Page 1

LASER IMAGER

Service Manual

Manufacturer:

2970 Ishikawa-machi, Hachioji-shi Tokyo 192-8505 Japan

CODE NO.0921(UL)

0922(CE)

Page 2

Page 3

Introduction

DRYPRO 832 is a totally dry processing laser imager. This product is easy to use and environmentally friendly

while maintaining sophisticated features and high image quality.

This manual provides repair precautions and a series of steps for service engineers who repair this machine (or

system including this machine).

This manual should be kept in a place handy for quick reference.

Cautions

1. Unauthorized reproduction of any part of this manual is prohibited.

2. The contents of this manual are subject to change without notice.

3. Any discrepancies, errors or omissions noted should be communicated to the manufacturer.

4. Notwithstanding item 3. above, the manufacturer accepts no responsibility whatsoever for any loss or

decrease in profits arising from usage of the product.

Trademark

Microsoft and Windows are registered trademarks or trademarks of Microsoft Corporation in the United

•

States and/or other countries.

• Windows 2000/XP stands for Microsoft Windows 2000/XP Professional operating system.

• Other company names and product names in this document are trademarks or registered trademarks of their

respective owners.

i

Page 4

How to Read This Manual

Structure of This Manual

This manual provides prior representations for safety and the method for repairing this machine in

below:

Chapter 1: Safety Precautions and Warnings

This chapter provides basic precautions which should be followed when repairing or using DRYPRO 832.

Thoroughly read this chapter before starting work and instruct users to familiarize with these precautions.

Chapter 2: Before Starting Repair Work

This chapter provides basic knowledge about the product before starting repair work on DRYPRO 832.

Chapter 3: Basic Operations

This chapter describes basic operations when repairing DRYPRO 832, including the procedures for installing or

removing a supply tray and exterior cover, opening or closing covers, and wearing a grounding strap.

Chapter 4: Replacing Supply Unit Loading Parts

This chapter describes how to replace loading parts in the supply unit when they fail and how to adjust after

replacing the loading parts.

Chapter 5: Replacing Tray Unit Loading Parts

This chapter describes how to replace loading parts in the tray unit when they fail and how to adjust after replacing

the loading parts.

eighteen

chapters

Chapter 6: Replacing Lispl-832 (Optional) Loading Parts

This chapter describes how to replace loading parts in Lispl-832 (optional) when they fail and how to adjust after

replacing the loading parts.

Chapter 7: Replacing Sub Scan Unit Loading Parts

This chapter describes how to replace loading parts in the sub scan unit when they fail and how to adjust after

replacing the loading parts.

Chapter 8: Replacing Loading Parts in Exposure Unit

This chapter describes how to replace loading parts in the exposure unit when they fail and how to adjust after

replacing the loading parts.

Chapter 9: Replacing Loading Parts in Heat Process Unit

This chapter describes how to replace loading parts in the heat process unit when they fail and how to adjust after

replacing the loading parts.

Chapter 10: Replacing Ejection Unit

This chapter describes how to replace loading parts in the ejection unit when they fail and how to adjust after

replacing the loading parts.

Chapter 11: Replacing Loading Parts in Main Unit

This chapter describes how to replace loading parts in the main unit when they fail and how to adjust after replacing

the loading parts.

Chapter 12: Replacing Loading Parts in the Exterior of Main Unit

This chapter describes how to replace loading parts in the exterior section of the main unit when they fail and how to

adjust after replacing the loading parts.

Chapter 13: Replacing and Cleaning Loading Parts on a Regular Basis

This chapter describes the procedures for replacing and cleaning loading parts on a regular basis.

Chapter 14: Setting and Adjustment

This chapter describes various setting and adjustment procedures for DRYPRO 832.

Chapter 15: DRYPRO 832 Utility Tool

This chapter describes each item of DRYPRO 832 Utility Tool.

ii

Page 5

Chapter 16: MainteTool

This chapter describes various maintenance using the service PC.

Chapter 17: Troubleshooting

This chapter provides solutions for errors that may occur.

Chapter 18: Technical Information

This chapter describes the technical information on block diagrams, wiring diagrams, board drawings, and function

timing charts for the DRYPRO 832.

iii

Page 6

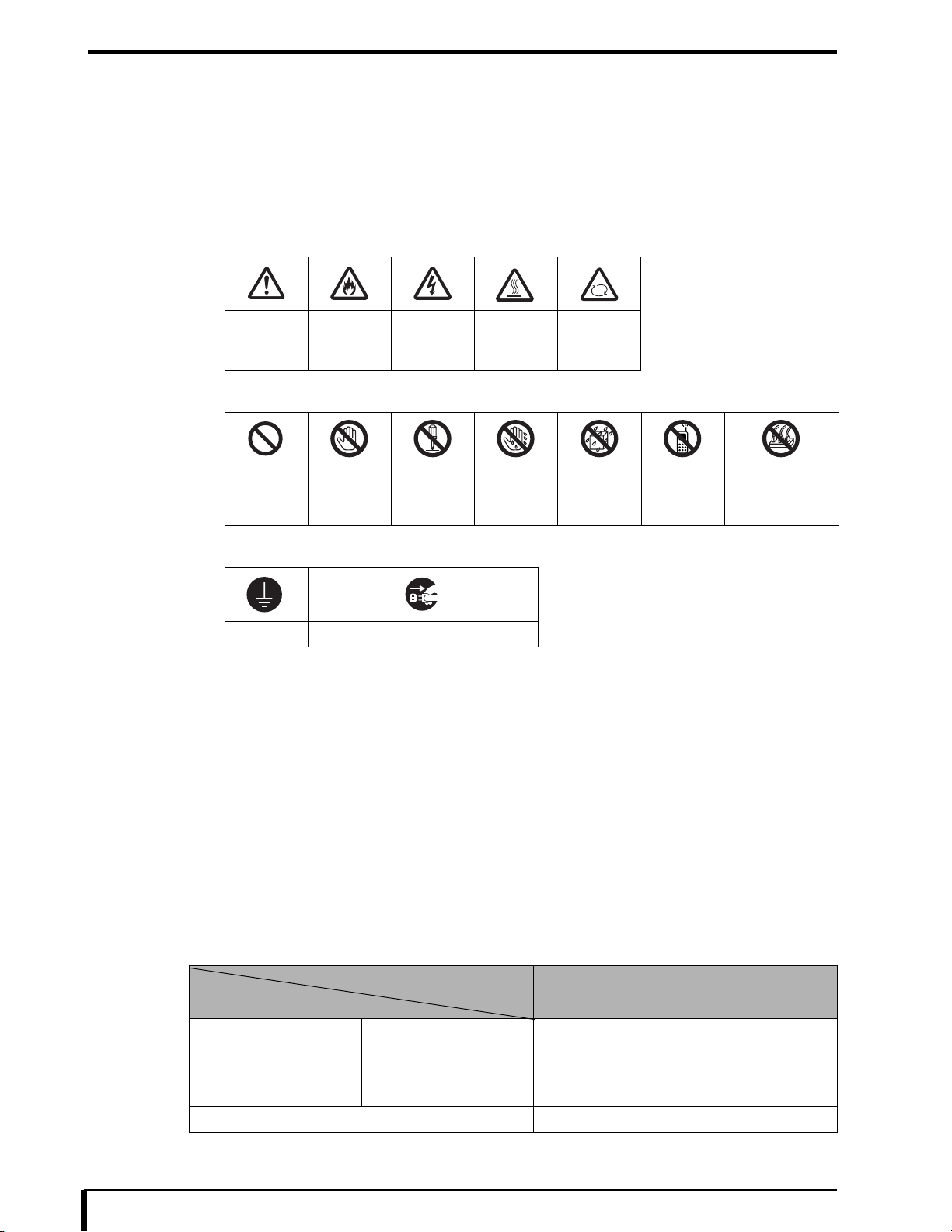

Alert Symbol Marks

Alert symbols alert the person(s) who installs this machine (or system including this machine) and other people to

matters and/or operation potentially hazardous to them when installing it.

Read these messages and follow instructions carefully.

Be sure to read all instructions and safety standards and become thoroughly familiar with the product before

installing this machine.

Description of Safety Signage

Symbols indicating that care (including danger and warnings) should be taken:

•

• Prohibition signs (indicating prohibited acts):

• Symbols indicating compulsory or required acts:

Signal Words

Signal words designate a degree or level of hazard seriousness inherent in products.

Signal words include the following three types, which are used according to risk of damage caused by danger and

the severity of damage:

General

Precautions

Prohibited Do not

Ground Remove plug from electrical outlet

Danger of

Fire

touch

Danger of

Electric

Shocks

Do not

disassemble

Danger of

Temperature

touch with

a wet hand

High

Do not

Danger of

Rotation

Do not

expose to

moisture

No mobile

phones

Star-burst

connection

prohibited

DANGER

Used to indicate an immediate and imminent danger that, if not avoided, is likely to cause death or serious injury,

serious property damage such as total loss of equipment and fire.

WARNING

Used to indicate a consequential (potential) danger that, if not avoided, is likely to cause death or serious injury,

serious property damage such as total loss of equipment and fire.

CAUTION

Used to indicate hazards that, if not avoided, could result in minor or moderate injury or cause partial loss of

equipment and computer data loss.

