Page 1

DRYPRO model 752

OPERATION MANUAL

LASER IMAGER

KONICA CORPORATION

No. 26-2, Nishishinjuku 1-chome, Shinjuku-ku, Tokyo 163-0512, Japan

CODE NO.

0463 (UL), 0467

(CE)

Page 2

Blank page

Page 3

DRY LASER IMAGER DRYPRO MODEL 752

Table of Contents

Introduction................................................................................ ii

Descriptions of Symbol Mark.....................................................iii

Descriptions on Warning Label................................................. iv

Warning Label............................................................................ v

Warning Label Location............................................................ vi

Safety Caution ..........................................................................vii

Precaution..................................................................................x

1. Name of Each Component..................................................1

1-1. Main Body.....................................................................1

1-2. Sorter LiS-752 (option) ................................................3

2. Structure .............................................................................4

3. How To Operate...................................................................5

3-1. Control Panel ...............................................................5

3-2. Start-up Operation........................................................6

3-3. Shut-down Operation....................................................8

3-4. Film Loading...............................................................11

4. Maintenance Mode............................................................ 16

4-1. Function of Maintenance Mode ..................................16

4-2. Switching Maintenance Mode.....................................17

4-3. How To Operate Maintenance Mode ..........................18

5. Troubleshooting.................................................................47

5-1. Error Display and Remedy..........................................47

5-2. Resetting Errors.......................................................... 49

5-3. Removing Jam............................................................ 52

5-4. When Film Fails to be Loaded....................................61

6. Service and Maintenance.................................................. 65

6-1. Periodical Maintenance and Inspection......................65

6-2. Replacing FILTER.......................................................66

6-3. Service and Maintenance Schedule...........................67

7. Specifications....................................................................69

Appendix..................................................................................71

HANDLING AND STORAGE OF DRY FILM............................72

This device uses laser. Direct exposure of the laser

on the skin or in the eyes may lead to serious

injuries. And, high voltage may be applied on some

sections in the device. Be careful not to suffer an

electrical shock upon handling the device.

Be sure to observe the following in order to prevent any danger.

1. NEVER remove the external and internal covers with a screwdriver, and others.

2. NEVER perform any operations, adjustments, or actions other than the specified in this

Operation Manual; otherwise, you may be exposed to dangerous radiation.

3. If any problem occurs in this device, contact a service person. NEVER use the troubled

device as it is dangerous.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 i

Page 4

•

•

Introduction

Thank you for purchasing Dry Laser Imager DRYPRO model 752.

The Dry Laser Imager DRYPRO model 752 makes all processing dried and improv es the en vironment and the

operability while maintaining high performance and high-quality images.

•

High-quality Image

µ

1) Realizing super-sharpened images with the pixel size of 40

2) Newly developing film that is most suitable for the imager and CR

3) Supporting 12-bit image input

4) Rendering high-quality images with advanced image interpolation processing technology

5) Installing the auto density control function for stabled image output

Operation environment

1) Shortening waiting time for output by high-speed processing capability (120 sheets / hour)

2) Simultaneously loading different sizes and types with the two trays

m (min.)

Imaging environment

Direct connection to diagnostic devices with DICOM communications function securing expandability on the open

network.

- Sorter LiS-752 is optional device.

ii DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 5

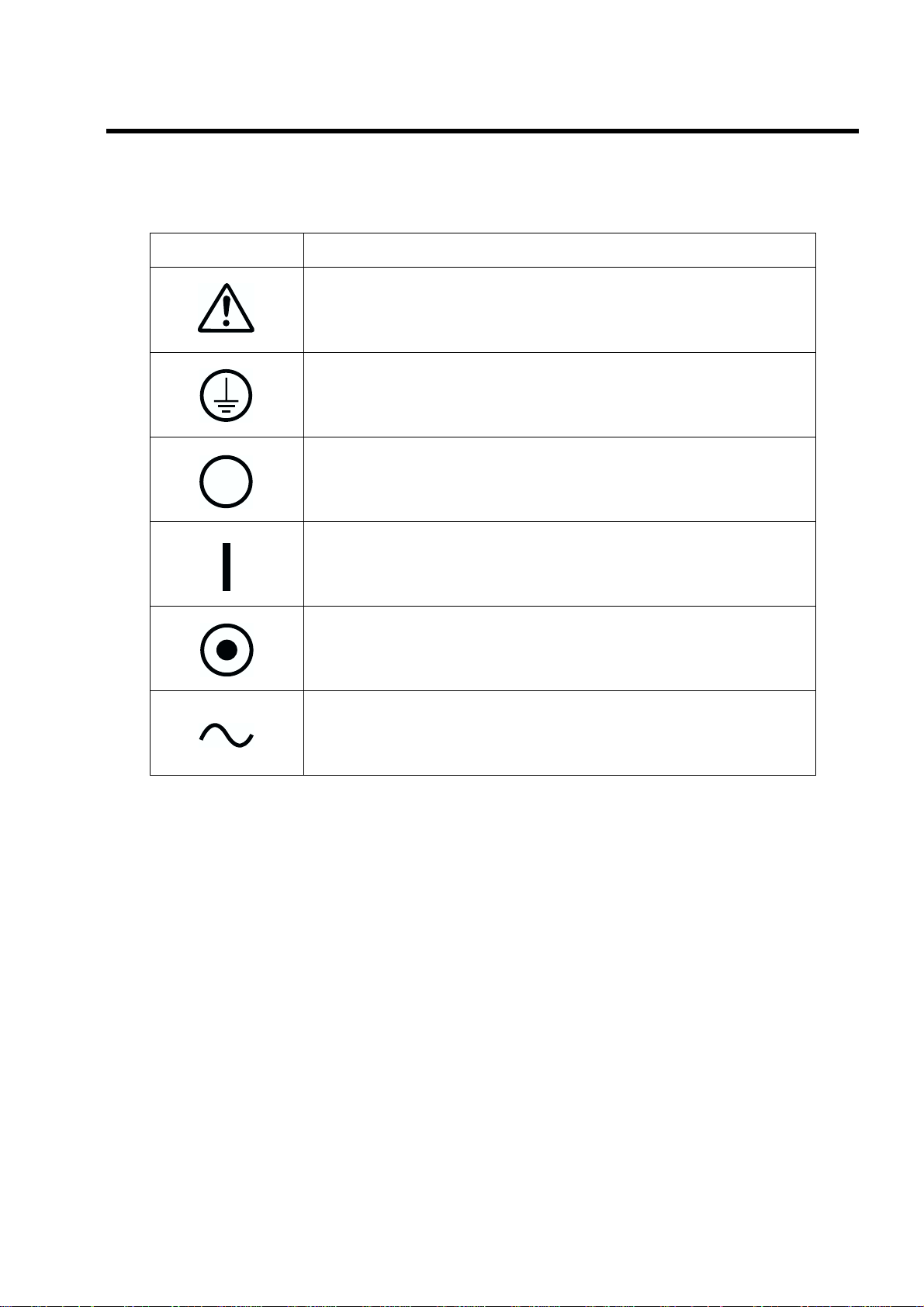

Descriptions of Symbol Mark

The meaning of following symbol marks described in this equipment and this manual is as the following table.

Symbol mark Descriptions of symbol mark

Attention

Consult accompanying document.

Protective earth (ground)

OFF (power: disconnection from the mains)

ON (power: connection to the mains)

ON (only for a part of equipment)

Alternating current

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 iii

Page 6

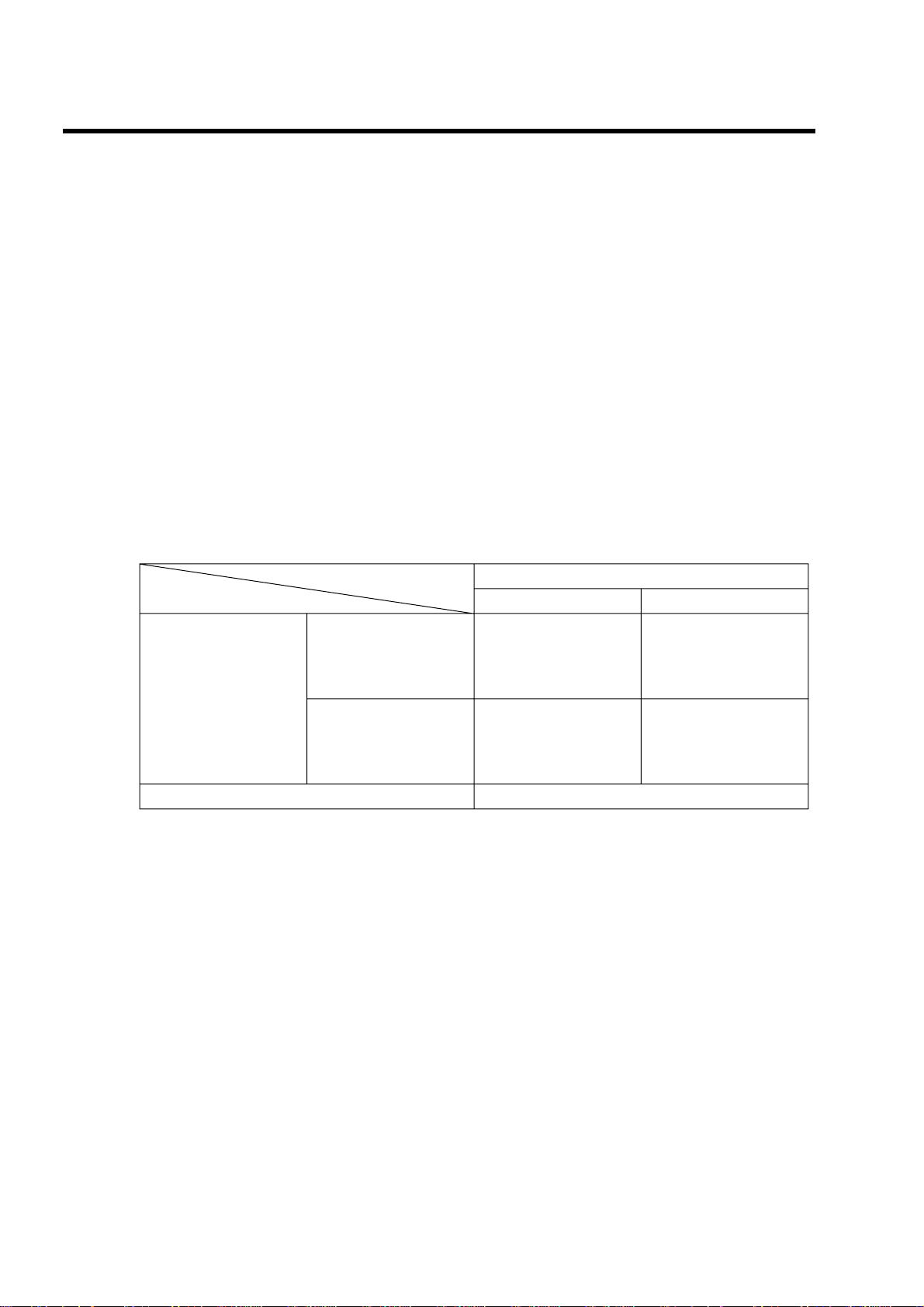

Descriptions on Warning Label

"

Descriptions on warning (caution label)

#

Caution labels imply the degree of the risk that may arise from incorrect use of this product.

#

There are three degrees of caution labels, and each is used depending on the level of risk and

damage caused by incorrect use and mishandling.

DANGER:

WARNING:

CAUTION:

Bodily injury

(and damage to

property)

If failed to avoid the risk, this implies the imminent danger level that may lead

to serious injury including a loss of life.

If failed to avoid the risk, this implies the danger level that may lead to serious

injury including a loss of life.

If failed to avoid the risk, this implies the danger level that may lead to

moderate damage or light injury. Also it is used when a physical damage

alone is expected.

Risk of Damage

High Low

Loss of life or serious

injury

(Damage is serious)

Moderate damage or

light injury

(Damage is light)

DANGER WARNING

WARNING or

CAUTION

CAUTION

Damage to property only CAUTION

[NOTE] : If the contents of this page are not legible, order a new manual.

iv DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 7

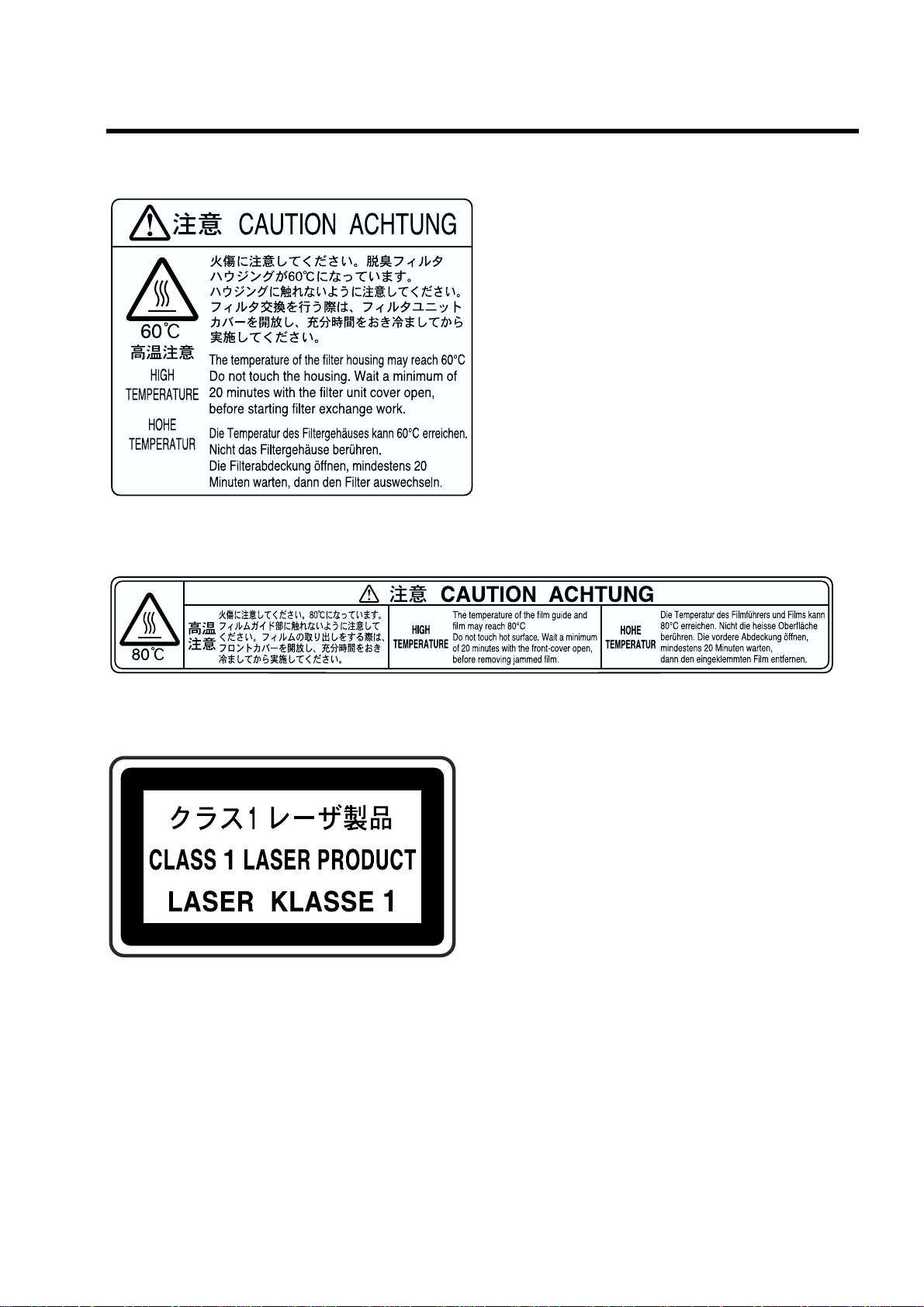

Warning Label

(1)

(2)

(3)

[NOTE] : If the contents of this page are not legible, order a new manual.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 v

