Page 1

QMS

3825/3225/2025

Print System

Administrators

Guide

1800367-001B

Page 2

Trademarks

QMS, QMS-PS, imPRESS, QUIC, Crown , the Crown logo, and the QMS logo are registered

trademarks of QMS, Inc. registered in the United States Patent and Trademark Office. PostScript

is a trademark of Adobe Systems, Incorporated for a page description language and may be

registered in certain jurisdictions. Throughout this manual, “PostScript Level 2” is used to refer to

a set of capabilities defined by Adobe Systems for its PostScript Level 2 page description

language. The se capab il ities, am on g other s, are imple ment ed in this produ ct throu gh a program

designed and developed by QMS which is compatible with Adobe's PostScript Level 2 language.

Macintosh, AppleTalk, and LocalTalk/Apple Computer, Inc. HP, HP PCL, and HP-GL are

registered trad emarks of Hewle tt-Pa c kard Comp any. DEC, DECnet, LN03, and VMS are

registered trademarks of Digital Equipment Corporation. UNIX/UNIX Systems Laboratories.

Proprietary Statement

The digitally encoded software included with your QMS 3825/3225/2025 Print System is

Copyrighted 1995 by QMS, Inc. All Rights Reserved. Thi s softwa re may not be reproduce d,

modified, displayed, transferred, or copied in any form or in any manner or on any media, in

whole or in part, without the express written permission of QMS, Inc.

Copyright Notice

This manual is Copyrighted 1995 by QMS, Inc., One Magnum Pass, Mobile, AL 36618. All

Rights Reserved. This manual may not be copied in whole or in part, nor transferred to any other

media or language , witho ut the expre s s writt en perm is sion of QMS, Inc.

Manual Notice

QMS, Inc. reserves the right to make changes to this manual and to the equipment describe d

herein without notice. Considerable effort has been made to ensure that this manual is free of

inaccuracies and omissions. However, QMS, Inc. makes no warranty of any kind including,

but not limited to, any implied warranties of merchantability and fitness for a particular

purpose with regard to this manual. QMS, Inc. assumes no responsibility for, or liability for,

errors contained in this manual or for incidental, special, or consequential damages arising out of

the furnishing of this manual, or the use of this manual in operating the equipment, or in

connection with the performance of the equipment when so operated.

Page 3

Contents

1 Introduction

How to Use this Manua l . ..... ..... ..... ..... ....... ..... ...... ..... ..... ..... ..... ....1-2

Typographic Conventions 1-3

Shipment Contents ..................... ....... ....... ..... ....... ....... ....... ..... ....1-4

QMS Product Registration ..........................................................1-5

Configuring the QMS 3825/3225/2025 Print System .................1-5

Methods of Confi gu ratio n ....... ..... ..... ....... ..... ...... ..... ..... ..... ..... ....1-5

Configuration for Individual Jobs 1-6

Configuration for Departmental Use 1-7

Before You Begin ........................... ......... ............ ............ ............ .1-8

Printing a Status Page 1-8

The Configuration Menus ............................................................1-9

Changing Defa ult Config ur atio n Se tting s .... ....... ......... ....... .....1 -1 1

Page 4

Selection of Choices 1-11

Alphanumeric Values 1-13

Saving Printer Con fig urati on Changes . . ......... ....... ....... ......... . 1-1 4

Upgrading Pr int System So ftware ... .............. ............ ....... ....... 1-1 5

Using the Printer’s Floppy Disk Drive 1-16

Using the Parallel Port 1-19

2 Installation Menu

Introduction . . .... ... ..... ...... . ....... .... ... ..... ...... . ....... ..... .. ..... ...... ... ..... .. 2 -2

Keypad Language . .......... ....... ............ ......... .......... ........... .......... .. 2-2

Passwords .... ....... ..... .............. ....... ............ ....... ............ ....... ......... 2 -3

Setting Passwords 2-3

Using Passwords 2-3

3 Operator Con trol Menu

Introduction . . .... ... ..... ...... . ....... .... ... ..... ...... . ....... ..... .. ..... ...... ... ..... .. 3 -2

Copies ............... .............. .............. .......... .............. ....... .............. ... 3-2

Duplex ............... .............. .............. .......... .............. ....... .............. ... 3-3

Tumble Duplex ............................................................................. 3-3

Collation ....................................................................................... 3-4

Orientation ................................................................................... 3-4

Inputbin ........................................................................................ 3-5

Outputbin ..................................................................................... 3-6

Chain Inputbi ns . ... ... ....... .... ... ...... ... ..... ..... .... ... ..... ...... ... ..... ...... ... 3-7

Crown Accounting .......... ........................................................... .. 3-7

Accounting Menu 3-8

Job Accounting Files 3-11

Accounting File Format Description 3-12

Accounting Files Description of Fields 3-13

QMS 3825/3225/2025 System Administrators Guideii

Page 5

Copying the Accounting Files 3-21

Processing Accounting Information on the Host 3-23

4 Administration/

Commu nications Submenu

The Communications Submenu ............................ .....................4-2

Timeouts ......................................................................................4-3

PS Wait Timeout 4-3

Emul Timeout 4-4

Job Timeout 4-4

ESP Timeout 4-4

Serial Commu nicati on . ..... ....... ....... ......... ...... ....... ....... ....... ..... ....4-5

Mode 4-6

Emulation 4-6

Min K Spool 4-6

Spool Timeout 4-6

End Job Mode 4-7

Def Job Prio 4-7

Baud Rate 4-7

Parity 4-7

Ignore Parity 4-8

Rcv Sw Flow Ctl 4-8

Xmit Sw Flow Ctl 4-8

Data Bits 4-8

Stop Bits 4-8

Hdwe Flow Ctl 4-9

PS Protocol 4-9

Parallel Communication ............................................................4-11

Mode 4-11

Emulation 4-11

Min K Spool 4-12

Spool Timeout 4-12

Data Bits 4-12

End Job Mode 4-12

Def Job Prio 4-13

PS Protocol 4-13

iii

Page 6

AppleTalk Communication .. ............................................. ........ 4-15

Mode 4-15

Connection 4-16

Min K Spool 4-16

Def Job Prio 4-16

Optional Interface ...................................................................... 4-16

5 Emulations Submenu

The Emulations Submenu .......................................................... 5-2

ESP Default Opti on ................ .. ..... ..... .... ... ....... .... . ....... .... ... ....... .. 5 -3

PCL 5 .... . ........... .............. . ........... ..................... . .... . ........... ............ 5- 4

Default Font 5-5

Symbol Set 5-5

Lines/Inch X100 5-5

Line Termination 5-6

Point Size X100 5-6

Retain Temporary 5-6

Scalable Fonts 5-6

Default Font Idx 5-7

Monochrome GL/2 5-7

Downld Location 5-7

LN03 Plus ......................................... ............ ............ ......... ........... 5-8

Product ID 5-8

Autowrap 5-8

Paper Size 5-9

Paper Override 5-9

X-Origin Inset 5-9

Y-Origin Inset 5-9

Reset Override 5-9

Orientation 5-10

PostScript .. ......... ........ ......... .......... ......... ......... ........ ......... .......... 5 -10

Lineprinter .... .......................... ............................... ..................... 5-11

Font 5-12

Point Sz 100ths 5-12

Character Map 5-12

Line Numbering 5-12

QMS 3825/3225/2025 System Administrators Guideiv

Page 7

Tab Stops 5-12

LF IS CRLF 5-12

CR IS CRLF 5-13

FF IS CRFF 5-13

Orientation 5-13

Autowrap 5-13

Lines Per Page 5-13

Margins 5-13

HP-GL ..........................................................................................5-14

Plotter 5-14

Scaling Percent 5-15

Origin 5-15

Reverse Image 5-15

Enhanced Mode 5-15

Expand Mode 5-16

Paper Type 5-16

Pens 1-8 5-16

CCITT Groups 3 and 4 ................ ....... ....... ..... ....... ....... ....... ..... ..5 -17

CCITT Commands 5-17

Command Syntax 5-17

imP RE SS .... .. ... .. ... .. ... .. .... ... .. ... .. ... .. .... . .... .. ... ... .. .... . .... .. ... .. ... .... . ..5 -2 4

Optional Emulations ..................................................................5-24

6 Special Pages and Startup

Options Subm enus

The Special Pages Sub m enu ..... ......... ....... ....... ......... ....... ...... ....6-2

Calibration Page 6-2

Header Page 6-3

Header Inputbin 6-3

Trailer Page 6-3

Trailer Inputbin 6-4

Status Page Type 6-4

The Startup Options Submenu ..................... ..............................6-5

Do Start Page 6-5

Do Sys Start 6-5

v

Page 8

Do Error Handler 6-6

7 Memory Submenu

Introduction . . .... ... ..... ...... . ....... .... ... ..... ...... . ....... ..... .. ..... ...... ... ..... .. 7 -2

QMS Memory Management 7-2

QMS Memory Definitions ............................................................7-3

