Konica Minolta DI5510, COVER INSERTER B DI5510/DI7210, C-404 DI5510/DI7210, FN-115 DI5510/DI7210, FN-10 User Manual

...Page 1

7662-4396-11

SERVICE MANUAL

FIELD SERVICE

Di551/Di650

Di5510/Di7210

Di5510: Europe and North America only.

2004.01

Ver. 1.0

Page 2

There are using both Official Options name and Popular Options name

in the Di551/Di650/Di5510/Di7210 Service Manual and Option Service

Manual.

EDH-4, EDH-7 : RADF

FN-112, FN-6, FN-121,

FN-10, FN-113, FN-122 : FNS

OT-104 : SF

C-403, C-404 : LT & LCT

Cover Inserter B, Cover Inserter E : PI

PK-2, PK-5 : PK

ZK-2, ZK-3 : PZ

In-System Writer : ISW

KONICA BUSINESS TECHNOLOGIES

CORPORATION COPYRIGHT ©2003

Page 3

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING

ITEMS

IMPORTANT NOTICE

. . . . . . . . . . . . . . . . . . S-1

. . . . .S-1

DESCRIPTION ITEMS FOR DANGER,

WARNING AND CAUTION . . . . .S-1

SAFETY WARNINGS

SAFETY INFORMATION

IMPORTANT INFORMATION

SAFETY CIRCUITS

INDICATION OF WARNING ON THE MACHINE

. . . . . . . . . . . . . . . . . . .S-2

. . . . . . . . . . . . . . .S-10

. . . . . . . . . . . S-10

. . . . . . . . . . . . . . . . . . S-11

. . .S-13

1. ADJUSTMENT

HOW TO USE THIS SECTION .................................1-1

[1] Scope and Precautions ..............................1-1

ADJUSTMENTS MADE WHEN REPLACING

PARTS.......................................................................1-1

LIST OF ADJUSTMENT ITEMS................................1-2

LCD ADJUSTMENT ..................................................1-4

[1] LCD Control Panel Adjustment ..................1-4

[2] LCD Panel Contrast/Key Sound

Adjustment .................................................1-4

SETTINGS AND ADJUSTMENTS MADE WITH THE

P FUNCTION.............................................................1-4

[1] Checking and Printing the P Function ........1-4

[2] Setting up the P Function ...........................1-4

MODE CHANGING MENU........................................1-5

[1] Mode Selection...........................................1-5

[2] Display Transition of 36 Modes ..................1-6

[3] Display Transition of 25 Modes ..................1-7

[4] Display Transition of Key Operation

Modes.........................................................1-7

25 MODE ...................................................................1-8

[1] Setting the 25 Mode ...................................1-8

[2] List of Adjustment Items for 25 Mode.........1-9

[3] Setting Software DIP Switches.................1-11

[4] Setting the Paper Size..............................1-24

[5] PM Count Resetting .................................1-25

[6] Setting the PM Cycle................................1-26

[7] Collecting Data .........................................1-26

[8] Copy Count by Parts to be Replaced

(Fixed Parts).............................................1-42

[9] Copy Count by Parts to be Replaced

(Optional Parts) ........................................1-47

[10] Setting Passwords....................................1-48

[11] Setting the Telephone Number and/or

Fax Number of the Service Center...........1-49

[12] Setting the Serial Number ........................1-50

[13] Displaying the ROM Version ....................1-50

[14] ISW Setting ..............................................1-51

[15] Setting Date..............................................1-51

36 MODE .................................................................1-52

[1] Setting Method .........................................1-52

[2] High Voltage Adjustment..........................1-52

[3] Charging Grid Voltage Adjustment...........1-53

[4] Drum Peculiarity Adjustment ....................1-54

[5] Drum Peculiarity Adjustment (Manual) .....1-60

[6] User Paper Setting ...................................1-60

[7]

Recall Standard Data (Process Adjustment)

[8] Tray Adjustment .......................................1-61

[9] Magnification Adjustment .........................1-62

[10] Timing Adjustment....................................1-65

[11] RADF Adjustment.....................................1-70

[12] Centring Adjustment .................................1-72

[13] Distortion adjustment (Copier)..................1-75

[14] Non-image area erase check ...................1-75

[15]

Recall standard data (Image adjustment)

[16] Running Test Mode ..................................1-77

3 DIS./ASSEMBLY2 ISW 3 DIS./ASSEMBLY1 ADJUSTMENT3 DIS./ASSEMBLY3 SERVICE3 DIS./ASSEMBLY

4 ELECTRIC PARTS LIST

...1-61

..1-76

Page 4

CONTENTS

3 DIS./ASSEMBLY1 ADJUSTMENT3 DIS./ASSEMBLY2 ISW3 DIS./ASSEMBLY3 SERVICE3 DIS./ASSEMBLY

4 ELECTRIC PARTS LIST

[17] Test pattern output mode ........................ 1-77

[18] Test pattern density setting ..................... 1-84

[19] Finisher adjustment ................................. 1-84

[20] List Output Mode ..................................... 1-91

47 MODE ................................................................ 1-92

[1] 47 Mode / Multi Mode Setting Method..... 1-92

[2] Adjustment Data Display ......................... 1-94

[3] Hard Disk Check...................................... 1-94

[4] Input checklist.......................................... 1-95

[5] Output checklist..................................... 1-103

OTHER ADJUSTMENT ........................................ 1-108

[1] Centring Adjustment.............................. 1-108

[2] Skew adjustment (Main body) ............... 1-111

[3] Adjusting the LCT Paper Feed Roller

Pressure (C-404 only) ........................... 1-111

[4] Paper up/down plate horizontal

adjustment (LCT only) ........................... 1-112

[5] Skew adjustment (LCT only) ................. 1-114

[6] Tray spring pressure adjustment........... 1-115

[7] Paper feed height (upper limit)

adjustment (LCT only) ........................... 1-117

[8] Pick-up release amount

adjustment (LCT only) ........................... 1-118

[9] RADF mounting position adjustment ..... 1-119

[10] RADF paper skew adjustment............... 1-120

[11] FNS Adjusting the magnets on the

by-pass conveyance guide plate

(FN-112/6/121/10) ................................. 1-121

[12] FNS adjusting the by-pass gate

(FN-112/6/121/10) ................................. 1-122

[13] FNS Adjusting the Shift Position

(FN-112/6/121/10) ................................. 1-124

[14] FNS Adjusting the paper exit solenoid

(FN-112/6/121/10) ................................. 1-125

[15] FNS Adjusting the mount location of the

paper exit arm (FN-112/6/121/10) ......... 1-127

[16] FNS Adjusting the mount location

of the alignment plates / U

(FN-112/6/121/10) ................................. 1-128

[17] FNS Adjusting the mount location

of the alignment plates / L (FN-6/10) ..... 1-129

[18] FNS Adjusting the stapling position

(Flat stapling) (FN-112/6/121/10) .......... 1-130

[19] FNS Adjusting the stapler vertical

positioning (FN-112/6/121/10) ............... 1-131

[20] FNS Adjusting the stapling position

(stapling-and-folding) (FN-6/10) ............ 1-133

[21] FNS Adjusting the angle of the folding

stopper (FN-6/10) .................................. 1-134

[22] FNS Adjusting the folding force

(FN-6/10) ............................................... 1-135

[23] FNS Adjusting the three-holding positions

(FN-6/10) ............................................... 1-136

[24] PK Adjusting the tilt of the punch hole position

(PK-2) .................................................... 1-137

[25] PK Adjusting the tilt of the punch hole position

(PK-5).....................................................1-138

[26] PK Adjusting the punch hole vertical position

(PK-2).....................................................1-139

[27] Sensitivity adjustment for the PK paper edge

sensor (PK-5) .........................................1-140

[28] PI Centering Adjustment (PK-2).............1-141

[29] Adjusting the tilt of PI (when PK punch

is used) (PK-2) .......................................1-142

[30] Sensitivity adjustment for the PZ paper edge

sensor (PZ) ............................................1-143

[31] FNS Stapler Driver Belt Position

Adjustment (FN-112/6/121/10)...............1-144

[32] Adjusting the PZ Paper-Path Switching

Solenoid (PZ) .........................................1-146

[33] Adjusting the Tension of the PZ Punch

Shift Timing Belt (PZ) .............................1-147

[34]

Adjusting the PZ 1st Folding Skew (PZ)

