KONICA MINOLTA Di251, Di351 Service Manual

Di251 / Di351

SERVICE MANUAL

[GENERAL]

4011-7990-11

INDEX (GENERAL)

GENERAL

MECHANICAL/ELECTRICAL

GENERAL

CONTENTS

1. SAFETY INFORMATION .................................................................................G-1

2. SPECIFICATION .............................................................................................G-6

3. PRECAUTIONS FOR INSTALLATION ............................................................G-9

3-1. Installation Site ........................................................................................G-9

3-2. Power Source ..........................................................................................G-9

3-3. Grounding ................................................................................................G-9

4. PRECAUTIONS FOR USE ..............................................................................G-10

4-1. To ensure that the copier is used in an optimum condition .....................G-10

4-2. Operating Environment ............................................................................G-10

4-3. Power Requirements ...............................................................................G-10

4-4. Note .........................................................................................................G-10

5. HANDLING OF CONSUMABLES ....................................................................G-11

6. OTHER PRECAUTIONS .................................................................................G-12

7. SYSTEM OPTIONS .........................................................................................G-13

i

1. SAFETY INFORMATION

Laser Safety

CAUTION: The use of controls, adjustment s or performance of procedures

other than those specified in this manual may result in hazardous radiation

exposure. Because of this, Minolta strongly recommends that you operate

your copy machine only as described in this docum enta tion.

Internal Laser Radiation

MaximumAverageRadiation Power: 19.5 µW (Di251)/27.8 µW (Di351) at laser aperture of

the print head unit

Wavelength: 770-795 nm (Di251)

775-795 nm (Di351)

This productemploys a Class 3b Laser Diode that emits an invisible laser beam.

The Laser Diode and Scanning Polygon Mirror are incorporated in the print head unit.

The print head unit is NOT A FIELD SERVICE ITEM.

Therefore, the print head unit should not be opened under any circumstances.