Page 8

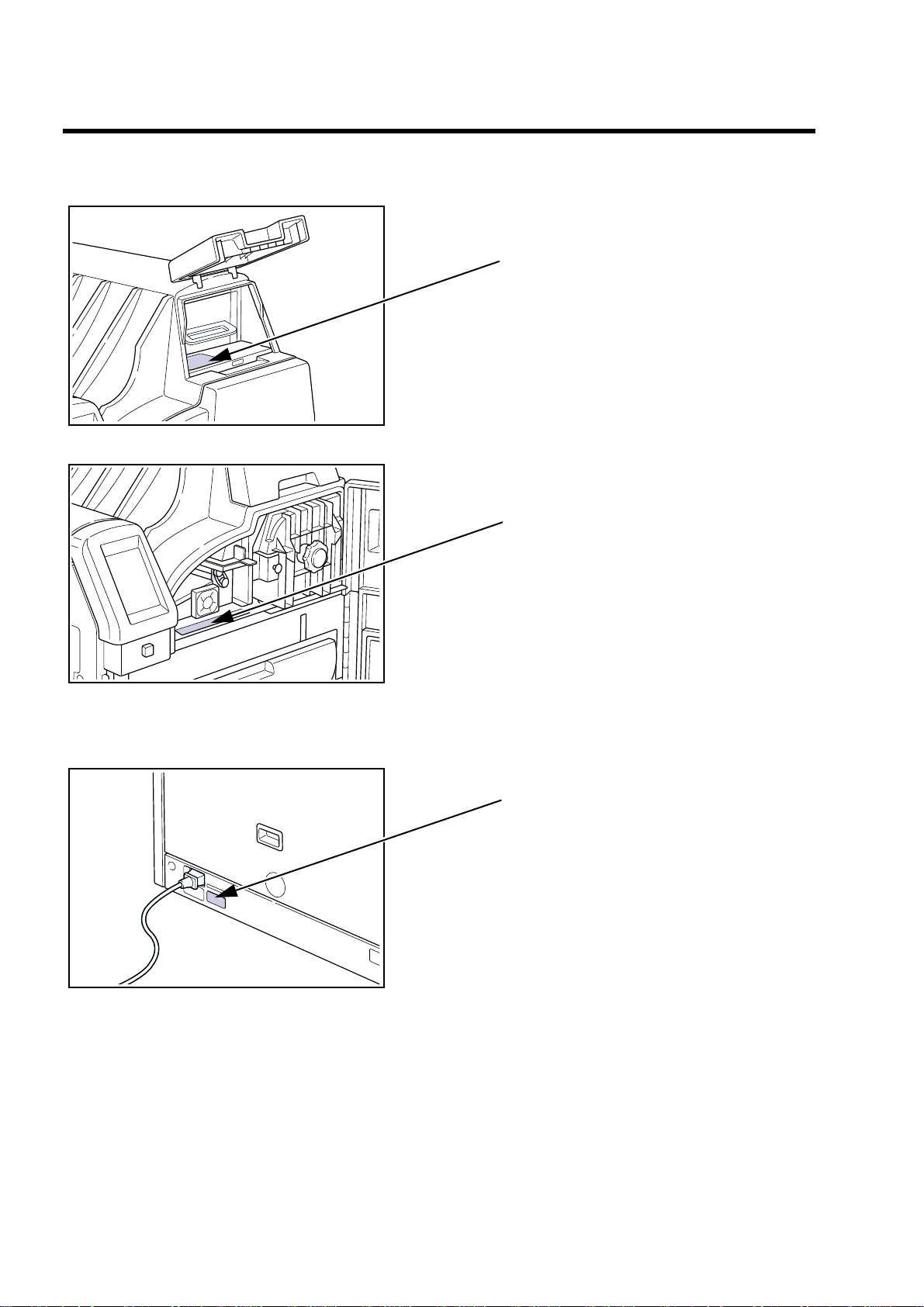

Warning Label Location

1) Front

(1)

2) Rear

(2)

(3)

[NOTE] : If the contents of this page are not legible, order a new manual.

vi DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 9

Safety Caution

Before operating this device, be sure to read Safety Caution.

Be sure to observe the safety cautions described here as they are very important for safety.

"

Cautions on installation

Never attempt to modify the device.

If you modify the device, this may cause a breakdown, electric shock, or fire.

For installation, contact a sales office where you purchased this device or

a service person.

If you install the device and there are any problems in installation, this may cause an electric shock or a fire.

Be sure to ground the device well.

Never connect the grounding cable to the gas pipe, water supply pipe, lighting rod, or the

grounding cable for telephone.

As for the electrical work (including grounding and communications cable

work) follow the local regulations on the technical standards.

If the work is not done properly, this may cause an electric shock or breakdown.

Use the power supply with sufficient capacities according to the specifications.

If you use any power supply other than the specifications, or the power supply with insuffi-

cient capacities, this may result in heating the electrical components or cause a fire.

"

Cautions on transporting, storing temporally, and servicing

If an abnormal sound, stench, or smoking occurs in this device, immediately turn the power OFF, then unplug the power cable. Contact a sales

office where you purchased this device or a service person.

If you continue using the troubled device, this may cause a breakdown, electric shock or

fire.

If any error other than the specified in this Operation Manual occurs, contact a service person.

If you repair it by yourself, and there are any problems on it, this may cause an electric

shock or fire.

When transporting, temporally storing, or re-installing this device, contact

a sales office where you purchased this device or a service person.

If you transporting or re-installing it by yourself, and there are any problems on it, this may

cause an electric shock or fire.

[NOTE] : If the contents of this page are not legible, order a new manual.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 vii

Page 10

Safety Caution

"

Cautions on use

Never open or close any covers other than the specified in this Operation

Manual.

High voltage may be applied on some sections in the device. If you touch them accidentally, you may suffer burns or an electric shock.

When replacing FILTER or removing film jams in the discharge section,

follow the procedure in this Operation Manual;

otherwise, a fire may be caused.

When touching the LCD (glass) on the control panel, do not give a strong

mechanical impact; otherwise it may be damaged. If the LCD is damaged,

immediately contact a service person.

This cause a breakdown or injuries.

Plug the power cable completely.

If dust is accumulated on the power plug, or the power cable is not plugged properly, this

may cause an electric shock or a fire.

Be sure to use the power cable supplied with this device. Do not use an

extension cord or do not connect another device to the same wall outlet;

otherwise, a fire or heating may be caused.

Be careful not to trip over the power cable to damage it.

If you continue using the damaged power cable, this may cause an electric shock or fire.

Do not block the air intake or the air outlet of this device;

otherwise, a breakdown may be caused.

Do not start up or shut off the device by plugging or unplugging the power

cable;

otherwise, an electric shock or breakdown may be caused.

If it is likely that lightning may occur, stop operating the device, and unplug

the power cable.

A breakdown may occur depending on the degree of lightning.

Do not use this device for any purpose other than printing image data;

otherwise, a breakdown may be caused.

Do not operate the switches with wet hands;

otherwise, you may suffer an electric shock.

[NOTE] : If the contents of this page are not legible, order a new manual.

viii DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 11

Safety Caution

When unplugging the power cable, do not pull it;

otherwise, the inner cable may be broken, and this may cause heating or a fire.

Do not let this device exposed to water by cleaning the device with a wet

cloth or placing the vase containing water on the device, etc;

otherwise, you may suffer an electric shock due to a leakage of currents.

Before you clean the device, be sure to stop operating it, and unplug the

power cable or turn the breaker OFF;

otherwise, you may suffer injury or the device may be broken do wn as the f an rotates at the

high speed in the device.

If the device is not going to be used for an extended period of time, unplug

the power cable for safety purpose;

otherwise, dust may be accumulated, resulting in heating or a fire.

As for any servicing other than "Servicing by User" described in this Operation Manual, contact a service person as they require an expert technology.

If you perform any service other than "Servicing by User" by yourself, and there are any

problems on it, this may cause an electric shock or fire.

If the smell is unpleasant, install a ventilating fan in a room where this

device is installed.

(Please determine the size and capacity of the fan according to the structure of a room.)

Although a chemical substance is discharged during operation, the

amount of emissions is within acceptable limits.

[NOTE] : If the contents of this page are not legible, order a new manual.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 ix

Page 12

Precaution

"

Disposal Precaution

When disposing the following used parts, accept the regulations of each

local government.

1)The DRYPRO 752 itself.

2)The packaging materials for DRYPRO 752.

3)The photosensitive materials used on the DRYPRO 752.

4)The lead and lithium batteries inside the DRYPRO 752, which can be

hazardous and must be disposed properly.

"

Precaution on Installation Location

Be sure to observe the following conditions for the installation location of

this device.

By installing this device in the Radiology Department, you could make the

work flow smooth.

1)Install the device in a location where it is not exposed to water.

2)Install the device in a location where it is not exceed the temperatures

or atmospheric pressure described in the specifications.

3)Install the device in a location where it is not exposed to direct sunlight.

4)Install the device in a flat place.

5)Install the device where there is no likelihood of being given by

vibration or impact.

6)Install the device in a location where there is no likelihood of being

adversely affected by chemical agents, or air containing gas, dust, salt

or sulfur, etc.

[NOTE] : If the contents of this page are not legible, order a new manual.

x DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 13

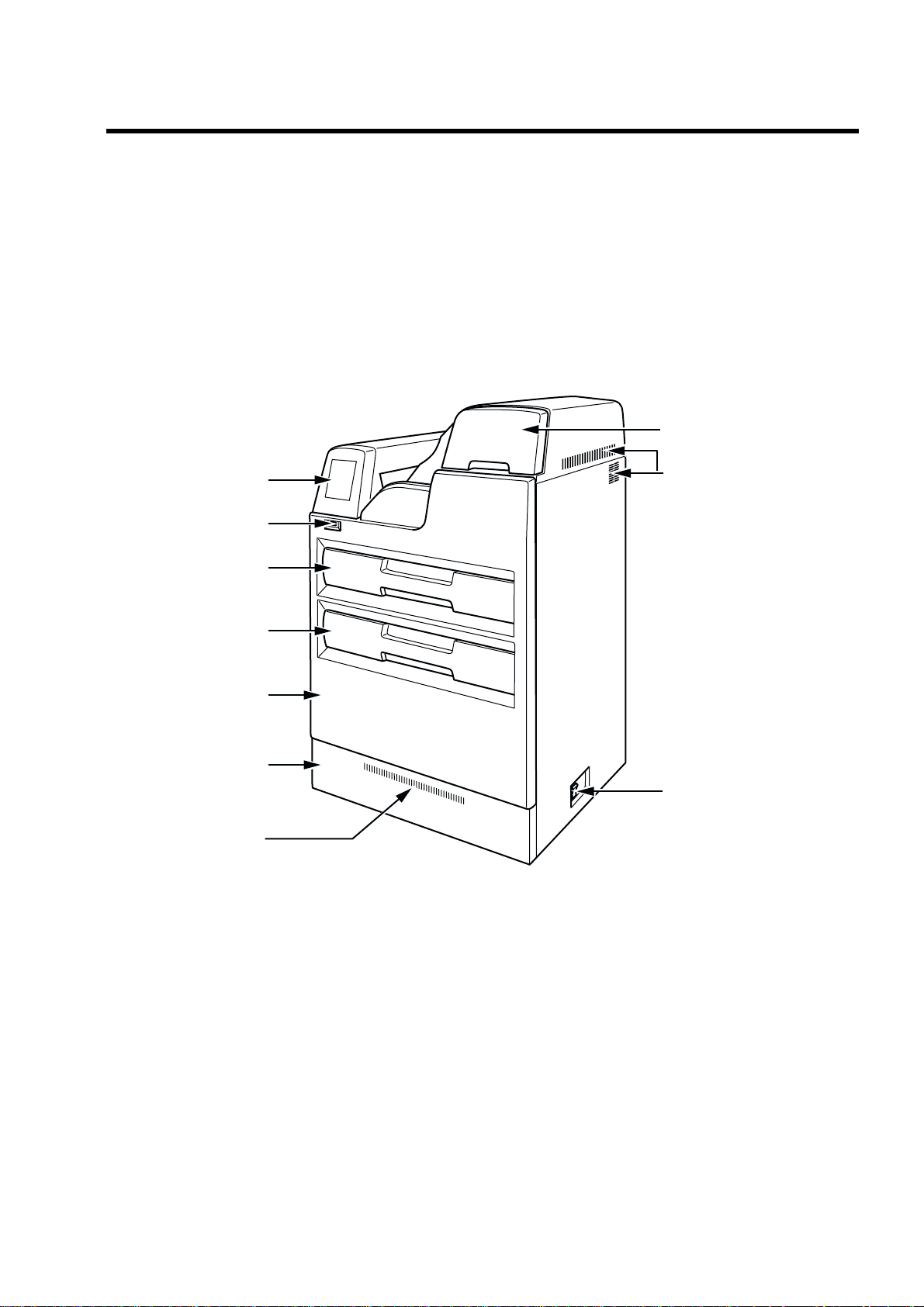

Control panel

Upper tray

Start switch

Lower tray

Front cover

Lower cover

Breaker

Filter unit cover

Air intake

Air intake

1. Name of Each Component

1-1.Main Body

"

Front Vie w

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 1

Page 14

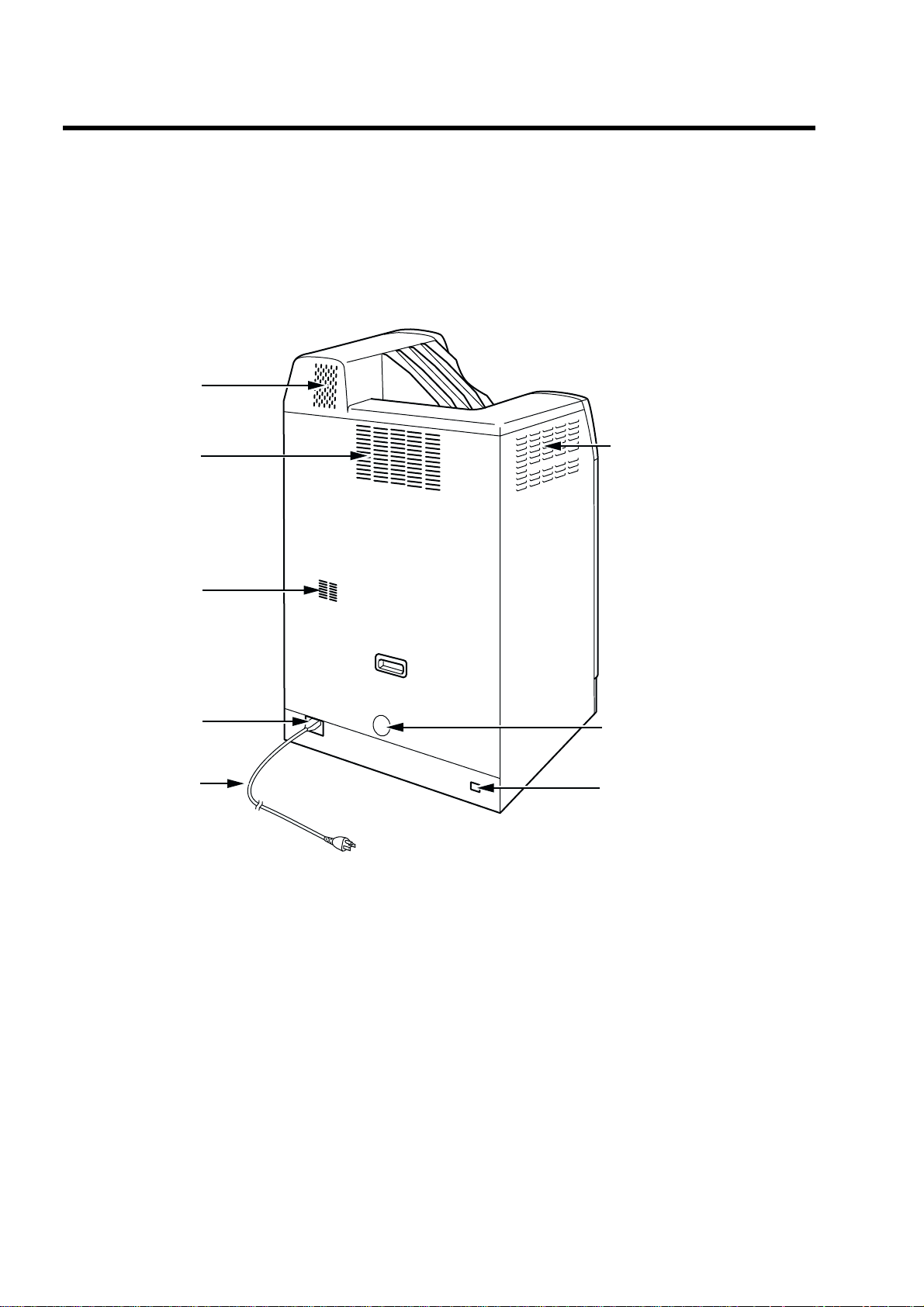

1-1.Main Body

"

