Konica Minolta C-403 DI5510/DI7210, FN-6 DI5510/DI7210, OT-104, COVER INSERTER B DI5510/DI7210, FN-112 DI5510/DI7210 User Manual

...Page 1

OPTION

SERVICE MANUAL

C-403/C-404

7663-4396-11

Cover Inserter B/E

EDH-4/EDH-7

FN-115/FN-7

FN-112/FN-6

FN-121/FN-10

FN-113/FN-122

OT-104

PK-2

PK-5

ZK-2/ZK-3

2004.01

Ver. 1.0

Page 2

Page 3

SERVICE MANUAL

C-403/C-404

2004.01

Ver. 1.0

Page 4

Page 5

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the Di551/Di650/Di5510/Di7210 service

manual on page .................................................... S-1

1. OUTLINE

C-403/C-404 PRODUCT SPECIFICATIONS ............1-1

CENTER CROSS-SECTIONAL DRAWING ..............1-2

DRIVE SYSTEM DRAWING......................................1-3

[1] Paper feed drive section.............................1-3

[2] Stacked paper up/down wire drive section .1-4

2. UNIT EXPLANATION

PAPER FEED SECTION...........................................2-1

[1] Composition ...............................................2-1

[2] Mechanisms ...............................................2-1

[3] First paper feed control ..............................2-2

[4] Up/down plate drive control........................2-4

[5] Remaining paper detection/No paper

detection control .........................................2-5

3. DISASSEMBLY/ASSEMBLY

PAPER FEED SECTION...........................................3-1

[1] Cleaning the Paper Dust Removing Brush.3-1

[2] Cleaning the LT feed PS (PS106)/

LT first paper feed PS(PS107) ...................3-1

[3] Removing and Reinstalling the

Paper Feed Roller Unit...............................3-2

[4] Replacing the Paper Feed Roller Rubber/

Feed Roller Rubber ....................................3-2

[5] Replacing the Double Feed

Prevention Roller Rubber ...........................3-3

[6] Replacing the LT feed MC (MC101)/

LT first paper feed MC (MC102).................3-5

[7] Replacing the C-403 Up/Down Wires.........3-6

[8] Replacing the C-404 Up/Down Wires.......3-10

2 UNIT EXPLANATION 1 OUTLINE3 DIS./ASSEMBLY

Page 6

1 OUTLINE2 UNIT EXPLANATION3 DIS./ASSEMBLY

Blank page

Page 7

1

OUTLINE

1 OUTLINE

Page 8

1 OUTLINE

Blank page

Page 9

C-403/C-404 PRODUCT SPECIFICATIONS

C-403/C-404

[1] Type

Type:

Side mount type large volume paper feed tray

[2] Functions

Standard size paper :

C-403

• Metric area

A4 / B5 / 8.5 x 11

Wide paper (314mm x 223mm max.)

• Inch area

8.5 x 11 / A4

Wide paper (314mm x 223mm max.)

C-404

• Metric area

A3 / B4 / A4 / A4R / F4

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R

Wide paper (314mm x 459mm max.)

• Inch area

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R

A3 / B4 / A4 / A4R / F4

Wide paper (314mm x 459mm max.)

Maximum quantity:

4000 sheets (80 g/m

2

or 20lbs)

[4] Maintenance

Maintenance:

Same as the main body

Machine life:

Same as the main body

[5] Operating Environment

Temperature:

10°C to 30°C (50°F to 86°F)

Humidity:

10% to 80%RH

Note: The information herein may be subject to

change for improvement without notice.

1 OUTLINE

[3] Machine Data

Power source

24V DC/5V (supplied from the main body),

AC27.3V

Max. power consumption

C-403 Max. 82W

C-404 Max. 100 W

Weight

C-403 Approx. 30 kg

C-404 Approx. 42 kg

Machine dimensions

C-403 430(W) x 639(D) x 690(H) mm

C-404 670(W) x 639(D) x 695(H) mm

1-1

Page 10

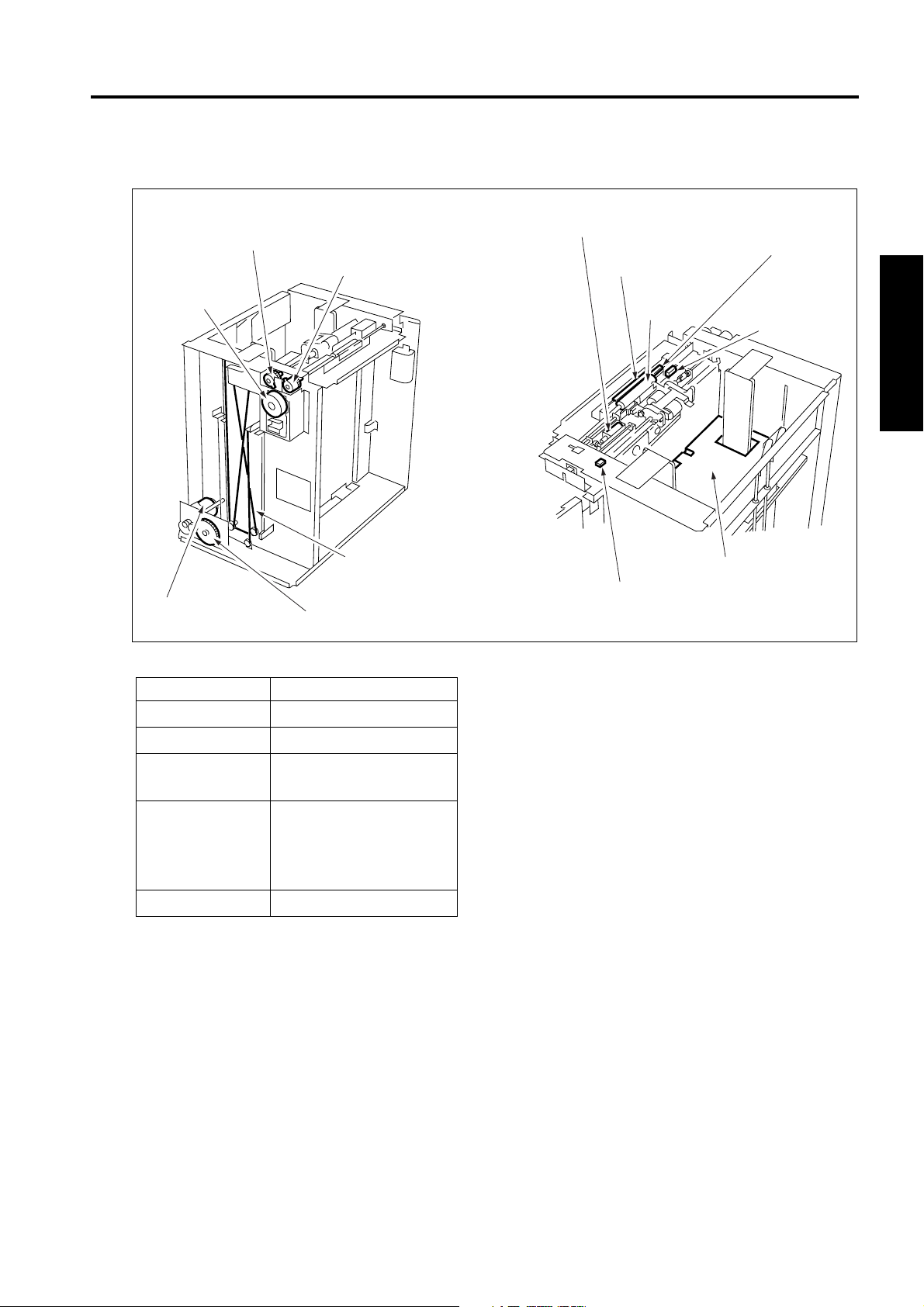

C-403/C-404

CENTER CROSS-SECTIONAL DRAWING

1 OUTLINE

Feed roller

Conveyance roller

Paper feed roller

Top cover

Up/down wire

(the other side

wire as well)

Double feed

prevention roller

Up/down plate

1-2

Page 11

DRIVE SYSTEM DRAWING

C-403/C-404

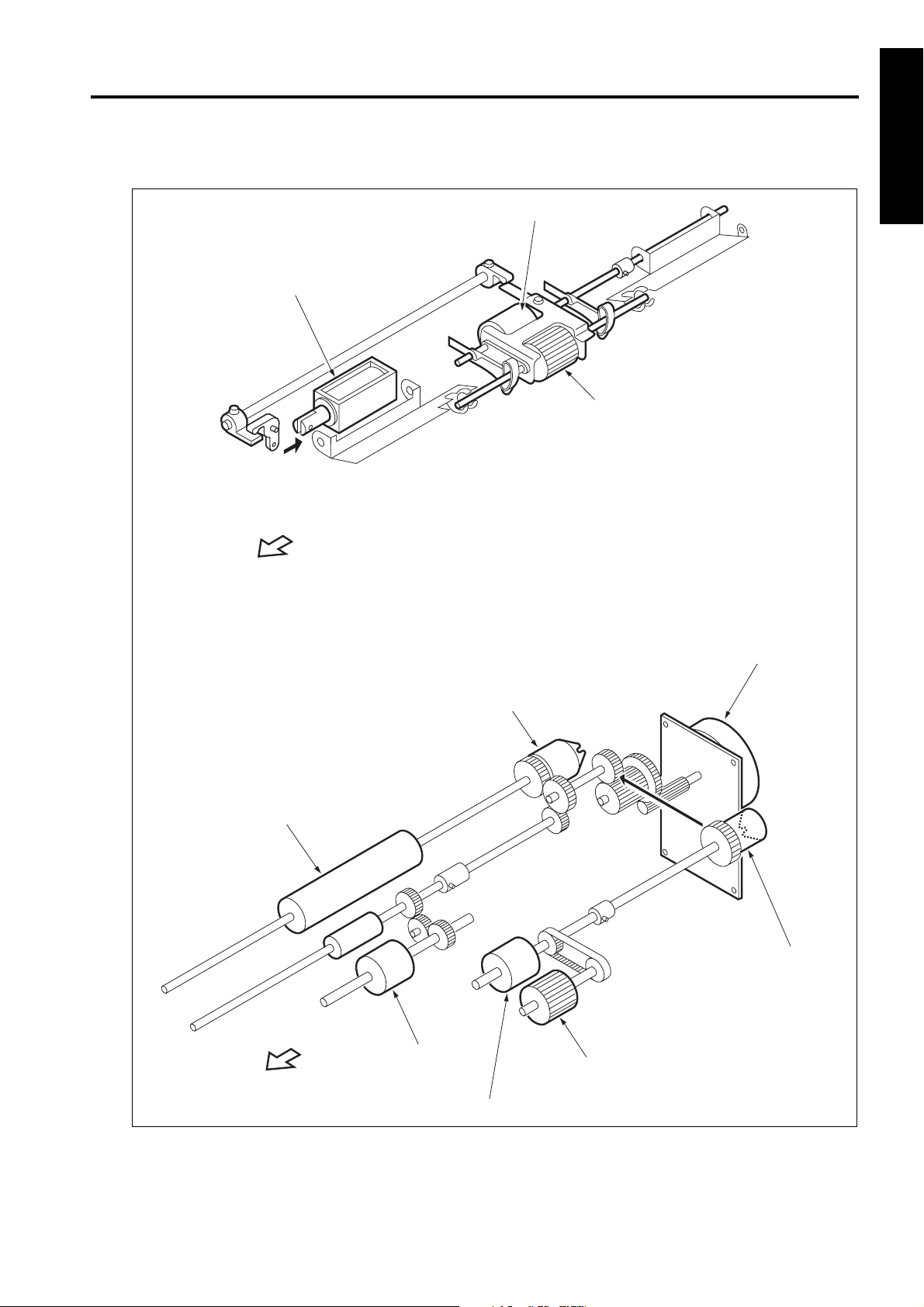

[1] Paper feed drive section

LT First paper feed SD

(SD100)

FRONT

1 OUTLINE

Feed roller

Paper feed roller

Conveyance roller

FRONT

LT First paper feed MC

(MC 102)

Double feed

prevention roller

LT paper feed motor

(M101)

LT feed drive MC

(MC101)

