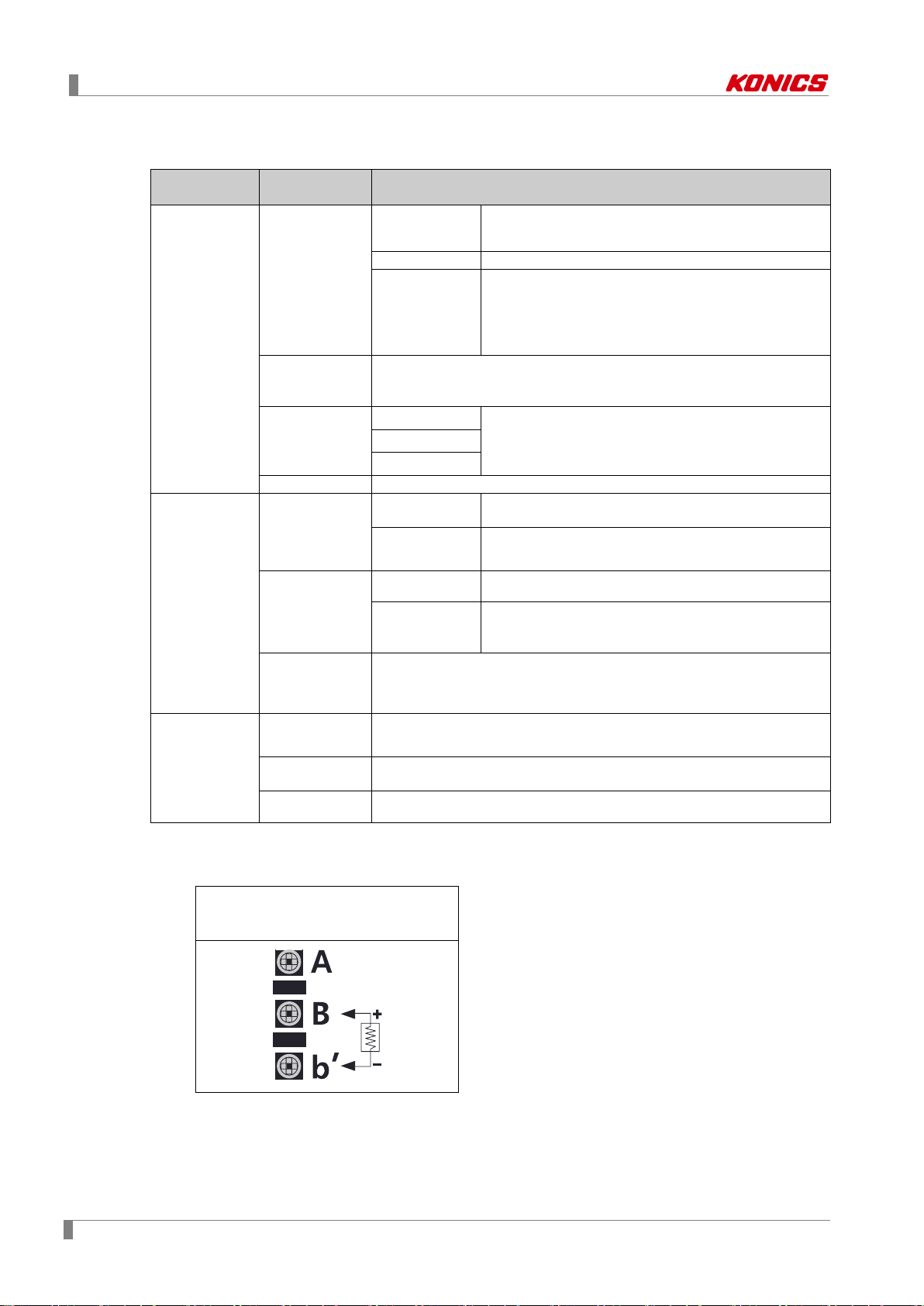

Input/Output

type

(supplied current: approx. 190µA)

Thermocouple

B, C (W5), E, G, J, K, L, L (Russia), N, P, R, S, T, U

RTD

Warm-up time: Max. 30 min

Thermocouple

Resolution

16-bit

No-contact

input

ON: Residual voltage max. 1V

OFF: Leakage current max. 0.1mA

Short-circuit: Approx. 4mA

Mechanical: Min. 20,000,000 operations

(3A 250V AC, 3A 30V DC)

Power output

Modbus RTU

IEEE802.3 10 BASE-T /

IEEE802.3U 100 BASE-TX (Modbus TCP)

Universal input

method

2.2 Input/Output

Type

Universal input

Option

3

input/output

※

Input type

Input

impedance

Display

accuracy

Digital input

Alarm relay

output

Description

RTD

JPt100Ω, DPt100Ω, DPt50Ω, Cu100Ω, Cu50Ω

Voltage: ±60mV, ±200mV, ±2V, 1-5V, ±5V,

Analog

Current: 0-20mA, 4-20mA (measureable when

using 250Ω shunt resistance)

-1V-10V

1

※

Voltage (V): Approx. 205kΩ

RTD, Thermocouple, Voltage (mV): Min. 200kΩ

2

※

Analog

Contact input

Capacity

Life cycle

At room temperature (25±5℃): ±0.1% F.S.±1-digit

Out of room temperature: ±0.2% F.S.±1-digit

ON: Max. 1kΩ, OFF: Min. 100kΩ,

250VAC 3A, 30VDC 3A, 1 Form A (resistive load)

Electrical: 100,000 operations

24±2VDC, Max. 60mA

4

Built-in over current protection circuit

※

※It is recommended to use shielded cable over AWG 24.

Comm.

※

output

for

transmitter

RS422/485

5

Ethernet

USB Device USB V2.0 Full Speed (Modbus RTU)

※1. Current measurement and connecti on examples

Connect 250Ω shunt resistance and set analog input type 0-20mA (shunt) / 4-20mA (shunt).

It is available to measure 0-20mA / 4-20mA current.

shunt resistance connection

18 © Copyright Reserved KONICS Co., Ltd.

2 Specifications

※2. ◎ At room temperature (23℃ ± 5℃)

RTD Cu50Ω (-200≤T≤200): (±0.1% F.S. or ±1.5℃, select the higher one) ±1-digit

RTD DPt50Ω (-200≤T≤500): (±0.1% F.S. or ±1.5℃, select the higher one) ±1-digit

Thermocouple R, S, C, G type (0≤T≤100): (±0.1% F.S. or ±4.0℃, select the higher one)

±1-digit

Thermocouple U, T type (-100≤T≤400): (±0.1% F.S. or ±2.0℃, select the higher one)

±1-digit

Thermocouple B type, below 400℃: There is no accuracy standards.

All thermocouples, below -100℃: (±0.3% F.S. or ±4.0℃, select the higher one) ±1-digit

◎ Out of room temperature range

RTD Cu50Ω (-200≤T≤200): (±0.2% F.S. or ±3.0℃, select the higher one) ±1-digit

RTD DPt50Ω (-200≤T≤500): (±0.2% F.S. or ±3.0℃, select the higher one) ±1-digit

※3. Input/Output is different by option. Refer to ‘1.3 Ordering information’.

※4. For supplying power for transmitter, it is recommened to use shield cable to reduce noise.

※5. RS422/485, ethernet, USB device communication outputs are not used at the same time.

※If sensor input line is longer, it is recommended to use shield cable to reduce noise.

Before the wiring, turn OFF the unit.

Be sure that the polarity of power for transmitter. If not, it may cause produc t dam age.

When supplying the over voltage at sensor input, it may cause product damage.

© Copyright Reserved KONICS Co., Ltd. 19

2 Specifications

Temperatu re r an ge

K (CA)

TC-K

-200.0 to 1350.0

-328.0 to 2462.0

73.2 to 1623.2

J (IC)

TC-J

-200.0 to 800.0

-328.0 to 1472.0

73.2 to 1073.2

E (CR)

TC-E

-200.0 to 800.0

-328.0 to 1472.0

73.2 to 1073.2

T (CC)

TC-T

-200.0 to 400.0

-328.0 to 752.0

73.2 to 673.2

B (PR)

TC-B

100.0 to 1800.0

212.0 to 3272.0

373.2 to 2073.2

R (PR)

TC-R

0.0 to 1750.0

32.0 to 3182.0

273.2 to 2023.2

S (PR)

TC-S

0.0 to 1750.0

32.0 to 3182.0

273.2 to 2023.2

N (NN)

TC-N

-200.0 to 1300.0

-328.0 to 2372.0

73.2 to 1573.2

C (TT)

1

TC-C

0.0 to 2300.0

32.0 to 4172.0

273.2 to 2573.2

G (TT)

TC-G

0.0 to 2300.0

32.0 to 4172.0

273.2 to 2573.2

L (IC)

TC-L

-200.0 to 900.0

-328.0 to 1652.0

73.2 to 1173.2

L (Russian type)

TC-L_R

0.0 to 600.0

32.0 to 1112.0

273.2 to 873.2

U (CC)

TC-U

-200.0 to 400.0

-328.0 to 752.0

73.2 to 673.2

Platinel Ⅱ

TC-P

0.0 to 1350.0

32.0 to 2462.0

273.2 to 1623.2

Cu50Ω

CU50

-200.0 to 200.0

-328.0 to 392.0

73.2 to 473.2

Cu100Ω

CU100

-200.0 to 200.0

-328.0 to 392.0

73.2 to 473.2

JPt100Ω

JPT100

-200.0 to 600.0

-328.0 to 1112.0

73.2 to 873.2

DPt50Ω

DPT50

-200.0 to 600.0

-328.0 to 1112.0

73.2 to 873.2

DPt100Ω

DPT100

-200.0 to 850.0

-328.0 to 1562.0

73.2 to 1123.2

-60.00-60.00mV

±60mV

Resolution: 10µV

-200.00-200.00mV

±200mV

Resolution: 10µV

-2.000-2.000V

±2V

Resolution: 1mV

1.000-5.000V

1-5V

Resolution: 1mV

-5.000-5.000V

5V

Resolution: 1mV

-1.00-10.00V

-1V-10V

Resolution: 10mV

(shunt)