Evaluation of Y our Printing Env ironm en t ................ ..... ... ....... .. 7-5

Printer Features and Memory Clients 7-6

Memory Sub menu ... ....... ...... ..... ... ..... ....... ....... ..... .... ..... ..... ....... .. 7 -8

Memory Clien ts .. ... ..... ..... .... ... ....... .... ... ..... ...... ... ... ...... ... ..... ...... ... 7-8

Spool Buffers 7-9

PS Heap 7-10

PostScript F ont Cache 7-10

Emulation 7-11

Temporary Emulation 7-12

Display List 7-12

Disk Cache 7-13

Frame Buffer 7-14

MB Printer Mem 7-14

System Memory 7-14

8 Engine, Miscellaneous,

and Disk Operations

Submenus

Eng in e Su bm e n u ... .. ........ ...... ........ ..... ......... ..... ......... ..... ......... .... 8-2

Image Alignment 8-3

Default Paper 8-5

Input Bin and Output Bin Names 8-5

Toner Low Action 8-5

Offset Stacking 8-5

Gamma Correction 8-6

Letterhead 8-6

QMS 3825/3225/2025 System Administrators Guidevi

Page 9

Rotate Duplex 8-7

Resolution 8-8

Print Mode 8-8

Powersave Mode 8-8

Maintenance Due 8-8

Miscellaneo us Op tio ns ............ ..... ..... ....... ..... ...... ..... ..... ..... ..... ....8-9

Restore Defaults 8-9

Clock Operations 8-10

Printer Name 8-10

Printer Type 8-10

The Disk Operations Submenu .................................................8-11

Identifying Hard Disks 8-11

Installing Optional Fonts and Emulations 8-12

Removing Fonts and Emulations 8-15

Formatting a Disk 8- 16

Backing Up the Hard Disk 8-17

Restoring the Hard Disk 8-18

A QMS Customer Support

Sources of Supp ort ........ ..... ... ..... ....... ....... ..... .... ..... ..... ....... ..... ... A-2

Your QMS Vendor A-2

Your Application Vendor or Manufacturer A-2

Q-FAX A-2

QMS Corporate Bulletin Board System A-3

CompuServe A-3

Internet A-3

QMS Customer Technical Assurance (CTA) A-4

QMS National Service Telephone Numbers A-4

QMS World-wide Offices ............................................................ A-5

B Cable Pinouts

Loc a lTal k ........... . .... .. ....... . .... .. .......... .............. . ........... .............. . ... B-2

Serial ............................................................................................ B-2

IBM PC/XT, PC/ AT, and Compatibl e Com puters ...... . ...... . ..... .. . B-3

vii

Page 10

Centronics Parallel ....................... ....... ............ ......... .......... .........B -3

Notes to the Centronics Parallel Cable

Index

❖

Pinouts Table B-4

QMS 3825/3225/2025 System Administrators Guideviii

Page 11

1

Introduction

In This Chapter . . .

■ How to use this manual

■ Configuring the printer

■ Methods of configu ra tio n

■ Printing a status page

■ The configuration m enus

■ The control panel keys

■ Changing default settin gs

■ Installing syst em software up g rad es

Page 12

How to Use this

Manual

How to Use this Manual

This manual is designed to help you, the system administrator, customize printer configurati on with as little trial and error as possible.

■ Chapter 1 - Introduction

This chapter introduces the printer and the confi guration me nu

structure and explains how to upgrade system software.

■ Chapter 2 - The Installatio n Menu

This chapter explains how to use the Installation m enu to establish password protection for the Operator Cont rol and Administ ra tion menus, and how to set the message window language.

■ Chapter 3 - The Operator Con trol Menu

This chapter explains the set-up opti ons in the Operator Cont rol

menu, which control the printer’s paper handling features, such

as the number of copies and whether collation is enabled. This

chapter also describes t he printer-based accounting features.

■ Chapter 4 - Administrati on /Co mm unica tion s Su bme nu

This chapter explains the host-print er communication configuration options i n the Administration menu.

■ Chapter 5 - Administrati on /Em ulati on s Subm en u

This chapter explains the configurat ion opti ons in the Emulat ion s

submenu of the Administration me n u.

■ Chapter 6 - Administrati on /Spe cia l Pages an d

Startup Sub menu s

This chapter covers options in the Special Pages and Startup

Options submenus of the Administrat ion menu, which control the

printing of special-purpose pages and printer start-up option s.

■ Chapter 7 - Administrati on/M emo ry Subm enu

This chapter explains memory confi gurat ion. Read this chapter

for instructions on customizing mem ory to achieve the most productive use of the printer in your printing environment.

QMS 3825/3225/2025 System Administrators Guide1-2

Page 13

How to Use this

Manual

■ Chapter 8 - Administration /Eng in e, Miscel lan eou s, and

Operations Submenus

This chapter explains the configu ration optio ns in the Engine,

Miscellaneous, and Disk Operations submenus of the Administration menu. These options control the printer’s image alignment

and input and output bin names, specialized dupl exing opt ions,

and the use of optional printer hard disk(s).

The appendixes to this manual cover QMS Customer Supp ort and

cable pinouts.

Typographic Conve ntions

The following typographic conve ntions are used in this manual:

Mixed-Case

Cour ier

Mixed-Case

Italic

Courier

UPPERCASE

COUR IER

Mixed-Case bold QMS Document Option Commands (DOC)

lowercase italic

UPPERCASE File and utility names

Text you type, and messages and information

displayed on the computer monitor

Variable text you type; replace the italicized word(s)

with information specific to your printer or workstation

Information displayed in the printer message window

Variable information in text

» Note: Notes co ntain tips, extra inform ation, or im po rtant infor mation

that deserves emp hasis or reiteration.

Caution:

Cautions present information that you need to know to avoid

equipment damage or extreme annoyance.

WARNING!

Warnin gs in dicate the possibility of personal in jur y if a

specific pro cedu r e is not per for m ed exactly as described in the

manual.

ACHTUNG!

Bitte halten Sie sich exakt an die im Handbuch besc h rieben e

Vorgehensweise, da so nst Verletzungsgefahr besteh en könnte.

Introduction

1-3

Page 14

Shipment

Contents

Shipment Contents

Your shipment contains the following:

■ The QMS 3825/3225/2025 Print System

■ The

■ The

■ The PS Executive Series Utilities on d isk

■ Two binders

■ The

■ The

■ The

■ The

■ Two paper cassettes (8.5" x 11" and 11" x 17", or A4 and A3)

■ A toner cartridge

■ An OPC drum

■ A cleaning unit

■ System software disks

■ A power cord

■ A warranty card

If you find any part of the shipment missing or damaged, contact the

shipping company or your vendor immediatel y. Do not return any

merchandise to QMS witho ut authorizat ion.

QMS 3825/3225/2025 Print System User’s Guide

QMS 3825/3225/2025 Print System Administrator’s Guide

QMS Crown Do cu men t Option Com m an ds

LN03 Plus Emulation for QMS Printe rs

QMS Crown Network Note s

QMS imPRES S Programm ing Langua g e

on disk

manual

manual

guide on disk

QMS 3825/3225/2025 System Administrators Guide1-4

Page 15

QMS Product

Registratio n

QMS Product Registration

QMS is committed to develop ing print systems tha t offer you flexible,

efficient solutions, so we’re interested in knowing how you plan to use

your printer. Register it now, and we’ll send you a special gift.

To register by mail, fill out and send in your warranty card. To register

by telephone, in the US call QMS toll-free at (800) 637-8049. In other

countries, refer to appendi x A, “QM S Customer Support,” for the

appropriate telephone number.

Configuring the QMS 3825/ 3225/2025 Print System

This manual guides you through the process of configuring the printer

options to meet your unique printin g requirem ent s. As with any network printer, one setting for any particular printer option may not meet

the needs of every user. As you are configuring the printe r, try to pick

the setting that meets the needs of most of the users.

Methods of Configuration

There are five major ways to configure your printer for your needs —

some appropriate for users and some only for system administrators .

Users configure options one job at a time using these methods:

■ An application

■ PS Executive Series Util it ies

■ QMS Docum ent Option Commands

System administrators configure the printer to meet the needs of an

entire department through these m eth ods:

Introduction

1-5

Page 16

Methods of

Configuration

■ The printer control panel

■ A remote console, for network users only

Configuration for Individual Jobs

Using an Application

Using an application is the best way for individual users to get the

results they want from the department al printe r. This helps prevent

confusion in network environments and saves unnecessary changes

at the printer control panel. Your application documentat ion explains

how to control printer settings: probably by choosing opt ions from a

printing menu.

Applications use printer drivers to send the appropriate commands to

the printer. If your application doesn’t have a QMS 3825/3225/ 2025

Print System driver, you can select a comparable PostScript driver,

such as another QMS driver or a LaserWriter driver. However, comparable drivers may not allow access to all of your printer’s features.

For best results, use the driver that accompanied your new printer.