[35] Adjusting the Position of the PZ 2nd

Folding Stopper (PZ) ..............................1-149

[36] Adjusting the PZ 2nd Folding Skew 2nd

Stopper Assembly (PZ) ..........................1-150

[37] FNS Adjusting the Magnets on Conveyance

Guide Plate B (FN-115)..........................1-151

[38] FNS Adjusting the Magnets on Conveyance

Guide Plate C (FN-115) .........................1-152

[39] FNS Adjusting the Sub-tray Paper Exit Gate

(FN-115).................................................1-153

[40] FNS Adjusting the Paper-Path Switching Gate

(FN-115).................................................1-154

[41] FNS Adjusting the By-pass Gate

(FN-115).................................................1-156

[42] FNS Adjusting the Shift Position

(FN-115).................................................1-157

[43] FNS Adjusting Opening/Closing

at the Paper Exit (FN-115) .....................1-158

[44] FNS Adjusting the Paper Exit-Opening

Solenoid (FN-115)..................................1-159

[45] FNS Adjusting the Paper Exit-Opening

Lower Guide Plate (FN-115) ..................1-160

[46] FNS Adjusting the Mount Location of

the Paper Exit Arm (FN-115)..................1-161

[47] FNS Adjusting the Mount Location of

the Upper Alignment Plates (FN-115) ....1-162

[48] FNS Adjusting the Tension of the Upper

Alignment Plate Drive Timing Belt

(FN-115).................................................1-163

[49] FNS Adjusting the Stapling Position

(Flat Stapling) (FN-115) ......................... 1-163

[50] OT-104 Testing Operation .....................1-164

[51] FN-113/122 Output Check Mode ...........1-166

[52] FN-113/122 Lengthwise Position

Adjustment of Punch Hole......................1-170

[53] FN-113/122 Adjustment of Solenoids ....1-171

[54] FN-113/122 Timing Belt Tension

Adjustment .............................................1-172

....1-148

Page 5

CONTENTS

[55] FN-113/122 Adjustment of the Elevator Tray

Upper Limit Sensor................................ 1-173

[56] FN-113/122 Adjustment of Elevator Tray Over

Detection Level...................................... 1-174

2. ISW

WHAT'S ISW?........................................................... 2-1

SETUP ...................................................................... 2-2

[1] ISW-compatible boards ............................. 2-2

[2] Data flow.................................................... 2-2

[3] Prepare the copier to start an ISW

transfer ...................................................... 2-2

[4] Preparing the copier to transfer ................. 2-4

[5] Relationships between processing states

and operational LEDs ................................ 2-5

[6] Rewriting procedure after an error

interruption................................................. 2-5

[7] Preparation when PZ is installed ............... 2-6

[8] Connecting to the ISW connector .............. 2-6

INTERNET ISW ........................................................ 2-8

[1] What is the Internet ISW ?......................... 2-8

[2] Operating environment.............................. 2-8

[3] Main features............................................. 2-8

[4] Initial setting............................................... 2-9

[5] Mail Remote Notification System............. 2-16

[6] Internet ISW using Web utility.................. 2-30

[7] Internet ISW by operation panel .............. 2-33

[8] Precautions for use.................................. 2-35

3. SERVICE

SERVICE SCHEDULE.............................................. 3-1

[1] Service Schedule....................................... 3-1

[2] Maintenance Items .................................... 3-2

[3] Main Body Periodic Inspection Items....... 3-10

[4] RADF [EDH-4/7] ...................................... 3-12

[5] FNS [FN-112/6] ....................................... 3-12

[6] FNS [FN-115] .......................................... 3-13

[7] LCT [C-403/404] ...................................... 3-13

[8] PI [Cover Inserter B/E]............................. 3-14

[9] PZ [ZK-2/3] .............................................. 3-14

[10] Periodic replacement parts list................. 3-15

[11] Optional replacement parts list ................ 3-18

COPY MATERIALS ................................................ 3-19

[1] Single unit supply .................................... 3-19

SERVICE MATERIAL LIST..................................... 3-20

4. ELECTRIC PARTS LIST

PARTS LAYOUT DRAWING.....................................4-1

[1] Di551/Di650/Di5510/Di7210 Parts Layout

Drawing ......................................................4-1

[2] EDH-4/7 Parts Layout Drawing ................4-12

[3] C-403/404 Parts Layout Drawing .............4-13

[4] FN-112/6/121/10 Parts Layout Drawing ...4-14

[5] Cover Inserter B/E Parts Layout

Drawing ....................................................4-17

[6] PK-2/5 Parts Layout Drawing ...................4-18

[7] ZK-2/3 Parts Layout Drawing ...................... 4-19

[8] FN-115 Parts Layout Drawing ..................4-20

[9] OT-104 Parts Layout Drawing..................4-22

CONNECTOR LAYOUT DRAWING........................4-23

[1] Di551/Di650/Di5510/Di7210

Connector Layout Drawing.......................4-23

[2] C-403/404 Connector Layout Drawing .....4-30

[3] FN-112/6/121/10 Connector Layout

Drawing ....................................................4-30

[4] Cover Inserter B/E Connector Layout

Drawing ....................................................4-31

[5] PK-2/5 Connector Layout Drawing ...........4-31

[6] ZK-2/3 Connector Layout Drawing .............. 4-32

[7] FN-115 Connector Layout Drawing............. 4-33

[8] OT-104 Connector Layout Drawing............. 4-33

JAM CODE LIST......................................................4-34

ERROR CODE LIST................................................4-50

TIMING CHART.......................................................4-69

[1] Di650 Timing Chart (1) .............................4-69

[2] Di650 Timing Chart (2) .............................4-70

[3] Di7210 Timing Chart (1) ...........................4-71

[4] Di7210 Timing Chart (2) ...........................4-72

[5] EDH-4/EDH-7 Timing Chart (1)................4-73

[6] EDH-4/EDH-7 Timing Chart (2)................4-74

[7] C-403/C-404 Time Chart ..........................4-75

[8] FN-112/FN-6/FN-121/FN-10

TIming Chart (1) .......................................4-76

[9] FN-112/FN-6/FN-121/FN-10

Timing Chart (2) .......................................4-77

[10] FN-112/FN-6/FN-121/FN-10

Timing Chart (3) .......................................4-78

[11] FN-112/FN-6/FN-121/FN-10

Timing Chart (4) .......................................4-79

[12] Cover Inserter B/Cover Inserter E

Timing Chart ............................................4-80

[13] PK-2 Timing Chart ...................................4-81

[14] PK-5 Timing Chart ...................................4-82

[15] ZK-2/ZK-3 Timing Chart ...........................4-83

[16] FN-115 Timing Chart (1) ..........................4-84

[17] FN-115 Timing Chart (2) ..........................4-85

[18] OT-104 Timing Chart ...............................4-86

[19] FN-113/FN-122 Timing Chart (1) ............4-87

[20] FN-113/FN-122 Timing Chart (2) ............4-88

OVERALL WIRING DIAGRAM................................4-89

[1] EDH-4/EDH-7 Overall Wiring Diagram.....4-89

[2] C-403/C-404 Overall Wiring Diagram.......4-90

3 DIS./ASSEMBLY1 ADJUSTMENT3 DIS./ASSEMBLY2 ISW3 DIS./ASSEMBLY3 SERVICE3 DIS./ASSEMBLY

4 ELECTRIC PARTS LIST

Page 6

CONTENTS

3 DIS./ASSEMBLY1 ADJUSTMENT3 DIS./ASSEMBLY2 ISW3 DIS./ASSEMBLY3 SERVICE3 DIS./ASSEMBLY

[3] Cover Inserter B/Cover Inserter E

Overall Wiring Diagram ........................... 4-91

[4] PK-2 Overall Wiring Diagram .................. 4-92

[5] PK-5 Overall Wiring Diagram .................. 4-93

[6] ZK-2 Overall Wiring Diagram................... 4-94

[7] FN-115 Overall Wiring Diagram .............. 4-95

[8] OT-104 Overall Wiring Diagram .............. 4-96

[9]

FN-113/FN-122 Overall Wiring Diagram

APPENDIX

[1] Di551/Di650 Overall Wiring Diagram......... A-1

[2] Di5510/Di7210 Overall Wiring Diagram..... A-2

[3] FN-112/FN-6/FN-121/FN-10

Overall Wiring Diagram ............................. A-3

..... 4-97

4 ELECTRIC PARTS LIST

Page 7

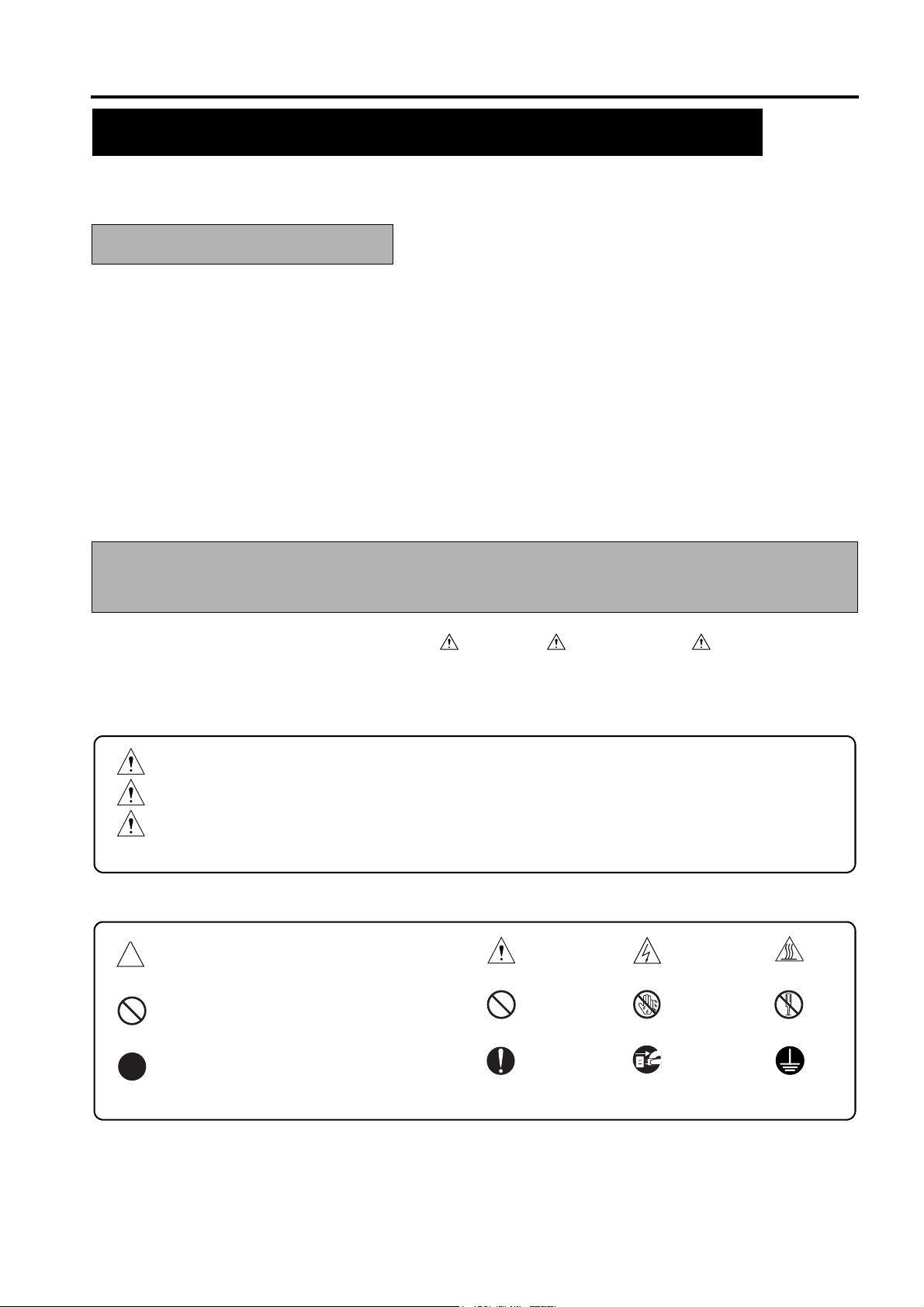

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before doing ser-

vice work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this copier as well as the risk of damage to

the copier, Konica Minolta Business Technologies, INC. (hereafter called the KMBT) strongly recommends that

all servicing be performed only by KMBT-trained service technicians.

Changes may have been made to this copier to improve its performance after this Service Manual was printed.

Accordingly, KMBT does not warrant, either explicitly or implicitly, that the information contained in this Service

Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to the copier while ser-

vicing the copier for which this Service Manual is intended.

Therefore, this Service Manual must be carefully read before doing service work both in the course of technical

training and even after that, for performing maintenance and control of the copier properly.

Keep this Service Manual also for future service.

DESCRIPTION ITEMS FOR DANGER, WARNING AND

CAUTION

In this Service Manual, each of three expressions “ DANGER”, “ WARNING”, and “ CAUTION” is defined

as follows together with a symbol mark to be used in a limited meaning.

When servicing the copier, the relevant works (disassembling, reassembling, adjustment, repair, maintenance,

etc.) need to be conducted with utmost care.

DANGER

WARNING

CAUTION

Symbols used for safety and important warning items are defined as follows:

:Precaution when using the copier.

:Action having a high possibility of suffering death or serious injury

:Action having a possibility of suffering death or serious injury

:Action having a possibility of suffering a slight wound, medium trouble, and

property damage

General precaution Electric hazard High temperature

:Prohibition when using the copier.

:Direction when using the copier.

