Page 1

SETUP INSTRUCTIONS

FN-113

FINISHER

Di551/Di650

NOTES

•Keep all packing materials out of the reach of children.

•Before setting up, be sure to unplug the power cord of the machine.

4698-7744-03 © MINOLTA CO., LTD. Printed in Japan

Page 2

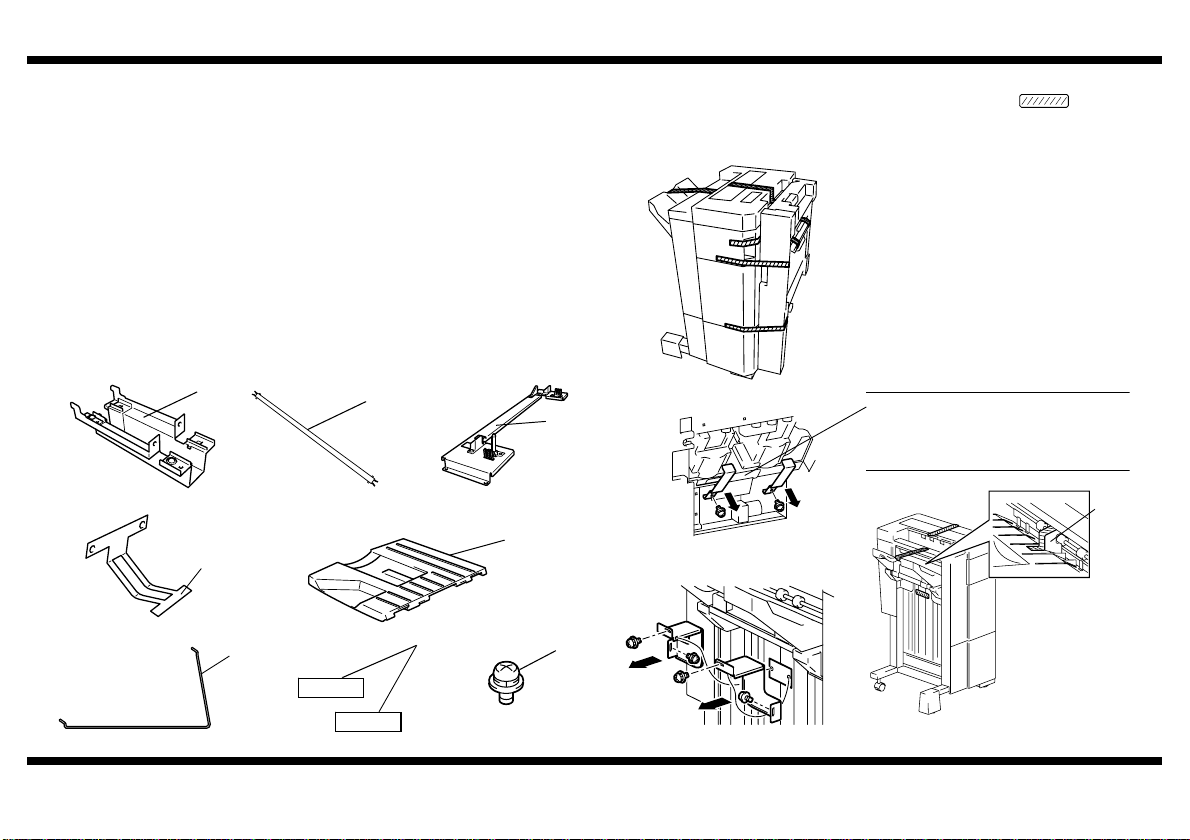

Components

NOTE

■

1. Feeder Attachment..................................................................................1

2. Pipe .........................................................................................................1

3. Fixing Bracket..........................................................................................2

4. Ground Plate ...........................................................................................1

5. Tray .........................................................................................................1

6. Wire Form................................................................................................1

7. Label........................................................................................................2

8. Screw ......................................................................................................8

9. Setup Instructions....................................................................................1

10. Cover.......................................................................................................1

FINISHER

Remove tape and fixing brackets.

: Tape

1. Open the vertical transport section of the

Finisher and remove tape and fixing brackets

from the Stapling Unit.

4698U003AA

4698-7744-03

1

4698U019AA 4698U002AA

2

C4611U005AA

5

4

4643U006AA

7

9646-0408-13

4643U010AA

6

4643U032AA

4698U004AA

3

Do not remove this part.

Use a mini-screwdriver to remove this

fixing bracket.

Cushion

4643U005AA

8

4698U020AA

4643U003AA

– 1 –

Page 3

NOTES

NOTE

•

Make sure that the Finisher is installed on a level surface.

•

Once the Finisher has been installed, do not move it unless absolutely necessary.

If it becomes absolutely necessary to move the Finisher, remove the Pipe both

from it and the machine. After the Finisher has been relocated, attach the Pipe

back again by following the steps given in “Attaching the Pipe.”

•

When moving the Finisher, press the side opposite to the Tray to prevent the Finisher from toppling over.