Paper feed roller

Feed roller

1-3

Page 12

C-403/C-404

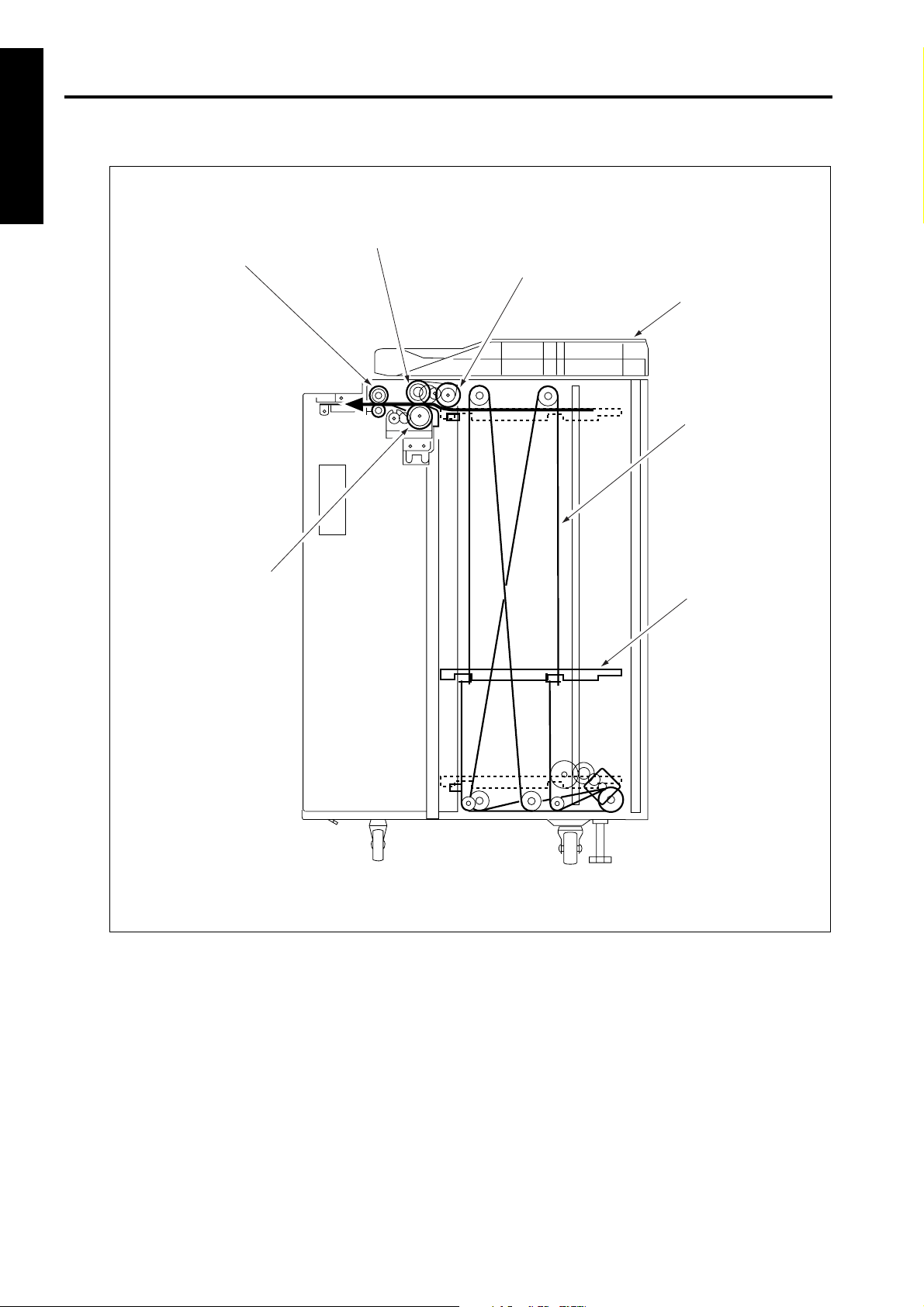

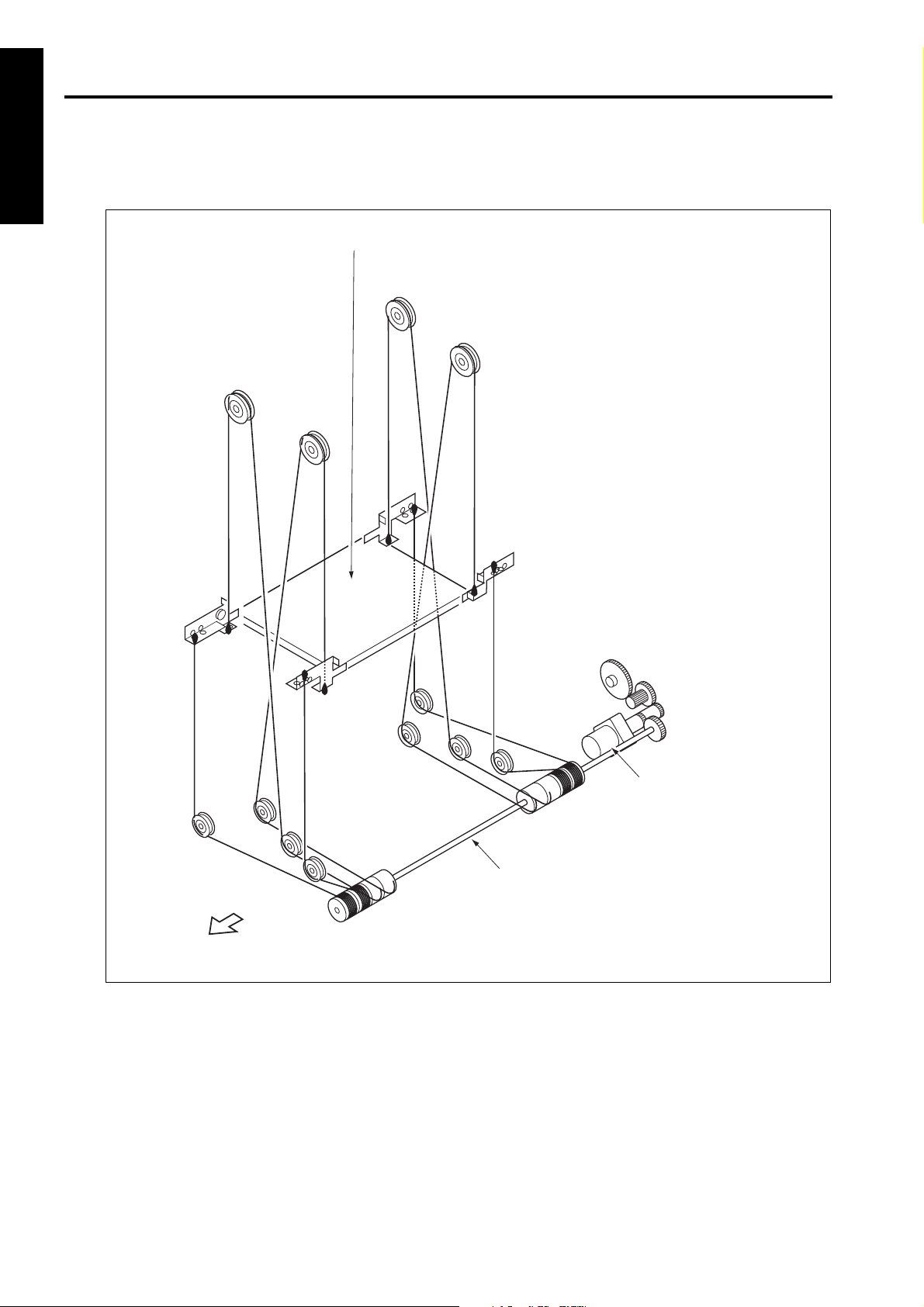

[2] Stacked paper up/down wire drive section

1 OUTLINE

a. C-403

Up/down plate

FRONT

LT up/down motor

(M100)

Up/down shaft

1-4

Page 13

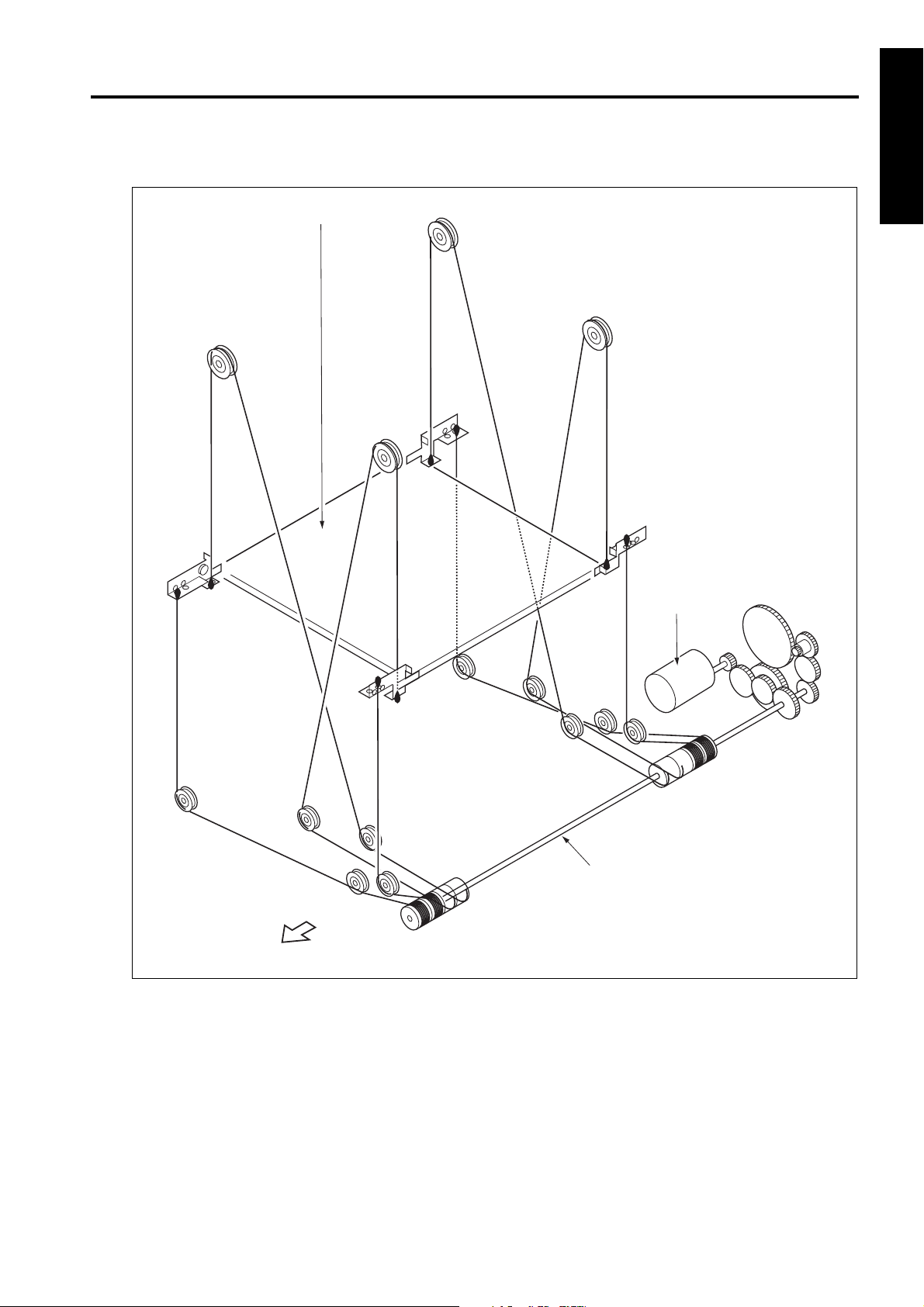

C-403/C-404

b. C-404

1 OUTLINE

Up/down plate

LT up/down motor

(M100)

FRONT

Up/down shaft

1-5

Page 14

1 OUTLINE

Blank page

Page 15

2

UNIT EXPLANATION

2 UNIT EXPLANATION

Page 16

2 UNIT EXPLANATION

Blank page

Page 17

PAPER FEED SECTION

[1] Composition

LT feed MC (MC101)

LT paper

feed motor

(M101)

LT first paper feed MC (MC102)

LT first paper feed SD

(SD100)

Paper dust

removing brush

Conveyance

roller

C-403/C-404

LT feed PS (PS106)

LT first paper

feed PS (PS107)

2 UNIT EXPLANATION

Up/down wire

(the other side wire as well)

LT up/down motor

(M100)

Remaining paper detection gear

[2] Mechanisms

Mechanism Method

Paper lifting *1 Wire drive

Paper feed Paper feed roller

No paper detection

Remaining paper

detection *2

Paper conveyance Roller conveyance

*1 Paper lifting

a.Up/down plate lifting drive operation

The up/down plate is lifted with the up/down

wires. When the top cover closes, LT up/down

motor (M100) rotates and the up/down plate connected to the up/down wires rises.

b.Up/down plate down drive operation

The up/down plate automatically lowers by 120

mm when the top cover is opened.

Subsequently, it is lowered by 120 mm each time

LT tray down drive switch (SW100) is pressed.

Photo sensor (PS108)

+actuator

Remaining paper detection gear+ photo sensor

(PS102, PS103, PS104,

PS105)

Up/down plate

LT tray down drive switch (SW 100)

*2 Remaining paper detection

The LCT is equipped with a remaining paper

detection gear which rotates together with LT up/

down motor (M100) driving the up/down plate.

The remaining paper detection gear has an actuator to turn ON/OFF LT remaining paper detection PS1 (PS102), LT remaining paper detection

PS2 (PS103), LT remaining paper detection PS3

(PS104), and LT remaining paper detection PS4

(PS105).

2-1

Page 18

C-403/C-404

2 UNIT EXPLANATION

Each sensor is turned ON/OFF according to the

rotating position of the remaining paper detection gear and since this is linked with the up/down

position of the up/down plate, the remaining

paper quantity in the LCT can be determined by

monitoring the ON/OFF of each sensor. The

remaining paper quantity detected with the four

sensors is displayed on the main body display.

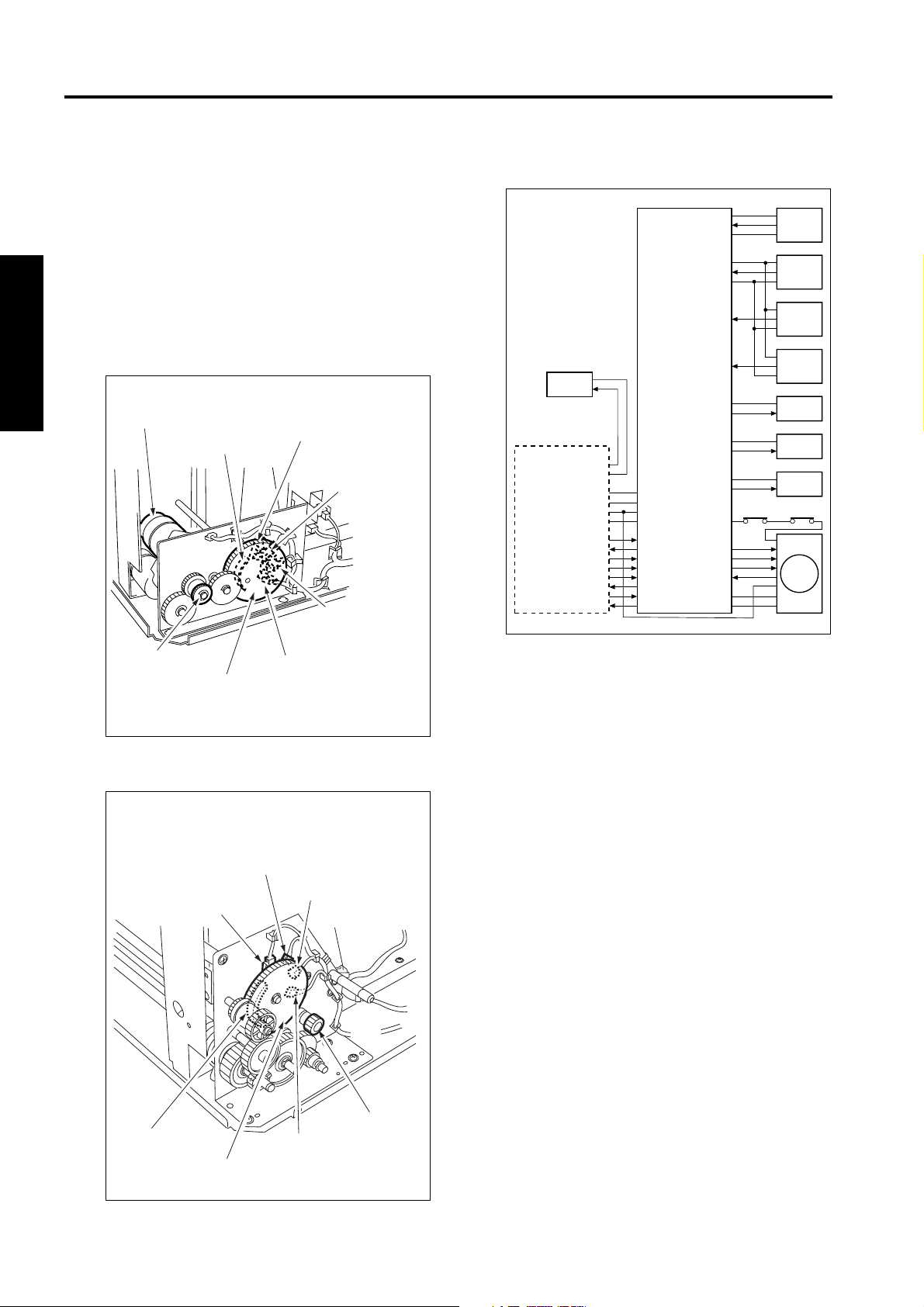

a. C-403

LT remaining paper

LT up/down motor (M100)

detection PS1

(PS102)

Actuator

LT remaining

paper detection

PS2 (PS103)

LT remaining

paper detection

PS3 (PS104)

Gear for M100

Remaining

LT remaining paper

detection PS4 (PS105)

paper detection

gear

b. C-404

LT remaining

paper detection

PS2 (PS103)

LT remaining paper

detection PS1 (PS102)

LT remaining paper

detection PS3 (PS104)