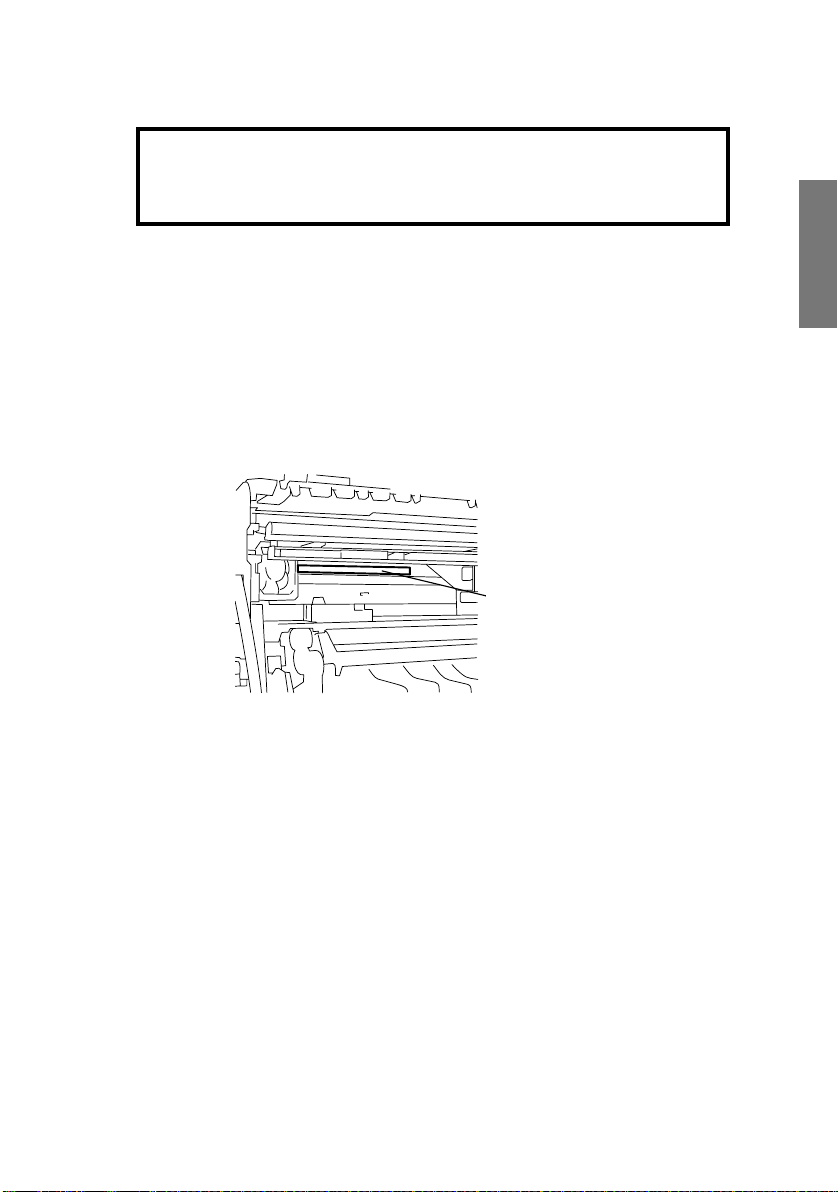

Laser Aperture of

the Print Head Unit

1166O263AB

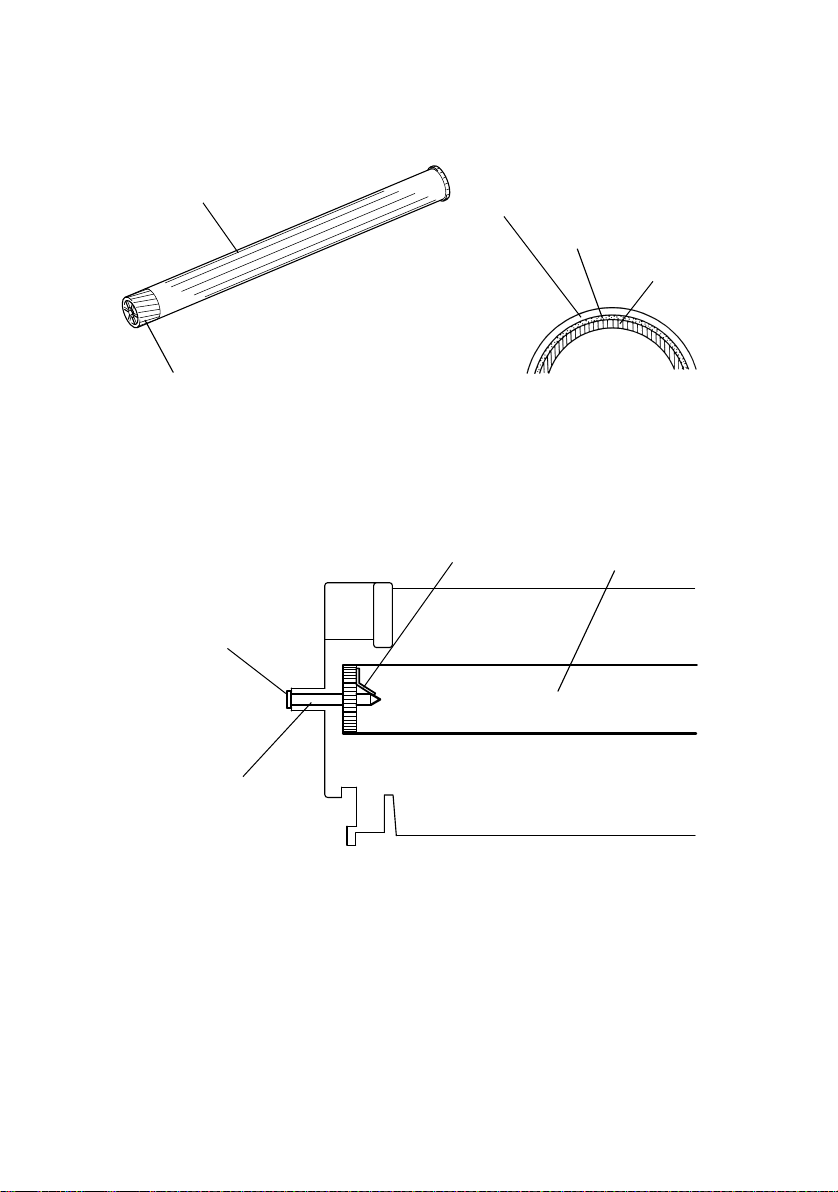

This figure shows the view inside the Right

Door with the I maging Unit removed.

CDRH re gulation

This copier is certified as a Class I Laser product under the Radiation Performance Standard according to the Food, Drug and Cosmetic Act of 1990. Compliance is mandatory for

Laser products marketedin t he United Statesand is reported to the Centerfor D evices and

RadiologicalHealth (CDRH) of t he U.S. Food and Drug Administration of the U.S. Departmentof Health and Human Ser vices (DHHS). This means thatthe devicedoes not produce

hazardouslaser radiation.

G-1

The la bel shown to page G-4 indicates compliance with the CDRH regulations and must be

attached to laserproducts marketed in the United States.

CAUTION: Use of controls,adjustments or performance of proceduresother than those

specified in this manual may result in hazardous radiationexposure.

This is a semiconductor laser.The maximum power of the laser diode is 5 mW (Di251)

15 mW (Di351) and the wavelength is 770-795 nm (Di251)/775-795 nm (Di351).

For Europe

CAUTION: Use of controls,adjustments or performance of proceduresother than those

specified in this manual may result in hazardous radiationexposure.

This is a semiconductorlaser. The maximum power of t he laserdiode is 5 mW (Di251)

15 mW (Di351) and the wavelength is 770-795 nm (Di251)/775-795 nm (Di351).

For Denmark

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse forstråling.Klasse 1 laser produkt der opfylderIEC60825 sikkerheds

kravene.

Dansk: D ette er en halvlederlaser.Laserdiodens højeste styrke er 5 mW (Di251)

15 mW (Di351) og bølgelængden er 770-795 nm (Di251)/775-795 nm (Di351).

For Finland

LUOKAN 1 LASERLAITE

VAROITUS

Laitteen käyt täminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa

käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARO

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättomälle lasersäteilylle. Älä

katso säteeseen.

Tämä on puolijohdelaser.Laserdiodin suurin teho on 5 mW (Di251)/15mW (Di351) ja

aallonpituuson 770-795 nm (Di251)/775-795nm (Di351).

For Sweden

KLASS 1 LASER APPARAT

VARNING

Om apparaten används på annat sätt än i denna bruksanvisning s pecificerats, kan

användarenutsättas för osynlig laserstrålning,som överskridergränsen f ör laserklass 1.

G-2

VARNING

Osynlig laserstråining när denna del är öppnad och spärren är urkopplad. Betrakta ej

stråien.

Det här är en halvledarlaser. Den maximala effekten för laserdioden är 5 mW (Di251)

15 mW (Di351) och våglängdenär 770-795 nm (Di251)/775-795 nm (Di351).

For Norway

ADVERSEL

Dersom apparatetbrukes på annen måte enn spesifisert i denne bruksanvisning,kan

brukeren utsettes för unsynlig laserstrålning, som overskrider grensenfor laser klass 1.

Dette en halveder laser.Maksimal effekttill laserdiode er 5 mW (Di251)/15 mW (Di351)

og b

φlgelengde er 770-795 nm (Di251)/775-795 nm (Di351).

Laser Safety Label

A laser safety label is attached to the outside of the copy machine as shown below.

Manufacturer’s

Name Plate

Laser safety label

CLASS 1 LASER PRODUCT

LASER KLASSE

1 PRODUKT

1166O252BA

The Manufacturer’s Name Plate is affixed at the position illustrated ab ove.

Please write down the Model Name and Serial No. of your copier here.

Model:

Serial No.:

G-3

4015O020AB

Label inside copy machine

The following laser safety label will be attached inside the copy machine as shown below.

Please read the following for your own protection.

Caution

Openingthe coverindicatedby the Caution labelmay exposeyouto harmful laserradiation

which could cause damage or loss of eyesight. Do not open the coverwhen the power is

on.

1166O234AA

G-4

ALL Areas

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Germany only

Explosinsgefahr bei unsachgemäßen austauschder batterie.

Ersatz nur durch denselben oder einen vom hersteller empfohlenen ähnlichentyp.

Entsorgunggebrauchter batterien nach angaben des herstellers.

CAUTION

VORSICHT!

Denmark only

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage t il leverandøren.

Norwayonly

Eksplosjonsfare ved feilaktig skifte av batteri.

Benyttsamme batteritype eller en tilsvarende type anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

Sweden only

Explosionsfaravid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av

apparattillverkaren.

Kasseraanvänt batteri enligt fabrikantens instruktion.

Finland only

Paristo voi räjähtää, los s e on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaantyyppiin.

Hävitä Käytetty paristo valmistajan ohjeiden mukaisesti.

ALL Areas

“Replace only with the same or equivalenttype recommended by the manufacturer.

Dispose of used IC Package accordingto the manufacturer’s instructions.”

ADVARSEL!

ADVARSEL

VARNING

VAROlTUS

CAUTION

Germany only

”Austausch nur durch denselben oder einen vom Hersteller empfohlenen,gleichwertigen

typ.Entsorgung gebrauchter Batterien nach A ngaben des Herstellers.

