Konica ip302 Service Manual

Model

IP-302

IMAGE PROCESSOR

with Parts Catalog

(For use with 7060 Service Manual)

CSM-IP302

FEBRUARY 1998

This page left blank intentionally.

IP-302

SERVICE MANUAL

FEBRUARY 1998

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Machines

U.S.A., Inc., strongly recommends that all servicing be

performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Machines

U.S.A., Inc., makes no representations or warranties,

either expressed or implied, that the information contained in this service manual is complete or accurate. It

is understood that the user of this manual must assume

all risks or personal injury and/or damage to the equipment while servicing the equipment for which this service manual is intended.

Corporate Publications Department

© 1998, KONICA BUSINESS MACHINES U.S.A., INC.

All rights reserved.

Printed in U.S.A.

CONTENTS

CONTENTS

SAFETY PRECAUTIONS

Installation Environment ....................................... v

Unauthorized Modifications ...................................... v

General Safety Guidelines....................................... v

Safeguards During Service Calls .............................. vi

Applying Isopropyl Alcohol ...................................... vi

Summary............................................................... vi

INTRODUCTION

Introduction ............................................................ 1-1

Start-up Process..................................................... 1-2

Data Flow Chart ...................................................... 1-3

INSTALLATION

Video Interface Kit ................................................2-1

Printer Installation .................................................2-2

Adjustment and Confirmation................................2-4

IP-302 Installation .................................................2-6

IP-302 Driver/Software Installation........................2-7

KN-101 Installation ...............................................2-8

KN-201 Installation ...............................................2-8

DISASSEMBLY AND REASSEMBLY

Tools .................................................................... 3-1

Removing the Covers.............................................. 3-2

Removing/Installing the Floppy/Hard Drive ................ 3-2

Removing/Installing the Power Supply ...................... 3-3

Removing/Installing the Motherboard ........................ 3-3

Removing/Installing the Memory (SIMM)............... 3-4

TROUBLESHOOTING

Tools ....................................................................4-1

Table ....................................................................4-1

APPENDIX

IP-302 Software Installation Guide........................ 5-1

CMOS Setup Program .......................................... 5-2

P5TXBpro Board Jumper Settings ........................ 5-4

POST and BOOT Error Messages......................... 5-5

BEEP Codes ......................................................... 5-6

Copier Codes ....................................................... 5-7

Limitations ............................................................ 5-7

25 Mode and P Function....................................... 5-8

Block Diagram ...................................................... 5-9

Motherboard Do's and Don'ts................................ 5-10

Special Tools ........................................................ 5-11

INDEX

PARTS CATALOG

iii

This page left blank intentionally.

SAFETY PRECAUTIONS

[1] Installation Environment

Safety considerations usually are directed toward machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal,

it is conceivable that the combination of the machine

and the room air could present a hazardous combination. This is because heat (such as from fusing units)

and electrical arcs (which can occur inside switches)

have the ability to ignite flammable substances, including air.

When installing a machine, check to see if there is

anything nearby which suggests that a potential

hazard might exist. For example, a laboratory might

use organic compounds which, when they evaporate,

make the room air volatile. Potentially dangerous conditions might be seen or smelled. The presence of

substances such as cleaners, paint thinners, gasoline,

alcohol, solvents, explosives, or similar items should

be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine,

and take appropriate action.

[2] Unauthorized Modifications

Konica has gained a reputation for manufacturing

reliable products. This has been attained by the combination of outstanding design and knowledgeable

service forces.

The design of the equipment is extremely important. It

is the design process that determines tolerances and

safety margins for mechanical, electrical, and electronic aspects. It is not reasonable to expect individuals not involved in product engineering to know what

effect may be caused by altering any aspect of the

machine’s design. Such changes have the potential of

degrading product performance and reducing safety

margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical

size differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace

or eliminate any fuse (including temperature

fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion

other than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

[3] General Safety Guidelines

This machine has been examined in accordance with

the laws pertaining to various product safety regulations prior to leaving the manufacturing facility to protect the operators and service personnel from injury.