Risk of damage

High Low

Bodily injury

(or property damage)

Property damage only CAUTION

Death or serious injury

(serious damage)

Minor or moderate injury

(minor damage)

DANGER WARNING

WARNING or

CAUTION

CAUTION

iv

Page 7

Contents

Contents

Introduction......................................................................................... i

How to Read This Manual ................................................................. ii

Structure of This Manual..................................................................ii

Alert Symbol Marks .......................................................................... iv

Signal Words .................................................................................... iv

Chapter 1 Safety Precautions and Warnings...................................1-1

1.1 Warning Labels ........................................................................1-2

1.1.1 Positions and Types of Warning Labels................................ 1-2

1.2 Safety Precautions...................................................................1-4

1.2.1 Precautions Following Requirements of

Laws and Regulations .......................................................... 1-4

1.2.2 General Precautions............................................................. 1-7

1.2.3 Handling Precautions ........................................................... 1-8

1.2.4 Servicing Precautions ........................................................... 1-9

1.2.5 Disposing of Parts................................................................. 1-9

Chapter 2 Before Starting Repair Work ...........................................2-1

2.1 Names of Parts ........................................................................2-2

2.1.1 Unit Exterior.......................................................................... 2-2

2.1.2 Unit Interior ........................................................................... 2-3

2.1.3 Supply Tray........................................................................... 2-3

2.1.4 Lispl-832 (optional) ............................................................... 2-4

2.2 Structure...................................................................................2-4

2.3 Tools, Measuring Instruments, and Jigs Necessary

for Servicing .............................................................................2-5

Chapter 3 Basic Operations.............................................................3-1

3.1 Removing/Installing Supply Tray..............................................3-2

3.2 Opening/Closing Cover............................................................3-4

3.2.1 Opening/Closing Front Cover ............................................... 3-4

3.2.2 Opening/Closing Right Cover ............................................... 3-5

3.3 Removing/Installing Exterior Cover..........................................3-6

3.3.1 Removing/Installing Lower Right Cover................................ 3-6

3.3.2 Removing/Installing Film Ejection Tray............................... 3-10

3.3.3 Removing/Installing Upper Right Cover.............................. 3-12

3.3.4 Removing/Installing Rear Cover ......................................... 3-18

3.3.5 Removing/Installing Rear Cover (Lispl-832) ....................... 3-20

3.3.6 Removing/Installing Left Cover........................................... 3-22

3.4 Installing a Grounding Strap...................................................3-24

3.5 Manually Unlocking the Tray..................................................3-24

Chapter 4 Replacing Supply Unit Loading Parts..............................4-1

4.1 Light Shield Unit.......................................................................4-2

4.1.1 Placing Loading Parts........................................................... 4-2

4.1.2 Removing/Installing Light Shield Assembly .......................... 4-3

4.1.3 Replacing Barrier Bag Detection Sensor .............................. 4-6

4.1.4 Replacing Film Height Detection Sensor .............................. 4-8

4.2 Pickup Unit.............................................................................4-10

4.2.1 Placing Loading Parts......................................................... 4-10

4.2.2 Removing/Installing Pickup Unit Assembly......................... 4-11

4.2.3 Replacing Pickup Transport Motor ..................................... 4-15

4.2.4 Replacing Pickup HP Motor................................................ 4-18

4.2.5 Replacing Pickup HP Sensor ............................................. 4-20

1

Page 8

Contents

Chapter 5 Replacing Tray Unit Loading Parts .................................5-1

5.1 Placing Loading Parts ..............................................................5-2

5.2 Replacing Supply Elevating Motor ...........................................5-3

5.3 Replacing Elevating Plate HP Sensor......................................5-6

5.4 Replacing Tray Lock Solenoid ...............................................5-10

5.5 Replacing Tray Detection Sensor ..........................................5-15

5.6 Replacing Outlet Light Shield Unit Assembly.........................5-20

Chapter 6 Replacing Lispl-832 (Optional) Loading Parts.................6-1

6.1 Light Shield Unit.......................................................................6-2

6.1.1 Placing Loading Parts........................................................... 6-2

6.2 Pickup Unit...............................................................................6-3

6.2.1 Placing Loading Parts........................................................... 6-3

6.3 Supply Unit...............................................................................6-4

6.3.1 Placing Loading Parts........................................................... 6-4

6.3.2 Replacing Elevating Transport Motor ................................... 6-5

6.4 Elevating Transport Unit...........................................................6-8

6.4.1 Removing/Installing Elevating Transport Unit....................... 6-9

6.4.2 Replacing Elevating Transport Nip

Opening/Closing Motor....................................................... 6-13

6.4.3 Replacing Elevating Transport Nip

Opening/Closing HP Sensor............................................... 6-15

6.4.4 Replacing Supply Outlet Sensor......................................... 6-18

Chapter 7 Replacing Sub Scan Unit Loading Parts.........................7-1

7.1 Placing Loading Parts ..............................................................7-2

7.2 Removing/Installing Sub Scan Unit (Including

the Exposure Unit and Position Regulation Unit).....................7-4

7.3 Replacing Sub Scan Unit (Including the

Position Regulation Unit)........................................................7-10

7.4 Replacing Right Cover Detection Sensor...............................7-12

7.5 Replacing Position Regulation Inlet Sensor...........................7-15

7.6 Replacing Position Regulation Transport Motor.....................7-19

7.7 Replacing Moderation belt .....................................................7-23

7.8 Replacing Transfer belt..........................................................7-25

7.9 Replacing Sub Scan Transport Motor....................................7-27

7.10 Replacing Sub Scan Nip Motor..............................................7-30

7.11 Replacing Sub Scan Inlet Sensor ..........................................7-34

7.12 Replacing Sub Scan Nip HP Sensor......................................7-38

7.13 Replacing V-sync Sensor.......................................................7-40

7.14 Replacing Reference Guide...................................................7-44

Chapter 8 Replacing Exposure Unit ................................................8-1

8.1 Placing Exposure Unit..............................................................8-2

8.2 Replacing Exposure Unit..........................................................8-3

Chapter 9 Replacing Loading Parts in Heat Process Unit ............... 9-1

9.1 Heat Process Unit Side............................................................9-2

9.1.1 Removing/Installing Heat Process Unit ................................ 9-3

9.1.2 Replacing Heater.................................................................. 9-7

9.1.3 Replacing Heat Process Temperature Sensor ..................... 9-8

9.1.4 Replacing Supply Cooling Fan ............................................. 9-9

9.2 Main Unit Side........................................................................ 9-11

9.2.1 Replacing Heat Process Motor ........................................... 9-12

9.2.2 Replacing Heat Process Cooling Fans 1 and 2 .................. 9-14

9.2.3 Replacing Deodorant Filter Detection Sensor .................... 9-16

9.2.4 Replacing Insulation Unit Fan............................................. 9-18

9.2.5 Replacing Deodorant Fan................................................... 9-20

2

Page 9

Contents

9.2.6 Replacing Internal Temperature Sensor ............................. 9-22

Chapter 10 Replacing Ejection Unit.................................................10-1

10.1 Placing Ejection Unit ..............................................................10-2

10.2 Replacing Ejection Unit..........................................................10-3

Chapter 11 Replacing Loading Parts in Main Unit........................... 11-1

11.1 Placing Loading Parts ............................................................ 11-2

11.2 Replacing Front Cover Sensor............................................... 11-3

11.3 Replacing Main Board............................................................ 11-7

11.4 Replacing Compact Flash.................................................... 11-11

11.5 Replacing MEC Board..........................................................11-14

11.6 Replacing Multiple Power Supply.........................................11-17

11.7 Replacing H-DRV Board ...................................................... 11-20

11.8 Replacing Noise Filter .......................................................... 11-22

11.9 Replacing Control Cooling Fan ............................................ 11-25

Chapter 12 Replacing Loading Parts in the Exterior of Main Unit....12-1

12.1 Placing Loading Parts ............................................................12-2

12.2 Removing/Installing Exterior of Operation Panel ...................12-3

12.3 Replacing LCD Board ............................................................12-6

12.4 Replacing Status Lamp ..........................................................12-8

12.5 Replacing Operation Switch Board ...................................... 12-11

Chapter 13

Replacing and Cleaning Loading Parts on a Regular Basis

13.1 Periodic Maintenance Tasks ..................................................13-2

13.2 Replacing Pickup Roller.........................................................13-3

13.3 Replacing Opposed Roller .....................................................13-7

13.4 Cleaning Guide ....................................................................13-11

13.5 Cleaning Control Box Intake Air Filter..................................13-13

13.6 Power Supply Unit Intake Air Filter Cleaning .......................13-14

...13-1

Chapter 14 Setting and Adjustment .................................................14-1

14.1 Image Unevenness Correction...............................................14-2

14.1.1 Density Correction .............................................................. 14-3

14.2 Checking and Adjusting Image Data Writing Position..........14-13

14.2.1 Checking Image Data Writing Position ............................. 14-13

14.2.2 Adjusting Main Scan OFFSET (Lateral)

Writing Position................................................................. 14-15

14.2.3 Adjusting Sub Scan OFFSET (Vertical)

Writing Position................................................................. 14-16