(shunt)

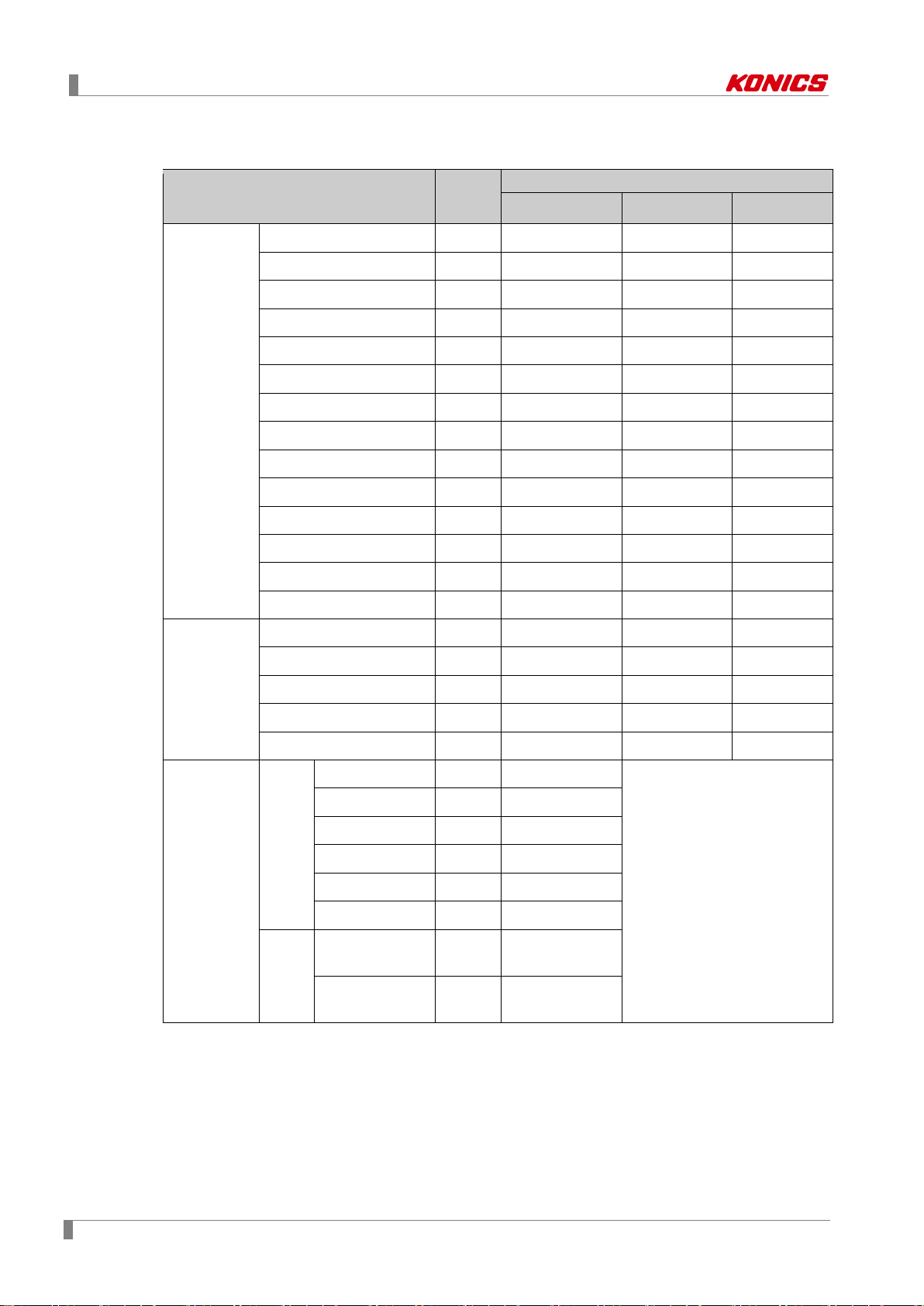

2.3 Input type and range

Input type Display

Thermocouple

※

2

※

3

※

℃ ℉

K

RTD

Voltage

-99999 to 99999

(display range depends on the

Analog

±

decimal point position.)

0-20mA

0-20mA

—

Current

(shunt)

4-20mA

4-20mA

—

※1. C (TT): Same as exisitng W5 (TT) type temperature sensor.

※2. G (TT): Same as existing W (TT) type temperature sensor.

※3. Russian L type temperature sensor is divided from general purpose L type.

20 © Copyright Reserved KONICS Co., Ltd.

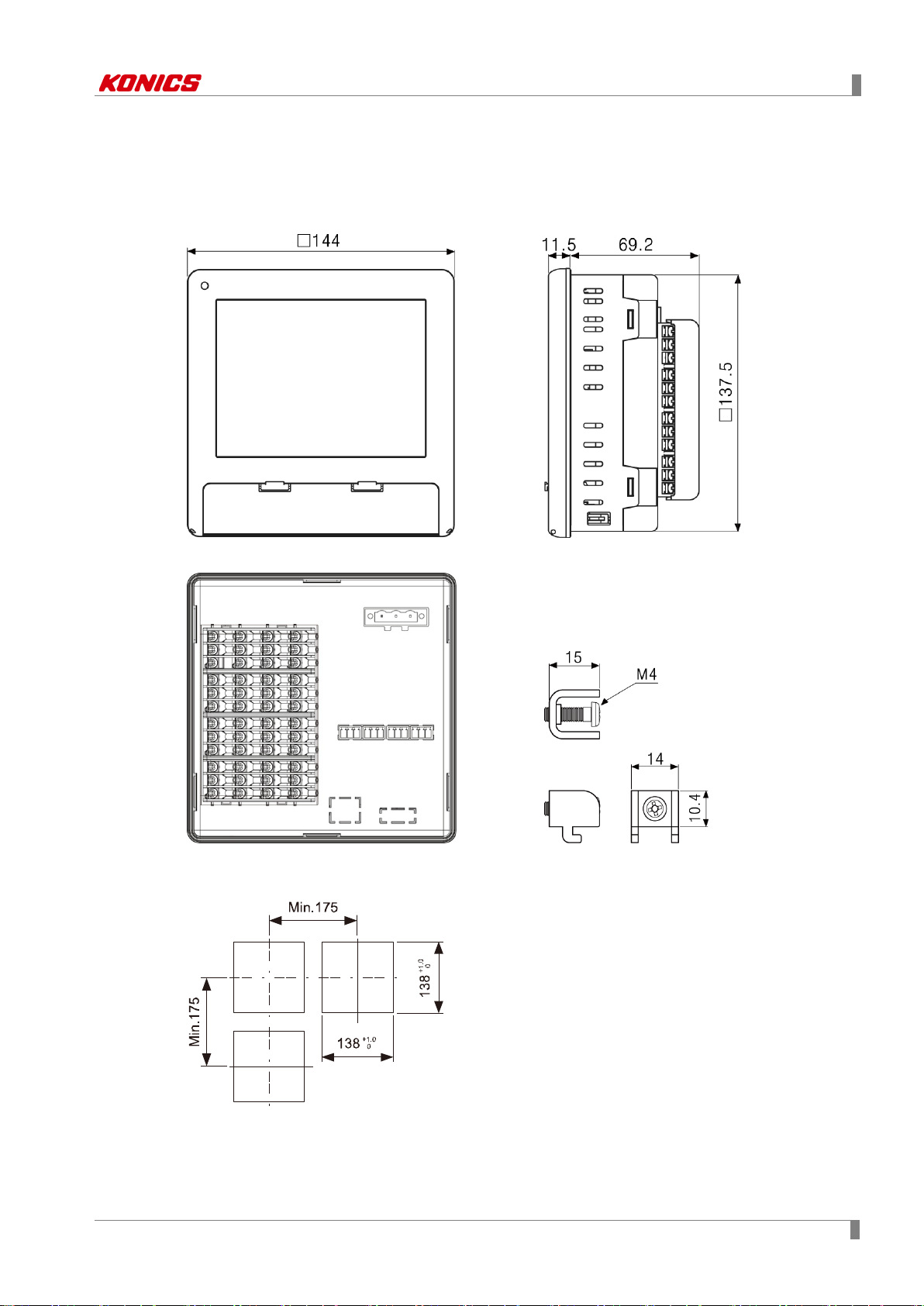

3 Dimensions

(Unit: mm)

3 Dimensions

3.1 KRN1000

3.2 Panel cut-out

※Use panel which is 1 to 5mm thickness.

© Copyright Reserved KONICS Co., Ltd. 21

3 Dimensions

22 © Copyright Reserved KONICS Co., Ltd.