FINISHER

■

4698U021AA

4698U022AA

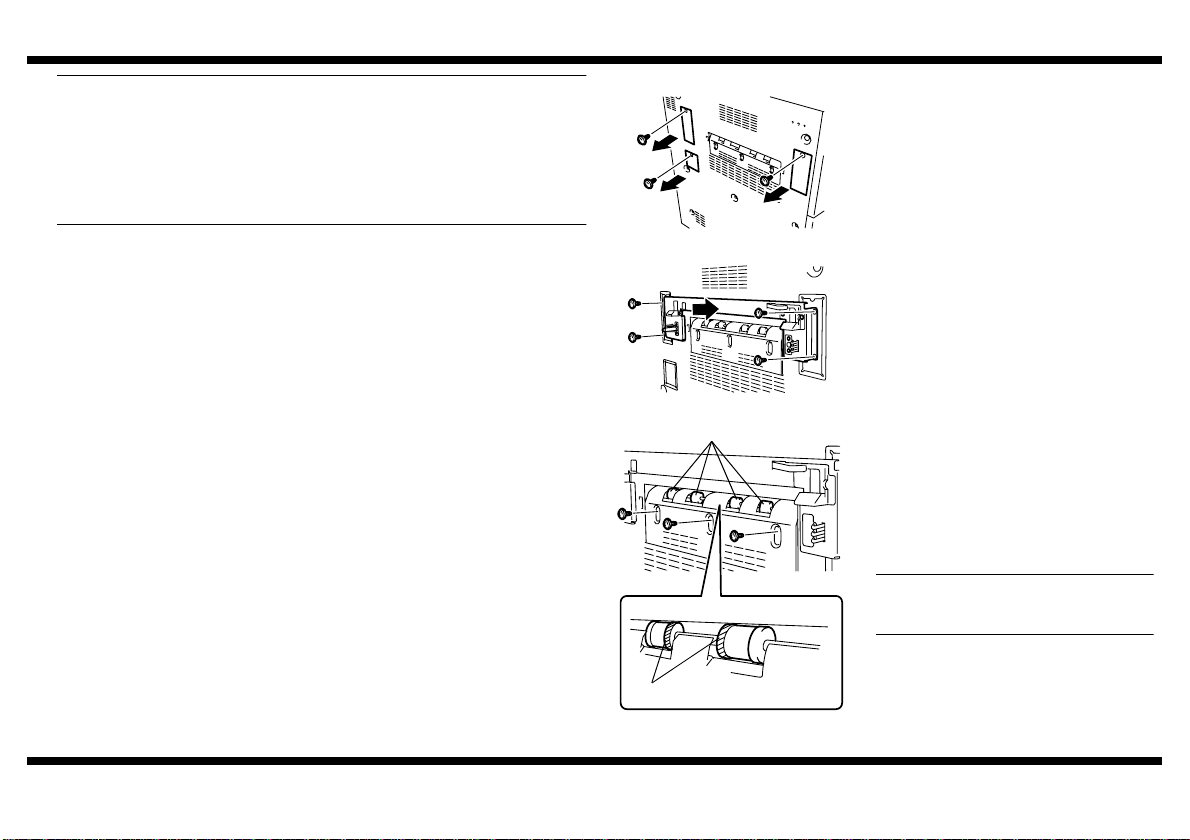

Attaching the Positioning Pin, Fixing Brackets, and Pipe

1. Remove the Left Covers (at three locations)

of the machine.

2. Install Fixing Bracket A.

Exit Rollers

3. Remove the Exit Roller Cover (three

screws).

4. Cut the inner Treaded Rubber Collars (4pcs.)

of each Exit Roller.

5. Reinstall the Exit Roller Cover (three screws)

which has been removed in step 3.

Make sure that the cover is doweled into

position.

4698-7744-03

Inner Side

4698U115AB

– 2 –

Page 4

4698U024AA

NOTE

4698U025AA

Ground Plate

6. Install the Feeder Attachment and Ground

Plate at the bottom on the left side of the

machine.

NOTE

Make sure of the correct direction of the

Feeder Attachment when installed. Check

that the rear of the Feeder Attachment is

hooked onto the inner side of the machine.

7. Fit one end of the Pipe into the mounting

guide on the Finisher Tray side and insert the

Pipe until a click is heard.

NOTE

At this time, do not press the Finisher up

against the machine, yet.

8. Slide the other end of the Pipe into the

Feeder Attachment installed in step 6.

FINISHER

■

4698U026AB

Adjusting the Position of the Finisher

1. Slowly move the Finisher toward the

machine and check the followings:

Alignment between the locations shown of

•

Fixing Bracket A mounted on the machine

and the stamped marks on the Finisher (at

the front and rear)

If the parts are not properly aligned with

each other , perf orm th ese st eps t o make an

adjustment.

2. Slowly move the Finisher away from the

machine and open the Vertical Transport

Section of the Finisher.

4698N025AB

4643U019AB

4698-7744-03

<When Removing the Pipe>

Using the tabs on the Finisher side, unlock the

Pipe and pull it out from the mounting guide.

Then, remove the Pipe together with the Feeder

Attachment installed in step 3. Next, pull the

Pipe out of the Feeder Attachment.