14.3 Checking and Fine Tuning the Print Size.............................14-17

14.3.1 Checking Print Size .......................................................... 14-17

14.3.2 Main Scan OFFSET Adjustment ...................................... 14-19

14.3.3 Sub Scan OFFSET Adjustment........................................ 14-20

Chapter 15 DRYPRO 832 Utility Tool ..............................................15-1

15.1 DRYPRO 832 Utility Tool Start ...............................................15-2

15.2 Print Queue/Delete.................................................................15-7

15.3 Print Condition........................................................................15-9

15.4 Test Print ..............................................................................15-12

15.5 Custom Border Setup...........................................................15-14

15.6 QC Pattern ...........................................................................15-15

15.7 Logo Setup...........................................................................15-16

15.8 Film Data..............................................................................15-18

15.9 Film Setup............................................................................15-20

15.10 Calibration Setup..................................................................15-23

3

Page 10

Contents

15.11 System Setup.......................................................................15-25

15.12 Time Layout .........................................................................15-28

15.13 System Reset.......................................................................15-30

15.14 Maintenance Schedule.........................................................15-31

15.15 HPRO Setup ........................................................................15-33

15.16 MEC Setup...........................................................................15-36

15.17 Product Setup ......................................................................15-37

15.18 Image Adjust ........................................................................15-39

15.19 Error History .........................................................................15-41

15.20 Densitometer........................................................................15-42

15.20.1 Built-in Densitometer Calibration ...................................... 15-42

15.20.2 Confirming After Density Calibration................................. 15-49

15.20.3 Creating QC PATTERN BASE.......................................... 15-51

15.21 Data Initialize........................................................................15-54

Chapter 16 MainteTool.....................................................................16-1

16.1 MainteTool Outline .................................................................16-2

16.2 Setting up Network.................................................................16-3

16.2.1 Connecting Service PC ...................................................... 16-3

16.2.2 Setting up Network for Service PC ..................................... 16-4

16.2.3 Sharing the Mainte_Tool Folder.......................................... 16-6

16.3 How to Start the MainteTool ...................................................16-9

16.4 Upgrade Information ............................................................16-12

16.5 Backing up Setup.................................................................16-15

16.5.1 Backup Method up to V1.01 ............................................. 16-15

16.5.2 Backup Method for V1.02 and Later................................. 16-18

16.5.3 Backing Up To MECH EEPROM ...................................... 16-25

16.6 Restoring Settings................................................................16-26

16.6.1 Restore Method up to V1.01............................................. 16-26

16.6.2 Restore Method for V1.02 and Later ................................ 16-29

16.7 Collecting Logs.....................................................................16-33

16.8 Collecting Job Data..............................................................16-37

16.9 IMAGER MEC I/O TEST ......................................................16-39

16.10 IMAGER PRINT I/O TEST ...................................................16-49

16.10.1 Measuring Laser Beam Intensity ...................................... 16-51

Chapter 17 Troubleshooting ............................................................17-1

17.1 Solutions When Trouble Occurs ............................................17-2

17.1.1 The DRYPRO 832 main unit will not start........................... 17-2

17.1.2 The DRYPRO 832 stops during startup.............................. 17-3

17.1.3 An error message is displayed ........................................... 17-4

17.1.4 Film Jam ............................................................................. 17-4

17.1.5 Trouble while using DRYPRO 832 ..................................... 17-4

17.1.6 Does not exit (shutdown).................................................... 17-5

17.1.7 Pickup malfunction trouble ................................................. 17-6

17.1.8 Print Image Trouble ............................................................ 17-7

17.2 Error display and solutions...................................................17-14

17.2.1 Operating panel display and solutions.............................. 17-14

17.2.2 Display and solutions for MainteTool ................................ 17-58

17.3 DRYPRO 832 Unit Replacement Procedure........................17-62

17.3.1 Replacing Main Board ...................................................... 17-63

17.3.2 Replacing the Compact Flash (CF) .................................. 17-64

17.3.3 Replacing the DRYPRO 832 ............................................ 17-82

17.3.4 Replacing Printlink5-IN ..................................................... 17-95

17.3.5 Replacing the MEC Board .............................................. 17-106

4

Page 11

Contents

Chapter 18 Technical Information ...................................................18-1

18.1 Placing Electronic Parts .........................................................18-2

18.1.1 Supply Unit ......................................................................... 18-2

18.1.2 Lispl-832 (Optional) ............................................................ 18-3

18.1.3 Sub Scan Unit, Justification Unit ........................................ 18-4

18.1.4 Heat Process Unit............................................................... 18-5

18.1.5 Ejection Unit ....................................................................... 18-6

18.1.6 Main Unit ............................................................................ 18-6

18.1.7 Exterior of Main Unit ........................................................... 18-7

18.2 Placing Mechanical Parts.......................................................18-8

18.2.1 Supply Unit ......................................................................... 18-8

18.2.2 Lispl-832 ............................................................................. 18-9

18.2.3 Sub Scan Unit, Justification Unit ...................................... 18-10

18.2.4 Exposure Unit ................................................................... 18-11

18.2.5 Heat Process Unit............................................................. 18-12

18.2.6 Ejection Unit ..................................................................... 18-13

18.2.7 Main Unit .......................................................................... 18-13

18.3 Board Diagram.....................................................................18-14

18.3.1 Main Board ....................................................................... 18-14

18.3.2 Main ScanRV, EEP Board Diagram.................................. 18-15

18.3.3 LCD Unit Board Diagram.................................................. 18-16

18.3.4 Operation SW Board Diagram .......................................... 18-16

18.3.5 STATUS LED Board Diagram........................................... 18-17

18.3.6 Multiple Power Supply ...................................................... 18-17

18.3.7 Noise Filter ....................................................................... 18-18

18.3.8 MEC Board Drawing......................................................... 18-19

18.4 Film Management Information .............................................18-21

18.4.1 Management Information Print Specifications .................. 18-21

18.5 Block Diagram......................................................................18-23

18.6 Writing Diagram ...................................................................18-24

18.7 Printing Operation Load Timing Chart (Standard 1 ch) ........18-29

18.8 Printing Operation Load Timing Chart (Standard 2 ch) ........18-30

5

Page 12

Page 13

Chapter

Chapter 1 Safety Precautions and

1

Warnings

This chapter presents safety precautions you need to know prior to

starting repair work on the product.

1.1 Warning Labels..................................................1-2

1.1.1 Positions and Types of Warning Labels ....... 1-2

1.2 Safety Precautions.............................................1-4

1.2.1 Precautions Following Requirements of

Laws and Regulations.................................. 1-4

1.2.2 General Precautions .................................... 1-7

1.2.3 Handling Precautions ................................... 1-8

1.2.4 Servicing Precautions .................................. 1-9

1.2.5 Disposing of Parts ........................................ 1-9

Page 14

Chapter 1 Safety Precautions and Warnings

1.1 Warning Labels

Various warning labels are attached to DRYPRO 832 on locations shown below:

When performing installation or maintenance work such as repairs, understand the meaning of warning labels and

be very careful in handling locations where warning labels are affixed to.

To avoid an accident during servicing work, do not remove or contaminate the label attached to. If the

Caution

1.1.1 Positions and Types of Warning Labels

information on the label is unreadable as it came unstuck or was contaminated, replace the label with a new one.

No. Precautions/Warning Labels

1 Laser Warning

2 Class 1 Laser Product

3 Caution Hot Label

4

Caution Hot (130 ℃ ) Label

1-2

Page 15

Chapter 1 Safety Precautions and Warnings

No. Precautions/Warning Labels

5 Laser Power Label

1-3

Page 16

Chapter 1 Safety Precautions and Warnings

1.2 Safety Precautions

Read all safety precautions thoroughly before using the product.

Be sure to observe the safety precautions described in this section.

1.2.1 Precautions Following Requirements of Laws and Regulations

Caution as to laser control

To prevent danger, make sure that only service engineers who received proper formal

training will remove the exterior cover or touch the inside of the equipment.

DRYPRO 832 Laser Unit Specifications

Item Specifications

Wavelength 784nm

Maximum output 260mW

(1) EMC Statement - DRYPRO 832 has been tested and found to comply with the limits for medical devices to the

IEC 60601-1-2: 2001, Medical Device Directive 93/42/EEC or the Electromagnetic Compatibility Directive 89/

336/EEC (use applicable directive). These limits are designed to provide reasonable protection against harmful

interference in a typical medical installation. DRYPRO 832 generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to other

devices in the vicinity. However, there is no guarantee that interference will not occur in a particular installation.

If DRYPRO 832 does cause harmful interference to other devices, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving device.

- Increase the separation between the equipment.

- Connect the equipment into an outlet on a circuit different from that to which the other device(s) are connected.

- Consult the manufacturer or field service technician for help.

(2) EMC Statement - Take precautions against DRYPRO MODEL 832 especially regarding EMC. Install and put

into service according to the EMC information provided in the manual.

(3) EMC Statement - Do not use mobile phones or pocket pagers in the vicinity of the DRYPRO MODEL 832. Use

of mobile phones or pocket pagers near the DRYPRO MODEL 832 can cause errors in operation due to

electromagnetic wave interference : such devices should be turned off in the vicinity of the unit.