Rear View

Air outlet

Air outlet

Air outlet

Power connector

Power cable

Air intake

Air outlet

Ethernet port (RJ45)

2 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 15

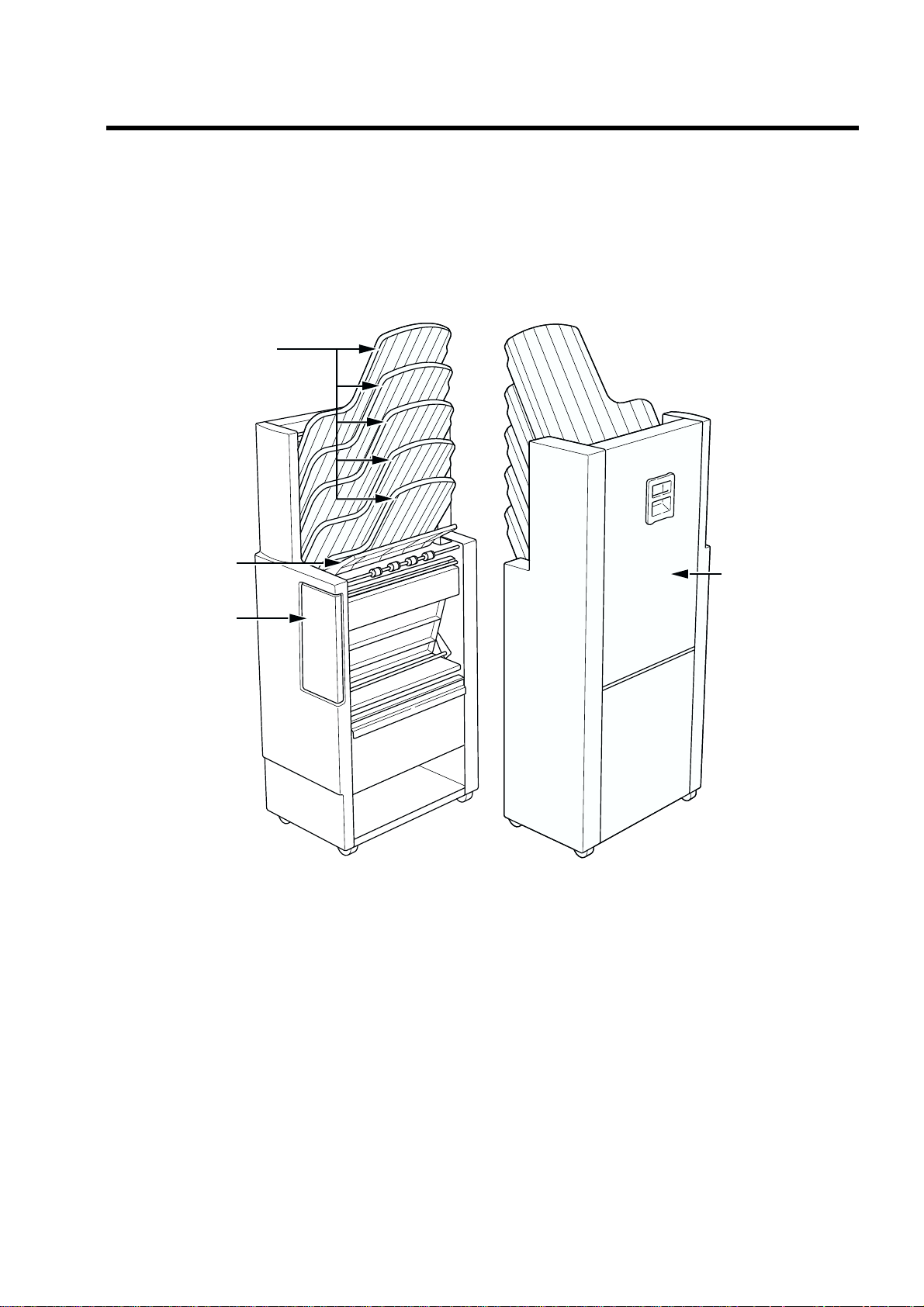

1-2.Sorter LiS-752 (option)

Sorter left cover

Front cover

Inlet guide

Bins

1-2.Sorter LiS-752 (option)

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 3

Page 16

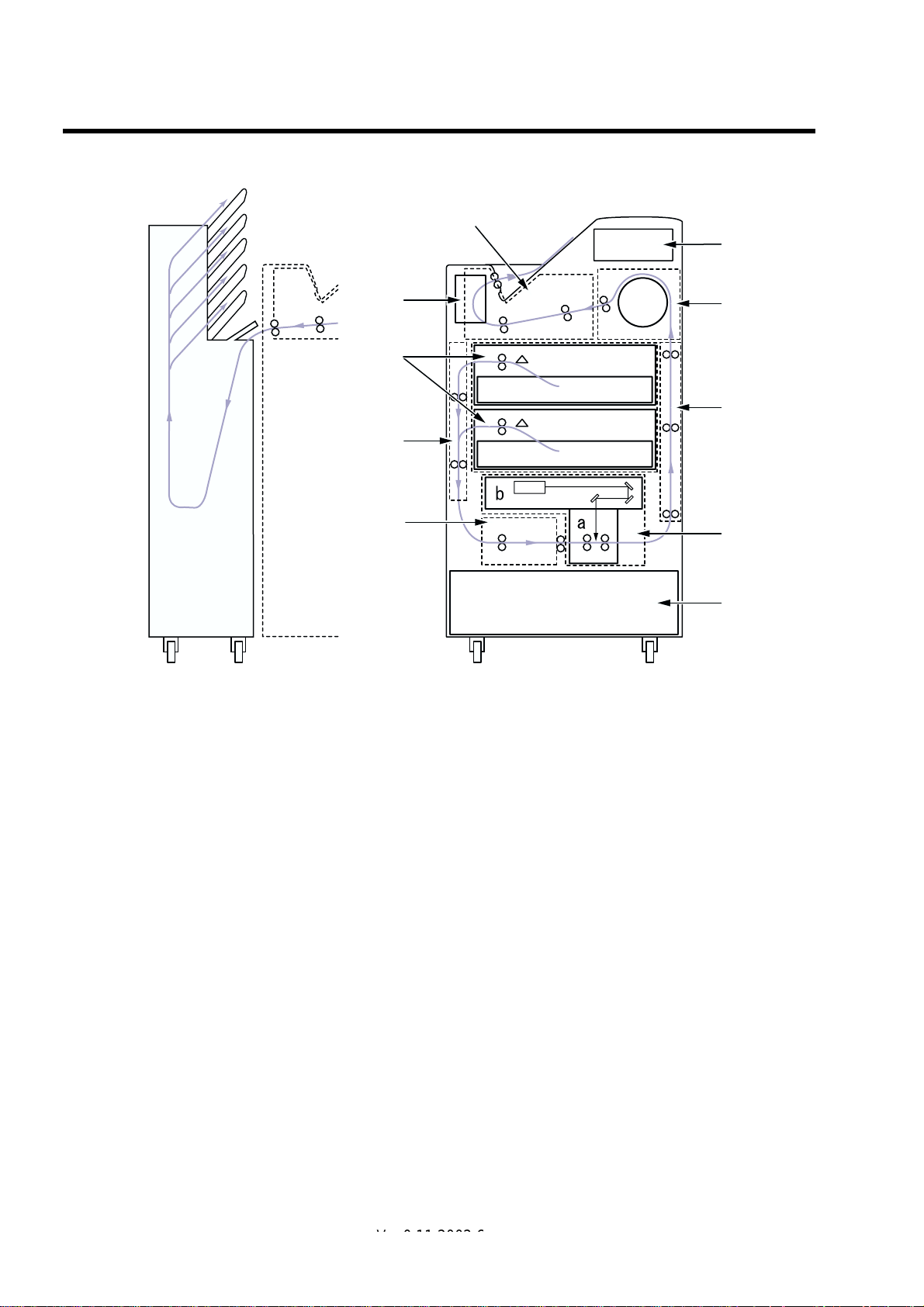

2. Structure

(7)

(8)

(10)

(1)

(2)

(11)

(3)

- Sorter LiS-752 is optional device.

(1) Supply section

Picks up each sheet of film from the tray unit, and sends

to the descent transport section.

(2) Descent transport section

Sends the picked-up film in the supply section to the

position control section.

(3) Position control section

Aligns the film sent from the descent transport unit horizontally, and sends it to the exposure section.

(4) Exposure section (a: Subscan unit, b: Optical

unit)

Performs a laser scanning in synchronization with the

film transport and prints an image on the film.

(5) Elevator transport section

Sends the film to the HPRO (Heat Processing) section

after the exposure.

(6)

(5)

(4)

(9)

(6) HPRO (Heat Processing) section

Processes the exposed film by heating.

(7) Cooling/Discharge section

Cools the heat-processed film and discharges it.

(8) Air-cooling section

Remove the odor generated by heat-processing with a filter.

(9) Electrical control section

Consists of the power supply unit for supplying the power to the

device and the control unit for controlling the entire device,

communicating with the diagnostic devices, and processing /

controlling images.

By installing an optional battery for UPS (uninterruptible power

supply), the system in the control unit can be backed up even

though power failure occurs due to electrical accidents.

(10)Control panel

Operates and makes settings of the device.

(11)Sorter (option)

Discharges the film discharged from the main body into the

specified bin.

4 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Ver.0.12 2002.7

Page 17

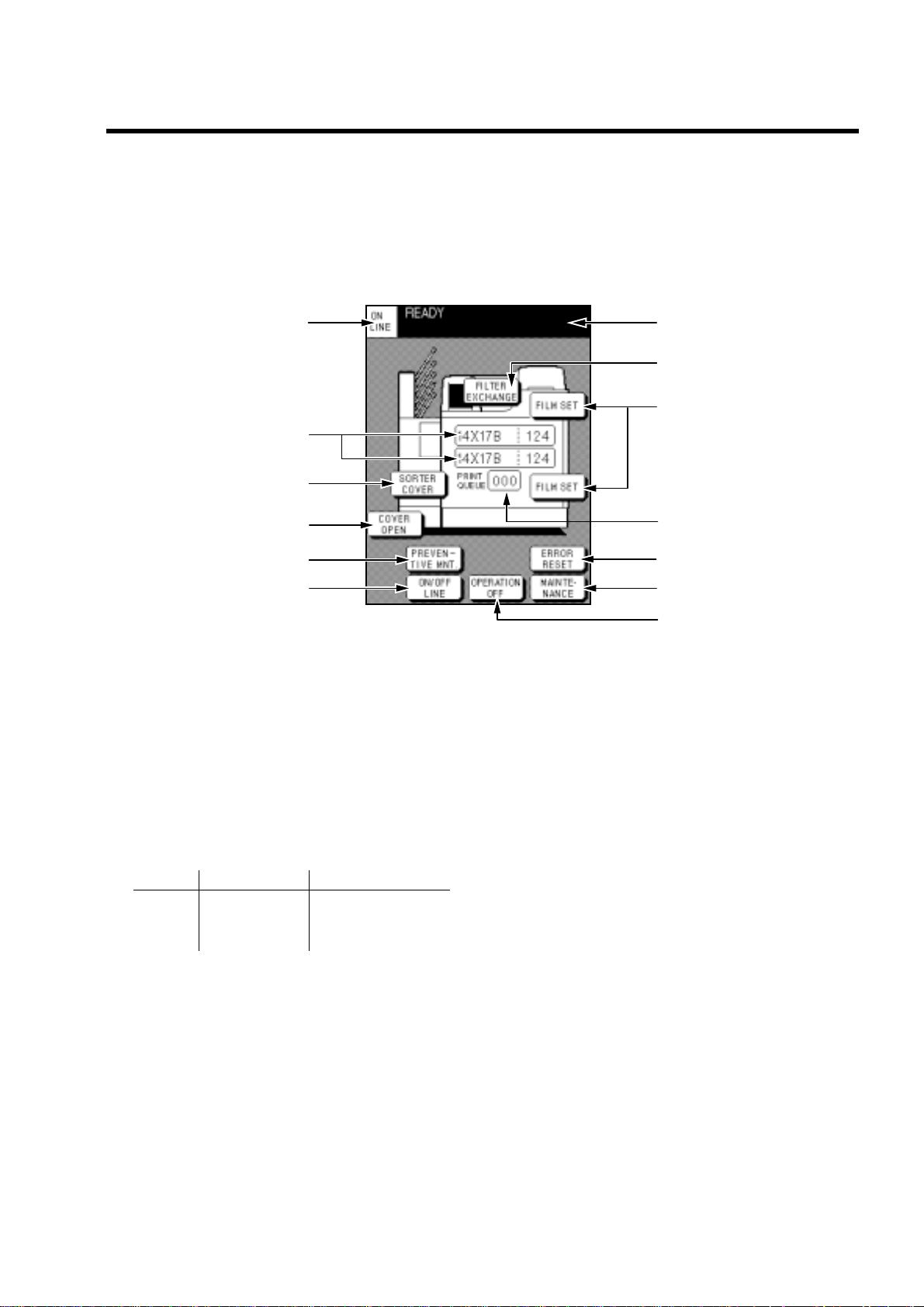

(2)

(11)

(8)

(4)

(9)

(7)

(5)

(1)

(3)

(12)

(10)

(13)

(6)

3. How To Operate

The operation, control and settings of this device can be made by using the control panel located on the main unit. The

following shows the operating procedures.

3-1.Control Panel

"

Description on screen

(1) ON LINE/OFF LINE Indication

Displays the ON LINE/OFF LINE status of the device.

(2) Message Column

Displays the status of the device.

READY. . . . . . . . . . Ready for print

PRINTING . . . . . . . In print process

WARMINGUP . . . . During warming-up

MAINTENANCE . . Maintenance mode

(3) Information of Loaded Film

Displays film type, size, number of remaining films in

the upper and lower trays respectively.

Size Film type No. of remaining films 14 x 17 B (SD-P) 0-125 14 x 14 C (SD-PC) 11 x 14 DRB (DR-P)

(4) PRINT QUEUE

Displays the number of films waiting to be printed.

(5) OPERATION OFF Key

(6) ON/OFF LINE Key

(7) MAINTENANCE Key

Turns the power OFF and stops the operation.

Switches connected/disconnected (ON LINE/OFF

LINE) to/from the diagnostic device for communications.

Switches to the maintenance mode to change the settings and perform the inspection. This key appears only

when the device is in the OFF LINE status. (Refer to

page 16 for details.)

(8) FILM SET / TRAY OPEN / CALIBRATION Key

The FILM SET key opens the tray when the film tray becomes

empty. (Refer to page 11 for details.)

The TRAY OPEN key opens the tray when a film jam occurs in

the tray. (For removing film jams, refer to page 52.)

The CALIBRATION key is displayed to prompt you to perform

density correction when [MESS] is selected in the WEEKLY

CALIBRATION settings. (Refer to page 24 for calibration.)

(9) ERROR RESET Key

Resets the device when an error occurs. This key appears only

when an error occurs. (Refer to page 49 for error reset.)