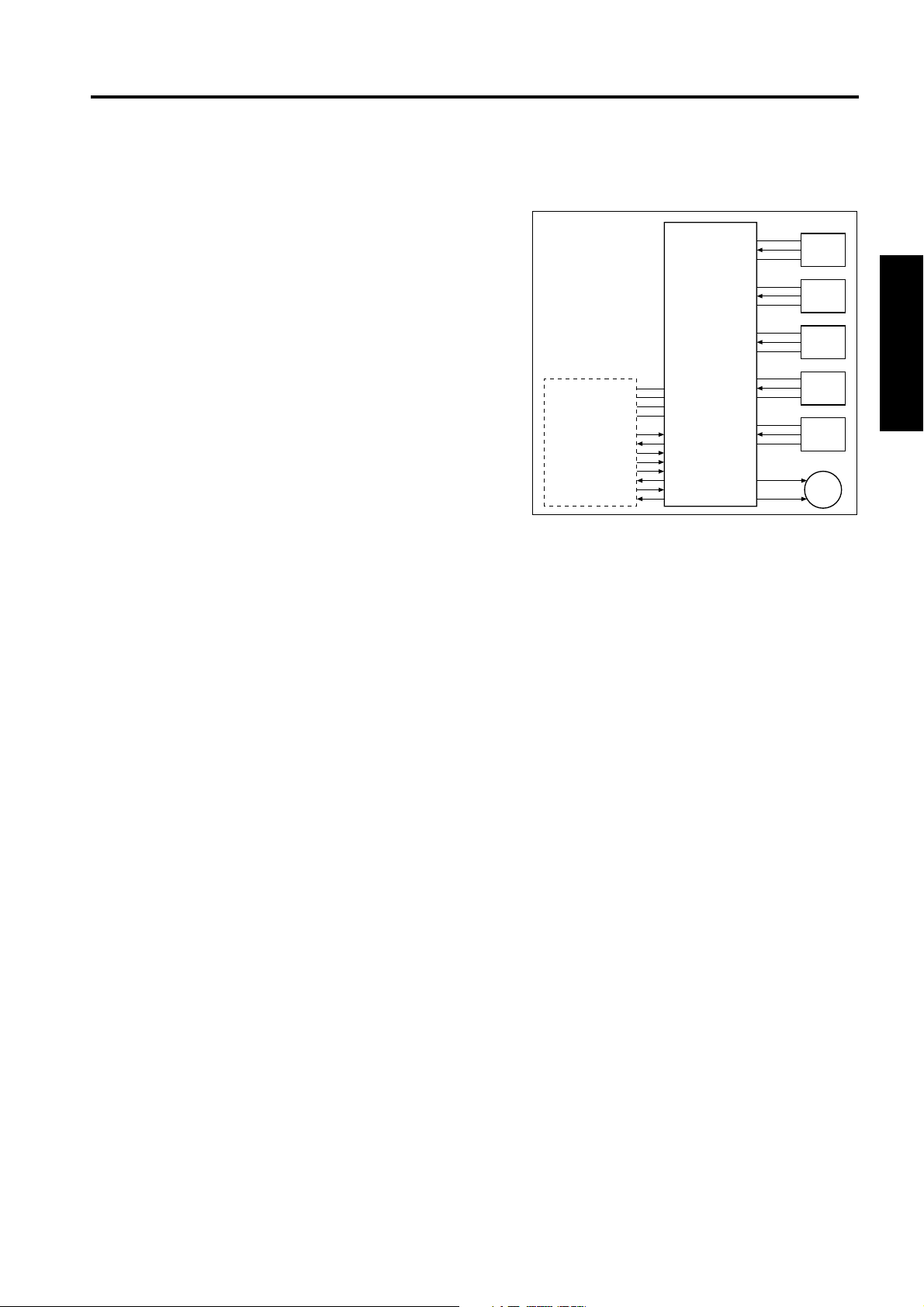

[3] First paper feed control

UPOP_PS

S_GND

CONV_PS

S_GND

PR_PS

SIDOP_PS

24V

CONT

24V

CONT

24V

CONT

24V

LCTM_CONT

LCTM_CLK

LCTM_F/R

LCTM_EM

GND

P_GND

5V

5V

MS101

5V

LT DB

HTR101

MAIN BODY

24V

PGND

5V

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

The first paper is fed by the paper feed roller and

the feed roller driven by M101(LT paper feed) via

MC101(LT feed MC). The paper feed roller and

feed roller touche the paper when SD100 (LT first

feed) is ON, feeding the paper to the conveyance

roller. Then, SD100 (LT first paper feed) turns

OFF to release the paper feed roller and feed

roller from the paper. The conveyance roller is

also driven by M101, by turning ON MC102 (LT

first feed MC), paper is fed to the main body.

The related signals are: PS100 (LT top cover

open/close detection), PS106 (LT feed), PS107

(LT first feed), and PS110 (LT jam access door

open/close detection).

PS100

PS106

PS107

PS110

MC101

MC102

SD100

MS102

M101

Actuator

Remaining paper

detection gear

Gear for M100

LT remaining paper

detection PS4 (PS105)

2-2

Page 19

C-403/C-404

1. Operation

a. First paper feed timing

(1) Start of first paper feed

At predefined interval after the START button is

pressed.

(2) Start of second and subsequent papers

When PS106 (LT feed) is turned OFF by the preceding paper.

(3) OFF timing

When the main body M7 (paper exit) turns OFF.

b. Interlock

The power supply line of M101 (LT paper feed) is

equipped with MS101 (LT interlock/1) and

MS102 (LT interlock/2). When the top cover is

opened, MS101 turns OFF, and when the jam

access door is opened MS102 turns OFF,

thereby cutting off the power supply to M101.

Furthermore, the top cover is equipped with

PS100 (LT top cover open/close detection) and

the jam access door is equipped with PS110 (LT

jam access door open/close detection) and

when either of these doors is opened during

paper feed, the M101 drive signal is turned OFF

to stop the paper feed operation.

c. Internal heater

The LCT is equipped with HTR101 (LT internal

heater) to protect the paper from humidity.

HTR101 is directly controlled by the main body

PRCB (printer control board) rather than by the

LTDB (LT drive board).

2. Signals

a. Input signals

(1) UPOP_PS (PS100 to LTDB)

Top cover open/close detection signal

[L]: Cover opened

[H]: Cover closed

(2) CONV_PS (PS106 to LTDB)

Conveyance roller exit paper detection signal

[L]: Paper detected

[H]: Paper not detected

(3) PR_PS (PS107 to LTDB)

Conveyance roller entrance (pre-registration

position) paper detection signal

[L]: Paper detected

[H]: Paper not detected

(4) SIDOP_PS (PS110 to LTDB)

Jam access door open/close detection signal

[L]: Door opened

[H]: Door closed

(5) LCTM_EM (M101 to LTDB)

M101 rotation error detection signal

[L]: M101 rotating

[H]: M101 not rotating

(6) IO_DTXD (MAIN BODY to LTDB)

Serial data to transmit main body PRCB (printer

control board) operating status to LTDB

(7) LCT_LATCH (MAIN BODY to LTDB)

IO_DTXD signal latch signal

(8) IO_DCLK (MAIN BODY to LTDB)

IO_DTXD signal clock signal

(9) ERR_OUT4 (MAIN BODY to LTDB)

Signal to notify LTDB (LT drive board) when there

is error in the main body

(10) ACK4 (MAIN BODY to LTDB)

Serial data transmission enable signal from LCT

to main body PRCB (printer control board)

2 UNIT EXPLANATION

2-3

Page 20

C-403/C-404

2 UNIT EXPLANATION

b. Output signals

(1) CONT (LTDB to MC101)

MC101 (LT feed MC) ON/OFF drive signal

[L]: MC101 ON

[H]: MC101 OFF

(2) CONT (LTDB to MC102)

MC102 (LT first paper feed MC) ON/OFF drive

signal

[L]: MC102 ON

[H]: MC102 OFF

(3) CONT (LTDB to SD100)

SD100 ( LT first paper feed) ON/OFF drive signal

[L]: SD100 ON

[H]: SD100 OFF

(4) LCTM_CONT (LTDB to M101)

M101 (LT paper feed) ON/OFF control signal

[L]: M101 ON

[H]: M101 OFF

(5) IO_URXD (LTDB to MAIN BODY)

Serial data to transmit the LTDB (LT drive board)

operating status to main body PRCB

(6) IO_UCLK (LTDB to MAIN BODY)

IO_URXD signal clock signal

(7) REQ4 (LTDB to MAIN BODY)

Serial data send request signal from LCT to main

body PRCB

(8) LCTM_CLK (M101 to LTDB)

M101 (LT paper feed) rotational speed control

clock signal

(9) LCTM_F/R (M101 to LTDB)

M101 (LT paper feed) rotational direction indication signal

This machine always indicates [H]: normal rotation.

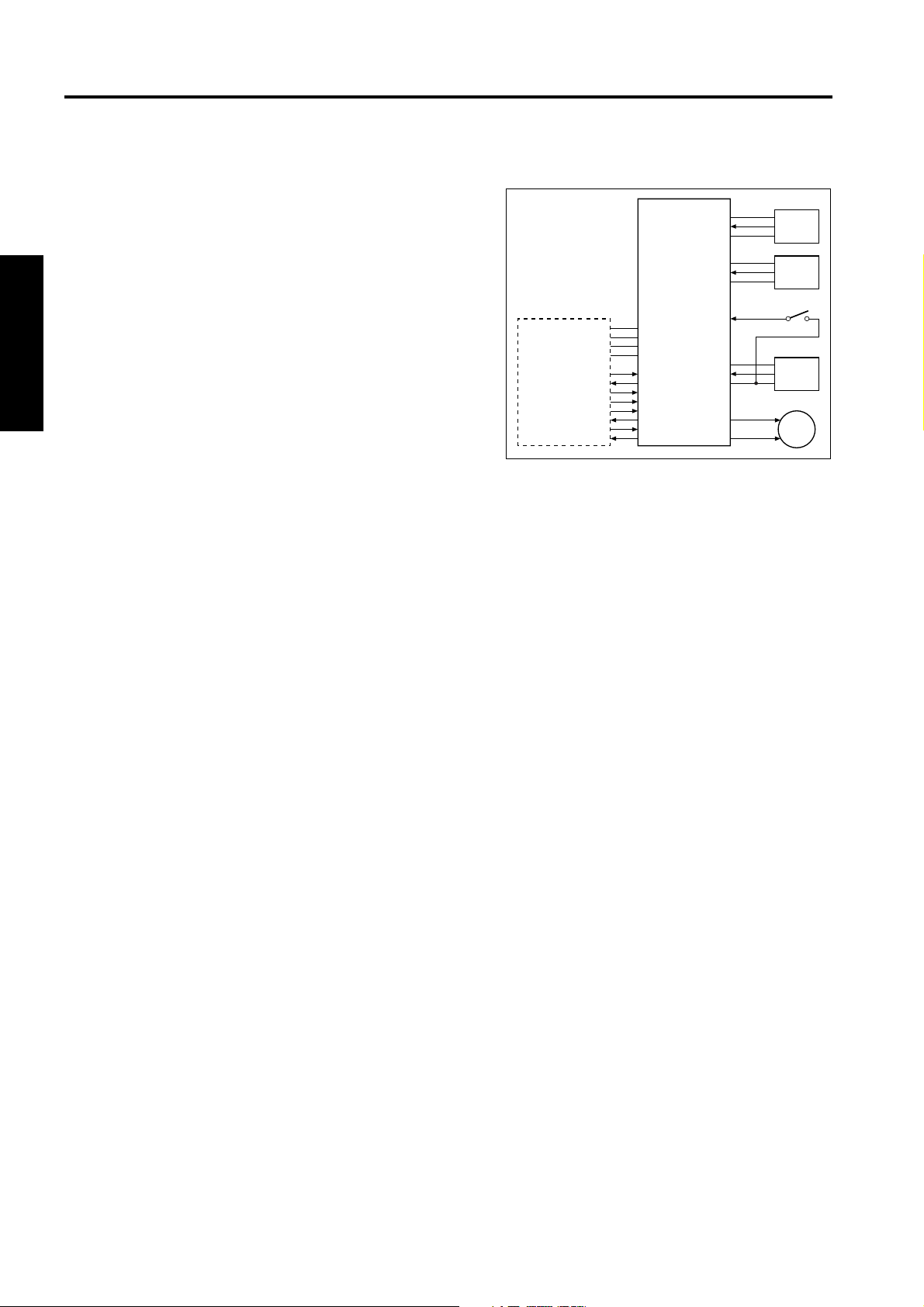

[4] Up/down plate drive control

LT DB

MAIN BODY

24V

PGND

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

5V

When the top cover opens or closes, M100 (LT

up/down motor) rotates forward or backward to

move the up/down plate up or down. The up/

down plate descends by 120 mm each time

SW100 (LT tray down drive) is pressed while the

top cover is opened.

The related signals are PS100 (LT top cover

open/close detection), PS101 (LT lower limit

detection), and PS109 (LT upper limit detection).

1. Operation

a. Up/down plate descend timing

(1) ON timing

When the top cover is opened and PS100 (LT top

cover open/close detection) is turned OFF, M100

rotates backward to lower the up/down plate.

When SW100 (LT tray down drive) turns ON by

pressing, M100 rotates backward to move the

up/down plate down.

(2) OFF timing

M100 turns OFF at predefined interval after

PS100 turns OFF or SW100 turns ON. This in

turn lowers the up/down plate by 120 mm.

(3) Others

The up/down plate descends by 120 mm each

time SW100 is pressed until PS101 turns ON to

indicate the bottom limit of the up/down plate.

UPOP_PS

S_GND

SIG

S_GND

DW_SW

UP_PS

S_GND

5V

5V

5V

D1

D2

PS100

PS101

SW100

PS109

M100

2-4

Page 21

C-403/C-404

b. Up/down plate ascend timing

(1) ON timing

When the top cover is closed and PS100 (LT top

cover open/close detection) is turned ON, M100

(LT UP/DOWN) rotates forward to raise the up/

down plate.

(2) OFF timing

When the up/down plate rises and PS109 (LT

upper limit detection) turns ON to indicate the

detection of the topmost paper, M100 (LT UP/

DOWN) turns OFF and stops the up/down plate.

The up/down plate also stops when the top cover

is opened and PS100 (LT top cover open/ close

detection) turns OFF.

2. Signals

a. Input signals

(1) SIG (PS101 to LTDB)

Up/down plate lower limit detection signal

[L]: Up/down plate not at lower limit

[H]: Up/down plate at lower limit

(2) UP_PS (PS109 to LTDB)

Up/down plate upper limit detection signal

[L]: Up/down plate not at upper limit

[H]: Up/down plate at upper limit

(3) DW_SW (SW100 to LTDB)

SW100 (LT tray down switch) ON/OFF detection

signal

[L]: SW100 ON

[H]: SW100 OFF

b. Output signal

(1) D1, 2 (LTDB to M100)

M100 (LT UP/DOWN) drive signal

These signals switches the direction of the drive

current to control the rotation direction of M100.

[5] Remaining paper detection/No paper

detection control

LT DB

MAIN BODY

24V

PGND

SGND

IO_DTXD

IO_UCLK

LCT_LATCH

IO_DCLK

ERR_OUT4

IO_URXD

ACK4

REQ4

5V

The remaining paper quantity is detected by

PS102 (LT remaining paper detection 1), PS103

(LT remaining paper detection 2), PS104 (LT

remaining paper detection 3), and PS105 (LT

remaining paper detection 4) and no paper

detection is made by PS108 (LT no paper detection).

The signals detected by these sensors are controlled by LTDB (LT drive board) and displayed on

the main body display.

1. Operation

a. Remaining paper detection control

The remaining paper quantity is determined from

the ON/OFF combination of sensors PS102 (LT

remaining paper detection 1), PS103 (LT remaining paper detection 2), PS104 (LT remaining

paper detection 3), and PS105 (LT remaining

paper detection 4) which detect the rotational

position of M100 (LT UP/DOWN) that is driving

the up/down plate. Each sensor turns ON or

OFF according to the position of the remaining

paper detection gear which is linked with the

rotation of M100.

The remaining paper quantity is detectable at

eight levels, but it is displayed on the main body

display as five levels.