(4) EMC Statement - Cable List

- AC Power Cable (3m)

(5) EMC Statement - The use of accessories, transducers and cables other than those specified, with the exception of

transducers and cables sold by KONICA MINOLTA MEDICAL & GLAPHIC, INC. as for internal components,

may result in increased emissions or decreased immunity of DRYPRO 832.

(6) EMC Statement - Do not use adjacent to or stacked with other equipment. If adjacent or stacked use is necessary,

confirm normal operation in the configuration in which DRYPRO 832 will be used.

1-4

Page 17

Chapter 1 Safety Precautions and Warnings

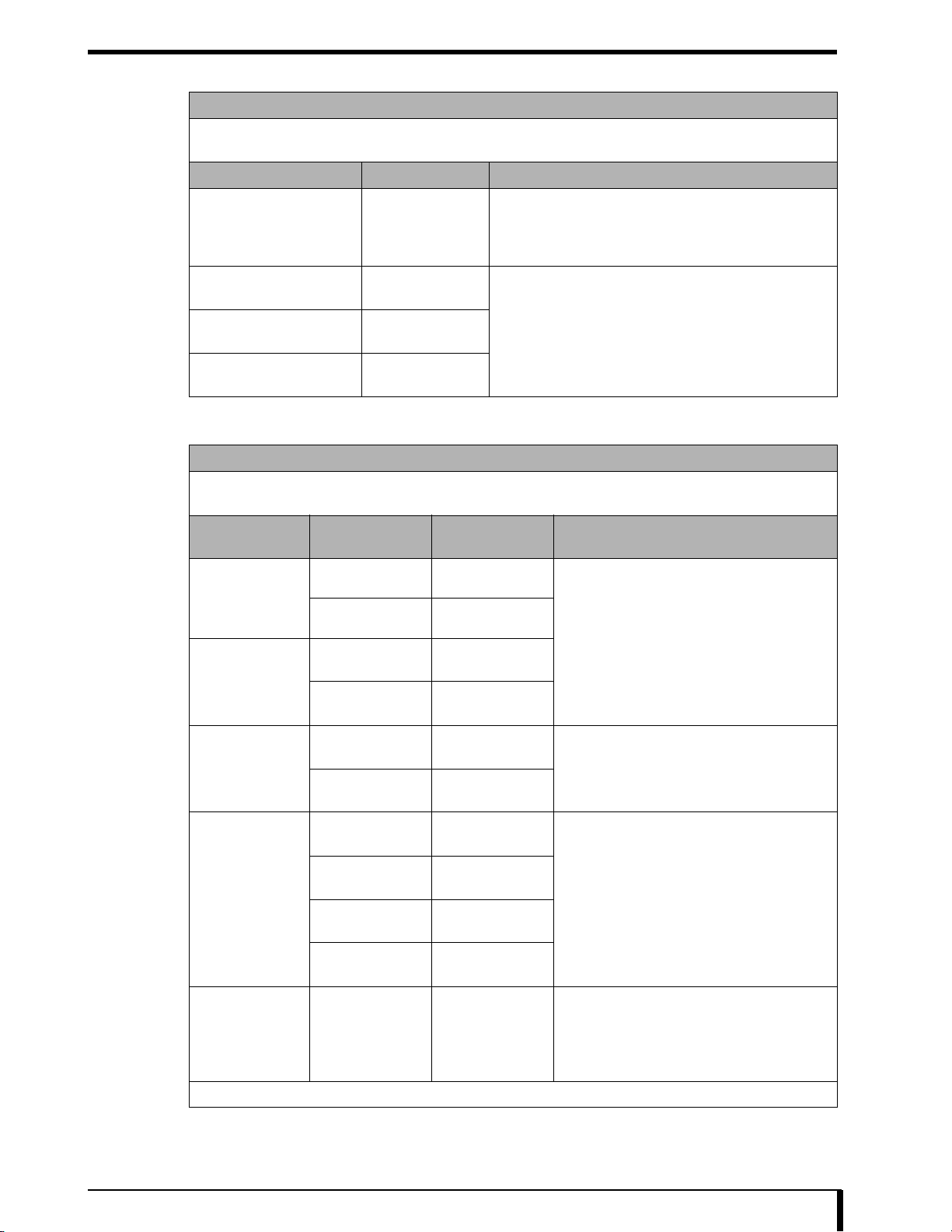

(7) EMC Statement

Guidance and manufacturer's declaration - electromagnetic emissions

The DRYPRO 832 is intended for use in the electromagnetic environment specified below.

The customer or the user of the DRYPRO 832 should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

The DRYPRO 832 uses RF energy only for its internal

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/flic

IEC 61000-3-3

Group 1

Class B

Class A

Applicable

(8) EMC Statement

Guidance and manufacturer’s declaration - electromagnetic immunity

The DRYPRO 832 is intended for use in the electromagnetic environment specified below.

The customer or the user or the DRYPRO 832 should assure that it is used in such an environment.

Immunity test

IEC 60601

test level

Compliance level Electromagnetic environment - guidance

function. Therefore, its RF emissions are very low and are

not likely to cause any interference in nearby electronic

equipment.

The DRYPRO 832 is suitable for use in all establishments

other than domestic and those directly connected to the

public low-voltage power supply network that supplies

buildings used for domestic purposes.

Electrostatic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

IEC 61000-4-11

Power frequency

(50/60Hz)

magnetic field

IEC 61000-4-8

±6kV contact ±6kV contact

±8kV air ±8kV air

±2kV for power

supply lines

±1kV for input/

output lines

±1kV

differential mode

±2kV

common mode

T (>95% dip

<5% U

in U

T) for 0.5 cycle

T (60% dip

40% U

in UT) for 5 cycles

T (30% dip

70% U

T) for 25 cycles

in U

T> (<95%

<5% U

dip in U

T) for 5 sec

±2kV for power

supply lines

±1kV for input/

output lines

±1kV

differential mode

±2kV

common mode

T (>95% dip

<5% U

in U

T) for 0.5 cycle

40% UT (60% dip

in UT) for 5 cycles

70% U

T (30% dip

T) for 25 cycles

in U

T> (<95%

<5% U

dip in U

T) for 5 sec

3A/m 3A/m

Floors should be wood, concrete or ceramic tile.

If floors are covered with synthetic material, the

relative humidity should be at least 30%. Mains

power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment. If the user

of the DRYPRO 832 requires continued

operation during power mains interruptions, it is

recommended that the DRYPRO 832 be

powered from an uninterruptible power supply

or a battery.

Power frequency magnetic fields should be at

levels characteristic of a typical location in a

typical commercial or hospital environment.

[NOTE] U

T is the a.c. mains voltage prior to application of the test level.

1-5

Page 18

Chapter 1 Safety Precautions and Warnings

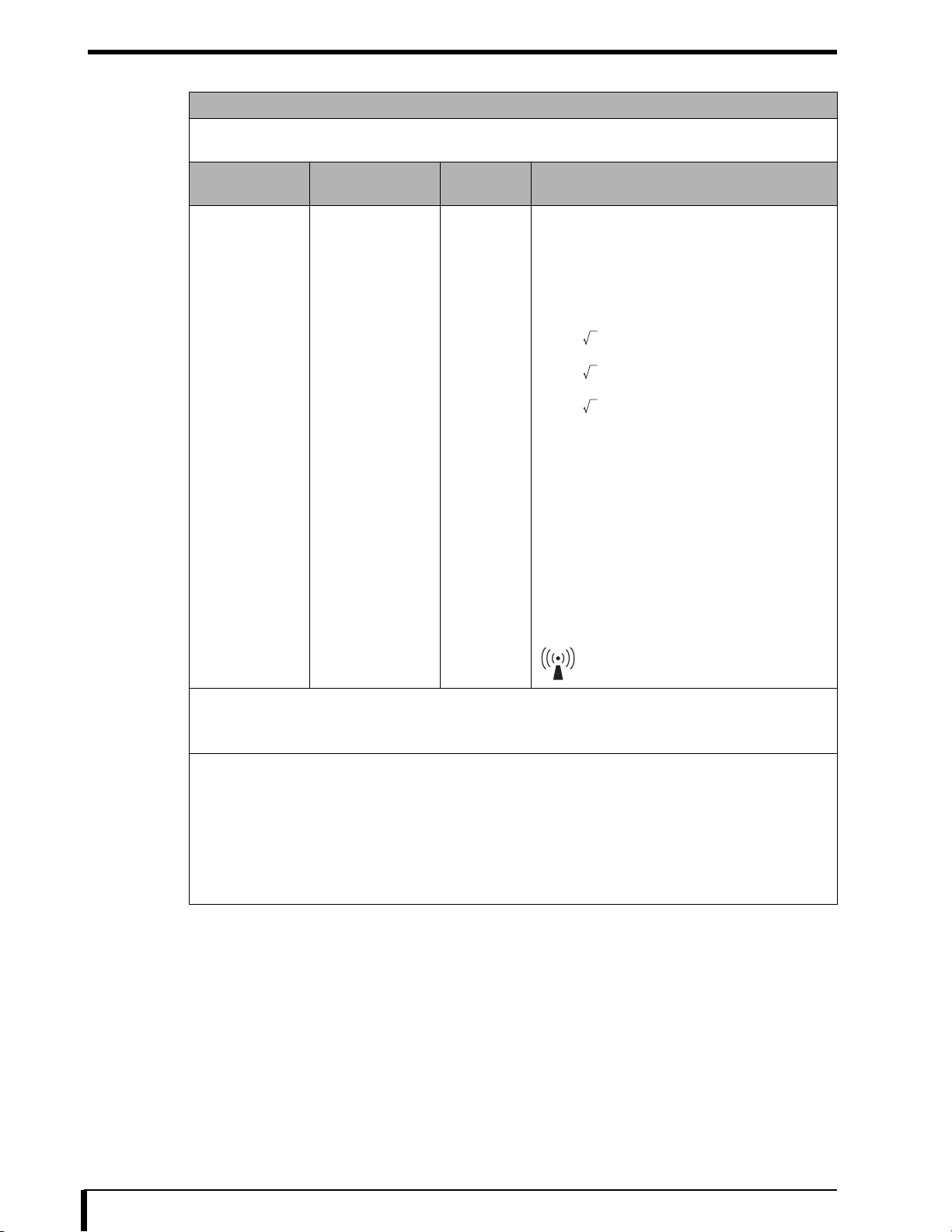

(9) EMC Statement

Guidance and manufacturer’s declaration - electromagnetic immunity

The DRYPRO 832 is intended for use in the electromagnetic environment specified below.

