Page 1

SERVICE MANUAL

PagePro

PagePro

1380 MF/1390 MF

1380 MF/1390 MF

FIELD SERVICE

2006.012006.01

Ver. 2.0Ver. 2.0

Page 2

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand

them before doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this product as well as

the risk of damage to the product, KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.

(hereafter called the KMBT) strongly recommends that all servicing be performed only by

KMBT-trained service technicians.

Changes may have been made to this product to improve its performance after this Service

Manual was printed. Accordingly, KMBT does not warrant, either explicitly or implicitly, that

the information contained in this Service Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to

the product while servicing the product for which this Service Manual is intended.

Therefore, this Service Manual must be carefully read before doing service work both in the

course of technical training and even after that, for performing maintenance and control of

the product properly.

Keep this Service Manual also for future service.

DESCRIPTION ITEMS FOR DANGER,

WARNING AND CAUTION

In this Service Manual, each of three expressions “ DANGER”, “ WARNING”, and

“ CAUTION” is defined as follows together with a symbol mark to be used in a limited

meaning.

When servicing the product, the relevant works (disassembling, reassembling, adjustment,

repair, maintenance, etc.) need to be conducted with utmost care.

DANGER: Action having a high possibility of suffering death or serious injury

WARNING: Action having a possibility of suffering death or serious injury

CAUTION: Action having a possibility of suffering a slight wound, medium

trouble, and property damage

Symbols used for safety and important warning items are defined as follows:

:Precaution when servicing the

product.

:Prohibition when servicing the

product.

:Direction when servicing the

product.

General

precaution

General

prohibition

General

instruction

Electric hazard High temperature

Do not touch

with wet hand

Unplug Ground/Earth

Do not

disassemble

S-1

Page 3

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNINGS

[1] MODIFICATIONS NOT AUTHORIZED BY KONICA MINOLTA

BUSINESS TECHNOLOGIES, INC.

KONICA MINOLTA brand products are renowned for their high reliability. This reliability is

achieved through high-quality design and a solid service network.

Product design is a highly complicated and delicate process where numerous mechanical,

physical, and electrical aspects have to be taken into consideration, with the aim of arriving

at proper tolerances and safety factors. For this reason, unauthorized modifications involve

a high risk of degradation in performance and safety. Such modifications are therefore

strictly prohibited. the points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

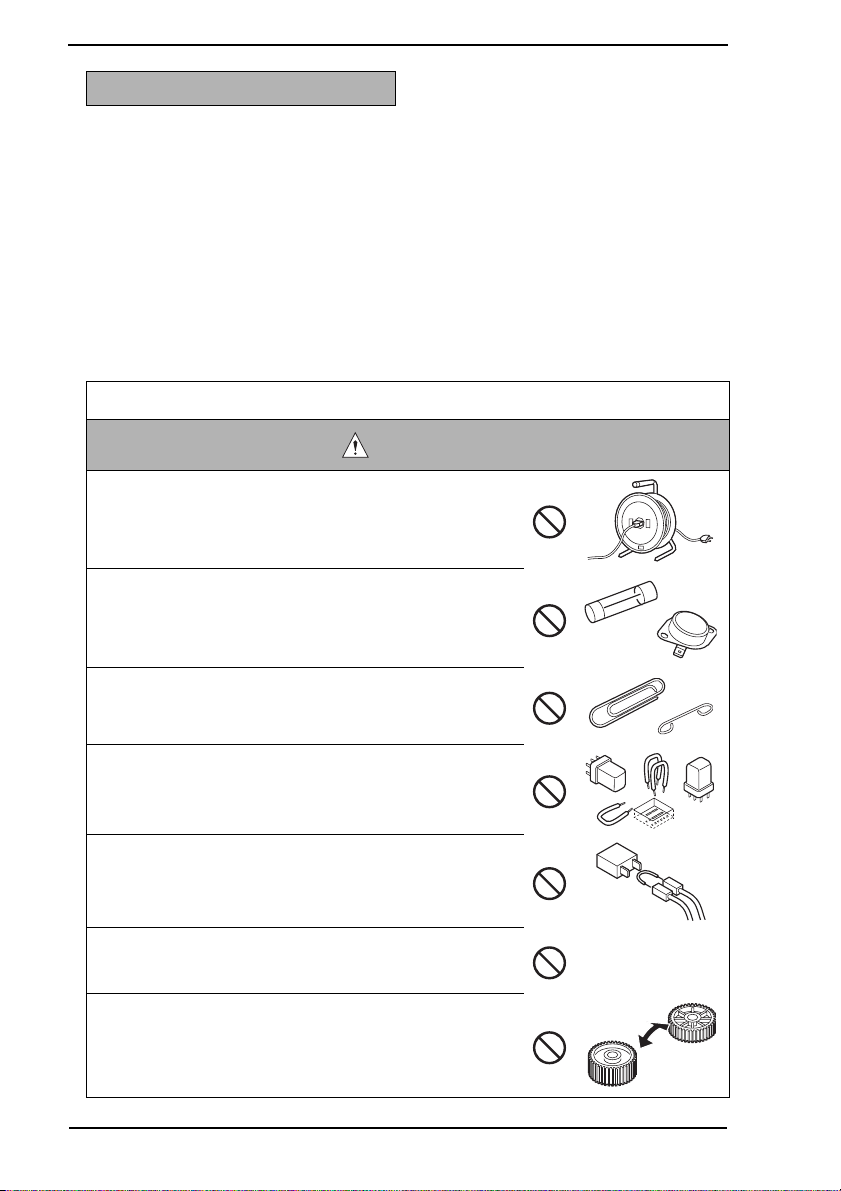

Prohibited Actions

DANGER

• Using any cables or power cord not specified by KMBT.

• Using any fuse or thermostat not specified by KMBT.

Safety will not be assured, leading to a risk of fire and

injury.

• Disabling fuse functions or bridging fuse terminals with

wire, metal clips, solder or similar object.

• Disabling relay functions (such as wedging paper between

relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.)

Safety will not be assured, leading to a risk of fire and

injury.

• Making any modification to the product unless instructed

by KMBT

• Using parts not specified by KMBT

S-2

Page 4

SAFETY AND IMPORTANT WARNING ITEMS

[2] POWER PLUG SELECTION

In some countries or areas, the power plug provided with the product may not fit wall outlet

used in the area. In that case, it is obligation of customer engineer (hereafter called the CE)

to attach appropriate power plug or power cord set in order to connect the product to the

supply.

Power Cord Set or Power Plug

WARNING

• Use power supply cord set which meets the following

criteria:

- provided with a plug having configuration intended for

the connection to wall outlet appropriate for the product's rated voltage and current, and

- the plug has pin/terminal(s) for grounding, and

- provided with three-conductor cable having enough current capacity, and

- the cord set meets regulatory requirements for the area.

Use of inadequate cord set leads to fire or electric shock.

• Attach power plug which meets the following criteria:

- having configuration intended for the connection to wall

outlet appropriate for the product's rated voltage and

current, and

- the plug has pin/terminal(s) for grounding, and

- meets regulatory requirements for the area.

Use of inadequate cord set leads to the product connecting to inadequate power supply (voltage, current capacity,

grounding), and may result in fire or electric shock.

• Conductors in the power cable must be connected to terminals of the plug according to the following order:

• Black or Brown: L (line)

• White or Light Blue: N (neutral)

• Green/Yellow: PE (earth)

Wrong connection may cancel safeguards within the

product, and results in fire or electric shock.

kw

S-3

Page 5

SAFETY AND IMPORTANT WARNING ITEMS

[3] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

KONICA MINOLTA brand products are extensively tested before shipping, to ensure that all

applicable safety standards are met, in order to protect the customer and customer engineer (hereafter called the CE) from the risk of injury. However, in daily use, any electrical

equipment may be subject to parts wear and eventual failure. In order to maintain safety

and reliability, the CE must perform regular safety checks.

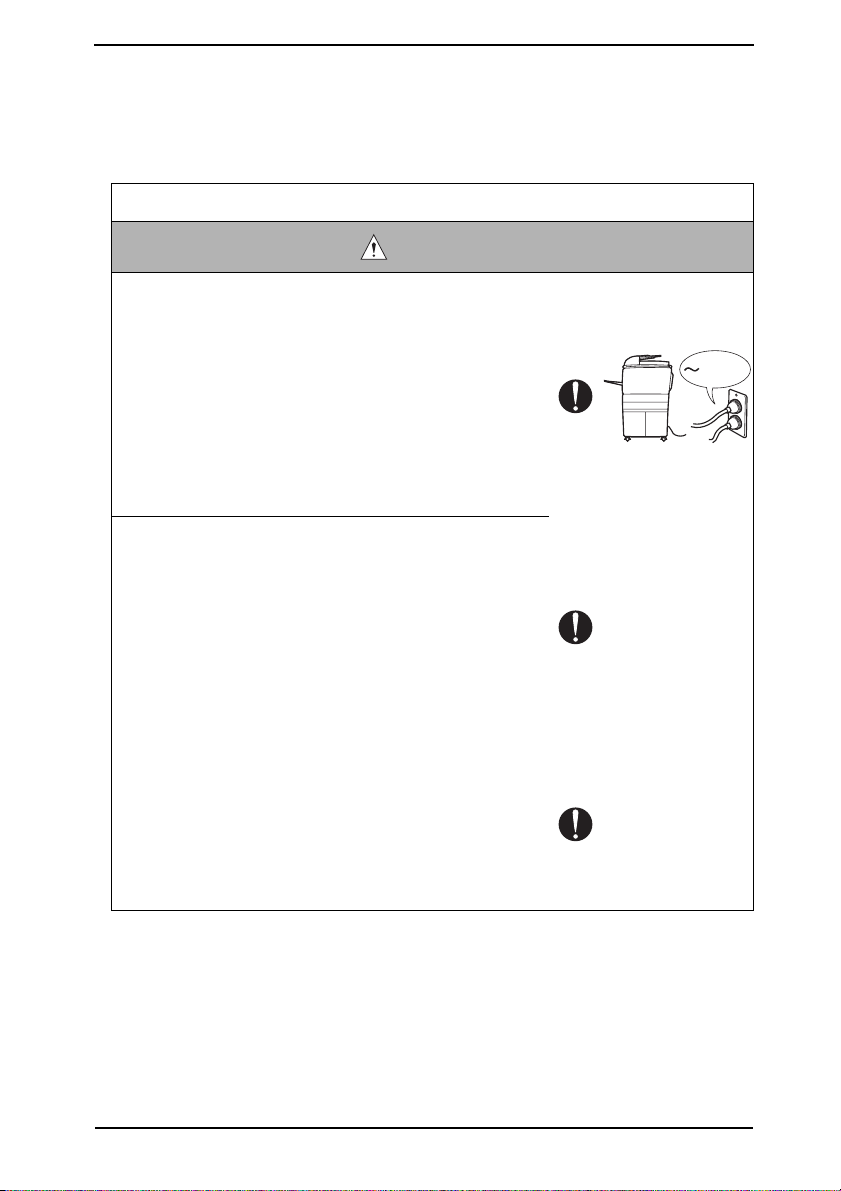

1. Power Supply

Connection to Power Supply

WARNING

• Check that mains voltage is as specified.

Connection to wrong voltage supply may result in fire or

electric shock.

• Connect power plug directly into wall outlet having same

configuration as the plug.

Use of an adapter leads to the product connecting to

inadequate power supply (voltage, current capacity,

grounding), and may result in fire or electric shock.

If proper wall outlet is not available, advice the customer

to contact qualified electrician for the installation.

• Plug the power cord into the dedicated wall outlet with a

capacity greater than the maximum power consumption.

If excessive current flows in the wall outlet, fire may

result.

• If two or more power cords can be plugged into the wall

outlet, the total load must not exceed the rating of the wall

outlet.

If excessive current flows in the wall outlet, fire may

result.

