Page 1

IP-421

SERVICE HANDBOOK

July, 2000

Ver. 1.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

KCSI42110

Page 2

COPYRIGHT ©2000

KONICA CORPORATION

All rights reserved

MF13JA1780

Page 3

Safety and Important Warning Items

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before

doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this equipment, as well as the

risk of damage to the equipment, Konica Corporation, strongly recommends that all servicing be

performed only by Konica-trained service technicians.

Changes may have been made to this equipment to improve its performance after this service

handbook was printed. Accordingly, Konica Corporation, makes no representations or warranties,

either expressed or implied, that the information contained in this service handbook is complete or

accurate. It is under-stood that the user of this service handbook must assume all risks or personal

injury and/or damage to the equipment while servicing the equipment for which this service handbook is intended.

Therefore, this Service Handbook must be read carefully before doing service work both in the

course of the technical training and even after that, for keeping the correct maintenance and control

of the copying machine. Keep the Service Handbook also for the future service. When it is impossible to read the description about safety and warning (due to contamination or tear), the relevant

page should be re-placed.

DESCRIPTION ITEMS FOR Danger, Warning AND Caution

In this Service Handbook, each of three expressions, “ Danger, Warning and Caution” is

defined as follows together with a symbol mark to be used in a limited meaning.

When servicing, the relevant works (disassembling, assembling, adjustment, repair and maintenance) need to be conducted with utmost care.

Danger: Actions having a high possibility of suffering death or serious

wound

Warning: Actions having a possibility of suffering death or serious wound

Caution: Actions having a possibility of suffering a slight wound, medium

trouble and material damage

C-1 IP-421 PRINT CONTROLLER

Page 4

Safety and Important Warning Items

SAFETY WARNINGS

● MODIFICATIONS NOT AUTHORIZED BY Konica

Konica copiers are renowned for their high reliability. This reliability is achieved through high-quality

design and a solid service network.

Photocopier design is a highly complicated and delicate process where numerous mechanical,

physical, and electrical aspects have to be taken into consideration, with the aim of arriving at

proper tolerances and safety factors. For this reason, unauthorized modifications involve a high risk

of degrading performance and safety. Such modifications are therefore strictly prohibited. The points

listed below are not exhaustive, but they illustrate the reasoning behind this policy.

Prohibited Actions :

(1) Using extension cables or a different power cord than specified by Konica.

(2) Using other fuses than specified by Konica. Safety will not be assured, lead-

ing to a risk of fire and injury.

(3) Disabling fuses or bridging fuse terminals with wire, metal clips, solder or

similar. (This applies also to thermal fuses.)

(4) Removing air filters (except for replacement).

(5) Disabling relay functions (such as wedging paper between relay contacts,

etc.).

(6) Disabling safety functions (interlocks, safety circuits, etc.). Safety will not be

assured, leading to a risk of fire and injury.

(7) Performing actions to copier not described in the instruction manual or the

service handbook.

(8) Using parts other than specified by Konica.

● CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

Konica copiers are extensively tested before shipping, to ensure that all applicable safety standards are met, in order to protect the customer and customer engineer from the risk of injury.

However, in daily use, any electrical equipment will be subject to parts wear and eventual failure. In

order to maintain safety and reliability, the customer engineer must perform regular safety checks.

Caution :

(1) Wear clothing that facilitates work and is designed for safety.

(2) Carry out all procedures carefully to prevent injury.

(3) Be sure to disconnect the power cord of the copier and all optional equip-

ment from the AC outlet.

Simply turning off the power switch is not sufficient, because paper feed

units or other electrical equipment may be powered also when the power

switch is turned off.

(4) Proceed with special care when performing operation checks or adjustment

while the unit is powered. When carrying out operation checks or adjustment while external covers are removed, the risk of electrical shock exists

when touching parts which carry high voltage or electrical charge. The risk

of injury exists when touching moving parts such as gears or chains.