The customer or the user or the DRYPRO 832 should assure that it is used in such an environment.

Immunity test

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

IEC 60601

test level

3Vrms

150 kHz to 80 MHz

3V/m

80 MHz to 2.5 GHz

Compliance

level

[3]V

[3]V/m

Electromagnetic environment - guidance

Portable and mobile RF communications equipment

should be used no closer to any part of the DRYPRO

832, including cables, than the recommended

separation distance calculated from the equation

applicable to the frequency of the transmitter.

Recommended separation distance

d=[1.2] P

d=[1.2] P 80 MHz to 800 MHz

d=[2.3] P 800 MHz to 2.5 GHz

where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in metres (m)

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey,

should be less than the compliance level in each

frequency range.

b

a

Interference may occur in the vicinity of equipment

marked with the following symbol:

[NOTE] At 80 MHz and 800 MHz, the higher frequency range applies.

[NOTE] These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects and people.

a Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically

with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site

survey should be considered. If the measured field strength in the location in which the DRYPRO 832 is used

exceeds the applicable RF compliance level above, the DRYPRO 832 should be observed to verify normal

operation. If abnormal performance is observed, additional measures may be necessary, such as re- orienting or

relocation the DRYPRO 832.

b Over the frequency range 150 kHz to 80 MHz, field strengths should be less than [3]V/m.

1-6

Page 19

Chapter 1 Safety Precautions and Warnings

(10) EMC Statement

Recommended separation distances between

portable and mobile RF communications equipment and the DRYPRO 832

The DRYPRO 832 is intended for use in and electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the DRYPRO 832 can help prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and

the DRYPRO 832 as recommended below, according to the maximum output power of the communications

equipment.

Rated maximum output

power of transmitter

W

0.01 0.12 0.12 0.23

0.1 0.380.380.73

11.21.22.3

10 3.8 3.8 8

100 12 12 23

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in

metres (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the

maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

[NOTE] At 80 MHz and 800MHz, the separation distance for the higher frequency range applies.

[NOTE] These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects and people.

Separation distance according to frequency of transmitter

m

150 kHz to 80 MHz

d=[1.2] P

80 kHz to 800 MHz

d=[1.2] P

800 kHz to 2.5 GHz

d=[2.3] P

1.2.2 General Precautions

Do not perform work or operation not contained in this manual.

If you accidentally conduct work, you may burn yourself or get an electric shock due to a

hot section and high voltage point contained in this machine.

Make sure to follow safety precautions on warning labels.

Make sure to follow safety precautions contained in this manual and on warning labels

attached to this machine. Failure to observe this caution can cause personal injury or

damage to this machine.

This product is equipped with a laser generator (class 3B).

Avoid eye or skin exposure to direct laser, as it could cause serious injury.

Wear special safety glasses whenever you perform operation check or the like with the

power turned on.

This machine can handle Class 1 laser products with the safety interlock not released.

Anyone with a cardiac pacemaker should keep away from this machine.

There is the danger of causing electromagnetic interference with cardiac pacemakers.

Removing exterior covers

To prevent danger, make sure that only service engineers who received proper formal

training will remove the exterior cover or touch the inside of the product.

1-7

Page 20

Chapter 1 Safety Precautions and Warnings

1.2.3 Handling Precautions

If unusual noise, odor, or smoke comes from this product, stop operation.

If unusual noise, odor, or smoke coming from this product is detected, immediately stop

operation. If you continue to operate it with abnormal condition left as it is, it could cause

an electric shock, fire, or damage to the product.

Be careful not to trip over or trample on the power cable.

If you continue to use the damaged cable, it could cause an electric shock, heat

generation or fire.

Do not remove the power plug by pulling on the power cable.

This could cause a break in the power cable, resulting in heat generation or fire.

Do not put drink or foreign object on the product.

Do not put drink such as juice or foreign objects such as clips and pins on this machine. If

you use this product with water or foreign object such as metals entered in this machine,

it can cause a short in the internal circuit, resulting in fire.

Do not block air intakes or outlets of the product.

If air intakes or outlets of the product are blocked, it can cause failure of the product or

reduce the accuracy of reading images.

Do not leave objects standing on the product or do not step on it.

Failure to observe this caution can cause damage to the product.

Do not use equipment such as mobile phone that emits electromagnetic

waves.

If you use equipment such as mobile phone that emits electromagnetic waves near the

product, it can have negative effect on the product.

1-8

Page 21

1.2.4 Servicing Precautions

Do not insert a piece of wire or metal.

Do not insert foreign objects such as metal strip or wire through vent or gap in the main

unit. Failure to observe this could cause an electric shock.

Be sure to turn OFF when servicing.

If you pull out the circuit board in this machine or remove connectors and cables with the

power turned on, it can cause serious accident.

Make sure to turn OFF the main power supply before starting these operations.

Do not remove lithium batteries carelessly.

The product contains lithium batteries. If you bring a lithium battery near fire or immerse it

in water, it could cause an explosion.

When handling internal electronic components of the product, wear a

wristband.

When handling internal electronic components, wear an antistatic wristband.

If you touch an energized electronic component such as circuit board, it can cause

damage.

Chapter 1 Safety Precautions and Warnings

Unplug the unit or turn OFF the main power supply before cleaning.

Be sure to unplug the unit or turn OFF the main power supply before cleaning this

machine.

You could get your finger caught in sliding or rotating parts.

1.2.5 Disposing of Parts

This DRYPRO 832 product (including lithium batteries), accessories,

optional accessories, consumables, and media are designated as

industrial waste.

When disposing of these, be sure to have them disposed of by authorized industrial

waste disposal firm in accordance with the applicable ordinances and regulations of the

local government.

1-9

Page 22

Page 23

Chapter

Chapter 2 Before Starting Repair

2

Work

This chapter provides basic knowledge about the product before

starting repair work on DRYPRO 832.

2.1 Names of Parts ..................................................2-2

2.1.1 Unit Exterior ................................................. 2-2

2.1.2 Unit Interior................................................... 2-3

2.1.3 Supply Tray .................................................. 2-3

2.1.4 Lispl-832 (optional)....................................... 2-4

2.2 Structure ............................................................2-4

2.3 Tools, Measuring Instruments, and Jigs

Necessary for Servicing.....................................2-5

Page 24

Chapter 2 Before Starting Repair Work

2.1 Names of Parts

Names of the parts that you need to know when installing the DRYPRO 832 unit are shown below.

2.1.1 Unit Exterior

No. Name No. Name

1 Front Cover 2 Lower Front Cover

3 Right Cover 4 Supply Tray

5 Tray Shutter 6 Lower Right Cover

7 Film Ejection Tray 8 Upper Right Cover

9 LAN Cover 10 Rear Cover

11 Left Cover 12 Operation Panel

13 Operation Switch 14 Main Power Supply

15 Cutter Pocket/Cutter 16 Operation Sheet Box

17 Exhaust Ducts

2-2

Page 25

2.1.2 Unit Interior

No. Name No. Name

1 Lever A 2 Lever B

3 Deodorant Filter Case

(Internal: deodorant filter)

Chapter 2 Before Starting Repair Work

4 Stabilizer

5 External Guide Unit Assembly

2.1.3 Supply Tray

No. Name No. Name

1 Film Regulation Pin 2 Cutter Guide

3 Intermediate Plate

2-3

Page 26

Chapter 2 Before Starting Repair Work

2.1.4 Lispl-832 (optional)

No. Name No. Name

1 Right Cover 2 Rear Cover

2.2 Structure

The structure of DRYPRO 832 is shown below.

Film is fed in the order from No. 1 to No. 5 during the printing process.

However, if the Lispl-832 option is installed and film is loaded into the Lispl-832, film is fed in order from No.7 to

No.2.

1 2

No. Name Function

1 Supply Unit Picks up film in the supply tray one by one and transports to the justification

unit.