• Make sure the power cord is plugged in the wall outlet

securely.

Contact problems may lead to increased resistance,

overheating, and the risk of fire.

kw

• Check whether the product is grounded properly.

If current leakage occurs in an ungrounded product, you

may suffer electric shock while operating the product.

Connect power plug to grounded wall outlet.

S-4

Page 6

SAFETY AND IMPORTANT WARNING ITEMS

Power Plug and Cord

WARNING

• When using the power cord set (inlet type) that came with

this product, make sure the connector is securely inserted

in the inlet of the product.

When securing measure is provided, secure the cord with

the fixture properly.

If the power cord (inlet type) is not connected to the product securely, a contact problem may lead to increased

resistance, overheating, and risk of fire.

• Check whether the power cord is not stepped on or

pinched by a table and so on.

Overheating may occur there, leading to a risk of fire.

• Check whether the power cord is damaged. Check

whether the sheath is damaged.

If the power plug, cord, or sheath is damaged, replace

with a new power cord (with plug and connector on each

end) specified by KMBT. Using the damaged power cord

may result in fire or electric shock.

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the power plug

and wall outlet.

Using the power plug and wall outlet without removing

dust may result in fire.

• Do not insert the power plug into the wall outlet with a wet

hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the

cable.

The cable may be broken, leading to a risk of fire and

electric shock.

S-5

Page 7

SAFETY AND IMPORTANT WARNING ITEMS

Wiring

WARNING

• Never use multi-plug adapters to plug multiple power cords

in the same outlet.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so

using a too long extension cord may result in fire.

Do not use an extension cable reel with the cable taken

up. Fire may result.

2. Installation Requirements

Prohibited Installation Places

WARNING

• Do not place the product near flammable materials or volatile materials that may catch fire.

A risk of fire exists.

• Do not place the product in a place exposed to water such

as rain.

A risk of fire and electric shock exists.

When not Using the Product for a long time

WARNING

• When the product is not used over an extended period of

time (holidays, etc.), switch it off and unplug the power

cord.

Dust collected around the power plug and outlet may

cause fire.

S-6

Page 8

SAFETY AND IMPORTANT WARNING ITEMS

Ventilation

CAUTION

• The product generates ozone gas during operation, but it

will not be harmful to the human body.

If a bad smell of ozone is present in the following cases,

ventilate the room.

a. When the product is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple products at the same time

Stability

CAUTION

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the product may

slide, leading to a injury.

Inspection before Servicing

CAUTION

• Before conducting an inspection, read all relevant documentation (service manual, technical notices, etc.) and

proceed with the inspection following the prescribed procedure, using only the prescribed tools. Do not make any

adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the product may break and a risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect

the power plugs from the product and options.

When the power plug is inserted in the wall outlet, some

units are still powered even if the POWER switch is

turned OFF. A risk of electric shock exists.

• The area around the fixing unit is hot.

You may get burnt.

S-7

Page 9

SAFETY AND IMPORTANT WARNING ITEMS

Work Performed with the Product Powered On

WARNING

• Take every care when making adjustments or performing

an operation check with the product powered.

If you make adjustments or perform an operation check

with the external cover detached, you may touch live or

high-voltage parts or you may be caught in moving gears

or the timing belt, leading to a risk of injury.

• Take every care when servicing with the external cover

detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

Safety Checkpoints

WARNING

• Check the exterior and frame for edges, burrs, and other

damage.

The user or CE may be injured.

• Do not allow any metal parts such as clips, staples, and

screws to fall into the product.

They can short internal circuits and cause electric shock

or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or

fire.

• Carefully remove all toner remnants and dust from electrical parts and electrode units such as a charging corona

unit.

Current can leak, leading to a risk of product trouble or

fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or

fire.

S-8

Page 10

SAFETY AND IMPORTANT WARNING ITEMS

Safety Checkpoints

WARNING

• Check electrode units such as a charging corona unit for

deterioration and sign of leakage.

Current can leak, leading to a risk of trouble or fire.

• Before disassembling or adjusting the write unit (P/H unit)

incorporating a laser, make sure that the power cord has

been disconnected.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• Do not remove the cover of the write unit. Do not supply

power with the write unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery specified in the Parts Guide Manual. Dispose

of the used lithium battery using the method specified by

local authority.

Improper replacement can cause explosion.

• After replacing a part to which AC voltage is applied (e.g.,

optical lamp and fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and

check whether the interlock functions properly.

If the interlock does not function, you may receive an

electric shock or be injured when you insert your hand in

the product (e.g., for clearing paper jam).

• Make sure the wiring cannot come into contact with sharp

edges, burrs, or other pointed parts.

Current can leak, leading to a risk of electric shock or

fire.

S-9

Page 11

SAFETY AND IMPORTANT WARNING ITEMS

Safety Checkpoints

WARNING

• Make sure that all screws, components, wiring, connectors, etc. that were removed for safety check and maintenance have been reinstalled in the original location. (Pay

special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of product trouble, electric shock, and fire exists.

Handling of Consumables

WARNING

• Toner and developer are not harmful substances, but care

must be taken not to breathe excessive amounts or let the

substances come into contact with eyes, etc. It may be

stimulative.

If the substances get in the eye, rinse with plenty of water

immediately. When symptoms are noticeable, consult a

physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

Handling of Service Materials

CAUTION

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are highly flammable and must be handled

with care. A risk of fire exists.

• Do not replace the cover or turn the product ON before

any solvent remnants on the cleaned parts have fully

evaporated.

A risk of fire exists.

S-10

Page 12

SAFETY AND IMPORTANT WARNING ITEMS

Handling of Service Materials

CAUTION

• Use only a small amount of cleaner at a time and take

care not to spill any liquid. If this happens, immediately

wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to

discomfort.

S-11

Page 13

SAFETY AND IMPORTANT WARNING ITEMS

[4] Laser Safety

• This is a digital machine certified as a Class 1 laser product. There is no possibility of

danger from a laser, provided the machine is serviced according to the instruction in this

manual.

4.1 Internal Laser Radiation

semiconductor laser

Maximum power of the laser diode 15 mW

Maximum average radiation power (*) 36.903 µW

Wavelength 770-800 nm

*at laser aperture of the Print Head Unit

• This product employs a Class 3b laser diode that emits an invisible laser beam. The laser

diode and the scanning polygon mirror are incorporated in the print head unit.

• The print head unit is NOT A FIELD SERVICEABLE ITEM. Therefore, the print head unit

should not be opened under any circumstances.

S-12

Laser Aperture of

the Print Head Unit

4558P0C504DA

Page 14

SAFETY AND IMPORTANT WARNING ITEMS

U.S.A., Canada

(CDRH Regulation)

• This machine is certified as a Class 1 Laser product under Radiation Performance Standard according to the Food, Drug and Cosmetic Act of 1990. Compliance is mandatory

for Laser products marketed in the United States and is reported to the Center for

Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration of

the U.S. Department of Health and Human Services (DHHS). This means that the device

does not produce hazardous laser radiation.

• The label shown on page S-16 indicates compliance with the CDRH regulations and

must be attached to laser products marketed in the United States.

.

CAUTION

• Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 15 mW

Wavelength 770-800 nm

All Areas

CAUTION

• Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

semiconductor laser

Maximum power of the laser diode 15 mW

Wavelength 770-800 nm

Denmark

ADVARSEL

• Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling. Klasse 1 laser produkt der opfylder IEC60825-1

sikkerheds kravene.

halvlederlaser

Laserdiodens højeste styrke 15 mW

bølgelængden 770-800 nm

S-13

Page 15

SAFETY AND IMPORTANT WARNING ITEMS

Finland, Sweden

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VARO ITUS!

• Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

puolijohdelaser

Laserdiodin suurin teho 15 mW

aallonpituus 770-800 nm

VARNING!

• Om apparaten används på annat sätt än i denna bruksanvisning specificerats,

kan användaren utsättas för osynlig laserstrålning, som överskrider gränsen för

laserklass 1.

halvledarlaser

Den maximala effekten för laserdioden 15 mW

våglängden 770-800 nm

VARO !

• Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättomälle lasersäteilylle. Älä katso säteeseen.

VARNING!

• Osynlig laserstråining när denna del är öppnad och spärren är urkopplad.

Betrakta ej stråien.

Norway

ADVERSEL

• Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning, kan brukeren utsettes för unsynlig laserstrålning, som overskrider grensen

for laser klass 1.