C-2 IP-421 PRINT CONTROLLER

Page 5

Safety and Important Warning Items

The following list is not exhaustive, but it includes actions which must be carried out at every service call.

Caution :

(1) Check external covers and the frame for sharp edges, burrs, or nicks.

(2) Check external covers and hinges for loosening or damage.

(3) Check wiring for squeezing or damage.

(4) Check power cord for insulation problems (conductor must not be exposed).

(5) Check that power cord is properly connected.

Warning :

(1) Verify that the copier is properly grounded. If a problem is detected, estab-

lish a proper ground connection.

(2) Connecting the ground lead to an improper point such as listed below re-

sults in a risk of explosion and electric shock.

Unsuitable ground points:

- Gas pipe

- Lightning rod

- Telephone line ground

- Plastic water pipe or water pipe or faucet that has not been approved by

authorities for grounding use

● PRECAUTIONS FOR ON-SITE SERVICE

Caution :

(1) Before performing maintenance work, read all relevant documentation (ser-

vice handbook, technical notices, etc.) and proceed according to the prescribed procedure, using only the prescribed tools. Do not carry out any

adjustments not described in the documentation.

(2) If the power cord is damaged, replace it only with the specified power cord.

If the power cord insulation has been damaged and there are exposed sections, shortcircuits and overheating may occur, leading to a serious fire risk.

(3) Do not route the power cord so that it can be stepped on or pinched. Other-

wise overheating may occur, leading to a serious fire risk.

(4) When disconnecting any cables, always grasp the connector and not the

cable (especially in the case of AC and high-voltage leads).

(5) Carefully remove all toner remnants from electrical parts, electrodes, etc.

(6) Make sure that wiring cannot come into contact with sharp edges, burrs, or

other pointed parts.

(7) Double-check to make sure that all screws, components, wiring, connec-

tors, etc. that were removed for maintenance have been reinstalled in the

original location. (Pay special attention to forgotten connectors, pinched

cables, forgotten screws, etc.)

(8) When installation and preventive maintenance, verify that the power cord

has been securely plugged into the AC outlet. Contact problems may lead

to increased resistance, overheating, and the risk of fire.

Warning :

(1) Before disassembling or adjusting the optical unit or any parts that use a

laser, make sure that the power cord has been disconnected.

C-3 IP-421 PRINT CONTROLLER

Page 6

Safety and Important Warning Items

(2) Do not remove the main cover of the write unit. Direct exposure of the eye to

laser beams may lead to blindness.

(3) Do not turn the copier on while the write unit is not installed in its normal

position.

(4) Danger of explosion if battery is incorrectly replaced, replace only with the

same or equivalent recommended by the manufacturer. Discard used bat-

teries according to the manufacture’s instructions.

Vorsicht :

(4) Expiosionsgefahr dei unsachegemäßem Austausch der Battetie. Ersatz nur

durch denselben oder einen vom. Hersteller empfohlenen gleichwertigen Typ.

Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

● HANDLING OF MATERIALS FOR SERVICING

Caution: Drum cleaner (alcohol-based) and roller cleaner (acetone- based) are

highly flammable and must be handled with care.

When using these materials for cleaning of copier parts, observe the

following pre-cautions.

(1) Disconnect the power cord from the AC outlet.

(2) Use only a small amount of cleaner at a time and take care not to spill any

liquid. If this happens, immediately wipe it off.

(3) Perform cleaning only in an environment where sufficient ventilation is assured.

Breathing large quantities of organic solvents can lead to discomfort.

(4) Do not replace the cover or turn the unit on before any solvent remnants on

the cleaned parts have fullyevaporated.

Caution: Toner and developer are not harmful sub-stances, but care must be

taken not to breathe excessive amounts or let the substances come

into contact with eyes etc.

If this happens, immediately rinse with eye wash and plenty of water,

and consult a physician.

● MEASURES TO TAKE IN CASE OF AN ACCIDENT

(1) If an accident has occurred, the distributor who has been notified first must

immediately take emergency measures to provide relief to affected persons

and to prevent further damage.