(10)COVER OPEN Key

Opens the front cover when film jams occur. This key appears

only when film jams occur. (For removing film jams, refer to

page 52.)

(11)FILTER EXCHANGE Key

This key appears when the FILTER has to be replaced. The procedure for replacing the FILTER appears. (For replacing the

FILTER, refer to page 66.)

(12)SORTER COVER Key

Displayed when a film jam occurs in the sorter (option). Displays the procedure for removing film jams. (For removing film

jams, refer to page 52.)

(13)PREVENTIVE MNT Key

Displayed when the periodical maintenance inspection period

comes. (Refer to page 67 for periodical maintenance inspection.)

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 5

Page 18

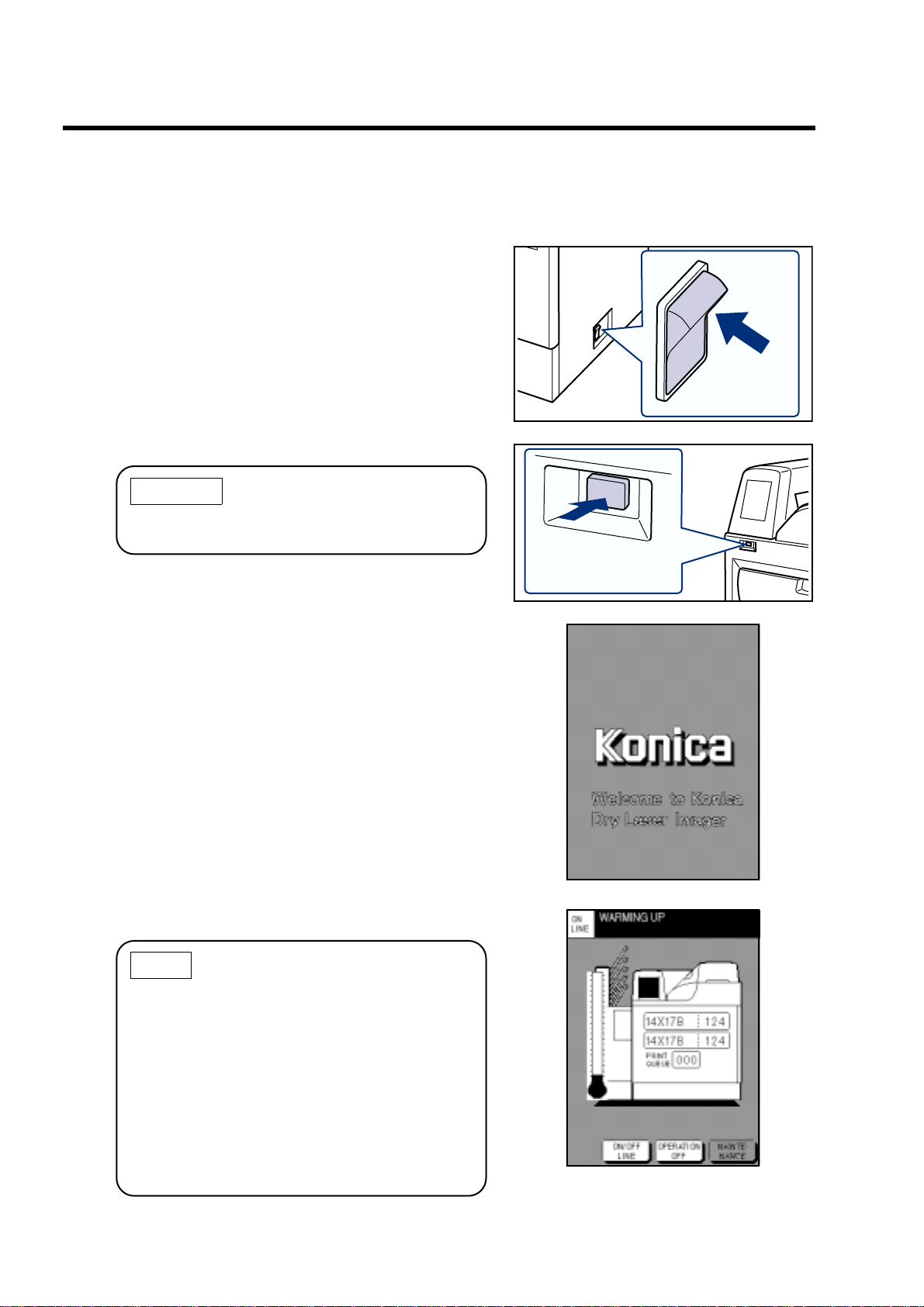

3-2.Start-up Operation

3-2.Start-up Operation

Follow the procedure below to turn on the power of the equipment.

(1) Turn ON the power of the breaker located at the

lower-right of the device.

Breaker

(2) Press the start switch below the control panel.

CAUTION

Pressing the start switch again turns OFF the

power. In this case, press the start switch again.

(3) The startup screen will appear.

Start switch

(4) The WARMING UP screen will appear in approx. 2

minutes.

NOTE

• Although printing cannot be made during

warming up, the data from the diagnostic

devices can be received. The received data

will be printed out after the device goes into

the READY status.

• Settings on the maintenance can be made

during warming up.

• It takes approx. 25 minutes for the device to go

to the READY status. Note that it depends on

temperature around the device.

6 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

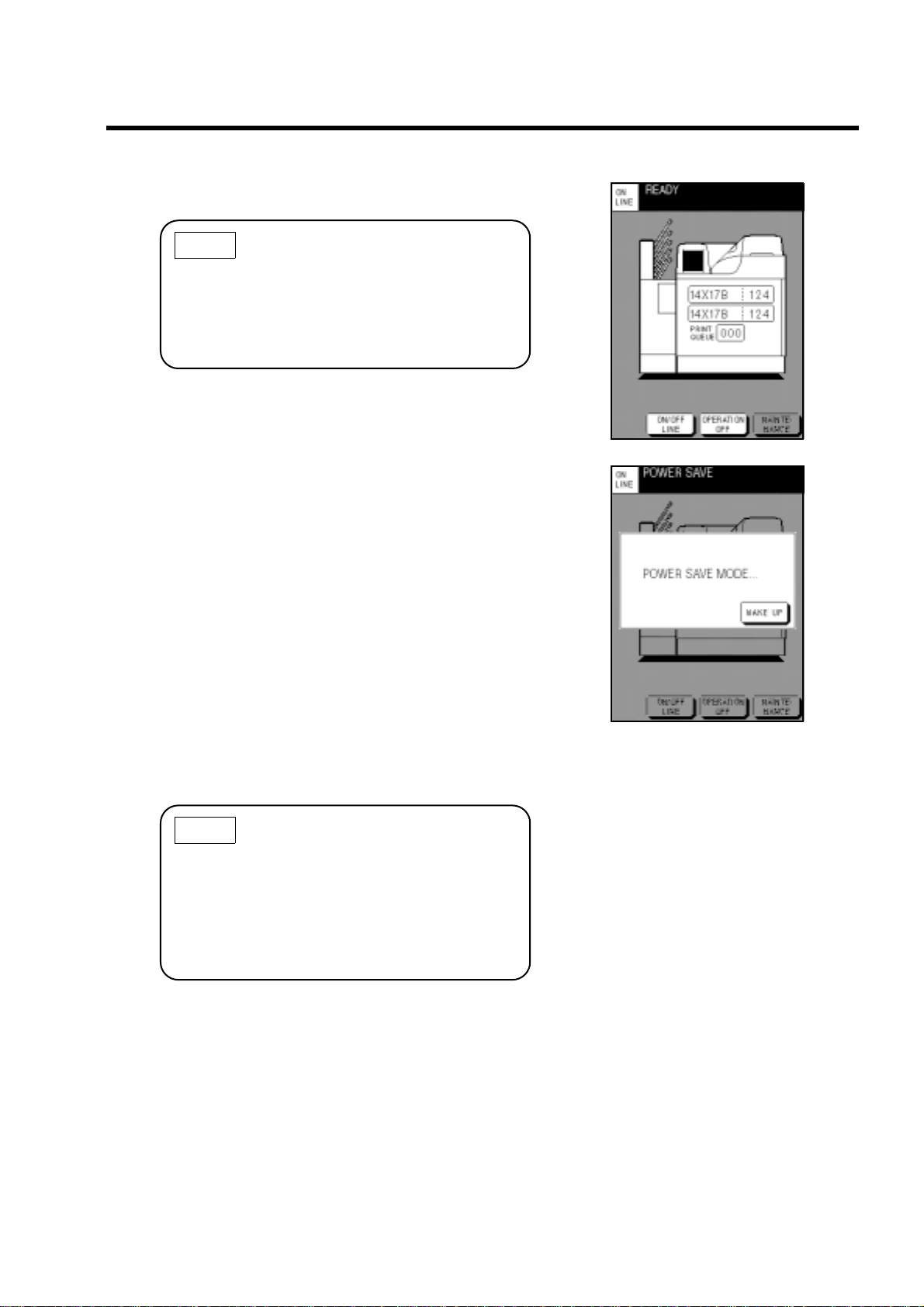

Page 19

(5) When READY appears on the message column,

printing can be made.

NOTE

Use the START TIMER function to set the device

to READY on the specified time without pressing

the start switch.

(Refer to page 18 for details on how to set the

START TIMER function.)

" Power saving mode

The DRYPRO has the power saving mode that saves

power consumption automatically after no data is

printed or no printing data is received for a specified

time.

When the DRYPRO goes into the power saving mode,

the screen on the right appears on the control panel,

and the backlight fades out. The power saving mode is

not enabled during OFF LINE mode.

The DRYPRO exits from the power saving mode and

starts warming up by performing the following operations.

• Touch [WAKE UP] on the control panel.

• When the DRYPRO receives printing data from a

diagnostic device, it exits from the power saving mode

automatically, and starts printing when it goes into the

READY status.

3-2.Start-up Operation

NOTE

• The time period ov er which the DRYPRO goes

into the READY status depends on the power

saving mode levels.

•You can set Use/Disuse or the level of the

power saving mode on the MAINTENANCE

MENU screen. (Refer to page 45.)

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 7

Page 20

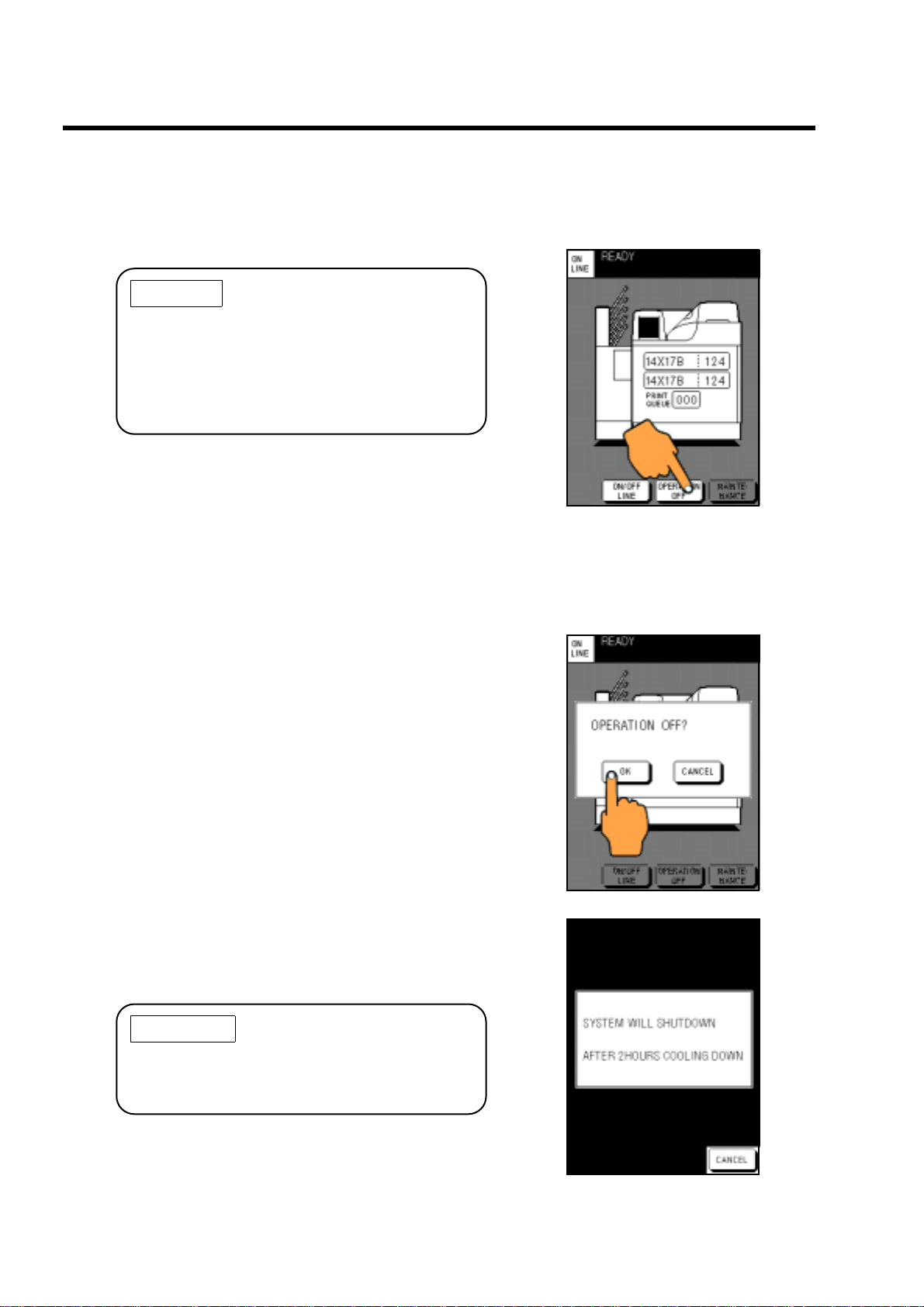

3-3.Shut-down Operation

3-3.Shut-down Operation

Following the procedure below to shut down the device.

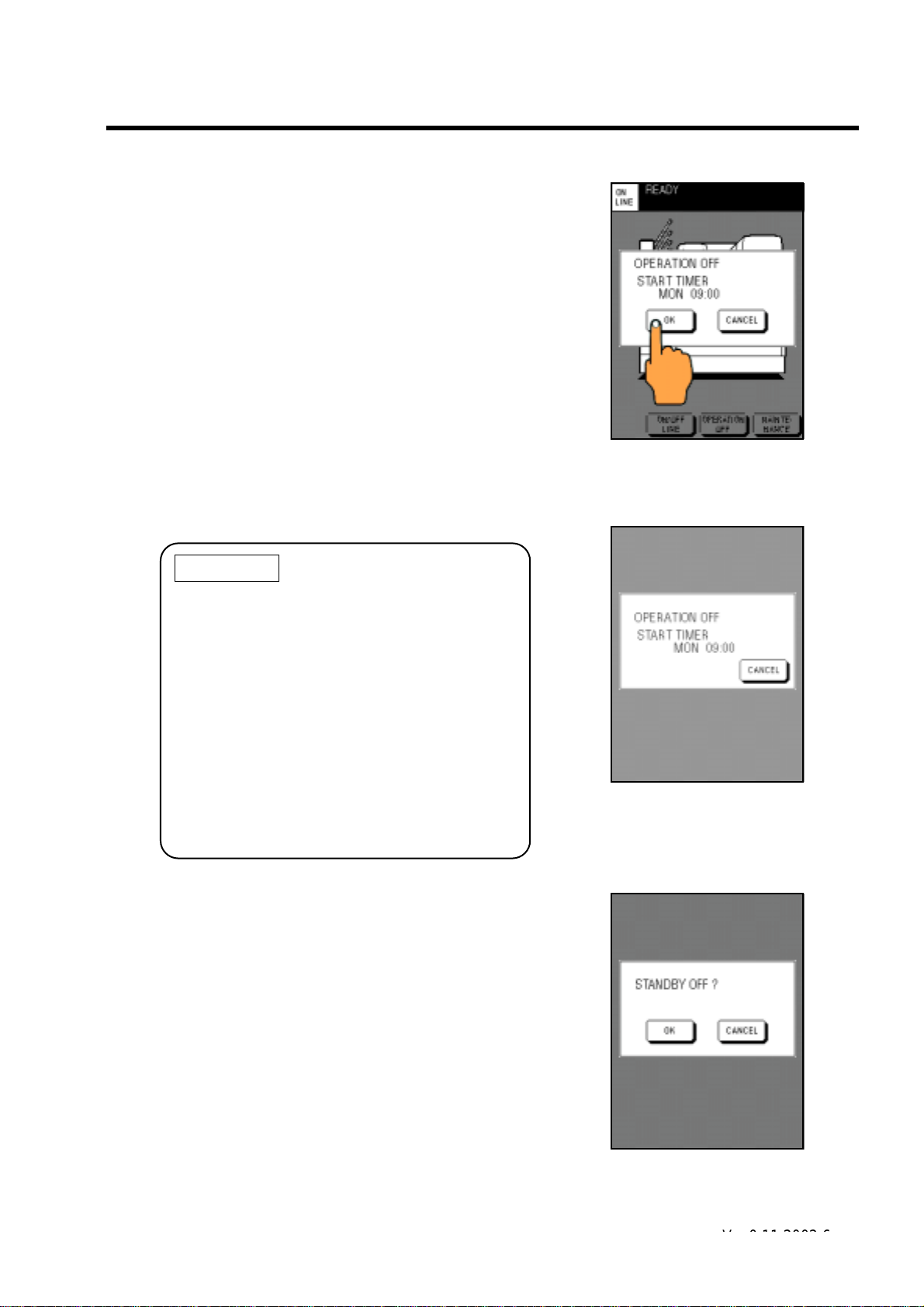

(1) Touch [OPERATION OFF] on the control panel.