halvleder laser

Maksimal effekt till laserdiode 15 mW

bølgelengde 770-800 nm

S-14

Page 16

SAFETY AND IMPORTANT WARNING ITEMS

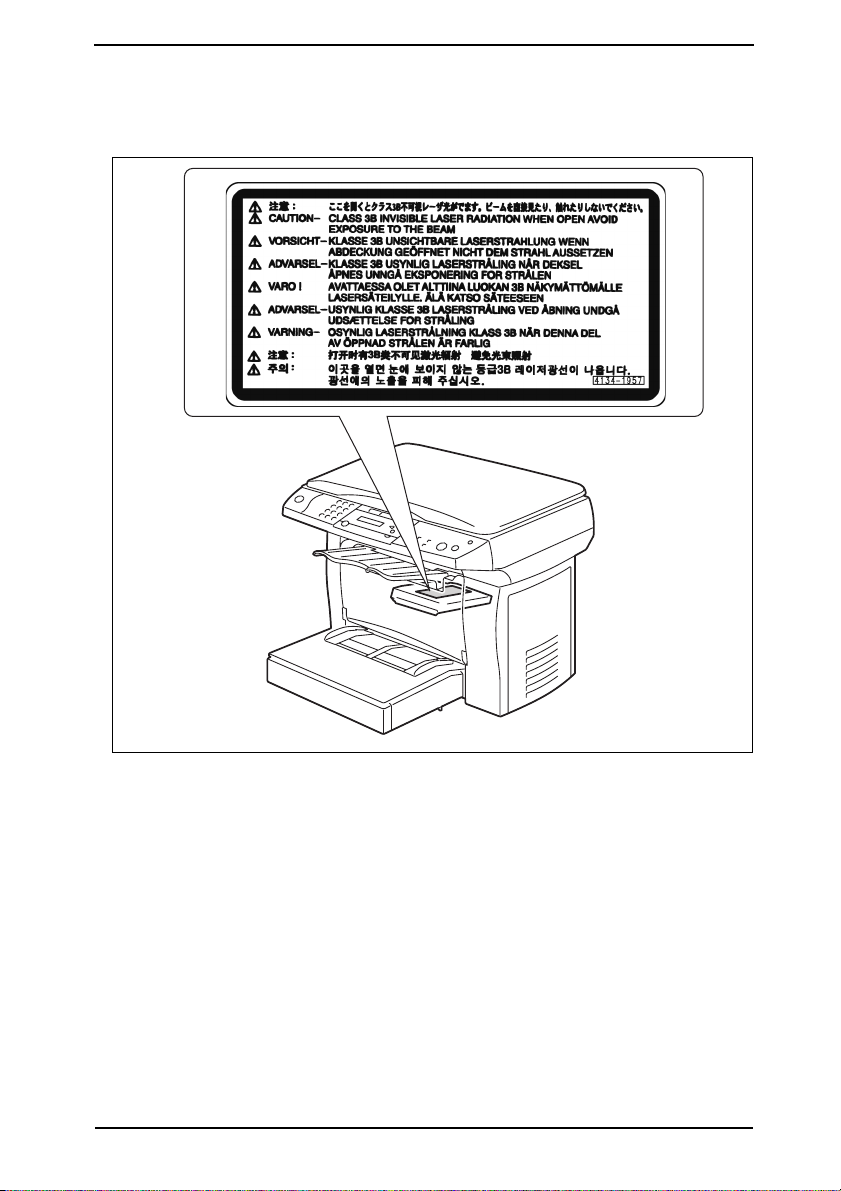

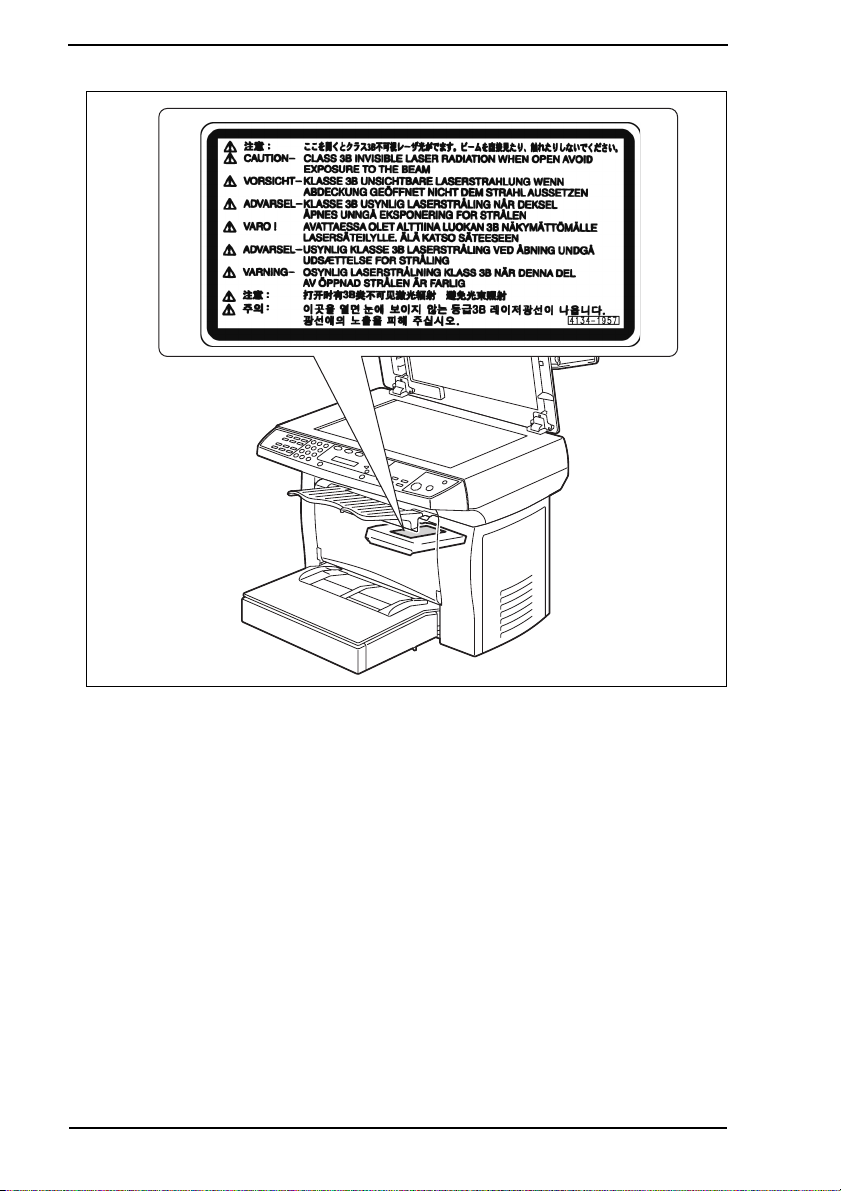

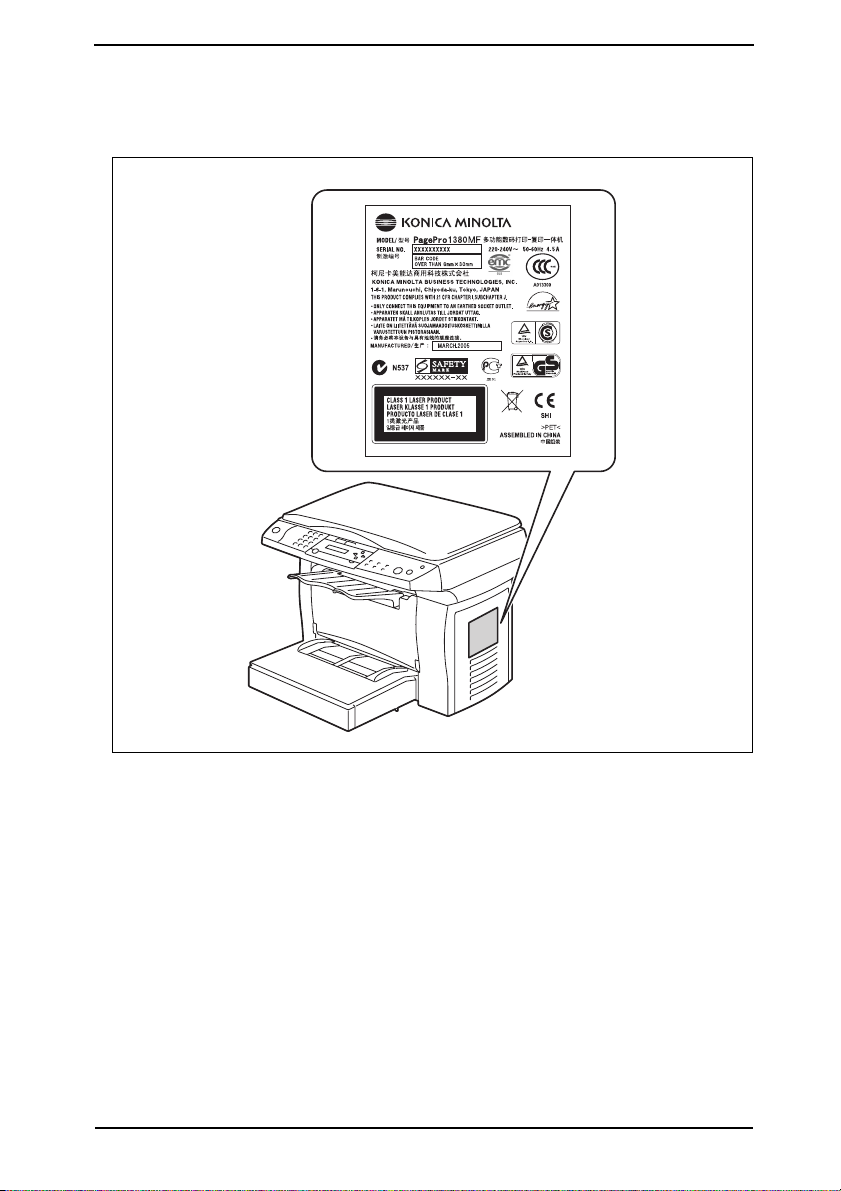

4.2 Laser Safety Label

• A laser safety label is attached to the inside of the machine as shown below.

A. PagePro 1380 MF

4558P0C501DA

S-15

Page 17

SAFETY AND IMPORTANT WARNING ITEMS

B. PagePro 1390 MF

S-16

4558P0C601DA

Page 18

SAFETY AND IMPORTANT WARNING ITEMS

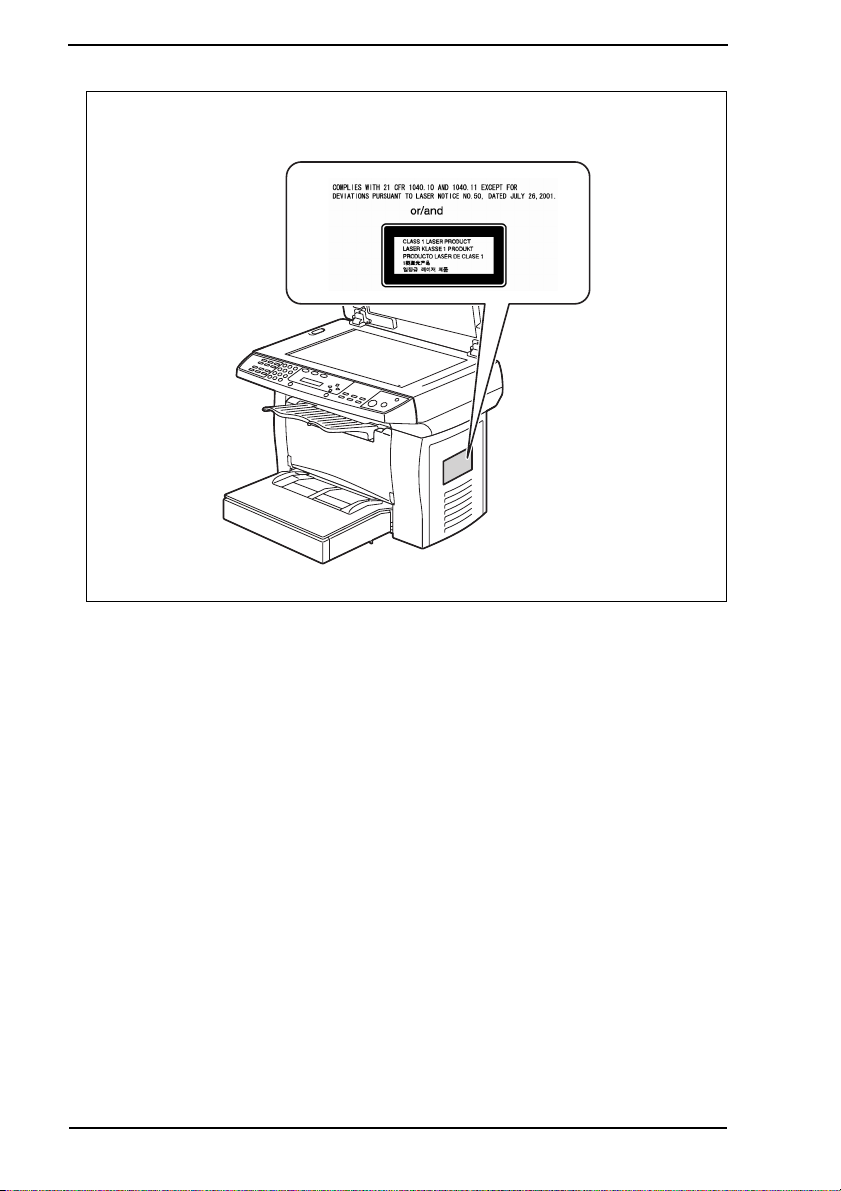

4.3 Laser Caution Label

• A laser caution label is attached to the outside of the machine as shown below.

A. PagePro 1380 MF

4558P0C505DA

S-17

Page 19

SAFETY AND IMPORTANT WARNING ITEMS

B. PagePro 1390 MF

4558P0C602DA

S-18

Page 20

SAFETY AND IMPORTANT WARNING ITEMS

4.4 PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT

• When laser protective goggles are to be used, select ones with a lens conforming to the

above specifications.

• When a disassembly job needs to be performed in the laser beam path, such as when

working around the printerhead and PC Drum, be sure first to turn the printer OFF.

• If the job requires that the printer be left ON, take off your watch and ring and wear laser

protective goggles.

• A highly reflective tool can be dangerous if it is brought into the laser beam path. Use

utmost care when handling tools on the user’s premises.

• The Print Head is not to be disassembled or adjusted in the field. Replace the Unit or

Assembly including the Control Board. Therefore, remove the Laser Diode, and do not

perform Control Board trimmer adjustment.

