Page 1

Who gives you a World Class 3-D Scanner with

LASER accuracy, One-button camera

simplicity

and an amazingly low price?

KONICA MINOLTA, that's who

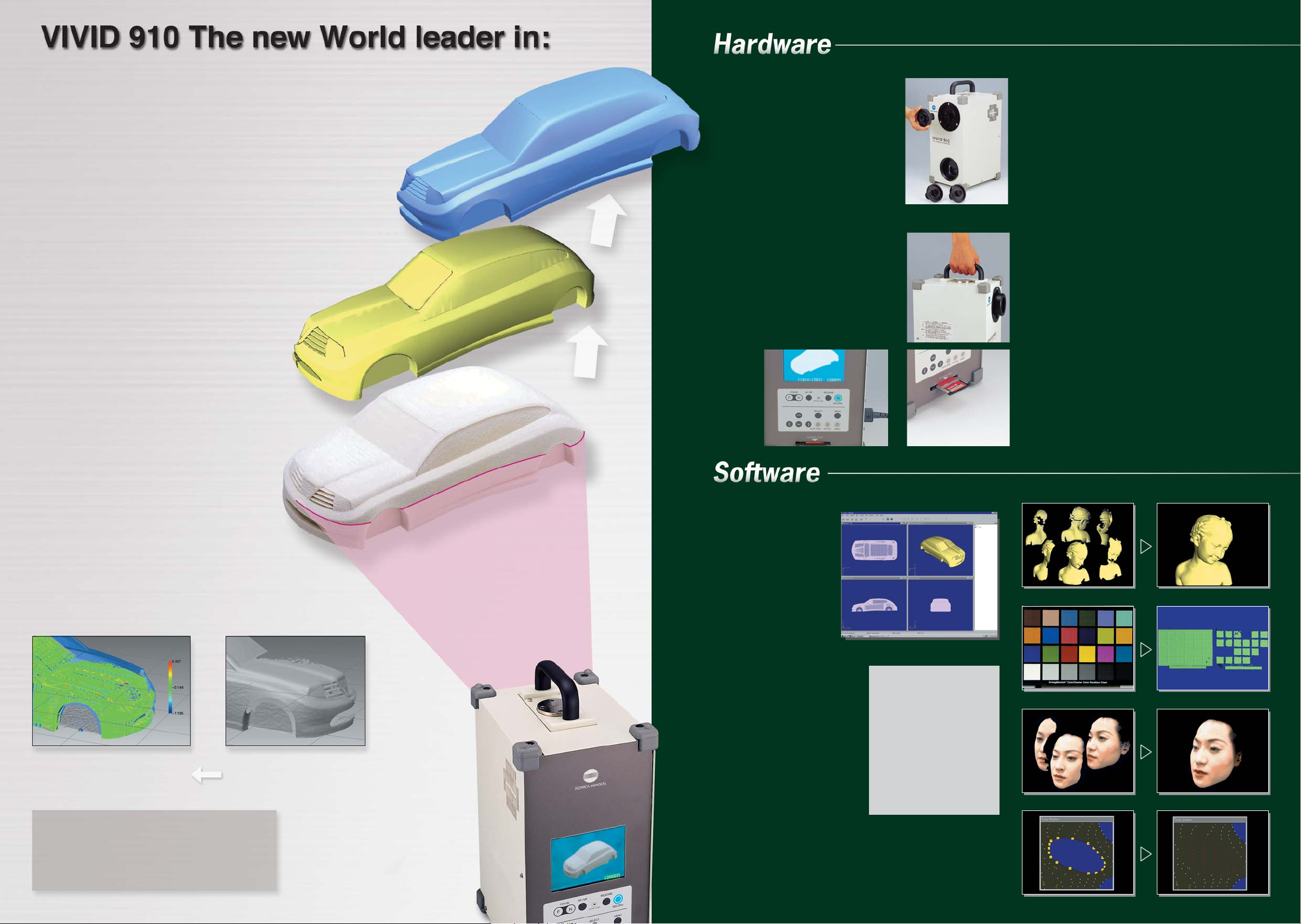

Page 2

Precision - ±0.008mm(over 300,000 points) typical based on Konica Minolta standard test method

Speed - scans in less than one second

Simplicity - point and shoot simplicity for consistently

excellent results

Flexibility - only Konica Minolta offers interchangeable

lenses for big and small parts and

"Dynamic Range Expansion technology"

VIVID 910' break-through innovation

for measuring from dark to shiny

surfaces in a single pass

Value - Konica Minolta sets a new price /

performance threshold

Who but Konica Minolta gives you the VIVID 910 3-D

Scanner, offering high-speed and high-accuracy, at a

high-value price? VIVID 910 is the newest of Konica

Minolta's VIVID family of 3-D scanners. You've come

to know Konica Minolta's VIVID digitizers, setting the

pace in 3-D digitizing with performance, attractive price,

simple camera-like operation, and rock-solid reliability.