VORSICHT!

G-5

2. SPECIFICATION

TYPE

ORIGINAL SCANNING SYSTEM

PHOTOCONDUCTOR

COPYING SYSTEM

RESOLUTION

PAPER FEEDING SYSTEM

EXPOSURESYSTEM

DEVELOPING SYSTEM

CHARGING SYSTEM

IMAGE TRANSFER SYSTEM

PAPER SEPARATING SYSTEM

FUSING SYSTEM

PAPER DISCHARGING SYSTEM

MAX. ORIGINAL SIZE

COPY PAPER TYPE

PaperSource 1st Drawer Manual Feed Tray

Plain paper (60 to 90 g/m

Transparencies ❍❍

Type

Dimensions

❍: Reliably fed

Thickpaper (91 to 157 g/m

Postcards (190 g/m

Recycled paper ❍❍

Maximum (Width

Minimum (Width

:

Console/Desktop Type

:

CCD Line Sensor

:

Organic Photoconductor

:

Electrostatic Dry PowderedImage Transfer to Plain

Paperwith a Laser

:

600 dpi

:

3-way system

Manual Feed Tray...Single

1st Drawer...............250 Sheets (Plain paper)

2nd Drawer.............500 Sheets (Plain paper)

:

Mirror Scanning, Slit Exposure

:

MT-HG System

:

Comb Electrode (1) DC Negative Corona with

Scorotron System

Roller Image Transfer

:

PaperSeparator Fingersand Charge Neutralizing

:

Plate

Heat Roller

:

Charge Neutralizing Brush

:

A3L, 11”

:

× Length) 297 × 432 mm 297 × 432 mm

× Length) 90 × 140 mm 90 × 140 mm

× 17”L

2

)

2

)

2

)

50 Sheets (Special paper)

35 CPM/25 CPM: Standard

❍❍

❍❍

❍❍

MULTIPLE COPIES

WARMING-UP TIME

FIRST COPY TIME

:

35CPM(1to999),25CPM(1to99)

:

35 CPM (70 sec. or less)

25 CPM (60 sec. or less)

A4C, 1st Drawer, full size mode

:

35 CPM (4.6 sec.), 25 CPM (5.8 sec.)

G-6

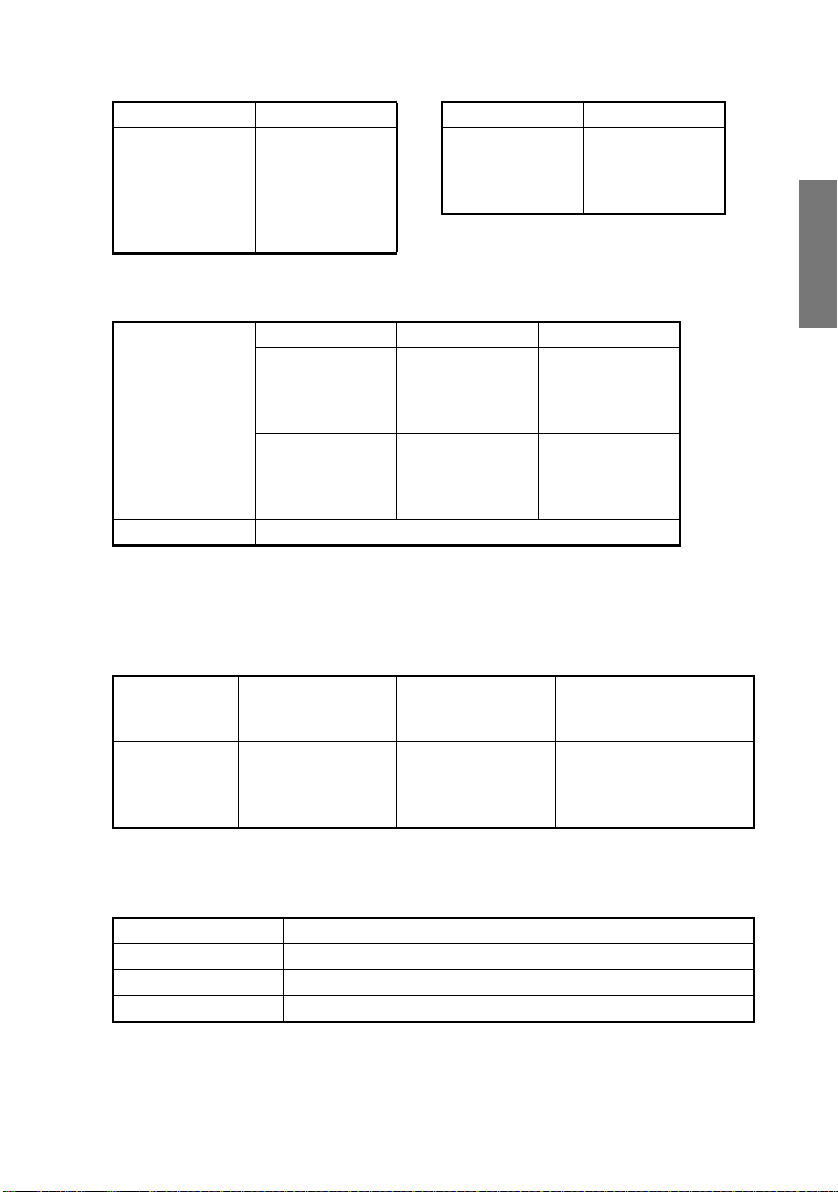

CONTINUOUS COPY SPEED (copies/min)

-Metric- -Inch-

Size Speed Size Speed

A3L

B4L

A4L

A4C

B5L

B5C

ZOOM RATIOS

Fixed

Variable 25 % to 400 % (in 0.1 % increments)

LENS

EXPOSURE LAMP

FUSING TEMPERATURE

20

23

27

35

30

40

Full Size

Enlargement

Reduction

Through Lens (F = 4.0, f = 62 mm)

:

FluorescentLamp

:

190 °C

:

11

× 17L

8-1/2

× 14L

8-1/2

× 11L

8-1/2

× 11C

- Metric - - Inch -

× 1.000 × 1.000

× 2.000

× 1.414

× 1.224

× 1.154

× 0.866

× 0.816

× 0.707

× 0.500

20

23

28

35

× 2.000

× 1.545

× 1.294

× 1.214

× 0.785

× 0.733

× 0.647

× 0.500

POWER/CURRENT CONSUMPTION (copier only)

ExposureLamp

(Rating)