SIG

S_GND

SIG

S_GND

SIG

S_GND

SIG

S_GND

0_PS

S_GND

5V

5V

5V

5V

5V

D1

D2

PS102

PS103

PS104

PS105

PS108

M100

2 UNIT EXPLANATION

2-5

Page 22

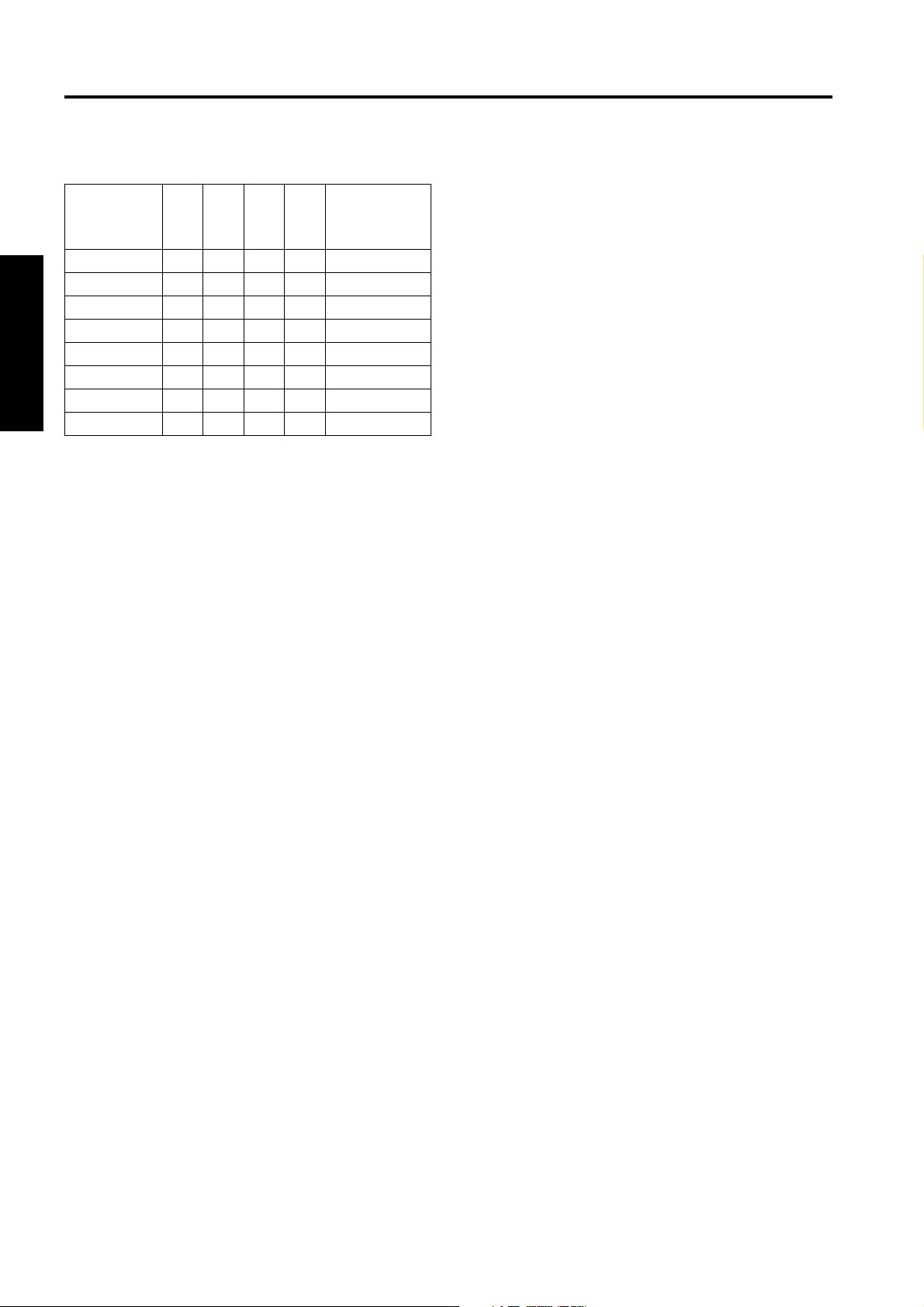

C-403/C-404

<Remaining paper quantity and display>

Stacked

paper

quantity

0 to 700 OFF OFF OFF OFF 1 flashing

701 to 1200 ON OFF OFF OFF 1 on

1201 to 1700 ON ON OFF OFF 2 on

1701 to 2200 ON ON ON OFF 2 on

2201 to 2700 ON ON ON ON 3 on

2701 to 3200 OFF ON ON ON 3 on

3201 to 3700 OFF OFF ON ON 4 on

2 UNIT EXPLANATION

3701 or more OFF OFF OFF ON 4 on

Caution:The remaining paper quantity is indicated on

b. No paper detection control

When there is no more paper inside the LCT,

PS108 (LT no paper detection) turns ON and a

message is displayed on the main body display.

PS102 PS103 PS104 PS105

the control panel with four horizontal bars.

Stacked paper quantity differs depending on

the thickness of the paper.

Remaining

paper quantity

display

2. Signals

a. Input signals

(1) SIG (PS102 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS102 OFF

[H]: PS102 ON

(2) SIG (PS103 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS103 OFF

[H]: PS103 ON

(3) SIG (PS104 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS104 OFF

[H]: PS104 ON

(4) SIG (PS105 to LTDB)

Remaining paper detection gear rotational position detection signal

[L]: PS105 OFF

[H]: PS105 ON

(5) 0_PS (PS108 to LTDB)

LCT no paper detection signal

[L]: No paper

[H]: Paper present

2-6

Page 23

3

DISASSEMBLY/ASSEMBLY

3 DIS./ASSEMBLY

Page 24

This section explains how to disassemble and reassemble the machine.

When disassembling and reassembling the machine, follow the precautions given below.

1. Be sure the power cord has been unplugged from the wall outlet.

3 DIS./ASSEMBLY

2. The disassembled parts must be reassembled following the disassembly procedure in reverse unless otherwise specified.

3. Care should be taken not to lose small parts. Care should also be

taken not to install small parts in wrong places.

4. Do not operate the machine before installing all the disassembled

parts completely.

5. Removal of some screws is prohibited in this section. Never loosen

them.

Page 25

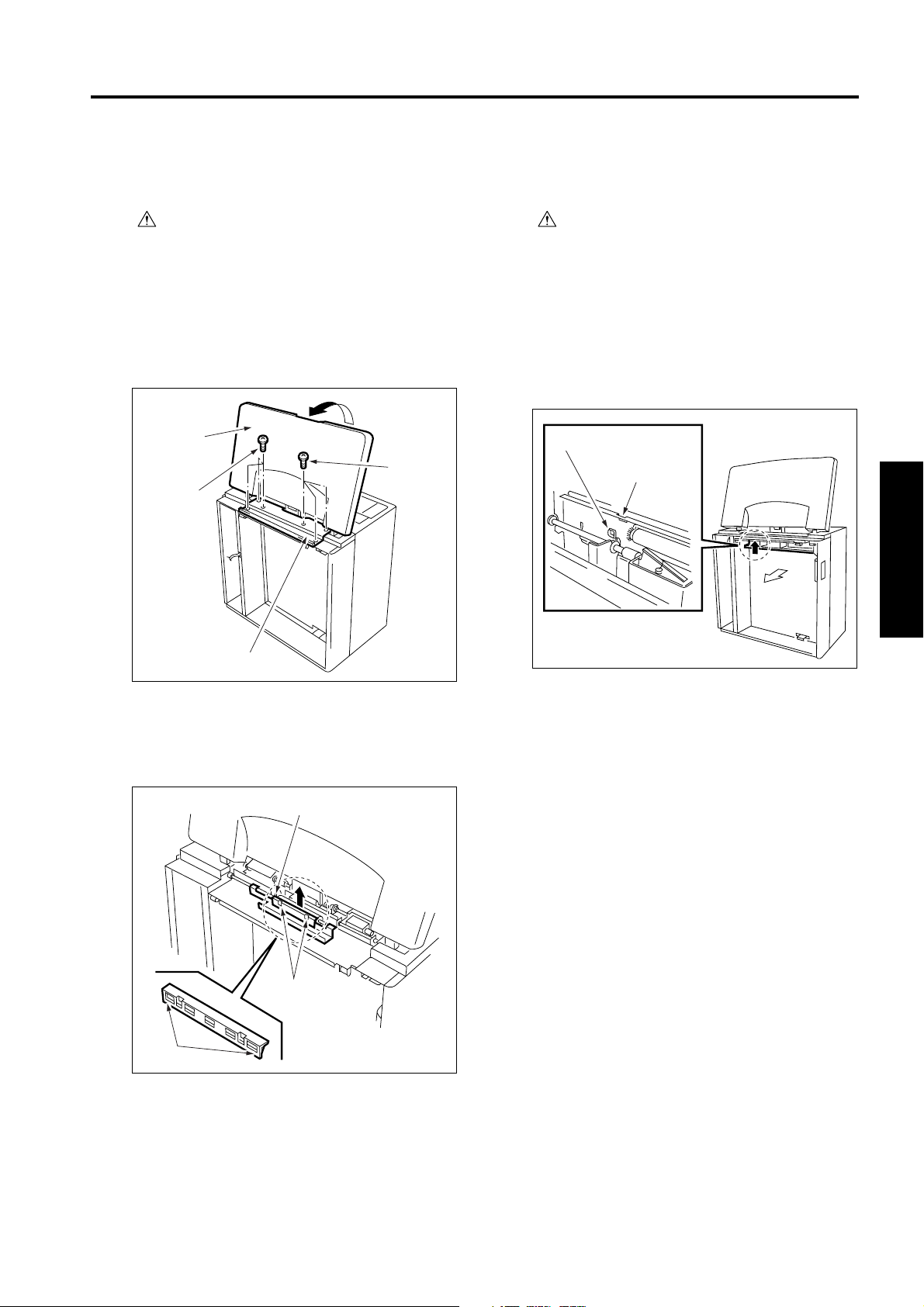

PAPER FEED SECTION

C-403/C-404

[1] Cleaning the Paper Dust Removing

Brush

Caution:If LT is connected to the main

body, make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Open the top cover.

(2) Remove six screws to detach the paper feed

cover B.

To p

cover

Screws

Screws

[2] Cleaning the LT feed PS (PS106)/LT

first paper feed PS (PS107)

Caution:If LT is connected to the main

body, make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Looking into the paper exit side of the LCT from

below, and clean sensors through the cavity for

LT feed PS (PS106) and the cavity for LT first

paper feed (PS107) using a blower brush.

Cavity for PS106

Cavity for PS107

Paper

exit

side

3 DIS./ASSEMBLY

Paper feed cover B

(3) Insert a flat bladed screwdriver in the cavities (in

two locations) for paper dust removing brush to

release the locking lugs, then remove the paper

dust removing brush.

Paper dust removing brush

Cavity

Locking lugs

(4) Clean the paper dust removing brush using a

blower brush.

(5) Reinstall the above parts following the removal

steps in reverse.

3-1

Page 26

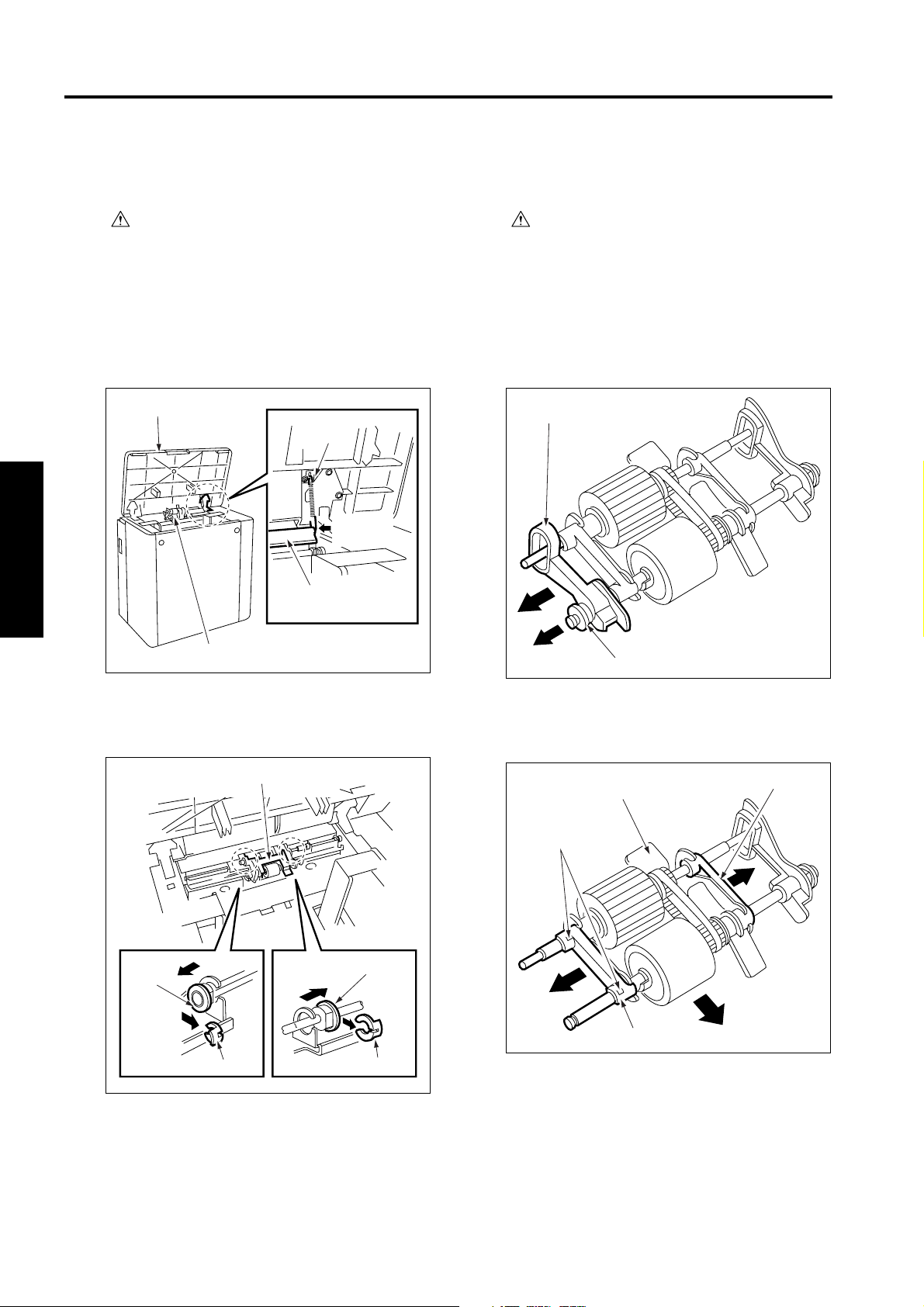

C-403/C-404

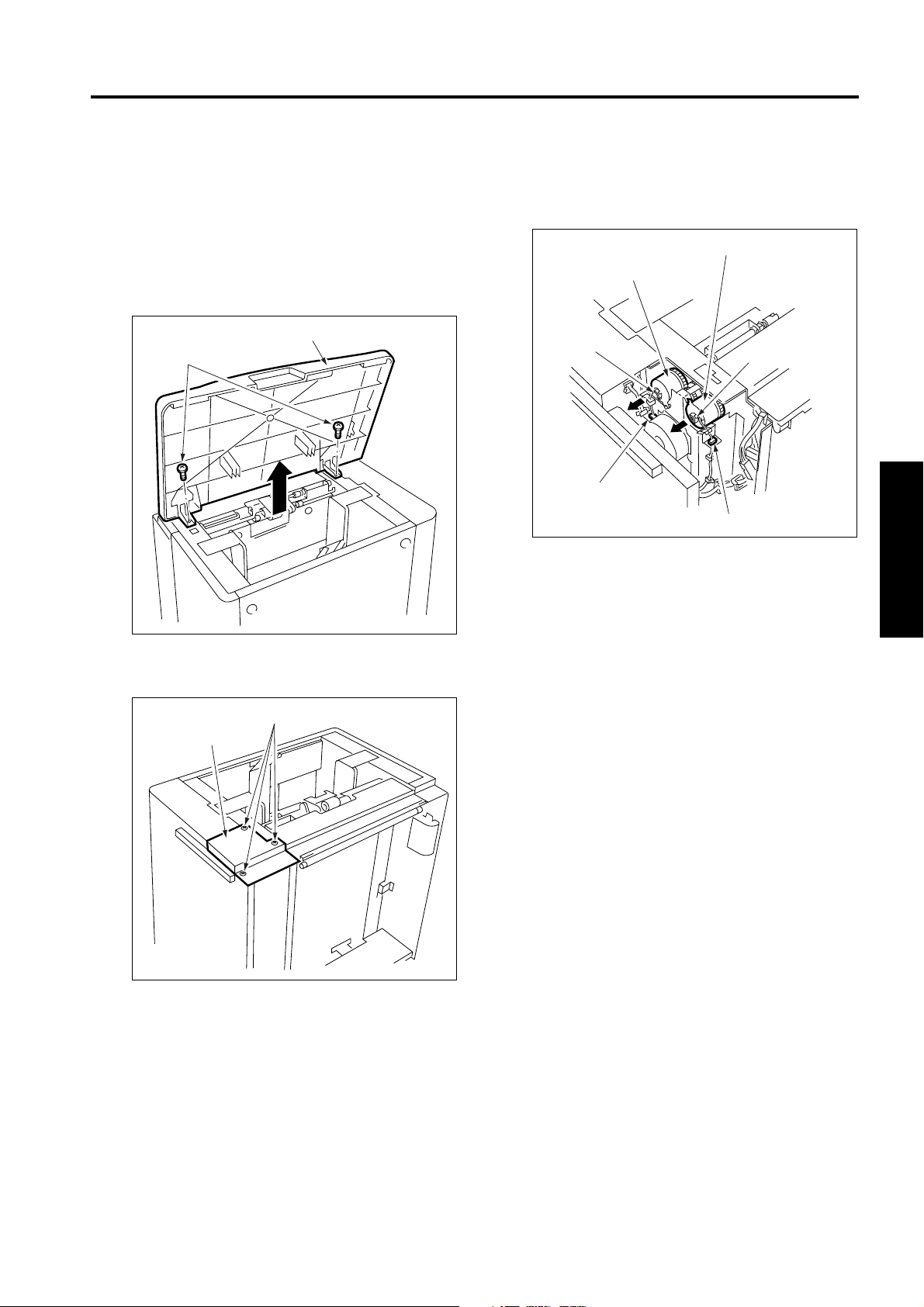

[3] Removing and Reinstalling the Paper

Feed Roller Unit

Caution:If LT is connected to the main

body, make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Open the top cover.