S-19

Page 21

SAFETY AND IMPORTANT WARNING ITEMS

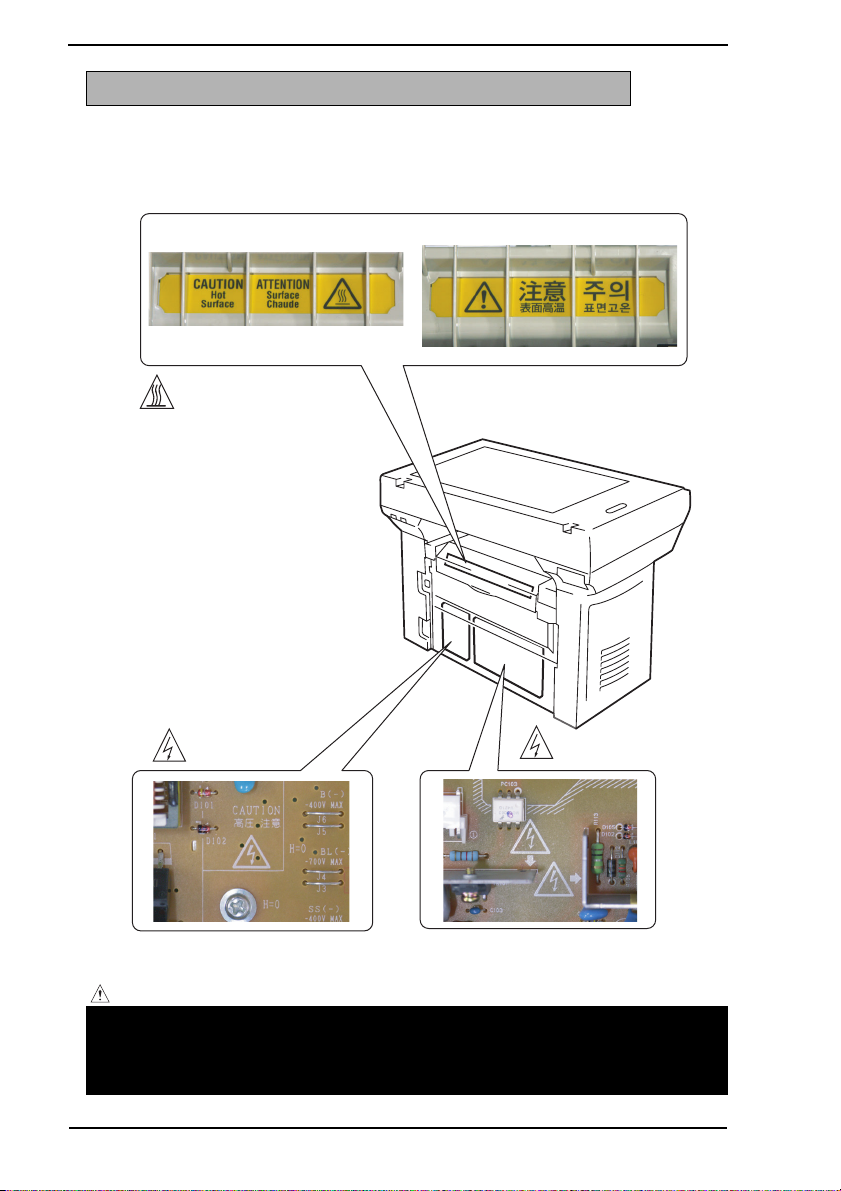

WARNING INDICATIONS ON THE MACHINE

Caution labels shown are attached in some areas on/in the machine.

When accessing these areas for maintenance, repair, or adjustment, special care should

be taken to avoid burns and electric shock.

High temperature

High voltage

CAUTION:

• You may be burned or injured if you touch any area that you are advised not to

touch by any caution label. Do not remove caution labels. If any caution label has

come off or become dirty and therefore the caution cannot be read, contact our

Service Office.

High voltage

4558P0C503DA

S-20

Page 22

INDEX (Field Service)

GENERAL

MAINTENANCE

DIS/REASSEMBLY,

ADJUSTMENT

CONTROL PANEL/SERVICE

MODE DESCRIPTIONS

TROUBLESHOOTING

Page 23

CONTENTS

GENERAL

1. SPECIFICATIONS ........................................................................................... G-1

(1) Main Unit .......................................................................................... G-1

(2) GDI Printer Function ........................................................................ G-3

(3) FAX Function (PagePro 1390 MF Only) .......................................... G-3

2. PARTS IDENTIFICATION ................................................................................ G-4

2-1. PagePro 1380 MF .................................................................................... G-4

2-2. PagePro 1390 MF .................................................................................... G-4

MAINTENANCE

1. MAINTENANCE SCHEDULE .......................................................................... E-1

1-1. Guidelines for Life Specifications Values by Unit ..................................... E-1

(1) Near Life Specifications Value ......................................................... E-2

(2) Life Specifications Value .................................................................. E-2

(3) Print Stop Value ............................................................................... E-2

2. REPLACEMENT/CLEANING OF PARTS ........................................................ E-3

(1) Cleaning the Paper Take-Up Roller ................................................. E-3

(2) Replacing the Paper Take-Up Roller ............................................... E-3

(3) Replacing the Image Transfer Roller ............................................... E-4

3. REPLACEMENT OF CONSUMABLES ............................................................ E-5

(1) Replacing the Toner Cartridge ......................................................... E-5

(2) Replacing the Drum Cartridge ......................................................... E-7

(3) Replacing the Fusing Unit ................................................................ E-8

DIS/REASSEMBLY,ADJUSTMENT

1. PRECAUTIONS FOR DISASSEMBLY/ADJUSTMENTS ................................. D-1

1-1. Parts That Must Not be Touched ............................................................. D-1

(1) Red-Painted Screws ........................................................................ D-1

(2) Variable Resistors on Boards .......................................................... D-1

(3) Other Screws not Marked with Red Paint ........................................ D-1

2. DISASSEMBLY/REASSEMBLY ...................................................................... D-2

2-1. Identification of and Removal Procedures for Exterior Parts ................... D-2

(1) PagePro 1380 MF ............................................................................ D-2

(2) PagePro 1390 MF ............................................................................ D-4

(3) Right Cover ...................................................................................... D-5

(4) Left Cover ........................................................................................ D-6

2-2. Removal of Circuit Boards and Other Electrical Components ................. D-7

(1) PagePro 1380 MF ............................................................................ D-7

(2) PagePro 1390 MF ............................................................................ D-9

(3) Removing the Power Supply Unit 2 (PU2) ....................................... D-11

(4) Removing the Mechanical Control Board (PWB-A) ......................... D-11

(5) Removing the Control Panel (PWB-O) ............................................ D-12

(6) Removing the Interface Board (PWB-FAX1)

<PagePro 1390 MF only> ................................................................ D-13

(7) Removing the NCU Board (PWB-FAX2)

<PagePro 1390 MF only> ................................................................ D-13

i

Page 24

(8) Removing the Power Supply Unit 1 (PU1) ...................................... D-14

(9) Removing the High Voltage Unit (HV1) ........................................... D-15

(10) Removing the Controller/Image Control Board (PWB-I) .................. D-15

(11) Removing the Socket Board (PWB-S) ............................................ D-17

2-3. Removal of Units ..................................................................................... D-18

(1) Removing the IR Unit ...................................................................... D-18

(2) Removing the PH Unit ..................................................................... D-19

2-4. Disassembly of the Image Reading Section ............................................ D-21

(1) Removing the IR Upper Cover (Original Glass) .............................. D-21

(2) Removing the Scanner Unit. ........................................................... D-21

(3) Removing the Timing Belt ............................................................... D-22

2-5. Disassembly of the Main Drive Section ................................................... D-23

(1) Removing the Main Motor (M1) ....................................................... D-23

(2) Removing the Tray 1 Paper Empty Sensor (PE1) ........................... D-23

(3) Removing the Paper Take-Up Solenoid (SL1) ................................ D-24

(4) Removing the Paper Take-Up Clutch Gear ..................................... D-25

(5) Removing the Torque Limiter .......................................................... D-27

(6) Disassembling the Fusing Unit ........................................................ D-28

2-6. Upgrading the Firmware .......................................................................... D-30

(1) Minimum System Requirements ..................................................... D-30

(2) Install the TWAIN Driver Software ................................................... D-30

(3) Install the Printer Driver ................................................................... D-30

(4) Procedure for Upgrading the Firmware ........................................... D-31

CONTROL PANEL/SERVICE MODE DESCRIPTIONS

1. CONTROL PANEL DESCRIPTIONS .............................................................. S-1

1-1. Names and Functions of Control Panel Parts ......................................... S-1

(1) PagePro 1380MF ............................................................................ S-1

(2) PagePro 1390MF ............................................................................ S-2

1-2. List of Error Status Message ................................................................... S-4

2. FUNCTIONS OF SWITCHES AND PARTS ON PWBs ................................... S-6

2-1. Circuit Board Locations ........................................................................... S-6

(1) PWB-I: Controller/Image Control Board .......................................... S-6

(2) PWB-FAX2: NCU Board (PagePro 1390 MF only) ......................... S-7

3. CONFIGURATION MENU ............................................................................... S-8

3-1. Configuration Menu ................................................................................. S-8

(1) Page Pro 1380 MF .......................................................................... S-8

(2) PagePro 1390 MF ........................................................................... S-9

3-2. Configuration Menu Procedures (PagePro 1380 MF) ............................. S-11

(1) Common Setup ............................................................................... S-12

(2) Copy Setup ...................................................................................... S-13

(3) Report ............................................................................................ S-13

3-3. Configuration Menu Procedures (PagePro 1390 MF) ............................. S-14

(1) Common Setup ............................................................................... S-15

(2) Copy Setup ...................................................................................... S-16

(3) Report ............................................................................................ S-17

(4) Fax Setup ........................................................................................ S-17

(5) PhoneBook ...................................................................................... S-21

ii

Page 25

(6) Special Fax ...................................................................................... S-21

4. Fax Report (PagePro 1390 MF only) ............................................................... S-23

4-1. Activity Log Report ................................................................................... S-23

4-2. Phone Book .............................................................................................. S-24

4-3. Tx Report ................................................................................................. S-25

(1) Transmit Report ............................................................................... S-25

(2) Multi TX Report ................................................................................ S-26

4-4. Lost Job Report ........................................................................................ S-27

4-5. Protocol Report ........................................................................................ S-28

4-6. Memory Job List ....................................................................................... S-29

5. Fax Protocols (PagePro 1390 MF only) ........................................................... S-30

5-1. G3 ECM (G3 Error Correction Mode) ....................................................... S-30

5-2. Line control ............................................................................................... S-31

(1) Procedure of G3 mode communication ........................................... S-31

5-3. Definition of Abbreviation / Terms ............................................................ S-32

(1) Definition of Abbreviation ................................................................. S-32

(2) Definition of Terms ........................................................................... S-33

TROUBLESHOOTING

1. INTRODUCTION .............................................................................................. T-1

1-1. Electrical Components Check Procedures ............................................... T-1

(1) Sensors ............................................................................................ T-1

(2) Switches ........................................................................................... T-2

(3) Solenoids ......................................................................................... T-2

(4) Motors ............................................................................................. T-3

1-2. Overall Control Configuration ................................................................... T-5

2. PAPER MISFEED ............................................................................................ T-6

2-1. Initial Check Items .................................................................................... T-6

2-2. Media Misfeed Displays ........................................................................... T-7

2-3. Locations of Misfeed Detection Sensors .................................................. T-7

2-4. Misfeed Detection Timing and Troubleshooting Procedures ................... T-8

(1) Paper Take-Up/Transport Misfeed ................................................... T-8

(2) Fusing/Exit Misfeed .......................................................................... T-9

3. MALFUNCTIONS/WARNINGS ........................................................................ T-10

3-1. List of Malfunctions .................................................................................. T-10

3-2. Malfunction Detection Timing and Troubleshooting Procedures .............. T-12

(1) 008: Polygon mirror motor error ....................................................... T-12

(2) 010: Fuser fan motor error ............................................................... T-13

(3) 020: H.V. abnormal .......................................................................... T-14

(4) 040: Laser error ............................................................................... T-14

(5) 080: Fuser warm up error ................................................................ T-15

(6) 100: Fuser temperature low ............................................................. T-16

(7) 200: Fuser overheat ......................................................................... T-16

4. MALFUNCTIONS RELATED TO POWER SUPPLY ....................................... T-17

4-1. Power is not Turned ON. .......................................................................... T-17