Main Applications

The VIVID 910 is ideal for the following applications:

• On-Line Quality Control Inspection of production

parts (i.e. CAI, CAT)

• First Article Inspection; Tool and Die Verification

• Industrial Design: capture design studies into CAD database

• Rapid Prototyping Input

• Reverse Engineering: create CAD legacy data from

master parts

• 3-D shape capture for Computer Aided Engineering

Analysis (CAE and FEA)

• Machine Vision

• Medical Applications:

• Surgical Planning (maxillofacial, dental and

orthopedic), orthotics and prosthetics, plastic surgery,

anthropometric measurements

• Archiving: Museums, Artifact & Antiquities cataloging,

Archeology, Anthropology research

• Computer graphics: Animation, Computer Simulations

• Web content creation/ on-line product catalog creation

Comparison with 3-D data

Certified Peformance

Who but Konica Minolta backs up the volumetric accuracy of their

digitizer products? Konica Minolta understands the importance of

quantifiable performance to organizations with ISO 9000 certification

and all who compete in today's quality-driven, manufacturing world.

Konica Minolta stands behind the VIVID 910 by offering a "Certificate

of Performance" traceable to national standards laboratories.

3-D data captured

by scanning

3-D data captured by scanning

A mockup is scanned by

Creation of NURBS surfaces

based on the captured data

Manufactured by: YAMASHITA&COMPANY

VIVID 910.

Flexibility: Variable digitizing Volumes by interchangeable Lenses

Autofocus

Who but Konica Minolta gives you the

flexibility to capture the hood ornament, the

whole hood, or the whole car? The VIVID

910 can digitize variable volumes (between

110 x 80 x 40 mm and 1200 x 900 x750

mm) while still maintaining precise

repeatability. Large part - small part, just

pick the right lens for the size of your scan.

The three lenses (telephoto, medium, wide

Rich 3-D Color

angle) are standard equipment and are as

easy to change as the lens on your SLR

camera. (TELE: f=25mm, MIDDLE

f=14mm, WIDE f=8)

Portable & Compact

Who but Konica Minolta understands

portability? VIVID 910 travels light -- it is

compact (213mm (8-3/8 in.) x 413mm

(16-1/4 in.) x 271mm (10-11/16 in.))

weighs only 11kg (24 lbs.) and is a standalone instrument. You don't even need a

host computer to use Vivid. Multiple

scans can be saved to the compact flash

memory or viewed immediately on the

rear-panel's color LCD viewfinder.

Main display examples

Advanced Polygon Editing Software (Standard Accessory)

●

Who but Konica Minolta

gives you a whole solution,

not just data? Each VIVID

910 includes Konica

Minolta's powerful polygonediting software. You can

operate the VIVID from your

host computer, perform

automatic data registration,

●

edit captured scan data (fill

holes, decimate, smooth,

etc), merge scans into a

single “watertight” mesh,

and export into a variety of

data formats.

Import Formats: *.stl, and *.cam, *.vvd, *.scn, *.cdm

Export Formats: *.dxf, *.obj Wavefront,

ASCII (point cloud data)

TIFF *.tif, * PDM

(texture map color data)

Software functions

Automatic and Manual data registration, data

merging, smoothing, sub-sampling and

curvature-based decimation, polygon checking

(intersections, degeneration, etc), texture

blending and merging, etc.

•

Point Group Editing

Selection via color, Bezier, rectangle tools,

interactive and parametric rotation, translation

of point groups, hole filling, smoothing, cloning

and deletion of point groups. Color editing:

color blending and merging of multiple color

scans

•

Camera Remote Operation

Image capture, auto/manual-ranging, (i.e.,

depth of field setting), auto/manual laser power

setting, camera data acquisition control, turntable control

•

Scan Data Display Modes

Wireframe, smooth shaded, flat shaded, color

image, texture mapping

(Konica Minolta proprietary)

SOFTIMAGE, VRML and STL

(polygonal data)

Required Host Computer

Windows® Workstation

• OS : Windows NT

Windows

• CPU : Pentium III or higher

• Main memory : 512MB or more

(1024MB or more recommended)

• Display : 800 x 600 or higher

• Graphic board : 3-Dlabs OXYGEN GVX1

(recommended*)

• SCSI interface : SCSI card by Adaptec

(ASPI library by Adaptec is also required.

