Page 1

SERVICE MANUAL

Models

7115F/7118F

Fax Unit (FK-117)

APRIL 2002

FSM-7115F/7118F

KONICA BUSINESS TECHNOLOGIES, INC.

Page 2

Page 3

7115F/7118F

SERVICE MANUAL

APRIL 2002

Fax Unit (FK-117)

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2002, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

1. Specificatio ns ... ....... ........ ........ ....... .... ........ ....... ........ ........ ....... .... ........ ....... .....1

2. Panel Desc rip ti on . ... ........................... ........................... ............... .... ............... .4

3. FAX CPU BLOCK DIAGRAM ..........................................................................9

4. ASSEMBLY / DIASSEMBLY ...........................................................................11

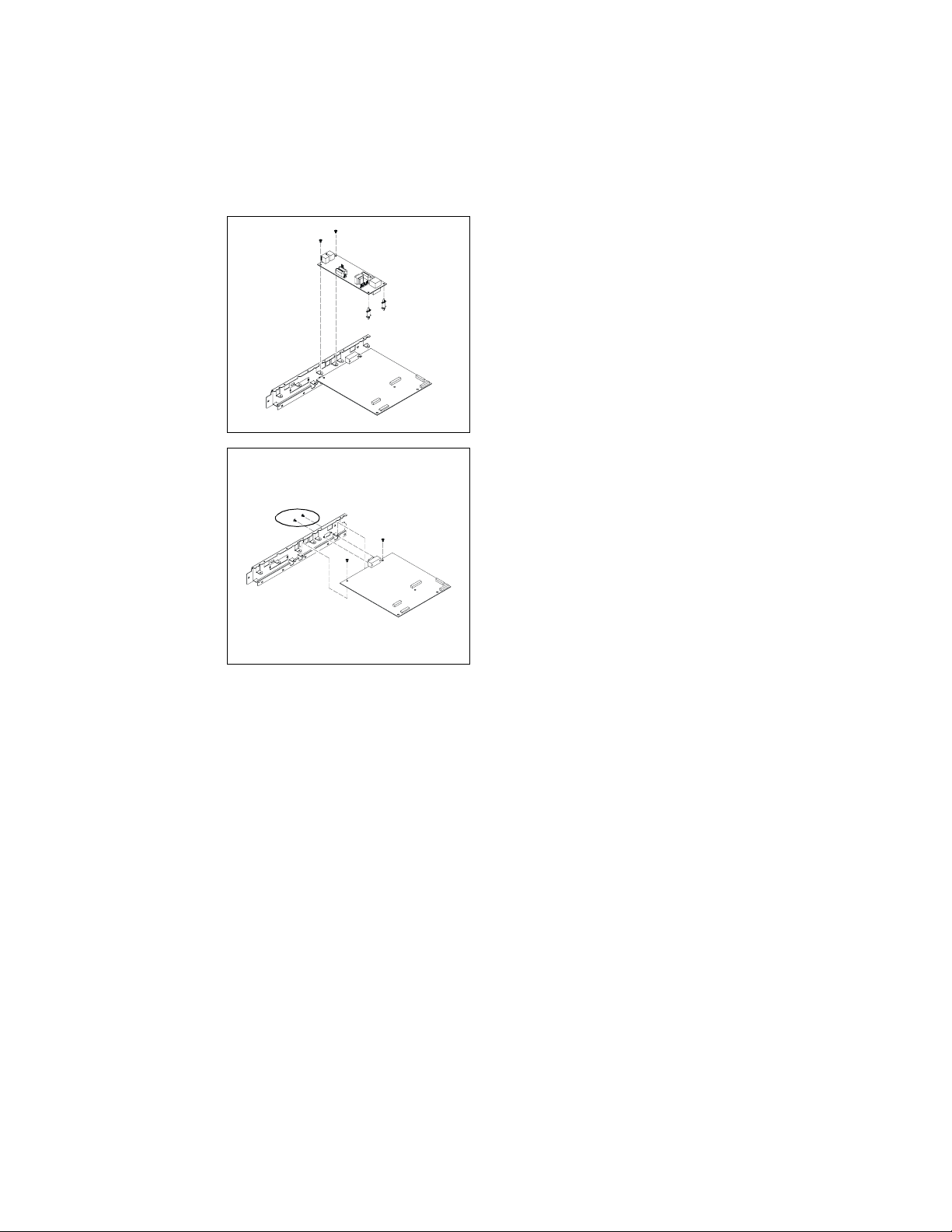

4-1. Fax Control ler Board Assem b ly and Disassem bl y ....................... ............1 1

(1) With Printer Controller Board ...........................................................11

(2) Without Pri nte r Co nt rol ler Board ............... .... .... ............... .... ............1 4

4-2. NCU Controller Board Assembly / Disassembly ......................................18

4-3. PWB-C Board Assembly / Disassembly ..................................................20

(1) With Fax Cont rol le r Board ..... .... .... ... ................ .... ... ................ ... .... .20

(2) With Fax and Printer Controller Board .............................................23

(3) With Printer Controller Board ...........................................................26

4-4. PWB-A Board Assembly / Disassembly ..................................................29

(1) With Fax or Printer Controller Board ...............................................29

4-5. Speaker and Ba tte ry Asse mb ly / Dis ass em b ly . .... ............... .... .... .... ........31

4-6. Fax Panel As se mbly / Disassemb ly .................. ............................... ........34

5. ADJUSTMENT ............ .... .... .... ............... .... .... ... ................ .... ... .... .... ............... .35

5-1. ADJUST JUMPER SWITCH ON NCU BOARD .......................................35

5-2. Upgrading Fax Co nt rol le r Firm war e ....... ... .... ................ ... .... ............... .... .36

(1) Upgrading Proc e dur e Using RS- 2 32C Inte rfa ce ............. .... .... ... .....36

(2) Upgrad in g P roc edure Using Teleph on e Li ne

(from fax mach in e to fax ma ch in e) ... .... .... .... ............... .... .... ............3 8

(3) Action Take n When Firm wa r e Upg rad in g Fai ls ................... .... ... .....40

(4) Upgrading Proc e dur e Using RS- 2 32C Inte rfa ce ............. .... .... ... .....41

6. Service Mod e Fun c tion ...................... .... ............... .... ............... ................ ... .....43

6-1. Descriptio n .......... ............ ........... ........ ........... ............ ........... ............ ........43

(1) HOW TO ENTER INTO SERVICE MODE ....................... ............... .43

(2) KEY DEFINITION ............................................................................43

(3) FUNCTIO N ITEMS ..........................................................................44

(4) Setting Proce du re ....... ............... .... ... ................ .... ... .... ............... .... .44

6-2. SERVICE’S CHOICE ...............................................................................45

(1) MARKETING AR EA ............................................. ............... ............46

(2) SHIPMENT DESTINATION .............................................................47

(3) MAINTENANCE COUNTER ............................................................47

(4) IU LIFE STOP MODE ......................................................................48

(5) ID ADJUST ......................................................................................48

(6) VG ADJUST ...................... ............... ................ ............... ............... .48

(7) LEADING EDGE ERASE .............. ............... ............... ............... .....49

(8) TRAILING EDGE ERASE ............................. ............... ............... .....49

(9) VERTICAL EDG E E RASE . ............... .... ................ ... ................ ... .....49

(10) LOOP ADJUST (TRAY1), (TRAY 2-5), (BYPASS) ..........................49

(11) PRIORITY FLS ................................................................................50

(12) TX SPEED .......................................................................................50

(13) RX SPEED ......................................................................................50

(14) TX LEVEL ........................................................................................50

(15) RX LEVEL .......................................................................................51

iii

Page 6

(16) DTMF LEVEL ..................................................................................51

(17) CNG LEVEL .............................. ............... ............... ........................5 1

(18) CED LEVEL .....................................................................................52

(19) ECM MO DE .... ............... ................ .............................. ............... .....52

(20) CODING SCHEME ............................................... ............... ............52

(21) REPORT DESTINATION ................................................................53

(22) TONER EMPTY REPORT .............................................................. .54

(23) IU LIFE REPORT .......... .......................................... ........................54

(24) MAINTENANCE REPORT ..............................................................54

(25) PROTOC OL REPORT .............. ............... .... ............... .... ............... .54

(26) CUSTOMER ID .................................................... ...........................54

6-3. ADJUST ....... ........... ............ ....... ............ ........... ............ ........... ........... .....5 5

(1) PRN MAIN REGIST Ad1 .................................................................55

(2) PRN SUB REG IST Ad2 .............................................................. .....56

(3) CCD M AIN ZOOM Ad3 ....................................................................56

(4) CCD SUB ZOOM Ad4 .....................................................................57

(5) CCD MAIN REGIST Ad5 ... ..............................................................57

(6) CCD SUB REGIST Ad6 ...................................................................58

(7) ADF SUB ZOOM Ad7 ......................................................................58

(8) ADF MAIN REGIST Ad8 ..................................................................59

(9) ADF SUB REGIST Ad9 ...................................................................59

(10) ATDC GAIN Ad10 ......................................... ...................................60

(11) Model Set tin g Ad1 1 .... ............... .... ... .... ................ ... .... ............... .... .60

(12) Serial number Ad12 ....................... ... ................ .... ............... .... ........60

6-4. COUNTER ... ................... ................... ................... ................... ................ 61

(1) Total Coun ter ...... ............... .... ............... ................ ... ................ ... .....61

(2) Size Counter ... .... .... .... ............... .... ... ................ .... ... .... ............... .... .61

(3) PM counte r ................. ............... ............... ............... ........................61

(4) Maintenanc e coun te r ......... .... ............... .... .... .... ............... .... .... ........62

(5) Supplies Life C ount er ............ ............... .... .... ............... .... .... ............62

(6) Applicati on Cou nter ........... .... ............... ................ ... ................ ... .....62

(7) Misfeed Counte r . .... ............... .... .... ... ................ .... ... ................ ... .... .62

(8) Trouble co u nte r .......... ... ................ ... ................ ............... .... ............6 3

(9) Paper Size Counter .........................................................................64

6-5. Display . ............... ................ ............... ............... ............ ............... ............ 6 5

6-6. FAX SET ..................................................................................................66

(1) PAPER FEED TEST ................................. .......................................66

(2) PROCESS CHECK .........................................................................66

(3) ATDC SENSOR ADJUST .............. .......................................... ........67

(4) PRINT TEST PATTERN ..................................................................67

(5) ADF FEED TEST .............................................................................67

(6) COPY ADF GLASS AREA ..............................................................68

(7) CCD M OVE T O HOME ...................................................................68

(8) UPLOAD FIRMWARE ......................................................... ............68

(9) FAX RES. COPY TEST ...................................................................68

6-7. SOFT SWITCH ........................................................................................69

6-8. REPORTING ........................................................................................... 70

iv

Page 7

(1) SERVICE DATA LIST ......................................................................70

(2) ERROR CODE LIST .............. .......................................... ................73

(3) T.30 PROTOCOL LI ST .. .... .... .... ............... .... .... .... ............... .... ... .... .74

6-9. Administrator number registration ............................................................77

6-10.Fixed z oo m change ............ ............... ............... ............... .... ............... .....78

6-11.FACTORY TEST .....................................................................................79

6-12.CLEAR DATA ................. .......................................... ...............................79

(1) DRAM CLEAR ....................... ............... ................ ...........................79

(2) SRAM CLEAR ............... ................ ... ................ ............... ............... .79

(3) TOTAL COUN T ................. .... ............... .... ............... .... ............... .....79

(4) PM COUNTER .................. ............... ............................... ............... .79

(5) MEMORY CLEAR ...........................................................................80

(6) TOTAL CLEAR ...................... .... ............... ............... .... ............... .... .80

6-13.SECURITY ..............................................................................................81

(1) Total Coun ter coun ti ng .. ................ ... ................ ............... .... ............8 1

(2) Size counter count ing .................... ... .... ................ ... .... .... ............... .82

(3) Plug-in coun te r cop ying En ab le /Dis a bl e ........... ............... .... .... ........82

(4) Machine co un te r ............ .... ............... .... ................ ............... .... ........82

7. Soft Switch Set ................................................................................................83

7-1. Descriptio n .......... ............ ........... ........ ........... ............ ........... ............ ........83

7-2. Default setting ..........................................................................................83

(1) Country for each Marketing area .......... ................ ... .... ............... .... .83

7-3. Default softs w itch setting for ea ch M ark e t ar ea .... ............... .... ............... .84

7-4. Soft Switch definition ...............................................................................86

(1) SOFT SWITCH: 01 ..........................................................................86

(2) SOFT SWITCH: 02 ..........................................................................87

(3) SOFT SWITCH: 03 ..........................................................................88

(4) SOFT SWITCH: 04 ..........................................................................89

(5) SOFT SWITCH: 05 ..........................................................................90

(6) SOFT SWITCH: 06 ..........................................................................91

(7) SOFT SWITCH: 07 ..........................................................................92

(8) SOFT SWITCH: 08 ..........................................................................93

(9) SOFT SWITCH: 09 ..........................................................................94

(10) SOFT SWITCH: 10 ..........................................................................95

(11) SOFT SWITCH: 11 ..........................................................................96

(12) SOFT SWITCH: 12 ..........................................................................97

(13) SOFT SWITCH: 13 ..........................................................................98

(14) SOFT SWITCH: 14 ..........................................................................99

(15) SOFT SWITCH: 15 ..........................................................................100

(16) SOFT SWITCH: 16 ..........................................................................100

(17) SOFT SWITCH: 17 ..........................................................................101

(18) SOFT SWITCH: 18 ..........................................................................102

(19) SOFT SWITCH: 19 ..........................................................................103

(20) SOFT SWITCH: 20 ..........................................................................104

(21) SOFT SWITCH: 21 ..........................................................................105

(22) SOFT SWITCH: 22 ..........................................................................106

(23) SOFT SWITCH: 23 ..........................................................................107

v

Page 8

(24) SOFT SWITCH: 24 ..........................................................................107

(25) SOFT SWITCH: 25 ..........................................................................108

(26) SOFT SWITCH: 26 ..........................................................................109

(27) SOFT SWITCH: 27 ..........................................................................110

(28) SOFT SWITCH: 28 ..........................................................................111

(29) SOFT SWITCH: 29 ..........................................................................112

(30) SOFT SWITCH: 30 ..........................................................................113

(31) SOFT SWITCH: 31 ..........................................................................114

(32) SOFT SWITCH: 32 ..........................................................................114

(33) SOFT SWITCH: 33 ..........................................................................115

(34) SOFT SWITCH: 34 ..........................................................................116

(35) SOFT SWITCH: 35 ..........................................................................117

(36) SOFT SWITCH: 36 ..........................................................................118

(37) SOFT SWITCH: 37 ..........................................................................119

(38) SOFT SWITCH: 38 ..........................................................................120

(39) SOFT SWITCH: 39 ..........................................................................121

(40) SOFT SWITCH: 40 ..........................................................................122

(41) SOFT SWITCH: 41 ..........................................................................123

(42) SOFT SWITCH: 42 ..........................................................................123

(43) SOFT SWITCH: 43 ..........................................................................124

(44) SOFT SWITCH: 44 ..........................................................................124

(45) SOFT SWITCH: 45 ..........................................................................125

(46) SOFT SWITCH: 46 ..........................................................................126

(47) SOFT SWITCH: 47 ..........................................................................127

(48) SOFT SWITCH: 48 ..........................................................................127

(49) SOFT SWITCH: 49 ..........................................................................128

(50) SOFT SWITCH: 50 ..........................................................................129

(51) SOFT SWITCH: 51 ..........................................................................130

(52) SOFT SWITCH: 52 ..........................................................................131

(53) SOFT SWITCH: 53 ..........................................................................131

(54) SOFT SWITCH: 54 ..........................................................................132

(55) SOFT SWITCH: 55 ..........................................................................133

(56) SOFT SWITCH: 56 ..........................................................................133

(57) SOFT SWITCH: 57 ..........................................................................134

(58) SOFT SWITCH: 58 ..........................................................................134

(59) SOFT SWITCH: 59 ..........................................................................135

(60) SOFT SWITCH: 60 ..........................................................................136

(61) SOFT SWITCH: 61 ..........................................................................137

(62) SOFT SWITCH: 62 ..........................................................................138

(63) SOFT SWITCH: 63 ..........................................................................138

(64) SOFT SWITCH: 64 ..........................................................................139

8. Fax Protoc ols ... ............... ............... ................ .............................. ............... .....140

8-1. G3 ECM (G3 Error Correction Mode) ......................................................140

8-2. Line Contro l ........ .... ............... .... ............... ................ .... ............... ............141

(1) Procedure of G3 mode c omm un ic ation ........ ............... .... .... ............1 41

9. Error Code .......................................................................................................142

9-1. Reception .................................................................................................142

9-2. Transmission ...........................................................................................144

vi

Page 9

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward

machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal, it is conceivable that the combination of the

machine and the room air could present a hazardous

combination. This is because heat (such as from

fusing units) and electrical arcs (which can occur

inside switches) have the ability to ignite flammable

substances, including air.