5. Miscellaneous Errors ........................................................................................ T-18

5-1. List of Miscellaneous Malfunctions ........................................................... T-18

iii

Page 26

5-2. Miscellaneous Malfunction Detection Timing and Troubleshooting

Procedures ............................................................................................... T-19

(1) Unlock scanner ................................................................................ T-19

(2) [Scanner Error] Lamp Error .............................................................. T-20

(3) [Scanner Error] AFE R/W Error ........................................................ T-20

(4) [Scanner Error] Home Sensor .......................................................... T-21

(5) [Scanner Error] Motor Stall .............................................................. T-21

(6) [Printer Error] Incorrect Toner .......................................................... T-22

(7) [Printer Error] IC Read Fail .............................................................. T-22

(8) [Printer Error] IC Write Fail ............................................................... T-22

6. IMAGE QUALITY PROBLEMS ........................................................................ T-23

6-1. Troubleshooting Image Quality Problems ................................................ T-23

6-2. Initial Checks ............................................................................................ T-23

6-3. Troubleshooting for Specific Image Quality Problems ............................. T-24

(1) Image reading system: Blank or black prints ................................... T-24

(2) Image reading system: Low image density ...................................... T-25

(3) Image reading system: Foggy background or rough image ............. T-26

(4) Image reading system: Black streaks or bands ............................... T-27

(5) Image reading system: Black spots ................................................. T-28

(6) Image reading system: Blank streaks or bands ............................... T-29

(7) Image reading system: Uneven image ............................................ T-30

(8) Printer system: Blank or black prints ................................................ T-31

(9) Printer system: Blank spots ............................................................. T-32

(10) Printer system: Smears on back ...................................................... T-32

(11) Printer system: Low image density .................................................. T-33

(12) Printer system: Foggy background .................................................. T-34

(13) Printer system: Blank streaks or bands ........................................... T-34

(14) Printer system: Black streaks or bands ............................................ T-35

(15) Printer system: Offset image ............................................................ T-35

(16) Printer system: Uneven image ......................................................... T-36

7. FAX ERROR (PagePro 1390 MF only) ............................................................ T-37

7-1. Outline ...................................................................................................... T-37

7-2. Types of Error .......................................................................................... T-37

(1) STOP ............................................................................................. T-37

(2) RX T1 Time Out ............................................................................... T-37

(3) Local mechanical error/resource error ............................................. T-38

(4) Dial failure ........................................................................................ T-38

(5) TX Comm. Error ............................................................................... T-38

(6) RX Comm. Error .............................................................................. T-38

(7) Compatibility Error ........................................................................... T-38

7-3. Definition of Error Code ............................................................................ T-39

(1) The 6th digit ..................................................................................... T-39

(2) The 5th digit ..................................................................................... T-39

(3) The 4th / 3rd digits ........................................................................... T-39

(4) The 2nd / 1st digits ........................................................................... T-40

iv

Page 27

GENERAL

Page 28

1. SPECIFICATIONS

(1) Main Unit

Desktop

Ty p e

Original scanning system

Photo conductor type

Copying system

Copy resolution

Scan resolution

Media feed-in system

Exposure system

Developing system

Drum-charging system

Image-transfer system

Media-separation system

Fusing system

Max. original size

Media

Source Tray1 Bypass Tray

Plain paper (60 to 90 g/m

Recycled paper (60 to 90 g/m

Types

Size

Range

Thick stock (91 to 163 g/m

:

Scanning in main scanning direction with an 8-line color

:

CCD sensor, and scanning in sub-scanning direction with

unit scanning and sheet feed-through system

OPC (Organic Photo Conductor)

:

Electrostatic dry-powdered image transfer to plain paper with

:

laser

600 dpi × 600 dpi

:

1200 dpi

:

2-way system (Tray1 and Bypass Tray)

:

Unit scanning slit exposure

:

FMT (Fine Micro Toning) single-component developing

:

Rotating brush with pre-charge film

:

Roller transfer

:

Curvature separation + charge neutralizing needle

:

Heat roller

:

Up to Legal size

:

216 mm × 297 mm (8.5 inch × 11.69 inch)

(16 to 24 lb.)

(16 to 24 lb.)

(24 to 43 lb.)

Transparencies ❍❍

Label sheets ❍❍

Envelopes ❍❍

Width

Length

2

)

2

)

2

)

❍❍

❍❍

❍❍

76 mm to 216 mm

3 inch to 8.5 inch

127 mm to 356 mm

5 inch to 14 inch

G-1

Page 29

Continuous copy speed

(page-to-page)

:

20 copies/minute

(full size, Letter, Text mode, 600 dpi × 300 dpi with ADF)

Continuous print speed

(1 scan, multiple copies)

Warm-up time

First-copy time

Zoom Ratios

Fixed

Var iable ×0.50 to ×4.00 (in ×0.01 increments)

Lens

Exposure Lamp

Fusing temperature

Power /Current Consumption (main unit only)

Voltage Maximum power consumption

110 V, 120-127 V 792, 864-915 W

220-240 V 990-1080 W

Power source : 110 V, 120V-127 V, 220-240 V 50/60 Hz

:

20 sheets/minute (at Letter, A4)

:

60 seconds (at a room temperature of 23 °C/

73.4 °F and at the rated voltage)

:

19 seconds or less

(full size, Letter, 600 dpi × 300 dpi with ADF)

Full size ×1.00

×0.78 (Legal to Letter)

Reduction

4 elements glass (F=7.43)

:

Cold Cathode Florescent Lamp

:

200 °C

:

×0.83 (Legal to A4)

×0.94 (A4 to Letter)

×0.97 (Letter to A4)

Main Unit Dimensions

PagePro 1380 MF

(including Document

Cover)

PagePro 1390 MF

(including ADF)

Main Unit Weight

Width....492 mm (14.7 inch)

:

Depth....465 mm (18.6 inch)

Height...410 mm (16.2 inch)

Width....492 mm (14.7 inch)

:

Depth....465 mm (18.6 inch)

Height...547 mm (21.5 inch)

14.2 kg (31.33 lb.)

:

G-2

Page 30

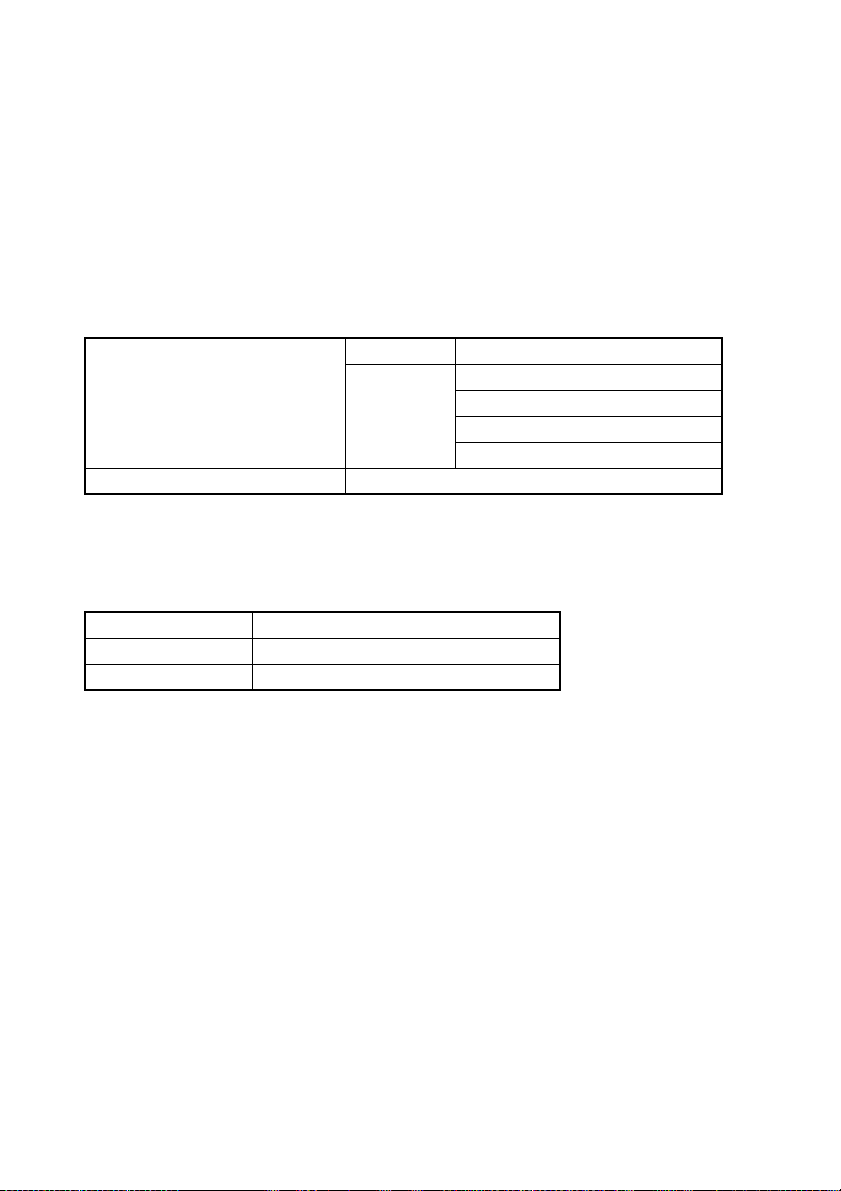

(2) GDI Printer Function

Shared with copier

RAM

Interfaces

Printer Language

Fonts

Supported Operating

Systems

Browser Software

(3) FAX Function (PagePro 1390 MF Only)

Compatibility

Scanning Resolution

Line

Modem Speed (kbps)

Coding Method

Max. Scanning Size

Memory Capacity

Number of Stored Pages

One touch dial

Speed dial

Group dial

Broadcast

Paper Size

Edge Erase

:

USB Revision 1.1/2.0

:

GDI

:

Windows

:

Windows XP (SP1 or later)/Windows 2000 (SP3 or later)/

:

Windows Me/Windows 98 (SP1)/Windows 98 Second Edition

Internet Explorer 4.0 or later

:

ITU Super G3 (ECM*) *: Error Correction Mode

:

STD: CD 8 lines/mm x FD 3.85 lines/mm

:

Fine: CD 8 lines/mm x FD 7.7 lines/mm

Super Fine: CD 8 lines/mm x FD 15.4 lines/mm

PSTN/ PBX

:

33.6, 31.2, 28.8, 26.4, 24.0, 21.6, 19.2, 16.8, 14.4, 12.0, 9.6,

:

7.2, 4.8, 2.4

MH/ MR/ MMR

:

ADF : 216 mm x 356 mm (8.5 inch x 14 inch)

:

Flatbed Glass: 216 mm x 297 mm (8.5 inch x 11.69 inch)

3.5 MB

:

170 pages when receiving

:

(ITU-T Test Chart No. 1, resolution: STD, A4 size)

12 numbers (6 keys + shift function)

:

100 fax numbers

:

6 groups (50 stations/group)

:

50 stations

:

A4, Letter, Legal, A5, B5

:

4 mm (top, bottom, left, right)

:

G-3

Page 31

2. PARTS IDENTIFICATION

2-1. PagePro 1380 MF

[3]

[1]

[2]

4558T1C501DA

1. Auto Document Feeder (ADF) Option

2. Main Unit PagePro 1380 MF

3. Document Cover

2-2. PagePro 1390 MF

[1]

[2]

1. Auto Document Feeder (ADF) 2. Main Unit PagePro 1390 MF

4558T1C502DA

G-4

Page 32

MAINTENANCE

Page 33

1. MAINTENANCE SCHEDULE

• To ensure that the machine produces good printed pages and to extend its service life, it

is recommended that the maintenance jobs described in this schedule be carried out as

instructed.

Part Clean Replace after . . .

Paper Take-Up Roller

Image Transfer Roller – 50,000 prints ☞ E-4

Drum Cartridge – 20,000 prints

Toner Cartridge –

Fusing Unit – 50,000 prints ☞ E-8

NOTES

• As a rule, the Drum Cartridge and Toner Cartridge are to be replaced by the user.