CAUTION

Be sure to check that PRINT QUEUE shows

"000" before performing the shut-down operation.

If you shut down the device when PRINT Q UEUE

shows any number other than "000", the remaining data that has not printed yet will be printed

out next time the device starts up.

(2) The confirm screen of OPERATION OFF appears.

Different confirm screens appear when the START TIMER is

set to ON and when not set.

• When START TIMER is not set to ON;

If START TIMER is not set to ON, when you touch [OPERATION OFF] on the normal screen, the confirm screen on the

right appears.

(1) Touch [OK] to perform OPERATION OFF, then the

message shown on the lower-right appears.

Touching [CANCEL] will go back to the normal screen.

(2) The device will be shut down in approx. 2 hours,

and the display on the control panel will go off.

The FILTER fan functions for approx. 2 hours until the HPRO

(heat processing) section is cooled down. During that time, the

backlight of the control panel fades out.

IMPORTANT

When you need to print out some data during

shut-down operation, touch [CANCEL] to go back

to the normal screen.

8 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 21

• When START TIMER is set to ON;

Operation OFF message

(Start Timer ON)

Standby mode message

Restart confirm message

If START TIMER is set to ON, when you touch [OPERATION

OFF] on the normal screen, the time at which the DRYPRO

goes into the READY status for the next time appears on the

confirm screen on the right.

(1) Touch [OK] to perform OPERATION OFF proce-

dure.

Touching [CANCEL] will go back to the normal screen.

When START TIMER is set to ON, the de vice will not turn of f,

and go into the standby mode.

In the standby mode, the backlight of the control panel fades

out with the time to go to READY for next time displayed.

[CANCEL] will appear after a lapse of certain time after the

device goes into the standby mode.

3-3.Shut-down Operation

IMPORTANT

•Touch [CANCEL] on the screen on which the

standby mode message appears if you wish to

make printing in the standby mode. The confirm message on the lower-right appears,

touch [OK] to restart the device.

• [CANCEL] will appear after a lapse of certain

time (approx. 2 minutes) after the device goes

into the standby mode.

•When you use the START TIMER function,

leave the breaker of the device ON after

OPERATION OFF procedure is made. (Refer

to page 18 for details on how to set the START

TIMER function.)

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 9

Ver.0.12 2002.7

Page 22

3-3.Shut-down Operation

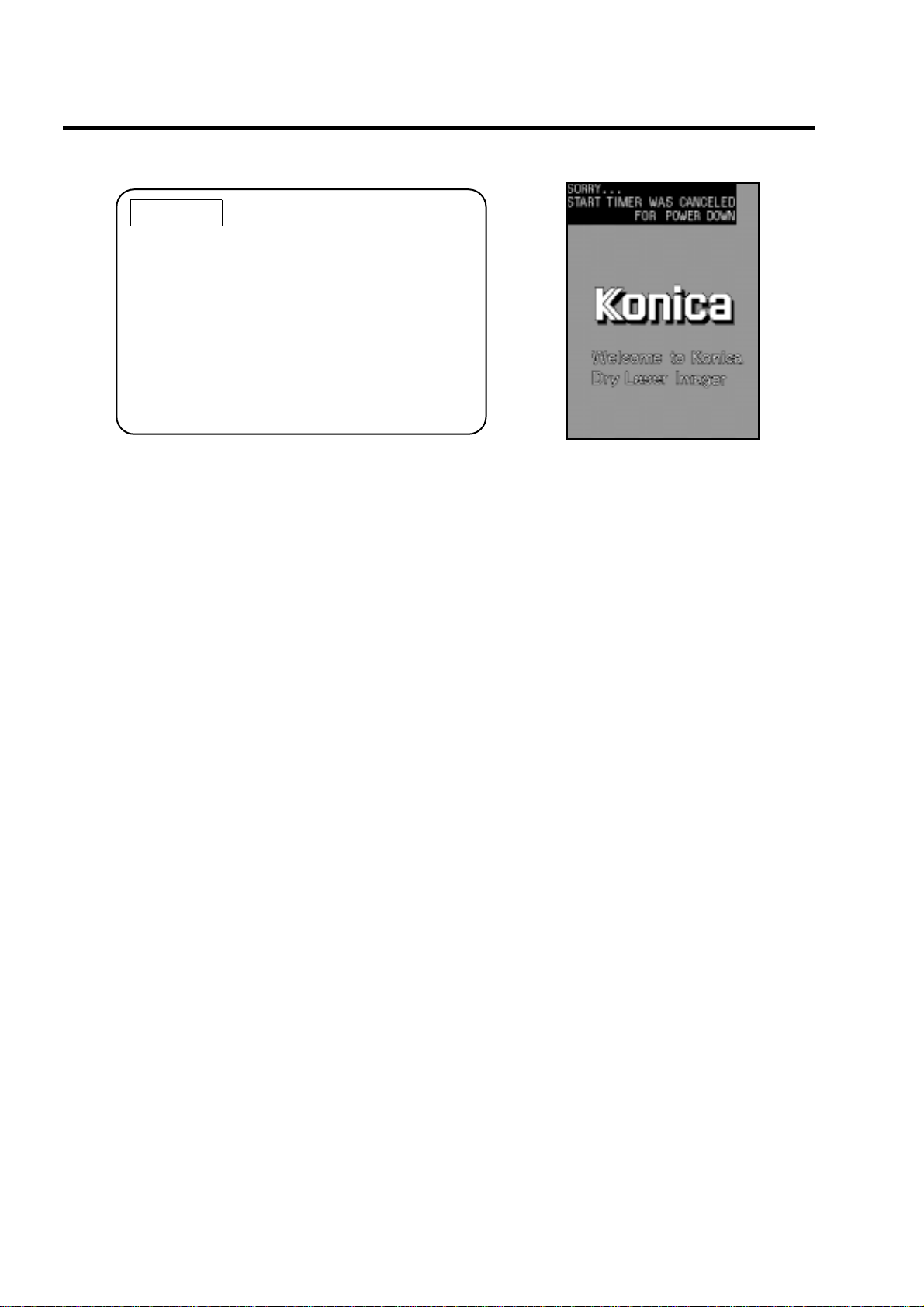

CAUTION

•When the power turns OFF even though you

set the START TIMER to ON, there is a possibility that a power failure may occur during the

standby mode.

Press the start switch to re-start the equipment.

• If a power failure occurs during the standby

mode, the message for showing the occurrence of a power failure appears on the Startup screen.

Power failure message

10 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 23

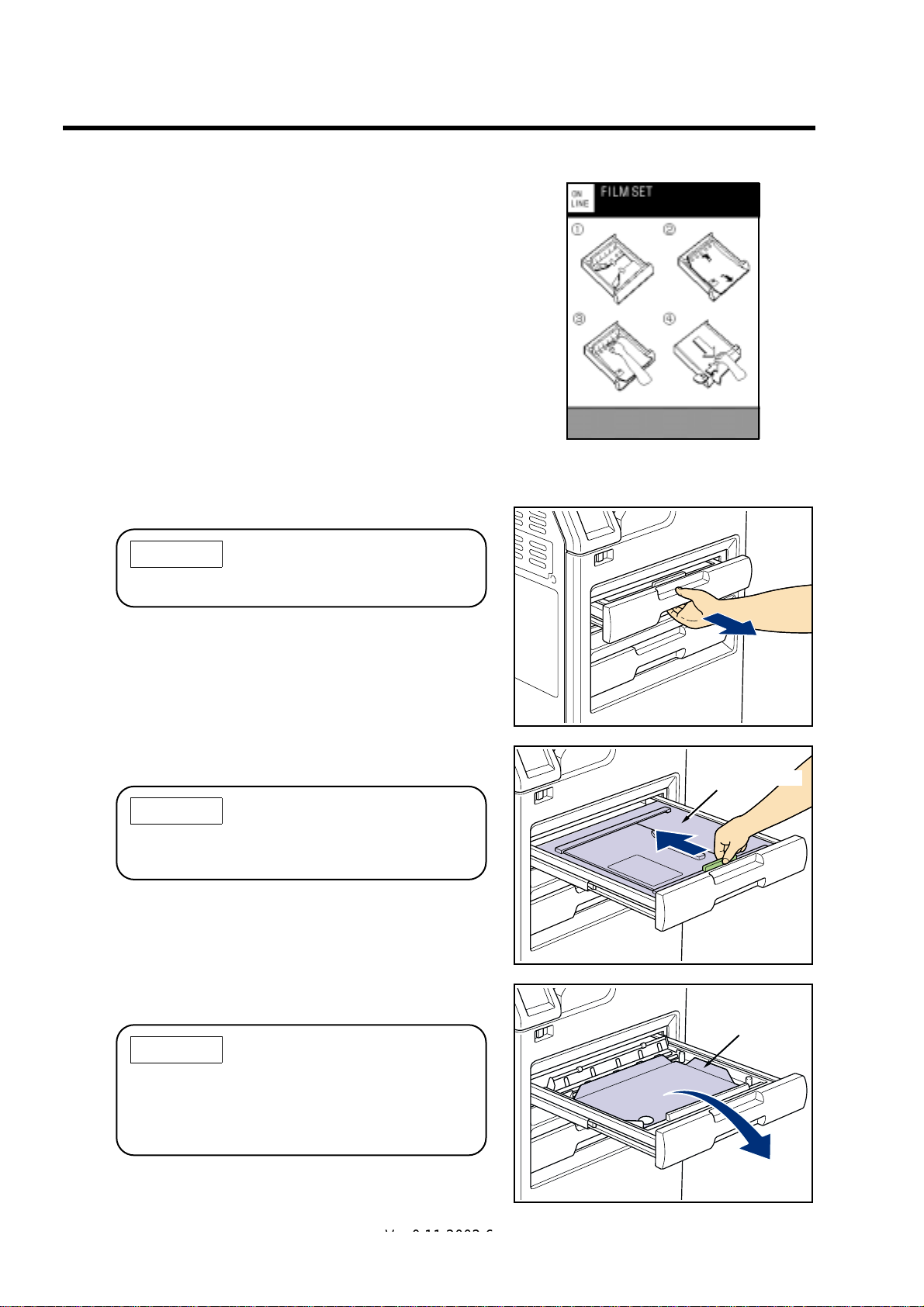

3-4.Film Loading

When the tray becomes empty, "FILM EMPTY" appears

and [FILM SET] is displayed on the right of the loading

film information of the empty tray.

The screen on the right shows that the upper tray

becomes empty.

• The film size for this device can be selected from

14"x17", 14"x11", and 14"x14". The film size for each

tray is set by a service person at installation.

• It is possible to receive print data from the diagnostic

device while the film is loaded.

Follow the procedure below to load the film.

(1) Touch the displayed [FILM SET].

The message showing the tray being opened appears.

3-4.Film Loading

Then, the empty tray pops out slightly, and the screen showing

the procedure for loading the film (next page) is displayed.

CAUTION

If a film is in print process, the cover will not open

until the printing completes. It will take max. 95

seconds.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 11

Message for tray being opened

Page 24

3-4.Film Loading

(2) Slowly pull out the opened tray as far as it goes.

CAUTION

Film loading screen

Do not place anything on the opened tray.

(3) Hold the handle (green par t) of the tray and open

the light shield cover fully.

CAUTION

The light shield cover of the tray cannot be

opened unless the tray is pulled out completely.

(4) Remove the resin tray and the empty film package

that remain in the tray.

CAUTION

Light shield cover

Resin tray

When disposing of the resin tray and the empty

film package, they should be treated as industrial

wastes. Dispose of them following the regulations of your institution.

12 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Ver.0.12 2002.7

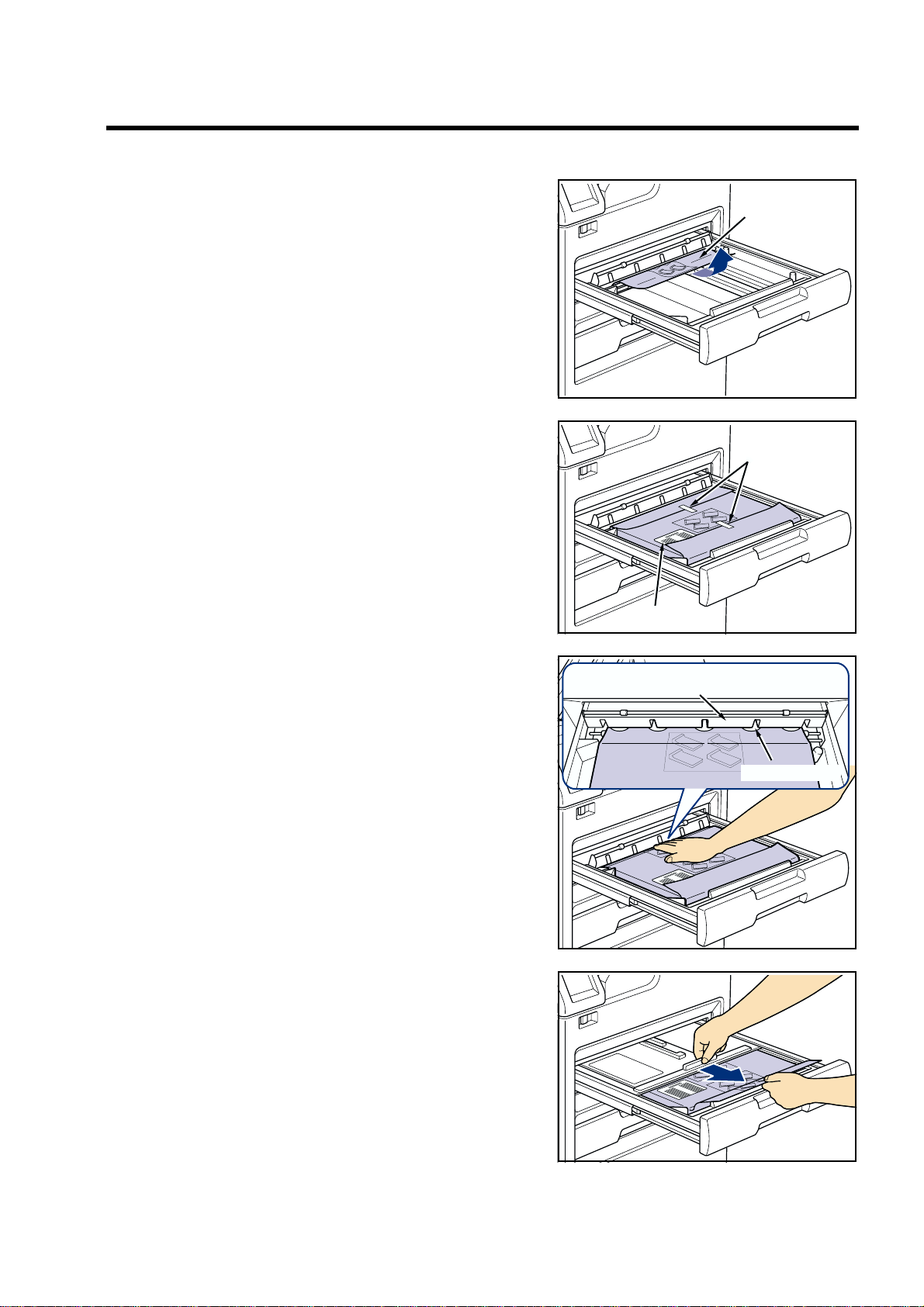

Page 25

(5) Load the package of new film so that the barcode

Empty package

Seals

Barcode

Retaining plate

Taking-up shaft

comes at the front-left position, and peel off the

seals at the edges of the package.