When installing a machine, check to see if there

is anything nearby which suggests that a potential hazard might exist. For example, a laboratory

might use organic compounds which, when they

evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The

presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

know what effect may be caused by altering any

aspect of the machine’s design. Such changes have

the potential of degrading product performance and

reducing safety margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical size

differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace or

eliminate any fuse (including temperature fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion other

than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica equipment has gained a reputation for being

reliable products. This has been attained by a combination of outstanding design and a knowledgeable

service force.

The design of the equipment is extremely important.

It is the design process that determines tolerances

and safety margins for mechanical, electrical, and

electronic aspects. It is not reasonable to expect

individuals not involved in product engineering to

General Safety Guidelines

This equipment has been examined in accordance

with the laws pertaining to various product safety

regulations prior to leaving the manufacturing facility

to protect the operators and service personnel from

injury. However, as with any operating device, components will break down through the wear-and-tear of

everyday use, as will additional safety discrepancies

be discovered. For this reason, it is important that the

technician periodically performs safety checks on the

equipment to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the equipment is

disconnected from its power source before continuing.

• Look for sharp edges, burrs, and damage on all

external covers and copier frame.

• Inspect all cover hinges for wear (loose or bro-

ken).

• Inspect cables for wear, frays, or pinched areas.

vii

Page 10

SAFETY PRECAUTIONS

• Ensure that the power cord insulation is not dam-

aged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND) of

the power cord to the frame of the copier -- ensure

continuity. An improperly grounded machine can

cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to any

electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

• Do not make any adjustments outside of the

specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to

clean parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that the

alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each piece

of equipment must be thoroughly inspected with respect to safety considerations as part of every routine

service call. The operability of the copier, and more

importantly, the safety of those who operate or service

the equipment, are directly dependent upon the conscientious effort of each and every technician.

Remember...when performing service calls, use good

judgment (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the equipment as well as those who service the copier depend

on it!

viii

Page 11

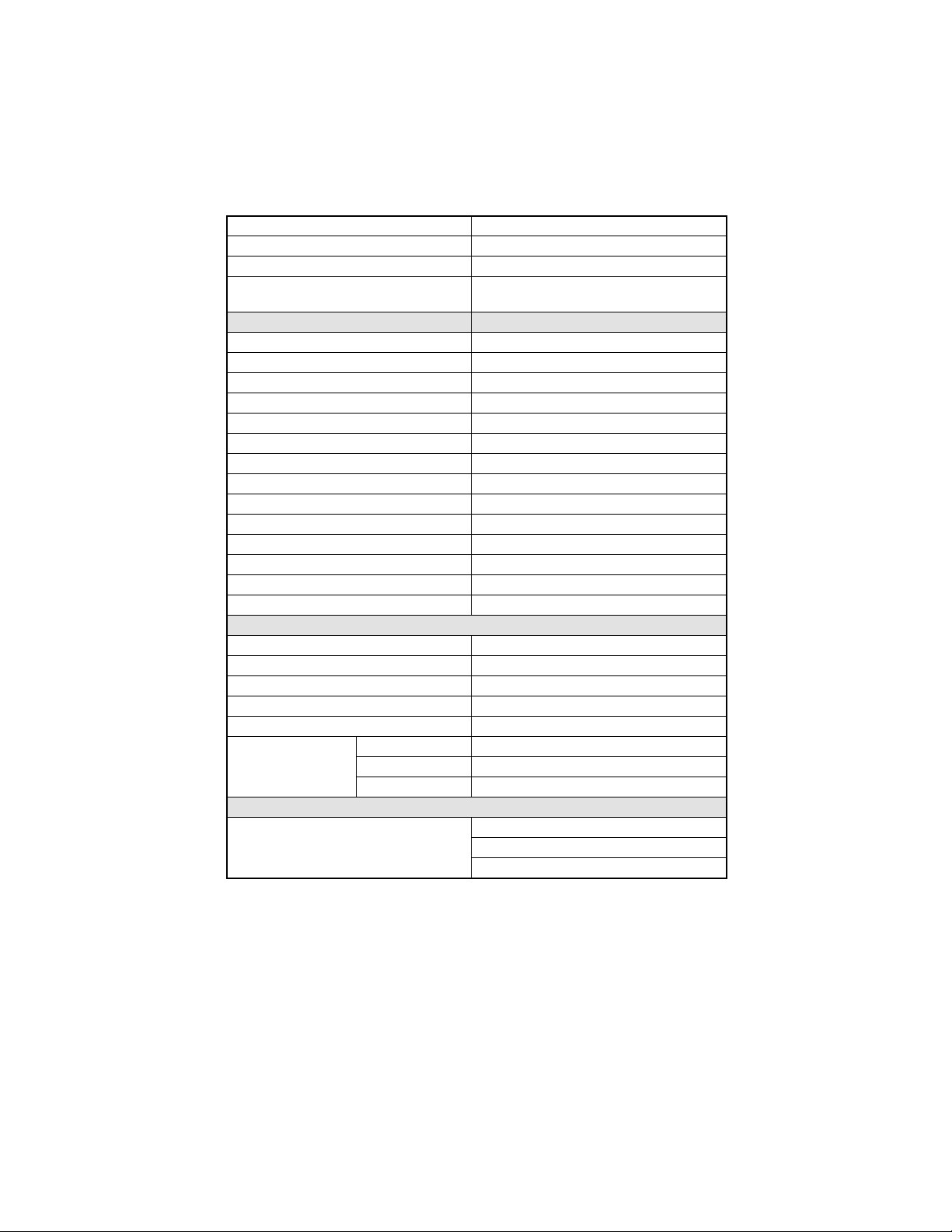

1. Specifications

Item Specifications

General

Protocol (Compatibility) Group3

Multi access Yes

Applicable line PSTN, PABX

Maximu m da t a rat e (bp s) 33.6k bp s, Auto m atic fall back

Coding scheme MH/MR/MMR/JBIG

Dual line No

Intern et fax Option

Error correction mode (ECM) Yes (FAX NIC required)

Standar d memory 4 MB

Option al memory 8 MB

Transmission

Max. Docu ment (Origi nal) size A3

Transmission speed

Broadcasting

3.0 sec.

ITU-T No.1, 33.6k with JBIG (A4-L)

143 Loca tio n per sessio n

Function Location

One to uc h key 27

Speed dial 100

On the fly (Ten ke y) 16

Total 143

Memory TX Yes

Quick me m o r y TX Yes

ADF TX Yes

Manual TX Yes

Timer TX Yes

Polling TX Yes - 30 files

Book TX Yes

Confidential mailbox TX Yes

Sub-address [SUB] capability Yes

Password [PWD] capability Yes

Relay initiate Yes

Relay broadcast Yes

Batch TX Yes

F code function Yes

1

Page 12

Item Specifications

Standa r d: 20 3 × 98 dpi / 8 × 3.85 dpm

TX resolution

Receiving

Max. recording paper size A3

Confidential mailbox RX Yes

Selective polling re ception Yes

Memory RX Yes

Memory RX mode Yes

RX reduction Yes

RX mode Auto/Manual

Printing mode

Footer Yes

RX resolution

Dialing

One-to uc h 27 key

Auto D i al

Auto redial Yes

Last redial Yes

Chain dial Yes

Combination dial Yes

Phone Book Yes

On-ho ok dial Yes

Scanning

Scanner type CCD

Size of document A5 - A3

Max. effective scan width

Maximum numbe r o f st acked orig inals 50 page s

Contra st contr ol Normal/ Dark/Li gh t

Gray scale 256 levels

Recording

Printer type Laser

Speed dial 100

Program mi ng dial 4 key (No.24 - No. 27 )

Group dia l 27

Fine: 203 × 196 dpi / 8 × 7.7 dpm

S-Fin e: 40 6 × 392 dpi / 16 × 15.4 dpm

100%

Bottom cut

Auto re du ction (70% - 10 0% )

Standa r d: 20 3 × 98 dpi / 8 × 3.85 dpm

Fine: 203 × 196 dpi / 8 × 7.7 dpm

S-Fin e: 40 6 × 392 dpi / 16 × 15.4 dpm

4896 pixels per scanning line length of 300 mm ±

1%

2

Page 13

Item Specifications

Printing resolution 600(H) × 600 (V) dpi

Smoothing Yes

Continuous printing sp eed

Report

TX confirmation report Yes

TX error report Yes

RX result report Yes

Activity report Yes

Memory data list Yes

Memory image list Yes

Key setting list Yes

Broadcast result report Yes

Relay broadcast report Yes

Machine status list Yes

Consum a ble or d er report Yes

PCL configuration page (for printer option) Yes

PCL font list (for printer option) Yes

Backup RAM lost report Yes

Other Features

Speaker Yes

Daylight saving time Yes

Ext.phone connector Yes

RTC backup 2.5 years

Multi-c opy 99 pa ge s

No toner Yes

Substitute receiving

PC Function

RS232 Por t func ti on

No paper Yes

Paper jam Yes

15 pp m ( 71 15F)

18 ppm (7118F)