However, as with any operating device, components

will break down through the wear-and-tear of everyday

use, as will additional safety discrepancies be discovered. For this reason, it is important that the technician

periodically performs safety checks on the machine to

maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the machine is

disconnected from its power source before continuing.

v

• Look for sharp edges, burrs, and damage on all

external covers and the machine frame.

• Inspect all cover hinges for wear (loose or bro-

ken).

• Inspect cables for wear, frays, or pinched areas.

• Ensure that the power cord insulation is not

damaged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND)

of the power cord to the frame of the machine -ensure continuity. An improperly grounded machine can cause an electrically-charged machine frame.

[4] Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to

any electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

[5] Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to clean

parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that

the alcohol has evaporated completely before

applying power or installing covers.

[6] Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each machine

must be thoroughly inspected with respect to safety

considerations as part of every routine service call.

The operability of the machine, and more importantly,

the safety of those who operate or service the machine, are directly dependent upon the conscientious

effort of each and every technician.

Remember...when performing service calls, use good

judgement (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the copier

as well as those who service the copier depend on it!

• Do not make any adjustments outside of the

specified range.

vi

INTRODUCTION

INTRODUCTION

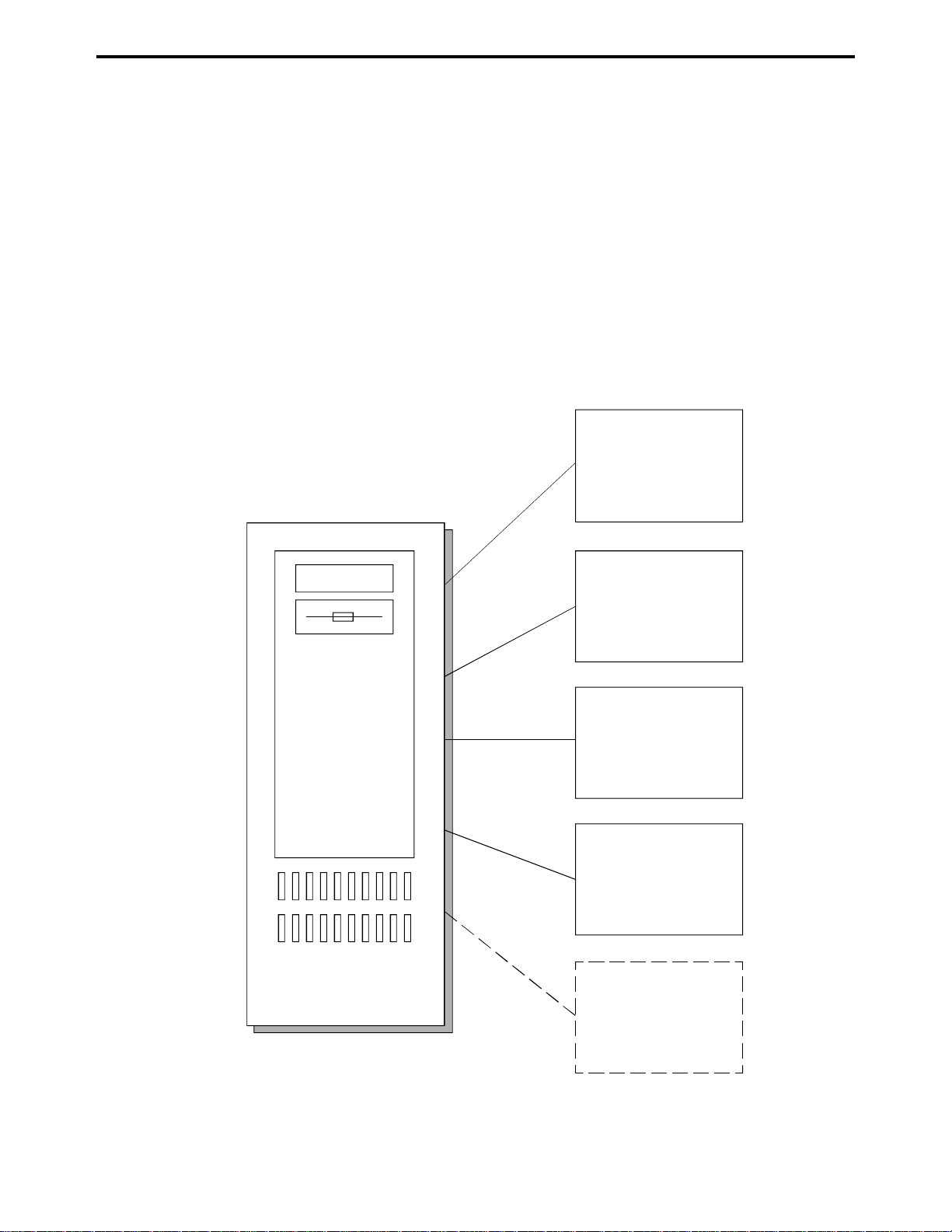

The IP-302 is an image processor that connects the model

7060 copier to a computer or computer network, allowing

it to be used as a printer. The image processor receives files

from the computer or network and translates them into

images to be printed on the copier/printer. Features and

specifications are given in the introduction section of the

controller's User’s Manual.

A video interface kit must be installed to connect the IP-302

to the 7060. Detailed instructions are given in the installation section of this manual. This section also provides