• The contents of the Maintenance List are subject to change without notice.

• For the part numbers, see the Parts Guide Manual and Parts Modification Notices.

When a media takeup failure occurs

A media take-up failure

occurs

3,000 or 6,000 prints,

depending on the capacity of

the Toner Cartridge

Ref. Page in

This Manual

☞ E-3

☞ E-7

☞ E-5

1-1. Guidelines for Life Specifications Values by Unit

• The life specifications value represents the number of printed pages produced or figures

equivalent to it when given conditions (see the table below) are met. It can be more or

less depending on how each individual printer is used.

Print Conditions

Job type Continuous

Media size A4 R/Letter R

B/W ratio B/W 5 %

E-1

Page 34

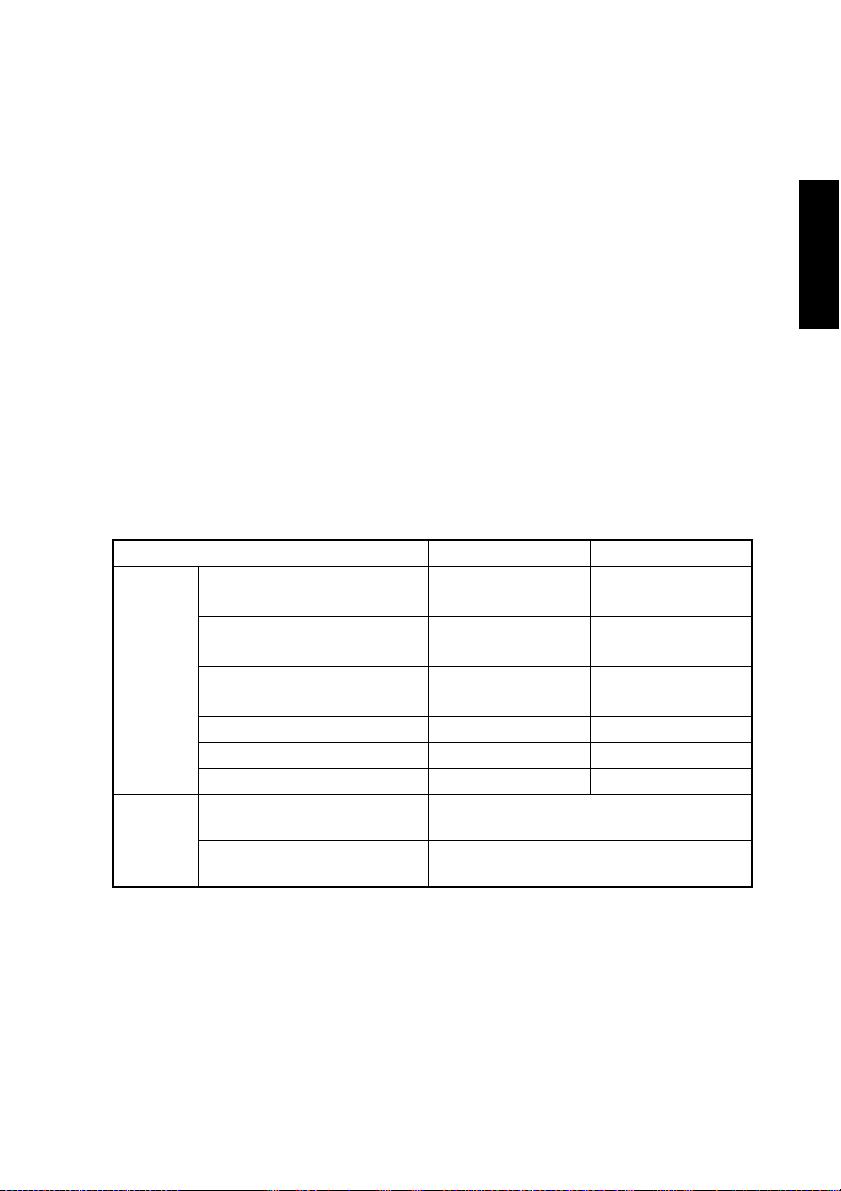

(1) Near Life Specifications Value

Part Near Life Value Detection

Page Pro 1380 MF: 80 %

Toner Cartridge

(2) Life Specifications Value

Part Near Life Value Detection

Toner Cartridge

(3) Print Stop Value

Part Print Stop Value Detection

Toner Cartridge

Page Pro 1390 MF: 75 %

(same calculation for each

Toner Cartridge)

100 %

(same calculation for each

Toner Cartridge)

120 %

(same calculation for each

Toner Cartridge)

The value used for detection of the

amount of toner still available for use is

provided as feedback information for calculating toner consumption, thereby

detecting a toner near empty condition.

The value used for detection of the

amount of toner still available for use is

provided as feedback information for calculating toner consumption, thereby

detecting a toner empty condition.

The value used for detection of the

amount of toner still available for use is

provided as feedback information for calculating toner consumption, thereby

detecting a print stop condition.

E-2

Page 35

2. REPLACEMENT/CLEANING OF PARTS

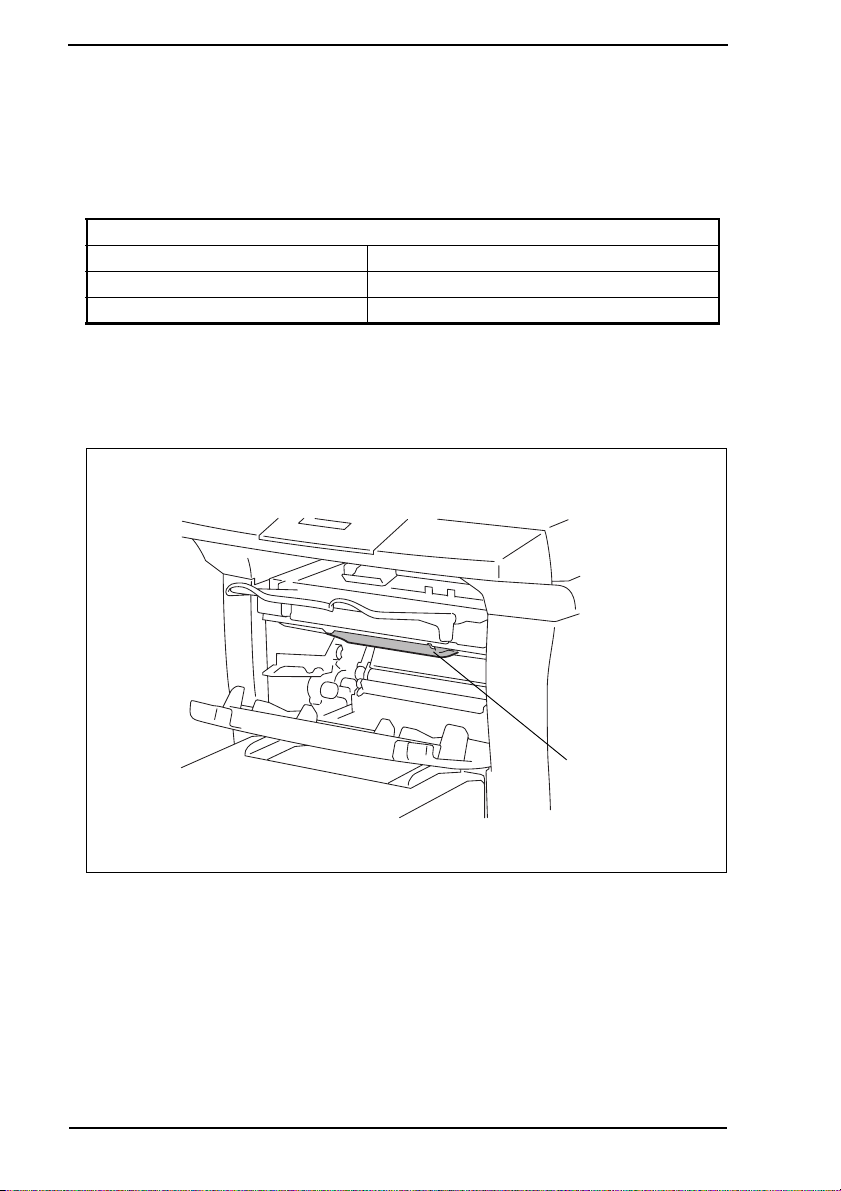

(1) Cleaning the Paper Take-Up Roller

1. Lift up the Exit Tray and remove it.

2. Open the Front Door.

3. Remove the Imaging Cartridge.

☞ E-5

NOTE

• The Imaging Cartridge consists of the Drum Cartridge, to which the Toner Cartridge is

mounted.

4. Using a soft cloth, wipe the surface of the Paper

Take-Up Roller clean of dirt.

4980E006AA

5. Close the Front Door.

6. Reinstall the Exit Tray.

(2) Replacing the Paper Take-Up Roller

1. Lift up the Exit Tray and remove it.

2. Open the Front Door.

3. Remove the Imaging Cartridge.

☞ E-5

4980E007AA

5. Insert a new Paper Take-Up Roller.

6. Reinstall the Imaging Cartridge.

7. Close the Front Door.

8. Reinstall the Exit Tray.

4. Remove the Paper Take-Up Roller.

E-3

Page 36

(3) Replacing the Image Transfer Roller

1. Lift up the Exit Tray and remove it.

2. Open the Front Door.

3. Remove the Imaging Cartridge.

☞ E-5

4. Press down the levers of the white bushings (one

on the right end and one on the left end of the

Image Transfer Roller) and slide the Image Trans-

fer Roller out of the Image Transfer Roller holder.

4136E018AA

5. Remove the two bushings (one on the right end

and one on the left end) and the gear from the

Image Transfer Roller.

6. Install the bushings and the gear in the new

Image Transfer Roller.

4136E019AB

4136E020AB

NOTES

• Do not touch, or dirty with chemicals or toner, the

surface of the Image Transfer Roller, as indentations in and dirt on the surface of the Image Transfer Roller adversely affect the quality of the printed

image.

• When handling the Image Transfer Roller, hold

onto the shaft and bushings of the roller.

• Do not place a new Image Transfer Roller directly

on the floor or other surface.

7. Insert the new Image Transfer Roller into the

Image Transfer Roller holder and push the levers

of the bushings into their original upward posi-

tions.

E-4

Page 37

3. REPLACEMENT OF CONSUMABLES

(1) Replacing the Toner Cartridge

<Removal Procedure>

1. Lift up the Exit Tray and remove it.

2. Open the Front Door.

4558F2C508DA

3. Remove the Imaging Cartridge.

4558F2C509DA

4. Pull the lever of the Toner Cartridge in the direc-

tion shown in the illustration and disconnect the

Toner Cartridge from the Drum Cartridge.

NOTE

• If the Drum Cartridge is to be placed on a floor or

4136E007AC

similar place, use care to prevent toner from scattering around.

<Installation Procedure>

4136E008AA

1. Take out a new Toner Cartridge and shake it in

the horizontal direction sufficiently to agitate the

toner.

NOTE

• DO NOT place the Toner Cartridge in an upright

position or shake it vigorously; otherwise, toner will

spill.

E-5

Page 38

4558F2C512DA

4136E009AC

2. Remove the protective cover from the Toner Car-

tridge.

3. Connect the new Toner Cartridge to the Drum

Cartridge.

NOTE

• Insert the Toner Cartridge along the guide pro-

vided on the side of the Drum Cartridge, making

sure that the Toner Cartridge is not tilted when it is

inserted.

4. Install the Imaging Cartridge in the printer.

NOTE

• Insert the Imaging Cartridge along the guides pro-

vided on the insides of the printer. Ensure that the

Imaging Cartridge is inserted straight.