LSD initial set

Class 1 function

TWAIN scanner function

3

Page 14

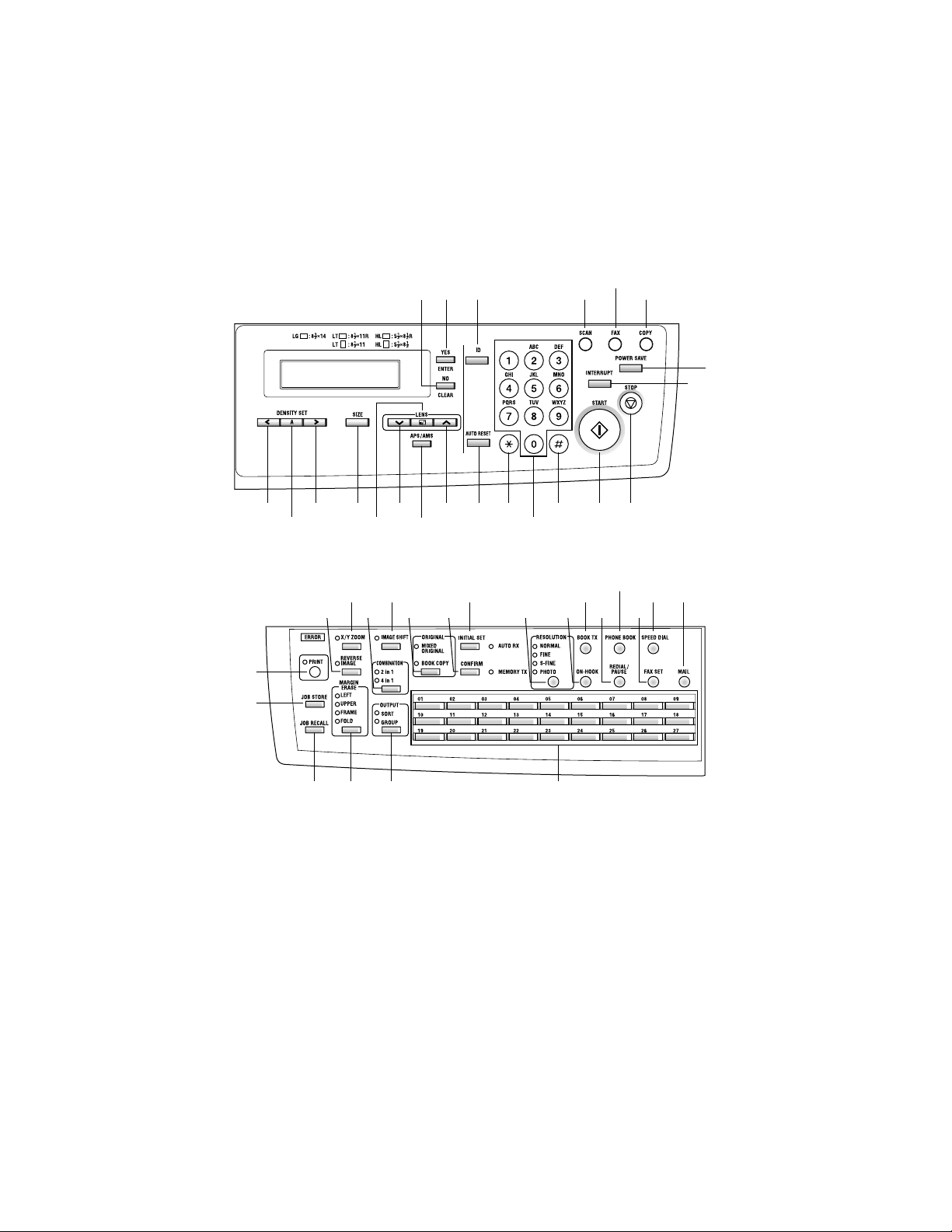

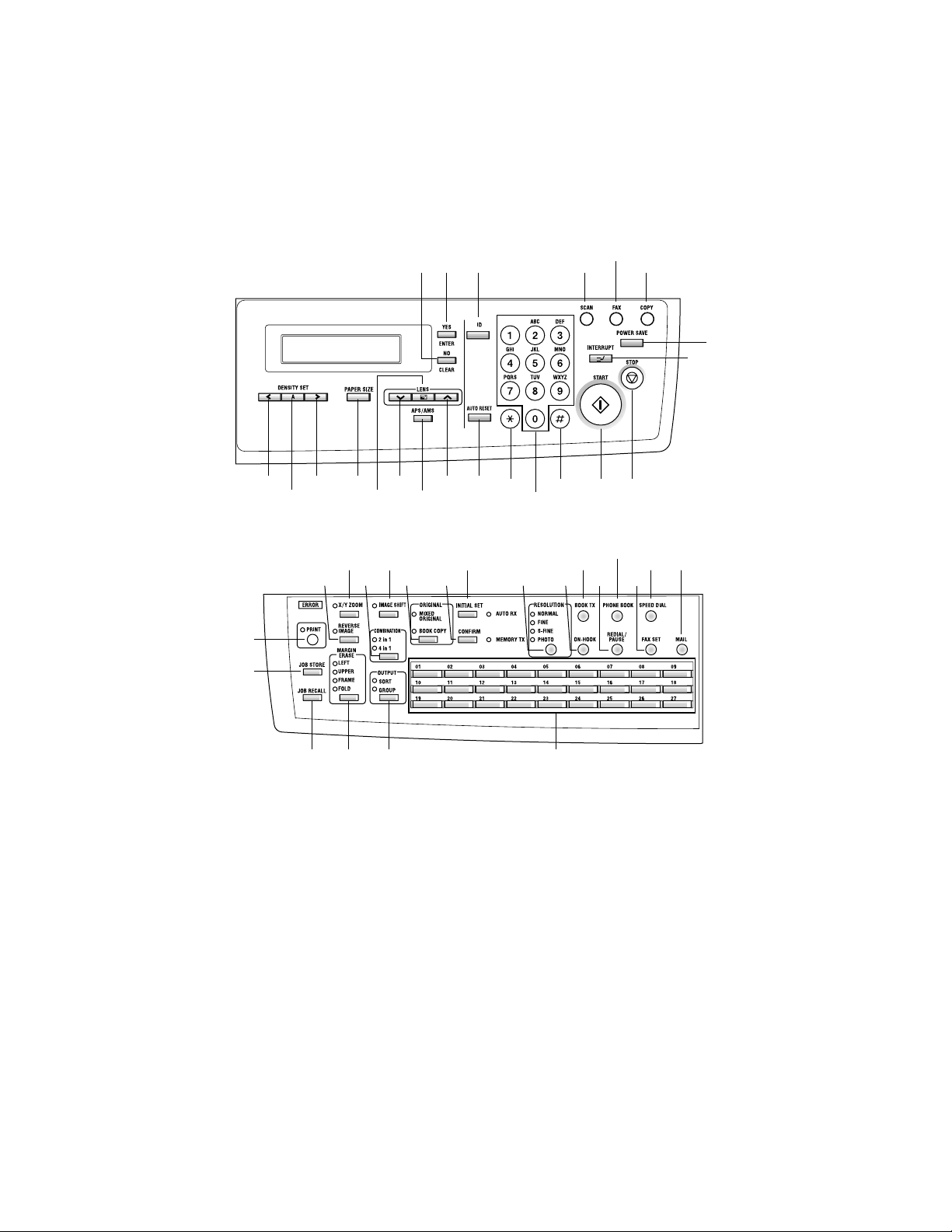

2. Panel Descr ipt ion

Except Europe Area

11

1291314

10

8

7

22

43

42

21 16

37

40 39 23

41

5315171920

18

4

16

2

27

293235

25 24

26283031333438 36

4

Page 15

Europe Area

11

1291314

10

8

7

22

43

42

21 16

37

40 39 23

41

18

315171920

4

165

2

27

293235

25 24

26283031333438 36

5

Page 16

Key Function

No. Key Function

1 Start Key

2Stop Key

3Auto Reset Key

4 KEYPAD

5 Tone Key Send tone signal.

6 Extern al Key External / Intern al function.

7 Interrupt Key Sets the copier into, or lets it leave the Interrupt mode.

POWER SAVE

8

Key

9ID Key

10 Co py Key Chan g e pa ne l di splay to Copy mode.

Start s a fax transmis sion .

Starts copying.

Stops the fax transmission or reception.

Stops the multi-page copy operation.

Return to the initial setting

Initial: Copy mode

Number of Copies 1

Zoom ratio: Full size

Copy Func tion: Ini t ia l se tt i ng by us er

Density : Initia l setting by us er

Copy mod e: Initia l se tt i ng by us er

Paper source: I ni ti a l se t ti ng by us er

Initial: Fax m ode

Date, Time, Memory volume, Mes-

Standby:

Under communication

RX in Memory:

RX in Mailbox:

Machine Error : Error message

Substitute RX in Memory: D isplay of memory RX

Number of RX pages: Content of error

Timer TX in Memory Display of standby and T

Polling TX in Memory Display of standby and P

Input fax number.

Input num er a l i n registration of name.

Input speed dial number.

Specify fax function o r initial set item.

Sets the copier into the Energy Saver mode.

If default of Personal id e nti fic a tio n is ON , it chang e s from t he

present section and is made a section number input screen.

sage prompting of the document

loading.

Communication status, Remote Station’s ID, Memory vol um e, Me ss a ge

prompting of the document loading.

Number of RX pages, Memory volume, Message prompting of the document lo ading.

Display of Mailbox RX, Memory volume, Message prompting of the document lo ading.

6

Page 17

No. Key Function

11 Fax Key Change panel display to Fax mode.

12 Scan Key Change panel display to Scan mode.

13 YES / ENTER Key Validate the item and number or character entered.

14 No/Clear Key

15

16

LENS Key, Up and

Down Keys

17

18 APS / APM Key Press to select either Auto Paper or Auto Size.

PAPER SIZE Key

19

(SIZE Key)

20

DENSITY Key, left

21

and right Keys

22

23 One-touch Dial Keys

24 Ma il Key

25 Spe ed Dial Key Call Speed dial.

26 FAX SET Key Call Fax communication function.

TEL BOOK Key

27

(PHONE BOOK Key)

28 Redeal/Pause Key

Clear number or character entered.

Back to the previous display.

Used to select a preset enlargement or reduction ratio.

With each press, a zoom ratio between ×0.50 and ×2.00 in

0.01 increments is selected.

Used to specify the selection above or below in setting

scree ns and m e nus.

Press to select the paper size.

Used to specify the scanning density of copies.

Used to spec if y the s el ec ti on at th e left or r ig ht in setting

screens.

1. One-touch di al 01 - 27

2. Gro up dial 01 - 27

3. Program dial 24 - 27

4. Input @ in registration of name.

5. Input “.” (dot signal) in registration of name.

6. Input “_” in registration of name.

7. Input “+” in registration of dial number.

8. Input “-” (minus signal) in registra t io n of dial number.

9. Input symbols in registration of name.

10. Input Europe an font in r e gistrati on of name.

11.When e nt e ring a n u mbe r or c ha rac t er, delete the char ac ter

or the plac e w ith cursor.

12. When entering a number or character, insert a space in

the place with cursor.

Change the function of One-touch key to either selection of

the registered destina tion or inpu t of cha r ac ter.

Retrieval and call R e gistered dial.

Call the last di aling numbe r.

When entering the dial numb er, ins ert a pause functio n in th e

place wit h cur sor.

7

Page 18

No. Key Function

29 Book TX Key Call book TX function.

30 ON- H O O K Key Press t o ans we r the call. Press again to hang up .

31 Resolution Key Select the resolution and the image mode for transm ission.

32 Initial Set Key

33 Confirm Key

34 Or iginal Key

35 IMAGE SHIFT Key Press to select the File Margin mode.

36 COMBINATION Key Press to select the Copy mode.

37 X/Y Zoom Key

38 REVERSE IMAGE Key

39 OUTPUT Key Press to select the finishing function.

ERASE Key

40

(MARGIN ERASE Key)

41 Job Reca ll Key

42 JOB STORE Key

43 PRINT Key / indicator

Set mac hi ne s ta tus, initia l set tin g for copy, Fax ope rations

and regis ter dials.

Display communication result.

Display machine counter.

Print repor t.

Select the Book Document ( page-by-p age)/Bo ok docum ent

(Spread).

Press t o make a copy with different zoo m ratios set for X

(horizontal) and Y (vertical) directions.

Press to copy an original with the o riginal ton al arrange ments r eversed.

Press to select the erase position.

Press to recall eit her one of the two jobs previously store d in

memory.

Press to select the Job Input mode. Two different jobs can

be programmed.

Lit while data received from personal computer is being

printed.

Blinks while data is being transferred.

For details, refer to the Printer Controller User Manual.

8

Page 19

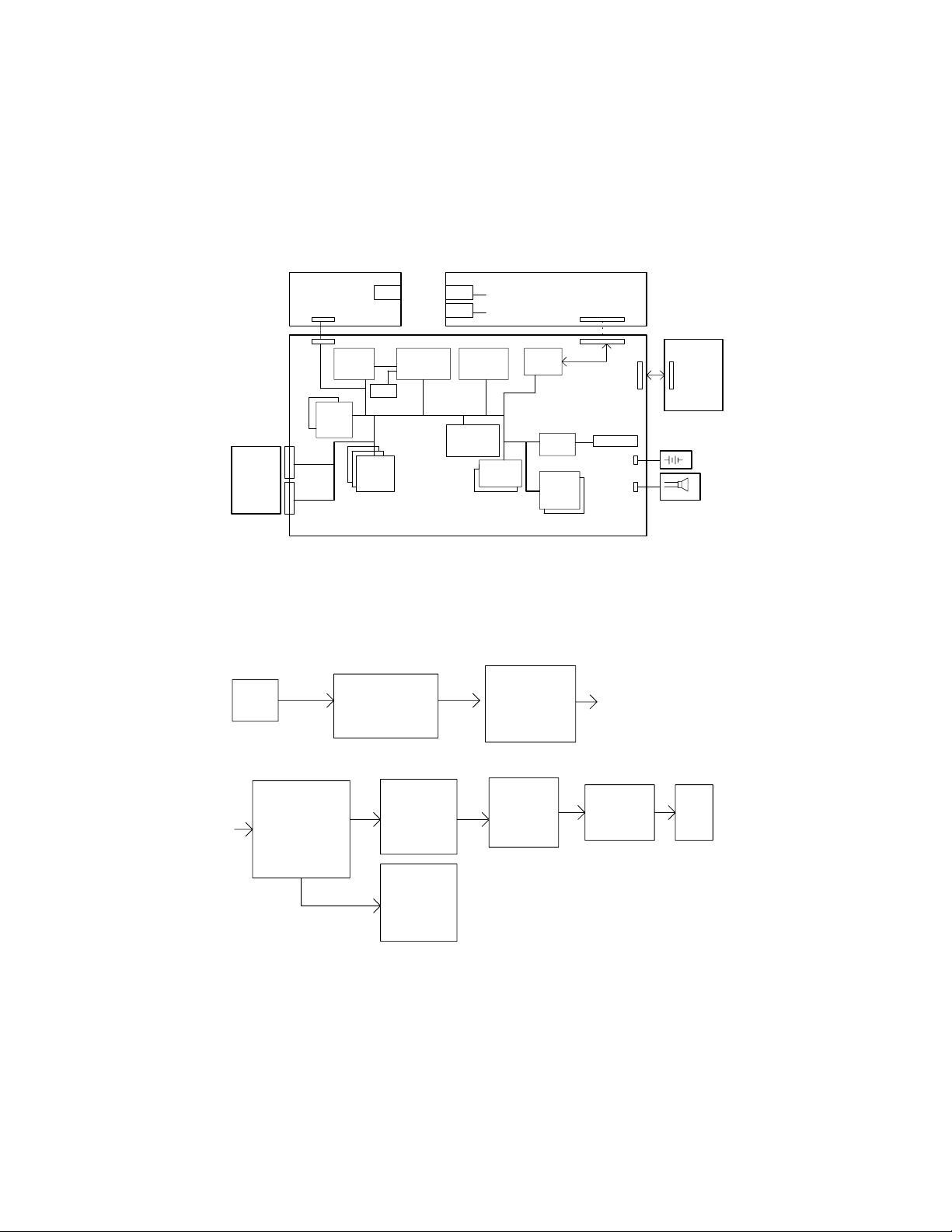

3. FAX CPU BLOCK DIAGRAM

FAX NIC

BOARD

JP5

OPTION

8MB

DRAM

Board

JP4

CN1

CN2

U1 U17 U40

NS32FX

164AV

25

U8/9

SRAM

32KX8

-70

2 Pices

U12/13/52

1. Memory TX Data Flow

CCD

PWB-C SDRAM

4MX16

JBIG FILE

FILE BUFFER

RTC

DRAM

1MX16b

3 Pices

RJ45

ASIC

NS32FX200

-25

U14

TEL

LINE

A/D BUS

DRAM

CONTROL

ASIC

NCU BOARD

CODEC

PM-22C

-33

FLASH

512KX16

-90

U4/61

U12/ U13/ U52

FAX CP U

EDO DRAM

FILE

MEMORY

MODEM

FM336

U27

U23

S-ASIC

EPROM

64KX8

-70

2 Pices

U5/6

CN1

Serial

CN6

CN5

COPIER

BOARD

JP2 JP14

BATTERY

CN3

CN7

SPEAKER

4507M503AC

U40

FAX PM-22C

ENCODE TTI

DECODE JBIG

ENCODE MH

MR...

U12/ U13/ U52

FAX CPU

DRAM

ENCODE

TEMP

BUFFER

FAX CPU

DRAM

DECODE

TEMP

BUFFER

U12/ U13/ U52

DRAM

FRAME

BUFFER

U12/ U13/ U52

9

MODEM

FM336

U23

NCU

4507M504AC

Page 20

2. Hook TX Data Flow

PWB-C SDRAM

CCD

4MX16

IMAGE DATA

PO BUFFER

U12/ U13/ U52 U12/ U13/ U52

FAX CPU

EDO DRAM

TEMP

BUFFER

DRAM

FRAME

BUFFER

3. TWAIN and C LASS1 Data F low

PWB-C SDRAM

4MX16

CCD

FAX PM- 22C

ENCODE

MH CODE

IMAGE DATA

PO BUFFER

U40 U12/ U13/ U52 U27

FAX CPU

EDO DRAM

TEMP

BUFFER

U12/ U13/ U52

FAX CP U

SCAN

BUFFER

U23

MODEM

FM336

U12/ U13/ U52

FAX CP U

SCAN

BUFFER

S-ASIC

FAX PM-22

ENCODE TTI

ENCODE IMAGE

DATA MH MR...