Using PS Executive Series Utilities

You can also use the PS Executive Series Utilities (shipped with your

printer) to control the printer from your host. See the README file on

the utilities disk for inform ati on on install ing th e utiliti es, and see the

utilities’ on-line help for det ails on using the softwa re .

Using QMS Document Option Commands

The QMS 3825/3225/2025 Print System provides a powerful feature

that can accommodate your requests (and the requests of any other

user on the network) without affecting the printer confi gurati on for

other print jobs. This feature is the set of QMS Docum ent Opti on

Commands or QMS DOC.

With QMS DOC, you can add commands to the beginnin g of your

files that, when interpreted by the printer, turn on specific file processing or document handling feature s available on the printer. Use QMS

DOC to specify an emulation, select a specific input bin or paper size,

QMS 3825/3225/2025 System Administrators Guide1-6

Page 17

Methods of

Configu ra tion

select duplex (double-sided) or simplex (single-sided) printing, select

page orientation and backgrounds, use number-up and booklet printing, and more. The features you select and the QMS DOC you use at

the beginning of your file take effect only for the current print job. After

your file prints, the QMS DOC comma nds added to the beginni ng of

the next file take effect for it. If no QMS DOC appears on the next file,

the printer’s default values resume.

QMS DOC is the key to making th e Q MS 3825/ 3225/2025 Print System a true departmental printer. The

Commands

mation on using the commands. Appendix C in your user’s guide,

“Document Option Commands, ” lists all the QMS DOC your printer

supports, plus instructions for using new and revised command s.

manual, included with your printer, gives complete infor-

QMS Crown Document Option

Using Other Printer Commands

PostScript operators and HP-GL and HP PCL commands can enable

job-specific features your applicat ion or page description language

can’t access. See the

(Adobe Systems, Inc., Reading, MA: Addison-Wesley, 1990, ISBN

0-201-18127-4) and the

Reference Manual

further information .

PostScript Languag e Re ference Manual

PCL 5 Printer Language Technical

(Hewlett-Packard part number 5961-050 9) for

Configuration for Departmental Use

Using the Control Panel

QMS printers are configured at the factory for the most typical printing

environments, so most users don’t have to use the contro l panel

often. However, if you do need to change a printer setting for all print

jobs (not just on a per-job basis), you can do so through the control

panel. In a shared printing environment, only the system administra tor should make changes though the printe r’s control panel.

Using a Remote Console

Most of the configuration choices that can be made at the control

panel can also be made through a remote console in many network

Introduction

1-7

Page 18

Before You Beg in

environments. To avoid confusion in a shared printing environm ent,

only the system administrator should make config uration ch anges.

Before You Begin

Before you start configuring the printer, you should have the following:

■ A security disk. This disk allows you to set passwords for the

printer set-up menus, and to set the messag e window langu age

(English, French, German, or Spanish).

■ A status page. The status page list s the current default setti ngs

for many of the printer options. Factory defa ult s are listed in

appendix D, “Factory Default Settings,” of the user’s guide, but a

status page shows current settings and serves as a reference so

you can always reset your printer to its most recent settin gs.

Printing a Status Page

There are two types of status page, standard and advanced. The

standard status page includes the followi ng items on one page:

■ Printer identification (the printer’s name, release information,

number of sheets printed)

■ Printer settings (printer set-up opt ions for paper hand ling)

■ Current memory configuration (printer mem ory settings)

■ Timeouts (printer timeout settin gs)

■ Communications settings and input buffer sizes (settings for

printer-host communicati on, including spool ing me mory siz es)

■ Hard disk status (list of installed hard disks currently on line)

■ Angle bracket, one-half inch from the bottom-lef t corner of the

page, for use in image a lignm ent.

QMS 3825/3225/2025 System Administrators Guide1-8

Page 19

The Co n figu r ation

Menus

The advanced status page prints multiple pages with the current

menu configurati on sett ings and font informat ion in additi on to the

standard status page information.

To select which type of status page to print, see “Status Page Type” in

the Special Pages submenu in chapter 6. After setting which type of

status page to print, press the Status Page key to print a status page.

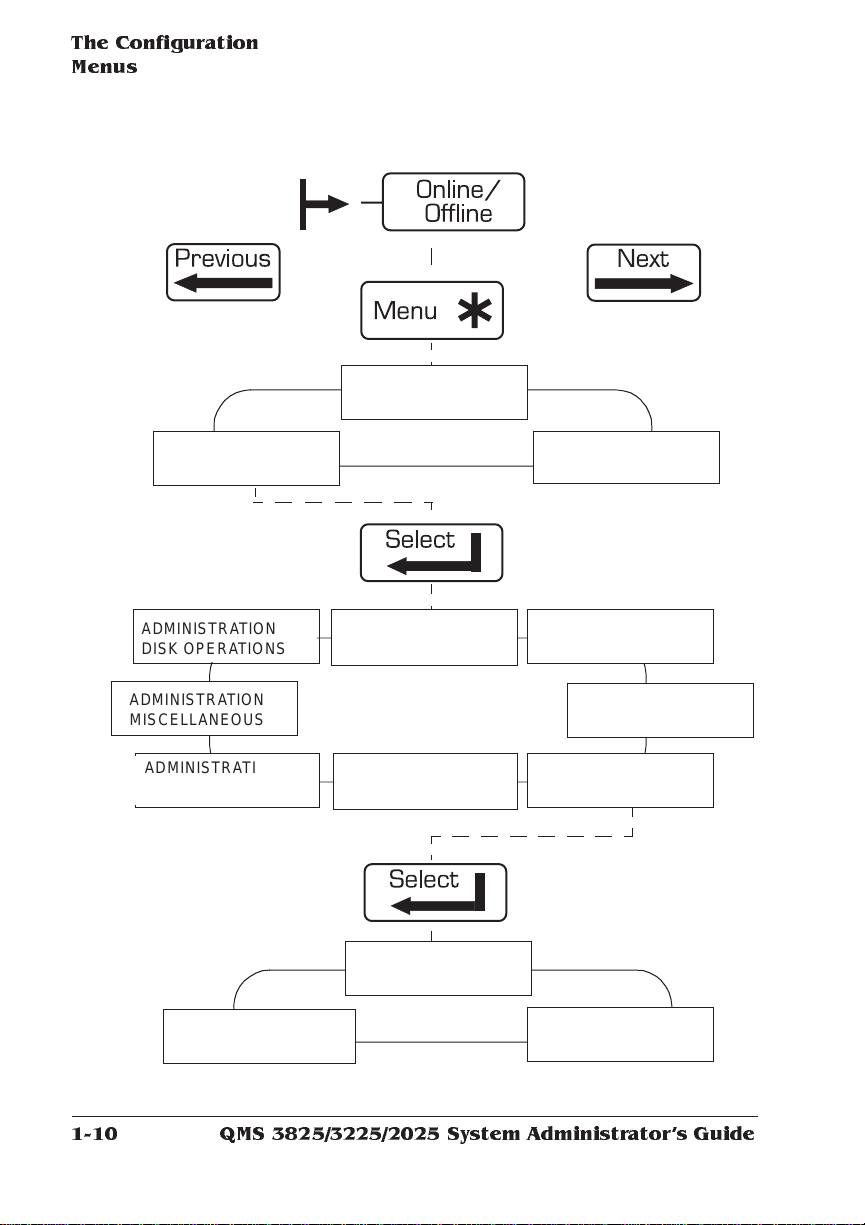

The Configuration Menus

The Configuration menu is divided into three main menus: Installation, Operator Control, and Admini strat ion.

■ The Installation menu, which appears only when the security disk

is inserted in the printer’s disk drive, is used to establish passwords for the Operator Control and Administration menus, and to

set the message window language.

■ The Operator Control me nu con trols the defau lt setting s of most

printer features.

■ The Administration menu is the largest of the three menus. It con-

trols the default settings of printer-ho st co mm uni ca tions, emulations, and other document-processing features.

Menus are arranged in a hierarchy as shown on the next page. To

access the configuration menu:

■ Press the Online/O ffline key to take the printer off line.

■ Press the Menu key to access the menu.

The top line of the message window displays the current menu level,

and the second line displays the first available option. Move down

one level by pressing the Select key. The Next and Previous keys

change the displayed option in the message window for the current

menu level. The options in each level are arranged in a loop, so

repeatedly pressing either the Next or Previous key returns you to the

option starting poin t.

Introduction

1-9

Page 20

The Configuration

Menus

CONFIGURATION

INSTALLATION

CONFIGURATION

ADMINISTRATION

ADMINISTRATION

DISK OPERATIONS

ADMINISTRATION

MISCELLANEOUS

ADMINISTRATION

ENGINE

STARTUP OPTIONS

DO ERROR HANDLER

ADMINISTRATION

COMMUNICATIONS

ADMINISTRATION

MEMORY

STARTUP OPTIONS

DO START PAGE

CONFIGURATION

OPERATOR

ADMINISTRATION

EMULATIONS

ADMINISTRATION

SPECIAL PAGES

ADMINISTRATION

STARTUP OPTIONS

STARTUP OPTIONS

DO SYS START

QMS 3825/3225/2025 System Administrators Guide1-10

Page 21

Changing Default

Configu ra tion

Settings

Changing Default Configuration Settings

There are two types of printer menu options: those that require you to

choose from a selection of possible choices and those that require

you to enter an alphanumeric value. Many default settings may never

need changing.