(2) If a report of a serious accident has been received from a customer, an on-

site evaluation must be carried out quickly and Konica Corporation must be

notified.

(3) To determine the cause of the accident, conditions and materials must be

recorded through direct on-site checks, in accordance with instructions is-

sued by Konica Corporation.

● CONCLUSION

Safety of users and customer engineers has topmost priority, ranking even higher than operability.

Safety depends on a appropriate maintenance work and is maintained by proper daily service work

conducted by customer engineers. When performing service, each copier on the site must be

tested for safety. The customer engineer must verify the safety of parts and ensure appropriate

management of the equipment.

C-4 IP-421 PRINT CONTROLLER

Page 7

Contents

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS ............................................ C-1

1. Overview

■ Product specifications ................................................................................ 1-1

● IP-421 print controller ..................................................................................................... 1-1

■ Product overview ........................................................................................ 1-3

● Capabilities of the IP-421 ................................................................................................ 1-3

● Startup sequence of the 7020 series + IP-421 system ................................................... 1-4

● Data processing of the IP-421 (See data flow) ............................................................... 1-4

● Data flow ......................................................................................................................... 1-5

■ Option ......................................................................................................... 1-6

● KN-303 Network card ..................................................................................................... 1-6

● Hard Disk (HD-103) ........................................................................................................ 1-6

● Post Script 3 (PS-341) .................................................................................................... 1-6

2. Disassembly/Assembly

■ Construction ............................................................................................... 2-1

■ Disassembly / Assembly procedures.......................................................... 2-2

● Removal/Installation of boards........................................................................................ 2-2

● Expanding the memory (MU-403/MU-404/MU-405) ....................................................... 2-5

● Installation / Removal of HD-103 .................................................................................... 2-7

● Installation / Removal of PostScript 3 option (PS-341) ................................................... 2-9

3. Troubleshooting

■ Troubleshooting .......................................................................................... 3-1

● Troubleshooting of the IP-421 and copier ....................................................................... 3-1

4. Appendices

■ Upgrading the Firmware ............................................................................. 4-1

● Rewriting the Flash ROM ................................................................................................ 4-1

● In case of failure in rewriting the firmware ...................................................................... 4-2

● Replacing ROM .............................................................................................................. 4-3

■ Functions of parts mounted on boards ....................................................... 4-4

● Connector ....................................................................................................................... 4-5

● Switch ............................................................................................................................. 4-5

● Jumpers .......................................................................................................................... 4-5

● Individual ICs’ functions .................................................................................................. 4-5

INDEX ..................................................................................................... Index-1

C-5 IP-421 PRINT CONTROLLER

Page 8

1

Overview

Page 9

■ Product specifications

● IP-421 print controller

Type: Built in Konica 7020 series copy machine

Paper size: A3, A4, A5, B4, B5, B6, 11"X17", 8.5"x14", 8.5"x11", 5.5"x8.5"

Paper feeding: Same as copier

Output stack capacity: Same as copier

Mode: Possible dual mode of copy machine/printer (up to 5 jobs)

Next job reservation: Next copy job can be reserved during print job.

Special printing features: Printing on both faces, choice of paper type, zoom

Chapter 1 Overview

function, choice of paper tray, choice of output tray,

choice of print quality, Alternate function, sort/

group function, staple function, layout function,

front/back cover intersheet function, booklet function, smoothing function, page protection function,

watermark function

Direction of printing: portrait, landscape

Resolution: 600 dpi

Scan Resolution: 600 dpi/400 dpi/300 dpi/200 dpi

Gradation: 2

Number of output pages: 1-999

Warm-up: Same as copier

CPU: Pentium MMX-166Mhz

Memory: 32MB (standard), expandable up to 160MB (option:MU-403 / MU-

404 / MU-405)

Cards: Controller board x1

PCI relay board x1

KN-303 Network card (option)

Option:Harddisk Drive (HD-103)

PS option (PS-341)