And compatible models recommended on

Windows

• Media drive : CD-ROM drive

* A graphic board supported by OpenGL must be

used. (For details, contact Konica Minolta.)

®

4.0 (Service Pack 6 or higher)

®

2000 (Service Pack 2 or higher)

®

2000*)

●

●

Easy to Use

Automatic data registration & merging

Dynamic Range Expansion Mode

Scan sample

Texture mapping & texture blending

Hole filling by data interpolation

Who but Konica Minolta, the leader in optical

technology, brings autofocus from the world of

photography to our precision measurement devices?

There is no need to move the VIVID back and forth,

or to manually adjust to guess at the optimal focus,

its automatic.

Who but Konica Minolta gives you color data is

second to none? Vivid's color images are

equivalent to a 3 CCD digital camera with full 24bit color depth. 640 x 480 x 24 bits. Konica

Minolta's expertise shows through with

MeasureMax, the ability to capture a wider range

of dark to shinny surface finishes that blind other

digitizers.

Who but Konica Minolta gives you camera-like

simplicity? Unlike some digitizers, there is no

lengthy set-up, warm-up and calibration process

before your can measure. No moving the

scanner back and forth until just the right

distance is reached: its automatic. No need to

manually adjust the scanner for different ambient

light conditions. Konica Minolta has eliminated

these quirks found in other scanners. Turn it on,

aim and frame using the LCD viewfinder, and shoot.

But what about scanning an object from all

sides? We've made that easy too. Konica

Minolta provides an optional rotating table to

index the scanned part and capture all sides in

one automated process. Each scan is

automatically aligned. Who else makes it this

easy?

(before) (after)

(before) (after)

Dynamic Range Expansion Mode

not usedused

(before) (after)

(before) (after)

Page 3

Theory of Operation

Basic Principle

The VIVID 910 uses LASER triangulation. The object is scanned by a plane of laser light coming from the Vivid's

source aperture. The plane of light is swept across the field of view by a mirror, rotated by a precise galvanometer.

This LASER light is reflected from the surface of the scanned object. Each scan line is observed by a single frame,

captured by the CCD camera. The contour of the surface is derived from the shape of the image of each reflected

scan line. The entire area is captured in 2.5 seconds (0.3 seconds in FAST mode), and the surface shape is

converted to a lattice of over 300,000 vertices (connected points). VIVID gives you more than a point cloud; a

polygonal-mesh is created with all connectivity information retained, thereby eliminating geometric ambiguities and

improving detail capture. A brilliant (24-bit) color image is captured at the same time by the same CCD. Unlike

other scanners, the VIVID has no parallax error, its "spot - on"!

High Accuracy Measurement

A high-accuracy scanner and a high-accuracy Calibration facility unit to be used for calculation of 3-D data have

been developed for the VIVID 910.

The 3-D reference chart traceable to the national standards has also been established to utilize the technology and

algorithm that enable higher accuracy measurement.

111X111 to 1196X1196mm (x)

83X83 to 897X897 (y)

Scanning field of view (x,y)

VIVID 910-to-object

distance (renge)

0.6m to 2.5m

VIVID 910

An object

System Block Diagram

CD-R

Poygon Editing Tool

(standard accessory)

PC (commercial available)

PC-AT

compatible machine

(OS-Windows NT® / Windows® 2000)

Bench Top Frame Set

(optional accessory)

White Balance Cap

Exchangeable Lenses

TELE

f=25mm

Rotating Stage Set

(optional accessory)

Rottating Stage Set

Bench Top Flame Set

Compact Flash Memory Card

PC Card Adapter

Tripod

Pan head

(standard accesoory)

(standard accesoory)

MIDDLE

f=14mm

128M

Compact Flash

Memory Card

(optional accessory)

WIDE

f=8mm

Specifications

Type Non-contact 3D digitizer VIVID 910

Measuring method Triangulation light block method

Auto Focus method Image surface AF (contrast method), active AF

Light-Receiving Lens TELE: Focal distance f=25mm

(Exchangeable) MIDDLE: Focal distance f=14mm

WIDE: Focal distance f=8mm

Scan Range (Depth of field)

Optimal 3D measurement Range

Laser class Class 2 (IEC 60825-1), "Eye safe", Class 1 (FDA)

Laser Scan Method Galvanometer-driven rotating mirror

X Direction Input Range 111 to 463mm (TELE), 198 to 823mm (MIDDLE),

(Varies with the distance) 359 to 1196mm (WIDE)

Y Direction Input Range 83 to 347mm (TELE), 148 to 618mm (MIDDLE),

(Varies with the distance) 269 to 897mm (WIDE)

Z Direction Input Range 40 to 500mm (TELE), 70 to 800mm (MIDDLE),

(Varies with the distance) 110 to 750mm (WIDE/FINE mode)

Precision (Z,Typ.)