24 V

20 W

POWER REQUIREMENTS : 230 V, 50/60 Hz

ENVIRONMENTAL CONDITIONS

Temperature 10 to 32 °C with a fluctuationof 10 °C or less per hour

Humidity 15 to 85 % RH with a fluctuation of 10 % RH or less per hour

Ambient Illumination 3,000 lux or less

Levelness 1° (1.75 mm/100 mm)

Fusing Roller

Heater Lamp

(Rating)

35 CPM: 800 W

25 CPM: 800 W

Max. Power

Consumption

(full system)

230 V: 1450 W

Max. Current

Consumption

(full system)

Metric area

35 CPM/25 CPM: 6 A

Inch area

35 CPM/25 CPM: 11.5 A

G-7

COPIER DIMENSIONS

COPIER WEIGHT

::Metric area

35 CPM: W...632 mm, D...707mm, H...647 mm

25 CPM: W...594 mm, D...707mm, H...647 mm

Inch area

35 CPM: W...25, D. ..27-3/4, H...25-1/2

25 CPM: W...23-1/2, D...27-3/4,H...25-1/2

Metric area

35 CPM: 60.5 kg, 25 CPM: 58.7 kg

Inch area

35 CPM: 133-1/2 lb,25 CPM: 129-1/2 lb

G-8

3. PRECAUTIONS FOR INSTALLATION

3-1. Installation Site

To ensure safety and utmost performanceof the copier,the copiershould NOT be used in a

place:

• Whereit will be s ubjected to extremely high or low t emperature or humidity.

• Whereit will be s ubjected to sudden fluctuations in either temperature or humidity.

• Which is exposed to direct sunlight.

• Which is in the direct air stream of an air conditioner, heater, or ventilator.

• Which has poor ventilation or is dusty.

• Which does not have a stable, level floor or where it will receive undue vibration.

• Which is near any kind of heating device.

• Whic h is near volatile flammables(thinner, gasoline, etc.).

• Where it may be splashed with water.

• Whic h puts the operator in the direct stream of exhaustfrom the copier.

• Where ammonia gas might be generated.

3-2. Power Source

• If any other electrical equipment is sourced from the same power outlet, make sure that

the capacityof the outlet is not exceeded.

• Use a power source with little voltage fluctuation.

• Neverconnect by means of a multiple socket any other appliances or machines to the

outletbeingusedforthecopier.

• Ensure that the copier does not ride on the power cord or communication cable of other

electricalequipment, and that it does not become wedged into or underneath the mechanism.

• Make the following checks at frequent intervals:

✽ Is the power plug abnormally hot?

✽ Are there any cracks or scrapes in the cord?

✽ Ha s the power plug been inserted f ully into the outlet?

✽ Does something, including the copier itself,ride on the power cord?

Use an outlet with a capacity of 15 A or more. 220 to 240 V, 10 A or more.

3-3. Grounding

• Always ground the copier to prevent receivingelectrical shocks in the case of electrical

leakage.

• Connectthe groundwire to the ground terminalof the outlet or a groundingcontactwhich

complies with the local electrical standards.

• Neverconnect the ground wire to a gas pipe, the ground wire for a telephone, lightning

arrester, or a water pipe for fear of fire and electrical shock.

G-9

4. PRECAUTIONS FOR USE

4-1. To ensure that the copier is used in an optimum condition

• Neverplace a heavy object on the copier or subject the copier to shocks.

• Insert the power plug all the way into the outlet.

• Do not attemptto removeany panel or cover which is secured while the copier is making

copies.

• Do not turn OFF the copier while it is making copies.

• Provide good ventilation when making a large number of copies c ontinuously.

• Never use flammable sprays near the copier.

• If the copier becomes inordinately hot or produces abnormal noise, turn it OFF and

unplug it.

• DonotturnONthepowerswitchatthesametimewhenyouplugthepowercordintothe

outlet.

• When unpluggingthe power cord, do not pull on the cord; hold the plug and pull it out.

• Do not bring any magnetizedobject near the copier.

• Do not place a vase or vessel containing water on the copier.

• Besure to turn OFF the power switchat the end of the workday or upon power failure.

• Use care not to drop paper clips,staples, or o ther small pieces of metal into the copier.

4-2. Operating Environment

The operating environmentalrequirements of the copier are as follows.

• Temperature:10to32°C

• Humidity:15 to 85 % RH

• Rate of temperature change: 10 °C/h

• Rate of humidity change: 10 % RH/h

4-3. Power Requirements

The power source voltage requirementsare as follows.

• Voltage f luctuation: AC 220 to 240 V ±10 %

• Frequency fluctuation: 50/60 Hz ±0.3 %

(copying performance assured)

+10 %/-15 % (paper feeding performanceassured)

4-4. Note

• It is prohibited to copy paper and hard currencies,government securities, and municipal

bonds (even when they are stamped as “Sample”).

• For fear of infringement of copyright, it is also prohibited to copy copyrightedworks,

including books, music, works of art, maps, drawings,motion pictures,and photos except

whenthecopyistobeusedonlypersonally.

G-10

5. HANDLING OF CONSUMABLES

Before using any consumables, a lways read the label on its container carefully.

• Paper can be easily damaged by dampness.To preventabsorption of moisture,store

paper, which has been removed from its wrapper but not loaded in the drawer, in a

sealed plastic bag in a cool, dark place.

• Keep consumables out of the reach of children.

• Do not touch the PC Dr um with bare hands.

• The same sized paper is of two kinds, short grain and long grain. Short grain paper

should only be fed through the copier crosswise, long grain paper should only be fed

lengthwise.

• If your hands become soiled with toner, wash them with soap and water.

• Do not throwaway any used consumables(PC Drum, starter,toner,etc.). They are to be

collected.

• Do not burn, bury in the ground, or throw into the water any consumables (PC Drum,

starter, toner, etc.).

• Donot store consumables in a p lacewhich:

✽ Is hot and humid.

✽ Is subject to direct sunlight.

✽ Hasanopenflamenearby.

G-11

6. OTHER PRECAUTIONS

Use the following precautions when performing service jobs for a copier that uses a laser.

• When a service job needs to be performed in the laser beam path, such aswhen working

around the printerhead or PC Drum, be sure first to unplug the power cord of the copier

from the outlet.

• If the job requires that the power cord be left plugged in, observe the following precautions.

1. Take off your watch, ring and any other reflective object and wear laser protective gog-

gles.