4558F2C508DA

5. Close the Front Door.

6. Reinstall the Exit Tray.

E-6

Page 39

(2) Replacing the Drum Cartridge

<Removal Procedure>

1. Remove the Imaging Cartridge.

☞ E-5

4136E011AC

<Installation Procedure>

4136E012AC

2. Pull the lever of the Toner Cartridge in the direc-

tion shown in the illustration and disconnect the

Drum Cartridge.

1. Connect the Toner Cartridge to a new Drum Car-

tridge.

NOTE

• Insert the Toner Cartridge along the guide pro-

vided on the side of the Drum Cartridge, making

sure that the Toner Cartridge is not tilted when it is

inserted.

2. Install the Imaging Cartridge in the printer.

4558F2C508DA

NOTE

• Insert the Imaging Cartridge along the guides pro-

vided on the insides of the printer. Ensure that the

Imaging Cartridge is inserted straight.

3. Close the Front Door.

NOTE

• After replacing the Drum Cartridge, be sure to

reset the OPC counter in the configuration menu.

☞ S-12

E-7

Page 40

(3) Replacing the Fusing Unit

NOTE

• Immediately after turning off the printer, the area around the Fusing Unit is extremely hot.

Therefore, in order to reduce the risk of burns, wait until the unit has cooled down before

performing any operation.

<Removal Procedure>

1. Remove the IR Unit.

☞ D-18

2. Remove the Exit tray.

☞ D-2

3. Remove four screws and the Upper Cover.

4558F2C022DA

4. Remove two screws, unplug three connectors,

and remove the Fusing Unit.

NOTE

• The surfaces around the Fusing Unit are very hot.

Use the utmost care not to touch any surfaces

other than the Fusing Unit.

4980E002AB

4980E003AA

5. Remove the Fusing Unit.

E-8

Page 41

<Installation Procedure>

1. Connect connector A.

A

B

C

4136E017AC

NOTE

• When replacing an individual part of the Fusing Unit due to a defective part or to correct

an image problem, see “Disassembling the Fusing Unit” in DIS/REASSEMBLY, ADJUSTMENT”.

☞ D-28

2. Mount the Fusing Unit in the printer and secure it

in position by tightening the two screws.

3. Connect connectors B and C.

NOTE

• When installing the Fusing Unit, route the harness

as shown in the illustration, making sure that no

part of the harness is wedged between the Fusing

Unit and printer.

E-9

Page 42

DIS/REASSEMBLY,

ADJUSTMENT

Page 43

1. PRECAUTIONS FOR DISASSEMBLY/ADJUSTMENTS

1-1. Parts That Must Not be Touched

(1) Red-Painted Screws

Purpose of the Red Paint

Red-painted screws show that the assembly or unit secured can be adjusted or set only at

the factory and should not be readjusted, set, or removed in the field.

If it becomes unavoidably necessary to disassemble any of these assemblies and units,

disassembly may be done provided that the conditions permitting reassembly are met.

Note also that when two or more screws are used on the part in question, only one repre-

sentative screw may be marked with red paint.

(2) Variable Resistors on Boards

Do not turn the variable resistors on boards for which no adjusting instructions are given in

ADJUSTMENT.

(3) Other Screws not Marked with Red Paint

PH Unit

D-1

4558F2C516DA

Page 44

2. DISASSEMBLY/REASSEMBLY

2-1. Identification of and Removal Procedures for Exterior Parts

(1) PagePro 1380 MF

[1]

[6]

[2]

[5]

[3]

[8]

[4]

[7]

4558F2C501DA

D-2

Page 45

No. Name Removal Procedure

1 Document Cover Open the Document Cover → Pull it straight up.

2 Right Cover ☞ D-5

3 Front Door

4Tray1

5 Bypass Tray –

6 Exit Tray Unhook the two tabs, and remove the Exit tray.

7 Left Cover ☞ D-6

8 Rear Cover

Open the Front Door. → While pressing in on one side,

remove the Front Door.

Hold down the main unit with one hand and pull Tray1

toward you.

Remove the Right Cover and the Left Cover. → Remove

two screws, and remove the Rear Cover.

D-3

Page 46

(2) PagePro 1390 MF

[6]

[1]

[2]

[5]

[3]

[4]

[8]

[7]

4558F2C601DA

D-4

Page 47

No. Name Removal Procedure

1ADF☞ D-9 of Auto Document Feeder Service Manual

2 Right Cover ☞ D-5

3 Front Door

4Tray1

5 Bypass Tray –

6 Exit Tray Unhook the two tabs, and remove the Exit tray.

7 Left Cover ☞ D-6

8 Rear Cover

(3) Right Cover

4558F2C520DA

Open the Front Door. → While pressing in on one side,

remove the Front Door.

Hold down the main unit with one hand and pull Tray1

toward you.

Remove the Right Cover and the Left Cover. → Remove

two screws, and remove the Rear Cover.

1. Remove two screws that secure the Right Cover

at the back and unhook it on the back.

2. Unhook tabs at five locations and remove the

Right Cover.

4558F2C522DA

NOTE

• When reinstalling the Right Cover, first hook the

tabs at three locations on the front side. Then,

while hooking the two tabs on the upper side, hook

the Right Cover on the back and tighten the

screws.

D-5

Page 48

(4) Left Cover

1. Remove two screws that secure the Left Cover at

the back and unhook it on the back.

4558F2C521DA

2. Unhook tabs at four locations and remove the

Left Cover.

NOTE

• When reinstalling the Left Cover, first hook the tabs

at two locations on the front side. Then, while

hooking the two tabs on the upper side, hook the

Left Cover on the back and tighten the screws.

4558F2C523DA

D-6

Page 49

2-2. Removal of Circuit Boards and Other Electrical Components

NOTES

• When removing a circuit board or other electrical component, refer to the precautions for

handling PWBs and follow the corresponding removal procedures.

• The removal procedures given in the following paragraphs omit the removal of the com-

ponent in question from a connector or a PWB support.

• Where it is absolutely necessary to touch the ICs and other electrical components on the

board, be sure to ground your body.

(1) PagePro 1380 MF

[5]

[1]

[4]

[2]

[7]

[3]

[6]

4558F2C502DA

D-7

Page 50

No. Symbol Name

[1] PWB-I Controller/Image Control Board ☞ D-15

[2] PU2 Power Supply Unit 2 ☞ D-11

[3] PWB-A Mechanical Control Board ☞ D-11

[4] PWB-O Control Panel ☞ D-12

[5] PWB-S Socket Board ☞ D-17

[6] PU1 Power Supply Unit 1 ☞ D-14

[7] HV1 High Voltage Unit ☞ D-15

Removal

Procedure

D-8

Page 51

(2) PagePro 1390 MF

[7]

[1]

[2]

[6]

[3]

[4]

[5]

[9]

[8]

D-9

4558F2C602DA

Page 52

No. Symbol Name

[1] PWB-I Controller/Image Control Board ☞ D-15

[2] PWB-FAX1 Interface Board ☞ D-13

[3] PWB-FAX2 NCU Board ☞ D-13

[4] PU2 Power Supply Unit 2 ☞ D-11

[5] PWB-A Mechanical Control Board ☞ D-11

[6] PWB-O Control Panel ☞ D-12

[7] PWB-S Socket Board ☞ D-17

[8] PU1 Power Supply Unit 1 ☞ D-14

[9] HV1 High Voltage Unit ☞ D-15

Removal

Procedure

D-10

Page 53

(3) Removing the Power Supply Unit 2 (PU2)

<PagePro 1380 MF>

1. Remove the Right Cover.

☞ D-2

2. Disconnect all connectors and flat cables from

the Power Supply Unit 2.

3. Remove three screws and the Power Supply Unit

2.

4558F2C003DB

<PagePro 1390 MF>

1. Remove the Right Cover.

☞ D-2

2. Disconnect all connectors and flat cables from

the Power Supply Unit 2.

3. Remove the screw, two PWB supports and the

Power Supply Unit 2.

4558F2C072DA

(4) Removing the Mechanical Control Board (PWB-A)

1. Remove the Right Cover.

☞ D-2

2. Disconnect all connectors and flat cables from

the Mechanical Control Board.

NOTE

• Use the utmost care not to snap off the flat cable.

3. Remove four screws and the Mechanical Control

4558F2C004DB

Board.

NOTE

• When the Mechanical Control Board is replaced,

upgrade the Firmware to the latest version.

☞ D-30

D-11

Page 54

(5) Removing the Control Panel (PWB-O)

1. Remove the Exit tray.

☞ D-2

2. Remove three screws.

4558F2C511DA

3. Unhook four tabs on the Control Panel.

NOTE

• Remove the Control Panel slowly and carefully, as

connectors are connected to it.

4558F2C514DA

PagePro 1380 MF

PagePro 1390 MF

4. Disconnect the connector(s) from the Control

Panel.

5. Remove the Control Panel.

4558F2C005DA

4558F2C069DA

D-12

Page 55

(6) Removing the Interface Board (PWB-FAX1) <PagePro 1390 MF only>

1. Remove the Right Cover.

☞ D-2

2. Disconnect two connectors from the Interface

Board.

3. Remove three screws and the Interface Board.

4558F2C071DA

(7) Removing the NCU Board (PWB-FAX2) <PagePro 1390 MF only>

1. Remove the Right Cover.

☞ D-2

2. Remove the Power Supply Unit 2.

☞ D-11

3. Disconnect the connector from the NCU Board.

4. Remove two screws, three PWB supports and

the NCU Board.

4558F2C073DA

D-13

Page 56

(8) Removing the Power Supply Unit 1 (PU1)

1. Remove the Fusing Unit.

☞ E-8

2. Remove three screws.

3. Remove the Power Switch stay.

4. Remove the Power Switch Assy.

4558F2C007DA

5. Disconnect the connector from the Power Supply

Unit 2.

4558F2C524DA

6. Remove six screws, disconnect three connectors,

and remove the Power Supply Unit Assy.

4558F2C008DB

4558F2C503DA

7. Remove four screws and the Power Supply Unit

1.

D-14

Page 57

(9) Removing the High Voltage Unit (HV1)

1. Remove the Power Supply Unit Assy.

☞ D-14

2. Remove the screw and the High Voltage Unit.

4558F2C504DA

(10) Removing the Controller/Image Control Board (PWB-I)

1. Remove the IR Unit.

☞ D-18

2. Remove four screws and the Controller/Image

Control Board Cover.

4558F2C009DA

3. Disconnect three flat cables from the Controller/

Image Control Board.

4558F2C010DB

4558F2C011DA

NOTE

• Use the utmost care not to snap off the flat cable.

4. Remove two screws and the Flat Cable Guide.

D-15

Page 58

PagePro 1380 MF

PagePro 1390 MF

4558F2C012DA

4558F2C74DA

4558F2C013DA

5. Disconnect all connectors from the Controller/

Image Control Board.

6. Remove three screws and the Controller/Image

Control Board.

NOTE

• When the Controller/Image Control Board is

replaced, upgrade the Firmware to the latest version.

☞ D-30

D-16

Page 59

(11) Removing the Socket Board (PWB-S)

1. Remove the IR Unit.

☞ D-18

2. Remove four screws and the Socket Board

Cover.

4558F2C014DA

3. Disconnect the flat cables from the Socket Board.

NOTE

• Use the utmost care not to snap off the flat cable.

4558F2C015DA

4. Remove the screw and the Socket Board Assy.

4558F2C016DA

D-17

Page 60

2-3. Removal of Units

(1) Removing the IR Unit

1. Remove the Left Cover.

☞ D-2

2. Remove the Right Cover.

☞ D-2

3. Remove the Rear Cover.

☞ D-2

PagePro 1380 MF

PagePro 1390 MF

4. Disconnect three connectors.

(Page Pro 1380 MF Only)

5. Disconnect four connectors.

(Page Pro 1390 MF Only)

4558F2C019DA

4558F2C068DA

6. Remove the screw.

4558F2C020DA

4558F2C021DA

7. Unhook two tabs, and then remove the IR Unit.

D-18

Page 61

(2) Removing the PH Unit

• NEVER attempt to replace the PH Unit while power is being supplied to the

printer. Doing so could lead to exposure to the laser beam, resulting in blind-

ness.