3-4.Film Loading

(6) Insert the back of the package between the retain-

(7) Close the light shield cover completely so that the

ing plate and the taking-up shaft firmly.

front of the package lies off the cassette.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 13

Page 26

3-4.Film Loading

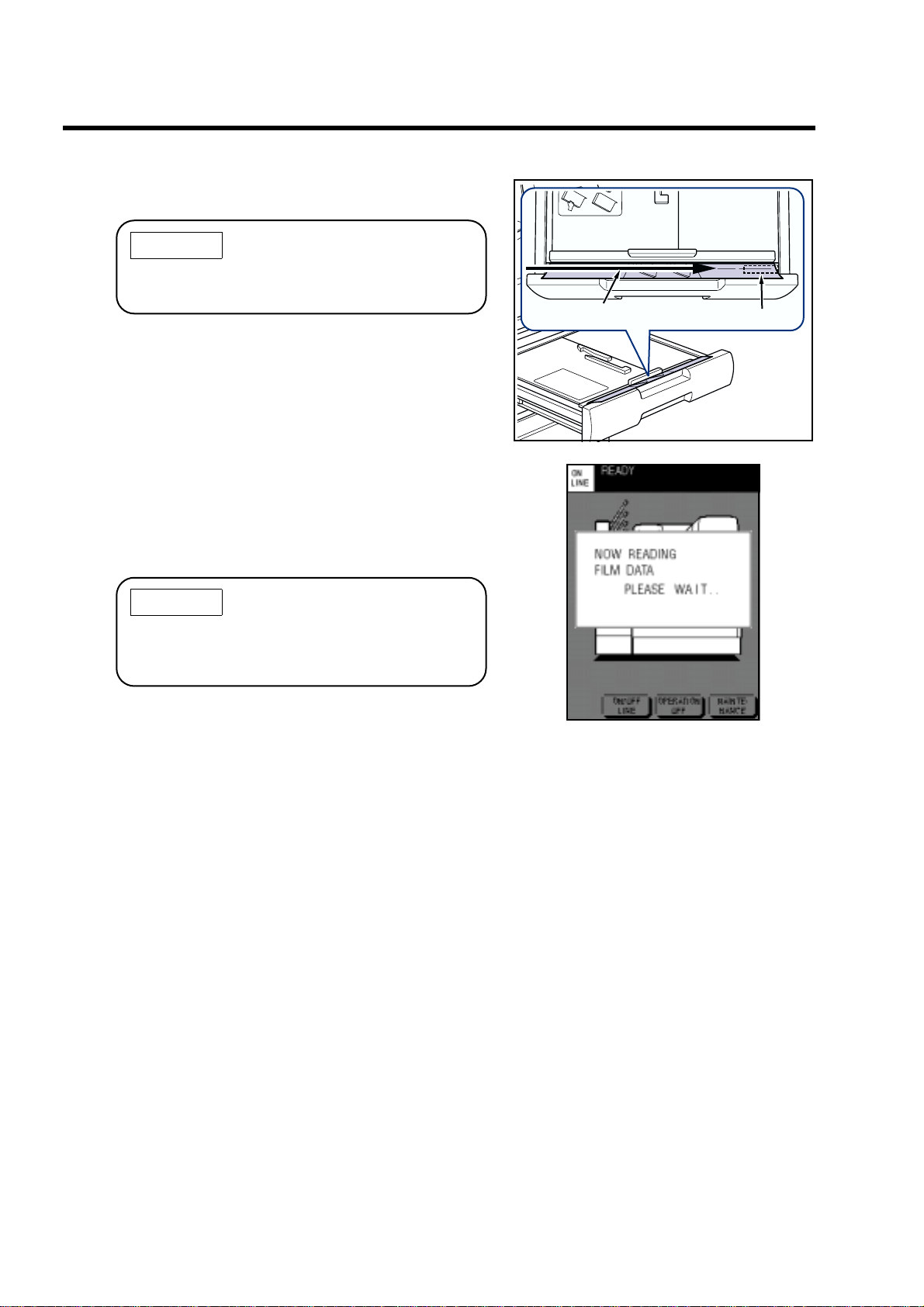

(8) Cut off the front of the package that lies off the cas-

sette with the supplied cutter.

CAUTION

Put the cutter after use into the pocket on the

right-front of the tray for storage.

(9) Push the tray to the back until it is locked.

When the tray goes into the back completely, the message

appears.

Then, the message of NOW READING FILM D ATA (barcode)

of the film package appears.

After reading the barcode is complete, the film of the calibration pattern for the auto density correction is discharged.

Cut off.

Pocket

CAUTION

If some films are queued, the automatic calibration is performed, but if no film is queued, the

automatic calibration is not performed.

Film data reading message

14 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 27

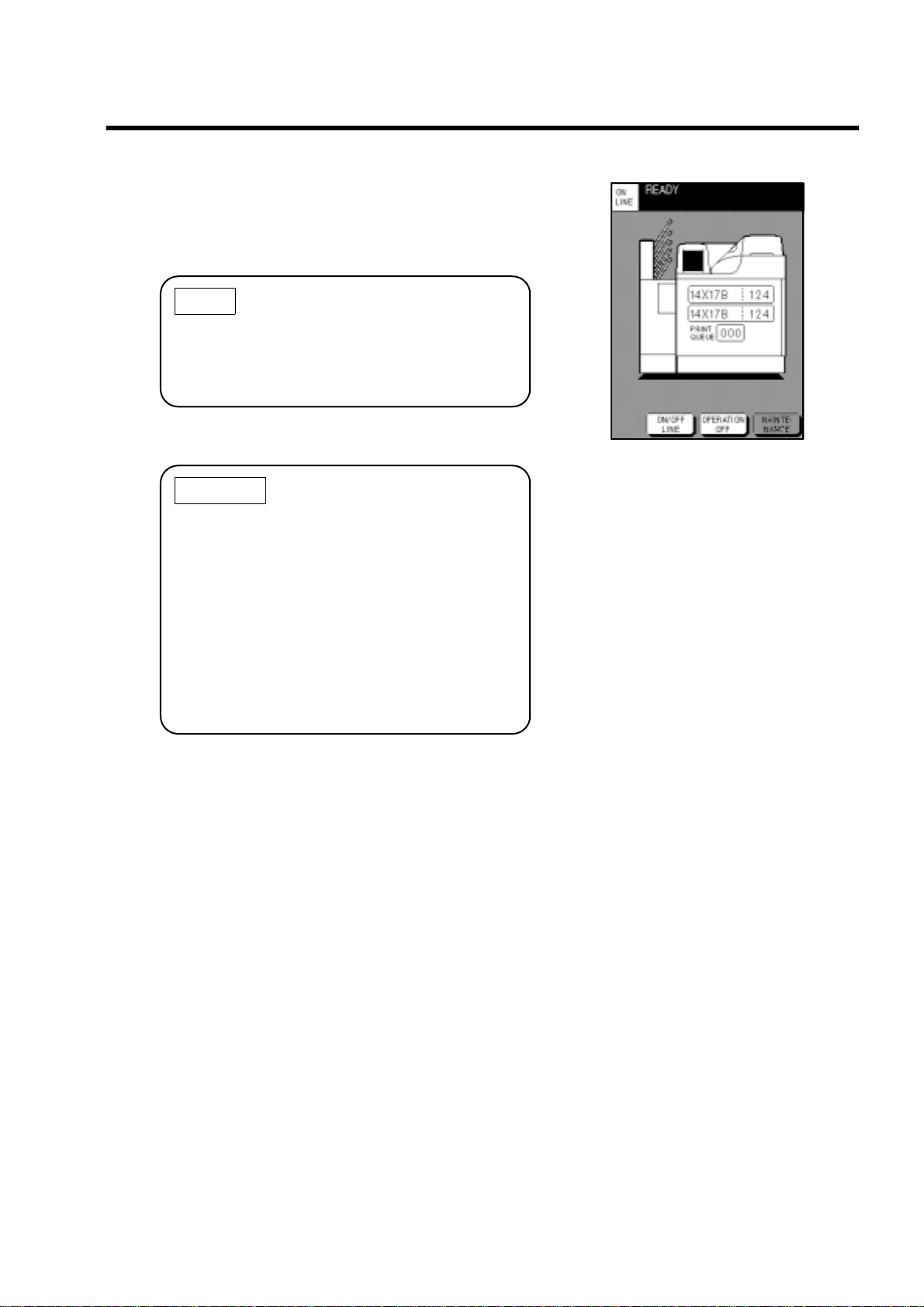

(10)The normal screen re-appears after the auto den-

sity correction, and print operation can be made. As

the data of the film that has been loaded newly is

displayed, verify the film size, type, and the number

of films.

NOTE

If the other tray is also empty, when you load the

film in one tray and close it, the other tray pops

out automatically.

Load the film by referring to Steps (2) or later.

CAUTION

• If you fail to cut off the film package, the barcode cannot be read and "FILM SET" is displayed again.

Open the tray again, and cut off the edge of

the package.

3-4.Film Loading

• If the first film cannot be picked up properly

because the package cannot be taken up correctly or other reasons, the error message

appears. In this case, remedy by following "5-

4. When Film Fails to be Loaded". (Refer to

page 61.)

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 15

Page 28

4. Maintenance Mode

4-1.Function of Maintenance Mode

This device has the maintenance mode that executes maintenance functions.

Touching [MAINTENANCE] on the control panel on OFF LINE will switch into the maintenance mode

and display the maintenance screen on the control panel.

In addition to the maintenance operations, the START TIMER function can be set, and re-printing of the

data that has already been printed can be made, etc.

• The print data from the diagnostic device cannot be received or printing cannot be made in the mainte-

nance mode.

The following shows the maintenance items that can be selected/executed in the maintenance mode.

No. Display Description

1START TIMER

2 TIME SET

3 PREVIOUS PRINT

4 CALIBRATION

5 TEST PRINT

6COVER OPEN

7PANEL ADJUST

8QUEUE CLEAR

9 COLD START

10 FILM DATA

11 PRINT CONDITION

12 USER LUT

13 FILMSET RETRY

14 POWER SAVE

Sets the START TIMER function to ON/OFF, and sets the start-up time for each day.

The START TIMER screen will appear. (Refer to page 18.)

Sets the time of the clock of the device. The TIME SET screen will appear.

(Refer to page 19.)

Re-prints the saved data that has been already printed out (PREVIOUS data).

The PREVIOUS PRINT screen will appear. (Refer to page 20.)

Prints the calibration sheet and corrects the density on the film. (Refer to

page 24.)

Prints out the SMPTE pattern to control the density.

The TEST PRINT screen will appear. (Refer to page 26.)

Open the front cover. (Refer to page 30.)

Adjusts the LCD contrast, the brightness of the backlight, and the touch area

in the touch panel.

The PANEL ADJUST screen will appear. (Refer to page 31.)

Clears the data queued in the device that has not been printed yet.

The QUEUE CLEAR screen will appear. (Refer to page 33.)

Cold-starts (re-start) the device. (Refer to page 35.)

CAUTION When the device is re-started b y COLD START, all

of the print data queued for printing and the saved

data that has been already printed out will be

deleted.

Confirms the sum of film. Sets the types of film to be counted, and date on

which film is counted. (Refer to page 36.)

Sets the print preferences for each of the connected diagnostic devices. (Refer to page 38.)

Creates user's own LUT curve, and applies it to the diagnostic device. (Refer to page 43.)

Used when the film fails to be loaded. (Refer to page 61.)

CAUTION Do not use this mode under the nor mal operation

as the number of films in the tray resets to 0.

Sets the power saving function of the device. (Refer to page 45.)

CAUTION

The print data from the diagnostic device cannot be received or printing cannot be made in the

maintenance mode. The print data queued for printing will be printed out after the device exits

from the maintenance mode.

16 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 29

4-2.Switching Maintenance Mode

" Start-up maintenance mode

(1) Touch [ON/OFF LINE] on the normal screen to

switch into OFF LINE.

ON LINE displayed on the upper-left corner of the screen

changes to OFF LINE, and [MAINTENANCE] appears on the

lower-right corner of the screen.

(2) Touch [MAINTENANCE].

The maintenance menu (MAINTENANCE) screen listing the maintenance items appears.

4-2.Switching Maintenance Mode

CAUTION

When touching [MAINTENANCE] during print,

"NOW PRINTING PLEASE WAIT" is displayed

and the maintenance screen does not appear

until the printing operation is complete.

The data queued for printing will be printed out

after the device exits from the maintenance

mode.

(3) Touch the key of an item to execute.

The set screen or messages that correspond to the selected item

appears.

For details on how to operate each maintenance item, refer to

the following pages.

" Shut-down maintenance mode

Touching [EXIT] on the maintenance menu screen will exit the device from the maintenance mode, and return to

the normal screen.

• When the normal screen re-appears, touch [ON/OFF LINE] to go back to OFF LINE.

• When PREVIOUS PRINT, CALIBRATION, or TEST PRINT is set, the pint data for those will be printed

out after the device exits the maintenance mode.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 17

Page 30

4-3.How To Operate Maintenance Mode

4-3.How To Operate Maintenance Mode

" Setting START TIMER Function

Setting the START TIMER function will start up the device from the Standby status automatically, and make it

into READY on the specified time. Setting the START TIMER function to ON/OFF, and the start-up time can be

made for each day.

Follow the procedure below to set the START TIMER.

(1) Touch [START TIMER] on the maintenance menu

screen.

The START TIMER screen will appear.

The key on the right of each day shows the ON/OFF of the

START TIMER.

"H" and "M" on the right of those keys show the hour and

minute for start time.

(2) Touch [ON] on the right of [START TIMER] to acti-

vate the START TIMER function.

Touching [OFF] clears the START TIMER function.

The selected key will be highlighted.

The key on the right of each day shows the ON/OFF of the

START TIMER.

(3) Touch the key on the right of each day on which you

wish to start the device automatically to display ON.

Touching the key again displays [OFF].

(4) When setting the time , touch H (hour) or M (min ute)

on the right of each day, then touch [$] / [%].

(5) After the settings are complete, touch [OK].

The setting becomes valid, and the maintenance menu screen

re-appears.

When you touch [CANCEL], the maintenance menu screen reappears without registering the settings.

IMPORTANT

When you set the START TIMER function to ON,

leave the breaker of the device ON.

18 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 31

4-3.How To Operate Maintenance Mode

" Setting Date/Time (TIME SET)

Follow the procedure below to set the date and time for the clock in the device. Set the time zone and the use/

disuse of the summer time depending on the areas in which you use the device. Follow the procedure below to

make settings.

(1) Touch [TIME SET] on the maintenance menu

screen.

The TIME SET screen will appear.