2. Keep users away from t he job site.

3. Do not bring a highly reflectivetool into the laser beam path during the service job.

G-12

7. SYSTEM OPTIONS

1

2

3

13

18

4015O218AA

1166O011AA

1166O012AA

14, 15

1166O014AA 1166O007AA

1166O008AA

19

1145M035AA

17

4002O102AA

4015O025AB

4015O028AB

16

4015O027AA

4002O099AA

4015O029AA

1166O190AA

11

12

4

5

6, 7

8

9

10

1. Duplexing Document Feeder AFR-17

2. Automatic Document Feeder AF-9

3. Original Cover Kit OC-3

4. Plug-In Counter

5. Duplex Unit AD-15 (35 CPM: Standard)

6. Paper Feed Unit PF-118

7. Paper Feed Unit PF-119

(35CPM/25CPM:Standard)

8. Large Capacity Cabinet PF-117

9. Copy Table

G-13

1166O191AB

10.Copy Desk

11. Pr inter Controller Pi3502

12.8MB/16MB/32MB Memory

13.Data TerminalDT-103

14.Finisher FN-109

15.Finisher FN-110

16.Job Tray JS-201

17.Shift TrayOT-102

18.Option TrayJS-100

19. Mailbin Finisher FN-5 04

MECHANICAL/

ELECTRICAL

CONTENTS

1. CROSS-SECTIONAL VIEW ............................................................................M-1

2. COPYING PROCESS ......................................................................................M-2

3. DRIVE SYSTEM ..............................................................................................M-4

4. OPERATING SEQUENCE ..............................................................................M-5

5. CPUOVERRUN MONIT OR FUNCTION .........................................................M-6

5-1. Processing Performed during Watchdog Function ..................................M-6

6. IMAGE STABILIZATION SYSTEM ..................................................................M-7

7. IMAGING CARTRIDGE (I/C) ...........................................................................M-8

7-1. I/C Drive Mechanism ...............................................................................M-9

7-2. Identification and Life of I/C .....................................................................M-9

8. P C DRUM ........................................................................................................M-10

8-1. Grounding of the PC Drum ......................................................................M-10

9. DRUM CHARGING ..........................................................................................M-11

(1) Ozone Fan .......................................................................................M-12

10. IR SECTION ....................................................................................................M-13

10-1.Construction of the Exposure Section .....................................................M-14

10-2.Image Processing Flow ...........................................................................M-15

10-3.Scanner and 2nd/3rd Mirrors Carriage Moving Mechanism ....................M-16

(1) Scanner Moving Mechanism ........................................................... M-16

(2) 2nd/3rd Mirrors Carriage Moving Mechanism .................................M-16

11. ORIGINAL SIZE DETECTING SYSTEM .........................................................M-17

11-1.Original Size Detecting Operation ...........................................................M-18

11-2.Original Size Detection ............................................................................M-18

11-3.Original Size Detection Timing ................................................................M-19

12. PH SECTION ...................................................................................................M-20

12-1.Laser Emission Timing ............................................................................M-21

13. DEVELOPING UNIT ........................................................................................M-22

13-1.Sleeve/Magnet Roller ..............................................................................M-23

13-2.Developing Bias .......................................................................................M-23

13-3.ATDC Sensor ..........................................................................................M-24

(1) ATDC Sensor Automatic Adjustment ..............................................M-24

(2) Toner Replenishing Control .............................................................M-24

(3) Toner Empty Control (T/C Recovery Mode) ....................................M-25

13-4.Toner Bottle Home Position Detection Mechanism .................................M-26

13-5.Toner Bottle Vibration Mechanism ..........................................................M-26

13-6.Main Hopper Toner Replenishing Mechanism ........................................M-27

13-7.Sub Hopper Toner Replenishing Mechanism ..........................................M-28

13-8.Sub Hopper Toner Empty Detection Control ...........................................M-28

14. PAPER TAKE-UP/FEED SECTION ................................................................ M-29

14-1.1st Drawer-in-Position Detection .............................................................M-29

14-2.1st Drawer Paper Empty Detection .........................................................M-30

14-3.1st Drawer Paper Near-Empty Detection ................................................M-30

14-4.1st Drawer Paper Lifting Plate .................................................................M-31

14-5.1st Drawer Paper Size Detection ............................................................M-31

(1) Paper Size Table According to Sensor/Switch Conditions ..............M-32

14-6.Drawer Paper Take-Up Mechanism ........................................................M-33

i

(1) Paper Separating Mechanism .........................................................M-33

14-7.Drawer Paper Take-Up Control ...............................................................M-34

(1) Paper Take-Up Roll .........................................................................M-34

(2) Paper Take-Up Retry Control ..........................................................M-34

(3) Paper Take-Up Interval Control .......................................................M-34

(4) Double Feed Paper Take-Up Control (35-cpm copier only) ............M-35

15. MANUAL BYPASS TRAY ................................................................................M-36

15-1.Manual Bypass Paper Take-Up Control ..................................................M-36

15-2.Manual Bypass Paper Empty Detection ..................................................M-36

16. SYNCHRONIZING ROLLERS .........................................................................M-37

16-1.Paper Dust Remover ...............................................................................M-37

16-2.Synchronizing Roller Drive Mechanism ...................................................M-38

17. IMAGE TRANSFER AND PAPER SEPARATION ...........................................M-39

17-1.PC Drum Paper Separator Fingers .........................................................M-39

18. PC DRUM CLEANING ..................................................................................... M-40

19. ERASE LAMP ..................................................................................................M-41

20. FUSING UNIT ..................................................................................................M-42

20-1.Fusing Unit Drive Mechanism ..................................................................M-43

20-2.Fusing Temperature Control ....................................................................M-44

(1) Temperature Control Table during Standby State and Copy Cycle M-44

20-3.CPM Control ............................................................................................M-44

21. PAPER EXIT UNIT ..........................................................................................M-45

22. OTHER UNITS AND MECHANISMS ..............................................................M-46

22-1.Memory Backup .......................................................................................M-46

22-2.Flash Memory ..........................................................................................M-46

22-3.Interior Cooling Mechanism .....................................................................M-47

(1) I/C Cooling Mechanism ...................................................................M-47

(2) Fusing Section Cooling Mechanism ................................................M-48