• NEVER attempt to disassemble or adjust the PH Unit. Doing so could lead to

exposure to the laser beam, resulting in blindness.

1. Remove the IR Unit.

☞ D-18

2. Remove the Exit tray.

☞ D-2

4558F2C022DA

CAUTION

3. Remove four screws and the Upper Cover.

4. Remove the Upper Door.

4558F2C023DA

4558F2C024DB

5. Disconnect the flat cable and the connector from

the Mechanical Control Board.

NOTE

• Use the utmost care not to snap off the flat cable.

D-19

Page 62

1

Precautions for Removal/Reinstallation of the PH Unit

• NEVER touch the window on the back of the PH Unit. A dirty window can cause image

quality problems.

2

3

4136D008AC

6. Remove three screws.

7. Remove the PH Unit.

NOTE

• When reinstalling the PH Unit, tighten the screws

in the numerical order shown in the illustration.

Window

4558F2C515DA

D-20

Page 63

2-4. Disassembly of the Image Reading Section

(1) Removing the IR Upper Cover (Original Glass)

1. Remove the Document Cover.

2. Remove the Control Panel Assy.

☞ D-12

3. Remove the three screws.

4. Remove the Control Panel bottom housing.

4558F2C025DA

5. Remove the three screws.

6. Remove the IR Upper Cover (Original Glass).

4558F2C026DA

(2) Removing the Scanner Unit.

1. Remove the IR Upper Cover (Original Glass).

☞ D-21

4558F2C017DB

4558F2C027DB

2. Disconnect two Flat Cables from the Scanner

Unit.

NOTE

• Use the utmost care not to snap off the flat cable.

3. Remove the Sliding Rod.

D-21

Page 64

4. Remove the Belt from the Scanner Unit.

NOTE

• When installing the Belt, route it as shown in the

illustration.

4558F2C028DB

(3) Removing the Timing Belt

1. Remove the Upper Cover Assy. (Original Glass).

☞ D-21

2. Remove the Scanner Unit.

☞ D-21

3. Remove the Timing Belt by unhooking it on both

sides.

4558F2C039DA

D-22

Page 65

2-5. Disassembly of the Main Drive Section

(1) Removing the Main Motor (M1)

1. Remove the Left Cover.

☞ D-2

2. Disconnect the connector.

3. Remove two screws.

4. Remove the Main Motor.

4136D010AB

(2) Removing the Tray 1 Paper Empty Sensor (PE1)

1. Remove the Imaging Cartridge.

NOTE

• The Imaging Cartridge is the Drum Cartridge, to which the Toner Cartridge is mounted.

2. Remove the Front Door.

3. Remove the Left and Right Covers.

☞ D-2

4. Disconnect one connector from the Mechanical

Control Board.

5. Unhook two tabs, disconnect one connector, and

remove the Paper Take-Up Upper Guide Assy.

4558FS2507DA

4136D013AA

6. Unhook two tabs and remove the tray.

D-23

Page 66

7. Disconnect one connector and remove the Tray 1

Paper Empty Sensor.

4136D014AA

(3) Removing the Paper Take-Up Solenoid (SL1)

1. Remove the Left Cover.

☞ D-2

2. Disconnect one connector of the Paper Take-Up

Solenoid.

4558FS2505DA

3. Remove one screw.

4. Remove the Paper Take-Up Solenoid.

4558FS2506DA

Precautions for Installation of the Paper Take-Up Solenoid

1. Mount the Paper Take-Up Solenoid and tighten one screw.

2. Turn the gear in the direction of the arrow shown below so that the flapper of the Paper

Take-Up Solenoid catches the stopper of the gear.

Stopper

Gear

Flapper

4980D067AA

D-24

Page 67

(4) Removing the Paper Take-Up Clutch Gear

1. Remove the IR Unit.

☞ D-18

2. Remove the Fusing Unit.

☞ E-8

3. Remove the Power Supply Unit 1.

☞ D-14

4. Remove the Paper Take-Up Upper Guide Assy.

☞ D-23

5. Disconnect the connector and remove the Cool-

ing Fan Motor.

4558F2C040DB

6. Disconnect the connector of the Main Motor.

☞ D-23

4980D074AA

4980D057AA

4558F2C022DA

7. Remove the Tray 1.

☞ D-2

8. Remove the Paper Lifting Plate Assy.

9. Remove two springs.

10. Remove four screws and the Upper Cover.

D-25

Page 68

4558F2C023DA

4558F2C024DB

4136D016AB

11. Remove the Upper Door.

12. Disconnect the flat cable and the connector from

the Mechanical Control Board.

NOTE

• Use the utmost care not to snap off the flat cable.

13. Remove four screws.

14. Remove the PH Base Plate Assy.

15. Disconnect the connector of the Paper Take-Up

Solenoid.

16. Remove two screws.

17. Remove the Left Frame.

4558F2C513DA

4136D018AA

18. Remove the screw.

19. Remove the Paper Take-Up Solenoid.

D-26

Page 69

20. Unhook two tabs and remove the Paper Take-Up

Clutch Gear.

4136D057AA

(5) Removing the Torque Limiter

1. Remove the Paper take up Clutch Gear.

☞ D-25

Torque Limiter

Coupling

Gear

4136D043AA

2. Unhook three tabs and take apart the Paper

Take-Up Clutch Gear then, remove the Torque

Limiter.

Precautions for Installation of the Torque Limiter

The Coupling Gear has five notches for adjustment of the Take-up Roller position. When

the Torque Limiter is replaced, adjust the set position of the Coupling Gear so that the Take-

up Roller becomes level. The procedure is as follow.

4136D044AA

After replacing the Paper Take-Up Clutch Gear

(Torque Limiter) on the shaft, rotate the Paper Take-

Up Clutch Gear by hand (the Solenoid Flapper needs

to be released).

4136D060AA

Look at the stop position of the Take-Up Roller from the Clutch Gear side.

D-27

Page 70

1. When the Roller is leaning in the clockwise direc-

tion, move the coupling Gear in the A direction.

4136D046AA

2. When the Roller is leaning in the counter clock-

wise direction, move the coupling Gear in the B

direction.

4136D045AA

(6) Disassembling the Fusing Unit

NOTE

• The Fusing Unit is extremely hot immediately after the Power Switch has been turned

OFF. Allow a sufficient time to let it cool down before starting the procedure to prevent

burn.

1. Remove the Fusing Unit.

☞ E-8

Lower Fusing

Roller section

Lower Fusing

Roller section

Upper Fusing

Roller section

4136D021AA

4136D022AA

2. Remove the two screws.

3. Remove the Fusing Unit is divided into the Upper

Fusing Roller section and Lower Fusing Roller

section.

4. Remove two bushings and the Pressure Roller.

D-28

Page 71

Upper Fusing

Roller

section

Precautions for Installation of the Bushings

• Make sure that the slits in the bushing are properly

aligned with the rib of the Fusing Unit.

4136D040AA

5. Remove one screw and the Thermistor.

NOTE

• When reinstalling the Thermistor, route the har-

ness as shown in the illustration.

4980D068AB

D-29

Page 72

2-6. Upgrading the Firmware

NOTES

• The PagePro 1380 MF or The PagePro 1390 MF TWAIN driver and printer driver must

already be installed on the host computer before firmware can be updated.

• If the PagePro 1380 MF or The PagePro 1390 MF TWAIN driver or printer driver is not

installed, follow the procedure described below to install the driver.

• If the drivers are already installed, skip to “Procedure for Upgrading the Firmware” and

upgrade the firmware.

(1) Minimum System Requirements

Operating System

Host Computer • Pentium III 500MHz and above, 64 MB RAM

(2) Install the TWAIN Driver Software

1. Make sure that the machine is not connected to the host computer.

2. Insert the PagePro 1380 MF or The PagePro 1390 MF Utilities & Documentation CD-

ROM into the CD-ROM/DVD drive.

3. The CD-ROM Installer automatically starts.

NOTE

• If the Installer does not automatically start, use Windows Explorer to browse the CD-

ROM and double-click “setup.exe.”

4. Follow the instructions on the screen.

5. Connect the PagePro 1380 MF or The PagePro 1390 MF to the host computer.

6. The “Found New Hardware” (Windows XP/2000) on the host computer shows up.

7. Follow the instructions on the screen.

(3) Install the Printer Driver

1. After installing the TWAIN driver, the “Found New Hardware” (Windows XP/2000) on

the host computer appears.

2. Follow the instructions on the screen.

NOTE

• Do not the “Add Printer” wizard to install the PagePro 1380 MF or The PagePro 1390 MF

driver and utilities.

• Windows XP or Windows 2000 (Windows ME/98SE cannot be

used)

D-30

Page 73

(4) Procedure for Upgrading the Firmware

1. Turn OFF the PagePro 1380 MF or The PagePro 1390 MF and the host computer.

2. Turn ON the PagePro 1380 MF or The PagePro 1390 MF.

3. Start up the host computer (Windows 2000/XP).

4. Copy the firmware grade data to the host computer.

5. After the hardware is detected, use a USB cable to connect the PagePro 1380 MF or

The PagePro 1390 MF to the host computer.

6. Double-click the “FWUpdate.exe” file to begin the firmware upgrade procedure.

4558F2C525DA

7. The “Firmware update utility” window appears, and the firmware upgrading starts auto-

matically.

D-31

4558F2C526DB

Page 74

8. Check the firmware upgrade status in the LCD display.

4558F2C527DB

NOTE

• Do not turn the PagePro 1380 MF’s or The PagePro 1390 MF’s Main Power Switch OFF

or ON while the message shown above is displayed.

D-32

Page 75

9. Check that the following message appears in the PagePro 1380 MF’s or The PagePro

1390 MF’s LCD display and the computer screen to indicate that the firmware upgrade

procedure is complete.

4558F2C528DA

10. Turn the PagePro 1380 MF’s or The PagePro 1390 MF’s Main Switch OFF, and then

ON again.

D-33

Page 76

CONTROL PANEL/SERVICE

MODE DESCRIPTIONS

Page 77

1. CONTROL PANEL DESCRIPTIONS

1-1. Names and Functions of Control Panel Parts

(1) PagePro 1380MF

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10]

[17][18][19]

[16]

No. Key Name Function

[1] 10-Key pad

Error LED • Lights when an error or malfunction occurs.

[2]

To n e r L E D

[3] Scan key • Press to enter the Scan mode.

[4] Copy key • Press to enter the Copy mode.

[5] -/+ key

[6] Menu key • Press to enter the configuration menu.

[7] Copy Quality key

[8] Collate key • Automatically collates multiple copies into sets.

[9] N in 1 key

[10] Toner Save key

[11] Stop/Reset key

[12] Start key • Starts a copy or scan job.

[13] Reduce/Enlarge key

• Use to enter the number of copies to be made

and any other numeric data.

• Flashes when the toner cartridge is empty or the

drum needs to be replaced.

• Stays on when the toner has been completely

consumed, a wrong toner cartridge is used, or

the drum needs to be replaced.

• Displays the options available for the selected

menu.

• Selects the document type for the current copy

job.

• Reduces original images to fit onto one sheet of

media.

• Saves toner by using less toner to print a document.

• Stops an operation at any time.

• In Standby mode, clears the copy options.

• Makes a copy smaller or larger than the original

document.

[12] [11][13][14][15]

S-1

Page 78

No. Key Name Function

[14] Light/Dark key

• Adjusts the document brightness for the current

copy job.

• Sets the number of copies.

[15] Copies key

(Each time the key is pressed, the count

increases by one page.)

[16] Select key • Selects the item displayed.

[17] Cancel key

[18] LCD Display

[19] Scan To key

• Deletes entered data or exits from the current

menu when pressed repeatedly.