1-1 IP-421 PRINT CONTROLLER

Page 10

Chapter 1 Overview

Interface: Parallel port

Based on Centronics (IEEE 1284)/Amphenol male 36pin connector

Network interface: (option)

KN-303 Network card

Network: Ethernet (100BaseTX/10BaseT)

Protocols: IPX/SPX (NetWare),

TCP/IP (LPD/LPR, peer-to-peer)

AppleTalk (EtherTalk)

Compliant OS:

Windows 95/98

Windows NT4.0/2000

Macintosh

Unix

Printer Language:

PCL

PostScript3 (option)

Printer drivers:

Windows 95/98 printer driver

Windows NT4.0/2000 printer driver

Host computer: A Windows based computer

Macintosh

Unix

Finisher: FS-107

paper tray unit: DB-209,DB-409

Size: 240 mm(W) x 160 mm(H) x 37 mm(D)

Weight: Approx. 1.1 kg

Power source: 5 V, 2 A or less (supplied from copier)

Operating conditions:temperature: 10-30˚C,

humidity: 20-80%RH (condensation not allowed)

Restrictive Conditions:

1-2 IP-421 PRINT CONTROLLER

• In the Printer mode, the EKC (Electric Key Counter) of the Konica

7020 series is not available.

• Although the Weekly Timer function of the Konica 7020 series is

available in the Printer mode, the power is not turned Off until

the data output is finished when print data remains in the E-RDH.

Notice: Specifications are subject to change for improvements without no-

tice.