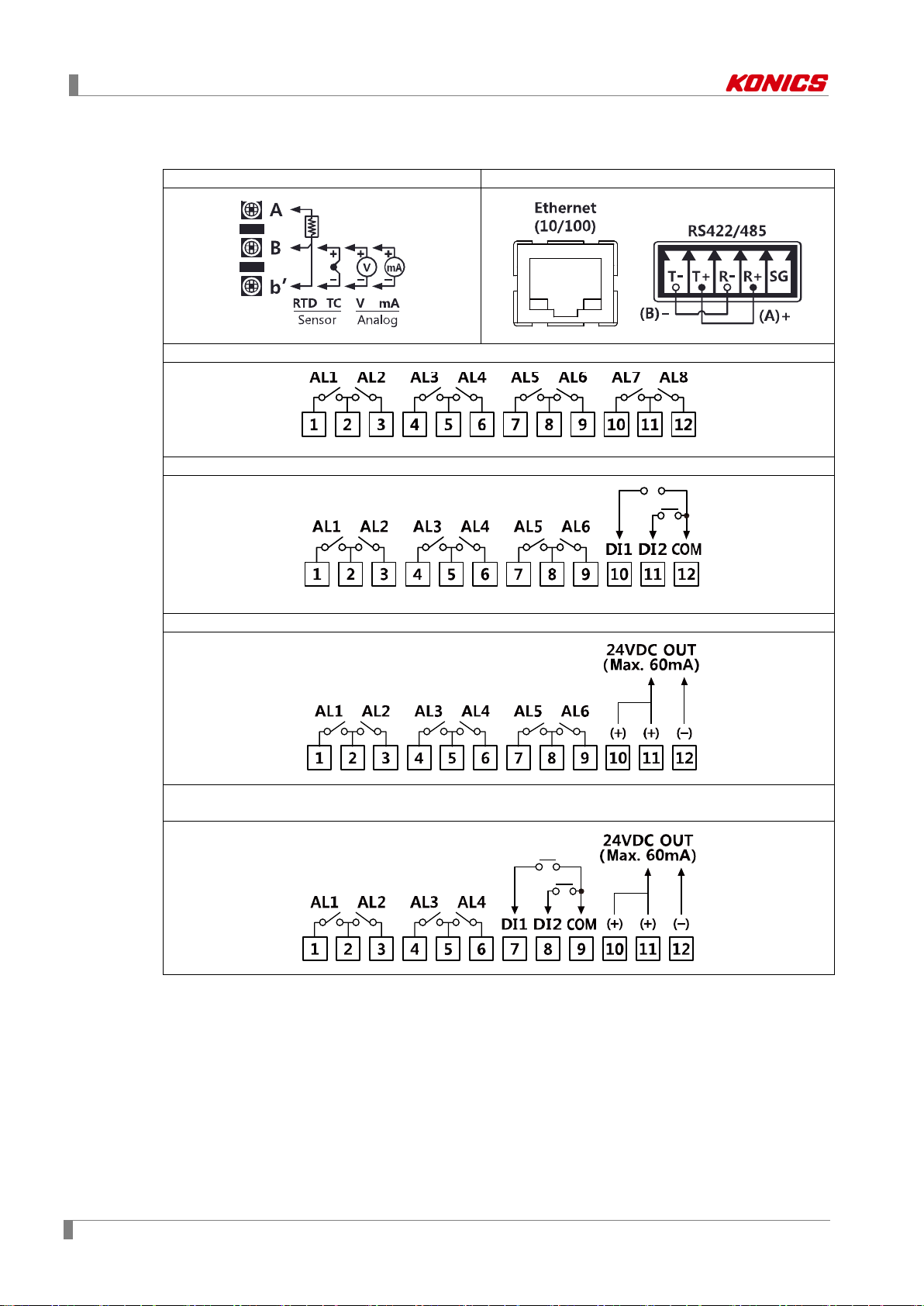

4 Connections

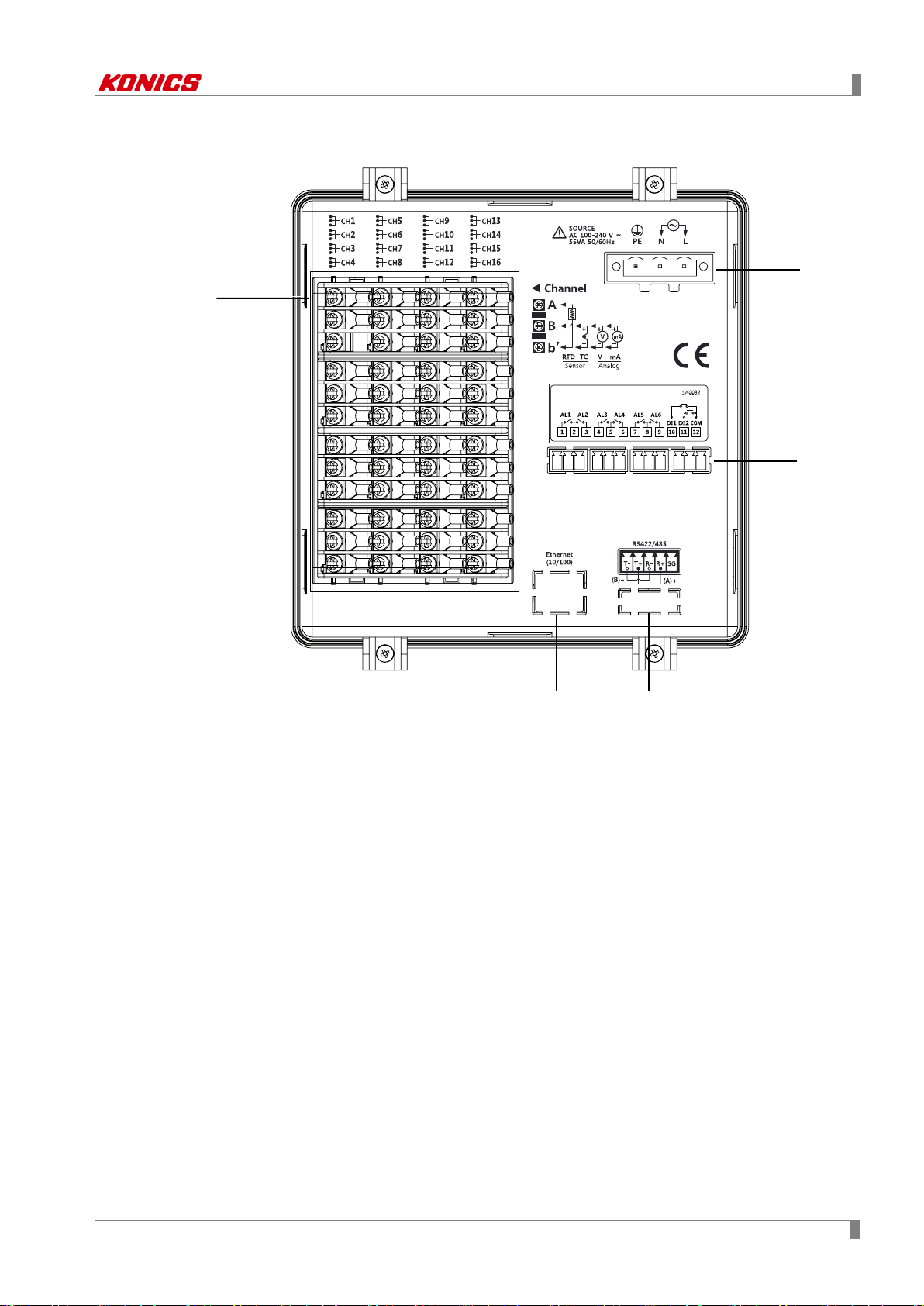

No

Descriptions

1

Connects universal input.

Connects option input/output (digital input (non-contact/contact), alarm output, power for

transmitter).

3

Connects communication output.

1 2 3

4 Connections

4.1 KRN1000

This figure is back side of KRN1000.

2

© Copyright Reserved KONICS Co., Ltd. 23

4 Connections

Universal input

Communication output

Option input/output 1 (alarm output 8 channels)

Option input/output 2 (alarm output 6 channels + digital input 2 channels)

Option input/output 3 (alarm output 6 channels + power for transmitter output)

Option input/output 4

(alarm output 4 channels + digital input 2 channel s + power for transmitter output)

4.2 Input/Output circuit

24 © Copyright Reserved KONICS Co., Ltd.