2 Justification Unit Regulates the horizontal position of the film transported from the supply unit

and transports it to the exposure unit.

3 Exposure Unit Scans laser beam in synchronization with the film transportation and writes

images on the film.

4 Heat Process Unit Processes the exposed film by heating.

5 Cooling Transport Unit Cools and discharges the heat processed film.

6 Deodorant Filter Removes odors emitted during the heat process. Periodic change is needed.

7 Lispl-832 (optional) Picks up film in Lispl-832 one by one and transports to the justification unit.

2-4

Page 27

Chapter 2 Before Starting Repair Work

2.3 Tools, Measuring Instruments, and Jigs Necessary for Servicing

In addition to the standard tools, the following tools, measuring instruments, and jigs are necessary for servicing

DRYPRO 832.

Name Remarks

Allen wrench

Stubby screwdriver

Cutter

Tape such as packaging tape

Laser goggles Those that block the laser wavelength of 784 nm.

Optical power meter The meter that can measure the laser wavelength of 784 nm.

IR card

Densitometer

Ethanol (ethyl alcohol)

Lens cleaner

Melamine foam Used to clean the heat process unit and cool transport unit.

Waste cloth (paper towel)

Vacuum cleaner

Cotton work gloves

Marking-off pin

2-5

Page 28

Page 29

Chapter

Chapter 3 Basic Operations

3

This chapter describes basic operations when repairing DRYPRO

832, including the procedures for installing or removing a supply tray

and exterior cover, opening or closing covers, and wearing a

grounding strap.

3.1 Removing/Installing Supply Tray........................3-2

3.2 Opening/Closing Cover......................................3-4

3.2.1 Opening/Closing Front Cover....................... 3-4

3.2.2 Opening/Closing Right Cover....................... 3-5

3.3 Removing/Installing Exterior Cover....................3-6

3.3.1 Removing/Installing Lower Right Cover ....... 3-6

3.3.2 Removing/Installing Film Ejection Tray ...... 3-10

3.3.3 Removing/Installing Upper Right Cover ..... 3-12

3.3.4 Removing/Installing Rear Cover ................ 3-18

3.3.5 Removing/Installing Rear Cover

(Lispl-832) .................................................. 3-20

3.3.6 Removing/Installing Left Cover .................. 3-22

3.4 Installing a Grounding Strap.............................3-24

3.5 Manually Unlocking the Tray............................3-24

Page 30

Chapter 3 Basic Operations

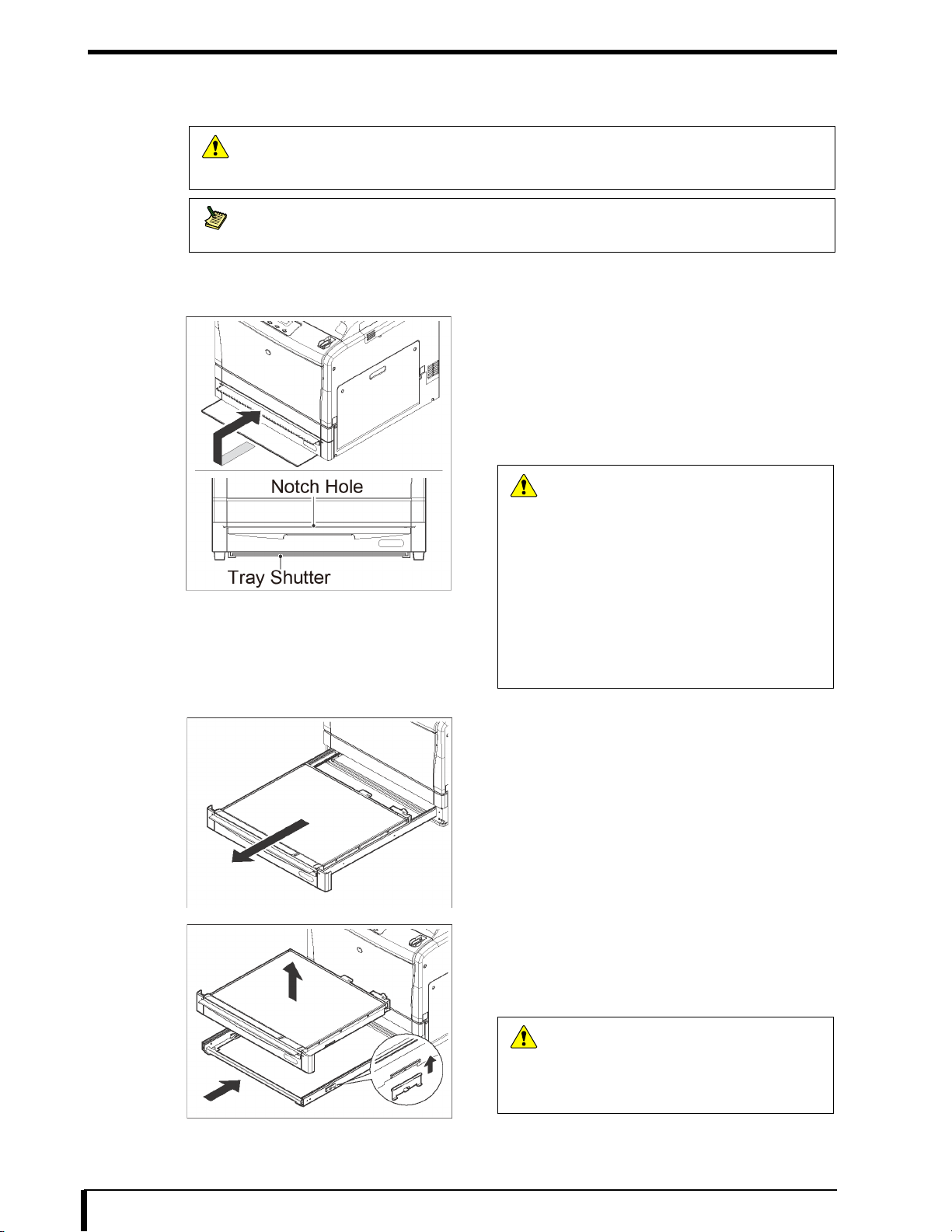

3.1 Removing/Installing Supply Tray

This section describes how to remove/install a supply tray.

Use the procedure for removing a supply tray provided here with power turned OFF when

Caution

installing or repairing DRYPRO 832. For information about how to remove a supply tray with

DRYPRO 832 turned ON, see the operation manual.

• Use the same procedure when removing Lispl-832 tray.

• When removing Lispl-832 tray, pull out the tray shutter on the lower part of Lispl-832.

Note

Removal Procedure

1 Pull the tray shutter out of the lower part of the

supply tray.

2 Insert the tray shutter into the slot in the upper

part of the supply tray with the tray shutter's UP

mark on the top surface toward you.

Inserting the tray shutter as far as it will go unlocks and

causes the supply tray to pop out several centimeters.

Caution

• When replacing loading parts, be sure to

replace with the tray shutter attached.

If some of the film remains on the tray, the

film may be exposed.

• Take sufficient care when handling the

tray shutter, as it may be impossible to

insert if it becomes deformed due to

rough handling.

• If you feel any resistance when inserting

the tray shutter, stop the procedure and

refer to “17.1.7 Pickup malfunction

trouble (Page 17-6)” to fix the problem.

3 Slowly pull out the supply tray fully.

4 Remove the tray from the rails.

Since the tray unit is held in by pins on both sides of the

rails, apply light pressure to remove.

5 Put the rails in the frame.

This is the end of the process of removing the supply tray.

Caution

If you leave the rails protruded, workers or other

people near by may come into contact with the

rails, resulting in personal injury or damage to the

equipment. Make sure to put the rails with the

tray unit removed in the frame.

3-2

Page 31

Installation Procedure

Chapter 3 Basic Operations

1 Pull out the rails.

2 Install the tray on the rails.

Place the supply tray so that the pinhole in the rails aligns

with the pin position on the back of the supply tray. Push in

the supply tray until it clicks into place.

• Be careful not to push the supply tray

Caution

excessively, as it can distort the rails.

• If the tray unit is not positioned properly, it

may interfere with the main unit and it

may become impossible to insert into the

unit.

3 Put the supply tray back into the main unit.

4 Remove the tray shutter and return it to the

previous position.

This is the end of the process of installing the supply tray.

Caution

Take sufficient care when handling the tray

shutter, as it may be impossible to insert if it

becomes deformed due to rough handling.

3-3

Page 32

Chapter 3 Basic Operations

3.2 Opening/Closing Cover

This section describes how to open or close the front cover and right cover.

3.2.1 Opening/Closing Front Cover

This section describes how to open or close the front cover.

How to open the front cover

1 Open the front cover.

The front cover will open by pulling its upper part on both

sides.

Do not push down or place objects on the

Caution

opened front cover. Failure to observe this

caution can cause the breakdown.

This is the end of the process of opening the front cover.

How to close the front cover

This is the end of the process of closing the front cover.

1 Close the front cover.

When closing the front cover, check that the two magnets at

the top edge of the front cover are in the correct position on

the main unit.

3-4

Page 33

3.2.2 Opening/Closing Right Cover

This section describes how to open or close the right cover.

How to open the right cover

Chapter 3 Basic Operations

1 Open the front cover.

The front cover will open by pulling its upper part on both

sides.