Page 11

Chapter 1 Overview

■ Product overview

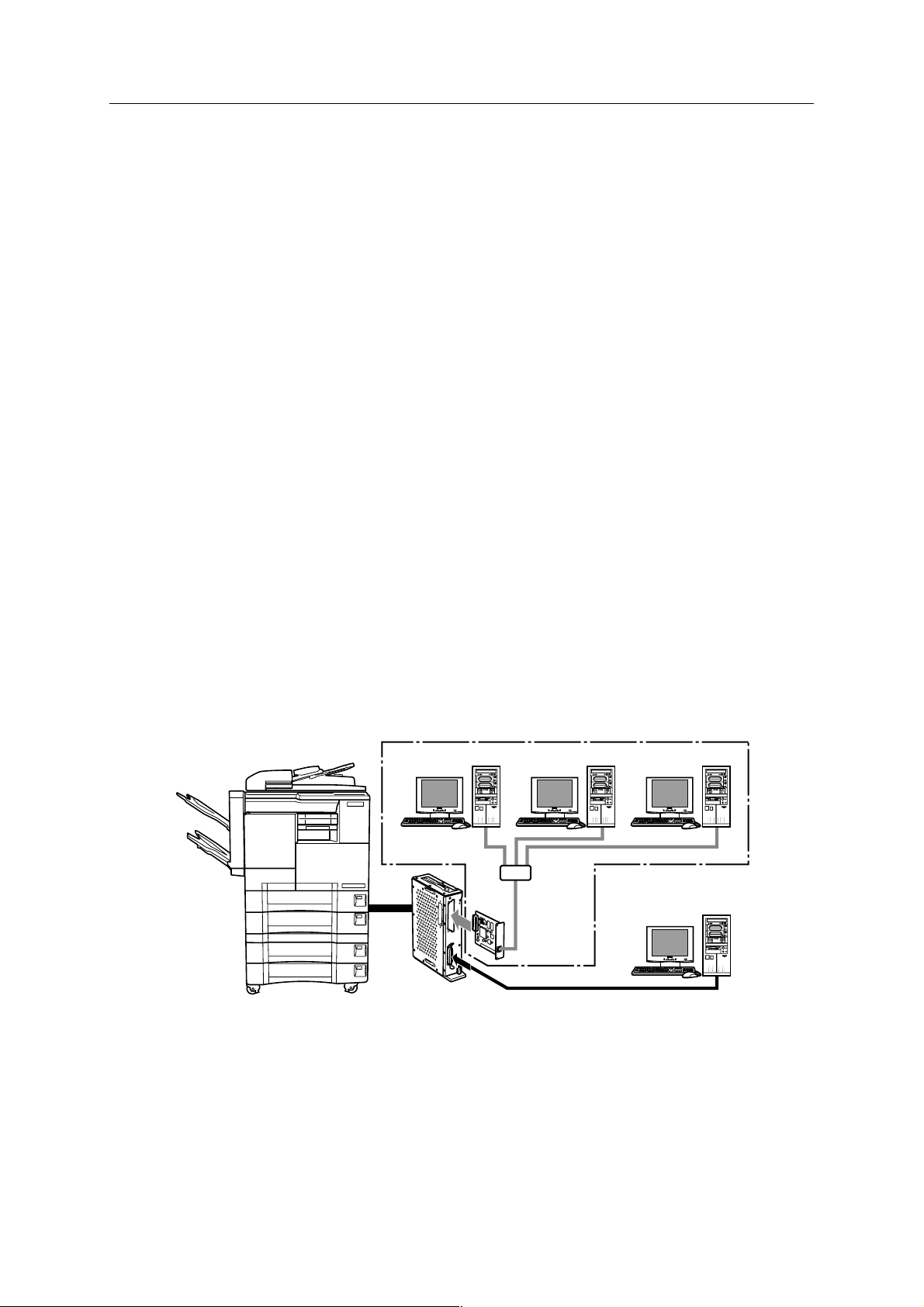

● Capabilities of the IP-421

The Konica IP-421 print controller allows you to use the Konica 7020 series copying machine as a

printer connected to computers and a network. It receives print jobs from computers and network

and converts them into image data (video data) that the Konica 7020 series copying machine prints

out.

The IP-421 print controller is characterized as follows.

• Built in the Konica 7020 series copying machine.

• The drivers interfacing with Windows 95/98 and NT4.0/2000 allow use of the

functions of the Konica 7020 series copying machine.

• The KN-303 Network card allows use of the IP-421 as a network printer.

• A system can be upgraded by the renewal of the flash memory.

This Service Handbook describes hardware construction, disassembly and assembly procedures,

troubleshooting, and appendixes (upgrading firmware, error messages, etc).

IP-421

KN-303

(OPTION)

1-3 IP-421 PRINT CONTROLLER

Page 12

Chapter 1 Overview

● Startup sequence of the 7020 series + IP-421 system

As the IP-421 is built in the 7020 series, supplying power to the IP-421 and its initialization starts as

soon as you turn on the copier. The startup sequence is as follows.

1. Turn on the copier.

Supplying power to start the IP-421 starts. Its CPU works to test the system memory

and the system program starts running.

2. The IP-421 performs system check.

3. On completion of system check, the controller is waiting print job.

If printer mode is selected, a message “Ready to print” appears.

● Data processing of the IP-421 (See data flow)

When you attempt to print a document data from a computer connected the IP-421, processing will

be made as follows.

1. The print job comes from the computer (or network) to the parallel port (or Ethernet port if

the KN-303 is used).

2. The CPU, mounted on IP-421, generates the bit map image of one page to another in the

image memory.

3. The bit map image is transferred in the form of video signals from the image memory to the

copier and printed.

1-4 IP-421 PRINT CONTROLLER

Page 13

● Data flow

Chapter 1 Overview

Print Commands

Interface

Print Controller

IP-421

Computer

Spooler

Parallel I / F(IEEE1284)

Parallel I / F

Application

Printer Driver

Browser

HTML

Ethernet I/F

(TCP/IP,IPX/SPX)

Network Card KN-303

(Option)

PCI bus

Input Buffer

Printer Engine

PDL command

Rasterized graphic data

Printer status

Harddisk HD-103

(Option)

PDL Processing (Rasterization)

Graphic memory

PCI bus

E-RDH memory

Engine(Print)

1-5 IP-421 PRINT CONTROLLER

Page 14

Chapter 1 Overview

■ Option

● KN-303 Network card

If the IP-421 is fitted with the KN-303 Network card, the 7020 series can be used as a remote printer

from any computer belonging to a network (NetWare/Windows).