(2) Remove the spring from the paper feed roller

unit.

Top cover

Spring

Remove

this.

Paper feed roller unit

3 DIS./ASSEMBLY

[4] Replacing the Paper Feed Roller Rub-

ber/Feed Roller Rubber

Caution:If LT is connected to the main

body, make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

(1) Remove the paper feed roller unit.

(2) Remove the bearing and paper feed reference

actuator.

Paper feed reference actuator

Paper feed roller unit

(3) After removing two stop rings, remove the two

bearings outward to remove the paper feed roller

unit.

Paper feed roller unit

Bearing

Stop ring

Bearing

Stop ring

Bearing

(3) Remove two stop rings.

(4) Remove two bearings outward to detach the

roller section from the roller fitting.

Roller fitting

Stop rings

Bearing

Bearing

(4) Reinstall the above parts following the removal

steps in reverse.

3-2

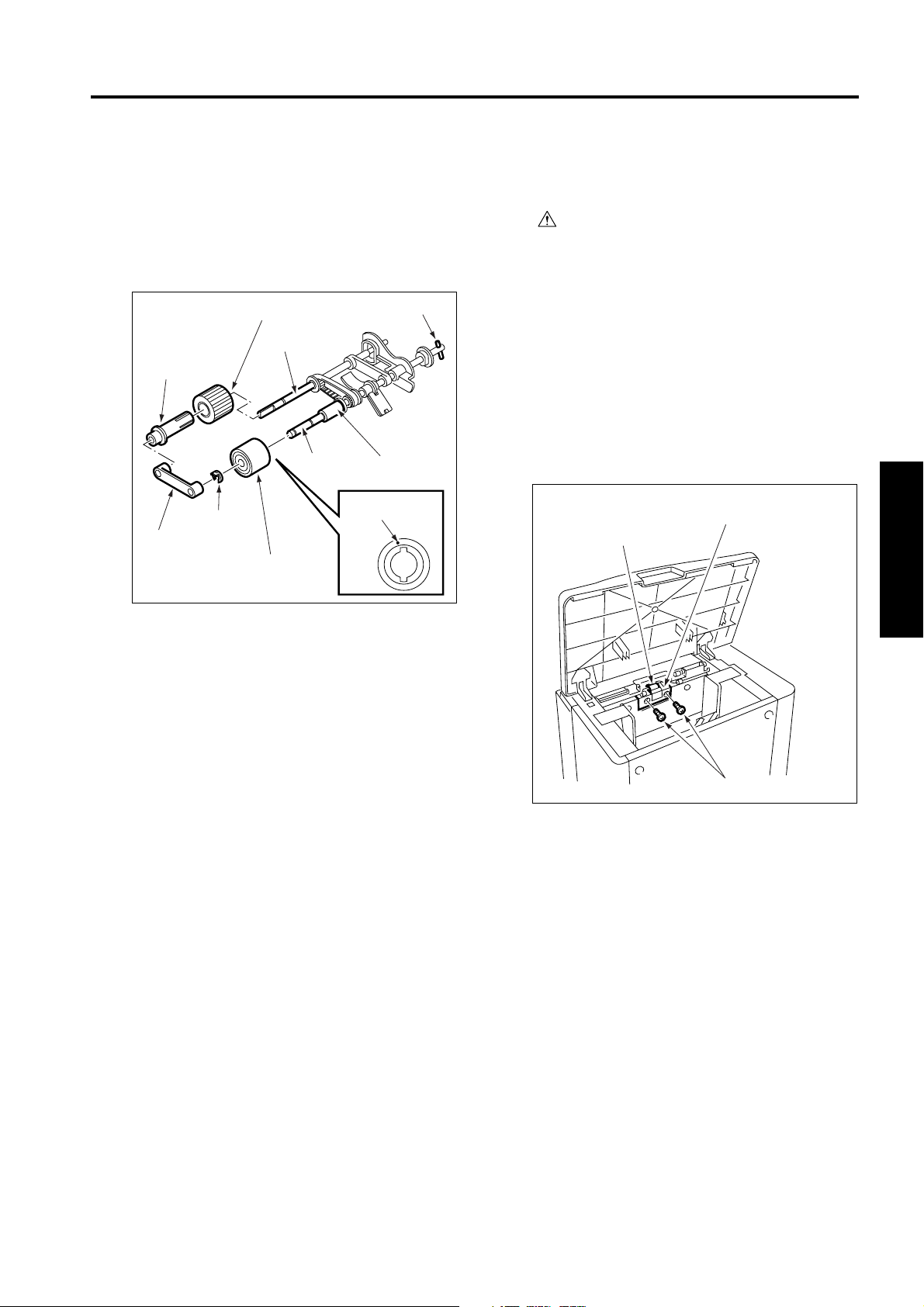

Page 27

C-403/C-404

(5) Remove the bearing from the opposite side of the

coupling, then remove the paper feed roller from

the shaft.

(6) Remove the stop ring to pull the feed roller from

the shaft.

(7) Remove the rubber from each roller.

Coupling

Feed roller

Paint mark

Paper feed

roller

Bearing

Paper feed roller rubber

Shaft

Shaft

Stop ring

Feed roller rubber

(8) Reinstall the above parts following the removal

steps in reverse.

Caution1: Make sure rollers and rubber por-

tions are oriented properly when

reinstalling them.

Caution2: Make sure the one-way clutch direc-

tion is correct.

Caution3: Check whether grease or the like is

present on each roller.

[5] Replacing the Double Feed Preven-

tion Roller Rubber

Caution:If LT is connected to the main

body, make sure that main body

power plug is disconnected

from the power outlet.

a. Procedure

Caution: With the power held on, press the LT

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

(1) Remove the paper feed roller unit.

(2) Remove two screws to detach the double feed

prevention roller unit cover.

Double feed

Double feed

prevention roller

prevention roller unit cover

Screws

3 DIS./ASSEMBLY

3-3

Page 28

C-403/C-404

(3) Remove two screws to detach the double feed

prevention roller unit.

(5) Remove the double feed prevention roller rubber

from the double feed prevention roller.

Caution: When reinstalling the double feed pre-

vention roller unit, tighten the screws

on the rear side first.

Double feed prevention roller unit

Screws

(6) Reinstall the double feed prevention roller in the

Paint mark

Double feed

prevention roller

Shaft

Double feed

prevention roller

rubber

reverse order of the removal procedure.

3 DIS./ASSEMBLY

(4) Remove two stop rings, fit the shaft into the D-cut

in the fitting, and remove the double feed prevention roller together with the shaft.

Caution1: Make sure the double feed preven-

tion roller rubber is oriented properly

when reinstalling it.

Caution2: Check whether scratch or the like is

Double feed prevention roller

visible on the pet cover for the drive

gear.

Caution3: Check whether grease or the like is

present on double feed prevention

roller.

D-cut

Stop ring

3-4

Page 29

C-403/C-404

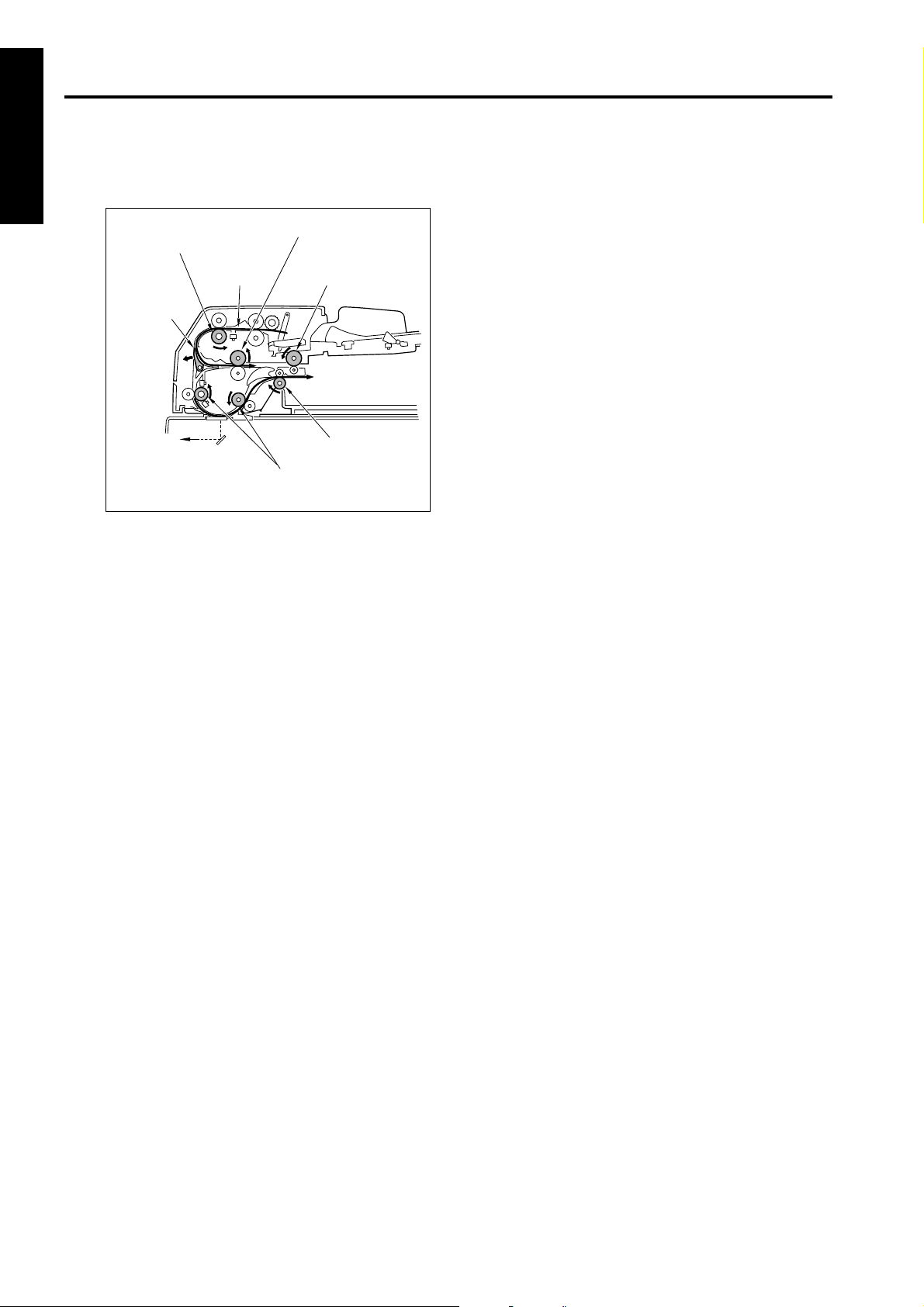

[6] Replacing the LT feed MC (MC101)/LT

first paper feed MC (MC102)

a. Procedure

(1) Open the top cover.

(2) Remove the spring from the paper feed roller

unit.

(3) Remove two screws to detach the top cover.

Top cover

Screws

(4) Remove three screws to detach the clutch

replacement cover.

(5) Disconnect two relay connectors (CN765,

CN766) of the clutches.

(6) Remove the stop ring to detach each clutch.

LT first paper feed MC (MC102)

LT feed MC (MC101)

Stop ring

Stop ring

Relay connector

(CN766)

Relay connector (CN765)

(7) Reinstall the above parts following the removal

steps in reverse.

Caution: When installing each MC, make sure

that the stopper of each clutch is on

the predefined position.

3 DIS./ASSEMBLY

Clutch

replacement cover

Screws

3-5

Page 30

C-403/C-404

[7] Replacing the C-403 Up/Down Wires

Caution: With the power held on, press the LT

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

a. Procedure

(1) Open the top cover.

(2) Remove the clutch replacement cover.

(3) Remove five screws to detach the right side

cover.

3 DIS./ASSEMBLY

Right side

cover

Screws

Screws

(5) Remove twelve screws to detach the rear cover.

Screw

Screws

Screws

Screws

Rear cover

(6) Remove the five relay connectors (CN749,

CN780, CN781, CN782, CN783) to disconnect

the wiring harness from the up/down motor

mounting assembly.

(7) Remove the E-ring to detach the up/down gear.

(8) Pull the pin from the shaft.

(9) Remove the E-ring to detach the bearing.

(10) Remove three screws to detach the up/down

motor assembly.

(4) After opening the jam access door, remove six

screws to detach the front cover.

Caution: When removing the front cover, close

the jam access door after removing

the screws.

Jam access door

Screws

Right side cover

Screws

Relay connector

Up/down

motor mounting

assembly

Shaft

(CN749)

Screw

Pin

Screw

Bearing

E-ring

Relay

connector

(CN780)

Relay

connector

(CN781)

Relay

connector

(CN782)

Relay

connector

(CN783)

Screw

Up/down

gear

E-ring

3-6

Page 31

(11) Replace the up/down wire following the instruc-

tions in “Removing Up/Down Wires’’ and “Installing Up/Down Wires.’’

Caution: Two sets of four up/down wires with

different length, one set at the front

and the other at the back, are used.

Wires with the same length can be

used either at the front or back if they

are used in the same location.

1323.6mm

Wire A

1250.3mm

Wire B

C-403/C-404

Wire C

Wire D

769.3mm

661mm

3 DIS./ASSEMBLY

3-7

Page 32

C-403/C-404

<Removing the Up/Down Wires>

Wire A

Wire B

Wire B

Wire A

Up/down plate

2. Release the metal

ball to remove wire

C.

18. Release the metal

ball to remove wire

A.

4. Release the metal

ball to remove wire

D.

14. Release the metal

ball to remove wire

A.

7. Release the metal

ball to remove wire

C.

9. Release the metal

ball to remove wire

3 DIS./ASSEMBLY

D.

12. Release the metal

ball to remove wire

B.

Wire C

Wire D

6. Remove the E-ring.

8. Remove the pulley.

10. Remove the pulley.

FRONT

Up/down

shaft

Wire D

Wire C

16. Release the metal

ball to remove wire

B.

1. Remove the E-ring.

3. Remove the pulley.

5. Remove the pulley.

15. Remove the Ering, then remove

the pulley to

release wire B.

11. Remove the E-ring,

then remove the

pulley to release

wire B.

13. Remove the pulley to

release wire A.

3-8

17. Remove the pulley

to release wire A.

Page 33

<Installing the Up/Down Wires>

C-403/C-404

Wire A

Wire B

7. Insert wire A in the

pulleys, then attach a

metal ball.

15. Insert wire C in the

pulleys, then attach a

metal ball.

12. Insert wire D in the

pulleys, then attach a

metal ball.

10. Insert wire B in the

pulleys, then attach a

metal ball.

Wire C

Wire D

13. Insert wire C in the up/

down shaft, attach a

pulley, and secure the

pulley with an E-ring.

14. Wind wire C around

the pulley by 6 turns in

such a manner that the

wire can be pulled

from over the pulley.

Wire B

Wire A

FRONT

Up/down plate

1. Insert wire A in

6. the up/down

shaft, attach

pulleys, then

pull the wire

from under the

pulleys.

Up/down

shaft

20. Insert wire B in the pulleys,

then attach a metal ball.

2. Insert wire A in the pulleys,

then attach a metal ball.

17. Insert wire D in the pulleys,

then attach a metal ball.

5. Insert wire B in the pulleys,

then attach a metal ball.

Wire D

Wire C

3 DIS./ASSEMBLY

18. Insert wire C in the up/

down shaft, attach a

pulley, and secure the

pulley with an E-ring.

19. Wind wire C around

the pulley by 6 turns

in such a manner that

the wire can be pulled

from over the pulley.

6 turns

6 turns

11. Insert wire D in the up/

down shaft, attach a

pulley, and wind wire

D around the pulley by

six turns in such a

manner that the wire

can be pulled from

over the pulley.

6 turns

3. Insert wire B in the up/

8. down shaft, attach a

pulley, and secure the

pulley with E-rings.

4. Pull wire B from under the

9. pulleys.