(3) Power Supply Section Cooling Mechanism .....................................M-49

ii

1. CROSS-SECTIONAL VIEW

2

1

18

3

4

5

67

8

9

10

11

12

1. 2nd Mirror

2. 3rd Mirror

3. Exposure Lamp

4. 1st Mirror

5. Lens

6. CCD Unit

7. Paper Exit Roller

8. Fusing Transport Roller

9. Right Fusing Roller

17

16

10.Image TransferRoller

11.Synchronizing Roller

12.Manual Bypass Tray

13.Manual Feed Paper Take-Up Roll

14.Paper SeparatorPad

15.Paper Take-Up Roll

16.Imaging Cartridge I/C

17.PH Unit

18.Left Fusing Roller

15

14

M-1

13

4011M001AA

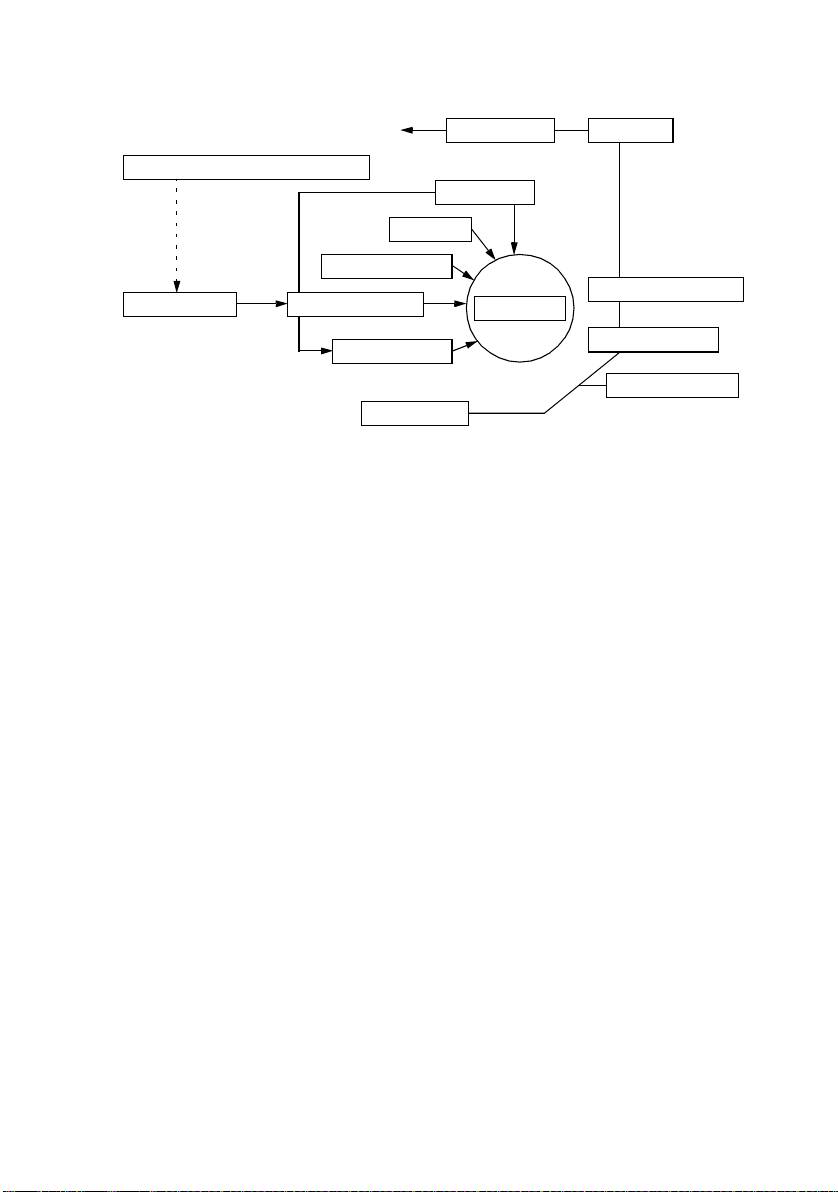

2. COPYING PROCESS

13. Fusing

10. Paper Separation

9. Image Transfer

8. Manual Bypass

3. PhotoelectricConversion Section

2. Drum Charging

4. MFB2 Board

5. Laser Exposure

14. Paper Exit

11. Cleaning

12. Erase

1. PC Drum

6. Development

7. Paper Feed

1. PC Drum

• Changes the image of the original projected onto the surface of the drum to a corresponding electrostatic latent image.

2. Drum Charging

• Generatesa negative DC charged layer on the surfaceof the PC Drum.

3. Photoelectric Conversion Section

• The CCD converts the light reflected off the original to a corresponding electrical signal

and outputs it to the IR image processing section.

4. MFB2 Board

• Convertsthe electrical signalto a corresponding 8-bit digitalimage signal, makesvarious

corrections,and outputs the results to t he memory.

• Compressesand stores in memory the digitalimage signal,and then outputsit to the PH

image processing section.

• After going through necessary corrections, the digital image signal is convertedto a correspondinganalog signal, based on which the intensity of the laser light is controlled.

5. Laser Exposure

• Alaser beam strikes the surface of the PC Drum, creating an electrostaticlatent image.

6. Development

• Negatively charged toneradheres to the latentimage onthe PC Drum surface,creatinga

visible image.

• AC/DC negative bias voltages are applied to the Sleeve/Magnet Roller, thereby preventing toner from sticking to the background.

• Toner scraped off by the cleaningmechanism is recycled.

7. Paper Feed

• Feeds sheets of paper from the appropriate paper source.

8. Manual Bypass

• Feeds sheets of paper from the Manual Bypass Tray.

9. Image Transfer

• Apositive charge is applied to the Image Transfer Roller to transfer the visible image on

the surfaceof the PC Drum onto the paper.

10.Paper Separation

• The PC Drum Separator Fingers remove paper from the surface of the PC Drum.

M-2

11. Cleaning

• Residual toner is scraped off the surface of the PC Drum.

• The toner is then recycled back to the Developing Unit.

12. Erase

• The PC Drum is exposed to light, which effectively neutralize any residual charge on the

surface of the PC Drum.

13. Fusing

• Heat and pressure applied by the Right and Left FusingRollers fuse toner on the paper.

14. Paper Exit

• Feeds paper out of the copier onto the Exit Tray.