● Hard Disk (HD-103)

By installing this optional hard disk to the IP-421, you can use the 7020 series copier as a scanner.

The scanned data can be read into your PC via an optional Network Interface Card.

● Post Script 3 (PS-341)

By installing this optional PostScript and the standard compact flash for PostScript to the IP-421,

you can use the 7020 series copier as a PostScript printer.

1-6 IP-421 PRINT CONTROLLER

Page 15

2

Disassembly / Assembly

Page 16

■ Construction

Chapter 2 Disassembly / Assembly

Expansion memory slot

PDL compact flash slot

Controller Board

PS compact flash slot

CPU cooling fan

Tool

PCI relay

board

Printer reray board

PS-341 slot

HD-103 connector

Parallel port connector

(CN502)

Caution:

If grounding is not made securely, the cards can be damaged during work. Make

sure to ground your body securely by using a wrist strap before starting to work.

• Use a Phillips head screwdriver.

Reference information:

As the IP-421 is provided with a “flash memory”, no tool is needed to replace ROM

for upgrading the firmware.

2-1 IP-421 PRINT CONTROLLER

Page 17

Chapter 2 Disassembly / Assembly

■ Disassembly/Assembly procedures

● Removal/Installation of boards

1. Remove the sliding cover. (2 screws)

Sliding cover

2. Remove the Board cover. (11 screws)

Board cover

3. Remove the side cover of the parallel connector side. (5 screws)

2-2 IP-421 PRINT CONTROLLER

Side cover

Page 18

4. Remove the printer relay board. (5 screws)

5. Remove the Board cover fixtures. (6 screws)

Chapter 2 Disassembly / Assembly

Board cover fixtures

Board cover fixtures

6. Remove the controller board unit and the side cover of the copying machine side all to-

gether.(9 screws)

2-3 IP-421 PRINT CONTROLLER

Page 19

Chapter 2 Disassembly / Assembly

7. Pull off the controller board at the connector (CN2) on the PCI relay board fitted to the side

cover.

CN2

8. Remove the PCI relay board. (6 screws)

CN4

9. To install, reverse the removal procedure.

Caution:

When installing the PCI relay board, be sure to securely plug in connectors (2 in

number).

2-4 IP-421 PRINT CONTROLLER

Page 20

Chapter 2 Disassembly / Assembly

● Expanding the memory (MU-403/MU-404/MU-405)

The IP-421 is provided with 32MB memory (standard specification). You can expand the memory

capacity up to 160MB by installing a DIMM card additionally into a slot on the controller board.

Caution:

• With the memory expanded, the IP-421 can rasterise more pages during waiting

previous print job than before expansion.

• If memory overflow occurs, expand the memory.

• The memory card slot is prepared for expansion of 32MB, 64MB or 128MB.

• When a memory except for Konica designation, the movement of IP421 can’t be

assured.

Installing DIMM

1. Insert the connector of DIMM obliquely.

2-5 IP-421 PRINT CONTROLLER

Page 21

Chapter 2 Disassembly / Assembly

2. Push the end of the DIMM and lock it with levers provided on both sides of the socket.

Caution:

The DIMM card can fit into the socket only in such a direction that the notch provided on the bottom of DIMM matches with the one on the socket.

Removing DIMM

1. Release the lock levers provided on both sides of the socket. Take out the DIMM in the

upper oblique direction.

2-6 IP-421 PRINT CONTROLLER

Page 22

● Installation / Removal of HD-103

1. Remove the Board cover on the IP-421. (11 screws)

2. Remove the printer relay board. (3 screws), then remove the flash card stopper plate. (2

screws)

Printer relay board

Chapter 2 Disassembly / Assembly

Board cover

Flash card

stopper plate

3. Connect the HDD to the connector of the printer relay board.

Caution:

Take care not to bend or break the pins of HDD.

