Page 1

1179-7744-03.fm Page 0 Thursday, November 9, 2000 1:47 PM

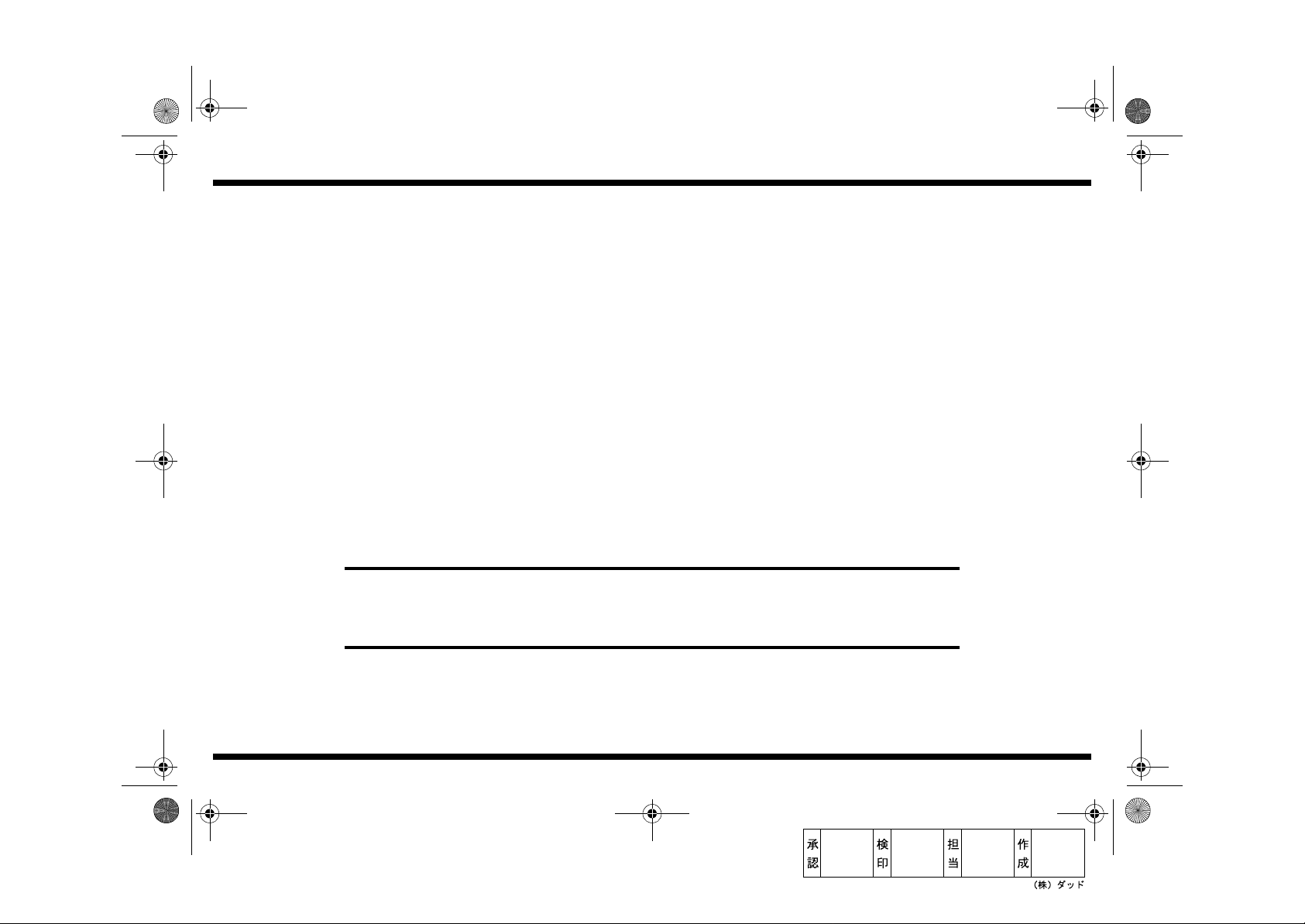

SETUP INSTRUCTIONS

CF9001

NOTE

•Keep all packing materials out of the reach of children.

•Before setting up, be sure to unplug the power cord of the copier.

•Keep all packing materials until you transport the machine to the customer.