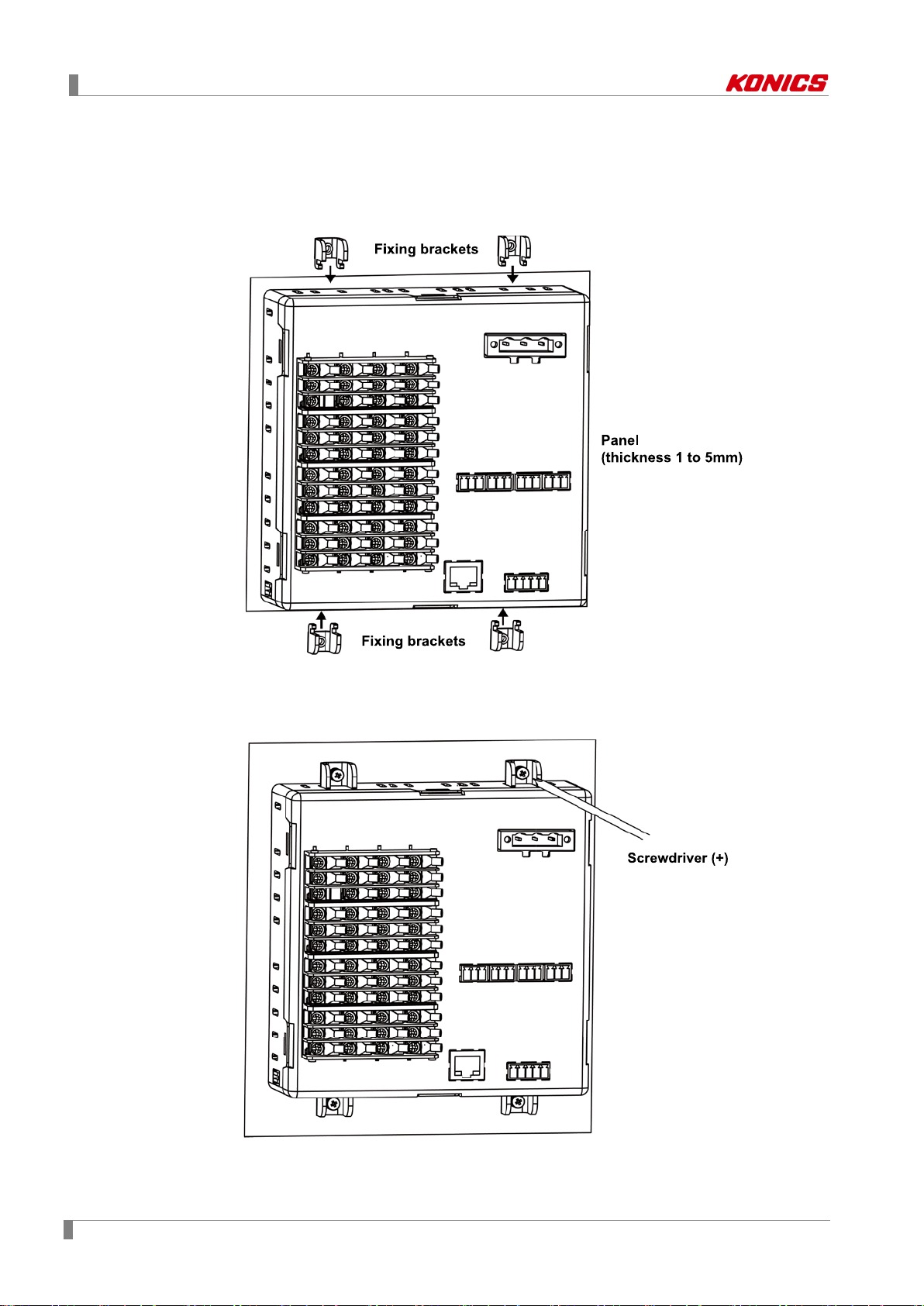

5 Installations

5 Installations

5.1 Environment

Install the unit in place where the below conditions are satisfied.

Place where ventilation is well

To prevent from malfunction and damage by overheating (use temperature range: 0 to

50℃), install this unit where ventilation is well.

In case installing several KRN1000, space each other by panel cut-out.

Place where vibration is not severe

If there is too much vibration, it may cause malfunction such as print error. For more

information about vibration, please refer to ‘2 Specifications’.

In case of temperature measurement with thermocouple temperature sensor at the place

where temperature is fluctuated, data error may occur. You should warm-up this unit over 30

min. to acquire accurate data before using it.

© Copyright Reserved KONICS Co., Ltd. 25

5 Installations

5.2 Installation Method

1st Install KRN1000 on the processed panel as panel cut-out diagram. Mount fixing

brackets on upper/lower parts.

2nd Tighten fixing brackets on upper/lower parts to fix on the panel with screwdriver (+)

with 0.4N•m torque.

26 © Copyright Reserved KONICS Co., Ltd.

5 Installations

5.3 USB to Serial driver

Install USB to serial driver which is applied for KRN100 sereis and connect DAQMaster and you

can set parameter setting.

Supporing operation system for USB to Serial driver is Windows XP, VISTA (32/64bit), 7

(32/64bit), 8 (32/64bit).

5.3.1 Driver installation

1st Visit our web site www.konics.com and download

'KRN1000_USB_To_Serial_Drivers.zip’ or visit

http://www.ftdichip.com/Drivers/VCP.htm and download the dedicated OS driver.

2nd Run CDM v2.xx.xx WHQL Certified.exe and install the driver.

(driver version may be different.)

© Copyright Reserved KONICS Co., Ltd. 27

5 Installations

3rd Connect the USB device port at KRN1000 front cover and PC USB port via USB

cable (A-Mini B 5-pin, 1.5m).

4th After recognizing the driver, the driver is automatically installed.

5.3.2 Check the driver

To check the driver, right click 'My computer' and select 'Properties' on pop-up menu. 'Device

Manager'' dialog appears. Check ‘Ports (COM & LPT)’ - 'USB To Serial Converter (COMx)'.

28 © Copyright Reserved KONICS Co., Ltd.

6 Screen

6 Screen

6.1 Initial booting screen

Below booting screens are initially displayed when power is supplied to KRN1000. These

screens progresses initial settings for KRN1000 to operate normally and checks inner system

memory.

If there is no error for inner system memory, booting is finished and KRN1000 operates normally.

Initial screen: Checking initial system memory error and processing module reset

If initial system memory error occurs,

If initial system memory error occurs, it does not operate normally.

Contact our company or seller.

Konics service center: +82-32-820-2356 to 7

© Copyright Reserved KONICS Co., Ltd. 29

6 Screen

Displays currently displayed group name.

group name and the set group name is displayed.

Select the displayed graph at the current screen.

vertical/horizontal mixed graph, digital group/all.

Displays at standard user mode.

(activated log-in function or log off status)

Displays at administor mode.

(activated log-in function and log-in as administor mode)

Displays at unlock.

(inactivated log-in function)

Status display

Measurement

part

6.2 Screen description

The screen consists of status display part and measurement value display part.

part

value display

6.2.1 Status display part

Section Icon Description

Menu Displays menu.

1

2

1

※

3

Esc Moves from menu to current screen.

Home Moves to main screen.

Group

Graph

Touch the icon and select the group. You can set the

Select one among bar graph, vertical/horizontal trend

graph, divided vertical/horizontal trend graph,

Lock

2

※

4

Lock Setting

Unlock

30 © Copyright Reserved KONICS Co., Ltd.

6 Screen

Data Record

Space

Alarm Record

Space

Event Record

Space

USB Memory No

Connection

USB Memory No

Save

Displays when internal memory data does not save at

USB memory.

USB Memory

Save

Displays when internal memory data saves at USB

memory.

SD Card No

Connection

SD Card

No Save

Displays when internal memory data does not save at SD

card.

Section Icon Description

No Alarm Displays at no alarm.

Alarm Displays when alarm occurs.

Internal Memory

Record

5

Internal Memory

No Record

6

7

Displays when recording measurement value of each

channel at internal memory.

Displays when displaying measurement value and no

recording it at internal memory.

Displays usage details of data recording space.

Displays empty space of alarm data memory.

Displays empty space of event data memory.

Displays when USB memory is not connected.

Displays when SD card is not connected.

SD Card Save Displays when internal memory data saves at SD card.

Displays date and time.

8

Date/Time

If summer time is set, "(s)" marks in front of time.

※1. For more information about screen graph, refer to ‘6.2.3 Graph’.

※2. For more information about lock and unlock, refer to ‘7.5.5 Log In’.

© Copyright Reserved KONICS Co., Ltd. 31

6 Screen

No

Item

Descriptions

2

1

6.2.2 Measurement value display part

Measurement value of each channel is displayed as graph and digital number.

One screen displays 6 channels and channel roation is maually or automatically setable.

For more information about channel roation and time, refer to ‘7.1.3 Group Setting’.

Measurement

1

value graph of

each channel

Measurement

value digital

2

number of each

channel

Displays the measurement value of each channel as graph.

Displays the measurement value of each channel as digital number.

32 © Copyright Reserved KONICS Co., Ltd.

6 Screen

6.2.3 Graph

Select the display graph at current screen. Touch the red square area to select the graph style.

The supported graphs are as below.

Bar graph

Vertical trend graph (V Trend)

© Copyright Reserved KONICS Co., Ltd. 33

6 Screen

Horizontal trend graph (H Trend)

Divided vertical trend graph (DV Trend)

The upper area is for real-time measurement value as vertical trend graph and the lower

area is for all records from start as vertical trend graph.

The lower area is available only when recording status.

Divided horizontal trend graph (DH Trend)

The right area is for real-time measurement value as horizontal trend graph and the left

area is for all records from start as horizontal trend graph.

The left area is available only when recording status.

34 © Copyright Reserved KONICS Co., Ltd.

6 Screen

Vertical mixed graph (V Mixed)

Measurement value of each channel is displayed as bar graph and vertical trend graph.

Horizontal mixed graph (H Mixed)

Measurement value of each channel is displayed as bar graph and horizontal trend graph.

Digital group

One screen displays measurement values of 6 channels.

© Copyright Reserved KONICS Co., Ltd. 35

6 Screen

All digitals

One screen displays measurement values of all channels.

36 © Copyright Reserved KONICS Co., Ltd.

6 Screen

No

Item

Descriptions

6.2.4 Pop-up menu

Touch the red square area at main screen and pop-up menu appears.

Starts recording the measurement value on the current screen.

1 Record

2 File

3 Remove Remove the installed external SD/USB memory.

Touch the Stop to stop the recording.

(when stop the recording during recording, data is not saved.)

- Move/Copy: Moves/Copies the saved log file of internal memory to

extenral memory.

-Record Info.: Displays saving path, log record period of currently

recording data.

© Copyright Reserved KONICS Co., Ltd. 37

6 Screen

No

Icon

Descriptions

6.2.5 Virtual keyboard

You can enter setting value via vertual keyboard.

Virtual keyboard is activated automatically when setting value enters. For entering numbers,

number virtual keyboard is activated.

Only English is supported to enter.

1

2

3

4

5

Displays keyboard input status.

Select English capital/small letter, number or sign.

Deletes the entered charaters.

Saves the entered characters.

Cancels the entered characters.

Enterable characters are as below.

English capital letters

38 © Copyright Reserved KONICS Co., Ltd.

6 Screen

English small letters

Signs and numbers

Number virtual keyboard

© Copyright Reserved KONICS Co., Ltd. 39

6 Screen

6.2.6 Color

Select the color.

KRN1000 supports 23 colors. Set the pen color, or background color of each group.

40 © Copyright Reserved KONICS Co., Ltd.

7 Menu

7 Menu

Touch the menu at top-left screen and menu displays. Menu consists as below.