General prohibition Do not touch with wet hand Do not disassemble

General instruction

S-1

Unplug

Ground/Earth

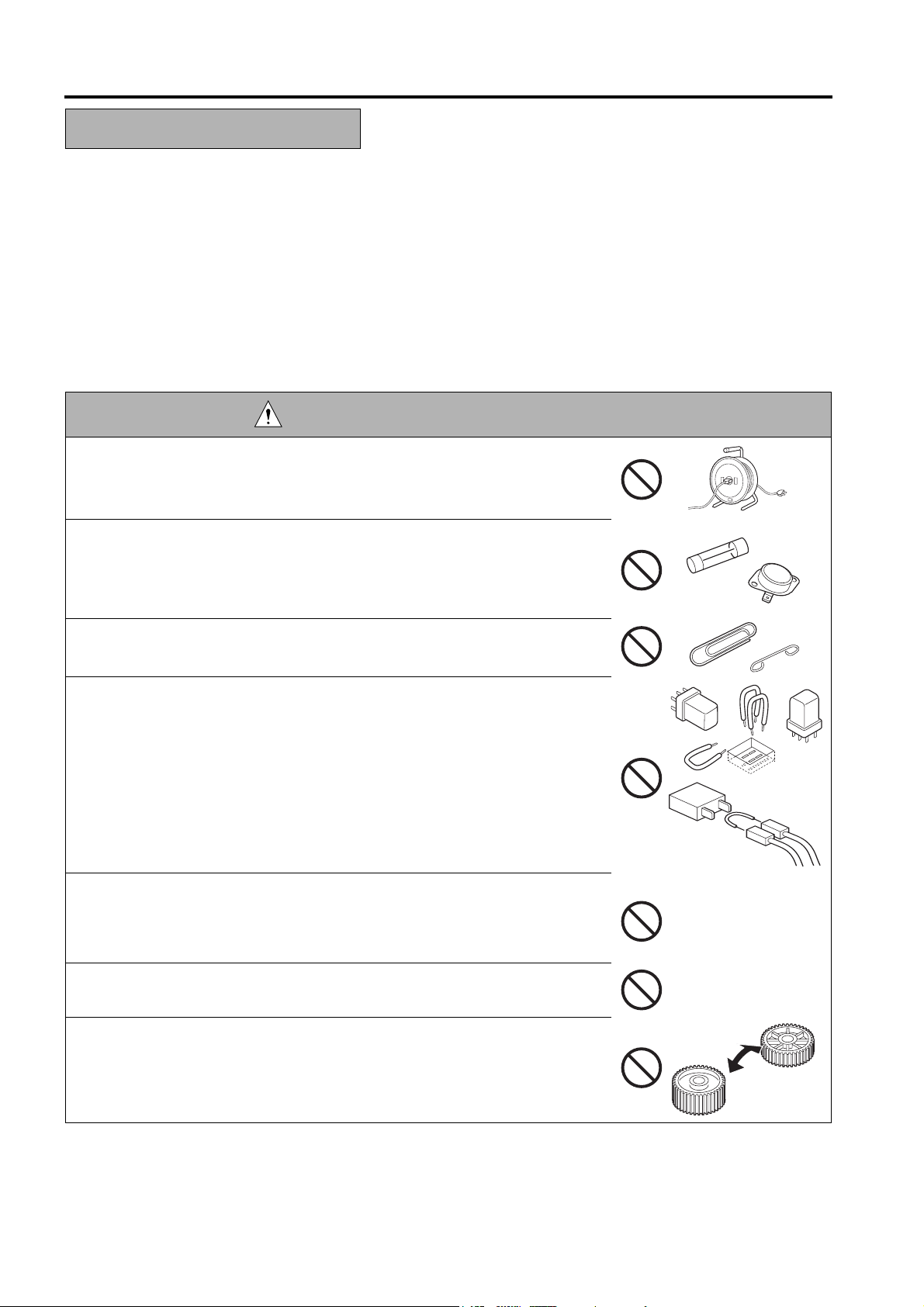

Page 8

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNINGS

[1] MODIFICATIONS NOT AUTHORIZED BY

KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

Konica Minolta brand copiers are renowned for their high reliability. This reliability is achieved through high-quality design

and a solid service network.

Copier design is a highly complicated and delicate process where numerous mechanical, physical, and electrical aspects

have to be taken into consideration, with the aim of arriving at proper tolerances and safety factors. For this reason, unau-

thorized modifications involve a high risk of degradation in performance and safety. Such modifications are therefore

strictly prohibited. the points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

DANGER : PROHIBITED ACTIONS

• Using any cables or power cord not specified by KMBT.

• Using any fuse or thermostat not specified by KMBT. Safety will not be

assured, leading to a risk of fire and injury.

• Disabling fuse functions or bridging fuse terminals with wire, metal clips, sol-

der or similar object.

• Disabling relay functions (such as wedging paper between relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.) Safety will not be

assured, leading to a risk of fire and injury.

• Making any modification to the copier unless instructed by KMBT

• Using parts not specified by KMBT

S-2

Page 9

SAFETY AND IMPORTANT WARNING ITEMS

[2] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

Konica Minolta brand copiers are extensively tested before shipping, to ensure that all applicable safety standards are met,

in order to protect the customer and customer engineer (hereafter called the CE) from the risk of injury. However, in daily

use, any electrical equipment may be subject to parts wear and eventual failure. In order to maintain safety and reliability,

the CE must perform regular safety checks.

1.Power Supply

WARNING: Wall Outlet

• Check that mains voltage is as specified. Plug the power cord into the dedi-

cated wall outlet with a capacity greater than the maximum power consump-

tion.

If excessive current flows in the wall outlet, fire may result.

• If two or more power cords can be plugged into the wall outlet, the total load

must not exceed the rating of the wall outlet.

If excessive current flows in the wall outlet, fire may result.

kw

WARNING: Power Plug and Cord

• Make sure the power cord is plugged in the wall outlet securely.

Contact problems may lead to increased resistance, overheating, and the

risk of fire.

• Check whether the power cord is damaged. Check whether the sheath is

damaged.

If the power plug, cord, or sheath is damaged, replace with a new power

cord (with plugs on both ends) specified by KMBT. Using the damaged

power cord may result in fire or electric shock.

• When using the power cord (inlet type) that came with this copier, be sure to

observe the following precautions:

a. Make sure the copier-side power plug is securely inserted in the socket

on the rear panel of the copier.

Secure the cord with a fixture properly.

b. If the power cord or sheath is damaged, replace with a new power cord

(with plugs on both ends) specified by KMBT.

If the power cord (inlet type) is not connected to the copier securely, a

contact problem may lead to increased resistance, overheating, and risk

of fire.

• Check whether the power cord is not stepped on or pinched by a table and

so on.

Overheating may occur there, leading to a risk of fire.

S-3

Page 10

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Power Plug and Cord

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the power plug and wall outlet.

Using the power plug and wall outlet without removing dust may result in

fire.

• Do not insert the power plug into the wall outlet with a wet hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the cable.

The cable may be broken, leading to a risk of fire and electric shock.

WARNING: Wiring

• Never use multi-plug adapters to plug multiple power cords in the same out-

let.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so using a too long

extension cord may result in fire.

Do not use an extension cable reel with the cable taken up. Fire may

result.

WARNING: Ground Lead

• Check whether the copier is grounded properly.

If current leakage occurs in an ungrounded copier, you may suffer electric

shock while operating the copier. Connect the ground lead to one of the

following points:

a. Ground terminal of wall outlet

b. Ground terminal for which Class D work has been done

S-4

Page 11

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Ground Lead

• Pay attention to the point to which the ground lead is connected.

Connecting the ground lead to an improper point such as the points listed

below results in a risk of explosion and electric shock:

a. Gas pipe (A risk of explosion or fire exists.)

b. Lightning rod (A risk of electric shock or fire exists.)

c. Telephone line ground (A risk of electric shock or fire exists in the case

of lightning.)

d. Water pipe or faucet (It may include a plastic portion.)

2.Installation Requirements

WARNING: Prohibited Installation Place

• Do not place the copier near flammable materials such as curtains or volatile

materials that may catch fire.

A risk of fire exists.

• Do not place the copier in a place exposed to water such as rain water.

A risk of fire and electric shock exists.

WARNING: Nonoperational Handling

• When the copier is not used over an extended period of time (holidays, etc.),

switch it off and unplug the power cord.

Dust collected around the power plug and outlet may cause fire.

CAUTION: Temperature and Humidity

• Do not place the copier in a place exposed to direct sunlight or near a heat

source such as a heater.

A risk of degradation in copier performance or deformation exists.

Do not place the copier in a place exposed to cool wind.

Recommended temperature and humidity are as follows:

Temperature: 10

Humidity: 10% to 80% (no dew condensation)

Avoid other environments as much as possible.

°C

to 30

°C

CAUTION: Ventilation

• Do not place the copier in a place where there is much dust, cigarette

smoke, or ammonia gas.

Place the copier in a well ventilated place to prevent machine problems

and image faults.

S-5

Page 12

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION: Ventilation

• The copier generates ozone gas during operation, but it is not sufficient to be

harmful to the human body.

If a bad smell of ozone is present in the following cases, ventilate the

room.

a. When the copier is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple copiers at the same time

CAUTION: Vibration

• When installing the copier, read the Installation Guide thoroughly. Be sure to

install the copier in a level and sturdy place.

Constant vibration will cause problems.

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the copier may slide, leading to a

injury.

CAUTION: Inspection before Servicing

• Before conducting an inspection, read all relevant documentation (service

manual, technical notices, etc.) and proceed with the inspection following the

prescribed procedure in safety clothes, using only the prescribed tools. Do

not make any adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the copier may break and a

risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect the power plugs from

the copier and options.

When the power plug is inserted in the wall outlet, some units are still pow-

ered even if the POWER switch is turned OFF. A risk of electric shock

exists.

• The area around the fixing unit is hot.

You may get burnt.

DANGER: Work Performed with the Copier Powered

• Take every care when making adjustments or performing an operation check

with the copier powered.

If you make adjustments or perform an operation check with the external

cover detached, you may touch live or high-voltage parts or you may be

caught in moving gears or the timing belt, leading to a risk of injury.

S-6

Page 13

SAFETY AND IMPORTANT WARNING ITEMS

DANGER: Work Performed with the Copier Powered

• Take every care when servicing with the external cover detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

WARNING: Safety Checkpoints

• Check the exterior and frame for edges, burrs, and other damages.

The user or CE may be injured.

• Do not allow any metal parts such as clips, staples, and screws to fall into the

copier.

They can short internal circuits and cause electric shock or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or fire.

• When disconnecting connectors, grasp the connector, not the cable.

(Specifically, connectors of the AC line and high-voltage parts)

Current can leak, leading to a risk of electric shock or fire.

• Carefully remove all toner remnants and dust from electrical parts and elec-

trode units such as a charging corona unit.

Current can leak, leading to a risk of copier trouble or fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or fire.

• Check electrode units such as a charging corona unit for deterioration and

sign of leakage.

Current can leak, leading to a risk of trouble or fire.

• Before disassembling or adjusting the write unit incorporating a laser, make

sure that the power cord has been disconnected.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• Do not remove the cover of the write unit. Do not supply power with the write

unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery speci-

fied in the Parts Guide Manual. Dispose of the used lithium battery using the

method specified by local authority.

Improper replacement can cause explosion.