NCU

PC

U40

4507M505AC

4507M506AC

4. RX (NON ECM, MH or MR) an d Print out Data Flow

U12/ U13/ U52

SOFTWARE

DECODE

IMAGE

DATA

U12/ U13/ U52

FAX CP U

EDO DRAM

PRINT

TEMP

BUFFER

ENGINE

NCU

U12/ U13/ U52

EDO

FILE

MEMORY

IMAGE

ASIC

U23

MODEM

FM336

U40

PM-22

DECODE

IMAGE

DA TA

C-ASIC

U12/ U13/ U52

DRAM

FRAME

BUFFER

10

U12/ U13/ U52

DECODE

TEMP

BUFFER

U17

FX200

PWB-C

SDRAM

FAX PAGE

BUFFER

U40

PM-22

DECODE

IMAGE

DATA

4507M508AC

Page 21

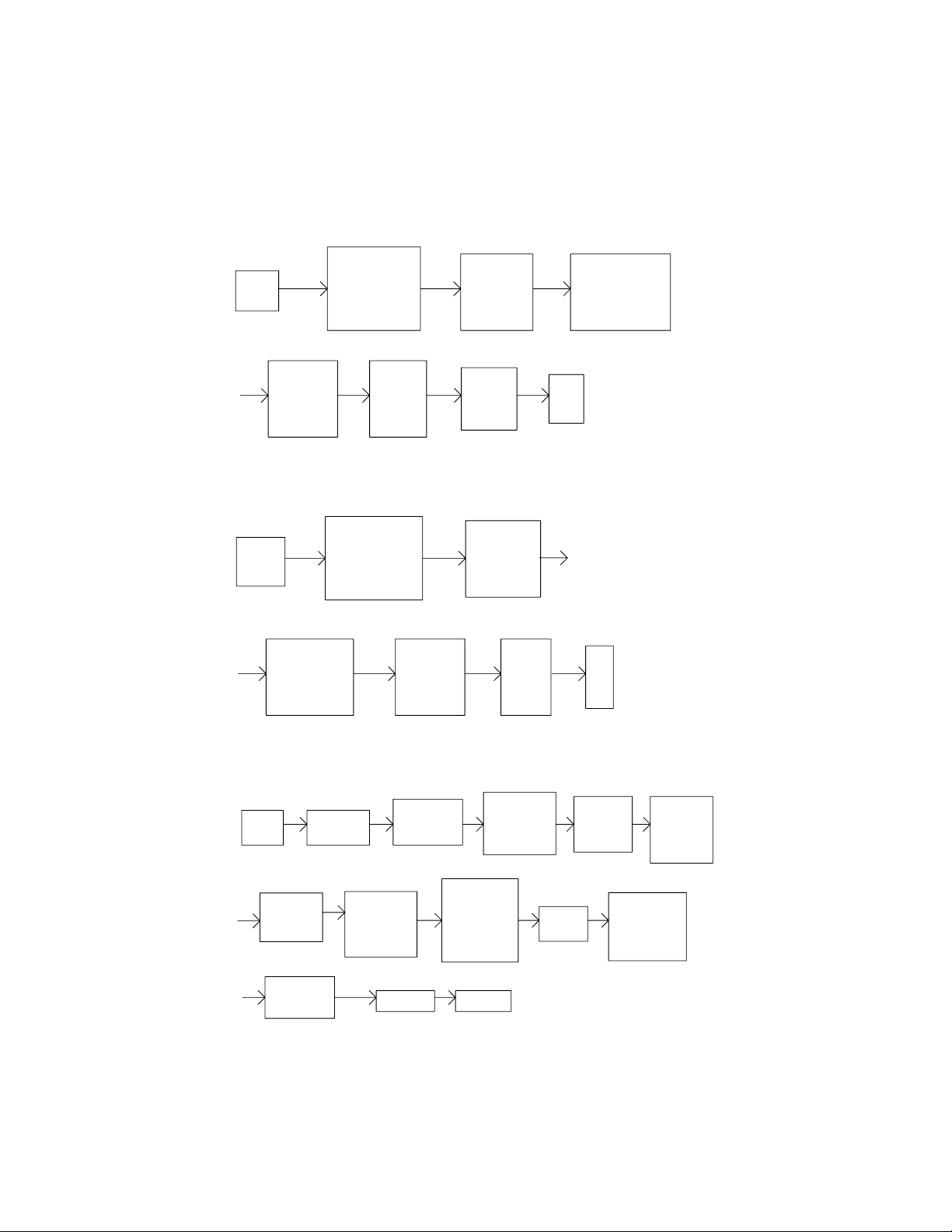

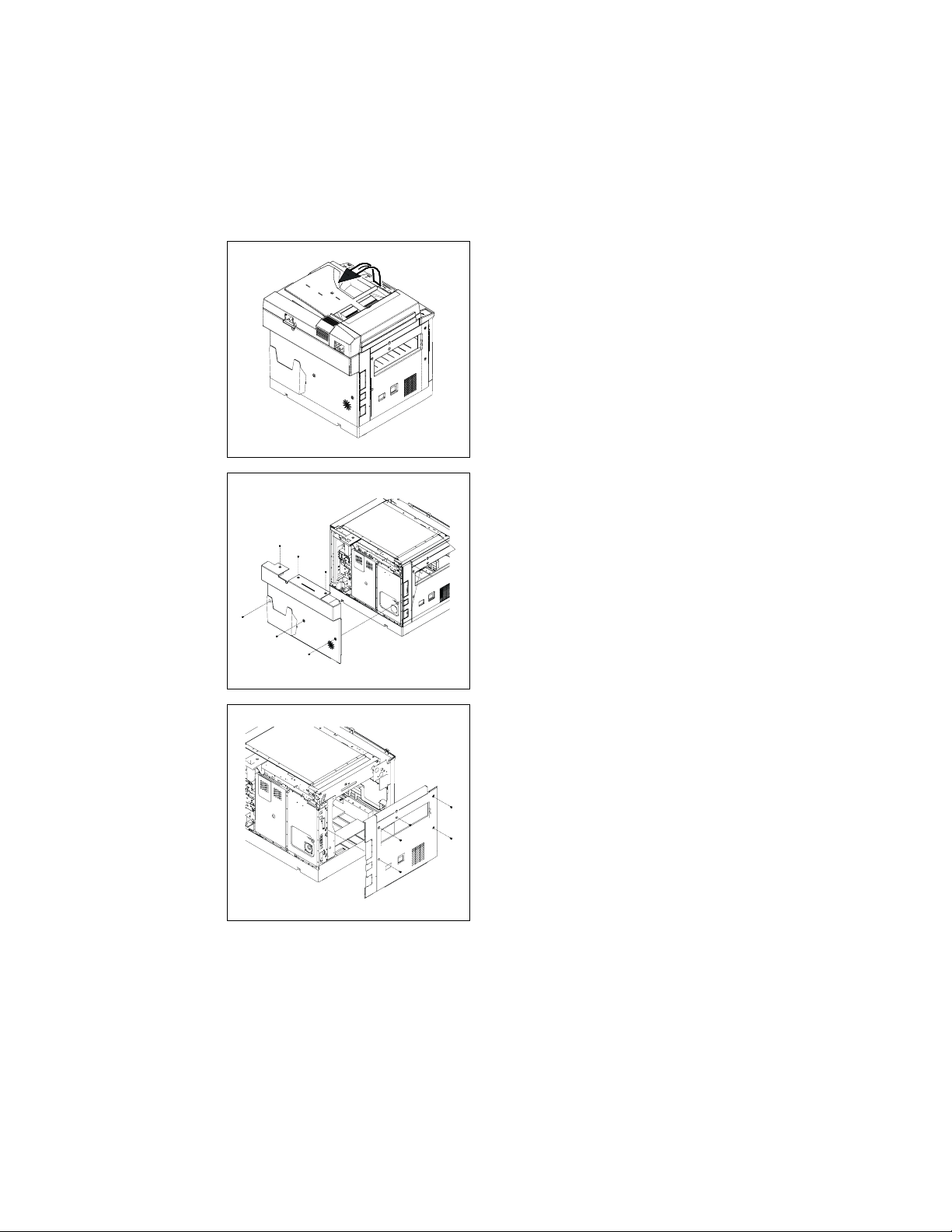

4. ASSEMBLY / DIASSEMBLY

e

4-1. Fax Controller Board Assembly and Disassembly

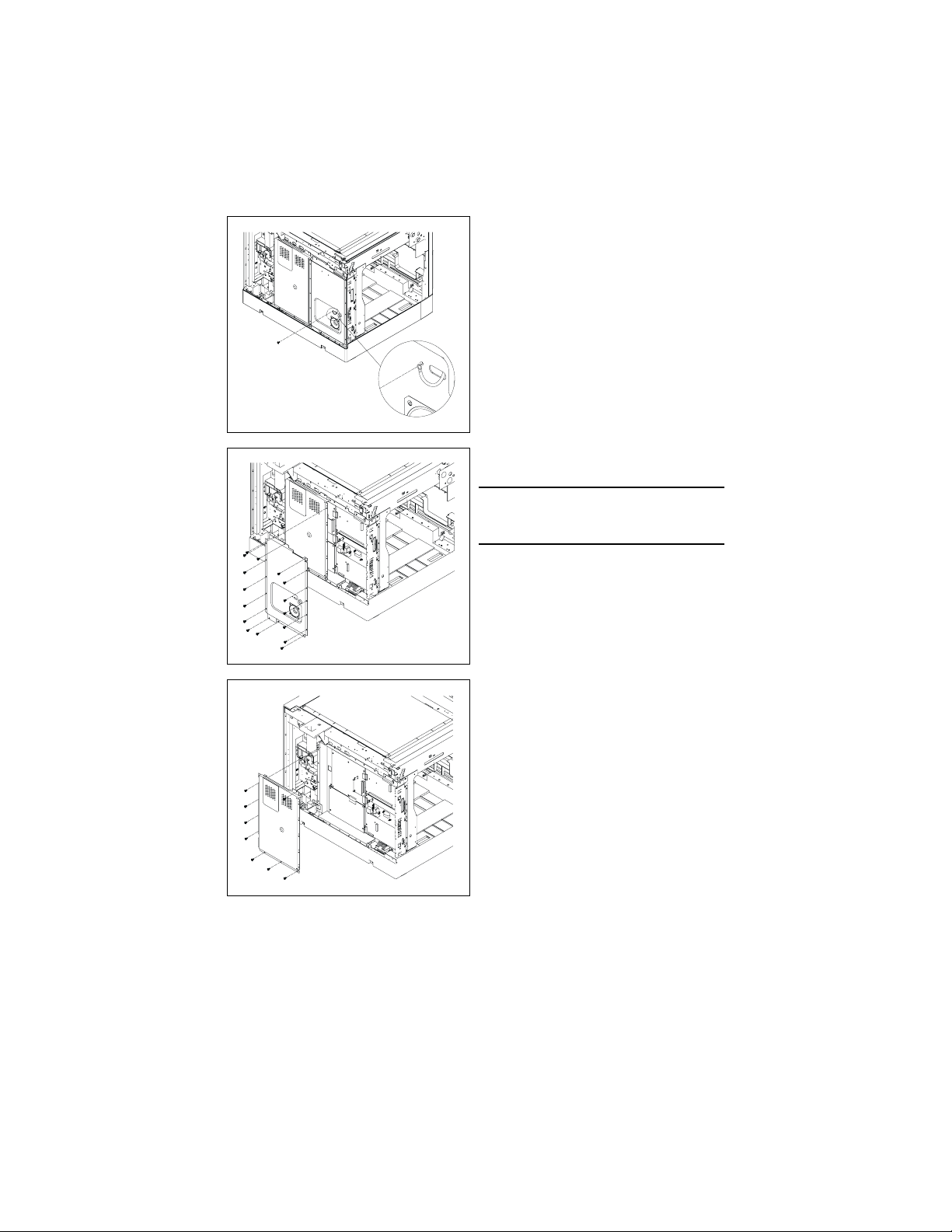

(1) With Printer Controller Board

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

4507D501AA

2. Re move the 6 screw s to r em ove the

Rear Cover and remove the Automatic

Document Feeder.

4507D502AA

4507D503AA

3. Re move the 5 screws to rem ove the Left

Cover.