© Copyright Reserved KONICS Co., Ltd. 41

7 Menu

No

Item

Descriptions

7.1 Display

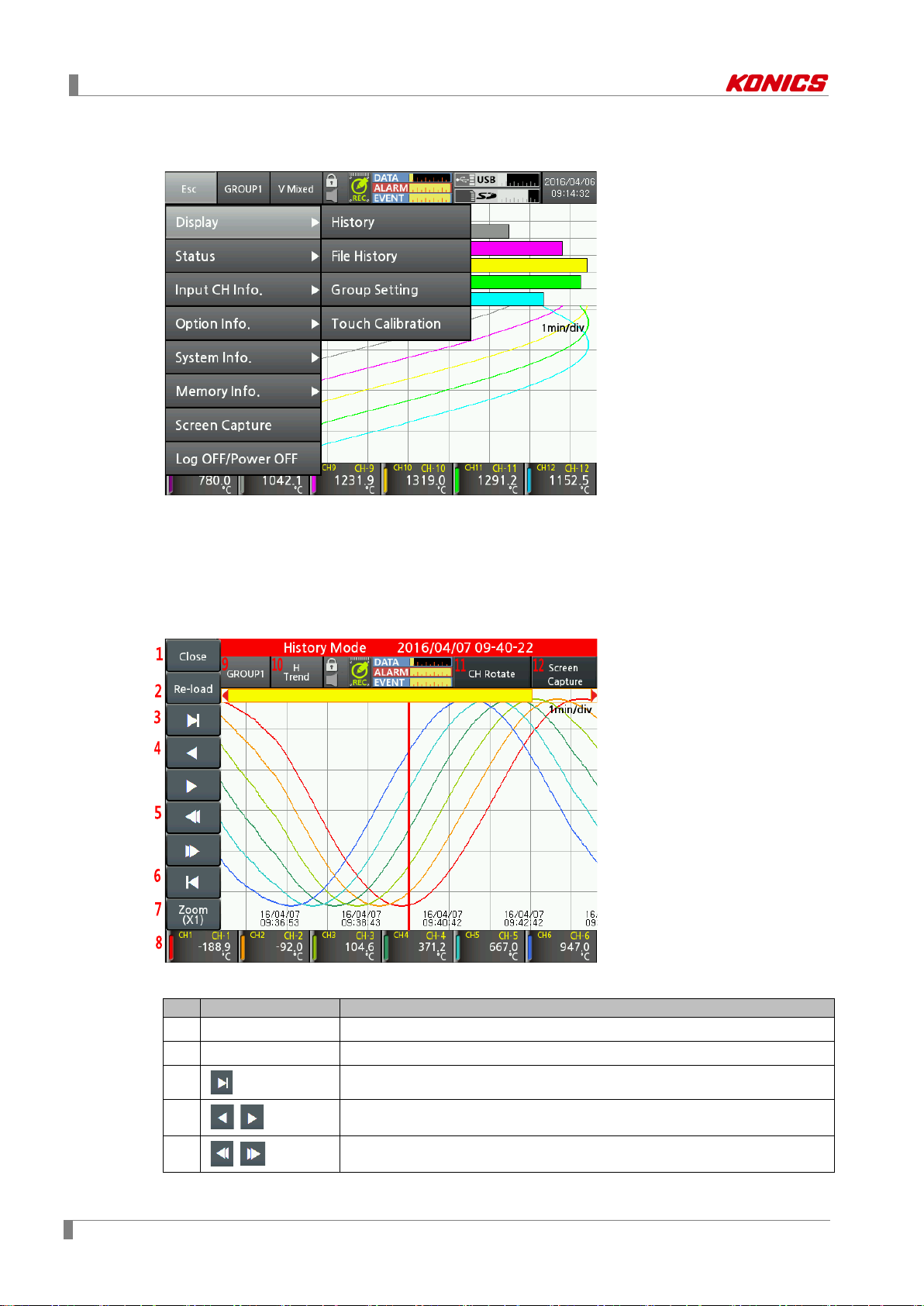

7.1.1 History

You can open the log file which is recording to check the dedicated data history (measurement

value and whole trend).

Move the history axis (vertical red line) at the desired time to check the dedicated data of each

channel.

42 © Copyright Reserved KONICS Co., Ltd.

1 Close Moves to the main screen.

2 Re-load Re-loads the measured data.It updates the latest data.

3

4

5

,

,

Moves to the latest data point of log file.

Moves the history axis to back/forward for 1 sec.

Moves the history log data to two-thirds back/forward of the screen.

7 Menu

No

Item

Descriptions

6

7 Zoom

8 CH Display

9

10 Graph

11 CH Rotate

GROUP□

Moves the old data point of log file.

Zooms in/out the screen from 1 to 1200 magnifications.

Touch the desired channel not to be displayed. The data value of the

channel is displayed as gray color.

Select the group.

You can change the group name. Refer to ‘7.1.3 Group Setting ‘.

Displays the desired graph as horizontal trend (H Trend) → divided

horizontal trend (DH Trend) →vertical trend (V Trend) → divided vertical

trend (DV Trend) graph by touching the icon.

Rotate the displayed 6 channels per one screen.

CH1/2/3/4/5/6 → CH7/8/9/10/11/12 → CH13/14/15/16

Save the current screen.

12 Screen Capture

Check the currently recording data history.

When recording stops, error message appears.

© Copyright Reserved KONICS Co., Ltd. 43

7 Menu

No

Item

Descriptions

Set group and channel information of the saved log file.

Displays each channel information such as tag name, input type,

7.1.2 File History

You can open the saved log file to check the dedicated data history (measurement value and

whole trend).

Move the history axis (vertical red line) at the desired time to check the dedicated data of each

channel.

File history screen is added group setting, channel information from history screen.

1 Group

2 Channel Info.

For more information about group setting, refer to ‘7.1.3 Group Setting’.

Setting method and details are same.

low/high-limit scale.

44 © Copyright Reserved KONICS Co., Ltd.

7 Menu

No

Item

Descriptions

Moves group. Touch “Group 1” or

to select the desired

group.

Main screen graph displays only 6 channels’ data.

the screen)

Displays group name.

Touch the name and change the group name via the virtual keyboard.

4

No. of CHs

Displays the set number of channels.

5

Background

Set the group background color via the color select dialog box.

Pen1-4/ 5-8

/9- 12/13-16

7.1.3 Group Setting

It sets for group and channel information.

You can set the max. 16 channels according to input channels.

Input channel is available to set duplicated to one or several groups. Set the channel to each

group and pen color.

Groups are up to 6.

1 Group

2 CH Rotation Time

,

Set the channel automatical rotation time.

Setting range: 0 to 3600s. (0: changing channels manually by touching

3 Name

6

7

Pen □

Set the channel, color, line style, min./max. value by each pen.

Min./Max. value of each channel is input range of the input type.

For more information, refer to ‘2.3 Input type and range’.

© Copyright Reserved KONICS Co., Ltd. 45

7 Menu

7.1.4 Touch Calibration

It corrects touch input via pointer calibration.

When starting touch calibration, total 5 points are displays one by one. Touch the point and

calibrate it. For more accurate touch, it is recommended to use a stylus pen.

If touch calibration is wrong, re-boot the unit as initial system value.

Touch the right-below area over than twice of the initial booting screen.

46 © Copyright Reserved KONICS Co., Ltd.

7 Menu

7.2 Status

7.2.1 Alarm List

It displays occurring alarm(channel, alarm type, relay, start/end time) during operation.

Alarm list displays alarm channel, type, relay, start/end time of occuring alarms. You can save or

delete the alarm list. Alarm list is saved as *.csv file format.

When turing OFF power of KRN1000 while alarm occurs, end time is displayed as "0000-00-00

00:00:00".

Touch ‘History’ to check the data of alarm occuring point as horizontal trend/vertical trend/divided

horizontal trend/divided vertical trend graph.

Divided trend graph is displays divided screen to compare and check different time of the one file.

When recording starts/stops several times from starting to completing alarm, several log files are

created.

If there are several log files from starting alarm to end alarm, it displays the history of first log file

which includes alarm start time.

© Copyright Reserved KONICS Co., Ltd. 47

7 Menu

No

Item

Descriptions

- Alarm No: Displays alarm output number.

alarms.

7.2.2 Event List

It displays occurring event (event message, occurrence time) during operation.

You can save or delete the event list. Event list is saved as *.csv file format.

Event message displays occuring event during device operation such as device power ON/OFF,

record start/stop, or external memory recognization, etc.

7.2.3 AO/DI Status

It displays alarm output and digital input status.

Alarm Output

1

Status

2 Digital Input Status

48 © Copyright Reserved KONICS Co., Ltd.

- Status: Displays alarm output ON, OFF status.

- Alarm CH: Displays the channel occuring alarm.

If alarms occur at several channels, it displays the number of occuring

- DI No.: Displays digital input number.

- Status: Displays digital input ON, OFF status.

- Type: Displays the set digital input.

For more information about digital input, refer to ‘7.4.2 Digital Input’.

7 Menu

No

Item

Descriptions

Copies the other channels parameters of the same group.

Select the channel to be copy.

Set the input type. Input types are total 27: thermocouple, RTD, voltage, current

(shunt). For more information, refer to ‘2.3 Input type and range’.

In case of temperature sensor input, set the low-limit graph scale value within

In case of analog input, it displays low-limit input value.

5

High-Limit

In case of temperature sensor input, set the high-limit graph scale value within

7.3 Input CH Info.

It sets input type of each channel, option, alarm, user unit.

During memory recording, you cannot set or change input channel settings.

7.3.1 Input/Display

1 Channel

2 Copy

Moves channel. Touch ‘CH1’ or

to change the channel.