S-7

Page 14

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Safety Checkpoints

• After replacing a part to which AC voltage is applied (e.g., optical lamp and

fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and check whether the

interlock functions properly.

If the interlock does not function, you may receive an electric shock or be

injured when you insert your hand in the copier (e.g., for clearing paper

jam).

• Make sure the wiring cannot come into contact with sharp edges, burrs, or

other pointed parts.

Current can leak, leading to a risk of electric shock or fire.

• Make sure that all screws, components, wiring, connectors, etc. that were

removed for safety check and maintenance have been reinstalled in the orig-

inal location. (Pay special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of copier trouble, electric shock, and fire exists.

DANGER: HANDLING OF SERVICE MATERIALS

• Toner and developer are not harmful substances, but care must be taken not

to breathe excessive amounts or let the substances come into contact with

eyes, etc. It may be stimulative.

If the substances get in the eye, rinse with plenty of water immediately.

When symptoms are noticeable, consult a physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

S-8

Page 15

SAFETY AND IMPORTANT WARNING ITEMS

DANGER : HANDLING OF SERVICE MATERIALS

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are

highly flammable and must be handled with care. A risk of fire exists.

• Do not replace the cover or turn the copier ON before any solvent remnants

on the cleaned parts have fully evaporated.

A risk of fire exists.

• Use only a small amount of cleaner at a time and take care not to spill any

liquid. If this happens, immediately wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to discomfort.

[3] MEASURES TO TAKE IN CASE OF AN ACCIDENT

1. If an accident has occurred, the distributor who has been notified first must immediately take emergency measures to

provide relief to affected persons and to prevent further damage.

2. If a report of a serious accident has been received from a customer, an on-site evaluation must be carried out quickly

and KMBT must be notified.

3. To determine the cause of the accident, conditions and materials must be recorded through direct on-site checks, in

accordance with instructions issued by KMBT.

4. For reports and measures concerning serious accidents, follow the regulations given in “Serious Accident Report/

Follow-up Procedures”.

[4] CONCLUSION

1. Safety of users and customer engineers depends highly on accurate maintenance and administration. Therefore,

safety can be maintained by the appropriate daily service work conducted by the customer engineer.

2. When performing service, each copier on the site must be tested for safety. The customer engineer must verify the

safety of parts and ensure appropriate management of the equipment.

S-9

Page 16

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY INFORMATION

IMPORTANT INFORMATION

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented

regulations for laser products manufactured since August 1, 1976. Compliance is mandatory for products mar-

keted in the United States.

This copier is certified as a “Class 1” laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. Since radiation emitted inside this copier is completely confined within

protective housings and external covers, the laser beam cannot escape during any phase of normal user opera-

tion.

S-10

Page 17

SAFETY CIRCUITS

SAFETY AND IMPORTANT WARNING ITEMS

This machine is provided with the following safety circuits

to prevent machine faults from resulting in serious acci-

dents.

[1] Overall protection circuit

[2] L2 and L3 (fixing heater lamps) overheating

prevention circuit

These safety circuits are described below to provide the

service engineer with a renewed awareness of them in

order to prevent servicing errors that may impair their

functions.

[1] Overall Protection Circuit

CBR1

NF

CBR2

1. Protection by CBR1 and CBR2 (circuit

breakers)

CBR1 and CBR2 interrupt the AC line instanta-

neously when an excessive current flows due to a

short in the AC line.

CAUTION:

The CBR1 and CBR2 functions must not

be deactivated under any circumstances.

[2] Protection by L2, L3 and L4 (fixing

heater lamps) overheating prevention

circuit

DCPS

RL1

PRCB

RL1

TH2

Control

section

AC driver

section

TH1

1. Protection by software

The output voltage from TH1 (fixing temperature

sensor 1) is read by the CPU. If this voltage is

abnormal, L2 (fixing heater lamp 1), L3 (fixing

heater lamp 2), L4 (fixing heater lamp 3) and RL1

(main relay) are turned OFF.

CAUTION:

Do not change the gap between the roller

and TH1. When replacing TH1, check the

specified mounting dimensions. The RL1

function must not be deactivated under

any circumstances.

TS2

TS1

L2

L3

L4

S-11

Page 18

SAFETY AND IMPORTANT WARNING ITEMS

2. Protection by the hardware circuit

The output voltages from TH1 and TH2 (fixing

temperature sensors) are compared with the abnor-

mality judgment reference value in the comparator

circuit. If the output voltage from TH1 or TH2

exceeds the reference value, L2 (fixing heater lamp

1), L3 (fixing heater lamp 2), L4 (fixing heater

lamp 3) and RL1 (main relay) are turned OFF in

hardware means.

CAUTION:

Periodically check the TH2 face contacting the roller, and replace TH2 if any

abnormality is detected.

Since TH1 (fixing temperature sensor)

face does not contact the roller, check the

distance from the roller and the sensor

orientation if any abnormality is detected.

The RL1 function must not be deactivated

under any circumstances.

3. Protection by TS1 (thermostat/U) and TS2

(thermostat/L)

When the temperature of the fixing roller (upper/

lower) exceeds the specified value, TSs are turned

OFF, thus interrupting the power to L2 (fixing

heater lamp/1), L3 (fixing heater lamp/2), and L4

(fixing heater lamp/3) directly.

CAUTION:

Do not use any other electrical conductor

in place of TS1 and TS2. Do not change

the distance between the roller and TS

(thermostat).