HDD

Printer relay board

2-7 IP-421 PRINT CONTROLLER

Page 23

Chapter 2 Disassembly / Assembly

4. Fix the HDD on the printer relay board with 4 screws.

5. Fit the printer relay board into the connector of the IP-421 print controller.

Printer relay board

6. Fix the flash card stopper plate with two screws, then fix the printer relay board with three

screws.

7. Fix the board cover on the IP-421. (11 screws)

8. To remove, reverse the installation procedure.

2-8 IP-421 PRINT CONTROLLER

Printer relay board

Flash card

stopper plate

Page 24

Chapter 2 Disassembly / Assembly

● Installation / Removal of PostScript 3 option (PS-341)

1. Remove the Board cover on the IP-421. (11 screws)

Board cover

2. Remove the printer relay board. (3 screws), then remove the flash card stopper plate. (2

screws)

Printer relay board

Flash card

stopper plate

3. Mount the Flash card on the printer relay board.

Caution:

Position the Flash card in correct direction as illustrated below.

2-9 IP-421 PRINT CONTROLLER

Page 25

Chapter 2 Disassembly / Assembly

4. Mount the PS-341 on the print controller board.

Caution:

Position the PS-341 by matching the cut corner to that on the board.

5. Fit the printer relay board into the connector of the IP-421 print controller.

PS-341

Printer relay board

6.

Fix the flash card stopper plate with two screws, then fix the printer relay board with three screws.

Printer relay board

Flash card

stopper plate

7. Fix the board cover on the IP-421. (11 screws)

8. To remove, reverse the installation procedure.

Caution:

To remove the PS-341, use a PCLL removing tool.

2-10 IP-421 PRINT CONTROLLER

Page 26

3

Troubleshooting

Page 27

Chapter 3 Troubleshooting

■ Troubleshooting

This section offers a summary of information on troubleshooting that technicians could refer to

easily and would minimize the time of interruption of work.

● Troubleshooting of the IP-421 and copier

Symptoms

Printer mode window does not

appear on the copier’s display

after power-on.

“Warming up” does not disappear.

“Initialization ” does not disappear on the copier screen.

Printout is defective, or nothing

can be printed.

IP-421 does not start.

Causes

No power supply to the IP-421.

Copier is in trouble.

The IP-421 has not started properly.

The controller board or some

boards of the copier are defective.

The controller board is inactive.

Actions

Check if the IP-421 is connected

with the copier properly.

Locate the cause of trouble of

the copier.

See the column of “IP-421 does

not start”.

Put the copier in 36 mode and

perform test. If it operates properly, controller board may be

failure.

Check the connector of the controller board. Replace the controller board as necessary.

Test print can be produced but

not from the parallel port.

Software of the IP-421 is destroyed.

The parallel port has something

wrong or the cable is wrong

or, the problem is on the computer side.

Reinstall the software of the IP-

421.

Check the cables (internal/external). Perform test using a

data generator or a well-proven

PC/I/O cable. Replace the controller board as necessary.

3-1 IP-421 PRINT CONTROLLER

Page 28

Chapter 3 Troubleshooting

Symptom

Test print can be produced but

not from the network port.

Test print can be produced and

all ports are good, but user jobs

cannot be printed.

Possible causes

The network card is inactive or

not installed properly.

Some software error has happened.

Actions

Examine the network card. Check

all connectors. Replace the network card as necessary.

IP-421’s software or application

program has something wrong.

Save the file, which failed to be

printed, in the disk and analyze

the problem by suitable means.

3-2 IP-421 PRINT CONTROLLER

Page 29

4

Appendices

Page 30

Chapter 4 Appendices

■ Upgrading the Firmware

The IP-421 uses a compact flash ROM and you can go two ways in upgrading the firmware.You can

update the firmware via a parallel port or you can replace the compact flash ROM.

● Rewriting the Flash ROM

Normally, use this method.

Preparation

• Connect the IP-421 through a parallel cable to the computer that is used to upgrade the

firmware.