11

Page 22

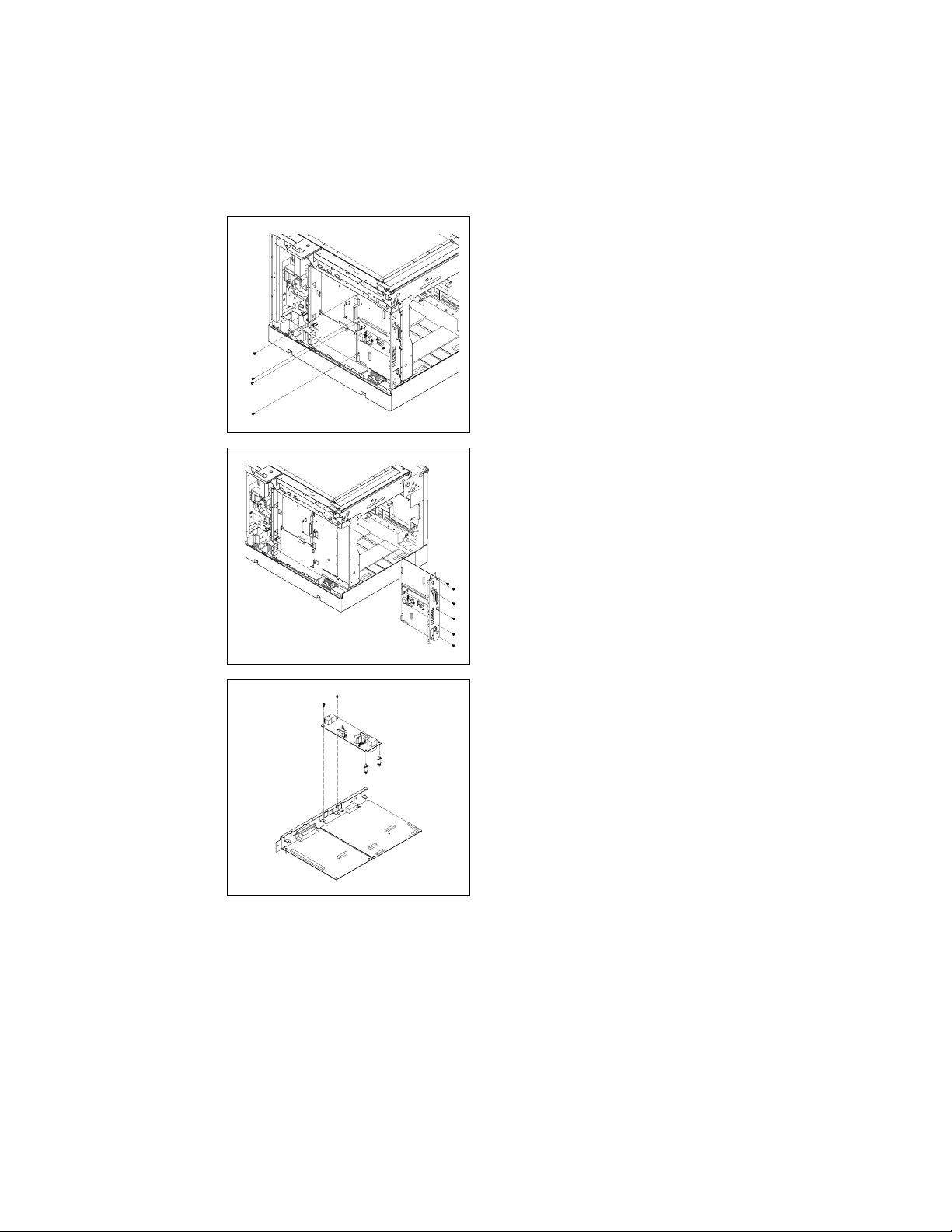

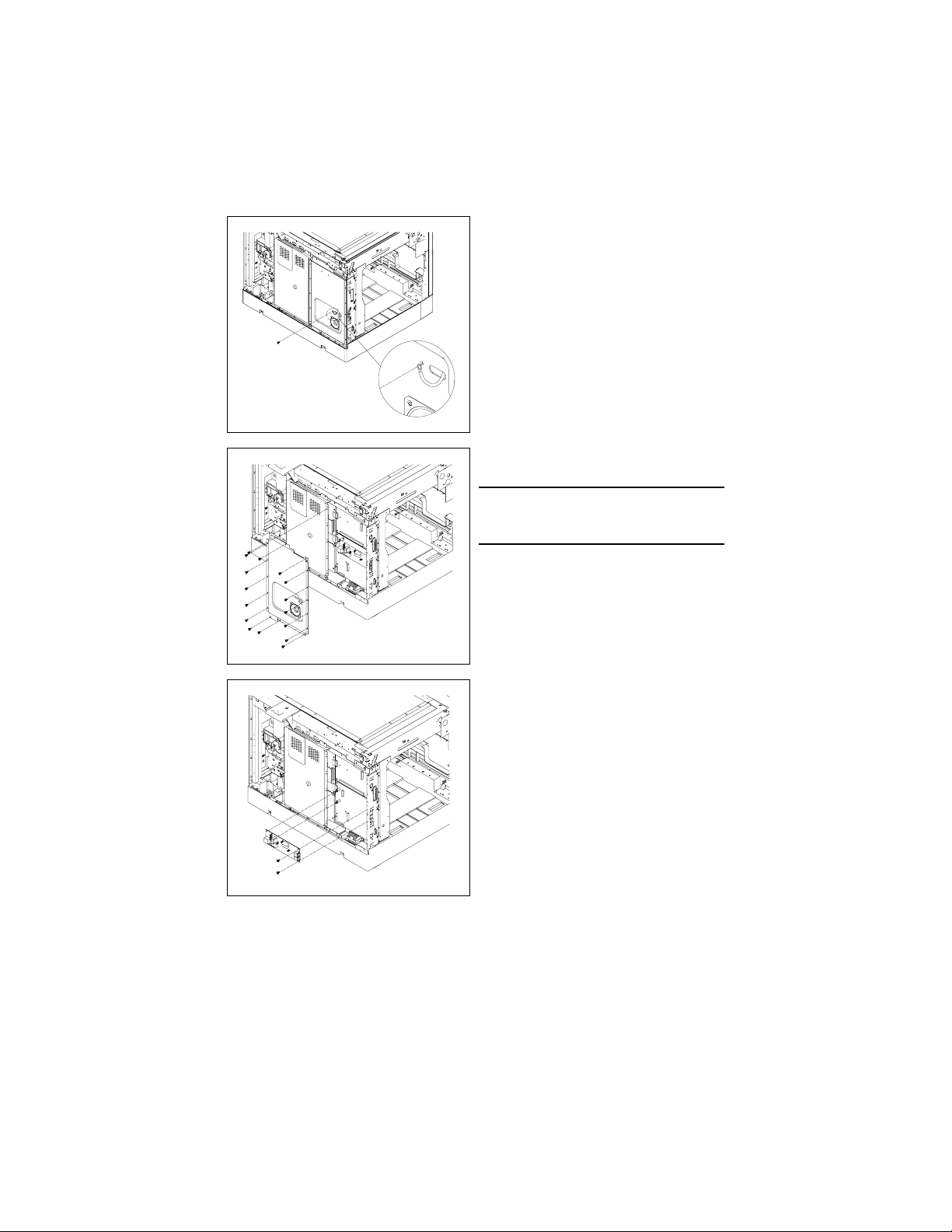

4507D504AA

4507D505AA

4. Re move the screw for th e gr ound wire of

the NCU Controller Board.

5. Remove the 16 screws to remove the

Fax Shield C over As sembly.

NOTE

• Remove the Speaker Connector before

removing the Fax Shield Cover Assembly.

4507D506AA

6. Re move the 8 screw s to r em ove the

Shield C over Assembly.

12

Page 23

4507D507AA

4507D508AA

7. Re move the 4 screw s for the Printer

Contro ller Board an d the Fax Contr olle

Board.

8. Remove the Battery C o nnector.

9. Re move the 6 screw s to r em ove the I/F

Bracket Assembly.

4507D509AA

10. Remove the 2 sc r ew s an d the 2 PW B

Supports to re move the NCU Controller

Board.

13

Page 24

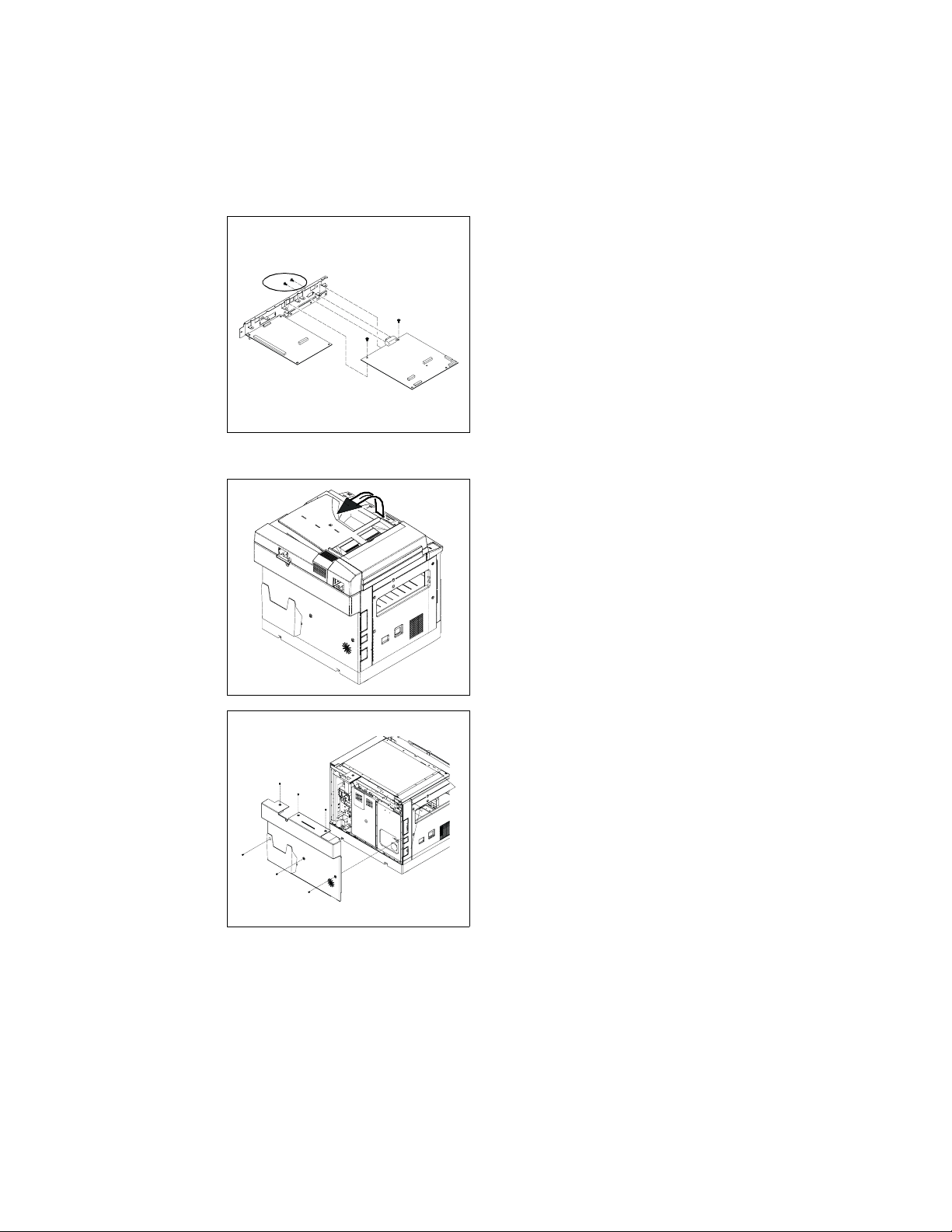

Shoulder Screws

e

4507D507AA

(2) Without Printer Controller Board

11. Remove th e 2 screws, the 2 shoulder

screws to remove the Fax Controller

Board.

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

4507D501AA

4507D502AA

2. Re move the 6 screw s to r em ove the

Rear Cover.

14

Page 25

4507D503AA

4507D504AA

3. Re move the 5 screws to rem ove the Left

Cover.

4. Re move the screw for th e gr ound wire of

the NCU Controller Board.

4507D505AA

5. Remove the 16 screws to remove the

Fax Shield C over As sembly.

NOTE

• Remove the Speaker Connector before

removing the Fax Shield Cover Assembly.

15

Page 26

4507D506AA

4507D511AA

6. Re move the 8 screw s to r em ove the

Shield C over Assembly.

7. Re move the 2 screw s for the Fax C o n troller Board.

8. Remove the Battery C o nnector

4507D512AA

9. Re move the 6 screw s to r em ove I/ F

Bracket Assembly.

16

Page 27

Shoulder Screws

10. Remove the 2 sc r ew s an d 2 PW B Supports to remove the NCU Controller

Board.

4507D513AA

11. Remove th e 2 screws, the 2 shoulder

screws to remove the Fax Controller

Board.

4507D514AA

17

Page 28

4-2. NCU Controller Board Assembly / Disassembly

e

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

4507D501AA

2. Re move the 6 screw s to r em ove the

Rear Cover.

4507D502AA

4507D503AA

3. Re move the 5 screws to rem ove the Left

Cover.

18

Page 29

4507D504AA

4507D505AA

4. Re move the screw for th e gr ound wire of

the NCU Controller Board.

5. Remove the 16 screws to remove the

Fax Shield C over As sembly.

NOTE

• Remove the Speaker Connector before

removing the Fax Shield Cover Assembly.

4507D515AA

6. Re move the 2 screw s an d the 2 P WB

Supports to re move the NCU Controller

Board from the Fax Controller Board.

19

Page 30

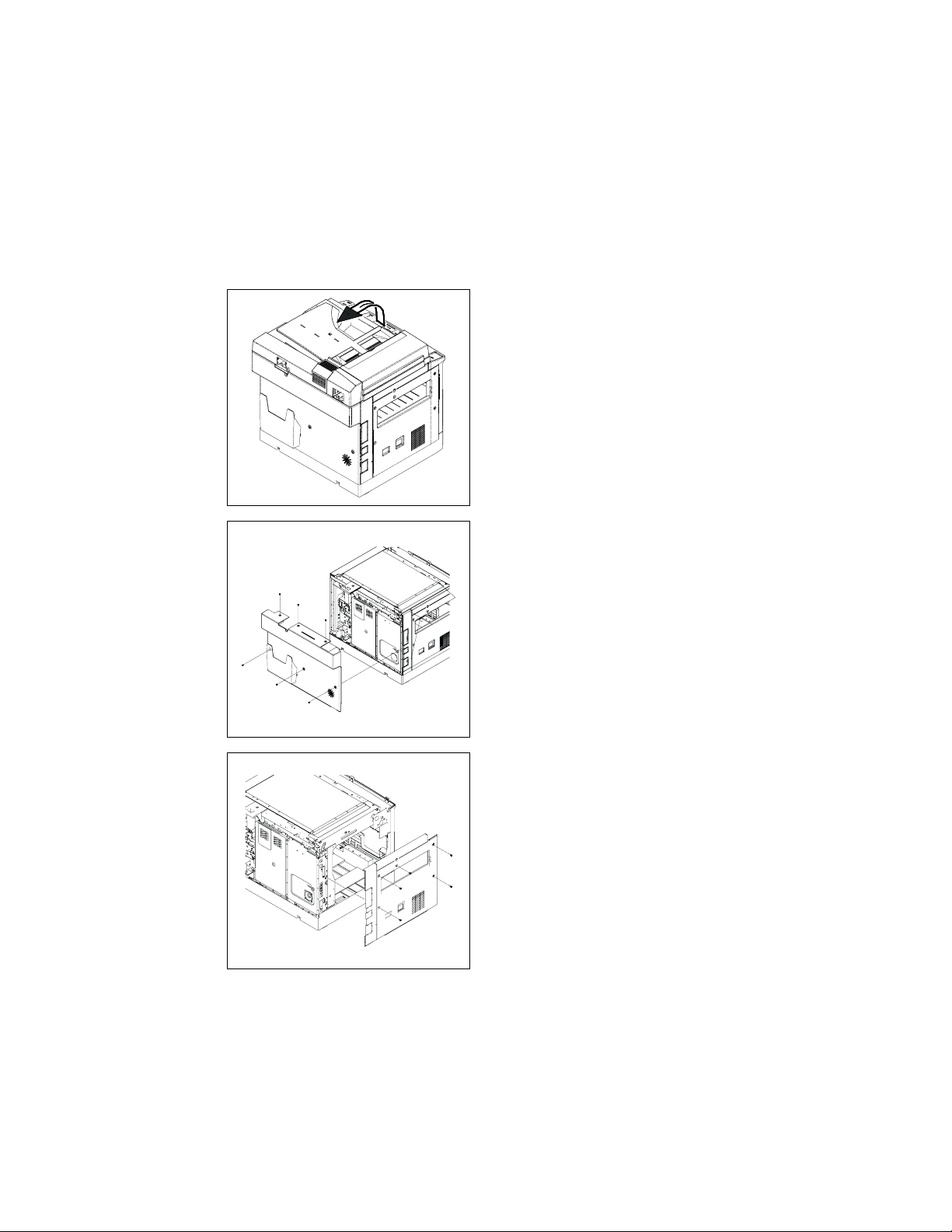

4-3. PWB-C Board Assembly / Disassembly

e

(1) With Fax Controller Board

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

4507D501AA

2. Re move the 6 screw s to r em ove the

Rear Cover.

4507D502AA

4507D503AA

3. Re move the 5 screws to rem ove the Left

Cover.

20

Page 31

4507D504AA

4507D505AA

4. Re move the screw for th e gr ound wire of

the NCU Controller Board.

5. Remove the 16 screws to remove the

Fax Shield C over As sembly.

NOTE

• Remove the Speaker Connector before

removing the Fax Shield Cover Assembly.

4507D506AA

6. Re move the 8 screw s to r em ove the

Shield C over Assembly.

21

Page 32

4507D511AA

4507D512AA

7. Re move the 2 screw s for the Fax C o n troller Board.

8. Remove the Battery C o nnector.

9. Re move the 6 screw s to r em ove the I/F

Bracket Assembly.

4507D516AA

10. Remove all co nnectors on the PWB-C

Board.

11. Remove the 6 s c rew s to r em ove the

PWB-C Board.