S-12

Page 19

SAFETY AND IMPORTANT WARNING ITEMS

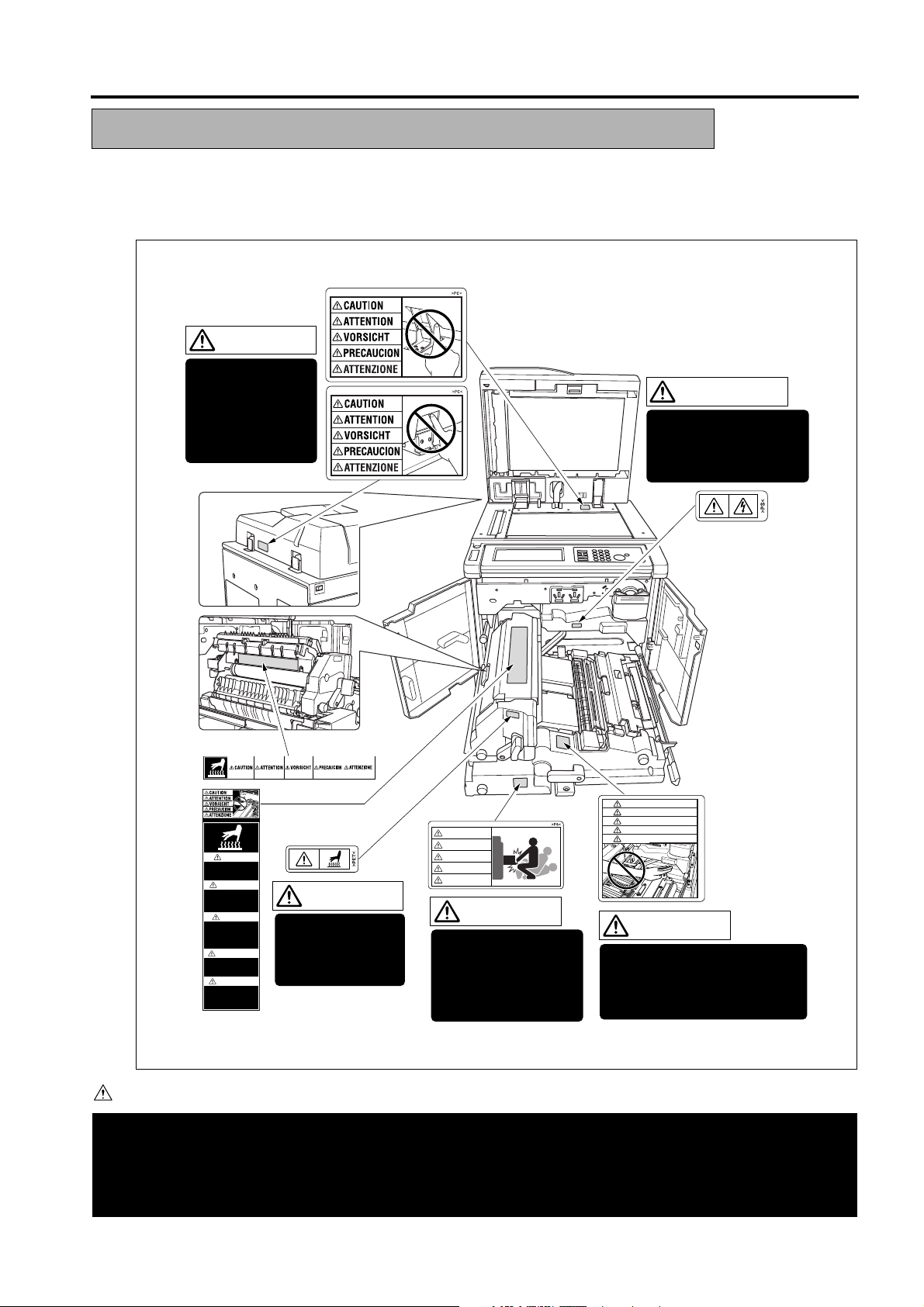

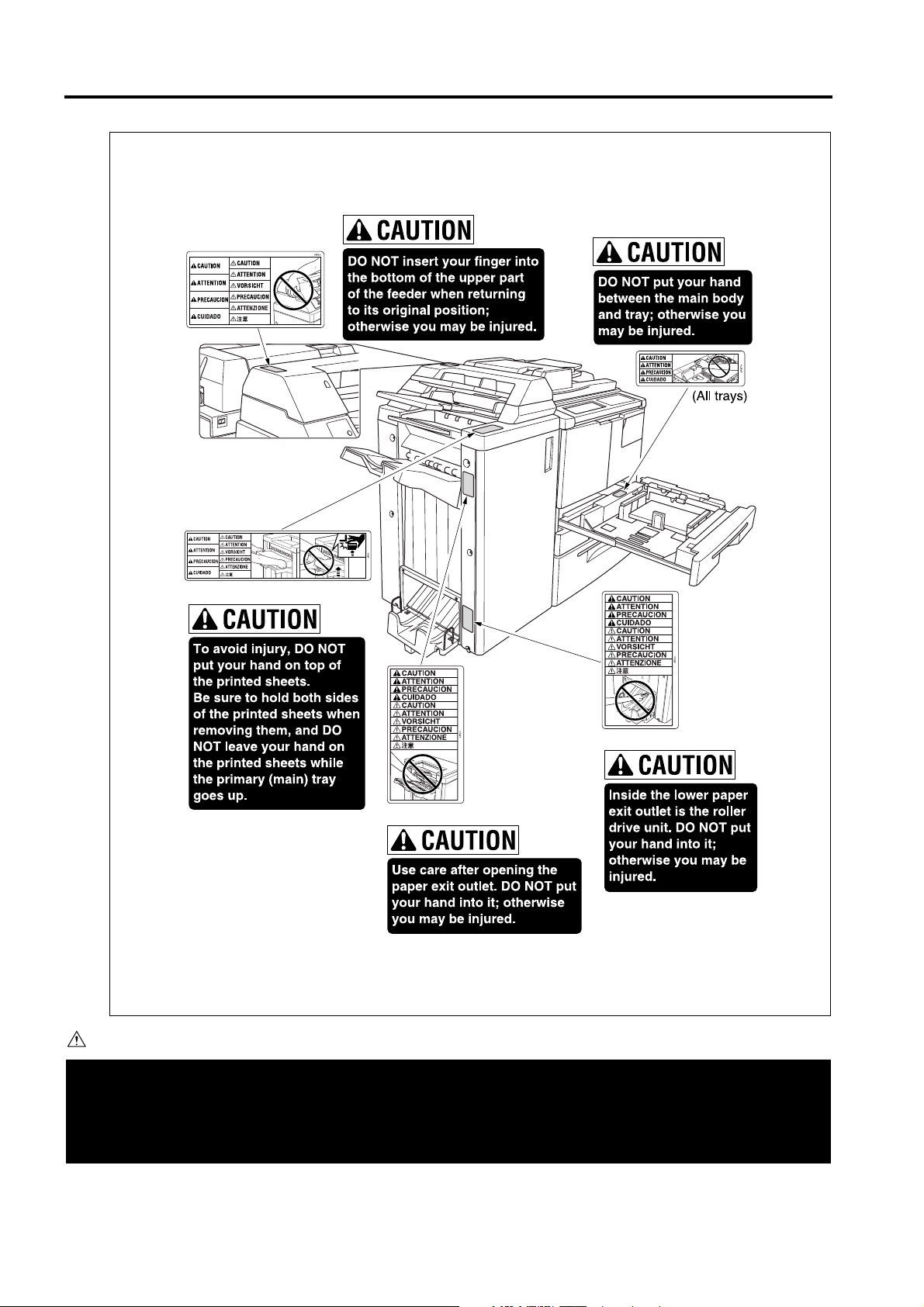

INDICATION OF WARNING ON THE MACHINE

Caution labels shown below are attached in some areas on/in the machine.

When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid burns and electric

shock.

CAUTION

DO NOT INSERT

your finger into the

two RADF hinge

portions;

otherwise you may

be injured.

WARNING

This area generates

high voltage. If touched,

electrical shock may

occur. DO NOT TOUCH.

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

CAUTION

DO NOT put your hand between

the main body and developing

fixing unit; otherwise you may

be injured.

CAUTION

High temperature!

Do not touch. Use care

when clearing paper.

ATTENTION

Temp rature lev e!

Risque de br lure. Soyez

prudent en retirant la

feuille coinc e.

VORSICHT

Hei§e OberflŠche!

Brandverletzungsgefahr.

Bei Beseitigung von

Papierstaus vorsichtig

vorgehen.

PRECAUCION

ÁTemperatura alta!

No tocar. Tener cuidado al

remover el papel.

ATTENZIONE

Alta temperatura!

Non toccare. Agire con

prudenza nel rimuovere la

carta.

CAUTION

The fixing unit is

very hot. To avoide

getting burned, DO

NOT TOUCH.

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

CAUTION

The conveyance fixing

unit is heavy. Use care

and draw it out gently;

otherwise you may be

injured.

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-13

Page 20

SAFETY AND IMPORTANT WARNING ITEMS

In the case of the Di551/Di650

(Finisher with

Cover Inserter B/E only)

CAUTION

(FN-112/FN-6/FN-121/FN-10 Finisher)

(FN-6/FN-10 Finisher only)

(FN-6/FN-10 Finisher)

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-14

Page 21

In the case of the Di5510/Di7210

DO NOT put your hand

between the main

body and tray;

otherwise you may be

injured.

SAFETY AND IMPORTANT WARNING ITEMS

The shift tray moves to and fro while

printing. DO NOT put your hand in

between the tray and tray supporting part;

otherwise you may be injured.

Also, DO NOT put your hand in the paper

exit outlet while the tray is moving;

otherwise you may be injured.

(OT-104 Shift tray)

DO NOT put your hand

between the main

body and tray;

otherwise you may be

injured.

(Main body tray 1 and 2)

(Main body tray 3 and 4)

7272sf006

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-15

Page 22

SAFETY AND IMPORTANT WARNING ITEMS

To avoid injury, DO

NOT put your hand

on top of the

printed sheets.

Be sure to hold

both sides of the

printed sheets

when removing

them, and DO NOT

leave your hand on

the printed sheets

while the primary

(main) tray goes up.

Use care after opening the

paper exit outlet.

DO NOT put your hand into

it; otherwise you may be

injured.

(FN-115 Finisher)