3-9

16. Insert wire D in the up/

down shaft, attach a

pulley, and wind wire

D around the pulley by

six turns in such a

manner that the wire

can be pulled from

over the pulley.

6 turns

Page 34

C-403/C-404

(12) After installing the up/down wires, make sure the

up/down wires are passed in the grooves in the

[8] Replacing the C-404 Up/Down Wires

a. Procedure

pulleys properly and wires do not run on the

sides of the pulleys. Also make sure the up/down

plate can be moved up and down smoothly by

hand.

Caution: With the power held on, press the LT

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

Caution: If the up/down plate does not move up

and down smoothly, reinstall the up/

down wires.

(13) Install the up/down wire drive motor assembly,

up/down gear, and relay connectors, following

the removal steps in reverse.

(14) Remove the E-ring to detach the idle gear.

(1) Remove the clutch replacement cover, side

cover (right), front cover, and rear cover following

the steps (1) to (5) in [7] Replacing the C-403 Up/

Down Wires.

(2) Remove the E-ring.

(3) Remove the five screws to detach the gear cover.

(4) Remove the two bearings.

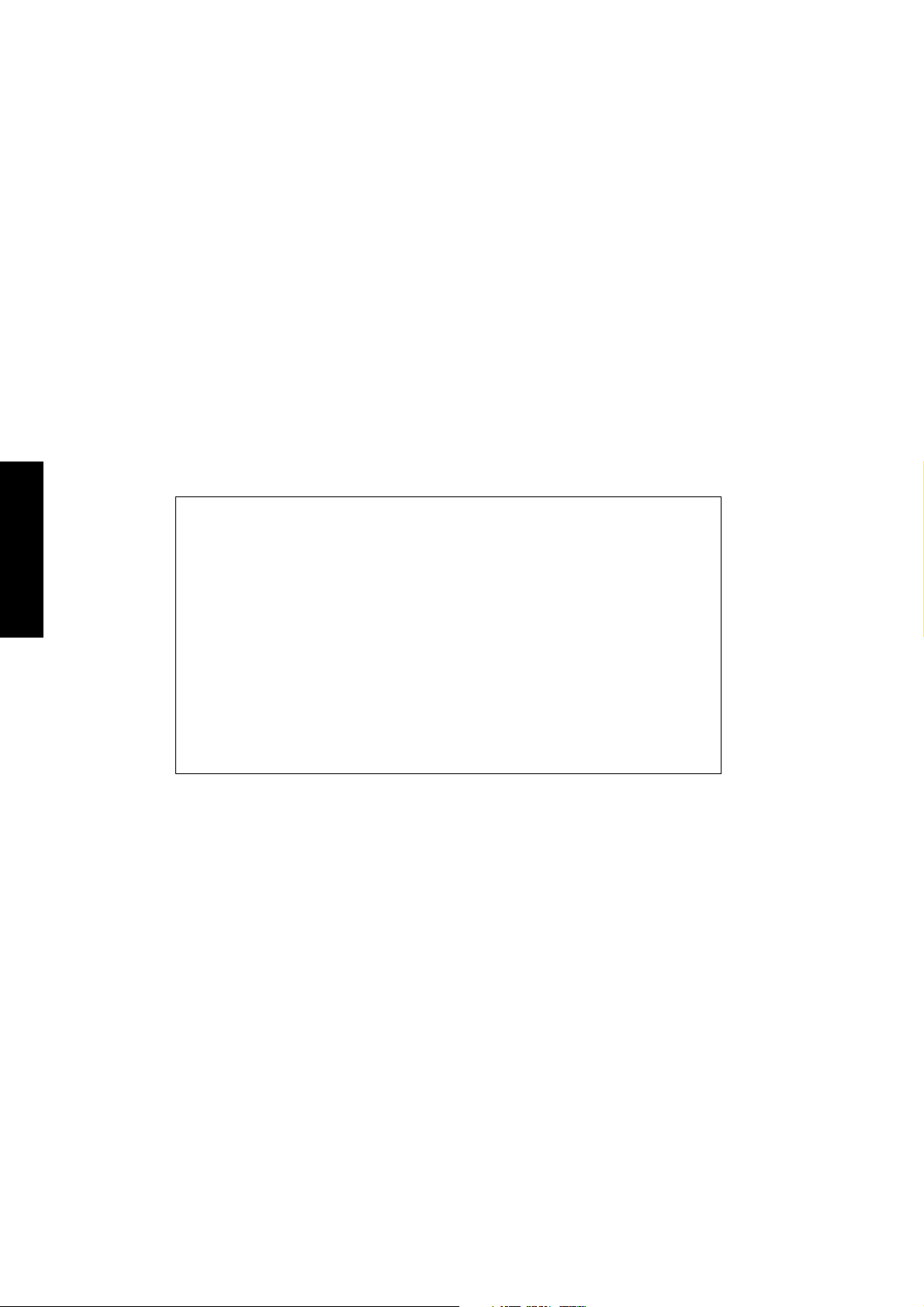

(15) Rotate the remaining paper detection gear until

the round hole in this gear is aligned with the

Screw

oblong hole in the up/down motor mounting

assembly.

Caution: Align when the up/down plate is in low-

est position.

3 DIS./ASSEMBLY

Up/down motor

mounting assembly

Remaining paper

detection gear

E-ring

Screw

Gear cover

Bearing

Screws

Bearing

Round

hole

Idle gear

E-ring

Oblong

hole

(16) Install the idle gear.

(17) Attach the covers following the removal steps in

reverse.

Caution1: After replacing the up/down wires,

make horizontal and centering

adjustment of the up/down plate.

(Refer to “ADJUSTMENT SECTION.”)

(5) Remove the gear A.

(6) Remove the E-ring to remove gear B.

(7) Remove the detent pin for gear B from the up/

down pulley shaft.

(8) Remove the E-ring and bearing to remove gear

C.

Gear A

Pin

Gear B

Bearing

Up/down pulley shaft

Gear C

E-ring

E-ring

3-10

Page 35

C-403/C-404

(9) Remove the bearing behind gear C.

(10) Remove the E-ring to remove the up/down gear.

(11) Remove the detent pin for up/down gear from the

up/down pulley shaft.

(12) Remove the E-ring to remove gear D.

(13) Remove the E-ring to remove the remaining

paper detection gear.

(14) Remove four relay connectors (CN780, CN781,

CN782, and CN783) to disconnect the wiring

harness from the up/down motor mounting

assembly.

Relay connector

(CN780)

Remaining paper

detection gear

Gear D

E-ring

Relay

connector

(CN781)

Relay connector

(CN782)

Up/down

motor mounting

assembly

(17) Replace the up/down wires following the instruc-

tions in “Removing the Up/Down Wires” and

“Installing Up/Down Wires.”

Caution: Two sets of four up/down wires with

different length, one set at the front

and the other at the back, are used.

Wires with the same length can be

used either at the front or back if they

are used in the same location.

1057.3mm

Wire A

692.1mm

Wire B

1321.7mm

Wire C

1303.1mm

Wire D

3 DIS./ASSEMBLY

Pin

Up/down

gear

E-ring

Up/down pulley shaft

Bearing

Relay

connector

(CN783)

E-ring

(15) Remove the E-ring to remove the bearing.

(16) Remove the six screws to remove the up/down

motor mounting assembly.

Up/down motor mounting assembly

Screws

Bearing

E-ring

Screws

3-11

Page 36

C-403/C-404

<Removing the Up/Down Wires>

Up/down plate

Wire C

Wire D

Wire C

Wire D

14. Release the metal

ball to remove wire

D.

7. Release the metal

ball to remove wire

A.

9. Release the metal

ball to remove wire

3 DIS./ASSEMBLY

B.

12. Release the metal

ball to remove wire

C.

Wire B

2. Release the metal

ball to remove wire

A.

18. Release the metal

ball to remove wire

D.

4. Release the metal

ball to remove wire

B.

16. Release the metal

ball to remove wire

C.

Wire A

1. Remove the E-ring.

3. Remove the pulley.

Wire A

6. Remove the E-ring.

8. Remove the pulley.

10. Remove the pulley.

Wire B

FRONT

11. Remove the E-ring,

then remove the

pulley to release

wire C.

Up/down shaft

13. Remove the pulley to

release wire D.

5. Remove the pulley.

15. Remove the E-ring,

then remove the

pulley to release

wire C.

17. Remove the pulley

to release wire D.

3-12

Page 37

<Installing the Up/Down Wires>

C-403/C-404

Wire C

Wire D

Wire C

Wire D

7. Insert wire D in the

pulleys, then attach a

metal ball.

15. Insert wire A in the

pulleys, then attach a

metal ball.

12. Insert wire B in the

pulleys, then attach a

metal ball.

10. Insert wire C in the

pulleys, then attach a

metal ball.

Wire A

Wire B

13. Insert wire A in the up/down

shaft, attach a pulley, and

secure the pulley with an E-ring.

14. Wind wire A around the pulley

by 6 turns in such a manner

that the wire can be pulled

from over the pulley.

6 turns

11. Insert wire B in the up/down shaft,

attach a pulley, and wind wire B

around the pulley by six turns in

such a manner that the wire can

be pulled from over the pulley.

Up/down plate

FRONT

3. Insert wire C in the up/down

8. shaft, attach a pulley, and

4. Pull wire C from under the

9. pulleys.

Up/down

shaft

1. Insert wire D in the

6. up/down shaft, attach

pulleys, then pull wire

D from under the

pulleys.

secure the pulley with E-rings.

20. Insert wire A in the

pulleys, then attach a

metal ball.

2. Insert wire D in the

pulleys, then attach a

metal ball.

17. Insert wire B in the

pulleys, then attach a

metal ball.

5. Insert wire C in the

pulleys, then attach a

metal ball.

Wire B

Wire A

18. Insert wire A in the up/

down shaft, attach a

pulley, and secure the

pulley with an E-ring.

19. Wind wire A around the

pulley by 6 turns in such

a manner that the wire

can be pulled from over

the pulley.

16. Insert wire B in the up/

down shaft, attach a

pulley, and wind wire B

around the pulley by six

turns in such a manner

that the wire can be

pulled from over the

pulley.

3 DIS./ASSEMBLY

6 turns

6 turns

6 turns

3-13

Page 38

C-403/C-404

(18) After installing the up/down wires, check whether

they are engaged with the pulleys properly and

whether they do not ride over the pulleys. Next,

move the up/down plate manually to check

whether it moves up and down smoothly.

Caution: If the up/down plate does not move

smoothly, remove the up/down wires

and install them again.

(19) Install the up/down motor mounting assembly,

relay connectors, remaining paper detection

gear, gear D, and up/down gear following the

removal steps in reverse.

(20) Rotate the remaining paper detection gear until

the round hole in this gear is aligned with the

oblong hole in the up/down motor mounting

assembly.

Up/down motor

mounting assembly

Remaining paper

detection gear

3 DIS./ASSEMBLY

Oblong hole

Round hole

Caution: Align them when the up/down plate is

at the bottom.

(21) Install gear C.

(22) Attach the other gears, gear cover, and external

covers following the removal steps in reverse.

Caution: After replacing the up/down wires,

make horizontal and centering adjust-

ment of the up/down plate. (Refer to

“ADJUSTMENT SECTION.”)

3-14

Page 39

SERVICE MANUAL

Cover Inserter B

Cover Inserter E

2004.01

Ver. 1.0

Page 40

Page 41

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the Di551/Di650/Di5510/Di7210

service manual on page ........................................ S-1

1. OUTLINE

COVER INSERTER B/E PRODUCT

SPECIFICATIONS.....................................................1-1

CENTER CROSS SECTION .....................................1-2

DRIVE SYSTEM DIAGRAM ......................................1-3

FEEDING PROCESS ................................................1-4

[1] Automatic Sheet Feeding

(online operation) ......................................1-4

[2] Manual Sheet Feeding (offline operation) ..1-4

2. UNIT EXPLANATION

EXTERNAL SECTION...............................................2-1

[1] Composition ...............................................2-1

[2] Mechanisms ...............................................2-1

[3] Interlock control ..........................................2-1

PAPER FEED UNIT...................................................2-2

[1] Composition ...............................................2-2

[2] Mechanisms ...............................................2-2

[3] Feed Control...............................................2-3

3. DISASSEMBLY/ASSEMBLY

EXTERNAL SECTION...............................................3-1

[1] Detaching / Re-installing

the External covers.....................................3-1

PAPER FEED UNIT...................................................3-2

[1] Replacing the Paper feed roller and

Feed roller ..................................................3-2

[2] Replacing the Double feed prevention roller

and Torque limiter ......................................3-3

2 UNIT EXPLANATION 1 OUTLINE3 DIS./ASSEMBLY

Page 42

1 OUTLINE2 UNIT EXPLANATION3 DIS./ASSEMBLY

Blank page

Page 43

1

OUTLINE

1 OUTLINE

Page 44

1 OUTLINE

Blank page

Page 45

Cover Inserter B/Cover Inserter E

COVER INSERTER B/E PRODUCT SPECIFICATIONS

[1] Type

Type:

Sheet feeder employing torque-limiter separation

[2] Functions

Automatic sheet feed (online operation):

The Cover Inserter B/E automatically feeds

sheets into the finisher in accordance with

instructions from the main body.

Manual sheet feed (offline operation):

User feeds sheets into finisher by operating the

PI operation panel.

User can select from the following four finishing

modes:

• Single-staple mode (staple at rear)

• Two-staple mode (flat stapling)

• Punch mode (with PK)

• Stitch-and-fold mode (available only if

mounted to the FN-6/10)

• Three-fold mode (available only if mounted

to the FN-6/10)

* Manual sheet feed is only available with the

lower tray.

This is not allowed for wide papers.

[3] Copy Paper

Plain paper:

60 to 90 g/m

paper, recycled paper

Special paper:

• 50 to 59 g/m

paper, recycled paper

• 91 to 200 g/m

paper, recycled paper

Printing paper:

• Double-sided art paper

• Mat coating paper

• High-quality paper

Upper tray copy sizes:

• Metric area

A4, A4R, B5, B5R, A5

• Inch area

8.5

11, 8.5×11R, 5.5×8.5

×

Lower tray copy sizes:

• Metric area

A3, B4, A4, A4R, B5, B5R, A5, F4

wide paper (314mm x 445mm max.)

• Inch area

17, 8.5×14, 8.5×11, 8.5×11R, 5.5×8.5,

11

×

wide paper (314mm x 445mm max.)

2

or 17lbs to 24lbs high-quality

2

or 13lbs to 16lbs high-quality

2

or 24lbs to 45lbs high-quality

Paper staking capacity:

Up to 200 sheets (when using 128 g/m

28lbs-equivalent paper) to max. height of

30mm

Paper curling:

Max. 10 mm

5 sheets

Amount of curl

2

or

[4] Power, Weight, Dimensions

Power source:

24VDC, 5VDC (supplied from FNS)

Maximum power:

30VA

Weight:

Approx. 10.5 kg

External dimensions:

Approx. 511(W)

620(D)×220(H) (mm)

×

[5] Maintenance

Maintenance:

Same as for the main body.

Service life:

Same as the main body.

[6] Operating environment

C (50°F to 86°F)

Temperature: 10 to 30

Humidity: 10 to 80% RH

Note: The information herein may be subject to

change for improvement without notice.

°

1 OUTLINE

1-1

Page 46

Cover Inserter B/Cover Inserter E

CENTER CROSS SECTION

1 OUTLINE

Up/down plate/U

Side guide plate

Paper feed roller

Feed roller

Up/down plate/L

Tray up/down motor/L (M202)

Paper feed roller

Double feed prevention roller

Tray up/down motor/U

(M201)

Conveyance roller /U

Feed roller

Conveyance roller /L

Double feed prevention roller

1-2

Page 47

DRIVE SYSTEM DIAGRAM

Feed roller

Sheet feed SD/U (SD201)

Conveyance MC/U (MC201)

Double feed prevention roller

Conveyance MC/L

(MC202)

Conveyance roller /U

Registration MC

(MC203)

Feed roller

Conveyance roller /L

Double feed prevention roller

Paper feed roller Paper feed roller

PI conveyance motor (M203)

Sheet feed SD/L (SD202)

Cover Inserter B/Cover Inserter E

1 OUTLINE

Feed roller

Paper feed roller

Tray up/down motor/U (M201)

Sheet feed SD/U/L

(SD201/SD202)

FRONT

FRONT

1-3

Tray up/down motor/L (M202)

Page 48

Cover Inserter B/Cover Inserter E

FEEDING PROCESS

[1] Automatic Sheet Feeding (online

1 OUTLINE

operation)

Tray up/down motors/U/L (M201/M202) raise the

Up/down plate/U/L.