instructions for installing the optional PostScript® upgrade

kit and the network interface cards available for the IP-302.

Other information included in this manual are: product

configuration; disassembly and assembly procedures;

troubleshooting tips; and an appendix section that includes

software installation and CMOS setup instructions,

motherboard jumper settings for setup verification, and

various tables containing error messages, beep codes,

and copier codes to assit the technician while troubleshooting. This manual is to be used as a supplement to the 7060

Service Manual.

Note: The IP-302, KN-101/KN-201 User's Manuals are not

included in this publication.

Pentium 200 MHz

DOS, Floppy Drive,

540 MB Hard Drive,

Serial & Parallel

IP-302

PostScript®

& PCL-5E

Interpreters

16 - 128 MB Image

and Processing

Memory

7060 Copier Interface

Card (CIC)*

(Image Transfer,

Operation Panel,

Status Information)

Optional Ethernet

Network Interface

Card

* The copier interface card (CIC) has also been referred to as

the printer control board (PCB) in other text.

1 - 1

INTRODUCTION

Start-up Process

When powering up these units, the initialization can be

made in either sequence: turning ON the IP-302 first or

turning ON the 7060 copier/printer first. The start-up process

is as follows (in this case, turning ON the IP-302 first):

1. Turn the IP-302 ON. The CIC (copier interface card), which

interfaces with the printer, starts up. The CIC indicates to

the printer that it is running and then waits for the printer

to power up. The CPU in the IP-302 tests the system

memory and then boots up.

2. Turn the copier ON. It sees that the IP-302 is connected

and running, and goes into the printer mode.

3. The CIC and the printer establish a link. The CIC initiates

transfer of configuration information.

4. After the system memory is tested (this will take a few

minutes), DOS boots up and then the system software

loads.

5. When the system is fully configured, READY is displayed. Printing may begin.

When a document is sent to be printed, the following

process takes place (see the diagram on page 1-3):

Data enters the IP-302 through the Ethernet card or one of

the I/O ports. The I/O controller software evaluates and

spools the data to either the PCL-5E interpreter or the

PostScript® interpreter. The interpreter then generates an

image into memory in bitmat form, which then travels

through the CIC to the printer.