7272sf007

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-16

Page 23

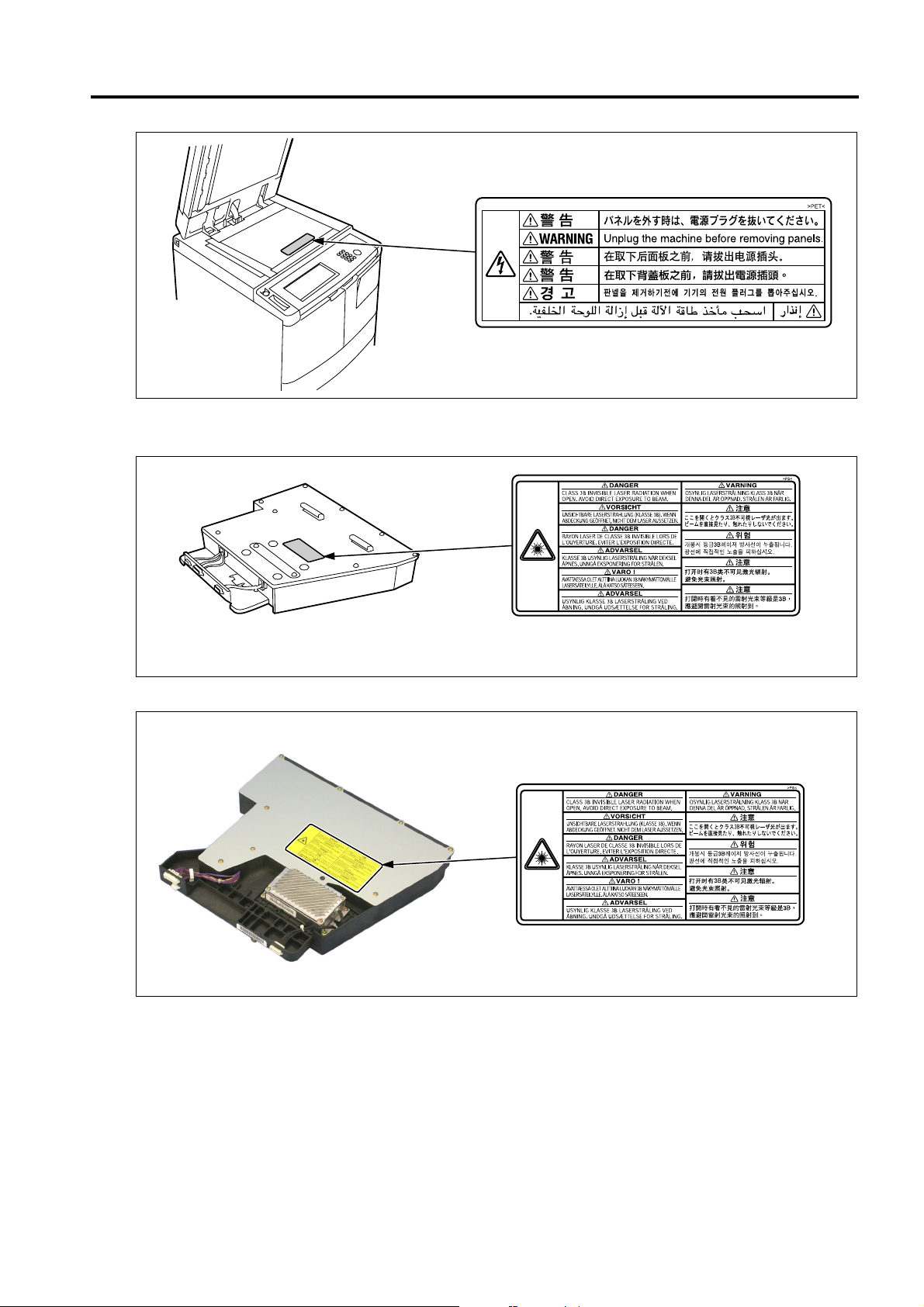

<SCANNER SECTION>

<WRITE UNIT>

In the case of the Di551/Di650

SAFETY AND IMPORTANT WARNING ITEMS

7272sf004

In the case of the Di5510/Di7210

7272sf005

7272sf001

S-17

Page 24

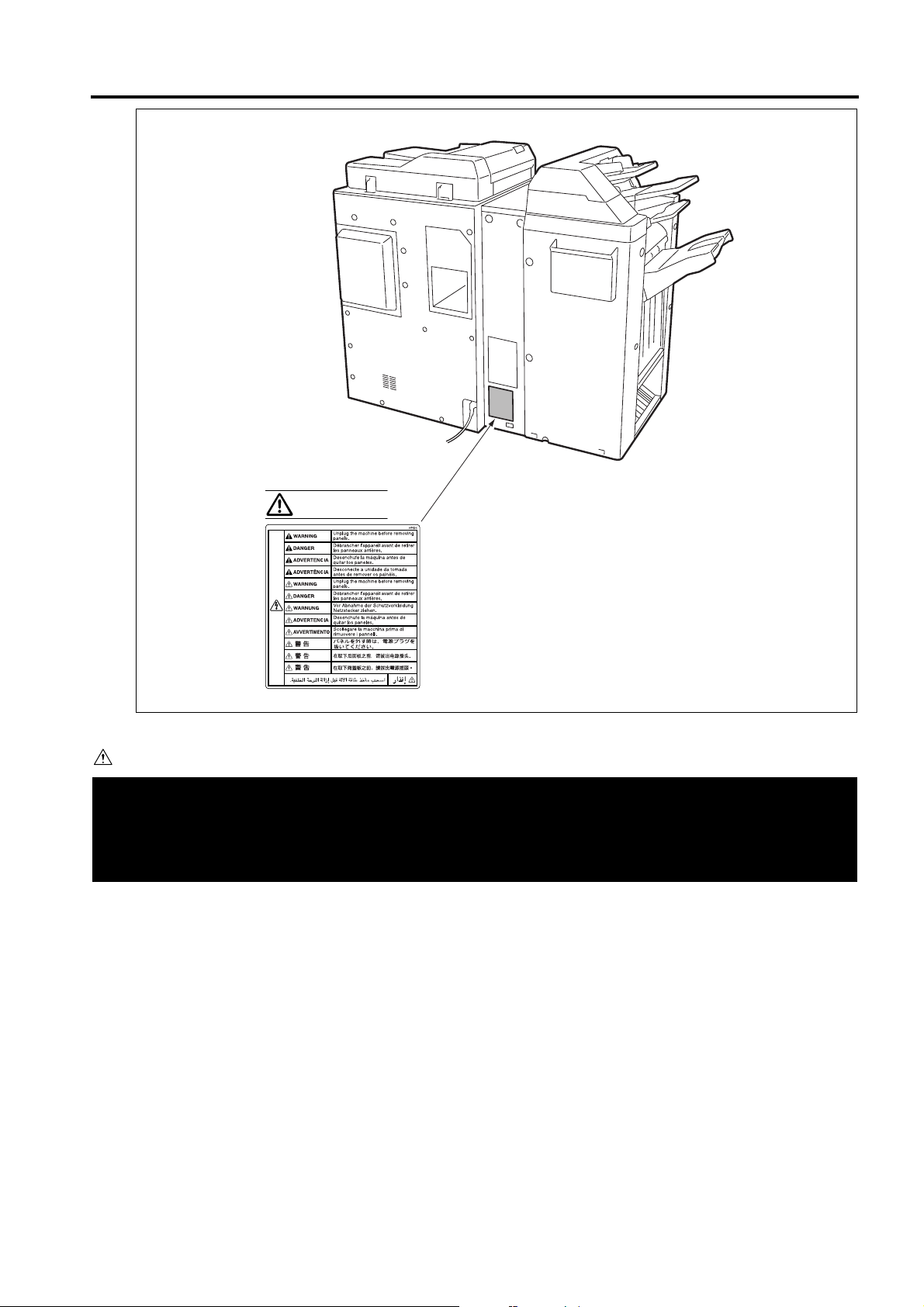

SAFETY AND IMPORTANT WARNING ITEMS

<REAR COVER>

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-18

Page 25

WARNING

SAFETY AND IMPORTANT WARNING ITEMS

<ZK Puncher with Z-folding>

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-19

Page 26

Blank page

Page 27

1

ADJUSTMENT

1 ADJUSTMENT

Page 28

1 ADJUSTMENT

Blank page

Page 29

HOW TO USE THIS SECTION

HOW TO USE THIS

SECTION

[1] Scope and Precautions

This section provides detailed information about

adjustment items and procedures. Before addressing

customer complaints, perform the following checks.

1. Check whether the power supply voltage meets

the specifications.

2. Check whether the power supply is properly

grounded.

3. Check whether this machine shares the power

supply with any other machine that draws large

current intermittently (e.g., elevator and air conditioner that produce electrical noise).

4. Check whether the installation environment is

good.

a. High temperature / High humidity, direct sun-

light, ventilation, etc.

b. Level of installed location

5. Check whether original has a problem that may

cause defective images.

6. Check whether the selected density value is correct.

7. Check whether the platen glass, slit glass, etc. is

soiled.

8. Check whether correct paper is used for copying.

9. Check whether copying materials and parts

(e.g., developer, drum, and cleaning blade) are

replenished and replaced when they reach the

end of their useful life.

10. Check whether toner remains.

When servicing the machine, observe the following

precautions:

ADJUSTMENTS MADE

WHEN REPLACING

PARTS

Adjustments (including checks) and settings are not

only required when a customer complaint about the

copy image quality is received, but also after replacing

or reassembling parts.

[How to Read Tables]

Components of the tables used in this section are as

follows:

1. Mode

Adjustment mode to be selected.

[P]: P mode

[25]: 25 mode

[36]: 36 mode

[47]: 47 mode

2. Code

Code and copy quantity setting button used in

each mode.

3. Page

Page in the "ADJUSTMENT" section.

4. Circled numbers

2

1

Indicate that adjustments (including

checks) must be made in order of precedence.

(Circle without numeric character):

Indicates that adjustments (including

checks) can be made independently.

1 ADJUSTMENT

11. Only either side of the AC line is shut off when the

SW1 (main power) of this machine is turned off.

Always unplug the power cord before starting

service work. If it is necessary to service the

machine with the power on, take care not to be

caught in the scanning gear of the exposure unit.

12. Special care should be taken when handling the

fixing unit because it operates at extremely high

temperatures.

13. The developing unit has a strong magnetic field.

Keep watches and measuring equipment away

from it.

14. Take care not to damage the drum with tools and

so on.

15. Do not touch IC pins with bare hands.

1-1

Page 30

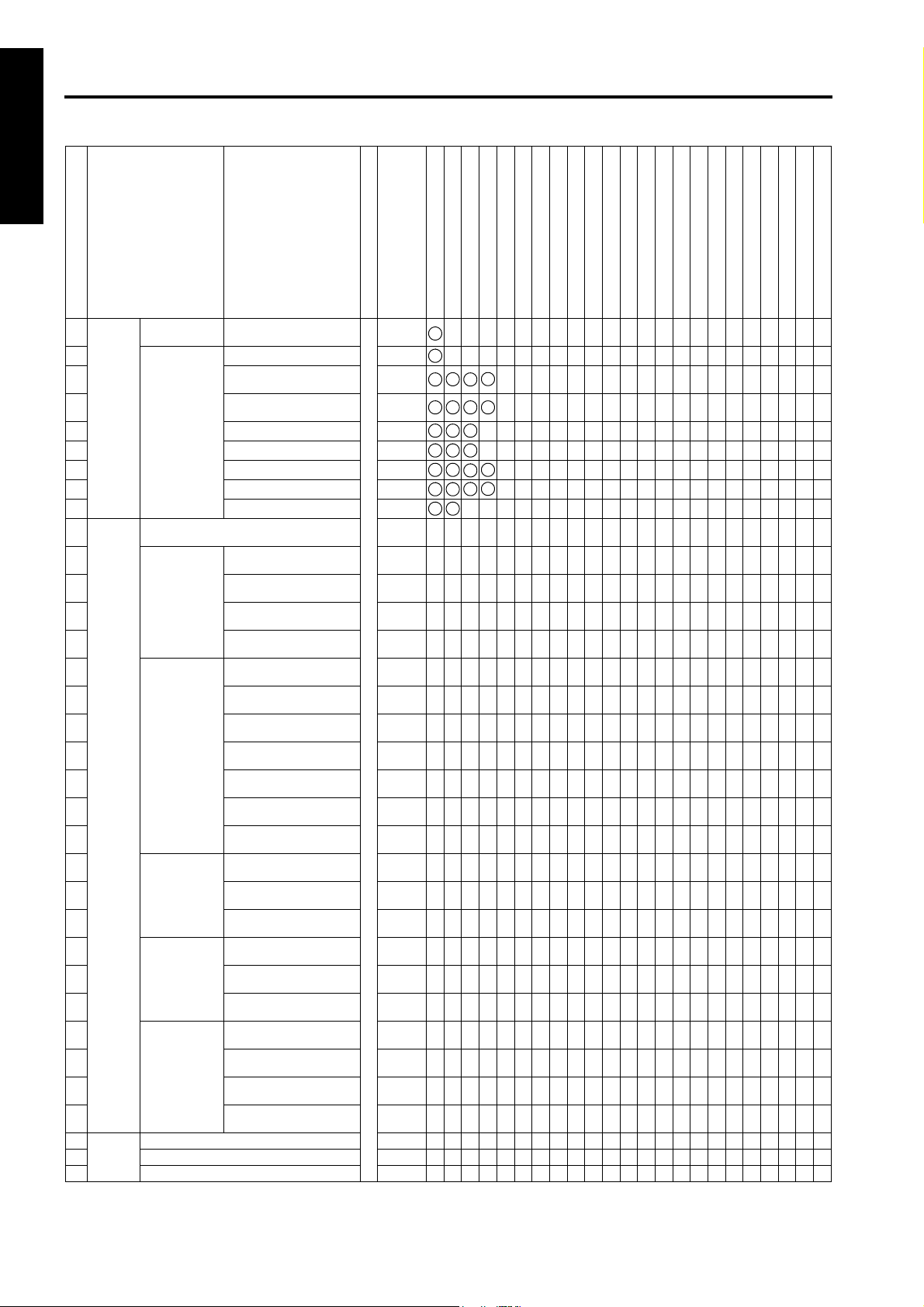

LIST OF ADJUSTMENT ITEMS

LIST OF ADJUSTMENT ITEMS

1 ADJUSTMENT

Item No.

Process

1

Adjustment

2

3

4

5

6

7

8

9

Image

10

Adjustment

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32 Finisher

Adjust-

33 Folding stopper adjustment 1-85

ment

34 Cover sheet tray size adjustment 1-86

Classification by Adjustment

High voltage

adjustment

Drum Peculiarity Adjustment

Tray Adjustment

Magnification

Adjustment

Timing Adjustment

RADF Adjustment

Centering

Adjustment

Warp Adjustment (Copier)

Stitch and fold stopper adjustment 1-85

Charging grid manual

adjustment

Blade setting mode

Auto maximum density

adjustment

Auto dot diameter

adjustment

LD1 offset adjustment

LD2 offset adjustment

Auto gamma adjustment (1dot)

Auto gamma adjustment (2dot)

Cartridge set mode

Printer vertical magnification adjustment

Printer horizontal magnification adjustment

Scanner (platen) vertical

adjustment

Scanner (RADF) vertical

adjustment

Printer leading edge timing adjustment

Printer registration loop

adjustment

Printer pre-registration

adjustment

Printer leading edge timing adjustment

Scanner (platen) leading

edge timing adjustment

Scanner (RADF) leading

edge timing adjustment

Scanner (RADF) registration loop adjustment

RADF density adjustment

RADF original size

adjustment

RADF incline offset

adjustment

Printer centering adjustment

Scanner (platen) centering adjustment

Scanner (RADF) centering adjustment

Scanner (platen) warp

(main scan)

Scanner (platen) warp

(sub-scan)

Scanner (RADF) warp

(main scan)

Scanner (RADF) warp

(sub-scan)

Adjustment Item

36

Mode

1-53

1-54

1-55

1-55

1-56

1-57

1-58

1-59

1-59

1-61

1-62

1-63

1-63

1-64

1-66

1-67

1-68

1-68

1-69

1-69

1-70

1-71

1-71

1-72

1-73

1-73

1-74

1-75

1-75

1-75

1-75

Page

Drum

Developer

Write unit

Dust-proof glass

Each tray unit

By-pass paper feed unit

Tray up/down wire

Registration roller

Registration unit

Registration clutch

Mis-centering detection sensor

ADU unit

CCD unit

Fixing unit

Memory board

RADF

LCT

FNS

Stapler unitPIPK (PK-2)

1

3

421

5 3 2 2

6 4 3

7 5 4

8 653

9 7

2 1

1

4

6

OO O

OO O

OOO

O OOO O

OOO

O

O

O

O

O

O

O

O

O

OO

OO

O

O

O

OO

(O)

OO

O

O

OO

OO

OO

(O)

OO

OO

OO

OO

OO

OO

OO

OO

PK (PK-5)

PZ

1-2

Page 31

LIST OF ADJUSTMENT ITEMS

1 ADJUSTMENT

Item No.