Selection of Choices

If an option has choices, the second line of the message window displays each choice one at a time. To view all the possible choices for

that option, press the Next key repeatedly. The menu cycles through

all the choices for that option. Th e Admini strat ion/ Com mun icati ons/

Serial/Baud Rate menu is an example of an option with a selection of

choices. The following example shows how to change the baud rate

for serial communicati on:

1 Press the Online/Offl in e key to take the printer off line.

2 Press the Menu key. The message wi nd ow displays

CONFIGURATION

OPERATOR CONTROL

3 Press the Next key until ADMINISTRATION displays on the

second line of the message window:

CONFIGURATION

ADMINISTRATION

4 Press the Select key. This opens the Admi nistrati on men u.

ADMINISTRATION now displays on the first line of the message window:

ADMINISTRATION

COMMUNICATIONS

Introduction

1-11

Page 22

Changing Default

Configur ation

Settings

5 Press the Select key again. This opens the Communications

menu. COMMUNICATIONS now disp lays on the first line of the

message window:

COMMUNICATIONS

TIMEOUTS

6 Press the Next key until SERIAL displays on the second line:

COMMUNICATIONS

SERIAL

7 Press the Select key to open the Serial subm en u:

SERIAL

MODE

8 Press the Next key until BAUD RATE displ a y s :

SERIAL

BAUD RATE

9 Press the Select key. The first choice in the set of baud rate

values displays on the bottom line. This value is also the current default setting:

BAUD RATE

*9600

10 P ress the Next key un til the value you wan t (for exampl e,

2400) displays:

BAUD RATE

2400

11 Press the S elec t key. Th e message window displ ays a con-

firmation message for three seconds:

2400

IS SELECTED

12 Th en, the messag e win do w displays the op tio n’s name:

SERIAL

BAUD RATE

You have now changed the baud rate to 2400. The change does not

QMS 3825/3225/2025 System Administrators Guide1-12

Page 23

Changing Default

Configu ra tion

Settings

take effect until you save the changes and place the printer ba c k on

line. Review “Saving Printer Conf igurat ion Chan ges” later in this

chapter.

Alphanumeric Values

When an option requires a value, you enter the value one digit or

character at a time. You use the Next and Previous keys to increase

or decrease the displayed character or digit value. Spaces can also

be used when a value, such as a password, must be an exact number

of characters. The Copies option in the Operator Control menu is an

example of an option that requires a value. The following instructions

show how to change a value:

1 Press the Online/Offl in e key to take the printer off line.

2 Press the Menu key. The follo wing messa ge displays i n the

message window:

CONFIGURATION

OPERATOR CONTROL

3 Press the Select key to open the Operator Con trol menu.

OPERATOR CONTROL now displays on the first line of the

message window:

OPERATOR CONTROL

COPIES

4 Press the Select key again to displ ay the curre nt valu e:

COPIES

001

5 Notice that the first digit is flashing . (The defaul t copy co unt

is 1.) You may select any number o f copi es up to 999. For

this example, we are setting the copy count to 159.

Introduction

1-13

Page 24

Saving Printer

Configur ation

Changes

6 Press the Next key once. The first digi t chan ges from 0 to 1.

Press the Select key.

COPIES

101

7 The second digit is now flashing. Press the Next key until the

second digit changes to 5. Press the Select key.

COPIES

151

8 The third digit is now flashi ng . Press the P revi ou s key until

the last digit changes to 9.

COPIES

159

9 Press the Select key. The message window momentarily con-

firms the chang e you have made:

159 COPIES

IS SELECTED

Then the message window displays the option’s name again.

You have now changed the copy count to 159 copies per print job.

The change does not take effect until you save the change and pl ace

the printer back on line. Review the next section, “Saving Printer Configuration Changes.”

Saving Printer Configuration Changes

Whenever you change a printer menu option, the printer prompts you

to save the change before you place the printer back on line. Saving a

menu change means that the new value of the option is recorded and

stored in the printer’s memor y. Once stored in memory, the value

takes effect automaticall y whenever the print er is turned on. Follow

these steps to save your configuration changes:

QMS 3825/3225/2025 System Administrators Guide1-14

Page 25

Upgrading P rint

System Softw a re

1 Press the Online/Offl ine key. The following message dis-

plays in the message window:

SAVE CHANGES?

NO

2 If you want to save all the configura tion chan ges yo u have

made, press the Next key (the message window displays YES

on the second line), and then press the Select key. You r

changes take effect when you press the Online/O ffli ne key

again.

3 If you do not want to save your changes, ju st press the

Select key to select NO. Press the Onli ne/ Offl ine key agai n.

If you ever save a menu change that you did not want to save, you

can always go back into the configuration menu and change it back to

the previous setting. There is also an option fo r resettin g all menu

options to their factor y default settings ( see “Rest ore Defaults” in

chapter 8, “Engine, Miscellaneous, and Disk Operations.”).

» Note: So me Administration menu chang es do not take effect until the

printer is restarted. Some chan ges cause the printer to reboot

automatically. Other s cause the m essag e

REBOOT NOW?

*YES

» Note:to a ppear in the message window. Press the Select key to reboot

the printer, or the Next and S elec t k eys to choose

your c o nfigu r a tion c h a n ges until the p rinter is restarted.

NO

and postpone

Upgrading Print System Software

Print system software upgrades for the QMS 3825/3225/ 2025 Print

System are supplied on 3.5" 1.44 MB di sks. Installin g system software upgrades requires copying the contents of the disks to the

printer ’s internal hard disk from the printer’s floppy disk drive or

Introduction

1-15

Page 26

Upgrad ing Print

System Software

through the parallel port. (To install through the parallel port you must

have the QMS system software loaded on your host com put er ). Both

procedures are explained in this section.

Using the Printers Floppy Disk Drive

To install system software upgrades via the printer’s floppy disk drive,

follow these instructions:

1 Turn the printer off and the n on again . The fol lowi ng mes-

sage displays in the message window :

QMS SOFTLOAD

READY TO BOOT

2 Once this message appears , you have 10 second s to press

the Select key. When you press the Select key, the following

message appears in the messag e window:

QMS SOFTLOAD

BOOT SYSTEM

» Note: If more than 10 seconds pass before you press the Select

key, the IDLE message appears. You m u st r etur n to step 1.

3 Press the Next key until INSTALL TO DISK appears on the

second line of the message window:

QMS SOFTLOAD

INSTALL TO DISK

4 Press the Select key to enter the Insta ll to Disk subm enu .

The following messag e appears in the messag e windo w:

INSTALL TO DISK

DISKETTE

5 Press the Select key to load the software from the printer’s

floppy disk dr ive. The followi ng mes sage ap pears in the window:

x.x

x.x

x.x

INSTALL TO DISK

TARGET DISK 6

QMS 3825/3225/2025 System Administrators Guide1-16

Page 27

Upgrading P rint

System Softw a re

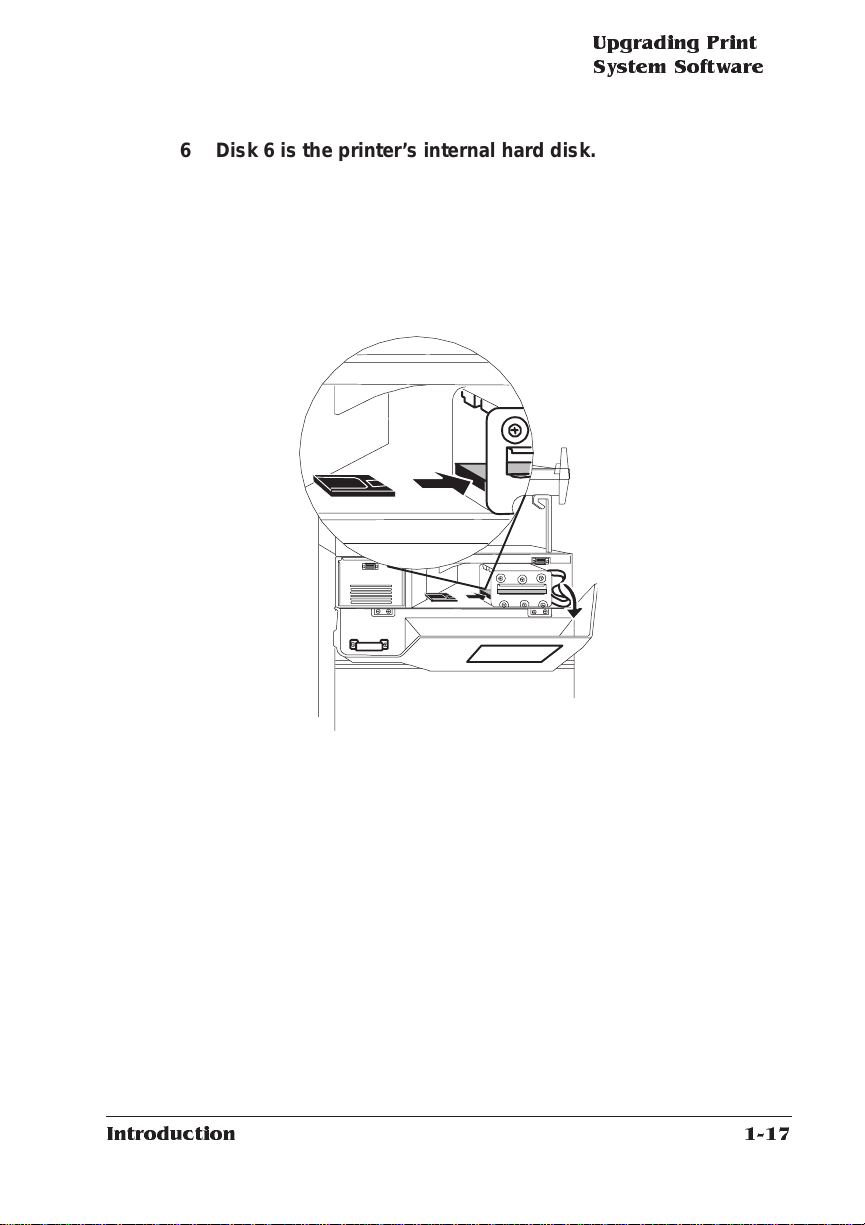

6 Disk 6 is the printer ’s internal hard disk. Press the S ele ct

key. The following message displays:

INSTALL TO DISK

INSERT DISK

7 Pull the control panel assemb ly away from the fron t of the

printer. The floppy disk drive is located inside the prin ter as

shown below.

8 Insert the first disk into the floppy disk drive, and then press

the Select key.

The message window reads INSTALL TO DISK/INSTALLING; then INSTALL TO DISK/DSK 6: before switching back to

INSTALL TO DISK/INSERT DISK when it is ready for the next

disk. Each disk takes several minutes to load. This process continues until all the disks have been loaded.

9 Press the Select key after inserti ng each disk.

10 Rem ov e the last disk and close the contro l panel assem bl y.

You have now completed installing the new system software and

are ready to boot the system.

Introduction

1-17

Page 28

Upgrad ing Print

System Software

11 Press the Me nu key. The message window displays the fol-

lowing message:

QMS SOFTLOAD

INSTALL TO DISK

12 P ress the Next key un til the message wi nd ow displays the

following message:

QMS SOFTLOAD

BOOT SYSTEM

13 Press the Select key to enter the Boot System submenu. The

following message ap pears in the message wind ow:

BOOT SYSTEM

HARD DISK

14 P ress the S elec t key and the follo wing mess age ap pear s:

BOOT SYSTEM

HARD DISK 6

15 Hard disk 6 is the internal hard disk. If you have any external

hard disks connected , you can cycle through them by pressing the Next key. For this example we are using the internal

hard disk. Press the Select ke y. The system begi ns load in g,

and the following message displays:

BOOT SYSTEM

LOADING

x.x

x.x

x.x

16 At this po int, DO NOT TOUCH ANY KEYS until the system

has completed load ing. The system m ay go throu gh many

cycles of rebooti ng , which may take several minu tes. When

the system rebooting is comple te, the message wi ndo w displays:

IDLE

» Note: If you do touch some keys dur ing this step, you m u st go

back to step 12 and start from there again.

QMS 3825/3225/2025 System Administrators Guide1-18

Page 29

Upgrading P rint

System Softw a re

Using the Parallel Port

To install system software up grades via the parallel port, follow these

instructions:

1 Turn the printer off and the n on again . The fol lowi ng mes-

sage displays in the window:

QMS SOFTLOAD

READY TO BOOT

2 Once this message appears , you have 10 second s to press

the Select key. When you press the Select key, the following

message appears in the messag e window:

QMS SOFTLOAD

BOOT SYSTEM

» Note: If 10 seconds pass before y ou press the S elect key, the IDLE

message appears. You must r etur n to step 1.

3 Press the Next key until INSTALL TO DISK appears on the

second line of the message window:

QMS SOFTLOAD

INSTALL TO DISK

4 Press the Select key to enter the Insta ll to Disk subm enu .

Then press the Next key until the following message appears

in the message window:

INSTALL TO DISK

PARALLEL

5 Press the Select key to load the software from the host

system parallel port. The following message appears in the

window:

x.x

x.x

x.x

INSTALL TO DISK

TARGET DISK 6

Introduction

1-19

Page 30

Upgrad ing Print

System Software

6 Disk 6 is the printer ’s internal hard disk. Press the S ele ct

key. The following message displays:

INSTALL TO DISK

CONNECTING....

7 Go to your host computer and send the syste m software.

The software is installed when the following messag e

appears:

INSTALL TO DISK

COMPLETE

8 Once you have completed installin g the system so ftware,

you are ready to boot the system. Return to your printer and

press the Menu key. The message windo w displ ays the following message:

QMS SOFTLOAD

INSTALL TO DISK

9 Press the Next key until the message wind ow displ ays the

following message:

QMS SOFTLOAD

BOOT SYSTEM

10 Press the Select key to enter the Boot System submenu. The

following message ap pears in the message wind ow:

BOOT SYSTEM

HARD DISK

11 Press the S elec t key and the fol lowi ng message ap pear s:

BOOT SYSTEM

HARD DISK 6

12 Hard disk 6 is the internal hard disk. If you have any external

hard disks connected you can cycle throu gh them by pressing the Next key. For this example we are using the internal

x.x

x.x

QMS 3825/3225/2025 System Administrators Guide1-20

Page 31

Upgrading P rint

System Softw a re

hard disk. Press the Select ke y. The system begi ns load in g,

and the following message displays:

BOOT SYSTEM

LOADING

13 At this po int, DO NOT TOUCH ANY KEYS until the system

has completed load ing. The system m ay go throu gh many

cycles of rebooti ng , which may take several minutes. When

the system rebooting is comple te , the followi ng message

appears:

IDLE

» Note: If you do touch so me keys during this stop, you must go

back to step 9 and start from there again.

❖

Introduction

1-21

Page 32

Page 33

2

Installation Menu

In This Chapter . . .

■ Setting the message window language

■ Setting and using passwords

Page 34

Introduction

Introduction

When the security disk is inserted in the printer’s disk drive, you can

access the Installation menu. The options in the In stall ati on men u

allow you to select the message window language and establish

passwords for the Operator Control and Admi nistrat ion menus

CONFIGURATION

INSTALLATION

INSTALLATION

USE ADMIN PWD

INSTALLATION

ADMIN PASSWORD

INSTALLATION

KEYP AD LANGUAGE

Keypad Language

Use the Keypad Language option to select message displays in

English, French, German, or Spanish. Th e defau lt is English.

INSTALLATION

OPERATOR PASSWRD

INSTALLATION

USE OPERATOR PWD

QMS 3825/3225/2025 System Administrators Guide2-2

Page 35

Passwords

Setting Passwords

The two password setti ng opti ons, Ope rator P as swrd and Adm in

Password, are options that require alphan ume ric values, which may

be up to 16 characters in length. If the password you choose is not 16

characters long, you must pad the remainder of the passwo rd with

spaces. See chapter 1, “Introduction,” for inform ati on on entering

alphanumeric values.

Using Passwords

The password enabling options, Use Opera tor Pwd and Use Adm in

Pwd, can be used to prevent unauthorized access to the printer’ s

configuration me nu.

If Use Operator Pwd is set On, anyone attempting to enter the Operator Control menu must enter the operator password before accessing

any of the submenus.

Passwords

If Use Admin Pwd is set On, anyone attempting t o enter the Administration menu must enter the Admin Password before accessing any of

the submenus.

Default for both is Off.

❖

Installation M enu

2-3

Page 36

Page 37

3

Operator Control Menu

In This Chapter . . .

■ Copies

■ Duplex and tumble duplex

■ Collation

■ Orientation

■ Input and output bins

■ Chaining input bins

■ Job accounting

Page 38

Introduction

Introduction

The options in the Operator Control menu allow you to set the default

values for the various paper handling features of the QMS 3825/

3225/2025 Print System. The Operator Control menu may be protected by a password (see chapter 2, “Installation Menu,” fo r more

information).

CONFIGURATION

OPERATOR CONTROL

OPERATOR CONTROL

ACCOUNTING

OPERATOR CONTROL

CHAIN INPUTBINS

R

E

P

O

U

O

P

T

OPERATOR CONTROL

INPUTBIN

Copies

The Copies option allows you to set the number of copies of each file

to be printed. The factory default value is 1. The maximum is 999.

Changing this option at the printer cont rol panel effects all print jobs.

Most applications can print multipl e copies. If you use your applica tion’s multiple-copy feature, keep the printer’ s Copies option set t o 1.