M-3

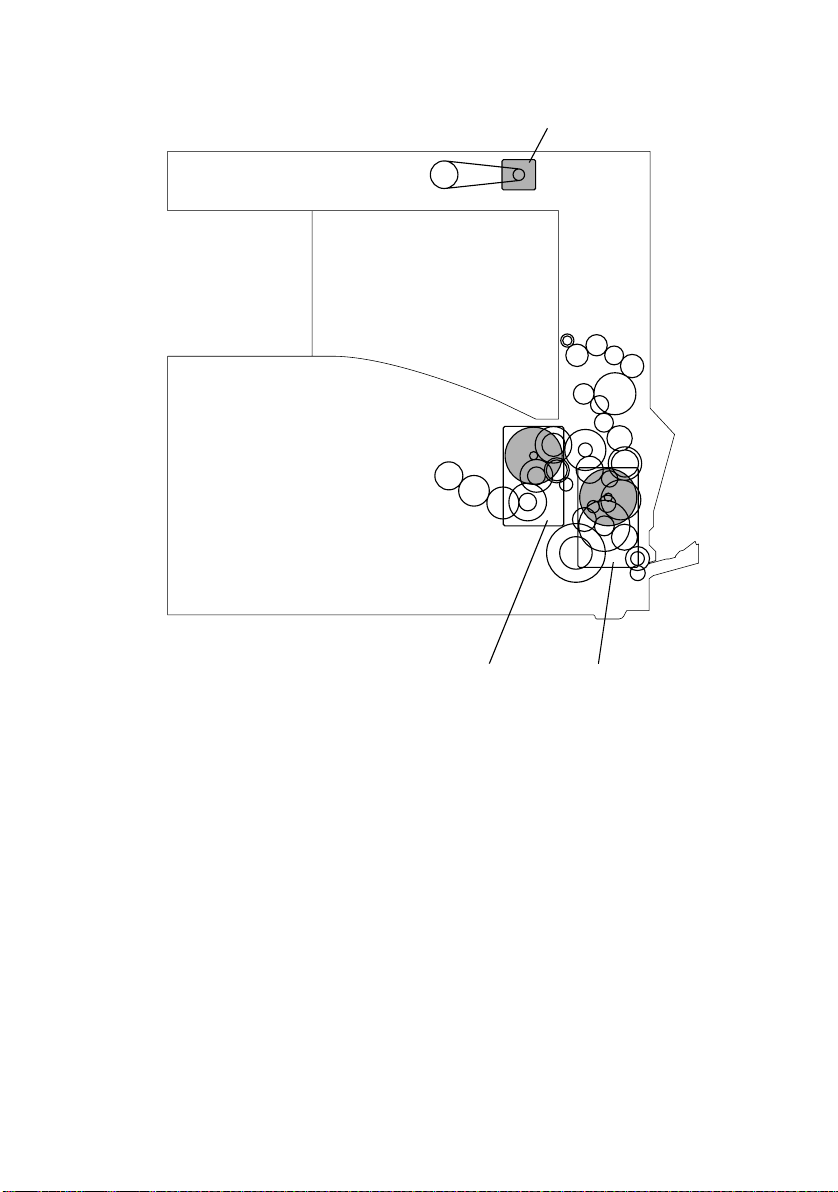

3. DRIVE SYSTEM

1

1. Scanner Motor M10

2. Main Motor M2

3. I/C Motor M1

M-4

32

4011M002AA

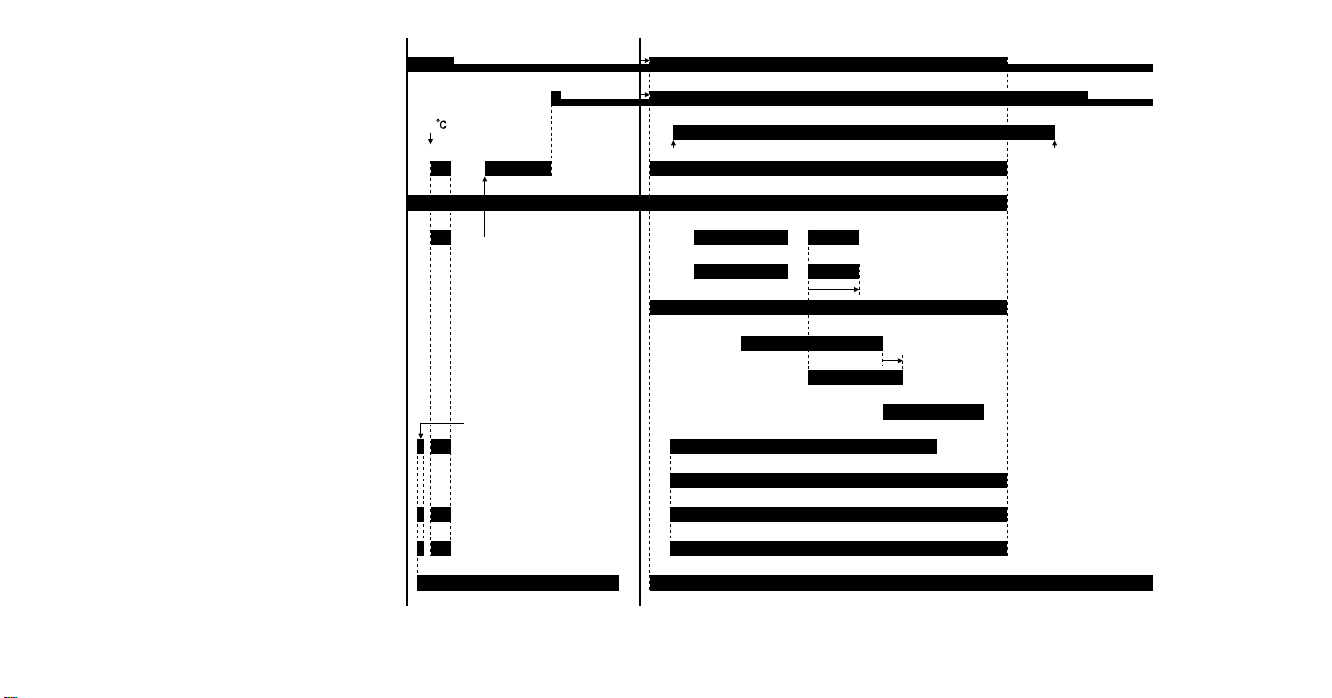

Power Switch ON Start key ON

Power Unit Cooling Fan Motor M4

Cooling Fan Motor M3

Ozone Fan Motor M8

Main Motor M2

Fusing Roller Heater Lamp H1

Full speed

170

Predrive

Half speed

Full speed

Fusing predrive

Half speed

Full speed

Full speed

*1 *2

Half speed

Half speed

4. OPERATING SEQUENCE

FrameMaker Ver5.5E(PC) Di251/Di351 MECHANICAL/ELECTRICAL

.05.03.01

M-5

Manual Feed Paper Take-Up Clutch CL2

1st Drawer Paper Take-Up Solenoid SL1

Polygon Motor M5

Synchronizing Roller Sensor PC2

Synchronizing Clutch CL1

Paper Exit Sensor PC3

I/C Motor M1

Laser

Drum Charge Bias

Image Transfer Bias

4011M028CA

Developing Bias

Warm-up completed

Agitation predrive

*1: When the Main Motor or I/C Motor remains energized for a continuous 300-ms period.

*2: When the Main Motor and I/C Motor remain deenergized for a continuous 10-s period.