The keys of DATE on the TIME SET screen show the date (D),

month (M), and year (Y) that are currently set.

The keys of TIME show the current time (hour (H) and minute

(M)).

(2) Touch the item key to be changed when setting the

date/time.

The selected key will be highlighted.

(3) Touch [$] / [%] to change the value.

The month (M) key shows each month in abbreviation (JAN to

DEC) every time you touch the [$] / [%] key.

(4) Confirm that "64" is displayed next to TIME ZONE.

"64" is code No. of time zone of Japan.

If any number other than "64" appears, display code No. "64"

next to TIME ZONE by touching [$] / [%].

For details on the area and code No. of time zone, refer to

Appendix at the end of this manual (page 71).

(5) Confirm that [OFF] next to SUMMER TIME is high-

lighted.

If [OFF] is not highlighted, touch [OFF] to highlight.

(6) After the settings are complete, touch [OK].

The setting becomes valid, and the maintenance menu screen

re-appears.

When you touch [CANCEL], the maintenance menu screen reappears without registering the settings.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 19

Page 32

4-3.How To Operate Maintenance Mode

" Re-printing Printed Page (PREVIOUS PRINT)

In this device, as the data that has already been printed is stored in the inner hard disk, re-printing can be made

later. In this case, it is possible to change the print preferences such as the LUT applied for printing, print density,

and contrast, etc.

Follow the procedure below to re-print.

NOTE

The print data in the device is stored for each diagnostic de vice . The page number is assigned to

each print data in order in which it is received from the diagnostic device and printed out. (The

page No. is printed on the upper part of the film as the film management information.)

Page No.Film management information

1 0 0 1 P 300 20 32768 662 115301771170003 1,0R01 CH1:REGIUS_350 PAGE:4

(1) Touch [PREVIOUS PRINT] on the maintenance

menu screen.

The PREVIOUS PRINT screen (diagnostic device select

screen) will appear.

The names of the connected diagnostic devices are listed on the

diagnostic device select screen.

(2) Touch the name of the diagnostic device from

which the print data is received to print.

The selected diagnostic device name will be highlighted.

When 10 or more diagnostic devices are connected, touch [$] /

[%] to scroll the list of the diagnostic device names.

(3) Touch on the upper part of the screen.

The print page set screen will appear.

20 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 33

(4) Touch the box on the right of [PAGE NO], and input

page No. that you wish to re-print.

In order to input the page No., touch the box on the right of

[PAGE NO.], then touch the numeric key on the lower portion

of the screen.

If you input the number incorrectly, touch [C] to clear it, and

input again.

(5) Touch the box on the right of [COPY] and input the

print count.

The procedure for inputting the print count is the same as the one for inputting the page No.

(6) If you print under the previous print conditions, con-

firm that [OFF] on the right of [CHANGE CONDITION] is selected, and touch [STORE].

The print data on the specified page will be queued.

If the specified page has been already deleted, "PREVIOUS

PAGE ERROR" is displayed.

CAUTION

4-3.How To Operate Maintenance Mode

The page specified on the PREVIOUS PRINT

screen will be printed out after the device exits

from the maintenance mode.

CAUTION

The amount of data that can be saved in the

device is about 100 pages.

When the storage becomes full, the data is

erased in order in which it is stored.

(7) Touch [ON] on the right of [CHANGE CONDITION]

when you print under different conditions from the

previous ones.

The LUT select screen will appear.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 21

Page 34

4-3.How To Operate Maintenance Mode

(8) Touch a LUT name you wish to apply for printing.

The selected LUT name will be highlighted.

(9) Touch on the upper part of the screen.

The print preference set screen (2/3) will appear.

(10)Touch the key on the right of the setting item, then

touch [$] / [%] to set the following items.

DENSITY : Adjust the density of an image.

Selectable from -7 to 7.

Setting a negative value will make the den-

sity lighter, and a positive value, darker.

CONTRAST : Adjust the contrast of an image.

Selectable from -7 to 7.

Setting a negative value will make the con-

trast lower, and a positive value, higher.

SMOOTH TYPE : Sets the smoothing type of an image.

SMOOTH TYPE Settings

OFF Does not perform the magnification

interpolation.

1 Performs the Biliner interpolation.

2-6 Performs the Cubic Spline interpo-

lation.

Increasing the value will smooth an

image greater.

7 Does not perform the magnification

interpolation. But prints out in the

MAGNIFICATION setting. When

you wish to change this setting, ask

a service person.

22 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 35

(11)Select NEGA/POSI by touching [NEGA] or [POSI].

(12)Touch on the upper part of the screen.

The print preference set screen (3/3) will appear.

(13)Touch the key on the right of the setting item, then

touch the numeric keys to set the following items.

MAX DENSITY : Sets the maximum density of an image.

MIN DENSITY : Sets the minimum density of an image.

Lo : (Not used for the current version.)

La : (Not used for the current version.)

SORTER : Sets the bin in the sorter (option) into

which the film is discharged.

4-3.How To Operate Maintenance Mode

(14)Touch [STORE].

The printing data on the specified page will be queued and the

print page set screen will re-appear.

If the specified page has been already deleted, "PREVIOUS

PAGE ERROR" is displayed.

(15) If there are other data to be printed, repeat from

Step (4) to set the print page.

If you wish to print the data from another diagnostic device,

touch to display the PREVIOUS PRINT screen, and

repeat from Step (2).

(16)To complete the settings of re-printing, touch [EXIT]

to return to the MAINTENANCE MENU screen.

(17)Touch [EXIT] to end the maintenance mode.

When the normal screen re-appears, the data on the specified

page will be printed out.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 23

Page 36

4-3.How To Operate Maintenance Mode

" Calibrating Density (CALIBRATION)

The device has the densitometer in the cooling/discharge section, which allows you to control the density

automatically.

If there is a problem with the density, print the calibration sheet from this screen to calibrate the density.

• Calibration

(1) Touch [CALIBRATION] on the maintenance menu

screen.

The message for selecting the tray will appear.

(2) Touch the key of the tray for which you wish to per-

form density correction.

The print data in the calibration sheet will be queued, and the

maintenance menu screen will re-appear.

If you wish to perform density correction for the other tray, repeat from Step (1).

(3) Touch [EXIT] to end the maintenance mode.

When the normal screen re-appears, the film in the selected

tray is transported and the calibration sheet is printed out. Wait

until printing is complete. After printing is end, the density cor rection is complete.

IMPORTANT

• The calibration sheet is used as the sampling

data (the data before the density correction)

for the automatic density correction.

When you check and control the density, use

the SMPTE pattern which is printed out by

TEST PRINT on the maintenance menu.

(Refer to page 26.)

24 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 37

• Automatic calibration

The DRYPRO has the automatic density calibration function

that perform the density calibration automatically after a lapse

of the specified time or specified number of printing. (Instead of

performing automatic calibration, you can make [CALIBRATION] appear on the screen to show you that the calibration

needs performing depending on the settings at installation.)

Or the automatic density calibration can be performed when the

film is loaded.

CAUTION

•Even after a lapse of the specified period or

specified number of printing, the automatic

calibration is not performed if printing data is

not queued. The automatic calibration is performed when the printing data is queued after

a lapse of the specified period or specified

number of printing.

• The automatic calibration is performed if the

printing data is not queued even when the film

is loaded. The automatic calibration is performed when the printing data is queued on

the next time.

4-3.How To Operate Maintenance Mode

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 25

Page 38

4-3.How To Operate Maintenance Mode

" TEST PRINT

Follow the procedure below to print out the SMPTE pattern in the device used for density control. Follow the

procedure below to print out.

• How to print out

(1) Touch the [TEST PRINT] key on the maintenance

menu screen.

The message for selecting the tray will appear.

(2) If you print under the previous print conditions,

touch the key of the tray in which film to be used is

loaded.

The confirm screen will appear. (Proceed to Step (13).)

(3)

Touch [CONDITION SET UP] when you print under

different conditions from the previous ones.

The TEST PRINT CH screen (diagnostic device select screen)

will appear.

The names of the connected diagnostic devices are listed on the

diagnostic device select screen.

26 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 39

(4) Select the diagnostic device name you wish to

apply as the exposure conditions of test printing.

The selected diagnostic device name will be highlighted.

When 10 or more diagnostic devices are connected, touch [$] /

[%] to scroll the list of the diagnostic device names.

(5) Touch on the upper part of the screen.

The LUT select screen will appear.

(6) Touch a LUT name you wish to apply for printing.

The selected user LUT name will be highlighted.

(7) Touch on the upper part of the screen.

The print preference set screen (2/3) will appear.

4-3.How To Operate Maintenance Mode

(8) Touch the key on the right of the setting item, then

touch [$] / [%] to set the following items.

DENSITY : Adjust the density of an image.

Selectable from -7 to 7.

Setting a negative value will make the den-

sity lighter, and a positive value, darker.

CONTRAST : Adjust the contrast of an image.

Selectable from -7 to 7.

Setting a negative value will make the con-

trast lower, and a positive value, higher.

SMOOTH TYPE : Sets the smoothing type of an image.

SMOOTH TYPE Settings

OFF Does not perform the magnification

interpolation.

1 Performs the Biliner interpolation.

2-6 Performs the Cubic Spline interpo-

lation.

Increasing the value will smooth an

image greater.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 27

Page 40

4-3.How To Operate Maintenance Mode

7 Does not perform the magnification

interpolation. But prints out in the

MAGNIFICATION setting. When

you wish to change this setting, ask

a service person.

(9) Select NEGA/POSI by touching [NEGA] or [POSI].

(10)Touch on the upper part of the screen.

The print preference set screen (3/3) will appear.

(11)Touch the key on the right of the setting item, then

touch the numeric keys to set the following items.

MAX DENSITY : Sets the maximum density of an image.

MIN DENSITY : Sets the minimum density of an image.

Lo : (Not used for the current version.)

La : (Not used for the current version.)

SORTER : Sets the bin in the sorter (option) into

which the film is discharged.

(12)Touch [STORE].

The confirm screen will appear.

If the tray is not selected, the screen for selecting the tray in

Step (2) will appear.

(13)Touch [OK].

The print data in the SMPTE pattern will be queued, and the

maintenance menu screen will re-appear.

Touching [CONDITION SET UP] allows you to redo the print

preference settings. (Steps (4) through (12))

(14)Touch [EXIT] to end the maintenance mode.

When the normal screen re-appears, the film in the selected

tray is transported and the SMPTE pattern is printed out. Wait

until printing is complete.

28 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 41

4-3.How To Operate Maintenance Mode

• How to control density

Each frame of the SMPTE pattern for this device which is printed out by TEST PRINT consists of 16-step wedge,

SMPTE pattern, and 1024-step gray scale. Measure the density of the 16-step wedge or SMPTE pattern and use it for the

density control.

IMPORTANT

• Use the SMPTE pattern for the density control.

• Do not use the calibration sheet that is printed

with the CALIBRATION function on the maintenance menu for density control.

• The calibration sheet is the sampling data for

the automatic density correction.

16-step wedge

SMPTE pattern

1024 -step gray scale

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 29

Page 42

4-3.How To Operate Maintenance Mode

" Opening/closing front cover (COVER OPEN)

When the front cover is required to open for some reasons including removing the film jams, follo w the procedure

below to open and close it.

(1) Touch [COVER OPEN] on the maintenance menu

screen.

The confirm message will appear.

(2) Touch [OK].

The front cover will unlock after a while when the message of

"NOW COVER OPENING PLEASE WAIT" appears.

(3) Pull the left side of the front cover toward you to

open it.

(4) In order to close the front cover, press the upper

and lower part of the front cover, and confirm that

you hear a click.

While the front cover is open, the screen shown on the lowerright appears.

When the front cover is closed, the maintenance menu screen

re-appears.

NOTE

The front cover has locks at the upper and lower

parts of the left of the cover.

30 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Screen for procedure

(Closing the front cover)

Page 43

4-3.How To Operate Maintenance Mode

" Adjusting control panel (PANEL ADJUST)

Follow the procedure below to adjust the contrast of the control panel and the brightness of the backlight.

If the response position to pressing is deviated from the key displayed on the control panel, the touch position also

can be adjusted.

• Adjusting the contrast and the brightness of the

backlight

(1) Touch [PANEL ADJUST] on the maintenance menu

screen.

The PANEL ADJUST screen will appear.

(2) Touch [$] / [%] on the right of [LCD CONTRAST] to

adjust the contrast of the LCD.

The contrast can be changed in 32 steps. Adjust the contrast so that you can easily see the LCD.

(3) Touch [$] / [%] on the right of [BACK LIGHT] to

adjust the brightness of the backlight.

The backlight can be changed in 20 steps. Adjust the brightness so that you can easily see the LCD.

(4) Touch [EXIT].

The maintenance menu screen will re-appear.

• Adjusting the touch position

(1) In order to adjust the touch position, touch [TOUCH

P.ADJ] on the PANEL ADJUST screen.

The touch position adjustment screen will appear.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 31

Page 44

4-3.How To Operate Maintenance Mode

(2) Touch the two corners (the position marked with "+" )

of the control panel.

When the touch positions are adequate, a beep sounds, then the

adjustment is completed displaying [OK].

CAUTION

Do not touch the control panel strongly with a

sharp pointed material such as a balled-pointed

pen.

(3) Touch [OK].

Touch position adjustment is completed, and the screen returns to the PANEL ADJUST screen.

CAUTION

When touching "+" on each corner, touch as

close to the corner of the displayed area of the

control panel as possible.

This enhances the accuracy.

32 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 45

4-3.How To Operate Maintenance Mode

" Clearing queued print data (QUEUE CLEAR)

Follow the procedure below to delete the data queued in the device.

The print data can be cleared for each diagnostic device, or all the queued print data can be cleared.

Or only the data queued latest in which an error occurs can be cleared.

When [ALL CHANNEL QUEUE] is selected, the print data registered by PREVIOUS PRINT or TEST PRINT

on the maintenance mode are also cleared.

Follow the procedure below to clear the queued print data.

(1)

Touch [QUEUE CLEAR] on the maintenance menu

screen.

The QUEUE CLEAR screen will appear.

(2) Touch [CHANNEL QUEUE] if you wish to clear the

data from the selected diagnostic device, and touch

[ALL CHANNEL QUEUE] if you wish to clear all the

data queued for printing.

When you touched [CHANNEL QUEUE], the diagnostic

device select screen (SCU SELECT) listing the names of the

connected diagnostic devices will appear.

When you touched [ALL CHANNEL QUEUE] or [ERROR

QUEUE], the confirm message for clearing will appear.

[ERROR QUEUE] should be used when [ERROR RESET]

cannot be used on the normal screen. (Refer to page 50.)

(3) When you touched [CHANNEL QUEUE], touch the

name of the diagnostic device from which the printing data to be cleared is received on the diagnostic

device select screen.

The confirm message for clearing will appear.

When 10 or more diagnostic devices are connected, touch [$] /

[%] before touching a diagnostic device name to scroll the list

of the diagnostic device names.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 33

Page 46

4-3.How To Operate Maintenance Mode

(4) Touch [OK] on the confirm message.

When you touch [ALL CHANNEL QUEUE] on Step (2), all

the printing data are cleared.

When you touched [CHANNEL QUEUE] in Step (2), the

printing data sent from the diagnostic device selected in Step

(3) are cleared.

If you wish to cancel deleting, touch [CANCEL].

CAUTION

• The amount of print data that can be registered in the device differs depending on the

diagnostic devices and the data types.

• The total data that can be stored is about 200

to 400 pages received from all the connected

diagnostic devices.

•When the data is full, the print data can no

longer be received from the diagnostic

devices.

34 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 47

4-3.How To Operate Maintenance Mode

" COLD START

The COLD START function re-starts the device.

IMPORTANT

When the device is re-started by COLD START, all of the print data queued for printing and the

saved data that has been already printed out will be deleted.

Follow the procedure below to re-start.

(1) Touch [COLD START] on the maintenance menu

screen.

The confirm message will appear.

(2) Touch [OK].

The message of processing will appear, and the device will restart.