4698U009AA

3. Remove the Lower Front Cover (two screws)

of the Finisher.

4643U021AB

– 3 –

Page 5

FINISHER

4643U020AA

Locking Bolt

Adjusting Bolt

4643U022AB

4698U027AA

4698-7744-03

4. Pull up and remove the caster covers (two).

Locking Bolt

Adjusting Bolt

7. After the check has been made, tighten the

upper locking bolts of the casters (at four

places), while holding the lower adjusting

bolts in position.

8. Reinstall the parts which have been

removed.

4643U029AA

Connecting the Hookup Cord

5. Holding the lower adjusting bolt of the caster

in position, loosen the upper locking bolt.

Then, turn the lower adjusting bolt to adjust

the height.

■

Connect the two connectors of the Hookup

•

Cord of the Finisher at the locations shown.

Then, screw the cover of the Hookup Cord

with care not to allow any of the wires to be

wedged by the cover.

<Two in the rear>

If the Positioning Pin is higher

: Turn the bolt clockwise.

If the Positioning Pin is lower

4698U010AA

: Turn the bolt counterclockwise.

<Two at the front>

If Fixing Bracket A is higher

: Turn the bolt clockwise.

If Fixing Bracket A is lower

: Turn the bolt counterclockwise.

4698U011AA 4698U012AA 4698U028AA

6. Press the Finisher against the machine and

check that clearance between the two is

a

equal at points a and b.

NOTE

If the clearance at a is not equal that at b,

b

readjust with the casters.

– 4 –

Page 6

Installing the Tray and Wire Form

■

Install the Tray and Wire Form that come with

•

the Finisher at the locations shown.

Install the cover furnished with the Finisher.

•

(For the mounting screw, use the screw that

has been removed in step 1 on p. 2.)

4643U024AA

4643U017AA 4698U035AB

Affixing the Labels

■

Affix the labels that come with the Finisher.

1. Label (for the copier)

4698U014AA

Label (for the electronic document handler)

Cover

FINISHER

4643U034AA

4643U035AA

(For copier)

(For electronic document handler)

4698U015AA

4698-7744-03

– 5 –

Page 7

Setting the software DIP switches (For U.S.A. and Canada Only)

NOTE

■

1. Plug the power cord of the machine in the

power outlet and turn ON the Main Power

Switch and Power Switch.

2. Access the “25-mode” screen. (Refer to the

Service Manual for the procedure.)

3. Touch “Software SW setting.”

4656U049CA

FINISHER

4698U037CA

6. Touch to select the switch bit number.

7. Select “1” using the ▲ or ▼ key on the right

or directly enter it from the 10-Key Pad.

If the 10-Key Pad is used to enter the bit

number, first highlight the bit number on the

right and then enter the number

4698U036CA

4698-7744-03

4. Touch to select the DIP switch number.

5. Select “22” using the ▲ or ▼ key on the left

or directly enter it from the 10-Key Pad.

NOTE

If the 10-Key Pad is used to enter the DIP

switch number, first highlight the DIP switch

number on the left and then enter the

number

8. Select ON for the switch.

4698U038CA

– 6 –

Page 8

4698U036CA

FINISHER

9. Se lect the DIP switch numb er aga in.

10.Select “22” using the ▲ or ▼ key on the left

or directly enter it from the 10-Key Pad.

NOTE

If the 10-Key Pad is used to enter the DIP

switch number, first highlight the DIP switch

number on the left and then enter the

number

11.Touch to select the switch bit number.

Checking the Hole Positions for Hole Punch

■

1. Plug the power cord of the machine and turn

ON the Power Switch.

2. Load the 1st Drawe r with A4-size or Lettersize crosswise paper.

3. Touch “OUTPUT MENU.”

4698U032CA

4. Touch “PUNCH” to highlight it.

4698U039CA

4698U040CA

4698-7744-03

12.Select “2” using the ▲ or ▼ key on the right

or directly enter it from the 10-Key Pad.

NOTE

If the 10-Key Pad is used to enter the bit

number, first highlight the bit number on the

right and then enter the number

13.Select ON for the switch.

14.Touch “RETURN.”

15.Turn OFF and ON the Power Switch of the

machine.

4698U033CA

5. Touch the desired hole punch position.

6. Touch “OK.”

4698U034CA

7. P r ess the Start key.

4002O280CB

– 7 –

Page 9

4643U031AA

NOTE

FINISHER

8. Fold the copy in half to check that holes are

in correct alignment with each other.

Specifications: 0 ± 2 mm

NOTE

If the specifications are not met, adjust the

hole positions for Hole Punch.

Adjusting the Hole Positions for Hole Punch

■

1. Open the Top Cover of the Finisher and

loosen the screw that secures the Hole

Punch Guide Plate.

Slide the green handle to the front or rear to

adjust the position of holes for Hole Punch.

4643U025AA

2. Tighten the screw which has been loosened

in step 1.

Make a copy again and check for correct

hole positions. If the specifications are not

still met, readjust.

4643U031AA

3. After the adjustment has been completed,

close the Top Cover.

4698-7744-03

– 8 –

Loading...

Loading...