22

Page 33

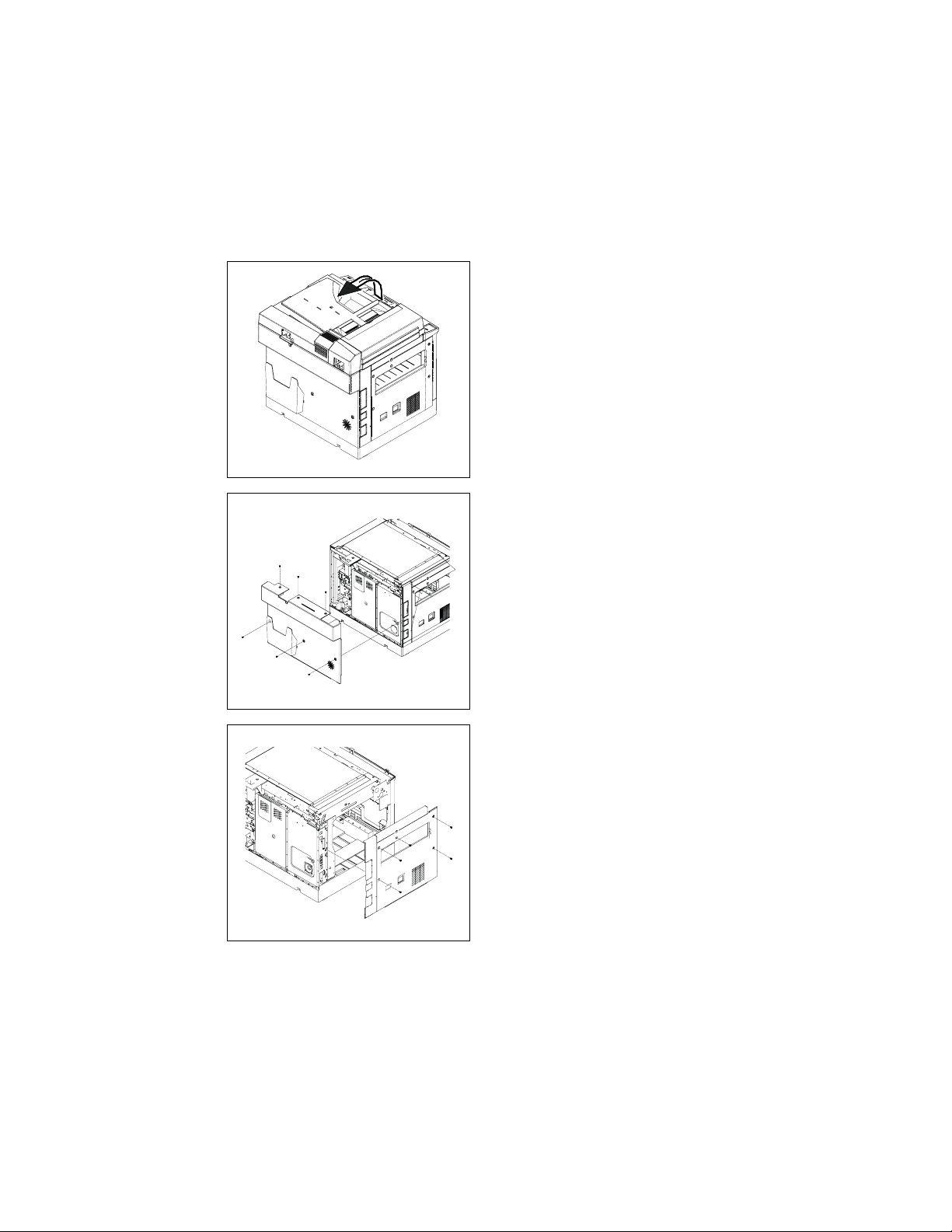

(2) With Fax and Printer Controller Board

e

4507D501AA

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

2. Re move the 6 screw s to r em ove the

Rear Cover.

4507D502AA

4507D503AA

3. Re move the 5 screws to rem ove the Left

Cover.

23

Page 34

4507D504AA

4507D505AA

4. Re move the screw for th e gr ound wire of

the NCU Controller Board.

5. Remove the 16 screws to remove the

Fax Shield C over As sembly.

NOTE

• Remove the Speaker Connector before

removing the Fax Shield Cover Assembly.

4507D507AA

6. Re move the 4 screw s for the Fax C o n troller Boar d an d the Printer Co ntro ller

Board.

7. Remove the Battery C o nnector.

24

Page 35

4507D508AA

4507D516AA

8. Re move the 6 screw s to r em ove the I/F

Bracket Assembly.

9. Re move all conn ec to r s on th e P WB-C

Board.

10. Remove the 6 s c rew s to r em ove the

PWB-C Board.

25

Page 36

(3) With Printer Controller Board

e

4507D501AA

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

2. Re move the 6 screw s to r em ove the

Rear Cover.

4507D502AA

4507D503AA

3. Re move the 5 screws to rem ove the Left

Cover.

26

Page 37

4507D517AA

4507D506AA

4. Remove the 16 screws to remove Fax

Shield C over.

5. Re move the 8 screw s to r em ove the

Shield C over Assembly.

4507D528AA

6. Re move the 2 screw s for the Printer

Controller Board.

27

Page 38

4507D518AA

4507D516AA

7. Re move the 6 screw s to r em ove the I/F

Bracket Assembly.

8. Re move all conn ec to r s on th e P WB-C

Board.

9. Re move the 6 screw s to r em ove the

PWB-C Board.

28

Page 39

4-4. PWB-A Board Assembly / Disassembly

e

(1) With Fax or Prin te r Controller Boar d

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

4507D501AA

2. Re move the 6 screw s to r em ove the

Rear Cover.

4507D502AA

4507D503AA

3. Re move the 5 screws to rem ove the Left

Cover.

29

Page 40

4507D504AA

4507D505AA

4. Re move the screw for th e gr ound wire of

the NCU Controller Board (With Fax

Controller Board only)

5. Remove the 16 screws to remove the

Fax Shield C over As sembly.

NOTE

• Remove the Speaker Connector before

removing the Fax Shield Cover Assembly.

(With Fax Controller Board only)

4507D506AA

6. Re move the 8 screw s to r em ove the

Shield C over Assembly.

30

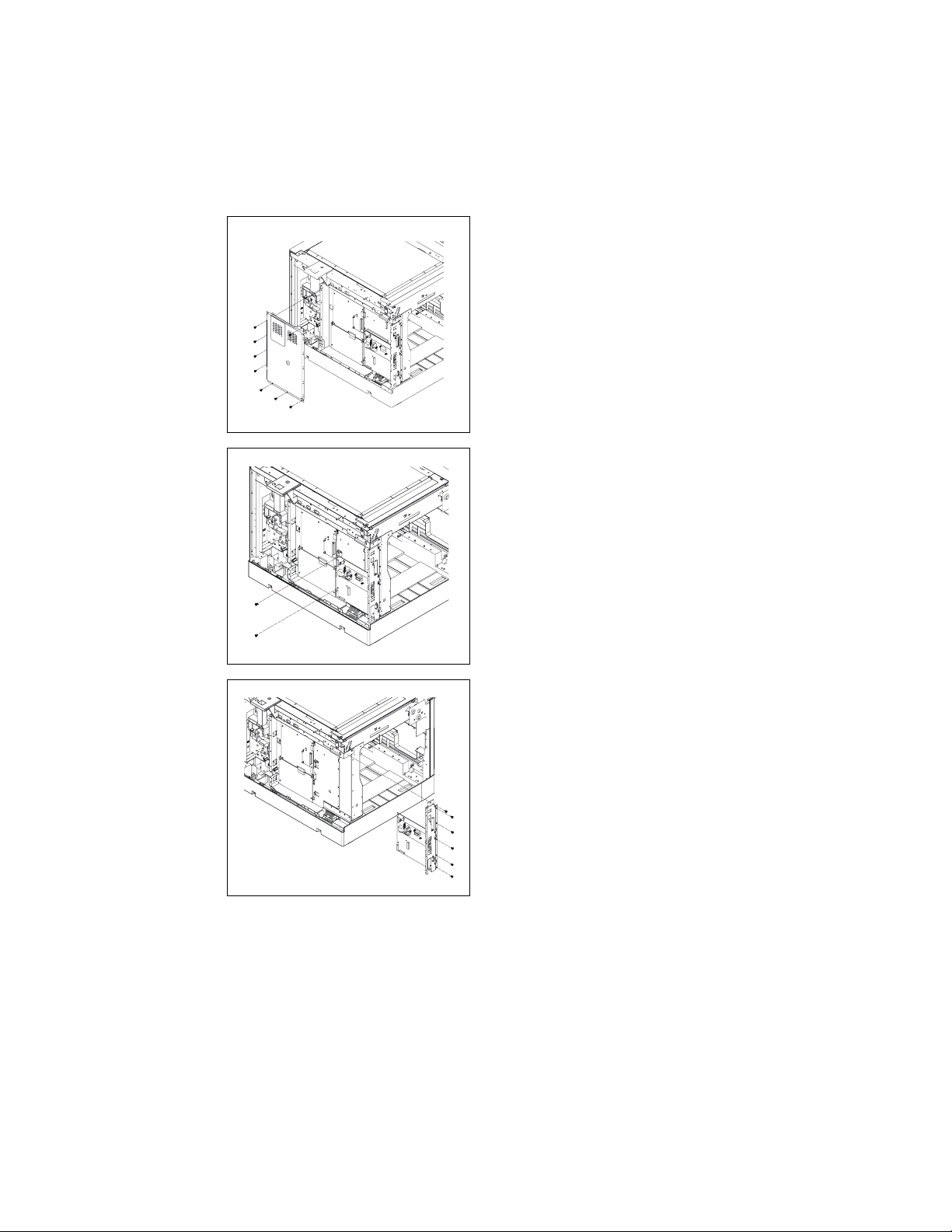

Page 41

7. Re move all conn ec to r s on th e P WB-A

e

Board (except for PJ20).

8. Re move the 4 screw s to r em ove the

PWB-A Board.

4507D522AA

4-5. Speaker and Battery Assembly / Disassembly

1. Turn off the power switch and remove th

power cord, then rais e the Auto m atic

Document Feeder.

4507D501AA

4507D502AA

2. Re move the 6 screw s to r em ove the

Rear Cover.

31

Page 42

4507D503AA

4507D504AA

3. Re move the 5 screws to rem ove the Left

Cover.

4. Re move the screw for th e gr ound wire of

the NCU Controller Board.

4507D505AA

5. Remove the 16 screws to remove the

Fax Shield C over As sembly.

NOTE

• Remove the Speaker Connector before

removing the Fax Shield Cover Assembly.

32

Page 43

4507D524AA

4507D525AA

6. Re move the 4 screw s to r em ove the

Speaker.

7. Remove the Battery Connector for the

Battery.

8. Re move the 2 screw s to r em ove the Battery Fix Plat e and the Bat tery.

33

Page 44

4-6. Fax Panel Assembly / Disassembly

• Remove the 4 screws to remove the Fax Controller Panel Assembly

NOTE

• Remove the 2 connectors on the Fax Controller Board.

34

4507D526AA

Page 45

5. ADJUSTMENT

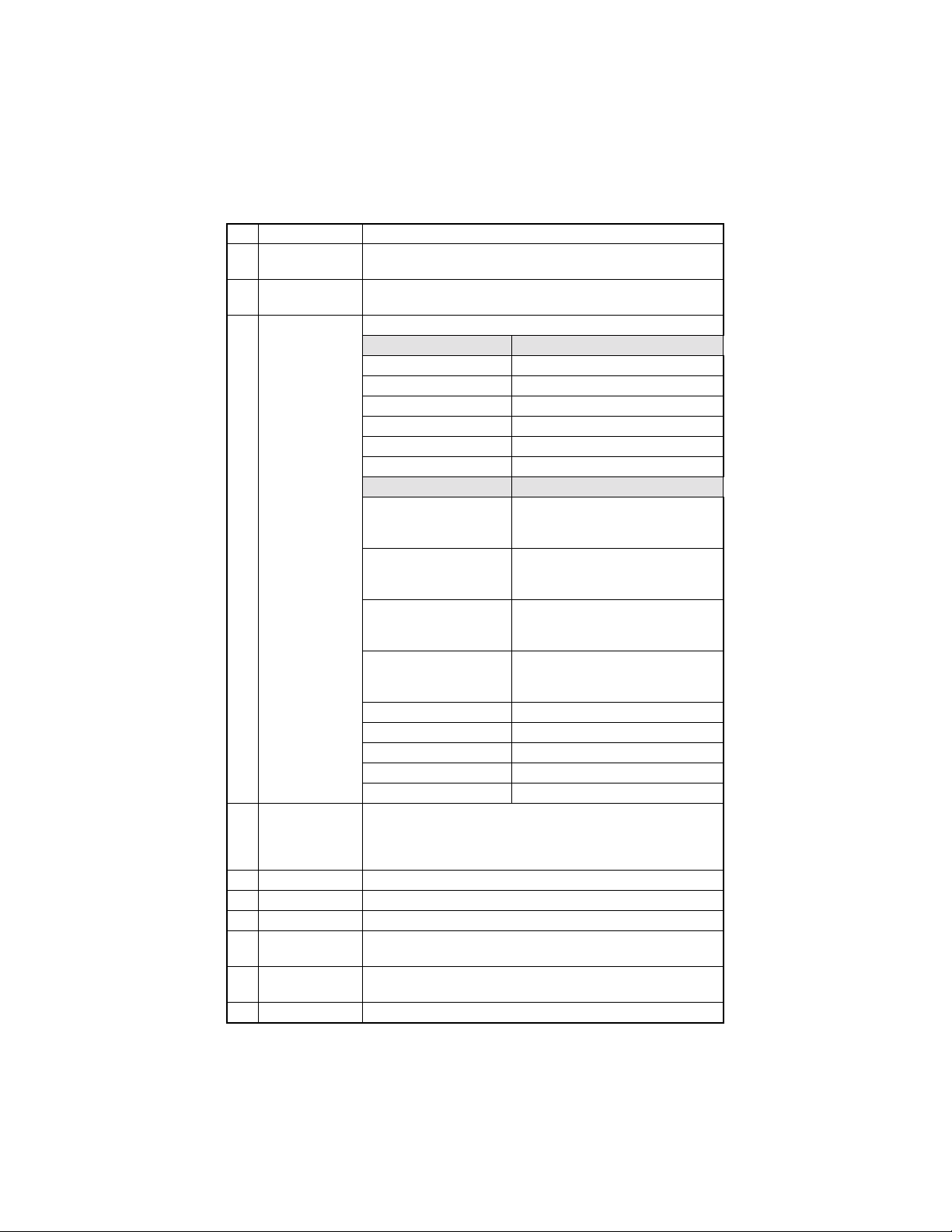

5-1. ADJUST JUMPER SWITCH ON NCU BOARD

• Make the correct settings of the jumper switches at six places on the NCU Board according to the applicable marketing area.

• Wh en the NCU Boar d has been replaced, check that the jumper switches are set as

shown below.

JP1

3 2 1

JP2

1

2

3

Setting --- 1,2 Setting --- 2,3

✽ Country Classification Jumper Switch Setting

Type JP1 ~ JP6 Country

USA, Canada, singapore, Malaysia, Hong Kong,

Russia, Iran, Bahrain, Qatar, Poland, Slovakia,

STD 12,12,12,12,23,23

CTR-21 12,23,23,23,12,12

Australia 12,23,12,12,23,23 Australia, China.

South Africa 23,23,12,12,23,23 South Africa.

China 12,12,12,12,23,12 China

Croatia, Czevh, Slovenia, Baltic, Romania,

Ukraine, Ku wait, P h il ipp in e, Taiwan, UAE, Korea,

New Zealand.

Finland, Iceland, Liec htenstein, Luxe mbourg,

Norway, Sweden, Belgium, Cyprus, Denmark,

F rance, Greece, Ireland, Ita ly, Netherlands,

Swit zerland, Germany, U.K, Portugal, Spain,

Turkey, Hungary, Austria.