Accuracy

Input Time 0.3

Transfer Time to Host Computer

Ambient Lighting Condition Office Environment,

Imaging Element 3-D data:1/3-inch frame transfer CCD

Number of Output Pixels 3-D data

Color data : 640 x 480 x 24 bits color depth

Output Format

Recording Medium Compact Flash memory card (128MB)

Data File Size Total 3-D and color data capacity: 1.6MB per data (for

Viewfinder 5.7-inch LCD (320 x 240 pixels)

Output Interface SCSI II (DMA synchronous transfer)

Power Commercial AC power 100 to 240V (50 to 60Hz),

Dimensions (WxHxD) 213 x 413 x 271 mm (

Weight Approx.11kg (25 lbs)

Operating temperature/ 10 to 40°C, relative humidity 65% or less with no

humidity range condensation

Storage temperature/

humidity range with no condensation

• Specifications are subject to change without notice.

• Product names in this brochure are trademarks of their respective companies.

0.6 to 2.5m (2m for WIDE)

0.6 to 1.2m

± 0.008mm (Condition: FINE mode, Minolta's standard)

TELE X: ± 0.22mm, Y: ± 0.16mm, Z: ± 0.10mm to the Z

reference plane (Conditions: TELE/FINE mode, Minolta's standard)

sec (FAST mode)

Approx. 1 sec (FAST mode), 1.5 sec (FINE mode)

Color data:3-D data is shared

3-D data

(Converted to 3-D data by the Polygon Editing

Software/ standard accessory)

Color data :

FAST mode), 3.6MB per data (for FINE mode)

rated current 0.6A (when 100Vac is input)

-

10 to 50°C, relative humidity 85% or less (at 35°C)

, 2.5

sec (FINE mode)

500 lx or less

: 307,000 (for FINE mode), 76,800 (for FAST mode)

:

Konica Minolta format, & (STL, DXF, OBJ, ASCII points, VRML)

RGB 24-bit raster scan data

8-3/8 x 16-1/4 x 10-11/16 in.

, 0.5

sec (COLOR)

(color separation by rotary filter).

(340,000 pixels)

)

SAFETY PRECAUTIONS

Read all safety and operating instructions

before operating the VIVID-910.

Minolta Corporation / ISD

EMail : VIVID3d@minolta.com

Web : www.minolta3d.com

Minolta Hong Kong Limited

Minolta Singapore (Pte) Ltd. 10, Teban Gardens Crescent Singapore 608923 Phone: 6563-5533 FAX: 6561-9879

Use only a power source of the

specified rating.

Improper connection may cause

a fire or electric shock..

Do not stare into the laser

beam.

(

MAX. 30mW 690nm / CLASS 1

(FDA), CLASS 2 (IEC) LASER

)

PRODUCT

3-91, Daisennishimachi, Sakai. Osaka 590-8551, Japan

101 Williams Drive, Ramsey, New Jersey 07446, U.S.A. Phone : 1-888-ISD-COLOR (in USA), 201-529-6060 (outside) FAX : 201-529-6070

Room 208, 2/F, Eastern Centre 1065 King's Road, Quarry Bay, Hong Kong, China Phone: 2565-8181 FAX: 2565-5601

CAUTION

CERTIFIED

EMail : 3dinfo@konicaminolta.jp

Web : http://sensing.konicaminolta.jp/vivid/

2001, 2002 KONICA MINOLTA SENSING, INC.

The manufacturing center of Konica Minolta Sensing

Inc. (Location: Aichi Pref., Japan) was approved by

the British certification organization Lloyd’s Register

Quality Assurance for certification under the ISO

9001: 1994 international quality management

system standards on March 3, 1995. Since its

establishment in 1990, the center has carried out the

development and production of precision

instruments and associated application software for

the measurement of color, light, and shape.

Certification was awarded to the center’s quality

management system, including design,

manufacturer, management of manufacture,

calibration and servicing.Certification was carried

over to the ISO 9001: 2000 standards in February,

2003.

ADKBPKADKBPK

Printed in Japan9242-4880-12

2

Loading...

Loading...