3 Input Type

Low-Limit

Graph

4

Scale/

Low-Limit

Input

© Copyright Reserved KONICS Co., Ltd. 49

the input range.

Setting range: Min. value of input range to high-limit graph scale value–F.S. 5%

E.g.) In case of TC-K input, -200.0 to 1350.0℃ of input range, and setting range

is -200.0 to 1272.5℃. (-F.S.=77.5)

7 Menu

No

Item

Descriptions

Graph

the input range.

In case of analog input, it displays high-limit input value.

- Temperature sensor input: 0, 0.0

(set the decimal point position for the scale value)

7

Tag Name

Set the channel name.

Low-Limit

Scale

High-Limit

Scale

Display

- Analog input: 72 display units are available. When not using unit, select blank.

Scale/

High-Limit

Input

Setting range: Low-limit graph scale value+F.S. 5% to Max. value of input range

E.g.) In case of TC-K input, -200.0 to 1350.0℃ of input range, and setting range

is -122.5 to 1350℃. (+F.S.=77.5)

6 Point

8

9

10

Unit

2

※

(set the decimal point for the measurement value)

- Analog input: 0, 0.0, 0.00, 0.000, 0.0000

Set the desired display value based on the measurement value.

1

It is activated only for analog (voltage, current (shunt)) input type.

※

- Temperature senosr input: Temperature units, ℃, ℉, ˚K are available.

※1. As below figure, for example, measured input values are ‘a’ and ‘b’ and the desired display

values are ‘A’, and ‘B’. In this case, about the input ‘a’ and ‘b’, it displays a=A, b=B as

linearly.

You can change display value about min./max. input value of the measurement value.

50 © Copyright Reserved KONICS Co., Ltd.

7 Menu

In case of input type, -60 to +60mV

Low Scale (low-limit scale value)=0.0, High Scale (high-limit scale value)=Set as 10.0, 20.0,

30.0, -20.0

Low Scale (low-limit scale value)=20.0, High Scale (high-limit scale value)=Set as -20.0

Low Scale (low-limit scale value)=-20.0, High Scale (high-limit scale value)=Set as 20.0

© Copyright Reserved KONICS Co., Ltd. 51

7 Menu

10

ml

26

cd

42

VA

58

mmH2O

11 t 27

lm

43 W 59

bar

12

Val

28

cd/m2

44

kW

60

Torr

15

barrel

31

m2/s

47

kVar

63

psi

16 - 32

cp

48

MVar

64

User0

※2. Supported display unit

No Unit No Unit No Unit No Unit No Unit

1 °C 17 % 33 V 49 mA

2 °F 18 Wt% 34 mV 50 A

3 °K 19 mass% 35 μV 51 kg/cm2

4 Kcal/m3 20 Vol% 36 kV 52 P

5 Kcal 21 ppm 37 Ω 53 kPa

6 cal 22 ppb 38 mΩ 54 MPa

7 j 23 mol 39 μΩ 55 N/m2

8 Btu 24 Space 40 s 56 N/mm2

9 l 25 lx 41 μs 57 inH2O

13 lb 29 rpm 45 MW 61 mmHg

14 oz 30 Hz 46 Var 62 mmAq

65 User1

66 User2

67 User3

68 User4

69 User5

70 User6

71 User7

72 User8

73 User9

In case of the complicated unit such as kg/cm

2

, screen quality may not be good.

52 © Copyright Reserved KONICS Co., Ltd.

7 Menu

No

Item

Descriptions

Special

Displays the applied measurement value as the set special function.

Two Unit is activated only for 4-20mA (shunt) input type.

3

Ref CH

Corrects error from input (thermocouple, RTD, voltage, current (shunt)), not

(depending on the set decimal point, the range is different.)

Adjusts high-limit error by regulating display value which is about

measurement value or applied scale.

Set the recording method of measured data by each channel.

Setting

value

Instant

Saves measurement value at every recording cycle.

Saves the average value of sampling measurement value

during recording cycle.

Saves the min. value of sampling measurement value during

recording cycle.

Saves the max. value of sampling measurement value during

recording cycle.

In some applications the fluctuating measured input causes the display value

may be different with input value.

No. of

7.3.2 Input Option

1 Channel

2

Func.

1

※

4 Two Unit

5 Input Bias

2

6

7

※

Span

Record

Method

8 Digital Filter

Moves channel. Touch ‘CH1’ or

to change the channel.

Depending on input type, applicable special functions are different.

Setting range

- Temperature sensor input: None, Difference (deviation)

- Analog input: Linear, Root, Square, Two Unit

from the recorder.

Setting range: -9999 to 9999, -999.9 to 999.9, -99.99 to 99.99, -9.999 to 9.999

-0.9999 to 0.9999

Descriptions

Average

Min

Max

to fluctuate. In this case accurate display/record is disable. This function is

able to make display value stable by input digital filter. Input digital filter uses

moving average method. It does not affet to display period but display value

Digital

9

Filters

3

※

menu is activated.

Setting range: 1 to 128

Set the number of samplings which apply to digital filter. Set Filter type and this

© Copyright Reserved KONICS Co., Ltd. 53

7 Menu

No

Item

Descriptions

In case of temperature sensor input type, set the alarm type and option for

Setting

value

Displays BURN after the display value increases as up scale

when input break.

Down

Scale

Displays BURN after the display value decreases as down

scale when input break

input break.

(it does not operate for analog (voltage, current (shunt)) input type.)

Descriptions

10

Burn-out

Action

None When input break, it displays BURN.

Up Scale

※1. Below pattern graph appears comparing the values which are appling liner, root, square for

analog input.

Low-limit input: -5 V, High-limit input: +5 V, Low-limit scale: -1000, High-limit scale: 1000

(a) Difference (deviation)

It is available to set for temperature sensor (Thermocouple, RTD) input type. It displays the

deviation of the measurement value of reference channel.

(display value = the measurement value of standard channel –the measurement value of

reference channel)

The channels which input type is analog (voltage, current (shunt)) cannot be as reference

channel. If reference channel is not set, it displays the measurement value of standard

channel.

If any one of reference channel, or standard channel is break (BURN), high-limit value

(HHHH), low-limit value (LLLL) status, it displays as correspond value. If the set reference

channel uses difference function, it displays the calcuated value based on actual

measurement value, not display value of reference channel.

54 © Copyright Reserved KONICS Co., Ltd.

7 Menu

(b) Linear

It applies low-limit scale and high-limit scale to low-limit input value and high-limit input value

and displays this values.

In case of low-limit input value: -5 V, high-limit input value: +5V, low-limit scale: -1000, highlimit scale: 1000,

and current input value is 2V, display value is 400.

Display value

=

(

400 =

×

7

× 2000 1000

10

Input value Low limit input value

High limit input value Low

limit input value

High limit scale Low limit scale)+ Low limit scale

(c) Root

In case voltage, current input type, this function calculates by Root () for the input value.

Differential pressure signal of differential pressure flow meter is calculated by Root (

) for

the desired pressure flow. This function is used for measuring flux by input value.

In case of low-limit input value: -5 V, high-limit input value: +5V, low-limit scale: -1000, highlimit scale: 1000,

and current input value is 2V, display value is approx. 673.32.

Display value

=

(

×

High limit scale Low limit scale)+ Low limit scale

Input value Low limit input value

High limit input value Low

limit input value

7

673.32 =

× 2000 1000

10

(d) Square

In case voltage, current input type, this function calculates by square for the input value.

Reverse of Root, flux signal is calcualted by suqare for differential pressure signal.

In case of low-limit input value: -5 V, high-limit input value: +5V, low-limit scale: -1000, highlimit scale: 1000,

and current input value is 2V, display value is -20.

Display value

=

×

(

Input value Low limit input value

High limit input value Low

limit input value

High limit scale Low limit scale)+ Low limit scale

20 =

7

× 2000 1000

10

(e) Two Unit

For compound pressure, if input pressure is lower than atmospheric pressure (0), it displays

the degree of a vacuum with mmHg unit. If input pressure is higher than or same as

2

atmospheric pressure (0), it displays positive pressure with kg/cm

When using Two Unit function, low-limit value is fixed as -760mmHg and the setting range of

2

kg/cm

In case of Two Unit, decimal point position is limited among 0, 0.0, 0.00. When using Two

Unit function, display unit is changed as mmHg or kg/cm

is 1 to 35.

2

automatically.

unit..

This function has two different unit values and it is impossible to calcuate by recording

method and digital filter and ignore it.

Setting range: 1 to 35

Two Unit function is available only when connecting shunt resistance 250Ω, and 4-

20mA (shunt) input type.

© Copyright Reserved KONICS Co., Ltd. 55

7 Menu

16

4-20mA output interval

X

Max. value of pressure range (E.g.: For -760mmHg to 3kg/cm2, it means "3")

1.033

Converted value from 760 mmHg to kg/cm2 unit value (same unit)

Y

Use pressure + 1.033 (E.g.: used pressure is ‘0’, it is 1.033)

4

Min. value of output (when output is 0) 4.00mA

Low-limit

value

High-limit

value

Gradient

value

Display

range

Low-limit

value

High-limit

value

Gradient

nt value

Unit changing point

(mA)

If pressure range is -760mmHg to 3kg/cm

displays -760mmHg for 4mA input and 8mA is unit changing point. For 20mA input, it displays

3kg/cm

2

.