When sheet feed SD/U/L (SD201/SD202) and

conveyance MC/U/L (MC201/MC202) come ON,

the drive of PI conveyance motor (M203) is transmitted and the sheets are fed, one by one, by

paper feed, feed, and double feed prevention rollers.

For the fed sheet, a loop is formed at the conveyance rollers /U/L to correct the bend temporarily,

and then the sheet is conveyed.

Sheets are stacked in the FNS as cover sheets

for papers conveyed from the main body, and

then applied with finishing processes.

Feed roller

Tray up/down motor (M201)

Paper feed roller

Up/down plate/U

Conveyance

roller /U

[2] Manual Sheet Feeding (offline opera-

tion)

M201/M202 (tray up/down/U/L) raises the Up/

down plate/L.

When sheet feed SD/U/L (SD201/SD202) and

conveyance MC/U/L (MC201/MC202) come ON,

the drive of PI conveyance motor (M203) is transmitted and all sheets set on the lower tray are fed

into the FNS stacker by paper feed, feed, and

double feed prevention rollers. FNS carries out

finishing processes.

In this case, a loop is formed at the conveyance

roller /L for the sheet and the bend is corrected

temporarily, and then the sheet is conveyed.

Paper feed roller

Up/down plate/L

Feed roller

Tray up/down

motor/L (M202)

Up/down plate/L

Tray up/down motor/L (M202)

Double feed prevention roller

Conveyance roller /L

Double feed prevention roller

Conveyance roller /L

1-4

Page 49

2

UNIT EXPLANATION

2 UNIT EXPLANATION

Page 50

2 UNIT EXPLANATION

Blank page

Page 51

EXTERNAL SECTION

[1] Composition

Connecting cover

Lower cover

Cover Inserter B/Cover Inserter E

Top cover

Release lever

2 UNIT EXPLANATION

Lower tray

[2] Mechanisms

Mechanism Method

Clearing paper jams*1 Release lever

*1 Clearing paper jams

Clear paper jams with the following procedure:

(1) Lift the release lever.

(2) In that status, lift up the upper tray in a slanting

direction.

Top cover

Release lever

(3) Remove paper jams.

Upper tray

Operation panel cover

[3] Interlock control

24V

24V

Interlock control uses MS201 (PI interlock MS)

that detects the opened upper tray.

1. Operation

a. Detecting the opened upper tray

MS201 (PI interlock) is a switch for the interlock.

When opening the upper tray of PI, MS201 goes

OFF and 24V power from FNS CB is shut off.

2. Signals

a. Input signals

(1) 24V, 24V (FNS CB to PIDB)

Input from a DC24V power source

MS201

24V

24V

PIDBFNS CB

2-1

Page 52

Cover Inserter B/Cover Inserter E

PAPER FEED UNIT

[1] Composition

Conveyance MC/U (MC201)

Double feed prevention roller

Tray up/down motor/U

(M201)

Conveyance roller /U

Conveyance MC/L

2 UNIT EXPLANATION

(MC202)

Registration MC

(MC203)

Feed roller

Sheet feed SD/U (SD201)

Paper feed roller

Width regulation plate

Up/down plate/U

Width regulation plate

Feed roller

Conveyance roller /L

Double feed prevention roller

Paper feed roller

[2] Mechanisms

Mechanism Method

Pickup section Upward feeding method,

Oscillated feed roller,

Paper feed roller

Sheet feed section Reverse torque limiter

method,

Double feed prevention

roller.

Torque limiter

PI conveyance motor

(M203)

Sheet feed SD/L (SD202)

Feed roller

Up/down plate/L

Tray up/down motor/L (M202)

Sheet feed SD/U/L

(SD201/SD202)

FRONT

Loop formation Thrust method

Conveyance rollers /U/L

2-2

Page 53

[3] Feed Control

Cover Inserter B/Cover Inserter E

24V

24V

MPI_DRV_SEL

MPI_M_CONT

MPI_M_F/R

MPI_SD_CONT

MPI_MC_CONT

M203 P/S

M203 CLK

M203 LD

M203 F/R

MPI_S_IN1_1

MPI_S_IN2_1

MPI_S_IN2_2

MPI_S_OUT1_1

MPI_S_OUT1_2

MPI_S_OUT2_1

MPI_S_OUT2_2

PS201 IN

PS206 IN

VR201 IN

VR202 IN

FNS CB

MS2

PG

PG

5V

5V

SG

SG

MC203

24V

24V

PG

PG

5V

5V

SG

SG

MPI_DRV_SEL

MPI_M_CONT

MPI_M_F/R

MPI_SD_CONT

MPI_MC_CONT

M203 P/S

M203 CLK

M203 LD

M203 F/R

MPI_S_IN1_1

MPI_S_IN2_1

MPI_S_IN2_2

MPI_S_OUT1_1

MPI_S_OUT1_2

MPI_S_OUT2_1

MPI_S_OUT2_2

PS201 IN

PS206 IN

VR201 IN

VR202 IN

MC203 24V

MC203 DRV

PIDB

M203 P/S

M203 CLK

M203 F/R

M203 LD

24V

24V

M201 DRV1

M201 DRV2

MC201 24V

MC201 DRV

SD201 24V

SD201 DRV

PS201 5V

PS201 IN

PS201 SG

PS202 5V

PS202 IN

PS202 SG

PS203 5V

PS203 IN

PS203 SG

PS204 5V

PS204 IN

PS204 SG

PS205 5V

PS205 IN

PS205 SG

VR201 5V

VR201 IN

VR201 SG

M202 DRV1

M202 DRV2

MC202 24V

MC202 DRV

SD202 24V

SD202 DRV

PS206 5V

PS206 IN

PS206 SG

PS209 5V

PS209 IN

PS209 SG

PS210 5V

PS210 IN

PS210 SG

PS207 5V

PS207 IN

PS207 SG

PS208 5V

PS208 IN

PS208 SG

PS212 5V

PS212 IN

PS212 SG

VR202 5V

VR202 IN

VR202 SG

5V

PG

PG

M203

M201

MC201

SD201

PS201

PS202

Upper tray

2 UNIT EXPLANATION

PS203

PS204

PS205

VR201

M202

MC202

SD202

PS206

PS209

Lower tray

PS210

PS207

PS208

PS212

VR202

M201/M202 (tray up/down/U/L) raises the Up/

down plate/U/L.

When SD201/SD202 (sheet feed/U/L) and

MC201/MC202 (conveyance/U/L) comes ON,

the drive of M203 (PI conveyance) is transmitted

and the sheets are fed one by one by paper feed,

feed, and double feed prevention rollers.

MC203 (registration) controls the drive force

transmitted to the conveyance rollers /U/L, which

forms a loop for the fed sheet.

The related signals are:

PS201/PS206 (PI passage U/L), PS202/PS207

(No sheet/U/L), PS203/PS208 (Sheet setting/U/

L), PS204/PS209 (Tray upper limit/U/L), PS205/

PS210 (Tray lower limit/U/L), PS212 (Sheet size/

L), and VR201/VR202 (Sheet size/U/L).

2-3

Page 54

Cover Inserter B/Cover Inserter E

1. Operation

a. Automatic sheet feeding (online)

(1) When the main body's START button turns ON,

M201/M202 (tray up/down/U/L) are driven in forward, which lifts the Up/down plate/U/L until

PS204/PS209 (tray upper limit/U/L) are activated.

(2) Concurrently, while M203 (PI conveyance) is

driven at low speed, SD201/SD202 (sheet feed/

U/L) and MC201/MC202 (conveyance/U/L)

come ON and sheets are fed into the FNS

stacker.

2 UNIT EXPLANATION

(3) When the last sheet on the Up/down plate/U/L is

fed and PS203/PS208 (sheet setting/U/L) come

OFF, the no-sheet-signal is sent to the main

body, causing the first feed of main body to stop.

After that, when PS202/PS207 (no sheet/U/L)

come OFF, M201/M202 (tray up/down/U/L) are

driven in reverse, which lowers the Up/down

plate/U/L until PS205/PS210 (tray lower limit/U/

L) are activated.

MC201

(conveyance/U)

M201

(tray up/down/U)

PS205

(

tray lower limit/U

M203 (PI conveyance)

MC202 (Conveyance/L)

PS210

(tray lower limit/L)

)

PS202 (no sheet/U)

PS204

(tray upper limit/U)

b. Manual sheet feeding (offline)

Only the lower tray is allowed.

(1) When the PI operation panel's START button

turns ON, M202 (tray up/down/L) is driven in forward, which lifts the Up/down plate/L until PS209

(tray upper limit/L) is activated.

(2) Concurrently, while M203 (PI conveyance) is

driven at low speed, SD202 (sheet feed/L) and

MC202 (conveyance/L) come ON and all sheets

set in the Up/down plate/L fed into the FNS

stacker.

(3) The FNS carries out the required finishing pro-

cesses (stapling, three-folding, etc.).

(4) PS207 (no sheet/L) comes OFF, M202 (tray up/

down/L) is driven in reverse, which lowers the

sheet tray until PS210 (tray lower limit/L) is activated.

z

MC202

M203

(PI conveyance)

M202 (tray up/down/L)

(conveyance/L)

Up/down plate/L

PS210

(tray lower limit/L)

PS207 (no sheet/L)

SD202

(sheet feed/L)

PS209 (tray upper limit/L)

M202

(tray up/

down/L)

PS208

(sheet setting/L)

PS203 (sheet setting/U)

Up/down

plate/U/L

PS207

(no sheet/L)

SD202

(sheet feed/L)

SD201

(sheet feed/U)

PS209 (tray upper limit/L)

c. Sheet conveyance

When the sheet fed from the paper feed unit at

low speed turns PS201/PS206 (PI passage /U/L)

ON, M203 (PI conveyance) changes its rotating

speed to high-speed. At this time, as MC203

(registration) turns OFF, the sheet is pressed

against the conveyance rollers /U/L to form a

loop. MC203 turns ON when a specified time has

passed since PS201/PS206 turned ON, and the

drive force of M203 is transmitted to the conveyance rollers /U/L. This causes the sheet whose

bend is corrected by loop formation to be conveyed into FNS.

When the sheet turns PS206 OFF, MC203 turns

OFF after a specified time. With the same timing,

MC203 changes its rotating speed to low-speed

and comes into feeding operation for the next

sheet.

2-4

Page 55

Cover Inserter B/Cover Inserter E

d. Detection of sheet size

VR201/VR202 (sheet size/U/L) detect the sheet

width.

Sheet length is detected by the combination of

PS203/PS208 (sheet setting/U/L) and PS212

(sheet size/L).

VR201 (sheet size/U)

VR212 (sheet size/L)

VR202 (sheet size/L)

PS208 (sheet setting/L)

PS203 (sheet setting/U)

Width regulation

plates

2. Signals

a. Input signals

(1) PS201 IN (PS201 to PIDB)

Detection signal of sheet passage on upper tray

L: Sheet passed

H: Sheet not passed

(2) PS202 IN (PS202 to PIDB)

Detection signal of no sheet on upper tray

L: Sheet detected

H: Sheet not detected

(3) PS203 IN (PS203 to PIDB)

Detection signal of sheet setting on upper tray

L: Sheet detected

H: Sheet not detected

(4) PS204 IN (PS204 to PIDB)

Detection signal of upper limit lf Up/down plate/U

L: Positioned at upper limit

H: Not positioned at upper limit

(5) PS205 IN (PS205 to PIDB)

Detection signal of lower limit of Up/down plate/U

L: Positioned at lower limit

H: Not positioned at lower limit

(6) PS206 IN (PS206 to PIDB)

Detection signal of sheet passage on lower tray

L: Sheet passed

H: Sheet not passed

(7) PS207 IN (PS207 to PIDB)

Detection signal of no sheet on lower tray

L: Sheet detected

H: Sheet not detected

(8) PS208 IN (PS208 to PIDB)

Detection signal of sheet setting on lower tray

L: Sheet detected

H: Sheet not detected

(9) PS209 IN (PS209 to PIDB)

Detection signal of upper limit of Up/down plate/L

L: Positioned at upper limit

H: Not positioned at upper limit

(10) PS210 IN (PS210 to PIDB)

Detection signal of lower limit of Up/down plate/L

L: Positioned at lower limit

H: Not positioned at lower limit

(11) PS212 IN (PS212 to PIDB)

Detection signal of sheet size on lower tray

L: Sheet detected

H: Sheet not detected

(12) VR201 IN (VR201 to PIDB)

Detection signal of sheet size on lower tray

(13) VR202

Detection signal of sheet size on lower tray

2 UNIT EXPLANATION

2-5

Page 56

Cover Inserter B/Cover Inserter E

(14) M203 LD (M203 to PIDB)

Achieves specified speed of M203

L: Achieves specified speed

H: Not achieves specified speed

(15) MPI_DRV_SEL IN (FNS CB to PIDB)

Switch signal between M201/M202, MC201/

MC202, and SD201/SD202

(16) MPI_M_CONT (FNS CB to PIDB)

Drive control signal of M201/M202

L: ON

H: OFF

(17) MPI_M_F/R (FNS CB to PIDB)

2 UNIT EXPLANATION

Rotating direction signal of M201/M202

L: Tray down

H: Tray up

(18) MPI_SD_CONT (FNS CB to PIDB)

Drive control signal of SD201/SD202

L: ON

H: OFF

(19) MPI_MC_CONT (FNS CB to PIDB)

Drive control signal of M201/M202

L: ON

H: OFF

(20) MC203 P/S (FNS CB to PIDB)

Drive control signal of M203

L: ON

H: OFF

(21) M203 CLK (FNS CB to PIDB)

Clock signal for controlling the rotating speed of

M203

(22) M203 F/R (FNS CB to PIDB)

Rotating direction signal of M203

L: CW

H: CCW

(23) MPI_S_OUT1_1 (FNS CB to PIDB)

Output selecting signal 1 of PS202 to 205

(24) MPI_S_OUT1_2 (FNS CB to PIDB)

Output selecting signal 2 of PS202 to 205

(25) MPI_S_OUT2_1 (FNS CB to PIDB)

Output selecting signal 1 of PS207 to 210,

PS211

(26) MPI_S_OUT2_2 (FNS CB to PIDB)

Output selecting signal 2 of PS207 to 210,

PS211

b. Output signals

(1) M201 DRV1, 2 (PIDB to M201)

Signal for driving M201

(2) MC201 DRV (PIDB to MC201)

Signal for driving MC201

L: ON

H: OFF

(3) SD201 DRV (PIDB to SD201)

Signal for driving SD201

L: ON

H: OFF

(4) M202 DRV1, 2 (PIDB to M202)

Signal for driving M202

(5) MC202 DRV (PIDB to MC202)

Signal for driving MC202

L: ON

H: OFF

(6) SD202 DRV (PIDB to SD202)

Signal for driving SD202

L: ON

H: OFF

(7) M203 P/S (PIDB to M203)

Drive control signal of M203

L: ON

H: OFF

(8) M203 CLK (PIDB to M203)

Clock signal for controlling the rotating speed of

M203

(9) M203 F/R

Rotating direction signal of M203

L: CW

H: CCW

(10) M203 LD (PIDB to FNS CB)

Achieves specified speed of M203

L: Achieves specified speed

H: Not achieves specified speed

(11) MPI_S_IN1_1 (PIDB to FNS CB)

Detection signal from PS202 to PS205

(12) MPI_S_IN2_1 (PIDB to FNS CB)

Detection signal from PS207, PS208, PS209 or

PS210

(13) MPI_S_IN2_2 (PIDB to FNS CB)

Detection signal from PS212

(14) PS201 IN (PIDB to FNS CB)

Detection signal of sheet passage on upper tray

L: Sheet passed

H: Sheet not passed

2-6

Page 57

(15) PS206 IN (PIDB to FNS CB)

Detection signal of sheet passage on lower tray

L: Sheet passed

H: Sheet not passed

(16) VR201 IN (PIDB to FNS CB)

Detection signal of sheet size on upper tray

(17) VR202 IN (PIDB to FNS CB)

Detection signal of sheet size on lower tray

(18) MC203 DRV (PIDB to MC203)

Signal for driving MC203

L: ON

H: OFF

Cover Inserter B/Cover Inserter E

2 UNIT EXPLANATION

2-7

Page 58

2 UNIT EXPLANATION

Blank page

Page 59

3

DISASSEMBLY/ASSEMBLY

3 DIS./ASSEMBLY

Page 60

3 DIS./ASSEMBLY

This section explains how to disassemble and reassemble the machine.