All the queued print data that has not been printed and the

saved data that has been already printed out will be deleted.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 35

Page 48

4-3.How To Operate Maintenance Mode

" Confirming and setting film count data

The sum of film can be confirmed. The film count can be confirmed for each of days, weeks, and months. Also

you can set the date on which the film is counted by week or by month.

• Confirming film count data

Follow the procedure below to confirm the film count.

(1) Touch [FILM DATA] on the maintenance menu

screen.

The film count data screen (FILM DATA) listing the film count

data by date will be displayed.

The displayed count data is the preset two film data (DATA1,

DATA2). For the details on how to set, refer to "Setting film

count preference" on the next page.

(2) Touch [WEEKLY] to display the film count data by

week. In order to display the film count data by

month, touch [MONTHLY].

Touching on the upper part of the list will display the

next page of the film count data. When touching , the

previous page appears.

Weekly film count Monthly film count

36 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 49

• Setting film count preference

Follow the procedure below to set the film count preferences.

(1) Touch [FILM DATA SETUP] on the film count data

screen.

The FILM DATA SETUP screen will appear.

(2) In order to set the film type for counting, touch

[DATA1] or [DATA2] on the right of the film size key,

then touch [$] / [%] on the lower part of the screen

to display a desired film size.

4-3.How To Operate Maintenance Mode

(3) Touch the film type on the right of the film size, then

touch [$] / [%] to display a desired film type.

(4) In order to set the date on which the data is

counted by week, touch the key on the right of

[WEEKLY DATA], then touch [$] / [%] on the lower

part of the screen to display a desired date.

(5) In order to set the date on which the data is

counted by month, touch the key on the right of

[MONTHLY DATA], then touch [$] / [%] on the lower

part of the screen to display a desired date.

(6) After the settings are complete, touch [OK].

The setting becomes valid, and the film count data screen reappears.

If you wish to cancel the settings, touch [CANCEL].

CAUTION

• The time at which the film is count each day

is fixed at 23:59:59.

• If you wish to set the date on which the film

is counted to the end of the month, set 31 to

[MONTHLY DATA]. On the month that ends

earlier than 31st, the film will be counted on

the final day of the month automatically.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 37

Page 50

4-3.How To Operate Maintenance Mode

" Setting print preference

The print preferences are set for each of the diagnostic devices. Follow the procedure below to set the print

preferences.

(1) Touch [PRINT CONDITION] on the maintenance

menu screen.

The print preference set screen (PRINT CONDITION) listing

the name of the connected diagnostic devices will appear.

(2) Touch a name of the diagnostic device for which the

print preferences are set.

The selected diagnostic device name will be highlighted.

When 10 or more diagnostic devices are connected, touch [$] /

[%] to scroll the list of the diagnostic device names.

(3) Touch on the upper part of the screen.

The LUT select screen (1/7) will appear.

(4) Touch a LUT name you wish to apply for printing.

The selected user LUT name will be highlighted.

For the LUT to be applied on the diagnostic device, you can

select one from 8 user LUTs.

It is necessary to copy and set the user own LUT or the LUT

recommended by Konica. (Refer to "Setting user LUT" on

page 42.)

(5) Touch on the upper part of the screen.

The print preference set screen (2/7) will appear.

38 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 51

(6) Touch the key on the right of the setting item, then

$] / [%] on the lower part of the screen to set

touch [

the following items.

DENSITY : Adjust the density of an image.

Selectable from -7 to 7.

Setting a negative value will make the den-

sity lighter, and a positive value, darker.

CONTRAST : Adjust the contrast of an image.

Selectable from -7 to 7.

Setting a negative value will make the con-

trast lower, and a positive value, higher.

SMOOTH TYPE : Sets the smoothing type of an image.

SMOOTH TYPE Settings

OFF Does not perform the magnification

interpolation.

1 Performs the Biliner interpolation.

2-6 Performs the Cubic Spline interpo-

lation.

Increasing the value will smooth an

image greater.

4-3.How To Operate Maintenance Mode

7 Does not perform the magnification

interpolation. But prints out in the

MAGNIFICATION setting. When

you wish to change this setting, ask

a service person.

DEFAULT TRAY: Sets whether the upper or lower tray is pri-

oritized when the tray is not specified from

the diagnostic device.

(7) After the settings are complete, touch on the

upper part of the screen once.

The print preference set screen (3/7) will appear.

(8) Touch the key on the right of the setting item, then

touch the numeric keys on the lower part of the

screen to set the following items.

MAX DENSITY : Sets the maximum density of an image.

MIN DENSITY : Sets the minimum density of an image.

Lo : (Not used for the current version.)

La : (Not used for the current version.)

SORTER :

Sets the bin in the sorter (option) into which the

film is discharged.

(9) After the settings are complete, touch on the

upper part of the screen once.

The print preference set screen (4/7) will appear.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 39

Page 52

4-3.How To Operate Maintenance Mode

(10)Touch the key on the right of the setting item, then

set the following items.

ORIENTATION : Sets the direction of an image.

PORTRAIT : An image is in the por-

trait orientation.

LANDSCAPE : An image is in the land-

scape orientation.

POLARITY : Selects the negative or positive of an

image.

TRIM :

BORDER : Selects a border color.

FLIP : Sets whether or not to enhance characters.

Selects whether or not to trim an image.

BLACK

CLEAR

ON : Enhances characters.

OFF : Does not enhance characters.

(11)After the settings are complete, touch on the

upper part of the screen once.

The print preference set screen (5/7) will appear.

(12) Select the item to be printed as the stamp with

[STAMP SELECT].

The item displayed in the highlighted key will be printed as the stamp.

(13)If you select [STAMP MESSAGE] in Step (12),

touch the frame under [STAMP MESSAGE], then

input the message to be printed as the stamp.

The keypad screen for inputting characters will appear.

The screen on the right shows the example of characters to be

input.

(14) Select the position at which the stamp is printed

with [STAMP DIRECTION].

Selects the position at which the stamp is printed from the four

keys. The stamp will be printed at the position of the line displayed in the highlighted key.

(15)After the settings are complete, touch on the

upper part of the screen once.

The print preference set screen (6/7) will appear.

40 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 53

(16)Sets the format of date to be printed on the film.

YEAR FORMAT :

Selects the format of year.

YY : Last two figures

YYYY : All four figures

MONTH FORMAT:

Selects the format of month.

TEXT : Character display

NUMERIC : Numeric display

DATESTAMP FORMAT:

Selects the format of date/time.

TIME+DATE

DATE+TIME

TIME ONLY

DATE ONLY

(17)After the settings are complete, touch on the

upper part of the screen once.

The print preference set screen (7/7) will appear.

(18)Set whether the settings in the diagnostic device is

prioritized or the settings in the DRYPRO is prioritized when the stamp and the print preferences are

sent from the diagnostic devices.

Each time you press the key, it will be highlighted and displayed in normal.

The print preferences set in this device are prioritized for the

item displayed in the highlighted key.

4-3.How To Operate Maintenance Mode

(19)After the settings are complete, touch [EXIT].

The message asking whether or not to save the settings appears.

(20)Touch [OK].

The setting becomes valid, and the maintenance menu screen

re-appears.

If you wish to cancel the settings, touch [CANCEL].

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 41

Page 54

4-3.How To Operate Maintenance Mode

• Setting user LUT

This device has LUTs recommended by Konica which are suitable for each type of diagnostic devices as a library. By

copying the LUT registered with the library to the user LUT in advance, it can be applied for the connected diagnostic

device.

Follow the procedure below to set the user LUT.

(1) Touch the user LUT name to be set on the LUT

select screen.

The selected user LUT name will be highlighted.

Up to 8 kinds of user LUTs can be set.

(2) Touch [LUT LIBRARY].

The LUT copy screen will appear.

(3) Select the type of the diagnostic device from the

seven keys on the upper part of the screen.

The name of the LUT that is suitable for the selected diagnostic

device appears on the eight keys displayed on the lower part of

the screen.

(4) Touch the name of the LUT to be applied.

The selected LUT name will be highlighted.

(5) Touch [OK].

The LUT information selected in Step (4) will be copied on the

user LUT selected in Step (1), then the LUT select screen will

appear.

Touching [GRAPH] will allow you to confirm a graph of the

selected LUT curve. (Refer to page 44.)

42 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 55

4-3.How To Operate Maintenance Mode

" Creating user LUT

Although this device has the LUT that is suitable for the diagnostic device at shipping, you also can create user's

own LUT by inputting the LUT characteristics. Follow the procedure below to create the user LUT.

(1) Touch [USER LUT] on the maintenance menu

screen.

The user LUT create screen (USER LUT) listing the name of

the connected diagnostic devices will appear.

(2) Touch a name of the diagnostic device on which the

user LUT is applied.

The selected diagnostic device name will be highlighted.

When 10 or more diagnostic devices are connected, touch [$] /

[%] to scroll the list of the diagnostic device names.

(3) Touch on the upper part of the screen.

The user LUT select screen will appear.

(4) Touch a LUT name you wish to apply on the diag-

nostic device.

The selected LUT name will be highlighted.

(5) Touch [DATA] on the lower part of the screen.

The LUT data screen (next page) will appear.

By touching [LUT LIBRARY] instead of [DATA], the user

LUT can by set using the LUT in the library stored in this

device. (Refer to "Setting user LUT" on page 42.)

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 43

Page 56

4-3.How To Operate Maintenance Mode

On the LUT data screen, the values (density x 100) of 16 points

of the LUT curve are displayed.

When inputting the digital value of the LUT data (12-bit digital

value converted from the density of each point: 0000 - 4095),

touch [DIGITAL] on the lower part of the screen. The digital

data of 16 points of the LUT curve will appear.

Touching [GRAPH] will allow you to confirm a graph of the

selected LUT curve.

(6) Touch [EDIT] on the LUT data screen.

The LUT data input screen (DENSITY) will appear.

(7) Touch the value of the point to be changed, and

enter a value with the numeric keys on the lower

part of the screen.

By touching [DIGITAL] / [DENSITY] on the lower part of the

screen, you can input the digital value of the density or the density value (density x 100).

(8) After the settings are complete, touch [OK].

The setting becomes valid, and the user LUT select screen reappears.

If you wish to cancel the settings, touch [CANCEL].

• Confirming the LUT curve

Of the screens of "USER LUT" and "PRINT CONDITION",

the screen for selecting or creating the LUT can display the

graph showing the characteristics of the LUT being selected or

created by touching [GRAPH] displayed on the screen.

•

On the graph display screen, touching [DIGITAL] or

[DENSITY] switches between the digital value and the

density value (density x 100) for showing the vertical axis

of the graph.

• Touching [EXIT] on the graph display screen will return

to the original screen.

• The graph display screen only allows you to confirm the

LUT curve. You cannot edit the LUT displayed on the

screen.

44 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 57

4-3.How To Operate Maintenance Mode

" Setting power saving mode

The DRYPRO has the power saving mode that saves power consumption automatically after no data is printed for

a specified time.

The power saving mode has two kinds of settings: [TOUCH PANEL POWER SAVE] for let the backlight of the

control panel fade out, and [HEAT ROLLER POWER SAVE] for lowering the temperature in the HPRO.

Follow the procedure below to set the power saving mode.

(1)

Touch [POWER SAVE] on the MAINTENANCE MENU

screen.

The power save set (POWER SAVE) screen will appear.

(2) In order to let the backlight of the control panel fade

out, touch [ON] on the right of [TOUCH PANEL

POWER SAVE].

(3) Touch the key on the right of [TIMER], then touch

the numeric keys on the lower part of the screen to

set the time (minute) to go into the power saving

mode.

(4) In order to save power consumption in the HPRO

section, touch [L], [M], or [H] on the right of [HEAT

ROLLER POWER SAVE].

[L], [M], or [H] shows the temperature in the HPRO section in

the power saving mode.[L] means that the temperature is the

lowest, and [M] means it is medium, and [H] means it is the

highest.

CAUTION

If you set the temperature to low, the power consumption can be saved much in the po wer sa ving

mode. However it takes longer for the DRYPRO

to exit from the power saving mode and go into

the READY status.

The recovering time period is about 10 minutes

when [L] is set, 6 minutes when [M] is set, and 3

minutes when [H] is set.

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 45

Ver.0.12 2002.7

Page 58

4-3.How To Operate Maintenance Mode

(5) Touch the key on the right of [TIMER], then touch

the numeric keys on the lower part of the screen to

set the time (minute) to go into the power saving

mode.

(6) After the settings are complete, touch [OK].

The setting becomes valid, and the maintenance menu screen

re-appears.

If you wish to cancel the settings, touch [CANCEL].

46 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 59

5. Troub leshooting

5-1.Error Display and Remedy

When an error occurs in the device, the error code and the description are displayed on the message

column on the control panel.

The following shows the errors and the remedies displayed in this device.

Error Code Description Remedy

E4A20

E4A21

E4110

E4112

E4126 The upper tray is open. Close the upper tray. E4210

E4212

E4226 The lower tray is open. Close the lower tray. E4111

E4113

E4211

E4213

E4310

E4311

E4312

E4410

E4411

E4510 The film cannot be sent from the elevator

E4511

E4610

E4611

E4710

E4120

E4220

E4A22

E4810

E4811

E4812

E4820

The front cover is open. Close the front cover.

The film cannot be sent from the upper

tray.

The film cannot be sent from the lower

tray.

The film cannot be sent from the descent

transport section.

Film jams occur between the descent

transport section and the exposure section.

transport section.

Film jams occur between the exposure

section and the elevator transport section.

Film remains in the HPRO (heat process-

ing) section.

Film jams occur in the HPRO (heat pro-

cessing) section.

No FILTER exists.

FILTER cannot be detected.

Film remains in the sorter basket. Remove the film from the inlet of the sorter. (Refer to page

The sorter cover is open. Close the sorter cover.

• Pull out the upper tray, and remove jammed film. (Refer to

page 53.)

• When a film jam occurs when loading the film, load the

film again. (Refer to page 61.)

• Pull out the lower tray, and remove film jam. (Refer to page

53.)

• When a film jam occurs when loading the film, load the

film again. (Refer to page 61.)

Open the front cover, and remove a jammed film. (Refer to

page 54.)

Open the front cover, and remove a jammed film. (Refer to

page 55.)

Open the front cover, and remove jammed film. (Refer to

page 56.)

Place FILTER.

Place FILTER in the specified place correctly. (Refer to page

66.)

58.)

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 47

Page 60

5-1.Error Display and Remedy

CAUTION

If an error that is not described in the previous page (Exxxx error or Fxxxx error) occurs, reset

the error by following "5-2. Resetting Errors".

If the same error is displayed repeatedly after error reset, touch [OPERATION OFF] to turn the

power OFF, and contact a service person. Do not turn off the breaker.

When an abnormal sound or smoke occurs from this device, immediately turn off the breaker of

the device, and unplug the power cable, and contact a service person.

48 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 61

5-2.Resetting Errors

When an error occurs in this device, [ERROR RESET]

appears as well as the error message.

After troubleshooting the errors according to the error

messages, touch [ERROR RESET] to reset the error

display.

• When a film jam error occurs, each key appears

depending on the locations in which a film jam occurs.

(For removing film jams, refer to page 52.)

The screen shown on the lower-right appears, then

returns to the normal screen.

5-2.Resetting Errors

DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6 49

Page 62

5-2.Resetting Errors

" When an error cannot be reset

If an error cannot be reset even by touching [ERROR

RESET] for some reasons, or an error persists even

after resetting, follow the procedure below.

• Clearing queued errors

By clearing the latest queued error, [ERROR RESET] may be activated.

(1)

Touch [QUEUE CLEAR] on the maintenance menu

screen.

The QUEUE CLEAR screen will appear.

(2) Touch [ERROR QUEUE].

The confirm message will appear.

(3) Touch [OK] on the confirm message.

The latest queued error is cleared.

When the normal screen re-appears, [ERROR RESET] may be activated.

50 DRYPRO MODEL 752 Operation Manual Ver.0.11 2002.6

Page 63

• Re-starting