3 2 1

JP6

1

2

3

1

2

3

1

2

JP3

3

1

2

3

1

2

3

4507D529AA

JP4

JP5

4507D530AA

35

Page 46

5-2. Upgrading Fax Controller Firmware

(1) Upgrading Procedure Using RS-232C Interface

1. Turn OFF the Power Switch.

2. Connect the Fax Board to the host computer using the RS-232C cable (Straight cable:

terminated in female 9 pin D-Sub connection on both ends).

3. Turn ON the Power Switch.

4. Start the host computer and run “DOS prompt” or “command prompt.”

5. Che ck th e nam e of the se r i al port t o be u sed.

NOTE

• COM1 or COM2 is usually set.

The ports that can be used can be checked with the device manager of Windows.

6. Using the DOS mode command, set the mode for the serial port. If the port used is

COM1, type C:\>mode com1:19,n,8,1 and then press the Enter key.

7. Check that the follo wing message appears, indicating th at the com1 device setting pro-

cedure is completed.

COM1: 19200,n,8,1-

8. Usi ng the C opy comman d, se nd the source file t o t h e Fax Boa r d.

type C:\>copy /b XXX.bin COM1 and then press the En ter key.

36

Page 47

9. The followi ng message appears on the Message Pane l and transfer of firmw ar e data is

started. (Wait until data transfer is completed.)

FIRMWARE DOWNLOAD

Data tra ns fer started

4507D531AC

Approx. 15 min.

FIRMWARE DOWNLOAD

Data transfer completed

4507D532AC

PROGRAM FLASH

4507D534AC

10. The following message appears on the Message Panel, indicating that the firmware has

been properly upgraded.

* PROGRAM COMPLETE *

CHANGE JP5-PJ8

4507D534AC

11. Type “exit” and then press the Enter key.

C:\>exit

12. Make sure that the host computer exits from “DOS prompt” or “command prompt.”

13.Turn OFF and then ON the Power Switch.

37

Page 48

(2) Upgrading Procedu r e Usin g Telephone Line (from fax m ach ine to fax m ach ine)

NOTE

• The firmware transmitter fax machine must be loaded with the latest version of the firmware. If the fi rmware is no t upgra ded, do th at by following th e “Upgrading Procedure

Using RS-232C Interface” described in the previous section.

<Setti ng s ma de on the fa x machine (receiver) to be upgraded>

Select “FULL” for REMOTE MONITOR of the Administrator Mode.

NOTE

• For the REMOTE M ONITOR setting, see “6-9 Administrator number registration.”

1. Press the [INITIAL SET] Key.

2. Press the [Down] Key three times.

ADMN. MANAGEMENT? OK=YES / or 1-3

3. Press the [YES] Key.

ADMN. NO= - - - - - -

4. Enter the Administrator number then press [YES] Key.

NOTE

• Default Administrator number is “000000”.

5. Press the D ow n Key two times, then pr e ss [YES] Key.

3 REMOTE MONITOR? OK=YES

6. Select “Full” using r i gh t/ l eft Key, and press the [YE S ] key.

<Firmw are trans mission procedure (transmitter operat ion)>

1 Set the fir m ware transmitte r fax m ac hi ne in to the Servi ce m od e.

INITIAL SET, Stop, 0, 0, Stop, 0, 1

2. Select “5. FAX SET” or “5. FUNCTION” by pressing the [Up] or [Down] K ey. Then press

[YES] Key.

3. Select “UPLOAD FIRMWARE” by pre ssing the [Up] or [Down] Key. Then press [Yes]

Key.

4. Type the telephone number, to which the firmware receiver fa x machine is connected.

(The relevant one touch dial number may be used if the telephone number has been

previous ly programm ed in it.)

NOTE

• Up to 16 telephone numb ers can be specified sim ult aneously for the firmware r eceiver

fax machi ne.

38

Page 49

5. Press the [Start] key. This starts transfer of the data.

The Mess a ge Panel of the tr an sm itter fax mac hine displays t he same sc re en as tha t

appear in g during ordinary faxing.

When th e da t a tran sf er is completed, the ordinary standby screen reappears on the

Message Panel.

<Operation of receiver after reception of firmware data>

1. Th e firmware rec e iver fax ma ch in e r ec ei ves th e firmware da ta .

The following message appears on the Message Panel, indicating that transfer of firmware data is st a rted.

NOTE

• Do not use an y of the pri nter and copier func tions until upgrading of firmware is completed.

FIRMWARE DOWNLOAD

4507D531AC

FIRMWARE DOWNLOAD

PROGRAM FLASH ROM

“ PLEASE WAIT! ”

Data tran s fer started

Approx. 15 min.

Data transfer completed

4507D532AC

Firmware being uploaded

4507D534AC

2. The following message appears on the Message Panel of the firmware receiver fax

machin e, indicating that upgrading of the firmware is completed.

PROGRAM COMPLETE

POWER SUPPLY OFF/ON

4507D534AC

3. Turn OFF and ON the Power Switch of the firmware receiver fax machine.

39

Page 50

(3) Action T aken When Firm ware Upgrading Fails

• Take the following action when upgradin g of f ir m wa re is not comple te ly p roperly.

CN6

U4

FlashROM

JP5

JP8

JP6

1

1

1

1

2

3

2

2

2

3

3

3

JP7

U61

Flash

ROM

U6

Service

Download

BIOS

U5

Service

Download

BIOS

4507D535AA

Service Download BIOS U5 and U6

(Parts No. : 27BE9701*)

1. Turn OFF the Power Switch.

2. Change the setting for jumper switches JP5 to JP8 on the Fax Board from “2-3” to “1-2.”

1

2

3

2

2

2

3

3

3

JP8JP7JP6JP5

1

2

3

1

1

1

2

2

2

3

3

3

4507D536AA

JP8JP7JP6JP5

1

1

1

3. Mount “Service Download BIOS U5 and U6” on memory sockets U5 and U6 on the Fax

Board.

4. Connect the Fax Board to the host computer using the RS-232C cable (DB-9 connec-

tor).

5. Start the host computer and start “DOS prompt” or “command prompt.”

6. Turn ON the Power Sw itc h. The Me s sa ge Panel will sh ow t he following m es sage.

WAIT PROGRAM

4507D534AC

40

Page 51

(4) Upgrading Procedure Using RS-232C Interface

1. Turn OFF the Power Switch.

2. Connect the Fax Board to the host computer using the RS-232C cable (Straight cable:

terminated in female 9 pin D-Sub connection on both ends).

3. Turn ON the Power Switch.

4. Start the host computer and run “DOS prompt” or “command prompt.”

5. Che ck th e nam e of the se r i al port t o be u sed.

NOTE

• COM1 or COM2 is usually set.

The ports that can be used can be checked with the device manager of Windows.

6. Using the DOS mode command, set the mode for the serial port. If the port used is

COM1, type C:\>mode com1:19,n,8,1 and then press the Enter key.

7. Check that the follo wing message appears, indicating th at the com1 device setting pro-

cedure is completed.

COM1: 19200,n,8,1-

8. Usi ng the C opy comman d, se nd the source file t o t h e Fax Boa r d.

type C:\>copy /b XXX.bin COM1 and then press the En ter key.

41

Page 52

9. The followi ng message appears on the Message Pane l and transfer of firmw ar e data is

started. (Wait until data transfer is completed.)

FIRMWARE DOWNLOAD

Data tra ns fer started

4507D531AC

Approx. 15 min.

FIRMWARE DOWNLOAD

Data transfer completed

4507D532AC

PROGRAM FLASH ROM

* PLEASE WAIT! *

4507D534AC

10. The following message appears on the Message Panel, indicating that the firmware has

been properly upgraded.

PROGRAM COMPLETE

POWER SUPPLY OFF/ON

4507D534AC

11. Type “exit” and then press the Enter key.

C:\>exit

12. Make sure that the host computer exits from “DOS prompt” or “command prompt.”

13.Turn OFF and then ON the Power Switch.

14. Change the setting for jumper switches JP5 to JP8 on the Fax Board from “1-2” to “2-3”

(to retur n to the initial setting ) .

15. Remove “Service Download BIOS U5 and U6” from memory sockets U5 and U6 on the

Fa x Boar d.

16. Turn ON the Power Switch.

42

Page 53

6. Service Mode Function

6-1. Description

(1) HOW TO ENTER INTO SERVICE MODE

• Press the foll ow ing keys in this order to enter the Service mo de:

INITIAL SET, STOP, 0, 0, STOP, 0, 1.

NOTE

• After exiting the Service mode, be sure to turn OFF and ON the Power Switch.

(2) KEY DEFINITION

Key Definition

Left Key Scroll Ba ck war d, M ove C u r s or Left

Right Key Scroll Forward, Move Cursor Right

Up Key Scroll Backward

Down Key Scroll Forward

Start Start Operation

Yes Enter the selected Mode

No/Panel R es e t

Stop

One Touch Key Function Index

Numeric Key Data Entry

Exit and return to next item

43

Page 54

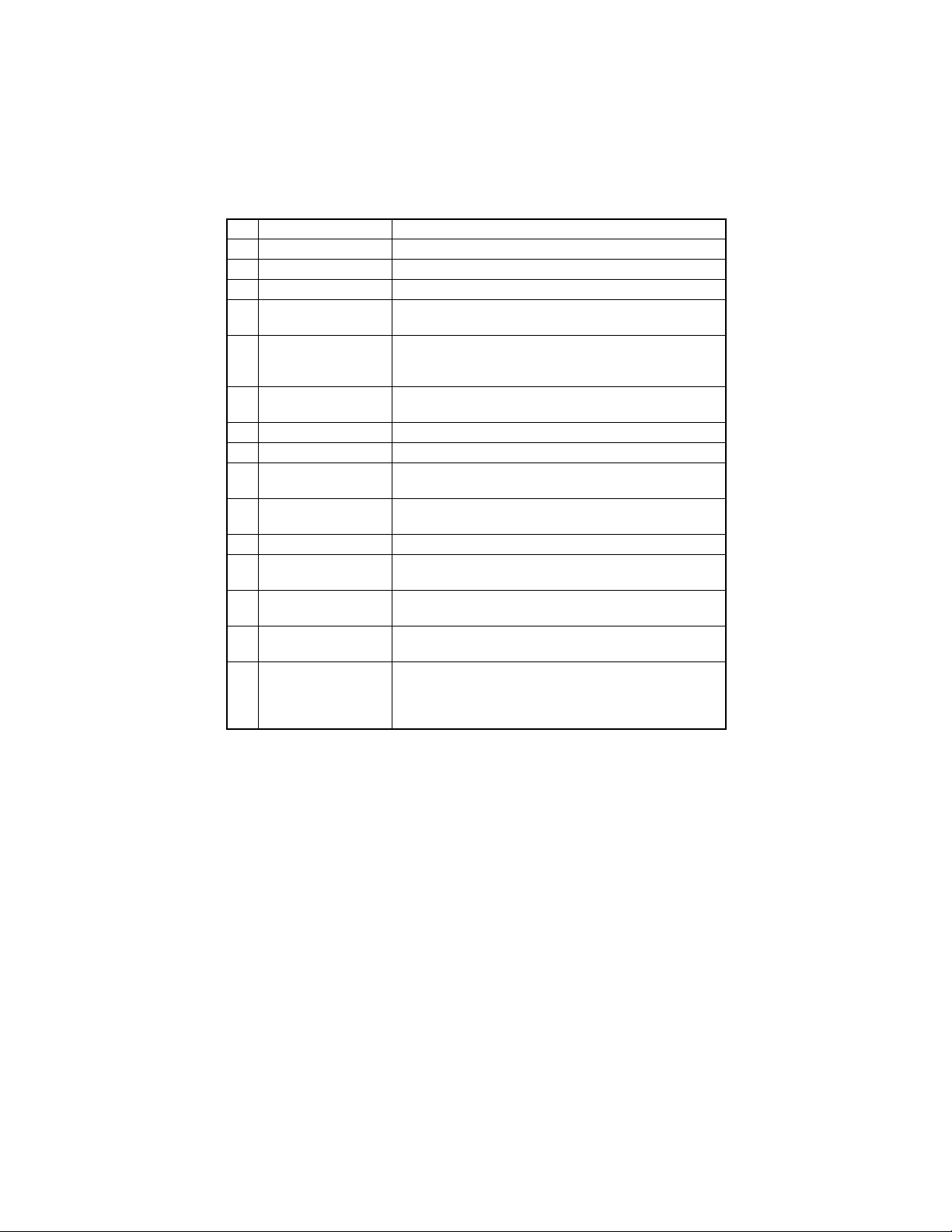

(3) FUNCTION ITEMS

No. Function Items displayed on the LCD panel

1 SERVICE’S CHOICE

2 ADJUST

3 COUNTER

4 DISPLAY

5 FUNCTION

6 SOFT SWITCH

7REPORT

8 ADMIN. REGISTRATION

9 FIXED ZOOM CHANGE

10 FACTORY TEST

11 CLEAR DATA

12 SECURITY

(4) Setting Procedure

1. Cal l the Service mode t o t h e sc re e n.

2. Using the [Up] or [Do wn] key, select th e d e sired function.

3. Press the Yes key to validate the function selected in step 2.

✽ Use the N o key to undo the previou s selectio n of the funct ion.

4. For individual selection of subfunctions, use [Left] or [Right] key, or [Up] or [Down] key.

5. Press the Yes key to validate the selection.

44

Page 55

6-2. SERVICE’S CHOICE

• T h e fol low i ng functi on items are available.

No. Function items displayed on the LCD panel

1 MARK ETING AREA

2 SHIPMENT DESTINATION

3 MAINTENANCE COUNTER

4 IU LIFE STOP MODE

5 ID ADJUST

6 VG ADJUST

7 LEADI N G ED G E ERASE

8 TRAILING EDGE ERASE

9 VERTICAL EDG E ERASE

10 LOOP ADJUST (TRAY 1)

11 LOOP ADJUST (TRAY 2-5)

12 LOOP ADJUST (BYPASS)

13 PRIORITY FLS

14 TX SPEED

15 RX SPEED

16 TX LEVEL

17 RX LEVEL

18 DTMF LEVEL

19 CNG LEVEL

20 CED LEVEL

21 E C M MO DE

22 CODING SCHEME

23 REPORT DESTINATION

24 TONER EMPTY REPORT

25 I U LIFE REPO RT

26 MAINTENANCE REPORT

27 PROTOCOL REPOR T

28 CUSTOMER ID

45

Page 56

(1) MARKET ING AREA

• Set the marketing area.

• I f you change the marke t in g a rea, the sof t swi tc h (1-64) will change a ut omatically.

MARKETING AREA Setting Proce du re

Use the on e t ou ch key, or [Up] or [Down ] key to selec t any nu m be r fro m 1 to 27 .

One Touch Marketing area One Touch Marketing ar ea

1

2 U.S.A. 16 GREECE

3 TAIWAN 17 ISRAEL

4SPAIN18AUSTRIA

5ITALY19GERMANY

6 BELGIUM 20 FRANCE

7 NORWAY 21 UNITED KINGDOM

8 SWEDEN 22 AUSTRALIA

9 NETHERLANDS 23 CHI NA

10 FINLAND 24 NEW ZEALAND

11 DENMARK 25 KOREA

12 SWITZERLAND 26 CZECH

13 IRELAND 27 SLOVAK

14 PORTUGAL

Use the [Up] or [Down] key to sele ct the number.