Do not push down or place objects on the

Caution

opened front cover. Failure to observe this

caution can cause the breakdown.

2 Open the right cover by rotating the lever B in the

direction of an arrow.

This is the end of the process of opening the right cover.

How to close the cover

This is the end of the process of closing the cover.

1 Close the right and front covers.

3-5

Page 34

Chapter 3 Basic Operations

3.3 Removing/Installing Exterior Cover

3.3.1 Removing/Installing Lower Right Cover

This section describes how to remove/install the lower right cover.

Be sure to turn off power and remove the power cable from the electrical outlet before removing

Caution

or installing the exterior cover or replacing loading parts.

Removal Procedure

1 Pull the tray shutter out of the lower part of the

supply tray.

2 Insert the tray shutter into the slot in the upper

part of the supply tray with the tray shutter's UP

mark on the top surface toward you.

Inserting the tray shutter as far as it will go unlocks and

causes it to pop out several centimeters.

Caution

• When replacing loading parts, be sure to

replace with the tray shutter attached.

If some of the film remains on the tray, the

film may be exposed.

• Take sufficient care when handling the

tray shutter, as it may be impossible to

insert if it becomes deformed due to

rough handling.

• If you feel any resistance when inserting

the tray shutter, stop the procedure and

refer to “17.1.7 Pickup malfunction

trouble (Page 17-6)” to fix the problem.

3 Remove the right cover screws.

・ Two screws (M4×8)

4 Open the front cover.

The front cover will open by pulling its upper part on both

sides.

Do not push down or place objects on the

Caution

opened front cover. Failure to observe this

caution can cause the breakdown.

3-6

Page 35

Chapter 3 Basic Operations

5 Open the right cover by rotating the lever B in the

direction of an arrow.

6 Remove the right cover from the external guide

unit assembly.

Slide the right cover upward, so that the tabs (four places)

inside the right cover are detached from the external guide

assembly, and then remove the cover.

7 Close the front cover and external guide unit

assembly.

8 Remove the lower right cover.

• Four screws (M4×8)

Slide the lower right cover downward so that the tabs (two

locations) on the lower right cover are detached from the

main unit, and then remove the cover.

This is the end of the process of removing the lower right cover.

3-7

Page 36

Chapter 3 Basic Operations

Cover Installation Procedure

1 Install the lower right cover.

• Four screws (M4×8)

Slide the lower right cover upward so that the tabs (two

locations) on the lower right cover hook onto the main unit

to install the cover.

2 Open the front cover.

The front cover will open by pulling its upper part on both

sides.

Do not push down or place objects on the

Caution

opened front cover. Failure to observe this

caution can cause the breakdown.

3 Open the right cover by rotating the lever B in the

direction of an arrow.

4 Install the right cover.

Hook the tabs (four locations) on the inside of the right cover

onto the external guide assembly, and slide the right cover

downward to install.

3-8

Page 37

Chapter 3 Basic Operations

5 Close the right and front covers.

6 Fit the right cover with screws.

• Two screws (M4×8)

7 Put the supply tray back into the main unit.

8 Remove the tray shutter and return it to its

original position.

Caution

This is the end of the process of installing the lower right cover.

Take sufficient care when handling the tray

shutter, as it may be impossible to insert if it

becomes deformed due to rough handling.

3-9

Page 38

Chapter 3 Basic Operations

3.3.2 Removing/Installing Film Ejection Tray

This section describes how to remove/install the film ejection tray.

Be sure to turn off power and remove the power cable from the electrical outlet before removing

Caution

or installing the exterior cover or replacing loading parts.

Removal Procedure

2 Remove the LAN cable from the connector cover

1 Remove the LAN cover.

slots.

3 Disconnect the LAN cable.

4 Remove the film ejection tray.

• Two screws (M4×8)

This is the end of the process of removing the film ejection tray.

3-10

Page 39

Installation Procedure

Chapter 3 Basic Operations

1 Install the film ejection tray.

• Two screws (M4×8)

2 Connect the LAN cable to the ethernet port.

3 Insert the LAN cable into the connector cover

slots.

4 Install the LAN cover.

First insert the tabs (two places) on the top side of the LAN

cover and then insert the tabs on the bottom side (two

places).

This is the end of the process of installing the film ejection tray.

3-11

Page 40

Chapter 3 Basic Operations

3.3.3 Removing/Installing Upper Right Cover

This section describes how to remove/install the upper right cover.

Be sure to turn off power and remove the power cable from the electrical outlet before removing

Caution

or installing the exterior cover or replacing loading parts.

Removal Procedure

1 Pull the tray shutter out of the lower part of the

2 Insert the tray shutter into the slot in the upper

supply tray.

part of the supply tray with the tray shutter's UP

mark on the top surface toward you.

Inserting the tray shutter as far as it will go unlocks and

causes it to pop out several centimeters.

• When replacing loading parts, be sure to

Caution

replace with the tray shutter attached.

If some of the film remains on the tray, the

film may be exposed.

• Take sufficient care when handling the

tray shutter, as it may be impossible to

insert if it becomes deformed due to

rough handling.

• If you feel any resistance when inserting

the tray shutter, stop the procedure and

refer to “17.1.7 Pickup malfunction

trouble (Page 17-6)” to fix the problem.

3 Remove the right cover screws.

• Two screws (M4×8)

4 Open the front cover.

The front cover will open by pulling its upper part on both

sides.

Do not push down or place objects on the

Caution

opened front cover. Failure to observe this

caution can cause the breakdown.

3-12

Page 41

Chapter 3 Basic Operations

5 Open the right cover by rotating the lever B in the

direction of an arrow.

6 Remove the right cover from the external guide

unit assembly.

Slide the right cover upward, so that the tabs (four places)

inside the right cover are detached from the external guide

assembly, and then remove the cover.

7 Close the front cover and external guide unit

assembly.

8 Remove the lower right cover.

• Four screws (M4×8)

Slide the lower right cover downward so that the tabs (two

locations) on the lower right cover are detached from the

main unit, and then remove the cover.

9 Remove the LAN cover.

3-13

Page 42

Chapter 3 Basic Operations

10 Remove the LAN cable from the connector cover

slots.

11 Disconnect the LAN cable.

12 Remove the film ejection tray.

• Two screws (M4×8)

13 Remove the connector cover.

14 Remove the upper right cover.

• Two screws (M4×8)

Slide the upper right cover upward so that the tab (one

location) on the upper right cover is detached from the main

unit, and then remove the cover.

This is the end of the process of removing the upper right cover.

3-14

Page 43

Installation Procedure

Chapter 3 Basic Operations

1 Install the upper right cover.

• Two screws (M4×8)

Slide the upper right cover downward so that the tab (one

location) on the upper right cover hooks onto the main unit

to install the cover.

2 Install the connector cover.

3 Install the film ejection tray.

• Two screws (M4×8)

4 Connect the LAN cable to the ethernet port.

3-15

Page 44

Chapter 3 Basic Operations

5 Insert the LAN cable into the connector cover

slots.

6 Install the LAN cover.

First insert the tabs (two places) on the top side of the LAN

cover and then insert the tabs on the bottom side (two

places).

7 Install the lower right cover.

• Four screws (M4×8)

Slide the lower right cover upward so that the tabs (two

locations) on the lower right cover hook onto the main unit

to install the cover.

8 Open the front cover.

The front cover will open by pulling its upper part on both

sides.

Do not push down or place objects on the

Caution

opened front cover. Failure to observe this

caution can cause the breakdown.

9 Open the right cover by rotating the lever B in the

direction of an arrow.

3-16

Page 45

Chapter 3 Basic Operations

10 Install the right cover.

Hook the tabs (four locations) on the inside of the right cover

onto the external guide assembly, and slide the right cover

downward to install.

11 Close the front and right covers.

12 Fit the right cover with screws.

• Two screws (M4×8)

13 Put the supply tray back into the main unit.

14 Remove the tray shutter and return it to its

original position.

Take sufficient care when handling the tray

Caution

shutter, as it may be impossible to insert if it

becomes deformed due to rough handling.

This is the end of the process of installing the upper right cover.

3-17

Page 46

Chapter 3 Basic Operations

3.3.4 Removing/Installing Rear Cover

This section describes how to remove/install the rear cover.

Be sure to turn off power and remove the power cable from the electrical outlet before removing

Caution

or installing the exterior cover or replacing loading parts.

Removal Procedure

1 Pull the tray shutter out of the lower part of the

supply tray.

2 Insert the tray shutter into the slot in the upper

part of the supply tray with the tray shutter's UP

mark on the top surface toward you.

Inserting the tray shutter as far as it will go unlocks and

causes it to pop out several centimeters.

• When replacing loading parts, be sure to

Caution

replace with the tray shutter attached.

If some of the film remains on the tray, the

film may be exposed.

• Take sufficient care when handling the

tray shutter, as it may be impossible to

insert if it becomes deformed due to

rough handling.

• If you feel any resistance when inserting

the tray shutter, stop the procedure and

refer to “17.1.7 Pickup malfunction

trouble (Page 17-6)” to fix the problem.

3 Remove the rear cover.

This is the end of the process of removing the rear cover.