2

, pressure transmitter outputs 4 to 20mA, and it

Range

-760mmHg to 1kg/cm2 12.130

-760mmHg to 5kg/cm2 6.740

-760mmHg to 10kg/cm2 5.498

-760mmHg to 15kg/cm2 5.031

-760mmHg to 20kg/cm2 4.786

-760mmHg to 25kg/cm2 4.635

-760mmHg to 30kg/cm2 4.533

-760mmHg to 35kg/cm2 4.459

Unit changing point = (

16

X+1.033

× Y) + 4

※2. When fixing low-limit scale value and high-limit scale value and set gradient, input range is 0

to 10V, low-limit scale value is 0.00, high-limit scale value is 10.00, the display values are as

below by changing gradient as 0.500, 1.000, 1.500.

scale

0.00 10.00 0.500

0.00 10.00 1.000

0.00 10.00 1.500

scale

adjustment

value

0.00 to

5.00

0.00 to

10.00

0.00 to

15.00

Same

result

=

scale

scale

adjustme

0.00 5.00 1.000

0.00 10.00 1.000

0.00 15.00 1.000

When fixing low-limit scale value and high-limit scale value and set gradient (subtraction

gradient), input range is 0 to 10V, low-limit scale value is 10.00, high-limit scale value is 0.00,

the display values are as below by changing gradient as 0.500, 1.000, 1.500.

56 © Copyright Reserved KONICS Co., Ltd.

7 Menu

Low-limit

value

High-limit

value

Gradient

value

Display

range

Low-limit

value

High-limit

value

Gradient

nt value

scale

10.00 0.00 0.500

10.00 0.00 1.000

10.00 0.00 1.500

scale

adjustment

value

10.00

to 5.00

10.00

to 0.00

10.00

to -5.00

Same

result

=

scale

10.00 5.00 1.000

10.00 0.00 1.000

10.00 -5.00 1.000

scale

adjustme

※3. Number of digital inputs

In case of 4 input digital filters and 25ms sampling setting, it displays input sampling value

as moving average for 0.1 sec (100ms).

D1 = S1 , D2 =

S1 + S2

2

, D3 =

S1 + S2 + S3

3

Display values of D1, D2, D3 are the initial operation before averaging 4 sampling values.

S1 + S2 + S3 + S4

D4 =

S3 + S4 + S5 + S6

D6 =

S5 + S6 + S7 + S8

D8 =

4

4

4

, D5 =

, D7 =

S2 + S3 + S4 + S5

4

S4 + S5 + S6 + S7

4

,

,

© Copyright Reserved KONICS Co., Ltd. 57

7 Menu

No

Item

Descriptions

Set alarm type for operation. You can set alarm type for each channel. When

alarm occurs, alarm icon appears and you can check alarm by channel.

It activates when alarm type is deviation high-limit alarm (DV.Hi) or deviation

channel, deviation high-limit alarm or deviation low-limit alarm occurs.

Set alarm setting value.

Setting range: Within the input/display range of the set input type

Set delay time (unit: sec.) to prevent alarm malfunction by wrong input from

output turns OFF. (Alarm ON channel clears the display.)

Set the output relay number to execute contact output by each alarm type.

9

Save Event

Set as ON to save alarm information when alarm occurs at alarm event file.

7.3.3 Alarm

You can set alarm up to 4. Alarm 1 to 4 are same setting items.

1 Channel

1

Type

※

2

3 Ref. CH

Option

※

4

2

5 Setting Value

3

Hys

※

6

ON/OFF

7

Delay

4

※

8 Alarm No.

Moves channel. Touch ‘CH1’ or

to change the channel.

low-limit alarm (DV.Lo). Set the reference channel for deviation high-limit

alarm (DV.Hi) or deviationlow-limit alarm (DV.Lo). When the display value of

the channel is smaller or larger than the display value of the set reference

Set alarm output operation for alarm type.

Set the interval between ON and OFF of alarm output.

external disturbance and noise.

- ON delay time: Even after standby the set time when alarm ON condition

(alarm ON channel flashes on screen), if it is still alarm condition, alarm

output turns ON. (Alarm ON channel flashes on screen).

- OFF delay time: Even after standby the set time when alarm clear condition

(alarm ON channel display is hold), if it is still alarm clear condition, alarm

If setting as ‘None’ and when alarm occurs, it displays alarm at screen and

saves alarm type and alarm occuring time but alarm does not output.

If setting output relay for alarm, the set relay turns ON. Alarm output displays

as Relay-□.

10 Copy Copies settings of the current channel to the other channel.

58 © Copyright Reserved KONICS Co., Ltd.

7 Menu

Type

Display

Alarm operation

Descriptions

1

No alarm

- - -

Alarm setting

Alarm setting

Alarm setting

Alarm setting

Setting value

Descriptions

Standard

alarm

If it is alarm condition, alarm output is ON. If it is a clear alarm condition,

alarm output is OFF.

Latch

Alarm latch

If it is alarm condition, alarm output is ON and maintains ON status.

When power is supplied and it is alarm condition, this first alarm condition

value setting or clear alarm forcedly

Alarm latch

sequence

If it is alarm condition, it operates both alarm latch and standby sequence.

is ignored and from the second alarm condition, alarm latch operates.

※1. Alarm type

Absolute

value

2

high-limit

alarm

Absolute

value

3

low-limit

alarm

Deviation

4

high-limit

alarm

Deviation

5

low-limit

alarm

Input

6

break

alarm

PV.Hi

(▲)

PV.Lo

(▼)

DV.Hi

(△)

DV.Lo

(▽)

SBA

(S)

Alarm setting value: 90℃

If display value is same or

higher than alarm setting

value, alarm output turns

ON.

Alarm setting value: 90℃

If display value is same or

lower than alarm setting

value, alarm output turns

ON.

If the deviation between

value: -10℃

value: 10℃

display value and the

display value of reference

channel is same or higher

than alarm setting value,

alarm output turns ON.

If the deviation between

value: 10℃

value: -10℃

display value and the

display value of reference

channel is same or lower

than alarm setting value,

alarm output turns ON.

In case input is not connected, or input cable is break during controlling,

alarm output turns ON. You can check whether input cable is break by

external contact of alarm output using buzzer or other devices.

H: Alarm output hysteresis

※2. Option

Normal

is ignored and from the second alarm condition, standard alarm operates.

StBy

Standby

alarm

When power is supplied and it is not alarm condition, from the first alarm,

standard alarm operates.

Condition of re-applied standby sequence: Power ON, change the alarm

La+St

and standby

When power is supplied and it is alarm condition, this first alarm condition

In case of alarm by alarm latch, to clear alarm output, use digital input for alarm clear or turn

OFF the power and turn ON it.

To clear alarm output by digital input, digital input function should be set as ‘Alarm Reset’.

Clearing alarm output is only when alarm option is alarm latch and alarm latch and standby

sequence, or alarm is out of operation range. Alarm output operates normally form the next

alarm output ON.

© Copyright Reserved KONICS Co., Ltd. 59

7 Menu

※3. Example of hysteresis operation

Alarm type: Absolute value high-limit alarm, Setting value: 200, Hysteresis: 10

※4. ON/OFF delay time

7.3.4 User Unit

You can use additional units with standard units.

Number of characters is from 1 to 6 digits.

60 © Copyright Reserved KONICS Co., Ltd.

7 Menu

No

Item

Descriptions

7.4 Option Info.

It sets alarm output, digital input, communication (RS422/485, Ethernet/USB).

7.4.1 Alarm Output

1 Alarm Mark

Alarm Mark

2

Type

Displays alarm information about occuring alarm.

-PV-Hi:

Set alarm display method.

Setting range: None, Change Color, Flash

, -PV-Lo: ▽, -DV-Hi: ▲, -DV-Lo: ▼, -SBA: ⓢ

3

4

Alarm□ Color

Relay-□

Set alarm color when Alarm On Type is “Change”.

Set alarm output method during occuring alarm.

Setting range: N.O., N.C.

© Copyright Reserved KONICS Co., Ltd. 61

7 Menu

No

Item

Descriptions

Set the operation type for digital input.

Setting range: None, Rec/Stop, Alarm Reset, Alarm ON, Capture

Set digital input operation status.

When opening it, the recording stops.

When DI type is set as ‘Alarm Reset’, select the desired relay to reset the

alarm.

When DI type is set as ‘Alarm ON’, select the desired relay to turn ON the

alarm.

7.4.2 Digital Input

1

DI-□ Type

(only when DI type is set as ‘Record/Stop’)

2

DI-□ Status

3 Alarm Reset

4 Alarm ON

5

Relay-□

- Edge: When supplying digital input over 0.3 sec, the recording starts.

When re-supplying it, the recording stops.

- Level: When shorting digital input over 0.3 sec, the recording starts.

Set alarm relay enable or disable.

62 © Copyright Reserved KONICS Co., Ltd.

7 Menu

No

Item

Descriptions

Set communication address.

available at the same communication line.

Set communication speed, baud rate.

Setting range: 2400, 4800, 9600, 19200, 38400 (unit: bps)

Set communication parity bit.

- Setting range: None, Odd, Even

Set communication stop bit.

- Setting range: 1, 2 (unit: bit)

To prevent possible error due to communicating with low speed Master

- Setting range: 5 to 99 (unit: ms)

6

Protocol

Set communication protocol. It supports only RTU.

Set enable/disable writing parameter setting values of KRN1000 via

regardless of communication write enable/disable setting.

8

RS422/485 Port

Set using/not using RS422/485 communication.

7.4.3 RS422/485

It sets about RS422/485 communication. Communication setting is available only at KRN1000

parameter. You can only check the items and by communication but cannot change the set.

RS422/485 communication makes set or monitor parameters at extenral upper system (PC or

graphic panel, etc.) and uses transfer data.

It is recommended to use our dedicated software program DAQMaster for monitoring. If you

want to develop monitoring program not using our DAQMaster program or to use the related

Modbus program, please refer to user manual for communication.

Visit our homepage (www.konics.com) to download DAQMaster program, and user manual for

communication.