OPERATOR CONTROL

COPIES

N

O

R

T

L

O

C

R

O

A

T

N

I

B

U

T

OPERATOR CONTROL

DUPLEX

(IF DUPLEXER INSTALLED)

OPERATOR CONTROL

TUMBLE DUPLEX

(IF DUPLEXER INSTALLED)

OPERATOR CONTROL

COLLATION

OPERATOR CONTROL

ORIENTATION

QMS 3825/3225/2025 System Administrators Guide3-2

Page 39

Duplex

Duplex

The Duplex option allows you to print on both sides of paper, if the

Advanced Paper Handling opt ion (duplexer, large-capacity input tray,

and system table) has been installed. Duplex choices are On and Off.

The default value is Off. Setting Duplex to On at the printer makes all

jobs print duplex. If you want to print individual jobs duplex, leave the

printer setting at Off and choose duplex through your application.

» Note: If yo u are printing letterh ead in duplex mode, the letterhead

paper m ust be loaded face down in the input bins.

Tumble Duplex

The Tumble Duplex option allows you to specify this advanced

duplexing option. To use Tumble Duplex, the Advan ce d Paper Handling option must be installe d, and both the Dupl ex and Tumble

Duplex options must be On. Choices for Tumble Duplex are On and

Off with a de fa u lt value of Off. The following illustration shows the difference between duplex and tumble dup lex, using three-holepunched paper as an example.

Operator Control M enu

Side 1

Side 1

Side 2

Portrait

Duplex

Side 2

Portrait

Tumble Duplex

Side 1

Side 1 Side 2

Side 2

Landscape

Landscape

3-3

Page 40

Collation

Collation

The Collation option allow s you to choose whether to print all copies

of a single page before any copies of the next page or whether to

print one copy of every page before starting the next entire copy.

Choices are On and Off with a default of On. The following illustration

shows the difference between collated and uncollated jobs.

Collated Uncollated

4

3

2

1

4

3

2

1

1

1

3

2

2

4

4

3

Orientation

Orientation allows you to select placement of the image on the phy sical sheet of paper. The choices are Portrait and Landscape. The

default is Portrait. If you specify orientation through your applicat ion,

keep the printer ’s Orientat ion opt ion set to Port rait.T he foll owing illustration shows page orientation relat ive to paper in the input bins.

Portrait

QMS 3825/3225/2025 System Administrators Guide3-4

Landscape

Page 41

Inputbin

The Inputbin option has a selection of choices for the printer’s default

paper source. The choices are Upper, Lower, and LCIT (if the

Advanced Paper Handling option is installed). Choose LCIT to use

the large-capacit y input tray on the 3825, 3225 , or 2025 Print Systems or the large-large-cap acity inpu t tray on the 3825 or 3225. The

default is Upper. These illustration s show where the input bins are

located:

Inputbin

Sheet size may be specified by the QMS DOC %%IncludeFeature:input comm and o r, if the printer is on a DECnet network, by the

VMS SHEET_SIZE param ete r. See

or

Commands

VMS Interface for QMS Printers

Outputbin

The Outputbin option allows you to choose the printer’s default output

stacker. The default is Upper and the choices for Outputbin are

Upper

Lower

Large-

Capacity

Upper

Lower

Large-Large-

Capacity

QMS Crown Document Option

for more information.

Operator Control M enu

3-5

Page 42

Outputbin

The illustration below show s the output bins. On the control panel

printer icon, the output bins are labeled 1, 2 , and 3 with 1 being the

Upper bin, 2 being the Lower bin, and 3 being the Side bin. The

optional Large Capacity Out put Stacker is not shown on the icon.

■ Upper

■ Lower

■ Side (The side, face-up bin, displays as an option only

when folded out for use.)

■ LCOS (On the 3825 only, if the optional Large-Capacity

Output Stack er is installed)

■ * (The printer stacks paper in any available face-down

bin — upper, lower, or LCOS, if installed).

Side

(folds out)

Upper

Lower

Side

(folds out)

LCOS (Optional)

Upper

Lower

Use the Side output bin for small jobs or when using special print

media that may have difficult y passing through to the main outp ut

bins. Since output is stacked face up in the Side bin, duplex jobs are

not stacked i n numerical ord er and have to be hand sorted.

QMS 3825/3225/2025 System Administrators Guide3-6

Page 43

Chain Inputbins

The Chain Inputbins option specif ies whether the print er switches to

another input bin containing th e same size paper when one input bin

is empty. The default value for Chain Input bin is O n.

Crown Accounting

Crown accounting, a tool to help you keep track of the use of printer

resources, is available on your QMS Print System, with or without a

network connection.

Paper use is the most commonly monitored resource. However,

Crown accounting also allows you to monit or

■ paper use per user

■ time consumed serving each user’s jobs

Chain Inputbins

■ connectivity options

■ frequency of jams

■ times of peak use

■ number, complexity, and average size of jobs per user

■ commonly used features, such as duplexing or finishing

» Note:If yo u are connected to a network via TCP/IP, you h ave a choice of

using Crown accounting or the standard TCP/IP accounting through

your U NIX host software. Se e the TCP/IP Prot ocol Option Users Guide

for more information on TCP/IP acc ountin g.

As jobs are printed on the QMS printer, the system collects information about different job parameters in relation to the jobs. When each

Operator Control M enu

3-7

Page 44

Crown Accounting

job completes, th e printer stores an ent ry for the job in the Job

Accounting file(s).

Caution:

Doing so may cause inconsistencies in the information stored.

Do not turn the pr inter off while th e disk is being accessed.

Accounting Menu

The Accounting menu includes five submenus, allowing you to enable

or disable job accounting, allocate disk space when accounting is

enabled, reset accounting, store job accounting inf ormati on in a single job file or in multiple file s, and copy the a c counti ng inf ormat ion to

a floppy disk.

Job accounting informat ion may be stored in a single file if it can be

retrieved via FTP on your host. Otherwise, the selected job accounting file should be spread into several files so that each of the files (or

segments) fits on a floppy disk.

Operator Control/Accounting Menu

Accounting Mode

Disk Space

Resetaccounting

Job File Segment

Copy to Floppy

Accounting Mode

The Accounting Mo de option enables or d isables job accounting.

Choices are Enabled or Disabled with a default of Enabled. When you

disable accounting, any files containing data remain untouched. However, empty files are removed to save disk space.

Disk Space

The Disk Space option allocates disk space for job accounting files.

The range of values is 51200 (50 KB) to 10240 (10 MB) with a default

value of 01024 KB (1 MB).

QMS 3825/3225/2025 System Administrators Guide3-8

Page 45

Crown Accounting

The amount of space required for each job can vary between 200 and

250 bytes, so each 1 MB in the job accounting file will store information on 4,000 to 5,000 jobs.

If the selected value is greater than the current value, the file size is

increased to reserve the extra space. If the value is smaller than the

current file size , any empty job accounting files are moved. If only one

file is used and it is not empty, it cannot be shrunk.

If no accounting information exists in the system when shrinking the

usage, the job accounting files are recreated using the new size. The

printer does not ask for confirmation for th is opera tio n. It takes effect

immediat el y.

Resetaccounting

The Resetaccounting option erases the A ccou nting files and recreates them using the current file size. If this operation is selected when

accounting is disabled, the files are removed but not recreated, thus

saving disk space. The range of values is Yes and No. The default

value is No.

This operation is also available as the resetaccount command for

the admin user at a remote console. See the

for more information on the rese ta ccou nt comm and .

Guide

When job files are more than 80% full but less than 100% full, the following message displays on the control panel and remote conso le:

xxxxxxxx

(

xxx%

is the percentage full, reported as 85%, 90%, or 95%.) This is

an appropriate time to copy these file s to floppies o r to transfer them

to your host computer using ftp if it is available to you. Then use the

option to reset the accounting files to empty after they are copied to a

floppy or to a host.

When the file is 100% full, the

xxx

message displays.

Operator Control M enu

FILE

FILE IS FULL

xxx%

Remote Console User’s

FULL

3-9

Page 46

Crown Accounting

» Note: When accounting is enabled and the Job Accounting files are

100% fu ll, no further print jobs are acc epted by the prin ter until

Resetaccou ntin g is selected or until Acco u ntin g is disabled. If you

disable Accountin g at this time, no job information is stor ed. You can

retrieve your accou ntin g files while they ar e fu ll an d then do the

Resetaccounting ope ratio n. Ho wever, to avoid delaying jo bs being sent

to the printer, it is advisable to perform the retrieve/reset operations

before the job accounting files fill up.

Job File Segment

The Job File Segment menu allows you to decide whether accounting

information is stored in the printer in a single file or in multiple files.

Choices are Single and Multiple, with Multiple as the defaul t.

Although it is convenient to store accounting data in a single file, the

multiple file option is useful if you must transfer your files to your host

via floppy disk.

If a single file is used, its size equals th e Disk Space value described

earlier in this section. The file name will be ACC1.JOB.