1 - 2

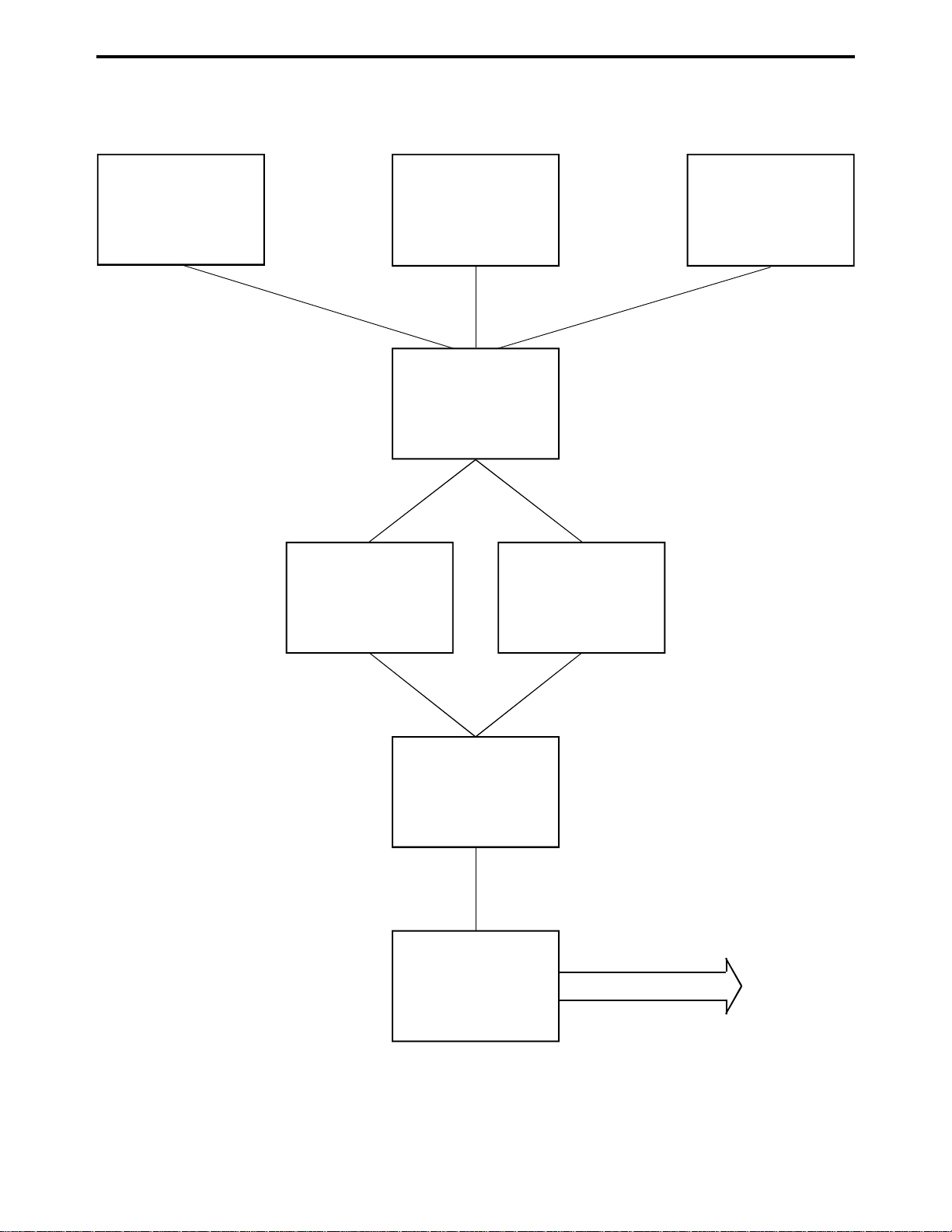

Data Flow Diagram

INTRODUCTION

Ethernet Card Serial Port

PCL-5E Interpreter

Parallel Port

I/O Controller Software

(with spooler)

PostScript

Interpreter

Image Memory

7060 Copier

Interface Card (CIC)

1 - 3

To 7060

INTRODUCTION

This page left blank intentionally.