No. Marketing a rea No. M arketing area

28 HUNGARY 38 HONG KONG

29 UKRAINE 39 PHILIPPINES

30 BALTIC 40 THAILAND

31 WEST EUROPE 41 INDONESIA

32 SLOVENIJA 42 OMAN

33 POLAND 43 UAE

34 ROMANIA 44 QATAR

35 RUSSIA 45 BAHRAIN

36 SINGAPORE 46 KUWAIT

37 MALAYSIA 47 SAUDI ARABIA

STANDARD

(Factor y use only)

15 SOUTH AFRICA

48 JAPAN

46

Page 57

(2) SHIPMENT DESTINATION

• Set the shippi ng destination.

No. Description

1JAPAN

2 INCH

3METRIC

4CHINA

• Default :

Sales Country Default Sales Countr y Default

Europe METRIC Korea METRIC

South Africa/ Australia METRIC China CHINA

Argentina METRIC US A/ Cana da INCH

Philippines METRIC Taiwan METRIC

(3) MAINTENANCE COUNTER

• T h e se t ting range of count value is 0-999999 .

• It is used as guideli ne s fo r the number of copier to be made before th e next mai ntenance

time.

• S e le ct the coun ting method of the main t e na nc e co unter.

Setting Procedure

1. Select the setting value using the [Left] or [Right] key.

2. Press the Yes key.

✽ When 1 or 2 is selected for the setting value, the count value entry screen automatically

appears.

3. Type the count value from the 10-Key Pad.

4. Press the Yes key.

Setting value Meaning Specification Default

0 NO COUNT Nothing ❍

1 PERMITS COPYING Display “M1”

2 INHIBITS COPYING Display “CALL SERVICE (M1)”

• W h en count val ue becomes zero , a minus count is performed. It is countable to -9 99 9 9.

47

Page 58

(4) IU LIFE STOP MODE

• The machine enters the IU Life Stop mode as soon as the count of the IU Life Counter

reaches the life value which is calculated by an internal counter.

• T h e in itial value of t h e IU Life C o un t er is 4 0,000.

• The IU Life Stop mode offers the following setting parameters:

Setting Value Description Default

Copying inhibited

“M2” is displayed w h en the IU Life C o unter reach e s

STOP

CONTINUOUS

• When “Continuous” is selected, the IU Life Counter continues counting down e ven after it

has re ad “0” and counts dow n to -99999 . In this case, h owever, pr int quality is not gu a ranteed.

(5) ID ADJUST

• Adjust the printi ng density. The setting v alues are as f ollows.

Setting Value Default

-3

-2

-1

40,000.

The message “Call Servi ce (M 2)” is displayed and the

print cycl e i s stop pe d wh en the IU Li f e C oun t er r e aches

50,000.

Copying permitted

“M2” is displayed and the print cycle is continued when

the IU Life Counter reaches 40,000.

0 ❍

1

2

3

❍

(6) VG ADJUST

• Vary the Vg voltage to adjust image density.

• The function is used when a fog or a void occurs.

• Increase the setting value to eliminate void.

• Decrease the setting value to eliminate fog.

Setting value De fault

-2

-1

0 ❍

1

2

48

Page 59

(7) LEADING E DGE ERAS E

• E rase the lea ding edge image , the erase width ranging from zero to 5 mm.

Setting value De fault

0 mm

1 mm

2 mm

3 mm

4 mm ❍

5 mm

(8) TRAILING EDGE ERASE

• Erase the trailing edge image, the erase width ranging from zero to 5 mm.

Setting value Default

0 mm

1 mm

2 mm

3 mm

4 mm ❍

5 mm

(9) VERTICAL EDGE ERASE

• E rase the rear and fro nt edges of the image.

Setting Value Default

0 mm

1 mm

2 mm

3 mm

4 mm ❍

5 mm

(10) LOOP ADJUST (TRAY1), (TRAY 2-5), (BYPASS)

• Adjust the length of the loop to be formed in paper before the Synchronizing Roller.

• W h en a skew or misfeed occurs.

• Can adjust for MP, Bypass and Tray 2 to Tray 5, setting value as below. (Unit=mm)

No.

Setting Value

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

-3.9 -3.3 -2.8 -2.2 -1.7 -1.1 -0.6 0 0.6 1.1 1.7 2.2 2.8 3.3 3.9

49

Page 60

(11) PRIORITY FLS

• Set the size of FLS. (F4 size)

Contents Default

330 x 203

330 x 210 ❍

330 x 216

330 x 220

337 x 206

(12) TX SPEED

• Transmit start speed setting. Choose the mode from among the following. Default is V.34

33600.

Mode Speed Default

V.34 33600, 31200, 28800, 26400, 24000, 21600, 19200, 16800 ❍

V.17 14400, 12000, 9600, 72 00

V.33 14400, 12000

V.29 9600, 7200

V.27 4800, 2400

(13) RX SPEED

• Reception start speed setting. Choose the mode from among the following. Default is

V.34 3360 0.

Mode Speed Default

V.34 33600, 31200, 28800, 26400, 24000, 21600, 19200, 16800 ❍

V.17 14400, 12000, 9600, 72 00

V.33 14400, 12000

V.29 9600, 7200

V.27 4800, 2400

(14) TX LEVEL

• PSK/FSK signal output l evel.

Setting Value Default

-2 dbm

.

.

-9 dbm ❍

.

.

-17 dbm

50

Page 61

(15) RX LEVEL

• Reception sensitivity level.

Setting Value Default

-36 dbm

.

.

-43 dbm ❍

.

.

-49 dbm

(16) DTMF LEVEL

• D u al tone outp ut level.

Setting Value Default

-2 dbm

.

.

-10 dbm ❍

.

.

-17 dbm

(17) CNG LEVEL

• C alling to ne ou t put level.

Setting Value Default

-2 dbm

.

.

-11 dbm ❍

.

.

-17 dbm

51

Page 62

(18) CED LEV EL

• Answer tone output level.

Setting Value Default

-2 dbm

.

.

-11 dbm ❍

.

.

-17 dbm

(19) ECM MODE

• Se lect err or correction mod e.

Setting Value Description Default

ON

OFF Any error is ignored during communication.

(20) CODING SCHEME

• Select compression method in TX/RX mode.

Setting Value Default

JBIG ❍

MMR

MR

MH

When an error occurs during communicati on, re-send

the frame where the error occurs.

❍

52

Page 63

(21) REPORT DESTINATION

• E n t er the telephone numb er for which the r e port is to be p rodu ced.

• Fax number specifications: An up-to-20-digit number that may consist of “0-9”, “ * ”, and

“#”. (0-9, #, *)

• W h en any of the following cond itions happe ns, the report is sent to the destination .

1. Toner-empty condition

(Refer to (22) TONER EMPTY REPORT)

2. The IU Life Counter exceeds the specifications.

(Refer to (23) IU LIFE REPORT)

3. The Mai ntenance C ounter reaches a preset value.

(Refer to (24) MAINTNANCE REPORT)

✽ The re port will be produced at a timing of 20 m i n., 24 hour s , 48 hou rs, a nd 7 2 ho urs aft e r

any of t he above conditions has occurred until the condition disappears.

✽ If two or more conditions occur, only one report will be p roduced.

<Report sample>

SERVICE REPORT

NAME: ABC

TEL: 886-3-4733507

DATE: APR.10.2001 12:20

The FAX’s fo llowing condition appears, the machine may not

work correctly, the Fax already sent a report to your dealer

automatically. They will contact you soon.

Toner status : Empty or Full

Maintenance counter : 125

Supplies life counter : 39938

53

Page 64

(22) TONER EMPTY REPORT

• Select to generate a report to a specific destination when toner empty (Copying inhibited)

status occurs in the engine.

Setting Value Description Default

OFF Not to generate report. ❍

ON Generat e a r e port to report destination.

(23) IU LIFE REPORT

• Select to generate the report when IU LIFE COUNTER becomes out of life, with the condition that the setting value of the counter is set to “STOP”.

Setting Value Description Default

OFF Not to generate a report. ❍

ON Generate a report to destination.

(24) MAINTENANCE REPORT

• Select to ge ne r ate t he repor t when Maintenanc e co un ter beco m es ze ro, with the condition that the setting v alue of th e counter is se t to “2”.

Setting Value Description Default

OFF Not to generate report. ❍

ON To generate a rep ort to repo rt de stination .

(25) PROTOCOL REPORT

• Print communica tion report. Choose one from among the following.

Setting Value Description Default

OFF Disable T.30 commu n ication report. ❍

ON Print T.30 communication report.

ON (ERROR) Print T.30 communication report when an error occurs.

(26) CUSTOMER ID

• Select to the maker name of this machine.

Setting Value Description Default

1KONICA ❍

2Other

54

Page 65

6-3. ADJUST

• Following table lists a ll the adjustm ent items available for the machine.

No. Indication on LCD Description

1 PRN MAIN REGIST Ad1 Adjust print start position in the CD direction for MP Tray.

2 PRN SUB REGIST Ad2 Adjust print start position in the FD direction.

3 CCD MAIN ZOOM Ad3 Adjust horizontal the zoom ratio in the CD direction.

4 CCD SUB ZOOM Ad4 Adjust the zoom ratio in the FD direction.

5 CCD MAIN REGIST Ad5 Adjust scan start position in the FD direction.

6 CCD SUB REGIST Ad6 Adjust scan start position in the CD direction.

7 ADF SUB ZOOM Ad7 Adjust ADF zoom ratio in the FD direction.

8 ADF MAIN REGIST Ad8 Ad jus t ADF start read ing po siti on in the CD dir e cti on.

9 ADF SUB REGIST Ad9 Adjust ADF start reading position in the FD direction.

10 ADTC GAIN Ad10 ATDC sensor Gain Ma nual adjustment .

11 MODEL SETTING Ad11

12 SERIAL NU M BER Ad12

(1) PRN MAIN REGIST Ad1

• Adjust the CD start po sition while pr inting using TRAY1.

• I t is used when the PH Unit ha s been replaced .

• Pre ss S TART key to copy for test.

• Press YES key to adjust setting..

Setting Value Contents Default

60 -4.0 m m

61 -3.9 m m

62 -3.8 m m

.

.

98 -0.2 m m

99 -0.1 m m

100 0 mm ❍

101 +0.1 mm

102 +0.2 mm

.

.

138 +3.8 mm

139 +3.9 mm

140 +4.0 mm

This test is for factory adju st me nt only and s ho ul d NOT

be used.

.

.

.

.

55

Page 66

(2) PRN SUB R EGIST Ad2

• A d ju st the FD start posi tio n w hil e printing us in g T RAY1.

• I t is used when the PH Unit ha s been replaced .

• Pre ss S TART key to copy for test.

• Press YES key to adjust setting.

Setting Value Contents Default

67 -6.14 mm

68 -5.95 mm

69 -5.77 mm

.

.

98 -0.37 mm

99 -0.19 mm

100 0 mm ❍

101 +0.19 mm

102 +0.37 mm

.

.

130 +5.58 mm

131 +5.77 mm

132 +5.95 mm

133 +6.14 mm

(3) CCD MAIN ZOOM Ad3

• Adjust CD zoom ratio during CCD scanning.

• It is used when the PH Unit or CCD Unit has been replaced.

• P ress START key to copy for tes t.

• Press YES key to adjust setting.

Setting Value Contents Default

97 -1.2 %

98 -0.8 %

99 -0.4 %

100 0 ❍

101 +0.4 %

102 +0.8 %

103 +1.2 %

.

.

.

.

56

Page 67

(4) CCD SUB ZOOM Ad 4

• Ad just vertical zoom ratio while CCD scanning.

• It is used when the PH Unit or the Scanner Drive Cables have been replaced, or when

the Scann er has been re m oved.

• P ress START key to copy for tes t.

• Press YES key to adjust setting.

Setting Value Contents Default

97 -1.2 %

98 -0.8 %

99 -0.4 %

100 0 ❍

101 +0.4 %

102 +0.8 %

103 +1.2 %

(5) CCD MAIN REGIST Ad5

• Ad just CD start position while CCD scanning.

• It is used when the PH Unit or CCD Unit has been replaced.

• Pre ss S TART key to copy for test.

• Press YES key to adjust setting.

Setting Value Contents Default

20 -8.0 m m

21 -7.9 m m

22 -7.8 m m

.

.

98 -0.2 m m

99 -0.1 m m

100 0 mm ❍

101 +0.1 mm

102 +0.2 mm

.

.

178 +7.8 mm

179 +7.9 mm

180 +8.0 mm

.

.

.

.

57

Page 68

(6) CCD SUB REGIST Ad6

• Ad just FD start position while CCD scanning.

• It is used when the PH Unit or the Scanner Drive Cables have been replaced, or when

the Scann er has been re m oved.

• Pre ss S TART key to copy for test.

• Press YES key to adjust setting.

Setting Value Contents Default

60 -4.0 m m

61 -3.9 m m

62 -3.8 m m

.

.

98 -0.2 m m

99 -0.1 m m

100 0 mm ❍

101 +0.1 mm

102 +0.2 mm

.

.

138 +3.8 mm

139 +3.9 mm

140 +4.0 mm

(7) ADF SUB ZOOM Ad7

• Adjust FD zoom ratio while ADF scanning.

• It is used when th e machine is set up, the PH Unit or Scann e r Dr iv e Cables have be e n

replaced, or the Scanner has been removed.

• Pre ss S TART key to copy for test.

• Press YES key to adjust setting.

Setting Value Contents Default

87 94.8 %

88 95.2 %

89 95.6 %

.

.

100 100 % ❍

101 100.4 %

102 100.8 %

.

.

111 104.4 %

112 104.8 %

113 105.2 %

.

.

.

.

.

.

.

.

58

Page 69

(8) ADF MAIN REGIST Ad8

• Adjust FD start position while ADF scanning.

• It is used when the machine is set up, or the PH Unit or CCD Unit has been replaced.

• Pre ss S TART key to copy for test.

• Press YES key to adjust setting.

Setting Value Contents Default

20 -8.0 m m

21 -7.9 m m

.

.

99 -0.1 m m

100 0 mm ❍

101 +0.1 mm

.

.

179 +7.9 mm

180 +8.0 mm

(9) ADF SUB REGIST Ad9

• Adjust FD start position while ADF scanning.

• It is used when t he PH Uni t or Scan ne r Drive Cables hav e been re plac ed , o r th e S ca nner

has be en r emoved.

• Pre ss S TART key to copy for test.

• Press YES key to adjust setting.

Setting Value Contents Default

50 -5.0 m m

51 -4.9 m m

52 -4.8 m m

.

.

98 -0.2 m m

99 -0.1 m m

100 0 mm ❍

101 +0.1 mm

102 +0.2 mm

.

.

148 +4.8 mm

149 +4.9 mm

150 +5.0 mm

.

.

.

.

.

.

.

.

59

Page 70

(10) ATDC GAIN Ad10

• Adjust the ATDC Sensor voltage.

• It is used when an IU of ano th er mac hi ne is to be us ed or the T/C cont rol vo lt a ge is to be

changed.

• The value, to which ATDC Sensor Automatic Adjustment has been adjusted, is to be the

setting value.

Setting Value Contents Default

123 5.39V

124 5.43V

125 5.48V

.

.

154 6.75V

155 6.79V ❍

156 6.84V

.

.

184 8.06V

185 8.11V

186 8.15V