If multiple files are selected, their combined size equals the File Size

value described earlier in this section. Each file will be 1 MB, except

the last file, which includes the remaining dedicated space. That is, if

you dedicate 10 MB to accounting and select multiple files, the printer

creates 10 files of 1 MB each. If you dedicate 5.5 MB to accounting,

the printer create s 5 files of 1 MB each and one of 500 KB. The Job

file names will be ACC1.JOB, ACC2.JOB, and so on.

Copy to Floppy

This option copies each of the Accounting files to 1.44 MB, DOS -formatted floppy disks, using the printe r’s internal floppy drive.

Insert a disk in the printer’s floppy drive, select the menu entry for the

first file you want to copy, and press Select. It takes several minut es

for the file to copy. When the copying is complete, the message window displays

COPY TO FLOPPY

*EXIT

QMS 3825/3225/2025 System Administrators Guide3-10

Page 47

Crown Accounting

Press Select and remove the disk. Then follow the same procedure to

copy additional files, using a separate disk for each file. There is a

menu entry for each possible file, but you need to copy only the ones

you use. The last selection copies the auxiliary accounting files to the

floppy disk. These files — ACC.STA, ACC.PAP, ACC.DIC — are

described later in this chapter.

» Note: Take th e prin ter off line while r etrieving accounting files so that

no jobs will be sent during the r etrieval pro cess. Jobs sent while data

is being retrieved m ay be lost from the accounting files.

Job Accounting Files

The following acco unting fil es are stored in ASCII form at on DSK6,

the printer ’s hard disk, in the DSK6:/ad mi n dire ctory:

x

■ Job Accounting File (ACC

This is the main accounting file. When each job co mpl ete s, the

printer stores an entry for the job in this file. The job accounting

file may be a single file or multiple files, with

when multiple files are used. Inform ati on in thi s file is kept intact

after the printer is turned off and back on again.

.JOB)

x

as the file number

■ Paper Accounting File (ACC. PAP)

This file contains de s criptio ns of the pape r typ es suppo rted on

the QMS 3825 Print System.

■ Status Accounting File (ACC. STA)

This file stores configuration inf orma tio n about accounting.

■ Dictionary File (ACC.DIC)

This file contains documentat ion about accounting and a description of the fields used in the other accounting files.

Caution:

it simpler to use the inform ation in different environments after it is

retrieved from the printer 's hard disk.

Operator Control M enu

All the acco unting files are stored in ASCII format to make

3-11

Page 48

Crown Accounting

Accounting File Format Description

Accounting files are recorded in ASCII format in a series of tagged

fields.

New fields can be added without losing backward compatibility,

because each field is tagged. A version field is included in the

ACC.STA file to identify the supported fields as the system evolv es.

» Note: Field 45 in the Job A ccounting File exam ple on page 3-13

illustrates that new fields can be added to the series but used where

logical, in this case between fields 6 and 7. Field 45, which p rovides

information about the interface used, was added in response to a

customer request.

Conventions

The following conventi ons are the same for job, paper, and status

files:

■ Tag Ide nti fie rs

These three-digit numbers are used to identify fields. The three-

digit number is used instead of a name to minimize use of disk

space. The Dictionary file (ACC.DI C) provi des the field nam es

associated with each tag identifier.

■ String Information

String information for record fiel d values is stored inside braces

(for example, {this is a string}). This allows spaces within string s

and stores only the necessary characters of a string value. String

fields for which no value is specified are stored as {}, instead of

using blanks or the maximum field size.

■ New Records

New records are separated by a <CR> character to increase

readability.

■ Separators

A typical record in any of the accounting files is a sequence of

pairs of tag identifiers and field values separated by commas.

The tag identifier and field value are separated by a colon.

QMS 3825/3225/2025 System Administrators Guide3-12

Page 49

Crown Accounting

Example

The following is an example of the format of an accounting file record:

1: 3, 2:{this is a string}, <CR>

In this example, the record has fields identified by tags 1 and 2. Since

these values don't use 3 digits for the tag identifier, spaces are stored

instead, to provide consistency and simplicity while using only a small

amount of extra space. In this exampl e, the value for the f ield ta gged

1 is the integer 3 and the value for the field tagged 2 is a string. The

<CR> represents the carriage return character.

Accounting Files Description of Fields

This section includes examples of a job accounting file, a paper

accounting file, and a status accounting file. Each exa mpl e is followed by a chart explaining the various fields, using data from the

example to help clarify the fields.

Job Accounting File Record Example

This is a sample record extracted from an actual job accounting file:

0: 6, 1: 1, 2:{ 8h 5m52}, 3:{ 2/ 7/95}, 4:3,

5:{lsmith}, 6:{}, 45:{ IF 1 Ethernet},

7:{Microsoft Word - WW6083WO.DOC}, 8:{}, 9:

2794, 10: 15414, 11: 1, 12: 0, 13: 2, 14: 3,

15: 0, 16:0, 17: 1, 18: 0, 19: 1,

20:3, 21: 2

Job Accounting File Record Description

Field IDDescription Example Explanation

0: The Job ID field is the

document’s nu mber. The numbe r

sequence restarts whenever the

printer is turned off and on again.

Operator Control M enu

0: 6 This is the 6th

job since the

printer was

restarted

3-13

Page 50

Crown Accounting

1: This field is the document’s

internally assigned priority.

2: This field indicates the time a

document arrived in the printer

by hour, minute, and second.

3: This field indicates the date a

document arrived in the printer.

4: This field is the document’s

completion code:

0 User aborted document

1 Printer aborted document

2 Emulation aborted

document

3 Successfully printed

document

5: The User Name field

corresponds to th e %%For DOC.

6: The Host Name field

corresponds to the %%Host

DOC.

45: T he Connection field indicates

the I/O port in which t he job

arrived.

7: The File Name field corresponds

to the %%Title DOC.

8: The Charge Number field

corresponds to the %%Charge

Number DOC. This field

identifies the account.

1:1 Priority 1, the

highest, has

been assigned

to this job

2:

{8h5m52}

3: {2/ 7/95} Printer received

4: 3 Job printed

5: {lsmith} L Smith sent job

6: {} No host name

45:IF 1

Ethernet

7: {Microsoft

Word WW6083WO.

DOC}

8: {} No charge

Printer received

job at 8:05:52

job on Feb. 7,

1995

successfully

assigned

This job arrived

via Ethernet

QMS DOC was

used to assign

the title

Microsoft Word WW6083WO.

DOC

number

assigned

QMS 3825/3225/2025 System Administrators Guide3-14

Page 51

Crown Accounting

9: The Compile Time field is the

processor time in milliseconds

(1/

second) spent translating

1000

the page description language.

Typically, it also includes

minimal other system activity.

10 T he Print Time field represents

the total elapsed time in

milliseconds(1/

used by the document since its

first page started printing until its

last page cleared the printer.

11: The Header Count field indicates

how many images comprise the

document header page(s)

subjob. An image equals one

page face.

12: T he Error Count field indicates

how many images comprise the

document error page(s) subjob.

An image equals one page face.

13: T he Body Count field represents

the number of images in the

actual document, excluding

multiple copies. An image equals

one page face.

14: T he Simplex Count field is

number of the page faces

printed, including body and

header pages and taking into

consideration multiple copies.

15: T he Duplex Count field

represents the sheet count of

duplex pages printed, taking into

consideration multiple copies.

1000

second)

9: 2794 Processor

spent 2.794

seconds

compiling the

page

10: 15414 Job took 15.414

seconds from

the start of the

first page to the

end of the last

page

11: 1 There is one

header page

12: 0 No error pages

13: 2 Two pages in

the document

14: 3 Three page

faces printed

15: 0 No duplex

pages

Operator Control M enu

3-15

Page 52

Crown Accounting

16: T he Finishing Options field is a

number formed by adding the

codes for the different options:

0None

2 Offset Stacking

17: T he Chunk Count field

represents the number of

collated chunks for this job. If the

complete document does not fit

in memory, chunk collation is

activated. A value of 1 for this

field indicates no partial collation

was necessary.

18: T he Jam field indicates how

many times the printer jammed

while printing the document.

19: T he Paper Types Count field

indicates how many different

types of paper were used in the

document and represents the

number of separate index entries

that follow the main record for the

document in the Job Accounting

file. A <CR> follows this field

before the index entries.

20: The Index Count field represents

the number of sheets of paper of

a specific type used by the

document. The actual description

of the paper is in the Paper

Accounting file.

21: T he Index field represents the

record number in the Paper

Accounting file that contains the

description for the preceding

paper count. A <CR> follows

each occurrence of this field.