When disassembling and reassembling the machine, follow the precautions given below.

1. Be sure the power cord has been unplugged from the wall outlet.

2. The disassembled parts must be reassembled following the disassembly procedure in reverse unless otherwise specified.

3. Care should be taken not to lose small parts. Care should also be

taken not to install small parts in wrong places.

4. Do not operate the machine before installing all the disassembled

parts completely.

5. Removal of some screws is prohibited in this section. Never loosen

them.

Page 61

EXTERNAL SECTION

Cover Inserter B/Cover Inserter E

[1] Removing / Re-installing the External

covers

Caution:

Make sure that the power cord of the main

body is unplugged from the power outlet.

a. Procedure

(1) Remove cap on the top cover.

(2) Remove four screws to detach the top cover.

Screws

Cap

Top cover

(5) Remove two screws, disconnect the relay con-

nector (CN232), and detach the operation panel

cover.

Relay connector (CN232)

Operation panel cover

(6) Reinstall the above parts following the removal

steps in reverse.

Screw

3 DIS./ASSEMBLY

(3) Remove one screw to detach the connector

cover.

(4) Remove three screws to detach the lower cover.

Screws

Lower cover

Screw

Connecting cover

3-1

Page 62

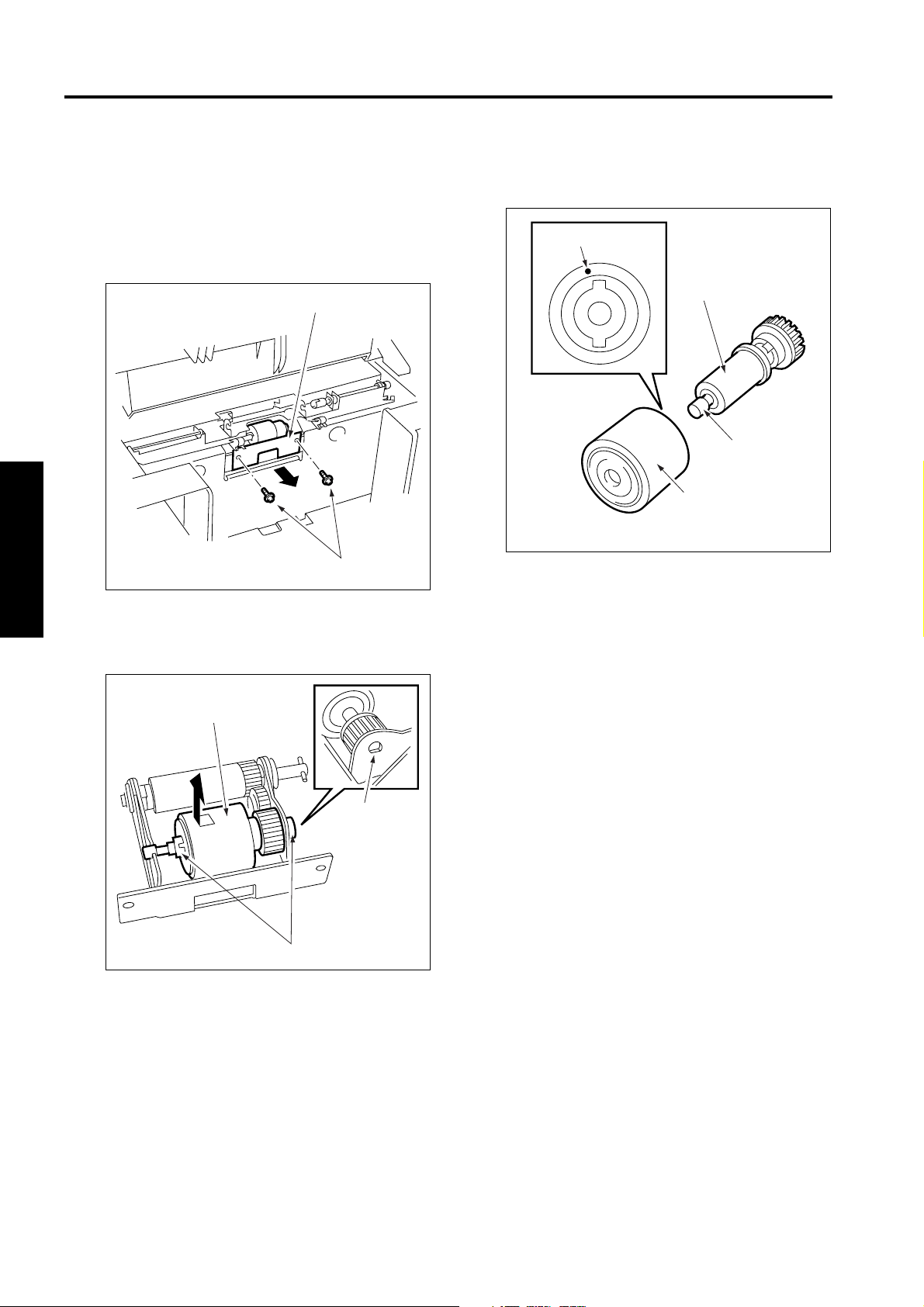

Cover Inserter B/Cover Inserter E

PAPER FEED UNIT

[1] Replacing the Paper feed roller and

Feed roller

Caution:

Make sure that the power cord of the main

body is unplugged from the power outlet.

a. Procedure

(1) When replacing the paper feed roller and feed

roller for the upper tray, detach the top cover.

(2) Remove the two stop rings, then shift the left and

right bearings outside, and remove the feed roller

unit.

3 DIS./ASSEMBLY

Stop

ring

Bearing

Stop ring

Bearing

(3) Remove actuator, three stop rings, three bear-

ings of the feed roller unit, then slide the roller

shaft in the direction of the allow to remove each

roller.

Paint mark

Rubber

Feed drive belt

Bearing

Rubber

Feed roller

Feed roller

Stop ring

Stop

rings

Paper feed roller unit

Bearing

Actuator

(4) When replacing the paper feed roller and feed

roller for the lower tray, open the upper tray and

perform the steps 2 and 3.

Top cover

Release lever

(5) Reinstall the above parts following the removal

steps in reverse.

Caution: Ensure that the mounting direction of

each roller and rubber is correct.

3-2

Page 63

Cover Inserter B/Cover Inserter E

[2] Replacing the Double feed prevent

roller and Torque limiter

Caution:

Make sure that the power cord of the main

body is unplugged from the power outlet.

a. Procedure

(1) When replacing the double feed prevent roller

and the torque limiter for the upper tray, detach

the top cover.

(2) Detach the paper feed roller unit.

(3) Release the hooks on both sides, remove the

double feed prevention roller assembly by lifting

up, then pull out the shaft, and remove the dou-

ble-feed-prevention roller together with the feed-

reverse gear.

Double-feed prevention roller

(5) When replacing the double feed prevention roller

and the torque limiter for the lower tray, open the

upper unit and perform the steps 2 and 3.

(6) Reinstall the above parts following the removal

steps in reverse.

Caution: Ensure that the mounting direction of

each roller and rubber is correct.

3 DIS./ASSEMBLY

Hooks

(4) Separate the double feed prevention roller and

the torque limiter from the double feed prevention

roller assembly.

Stop rings

Double feed prevention roller

Torque limiter

Notch

3-3

Page 64

3 DIS./ASSEMBLY

Blank page

Page 65

SERVICE MANUAL

EDH-4/EDH-7

2004.01

Ver. 1.0

Page 66

Page 67

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the Di551/Di650/Di5510/Di7210 service

manual on page .................................................... S-1

1. OUTLINE

EDH-4/EDH-7 PRODUCT SPECIFICATIONS ..........1-1

CENTER CROSS-SECTIONAL DRAWING ..............1-2

DRIVE SYSTEM DIAGRAM ......................................1-3

ORIGINAL CONVEYANCE PROCESS.....................1-4

[1] Single side original copy mode...................1-4

[2] Double side original copy mode .................1-5

[3] Mixed original copy mode...........................1-6

[4] Z fold original copy mode ...........................1-6

2. UNIT EXPLANATION

EXTERNAL SECTION...............................................2-1

[1] Composition ...............................................2-1

[2] Mechanism .................................................2-1

ORIGINAL FEED / CONVEYANCE / EXIT

SECTION...................................................................2-2

[1] Composition ...............................................2-2

[2] Mechanism .................................................2-2

[3] Original Feed / Conveyance / Scan

Control........................................................2-4

[4] Original Reversal and Conveyance

Control........................................................2-7

[5] Original Size Detection Control ..................2-9

3. DISASSEMBLY/ASSEMBLY

EXTERNAL SECTION...............................................3-1

[1] Removing the RADF ..................................3-1

[2] Reinstalling the RADF ................................3-2

ORIGINAL FEED/CONVEYANCE/EXIT SECTION...3-4

[1] Replacing the Pickup Roller and

Conveyance Roller Rubber ........................3-4

[2] Cleaning the Cleaning Pad.........................3-6

[3] Replacing the Double Feed Prevention

Roller / Double Feed Prevention Roller

Rubber........................................................3-6

2 UNIT EXPLANATION 1 OUTLINE3 DIS./ASSEMBLY

Page 68

1 OUTLINE2 UNIT EXPLANATION3 DIS./ASSEMBLY

Blank page

Page 69

1

OUTLINE

1 OUTLINE

Page 70

1 OUTLINE

Blank page

Page 71

EDH-4/EDH-7 PRODUCT SPECIFICATIONS

EDH-4/EDH-7

[1] Type

Type

Sheet-through type reversible DF

[2] Functions

Original size:

• Metric area

A3 / B4 / A4 / A4R / B5 / B5R / A5 / A5R / B6R

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R /

5.5 x 8.5 / 5.5 x 8.5R

• Inch area

11 x 17 / 8.5 x 14 / 8.5 x 11 / 8.5 x 11R /

5.5 x 8.5 / 5.5 x 8.5R

A3 / B4 / A4 / A4R / B5 / B5R / A5 / A5R / B6R

• All sizes are detected through the APS.

• Mixing of original sizes possible.

Original type:

Plain original

EDH-4

EDH-7

Special original

Original feed and conveyance ability may be

inferior to the above high quality papers.

The following types of original cannot be used

• Fine quality paper less than 35g/m

• Fine quality paper more than 201g/m

lbs

• OHP film

• Blueprint masters

• Label original

• Offset masters

• Bonded originals

Original curling:

10 mm maximum

50g/m2 to 130g/m2 high quality paper

50g/m2 to 200g/m2 high quality paper

2

or 10 lbs

2

or 54

Original read speed (copies per minute, 600dpi):

Mode Original size Feed speed

Single sided original

Double sided original

Original feed layout:

Face-up placement, centered, U-turn feed/

straight eject, switch-back reversal method

(paper fed in order of 2

double sided original copy).

Original image read position:

At the slit glass section

A4/8.5x11

A4/8.5x11

1 → 4 → 3 during the

→

65 (EDH-4)

70 (EDH-7)

38 (EDH-4)

41 (EDH-7)

[3] Machine Data

Power source:

DC24V / 5V (supplied from the main body)

Max. power consumption:

Less than 120VA

Weight:

Approx. 11.5kg

Machine dimensions:

Unit: mm

570

600

1 OUTLINE

Original

Amount of curl

Maximum number of stacked originals:

2

100 sheets maximum (80g/m

or 22 lbs)

150

[4] Maintenance

Maintenance:

Same as the main body

[5] Operating Environment

Temperature:

10 to 30

Humidity:

10% to 80% RH

Note: The information herein may be subject to

change for improvement without notice.

1-1

C (50°F to 86°F)

°

Page 72

EDH-4/EDH-7

CENTER CROSS-SECTIONAL DRAWING

1 OUTLINE

Double feed prevention roller

Registration roller

Reversal roller

Reverse gate

Original conveyance roller 1

Original conveyance roller 2

Original feed roller

Pickup roller

Original pressing board

Original exit gate

Original feed tray

Original exit reversal roller

Original exit tray

Original exit roller

1-2

Page 73

DRIVE SYSTEM DIAGRAM

EDH-4/EDH-7

1 OUTLINE

Original feed MC (MC301)

Registration roller

Reversal roller

Original exit gate

Original feed motor (M301)

Original feed roller

Pickup roller

Double feed prevention roller

Original exit reversal roller

Original pressing board

Reverse gate

Original conveyance motor

(M302)

Conveyance roller2

Conveyance roller1

Original stopper actuator

(EDH-7)

FRONT

Pressure roller release SD

(SD303)

(EDH-7)

Exit gate drive SD

(SD302)

Reverse gate drive

SD (SD301)

Original exit roller

(EDH-7)

df3221001

1-3

Page 74

EDH-4/EDH-7

ORIGINAL CONVEYANCE PROCESS

1 OUTLINE

The EDH-4/EDH-7 consists of an original feed section, conveyance section, reversal section, and original exit

section.

Original feed section

Conveyance section

Slit glass (Read section)

The original faced up on the original feed tray is

fed from the topmost original. The fed original is

not conveyed to the original glass. Instead, it is

read when it passes the slit glass placed in the

conveyance path.

The EDH-4/EDH-7 operation consists of single

Reversal section

Original exit section

After completing the registration loop, the registration roller re-feeds the original and the original

is conveyed to the read section. The original is

conveyed by the conveyance roller. The scanning starts when the original registration PS

(PS306) turns on.

side original copy mode, double side original

copy mode, mixed original copy mode and Z fold

Registration roller

mode. Each has a different conveyance path.

[1] Single side original copy mode

(single side to single side, single side to double

side)

The original set in the original feed tray is

pressed to the pick up roller by the original pressing board. The pick up roller and original feed

roller pre-feed the original until the original registration PS/1 (PS304) turns ON and original

reaches the registration roller.

Original feed roller

Registration roller

Original registration PS/1

(PS304)

Pickup roller

Original pressing board

Original conveyance

PS (PS306)

Conveyance roller

The original is read when it passes over the slit

glass. The original that has been read is ejected

to the original exit section by the original exit

roller, passing along the circumference of the

original exit guide. The next original is pre-fed if

there is one.

Next original

Original exit roller

Original exit guide

Slit glass

1-4

Page 75

EDH-4/EDH-7

[2] Double side original copy mode

(single side copy, double side copy)

The order by which original is scanned is 2

4 → 3 during the double side original copy

→

mode; the back side is scanned first, then the

front side.

The original set on the original feed tray is pre-fed

by the pickup roller and original feed roller until

the original registration PS/1 (PS304) turns ON

and original reaches the registration roller. Then,

the reverse gate opens, and the registration roller

conveys the original to the reversal section. The

reversal roller and original exit reversal roller feed

the original inside the reversal section.

Original registration PS/1

(PS304)

Registration roller

Original exit reversal

roller

→

1

The reading of the back side of the original starts

when the original conveyance PS (PS306) turns

ON. The original exit gate lowers and the original

is fed to the original exit reversal roller when the

back side is scanned. The pressure on the original exit reversal roller is released for a specified

period of time. The leading edge and the trailing

edge of the original brush against each other at

the original exit reversal roller. The next original

is pre-fed if there is one.

Next original

Original exit reversal

roller

Original exit gate

Conveyance roller

Original conveyance PS

(PS306)

1 OUTLINE

Reversal roller

Reverse gate

The original is conveyed to the edge of the

reverse gate until it stops when the specified time

has passed since the PS304 detects the trailing

edge of the original. The original flips over and

the reverse gate closes. The reversal roller and

the original exit reversal roller turn to the reverse

direction, and feed the original to the read section.

Next original

Original exit reversal

roller

Reversal roller

Reverse gate

The original is conveyed to the original reversal