• Prepare the replacing firmware in the hard disk of the computer or in the form of CD-ROM.

• Turn on the copier’s main and auxiliary powers.

Procedure of rewriting the firmware

1. On the monitor screen of the computer, click the Start button. Click and select [MS-DOS

Prompt] from [Program].

The [MS-DOS prompt] appears.

2. Responding to the [MS-DOS prompt], designate the folder where the firmware is held.

Execute a COPY command and press the Enter key.

<Example> C:\copy filename.xxx lpt1 /b

3. On completion of file transfer from the computer, a message indicating the completion of

transfer appears on the copier LCD control panel. Press the OK button.

Now rewriting the firmware starts.

4-1 IP-421 PRINT CONTROLLER

Page 31

Chapter 4 Appendices

A message indicates that the firmware is being rewritten.

4. On completion of firmware renewal, a message indicating the completion appears. Then

turn off and on the Main SW of the copier.

● In case of failure in rewriting the firmware

If rewriting the firmware fails for some reason, it may be possible to redo the rewriting procedure

when the error happened in file transfer from the computer. Turn off and on the Main SW of the

copier and try the procedure again.

4-2 IP-421 PRINT CONTROLLER

Page 32

● Replacing ROM

The firmware can be upgraded even by replacing the ROM.

Replace the ROM if it is impossible to update the firmware via a parallel port.

1. Remove Flash card stopper plate on sub panel.

Chapter 4 Appendices

2. Remove Flash card.

3. Install Flash card.

4. Install Flash card stopper plate.

4-3 IP-421 PRINT CONTROLLER

Page 33

Chapter 4 Appendices

■ Functions of parts mounted on boards

CN1

CN8

Memory

Oscillator

PCIset

CN7

KPC01

PPBC

SW2

Clock Generator

JP2

Boot ROM

PCIset

JP3

CN3

CPU

SW1

CN4

CN9

CN5

4-4 IP-421 PRINT CONTROLLER

Page 34

Chapter 4 Appendices

● Connector

CN1: Expansion memory

CN3: PS-341 (option)

CN4: Printer relay board

CN5: Printer relay board

CN7: PCI relay board

CN8: PCI relay board

CN9: Parallel port connector

● Switch

SW1: Resets system. (only for development purpose) No need to operate the switch.

SW2: Switch boot system. (only for development purpose) No need to use the switch.

● Jumpers

No need to use the jumpers.

JP2: Not installed (no function)

JP3: For production purpose

● Individual ICs’ functions

CPU: Central processing unit

BootROM: System booting-up parameter

KPC01: Image rotation through 90 degrees/error diffusion processing

PPBC: Bridge from each PCIset to the PC bus

PCIset: Bridge from different points to PPBC

4-5 IP-421 PRINT CONTROLLER

Page 35

INDEX

INDEX

A

Assembly....................................................... 2-2

B

boards ........................................................... 4-4

C

Connector...................................................... 4-5

Construction .................................................. 2-1

D

Data flow ....................................................... 1-5

DIMM..................................................... 2-5, 2-6

Disassembly .................................................. 2-2

E

Expanding the memory ................................. 2-5

F

R

ROM .............................................................. 4-3

S

SAFETY AND IMPORTANT

WARNING ITEMS .................................. C-1

specifications................................................. 1-1

Startup sequence .......................................... 1-4

Switch............................................................ 4-5

T

Troubleshooting ............................................. 3-1

Firmware ....................................................... 4-1

flash memory ................................................ 1-3

Flash ROM .................................................... 4-1

H

HD-103 ...................................................1-6, 2-7

I

IC ............................................................... 4-5

J

Jumpers ........................................................ 4-5

K

KN-303 .......................................................... 1-6

M

MU-403 ......................................................... 2-5

MU-404 ......................................................... 2-5

MU-405 ......................................................... 2-5

P

PostScript 3 option ........................................ 2-9

Protocols ....................................................... 1-2

PS-341 ...................................................1-6, 2-9

Index-1

Loading...

Loading...