1 - 4

INSTALLATION

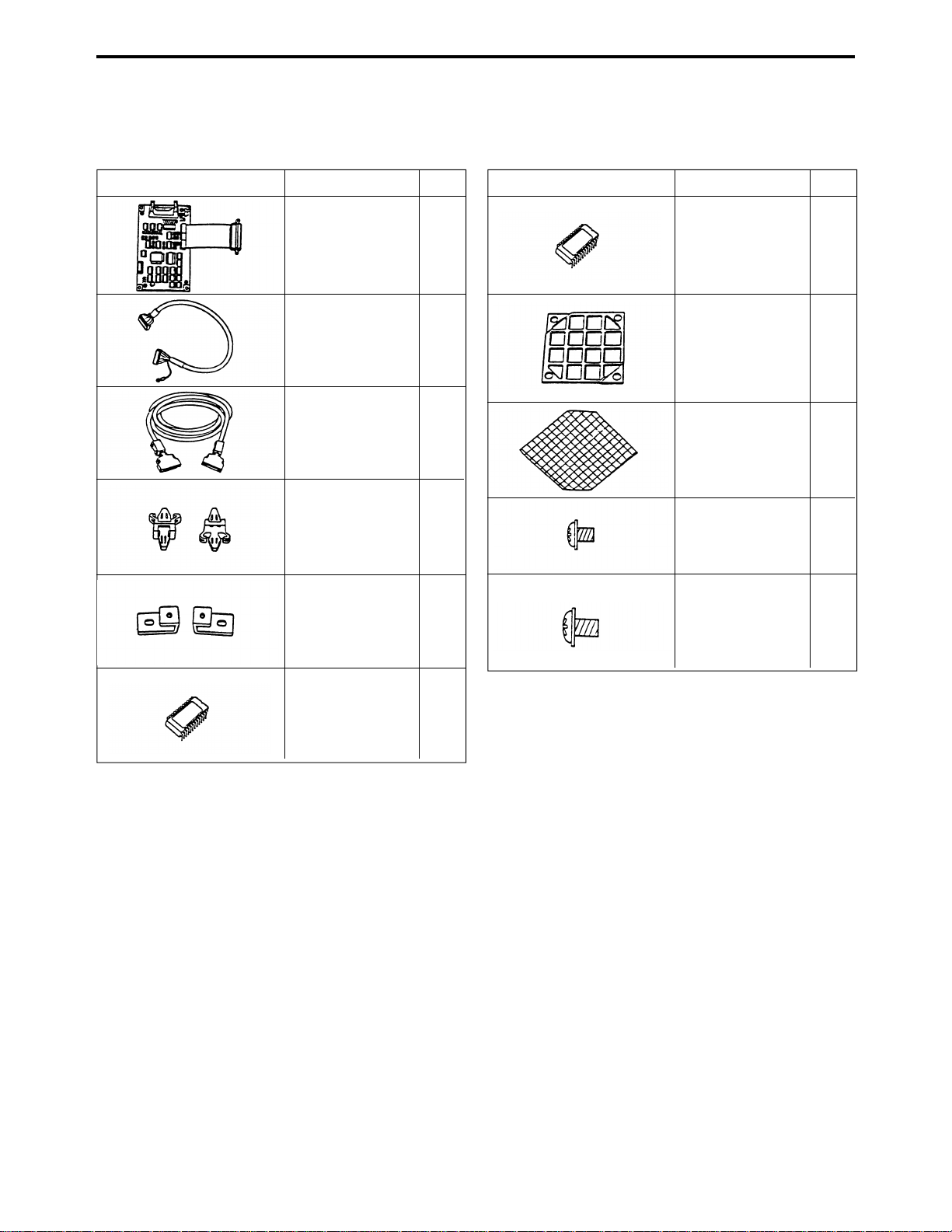

[1] Video Interface Kit (p/n: PC/UA 950–791)

INSTALLATION

CONTENTS

PART NAME QTY

Printer I/F board

[12ST-9010]

Wiring 1

[12ST90160]

Printer wiring

[12ST90190]

Board support

spacer

[12ST73970]

Board ground

plate

[12ST73980]

CONTENTS

1

1

1

2

2

PART NAME QTY

Main control

EPROM 2 (C2)

[12ST-9160]

Filter support

plate

[25AA73221]

Cleaner cooling

filter

[25AA73230]

TP screw (M3x4)

[00Z193041]

TP screw (M4x6)

[00Z194141]

1

1

1

4

1

Main control

EPROM 1 (C1)

[123G-9210]

1

2 - 1

Loading...

Loading...