Finisher

35

Adjustment

36

37

38 1st Z- fold position adjustment

39 2nd Z-fold position adjustment 1-89

40 Three-fold position adjustment 1-90

41 2 positions staple pitch adjustment 1-91

42 Tray Centering Adjustment 1-108

43 RADF Mounting Position Adjustment 1-119

44 RADF Skew Adjustment 1-120

RADF Paper Skew

45

Adjustment

46

47 PI Centering adjustment 1-141

48 PK Adjusting the Skew of Punched Holes Position 1-137

PK Adjusting the Vertical Positioning of Punched

49

Holes

50 Drum Count Reset 1-42

51 Developer Count Reset 25 1-42

52 Web Counter Reset 1-42

Classification by Adjustment

Punch Adjustment

Punch vertical position

adjustment

Punch horizontal

position adjustment

Punch regist loop adjustment

Face side of original

paper

Back side of original

paper

Adjustment Item

Mode

1-87

1-87

36

1-88

1-88

1-120

1-121

Other Adjustments

1-139

Caution: Replacing the image control board

• When a damaged image control board is replaced, the memory board on this board must be used on the

new image control board.

Only when the memory board is damaged, use a new memory board on a new control board.

Since the new memory board does not have adjustment data, the all adjustments are required. Before making the all adjustments, make the

47mode-92(output) " setting to make the new memory board effective.

"

• After making any adjustment, make the “47mode -96 (output) setting”. After made the “47mode-96 (output)”

setting, the adjustment data is saved.

• However, the “47mode-92” and -96” settings are protected to prevent them from careless operation. In order

to make “47mode -92” and -96” settings using the saved adjustment data, the protection must be disabled.

For the unprotection method, contact the service manager ot the authorized distributor.

Page

Drum

O

O

Developer

Write unit

Dust-proof glass

Each tray unit

By-pass paper feed unit

Tray up/down wire

Registration roller

Registration unit

Registration clutch

Mis-centering detection sensor

ADU unit

CCD unit

Fixing unit

Memory board

RADF

LCT

FNS

Stapler unitPIPK (PK-2)

OOO

O OOO

OOO

OO

OO

OO

OO

OO

O

O

O

O

O

PK (PK-5)

3

1

2

PZ

1-3

Page 32

LCD ADJUSTMENT

LCD ADJUSTMENT

[1] LCD Control Panel Adjustment

Enter the key operator mode and select " Touch

1 ADJUSTMENT

panel adjustment" to adjust the LCD touch panel.

*If you cannot select the touch panel adjustment

mode pressing any numeric key after entering key

operator mode will take you directly to " Touch

panel adjustment".

[2] LCD Panel Contrast/Key Sound

Adjustment

Enter the key operation mode and select " LCD

Panel contrast/Key sound adjustment" to adjust the

contrast, backlight, and/or buzzer as desired.

10

10

SETTINGS AND ADJUSTMENTS MADE WITH THE

P FUNCTION

The P function allows you to perform following numerical value checks using the P button:

1. Total counter

2. Copier counter

3. Printer counter

4. * PM counter

5. Density Shift (Auto <Text/Photo>)

7

6. Density Shift (Inclease Contrust)

7. Density Shift (Photo)

8. Density Shift (Text)

* PM counter is only displayed when Check

key is pressed on the operation panel.

!

[1] Checking and Printing the P Function

1. Turn ON the SW2 (sub power).

2. Press the P button.

3. Counter list is displayed.

4. Press the key.

5. Press the START button to print out the counter

list. The P function is cancelled automatically.

6. If the counter list need not be displayed, press the

EXIT

COUNTER MENU

key.

[2] Setting up the P Function

1. Turn ON the SW2 (sub power).

OK

SPECIAL

ORIGINAL

OK

2. Press the key.

3. Select the required image quality, text, photo etc.

Then press the P button to set the desired density

shift.

4. Enter a value (0-5) with a numeric key, then press

the key. The smaller the value, the darker

the density.

5. Press the key to return to the Basic screen.

1-4

Page 33

MODE CHANGING MENU

[1] Mode Selection

MODE CHANGING MENU

You can select a mode from the following [Mode changing menu: [Select mode] without turning OFF and ON

the power switch.

1

Basic screen

2

3-6 mode

3

2-5 mode

4

Key operation mode

5

4-7 mode

Step Operation

Turn on the SW2 (sub power).

1

Press P button and wait until [Enter pass-

word for mode selection] message

2

appears.

1 ADJUSTMENT

Enter the password 9272 and press the

Start button.(Note that this password is

3

fixed and cannot be changed.)The [Mode

changing menu] appears.

Enter the number to select the desired

4

mode.

To return to the [Mode changing menu],

press P button and wait until the menu

5

appears again.

Upon completion of the adjustment, press

6

EXIT

key to return to the Basic screen.

1-5

Page 34

MODE CHANGING MENU

[2] Display Transition of 36 Modes

1 ADJUSTMENT

x : Factory exclusive use. Service is not used.

3-6 Modus / Adjustment mode

1 Process adjustment

2 Image adjustment

3 Running test mode

4 Test pattern output mode

5 Test pattern density setting

6 Finisher adjustment

7 List output mode

Process adjustment mode menu

1 High voltage adjustment

2 Drum peculiarity adjustment

3 Drum peculiarity adjustment

(hand op) x

4 User paper setting

5 Recall standard data

Image adjustment mode menu

1 Tray adjustment

2 Magnification adjustment

3 Timing adjustment

4 EDH adjustment

5 Centering adjustment

6 Warp adjustment (Copier)

7 Non-image area erase check

8 Recall standard data

Running test mode menu

1 Intermittent copy mode

2 Paperless running mode

3 Paperless mode

4 Paperless endless mode

5 Running mode

Finisher adjustment mode menu

1 Stapling&Folding stopper adjustm.

2 Folding stopper adjustment

3 Cover sheet tray size adjustment

4 (Not use this model)

5 Punch adjustment

6 Z-Folding position adjustment

7 Three Folding position adjustment

8 2 Positions staple pitch adjustm.

List output mode menu

1 Machine management list 1

2 Adjustment data list

3 Black ratio data list

4 Machine management list 2

5 Parameter list

6 Memory dump list

7 Font pattern

High voltage adjustment mode menu

1 HV adjustment (Charge) x

2 HV adjustment (Transfer) x

3 HV adjustment (Separation-AC) x

4 HV adjustment (Separation-DC) x

5 HV adjustment (Charging grid voltage)

6 HV adjustment (Bias of development) x

7 Transfer guide confirm x

8 HV adjustment (TGR) x

Drum peculiarity adjustment mode menu

1 Blade setting mode

2 Auto maximum density adjustment

3 Auto dot diameter adjustment

4 LD 1 offset adjustment

5 LD 2 offset adjustment

6 LD 1 bias adjustment x

7 LD 2 bias adjustment x

8 Auto gamma adjustment(1dot)

9 Auto gamma adjustment(2dot)

10 Cartridge set mode

Magnification adjustment mode menu

1 Printer drum clock adjustment

2 Printer horizontal adjustment

3 Scanner drum clock adjustment

4 EDH drum clock adjustment

Timing adjustment mode menu

1 Printer restart timing adjustment

2 Printer resist loop adjustment

3 Printer pre-resist adjustment

4 Printer lead edge timing adjustment

5 Scanner restart timing adjustment

6 EDH restart timing adjustment

7 EDH resist loop adjustment

EDH adjustment mode menu

1 EDH density adjustment

2 EDH original size adjustment

3 EDH Incline offset adjustment

Centering adjustment mode menu

1 Printer centring adjustment

2 Scanner centring adjustment

3 EDH centring adjustment

Punch adjustment mode menu

1 Punch vertical position adjustment

2 Punch horizontal position adjustment

3 Punch resist loop adjustment

Z-folding position adjustment mode menu

1 1st Z-holding position adjustment

2 2nd Z-holding position adjustment

1-6

Page 35

[3] Display Transition of 25 Modes

2-5 Modus /Memory setting mode

1 Software SW setting

2 Paper size setting

3 PM count

4 Data collection

5 Parts counter

6 Password setting

7 Telephone number setting

8 M/C serial number setting

9 Indication of ROM version

10 RD mode setting

11 ISW

12 Setting date input

Collecting data menu

1 Total count of each paper size

2 Copy count of each paper size

3 Print count of each paper size

4 EDH count

5 Scanner count

6 Black ratio of each section

7 Black ratio ranking list

Copy count of part menu

1 Count of special parts

2 Count of each parts

[4] Display Transition of Key Operation Modes

System initial setting menu

1 Date & Time setting

2 Language select setting

3 IP adress setting / Tandem

4 E-mail transmission setting

User setting mode menu

Key operator mode menu

1 System initial setting

2 Copier initial setting

3 User setting mode

4 E.K.C function setting *1

5 Lock / delete program memory

6 Paper type / Special size set

7 Panel contrast / Key sound adj.

8 Key operator data setting

9 Weekly timer

10 Control panel adjustment

11 Tray auto select setting

12 Energy saver setting

13 Memory switch setting

14 Machine management list print

15 * Not use Minolta!

16 Side 2 lens adjustment

17 Finisher adjustment

18 HDD management setting

19 Scanner transmission setting

20 Non-image area erase setting

21 Background adjustment

*2

22 Timing adjustment

23 Centering adjustment

*1 Name of system

*2 These menus are displayed by

switching DIPSW.

E.K.C: Except UAS area

E.C.M: USA area only

1 User density level 1setting

2 User density level 2 setting

3 User lens mode ratio setting

Weekly timer setting menu

1 Weekly timer ON/OFF setting

2 Timer setting

3 Timer action ON/OFF setting

4 Lunch hour off setting

5 Timer interrupt password set

Management list print mode menu

1 Program memory list

2 User management list

3 E.K.C. management list

4 Font pattern list

Finisher adjustment mode menu

1

Stapling & Folding stopper adjust.

2 Folding stopper adjustment

3 Trimmer stopper adjustment

4 Punch adjustment

5 Z-Folding position adjustment

6

Three-Folding position adjustment

7

2-Positions staole pitch adjustment

Memory switch menu

8 JAM data of time series

9 JAM count

10 Count of each copy mode

11 SC count

12 JAM count of each section

13 SC count of each section

1 Panel reset timer

2 Panel reset key function

3 EDH-Original effect

4 Program memory auto recall -305 Finisher mode by Full-Auto

6 Initial by Key Counter insert

7 Erasure outside area of original

8 EDH frame erasure selection

9 Automatic tray switching

10 Platen APS

11 EDH APS

12 Platen AMS

13 EDH AMS

14 Select tray when APS cancel

15 Platen original size detect

16 EDH original size detect

17 Platen original size detect (SMALL)

18 Rotation

19 Staple mode reset function

20 JOB offset operating

21 Continuation print

22 Key click sound

23 1 SHOT indication time

24 Energy saver screen

25 Start Key latch function

26 Stop Key function

27 Auto select of Booklet copy

MODE CHANGING MENU

1 ADJUSTMENT

28 E.K.C. Password

29 Arrow key change [Image shift]

30 Exit direction of 1 sheet

31 An interruption suspended way

32 E.K.C. password input timing

33 Sound (No paper, toner/ JAM)

34 Reserve copy function

35 Scan stop by pull out tray

36 Change page no. Pos. (booklet)

37 Timer which prohibits print

38 Bookmark fanction

39 Delete of overlay image

40 Orig. direction/binding mode

41 Image stored cont. (SRV)

42 Image recalled cont. (SRV)

43 Exit direction

44 I/P SCAN Address manual input

45 I/P SCAN E-Mail function mask

46 I/P SCAN HDD function mask

47 I/P SCAN FTP function mask

48 State of Platen/ EDH (Reset)

49 Priority tray (blank overlap)

50 Auto select the binding mode

51 IP SCAN E-Mail file form

52 IP SCAN HDD file form

53 IP SCAN FTP file form

54 Printing side (Three-Folding)

1-7

Page 36

25 MODE

25 MODE

[1] Setting the 25 Mode

This machine has an adjustment mode called the "25

1 ADJUSTMENT

Mode". Select this mode to rewrite data in the non-volatile memory or make various settings.