5. CPU OVERRUN MONITOR FUNCTION

• The CPU overrun monitor function (watchdog function) is a self-monitoringfunction that

determines whether any of the CPUs mounted on the copier overruns.

• If this functiondetects that a CPU overruns,the copier automaticallyresets the CPU,

restarting the logic circuit and mechanism.

• The copier CPU not only performs the self-monitoring function, but also checks the communicationstatus with the option’s CPU.

5-1. Processing Performed during Watchdog Function

The following operations are performedwhen a CPU operates erratically.

If a copier CPU overruns:

• All CPUs includingthose of the options are reset and a restart sequence is performed.

• Ifthe overrun occurs during a copy cycle, the copier triesto feed all sheets of paper out of

itselfbefore resetting theCPU. (Any sheet of paper that could not be fed out of the copier

is detected as a sheet of paper left when the restart sequence is later carried out.)

If an erratic operation is detected in communications with the option’s CPU:

• The copier turns OFF and O N the option’s relay and performs a restart sequence of the

option.

• If the overrun occurs during a copy cycle, the copier stops the paper take-up operation,

feedsall sheets of paperout of itself,and then performsa restart sequence of the option.

M-6

6. IMAGE STABILIZATION SYSTEM

• Thefollowing image stabilization controls are provided to ensure stabilized copy image.

Item Purpose Control

PC Drum temperature

correction

PC Drum deterioration

correction

Grid Voltage: Vg

To compensate for any change

in ID due to changing PC Dr um

temperatures.

To compensate for degraded

sensitivity caused by a deteriorating PC Drum.

PC Drum

Sleeve/

Magnet Roller

Developing Bias: Vb

I/CThermistor is used to detect

temperatureand, according to

the detectedtemperature,Vg/

Vb is corrected.

Vg is correctedaccording to the

period of time during which the

PC Drum has turned.

PC Drum Charge Corona

I/C Thermistor TH2

PC Drum Revolution

Counter

M-7

CPU

1171M028AA

7. IMAGING CARTRIDGE (I/C)

• This copier employs an Imaging Cartridge (“I/C” in this manual).

• The I/C contains a PC Drum, DevelopingUnit, PC Drum Charge Corona, and a Cleaning

Unit as one unit.

Toner Supply Port

1171M002AA

1171M003AA

ATDC Sensor UN2

M-8

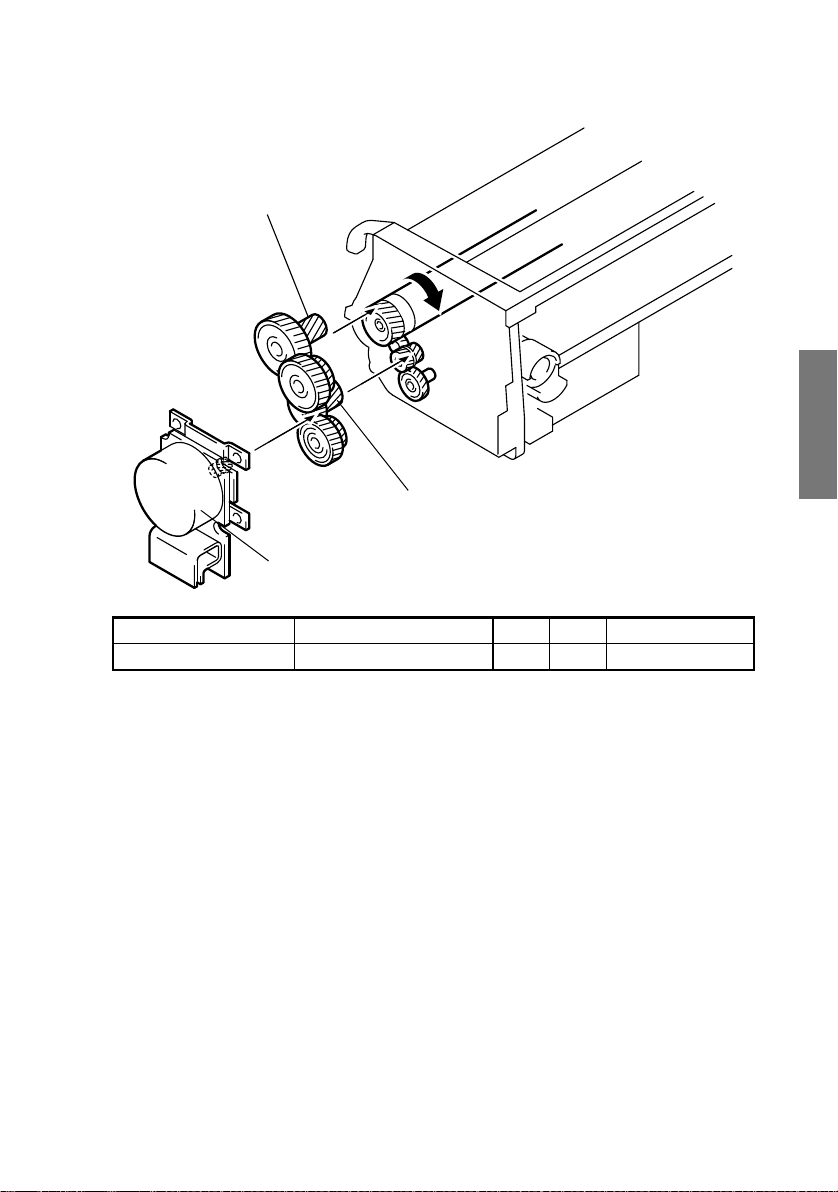

7-1. I/C Drive Mechanism

• Drive from the I/C Motor is transmitted via a gear train to the PC Drum and Hopper.

PC Drum Drive Gear

Hopper Drive Gear

I/C Motor M1

4011M021AA

ElectricalComponent Control Signal ON OFF Wiring Diagram

M1 PJ5A-3 L H 5-G

7-2. Identification and Life of I/C

• When the Start key is pressed or the Side Cover is opened and closed, the copier determines whether the I/C is new or one which has been used previously.

• The copier monitors the I/C life by storing in memory the period of time during which the

PC Drum has turned. The data is c leared when a new I/C is installed in the copier.

M-9

8. PC DRUM

• The PCDrum consists of an aluminum base coated with a charge generation layer and a

charge transport layer.

PC Drum

1167M007AA

Gear

(PC Drum Cross-Section)

Charge Transport Layer

Charge GenerationLayer

AluminumBase

1139M007AA

8-1. Grounding of the PC Drum

• The potentialof the areas on the surface of the PC Drum exposedto the laser light is

grounded to the frame.

Ground Point

Ground Plate

PC Drum

Shaft

1171M005AA

M-10

Loading...

Loading...