16: 0 No finishing

options

17: 1 Entire job

printing in one

collated unit

18: 0 No jams during

this document

19: 1 One type of

paper used in

this job

20: 3 Job used three

sheets of paper

21: 2 A description of

the paper type is

in Paper

Accounting file

number 2

QMS 3825/3225/2025 System Administrators Guide3-16

Page 53

Crown Accounting

Paper Accounting File Record Example

The following example shows a Paper Accoun ting file:

22: 8268, 23: 11693, 24: 75, 25:{ white}, 26:{

plain}, 27:{ },

22: 8500, 23: 11000, 24: 75, 25:{ white}, 26:{

plain}, 27:{ },

22: 7165, 23: 10118, 24: 75, 25:{ white},

26:{ plain}, 27:{ },

22: 14000, 23: 8500, 24: 75, 25:{ white},

26:{ plain}, 27:{ },

22: 16535, 23: 11693, 24: 75, 25:{ white}, 26:{

plain}, 27:{ },

22: 14331, 23: 10118, 24: 75, 25:{ white}, 26:{

plain}, 27:{ },

22: 17000, 23: 11000, 24: 75, 25:{ white}, 26:{

plain}, 27:{ },

22: 7500, 23: 10500, 24: 75, 25:{ white},

26:{ plain}, 27:{ },

22: 8268, 23: 5827, 24: 75, 25:{ white}, 26:{

plain}, 27:{ },

Paper Accounting File Record Description

The Paper Accounting file has one record for each of the nine possible paper sizes. Field 21 refers to a specific record in the Paper

Accounting file. In the example above, Fi eld 21 indi ca tes tha t the

paper is of the second type. Therefore, the second record from the

Paper Accounting file describes the pap er used. The second record

tells you:

Field ID Description Example Explanation

22: The Paper Width field contains

the paper width in mils (1/

23: The Paper Height field contains

the paper height in mils (1/

Operator Control M enu

1000

1000

22: 8500 The paper is

").

23: 11000 Paper is 11000

").

8500 mils or

8.5" wide

mils or 11” high

3-17

Page 54

Crown Accounting

24: The Paper Weight represents the

weight per surface square units

(g/m2)

25: The Color field indicates the

color of the paper.

26: The Type field indicates

additional properties of the

paper.

27: The Label field represents a

name for the paper type.

24: 75 Paper weighs

25: white Paper is white

26: plain Paper is plain

27: { } No paper type

75 g/m

name

2

» Note: Fields 24, 25, 26, and 27 are designed primarily for future

enhancements to the accounting capabilities.

Status Accounting File Record Example

The following is an example of the Status Accounting file:

28: 1, 29: 9, 30: 1048576, 31: 1048576, 32:

74993, 33: 74993, 34: 1, 35: 1, 36: 309, 37:2,

38:1, 39:0, 40:0, 41:31, 42:23, 43:31, 44:31

Status Accounting File Record Description

Field ID Description Example Explanation

28: The Version field indicates the

accounting file’s version

number. The initial version is 1.

29: The Number of Paper T ypes f ield

indicates how many records are

in the Paper Accounting file.

30: The Job Accounting File Size

field indicates how many bytes

are dedicated to accou nting files.

Maximum is 10 MB.

28: 1 This is the first

version of the

file

29: 9 The paper

accounting file

has 9 records

30:

1048576

1048576 bytes,

or 1 MB, is

dedicated to

accounting

QMS 3825/3225/2025 System Administrators Guide3-18

Page 55

Crown Accounting

31: The Last Job File Size field

indicates the size of the last file.

In the multiple-file configurat io n,

each file is 1 MB except the last,

which holds any remaining

space.

32: The Job File Usage field

indicates in bytes the total

current use in all the job files.

33: The Current Job File Usage field

indicates in bytes the current

level of use in the current Job

Accounting file.

34: The Maximum Number of Job

Files field indicates the

maximum number of job files.

For example, even if your system

is configured for multiple files, if

only 1 MB is dedicated to

accounting, the maximum

number of files is 1. If 5.5 MB is

dedicated to accounting, the

maximum number of files is 6.

35: The Current Job File field

indicates which file has been

used most recently. By

comparing this with Field 33, you

can determine which file is

current and how much space is

left in it.

31:

1048576

32: 74993 All accounting

33: 74993 The accounting

34: 1 There can be

35: 1 The most

1048576 bytes,

or 1 MB, is in

the last file

files total 74993

bytes

file which is

currently

receiving data

totals 74993

bytes

only 1 job

accounting file.

Although the

printer is

configured for

multiple files

(see field 37)

there is only one

because only 1

MB is

dedicated to

accounting

recently used

file is File 1

Operator Control M enu

3-19

Page 56

Crown Accounting

36: The Number of Jobs field

indicates how many documents

are accounted for in the Job

Accounting file(s). A value of 0

can mean that no jobs have

been printed or that accounting

is disabled.

37: The Multifile field has a value of

1 if a single file is used and a

value of 2 if multiple files are

used to store job information.

38: The Enabled field indicates

whether accounting is currently

enabled or disabled.

1 Enabled

0 Disabled

39: The Job File Full flag indicates

whether the Job Accounting file

is full.

1 File is full; Resetaccounting

should be performed

0 Job accounting file is not full

40: The Paper Accounting File Full

flag indicates whether the Paper

Accounting file is full.

1 File is full; Resetaccounting

should be performed

0 Job accounting file is not full

41: The User field indicates the

maximum character length of the

User Name field in the Job

Accounting file. User names are

assigned w ith QMS DOC.

42: The Host field indicates the

maximum character length of the

Host Name field in the Job

Accounting file. Host names are

assigned w ith QMS DOC.

36: 309 Current Job

Accounting files

hold data on

309 jobs

37: 2 Job Accounting

is set for

multiple files

38: 1 Accounting is

currently

enabled

39: 0 Accounting files

are not full

40: 0 The Paper

Accounting file

is not full

41: 31 The User name

can be up to 31

characters

42: 23 The Host name

can be up to 23

characters

QMS 3825/3225/2025 System Administrators Guide3-20

Page 57

Crown Accounting

43: The File field indicates the

maximum character length of the

File Name field in the Job

Accounting file. File names are

assigned w ith QMS DOC.

44: The Charge field indicates the

maximum character length of the

Charge Number field in the Job

Accounting file. Charge

numbers are assigned with QMS

DOC.

43: 31 The File Name

can be up to 31

characters

44: 31 The Charge

field can be up

to 31 characters

Copying the Accounting Files

Accounting files should be transferred to your host computer periodically to keep the printer from being overloaded with data and to allow

you easy analysis of data.

» Note: The printer mu st be o ff line when any of the o perations

discussed in this section are perform ed. U se the

DSK6:/admin directory to see which accounting fi les you are going to

retrieve. The

ls

andcpcommands are issued from a remote console.

Copy the accounting information in one of the following ways, which

are described in detail in the next section.

ls

command in the

■ Use the Copy to Floppy Accounting menu option

■ Use the cp com ma nd from a remote consol e

■ Use the File Transfer Protocol (FTP) if a TCP/IP connection is

available to the printer

Using the Copy to Floppy Menu Option

This option copies each of the accounti ng files to 1.44 MB floppy

disks, using the printer’s internal floppy drive.

1 Insert a 3.5", DOS-formatted flo pp y disk into the printer’s

internal floppy disk drive.

Pull the control panel toward you to open the front of the printer

and access the floppy disk drive.

Operator Control M enu

3-21

Page 58

Crown Accounting

2 In the Operator Control /A ccou nti ng men u, choo se Cop y to

Flop py.

3 Select the files you want to copy, choosing from the Job

Accounting Files (ACC1. JOB throug h ACC10. JOB),

ACC.STA, ACC.PAP, ACC.DIC.

Since each file is 1 MB, you need a separat e floppy disk for each

file. Not all files will exist, so you need to copy only the ones that

are necessary.

4 Remove the flop py disk from the pr inte r and take it to your

host compu ter.

Using the cp Command

Use the cp comma nd to download a c counting info rmat ion f rom the

printer's hard disk to a floppy disk as follows:

1 Using a remote console , take the printer off line.

2 Insert a 3.5" DOS-formatted flop py disk into the printer’s

floppy disk drive.

3 Download the accou nti ng infor matio n to the flo ppy disk

using the following commands:

» Note: The device names (DS K6 or FLP0) must be uppercase. The

file names can be either uppercase or lo werc ase. If multiple Job

Accounting files are used, each of the AC Cx.JOB files should be

retrieved. (x is the nu mber of each subsequent Job Accounting

file.)

cp DSK6:/admin/acc1.job FLP0:/acc1.job↵

cp DSK6:/admin/acc.pap FLP0:/acc.pap↵

cp DSK6:/admin/acc.sta FLP0:/acc.sta↵

cp DSK6:/admin/acc.dic FLP0:/acc.dic↵

4 Remove the flop py disk from the pr inte r and take it to your

host compu ter.

QMS 3825/3225/2025 System Administrators Guide3-22

Page 59

Crown Accounting

Using the File Transfer Protocol (FTP)

» Note: FTP works only when the printer message window displays

If multiple Job Accounting files are used, each o f the ACCx.JOB files

should be copied. (x is the nu mber of each su bseq uent Job Accounting

file.)

Use FTP on the host to copy the files from the printer ’s hard disk to