• Six screws (M4×8)

Remove the upper two screws and the one screw

in the center from the rear cover and loosen the

Note

bottom three.

3-18

Page 47

Installation Procedure

Chapter 3 Basic Operations

1 Install the rear cover.

• Six screws (M4×8)

2 Put the supply tray back into the main unit.

3 Remove the tray shutter and return it to its

original position.

Take sufficient care when handling the tray

Caution

shutter, as it may be impossible to insert if it

becomes deformed due to rough handling.

This is the end of the process of installing the rear cover.

3-19

Page 48

Chapter 3 Basic Operations

3.3.5 Removing/Installing Rear Cover (Lispl-832)

This section describes how to remove/install Lispl-832 tray rear cover.

Be sure to turn off power and remove the power cable from the electrical outlet before removing

Caution

or installing the exterior cover or replacing loading parts.

Removal Procedure

1 Pull the tray shutter out of the lower part of the

supply tray.

2 Insert the tray shutter into the slot in the upper

part of the supply tray with the tray shutter's UP

mark on the top surface toward you.

Inserting the tray shutter as far as it will go unlocks and

causes it to pop out several centimeters.

Caution

• When replacing loading parts, be sure to

replace with the tray shutter attached.

If some of the film remains on the tray, the

film may be exposed.

• Take sufficient care when handling the

tray shutter, as it may be impossible to

insert if it becomes deformed due to

rough handling.

• If you feel any resistance when inserting

the tray shutter, stop the procedure and

refer to “17.1.7 Pickup malfunction

trouble (Page 17-6)” to fix the problem.

3 Remove the rear cover.

This is the end of the process of removing the rear cover.

• Six screws (M4×8)

3-20

Page 49

Installation Procedure

Chapter 3 Basic Operations

1 Install the rear cover.

• Six screws (M4×8)

2 Put the supply tray back into the main unit.

3 Remove the tray shutter and return it to its

original position.

Take sufficient care when handling the tray

Caution

shutter, as it may be impossible to insert if it

becomes deformed due to rough handling.

This is the end of the process of installing the rear cover.

3-21

Page 50

Chapter 3 Basic Operations

3.3.6 Removing/Installing Left Cover

This section describes how to remove/install the left cover.

Be sure to turn off power and remove the power cable from the electrical outlet before removing

Caution

or installing the exterior cover or replacing loading parts.

Removal Procedure

1 Pull the tray shutter out of the lower part of the

supply tray.

2 Insert the tray shutter into the slot in the upper

part of the supply tray with the tray shutter's UP

mark on the top surface toward you.

Inserting the tray shutter as far as it will go unlocks and

causes it to pop out several centimeters.

• When replacing loading parts, be sure to

Caution

replace with the tray shutter attached.

If some of the film remains on the tray, the

film may be exposed.

• Take sufficient care when handling the

tray shutter, as it may be impossible to

insert if it becomes deformed due to

rough handling.

• If you feel any resistance when inserting

the tray shutter, stop the procedure and

refer to “17.1.7 Pickup malfunction

trouble (Page 17-6)” to fix the problem.

3 Remove the left cover.

This is the end of the process of removing the left cover.

• Four screws (M4×8)

Slide the left cover upward so that the tabs (two locations)

on the inside of the left cover detach from the main unit, and

remove the cover.

Remove two screws on the upper part of the left

cover and loosen two screws on the lower part.

Note

3-22

Page 51

Installation Procedure

Chapter 3 Basic Operations

1 Install the left cover.

• Four screws (M4×8)

Slide the left cover downward so that the tabs (two

locations) inside the left cover hook onto the main unit to

install the cover.

2 Put the supply tray back into the main unit.

3 Remove the tray shutter and return it to its

original position.

Take sufficient care when handling the tray

Caution

shutter, as it may be impossible to insert if it

becomes deformed due to rough handling.

This is the end of the process of installing the rear cover.

3-23

Page 52

Chapter 3 Basic Operations

3.4 Installing a Grounding Strap

To avoid damage to the system board caused by electrostatic discharge, wear a wrist

Caution

grounding strap when accessing the system board for work.

3.5 Manually Unlocking the Tray

1 Ground yourself by using a wrist grounding strap

and put the other clip in a metal part of the main

unit that makes a good ground.

Caution

• Manually unlocking the tray is a method of releasing the tray lock when you can not insert

the tray shutter and/or can not pull out the supply tray due to some type of resistance within

the supply unit.

• Because the film inside the supply tray will be exposed when the tray is pulled out by

manually operating the tray lock lever, that film will no longer be usable.

1 Refer to step 3 of “3.3.4 Removing/Installing Rear

Cover (Page 3-18)” and remove the rear cover.

With the Lispl-832, refer to step 3 of “3.3.5

Removing/Installing Rear Cover (Lispl-832)

Note

(Page 3-20)” and remove the rear cover.

2 Pull the tray lock lever towards you.

The tray lock will be released.

3-24

Page 53

Chapter

Chapter 4 Replacing Supply Unit

4

Loading Parts

This chapter describes how to replace loading parts in the supply unit

when they fail and how to adjust after replacing the loading parts.

4.1 Light Shield Unit.................................................4-2

4.1.1 Placing Loading Parts .................................. 4-2

4.1.2

4.1.3 Replacing Barrier Bag Detection Sensor ..... 4-6

4.1.4 Replacing Film Height Detection Sensor ..... 4-8

4.2 Pickup Unit.......................................................4-10

4.2.1 Placing Loading Parts ................................ 4-10

4.2.2

4.2.3 Replacing Pickup Transport Motor............. 4-15

4.2.4 Replacing Pickup HP Motor ....................... 4-18

4.2.5 Replacing Pickup HP Sensor ..................... 4-20

Removing/Installing Light Shield Assembly

Removing/Installing Pickup Unit Assembly

... 4-3

... 4-11

Page 54

Chapter 4 Replacing Supply Unit Loading Parts

4.1 Light Shield Unit

4.1.1 Placing Loading Parts

The light shield unit in the supply unit includes the following loading parts.

No. Name Functions and Reference Sections

1 Barrier bag detection

sensor

2 Film height detection

sensor

This photo sensor detects the presence or absence of the barrier bag.

For more information, see “4.1.3 Replacing Barrier Bag Detection Sensor

(Page 4-6)”.

This photo sensor detects the height of film loaded in the supply tray.

For more information, see “4.1.4 Replacing Film Height Detection Sensor

(Page 4-8)”.

4-2

Page 55

Chapter 4 Replacing Supply Unit Loading Parts

4.1.2 Removing/Installing Light Shield Assembly

This section describes the procedure for removing or installing the light shield unit assembly when replacing loading

parts in the light shield unit.

Be sure to turn off power and remove the power cable from the electrical outlet before removing

Caution

Work outline

The number of personnel and the estimated work hours required to replace load parts is as follows:

or installing the exterior cover or replacing load parts.

Number of

Personnel

1 3 minutes each

Requirements

The procedure for replacing loading parts requires the following tools:

No. To ol s No. Tools

1 Various types of screwdrivers 2

Work Hours

Removal Procedure

1 Pull the tray shutter out of the lower part of the

2 Insert the tray shutter into the slot in the upper

Tray (container for screws and parts removed)

supply tray.

part of the supply tray with the tray shutter's UP

mark on the top surface toward you.

Inserting the tray shutter as far as it will go unlocks and

causes it to pop out several centimeters.

• When replacing loading parts, be sure to

Caution

replace with the tray shutter attached.

If some of the film remains on the tray, the

film may be exposed.

• Take sufficient care when handling the

tray shutter, as it may be impossible to

insert if it becomes deformed due to

rough handling.

• If you feel any resistance when inserting

the tray shutter, stop the procedure and

refer to “17.1.7 Pickup malfunction

trouble (Page 17-6)” to fix the problem.

3 Slowly pull out the supply tray fully.

Do not place objects on, lean on, or apply

Caution

4-3

loads on the pulled out supply tray.

Page 56

Chapter 4 Replacing Supply Unit Loading Parts

4 Remove the lower front cover.

• Two screws (M3×8)

5 Remove the connector (JJ48).

For Lispl-832, remove the Lispl-832 side connector (JJ48).

When removing the connector, do not pull by

Caution

the wires, but hold the tab on the connector

with your fingers.

Pulling by the wires too tightly can cause a

break.

This is the end of the process of removing light shield unit assembly.

• When replacing the barrier bag sensor, go to “4.1.3 Replacing Barrier Bag Detection Sensor (Page 4-6)”.

• When replacing the film height detection sensor, go to “4.1.4 Replacing Film Height Detection Sensor (Page

4-8)”.

Installation Procedure

6 Remove the light shield unit assembly.

• Two screws (M3×8)

When removing the light shield unit

Caution

assembly, be careful not to cause the sensor

to come into contact with the parts inside the

main unit.

1 Install the light shield unit assembly.

• Two screws (M3×8)

When installing the light shield unit

Caution

assembly, be careful not to cause the sensor

to come into contact with the parts inside the

main unit.

4-4

Page 57

Chapter 4 Replacing Supply Unit Loading Parts

2 Connect the connector (JJ48).

For Lispl-832, remove the Lispl-832 side connector (JJ48).

Be sure to push the connector all the way in

Caution

when connecting it.