1 Comm. Address

2 Buad Rate

3 Parity Bit

4 Stop Bit

Response Wait

5

Time

7 Comm. Write

The set communication address is applied to RS422/485, Ethernet, USB

device communication. Duplicated communication address setting is not

(PC, PLC, etc), set communication response wait time.

If setting too short communication response wait time, communication

error may occur in Master.

RS422/485 communication. Reading parameter setting value is available

Over two communications among RS422/485, Ethernet, USB Device communication are not

activated at the same time. Set one communication and the others are automatically not

activated.

© Copyright Reserved KONICS Co., Ltd. 63

7 Menu

No

Item

Descriptions

Set the IP address to recognize deivce on the network.

IP conflict.

To recognize network ID part and host ID part of IP address, set 32-bit

address allowing to IP packet receiver.

3

Default Gateway

Set IP address to connect Iprouter directly.

Set enable/disable writing parameter setting values via ethernet

of communication write enable/disable setting.

Set enable/disable ethernet communication.

When ethernet port is setting as enable, USB device is disable.

Set enable/disable writing parameter setting values via USB

of communication write enable/disable setting.

Set enable/disable USB communication.

When USB device is setting as enable, ethernet port is disable.

7.4.4 Ethernet/USB

This function is for remove transferring/managing data at the long distance via ethernet/USB

communication.

You can manage each device data by assigning the fixed IP at the dedicated device.

1 IP Address

2 Subnet Mask

4 Comm. Write

5 Ethernet Port

USB Comm.

6

Write

7 USB Device

If there are same IP on the network, communication does not operate by

communication. Reading parameter setting value is available regardless

communication. Reading parameter setting value is available regardless

64 © Copyright Reserved KONICS Co., Ltd.

7 Menu

Item

RS485

Ethernet

USB Device

Compliance with EIA

RS422/485

Compliance with USB

V2.0

1 unit

connection units)

Single cable within

over CAT 5 E)

Communication

method

Full duplex /

Half duplex

Communication

method

Communication

speed

2400/4800/9600/19200

/38400bps

Communication

response wait time

Start bit

1-bit (fixed)

- - Data bit

8-bit (fixed)

- - Parity bit

None, Odd, Even

- - Stop bit

1, 2-bit

- - Protocol

Modbus RTU

Modbus TCP

Modbus RTU

Ethernet

communication

USB device

communication

Interface

Applied standard

Max. connection

Communication

distance

synchronization

1

※

-

31units

(address: 1 to 127)

Within max. 1km

(below 9600bps)

Asynchronous Asynchronous Asynchronous

5 to 99 ms - -

(number of concurrent

100m (recommended

Full duplex -

10/100Mbps 12Mbps (Full Speed)

1 unit

Single cable within 1.5m

※1. In case of Ethernet connection, and connecting through the network such as network hub

(HUB) and gateway, etc, there is no distance limit, but it is recommaned to use min. network.

Please use communication cables which is satisfied the below conditions.

RS422/485

communication

Shield twisted pair wire over AWG 24, characteristic impedance 100Ω,

capacity component 50pF/m, cable length max. 1km

Over CAT5E, cable length max. 100m

Single cable built-in ferrite core within 1.5m

USB device is recognized as USB to Serial device and communication speed: 115200bps, start

bit: 1-bit, data bit: 8-bit, parity bit: none, stop bit: 1-bit are fixed.

USB Device communication may cause recognition error by external noise and environment

during connecting PC. If there is error, please re-connect this. Please use USB Device as for

setting. During communication, if you chaging the communication settings, it may cause

communication error.

RS422/485 communication port of KRN1000 has 5 terminals; RXD0-, RXD0+, TXD0-, TXD0+,

GND.

When using terminal resistance, connect the terminal resistance at the end of recordor at

connected communication line and turn ON the terminal resistance which is connected with PC.

© Copyright Reserved KONICS Co., Ltd. 65

7 Menu

No

Item

Descriptions

1

Date Setting

Set the current date (year, month, day).

2

Apply

Apply the set date.

3

Time Setting

Set the current time (hour, min, sec).

4

Apply

Apply the set time.

Set the data type to display KRN1000 system.

(year), dd (day)/mm (month)/yy (year)

Set the summer time duration. Set enable to summer time and designate

start date and end date of summer time.

Set the summer time bias.

Setting range: -1 hour, -30 min, 30 min, 1 hour

7.5 System Info.

It sets about KRN1000 system such as date, time, reservation recording, and option, etc.

7.5.1 Date/Time

It sets system date, time of KRN1000. Based on the set date (year, month, day) and time (hour,

min, sec), data is recorded and saved. You can check the record time based on the set time.

Must set the current time before recording the data.

5 Date Type

6 Summer Time

7 Time

66 © Copyright Reserved KONICS Co., Ltd.

Setting range: yyyy (year)/mm (month)/dd (day), mm (month)/dd (day)/yy

7 Menu

No

Item

Descriptions

7.5.2 Reservation

It sets reservation recording time to start and finish recording.

Reservation

1

Date

Reservation

2

Time

Reservation

3

Type

※1. Repeat

Set the reservation recording period (start date, end date).

Set Reservation Type as Repeat or Signel, you can set reservation date.

Set the reservation recording time (start time, end time).

Set Reservation Type as Repeat or Signel, you can set reservation date.

Set reservation recording type.

Setting range: Disable, Repeat, Single

1

- Repeat

※

: Records from the start time to end time at every day during start

date to end date. If start time is later of end time, it records and saves until

end of next day.

2

- Single

※

: Records from the start date and time to end date and time.

Set the date and time as above and it records as below chart.

© Copyright Reserved KONICS Co., Ltd. 67

7 Menu

If start time is later of end time, it records and saves until end of next day.

Set the date and time as above and it records as below chart.

※2. Single

Set the date and time as above and it records as below chart.

68 © Copyright Reserved KONICS Co., Ltd.

7 Menu

No

Item

Descriptions

Set KRN1000 device name.

It supports English capital/small letter, sign and number up to 16 characters.

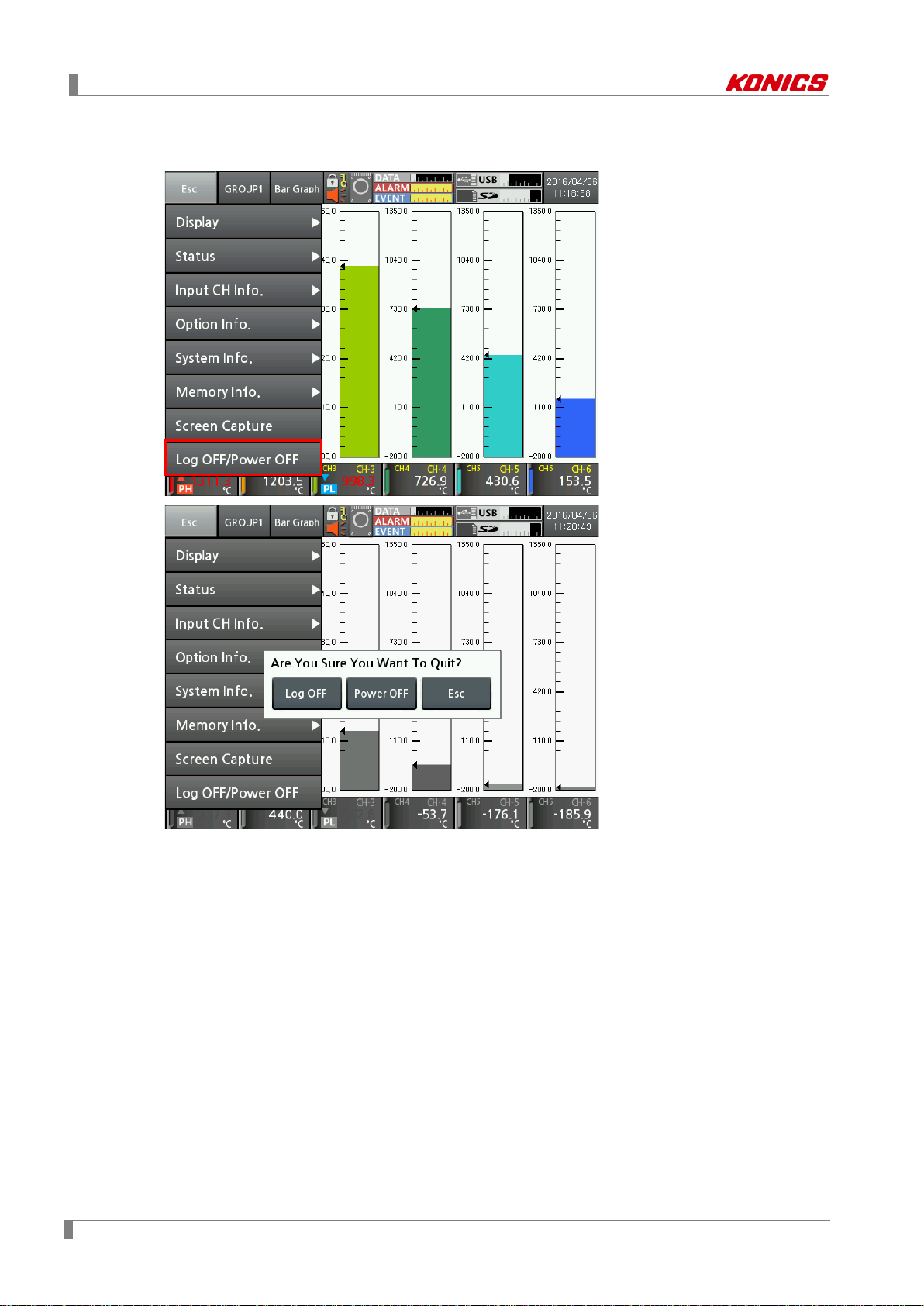

Set KRN1000 display langauge.

It supports Korean, English and Chinese.