1. Turn OFF the SW2 (sub power).

2. While pressing the copy quantity setting button 2

and 5, turn ON the SW2 (sub power).

The Memory setting mode menu Screen will

appear.

Now the machine is in the 25 mode, disabling normal copy operations.

[Memory setting mode menu Screen]

3. Press the numeric button of the desired setting

item.

The associated setting screen will appear.

4. Enter data in the setting screen.

5. Turning OFF the SW2 (sub power) cancels the 25

mode.

6. New data will take effect after restart.

1-8

Page 37

[2] List of Adjustment Items for 25 Mode

Adjustment Item Menu Remarks

Software DIP SW setting See "list of Software DIP

1

Paper size setting

2

PM count Resetting PM Count

3

Setting PM cycle

Data collection (Di551/Di650) Total count of each paper size

4 1

Copy count of each paper size

2

Print count of each paper size

3

RADF count

4

Pixel ratio of each section

5

Pixel ratio ranking list

6

JAM data of time series

7

JAM count

8

Count of each copy mode

9

SC count

10

JAM count of each section

11

SC count of each section

12

Data collection (Di5510/Di7210)

Parts counter Count of special parts COUNT RESET

5 1

Password setting Key Operator password 4 digits

6

Telephone/Fax number set-

7

ting

Total count of each paper size

1

Copy count of each paper size

2

Print count of each paper size

3

RADF count

4

Scanner count

5

Pixel ratio of each section

6

Pixel ratio ranking list

7

JAM data of time series

8

JAM count

9

Count of each copy mode

10

SC count

11

JAM count of each section

12

SC count of each section

13

Count of each part COUNT RESET

2

EKC master key code 8 digits

Weekly timer password 4 digits

HDD management password 4 digits

Customer support telephone number 16 digits

Customer support FAX number 16 digits

25 MODE

1 ADJUSTMENT

Switches".

Part name setting

P/N setting

Limit Setting

1-9

Page 38

25 MODE

1 ADJUSTMENT

Adjustment Item Menu Remarks

M/C serial number setting Main body

8

Optional tray

Finisher

Indication of ROM version Indication of versions of

9

ROMs installed in the image

control, printer control, finisher, and Z-fold.

RD-mode setting

10

ISW updating

11

Setting date input

12

1-10

Page 39

[3] Setting Software DIP Switches

1. Procedure

Bring up the Software DIP SW Setting screen

and set software DIP switches.

Step Operation

Enter the 25 mode.

1

[Memory setting mode menu Screen]

2

Select " Software DIP SW setting".

[Software DIP SW setting screen]

Select a DIP switch number.

Use the or key or numeric

3

keys.

To use numeric keys, press the DIP

switch number key at the left before

entering a DIP switch number.

Select a bit number of the selected DIP

switch.

1

25 MODE

1 ADJUSTMENT

Use the or key or numeric

4

keys.

To use numeric keys, press the bit number key at the upper center before entering a DIP switch number.

Select ON (=1), or OFF (=0) of the

switch.

Use the or key.

5

ON

OFF

Press the key to return to the

6

ON OFF

: Sets 1.

: Sets 0.

RETURN

Memory setting mode menu Screen.

For the function of each switch, refer to “list of

Software DIP Switches”.

1-11

Page 40

1 ADJUSTMENT

25 MODE

< List of Software Switches >

Note: Be sure not to change bits with no particular reference made of the function.

DIPSW

No.

DIPSW 1

DIPSW2

DIPSW3

DIPSW4

DIPSW5

DIPSW 6

Bit Function 0 1

0 Condition for stopping copying after indica-

tion of toner supply

1 000

2 Method for stopping copying after indica-

tion of toner supply

3 000

Inhibition of copying when PM count is

4

reached

5

Number of copies made before inhibition of

6 000

copying when PM count is reached

7 000

Hard disk connection

0

* 1 * 1

* 2 * 2

Disabled Inhibited 0 0 0

* 3 * 3

Disconnected Connected 0 0 0

1 Electrode cleaning cycle (when power is

2 000

turned ON, fixing temperature is 50ºC or

3 000

less)

4 Electrode cleaning cycle (after power is

turned ON)

5 000

-

6

-

7

-

0

SC latch

1

25, 36, 47 mode password request (pass-

2

word: 9272)

Charger cleaning function

3

Transfer/separation cleaning function

4

-

5

47 mode 15-01 data collection clearing

6

JobEditor connection

7

ADF automatic skew adjustment

0

Inhibition of postcard double sided copy

1

-

2

-

3

Key counter removal recovery

4

Inhibition of magnified APS

5

Fixed magnification rate setting change in

6

key operator mode

A3 (11x17) counting method

7

0 Image density selection (Toner concentra-

tion threshold)

1 000

2 Image density selection (laser PWM) for

copier

3 000

-

4

-

5

-

6

-

7

* 4 * 4

* 5 * 5

-

-

-

-

-

-

Unlatched Latched 0 0 0

Not requested Requested 0 0 0

ON OFF 0 0 0

ON OFF 0 0 0

-

-

Disabled Enabled 0 0 0

Disconnected Connected 0 0 0

Enabled Disabled 0 0 0

Disabled Enabled 0 0 0

-

-

-

-

Disabled Enabled 0 0 0

Enabled Disabled 0 1 0

Enabled Disabled 1 0 0

Incremented by 1Incremented by

2

* 7 * 7

* 8 * 8

-

-

-

-

-

-

-

-

0

Transfer/separation output for plain paper

1 000

* 9 * 9

Initial Value

Japan Inch Metric

111

111

000

000

000

000

000

000

000

010

001

000

000

111

000

111

000

000

000

2 000

3

Transfer/separation output for thick paper

4 000

5

Transfer/separation output for thin paper

6 000

-

7

* 10 * 10

* 11 * 11

-

-

000

000

000

1-12

Page 41

25 MODE

DIPSW

No.

DIPSW 7

DIPSW8

DIPSW 9

DIPSW10

DIPSW11

Bit Function 0 1

0

Toner guide roller current correction

1 000

TSL user-specified paper control

2

(Di5510/Di7210) (Note1)

TSL postcard control (Di5510/Di7210) (Note1)

3

-

4

5

Transfer/separation output for recycled

6 000

paper

7 000

0

Image density selection (laser PWM) for IP

1 000

2

Fixing roller initial rotation

3 111

4

Fixing roller initial rotation time setting

5 000

A3(11

6

Store on hard disk

7

Operation at key counter removal (copy)

0

Operation at key counter removal (print)

1

2

Message switching

3 000

17) PM counter switch

×

* 12 * 12

Lighted Not lighted 0 0 0

Lighted Not lighted 0 0 0

-

-

* 13 * 13

* 35 * 35

* 14 * 14

* 15 * 15

1 count 2 count 0 0 0

Enable Disable 0 0 0

Same as stop

key

Ignored

Immediate

stop (JAM)

Same as

DIPSW9-0

* 16 * 16

4

5 000

Copy count limit

6 000

* 17 * 17

Initial Value

Japan Inch Metric

000

000

000

000

000

011

0 0 0

000

000

000

7 000

0

Page memory allocation when powered.

1 000

Page memory allocation when job starts

2

Duplex shift printing from Adobe PS3

(Di551/Di650) (Note2)

3

Fixing low power recalling temperature setting (Di5510/Di7210) (Note3)

* 18 * 18

* 19 * 19 0 0 0

Common shift

Recalled after

45 seconds

Independent

shift

Recalled after

30 seconds

4

Transfer/separation output for high-quality

5 000

paper

6 000

* 20 * 20

000

000

000

000

7 000

-

0

-

1

Index paper rear end erasing amount 3mm erased

2

SC/E code screen switchover

3

Selection of filter for jagged edges on slanting lines

4

Tone switchover in photo mode

5

Fixing control for domestic normal temperature and

6

normal humidity environment (Di5510/Di7210)

JAM indication screen type

7

-

-

-

-

000

000

1mm erased 0 0 0

Switched

Not switched (All

are F codes)

000

Not selected Selected 0 0 0

2bitED-2dot

PWM

Priority in

WUT

Without Jam code

1bitED-1dot

PWM

Priority in fixing condition

000

000

With Jam code 0 0 0

1 ADJUSTMENT

Note 1:

TSL does not light up at all when this lamp does not light up.

When this lamp lights up, TSL does not light up for the last one-fifth part of a document divided in the feeding

direction but lights up for the remained four-fifth part.

Note 2: When printing from Adobe PS3 driver in duplex mode with image shift function, shift amount of copier

(it can set from “APLICATION-Image sift”) is used for print job.

0: Both front and back side is decided by the front side shift amount data of copier.

1: The shift data for each front and back side set in copier is used for duplex print mode.

Note 3:

The time recalled from low-powered state can be selected from 45 seconds or 30 seconds.

For the temperature set for low-powered state, the temperature set for 30-second lapse is higher than that for

45-second lapse.

1-13

Page 42

25 MODE

1 ADJUSTMENT

DIPSW

No.

DIPSW 12

DIPSW 13

DIPSW14

DIPSW15

DIPSW16

DIPSW17

Bit Function 0 1

Every 10 copies

Black stripe creation interval

0

Coin vendor paper size signal switchover

(Di551/Di650)

1

Shifting from A3 to A3R (Di5510/Di7210)

-

2

Printer automatic centering correction

3

High voltage output in 36/47 mode

4

Paper exit direction of booklet mode

5

-

6

-

7

Size detection 1

0

Size detection 2

1

Size detection 3

2

3

Size detection 4

4 010

5

F4 size detection

6 000

-

7

0 Size detection 5 (main body)

-

1

-

2

3 Size detection 5 (by-pass feed)

4 Size detection 5 (platen)

5 Size detection 5 (ADF)

6 Size detection 5 (PI)

-

7

RD mode type selection

0

1

Maximum number of sheets to an be stapled

2 000

3

FNS alarm stop SW * 24 * 24

4 000

(Di551/Di650)

Every 12 copies

(Di5510/Di7210)

A3 A3R 0 0 0

Disabled Enabled 0 0 0

-

Enable Disable 0 0 0

Not output Output 1 1 1

Face down Face up 0 0 0

-

-

A5 5.5 x 8.5 0 1 0

A4R 8.5 x 11R 010

8.5 x 14 F4 0 0 1

* 21 * 21

* 22 * 22

-

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

-

-

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

-

Telephone line

* 23 * 23

Every 50 copies

(Di551/Di650)

Every 60 copies

(Di5510/Di7210)