1179-7744-03 © MINOLTA CO., LTD. Printed in Japan

Page 2

1179-7744-03.fm Page 1 Thursday, November 9, 2000 1:47 PM

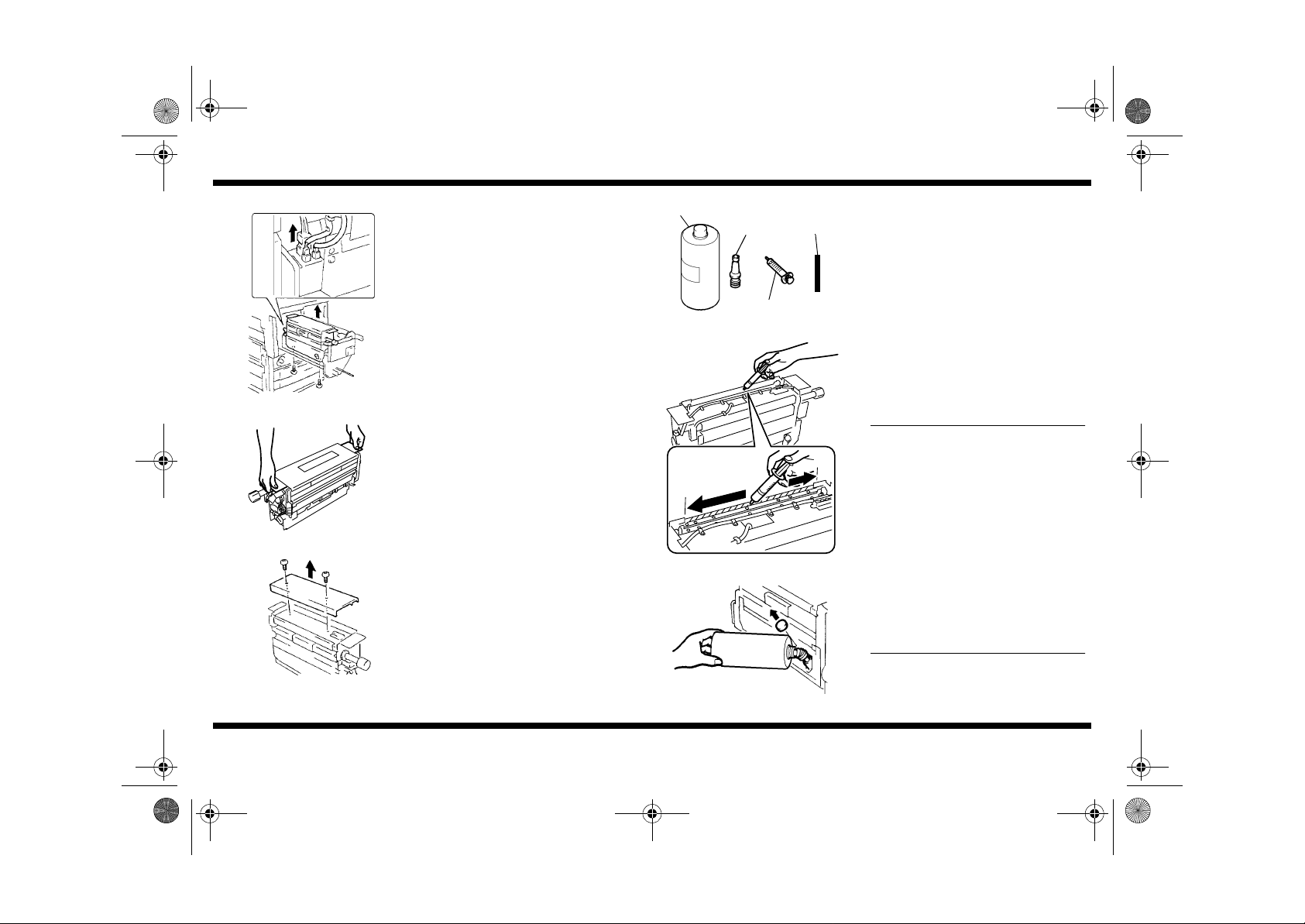

UNPACKING

■

1. Check to see that the following items are contained in the box of accessories.

CF9001

2. Peel off the pieces of tape and remove the cushions from the copier.

For Europe : Unwrap the power cord and plug it into the copier.

Copy Tray.................................................................................................1

PC Drum...................................................................................................1

Fusing Oil (For the U.S.A.).......................................................................1

Tube.........................................................................................................1

Syringe.....................................................................................................1

Cover........................................................................................................1

PC Drum Key ...........................................................................................1

Spring.......................................................................................................1

Starter Chute............................................................................................4

Labels................................................................................................. 1 set

Jumper Harness.......................................................................................1

Operator's Manual (For the U.S.A.)..........................................................1

Operator's Manual Holder ........................................................................1

Creative Image Book................................................................................1

Quick Guide..............................................................................................1

Stopper.....................................................................................................1

Mag Roller Shield.....................................................................................4

Screw (9739-0408-14)..............................................................................1

Power Cord (For the U.S.A.)....................................................................1

Customer Warranty Registration (For the U.S.A.)....................................1

Tape

Tape

Tape

ADJUSTING THE FEET

■

1179N001AA

Tape

Sheet

Tape

1179U001AC

Using a wrench, turn the Support Feet found

underneath the copier near the front two

corners.

CAUTION

To reduce the risk of injury due to

unstable equipment, adjust the Support

Feet before use.

1179-7744-03

– 1 –

Page 3

1179-7744-03.fm Page 2 Thursday, November 9, 2000 1:47 PM

CF9001

1144U003KA

1144U007KA

4460N001AA

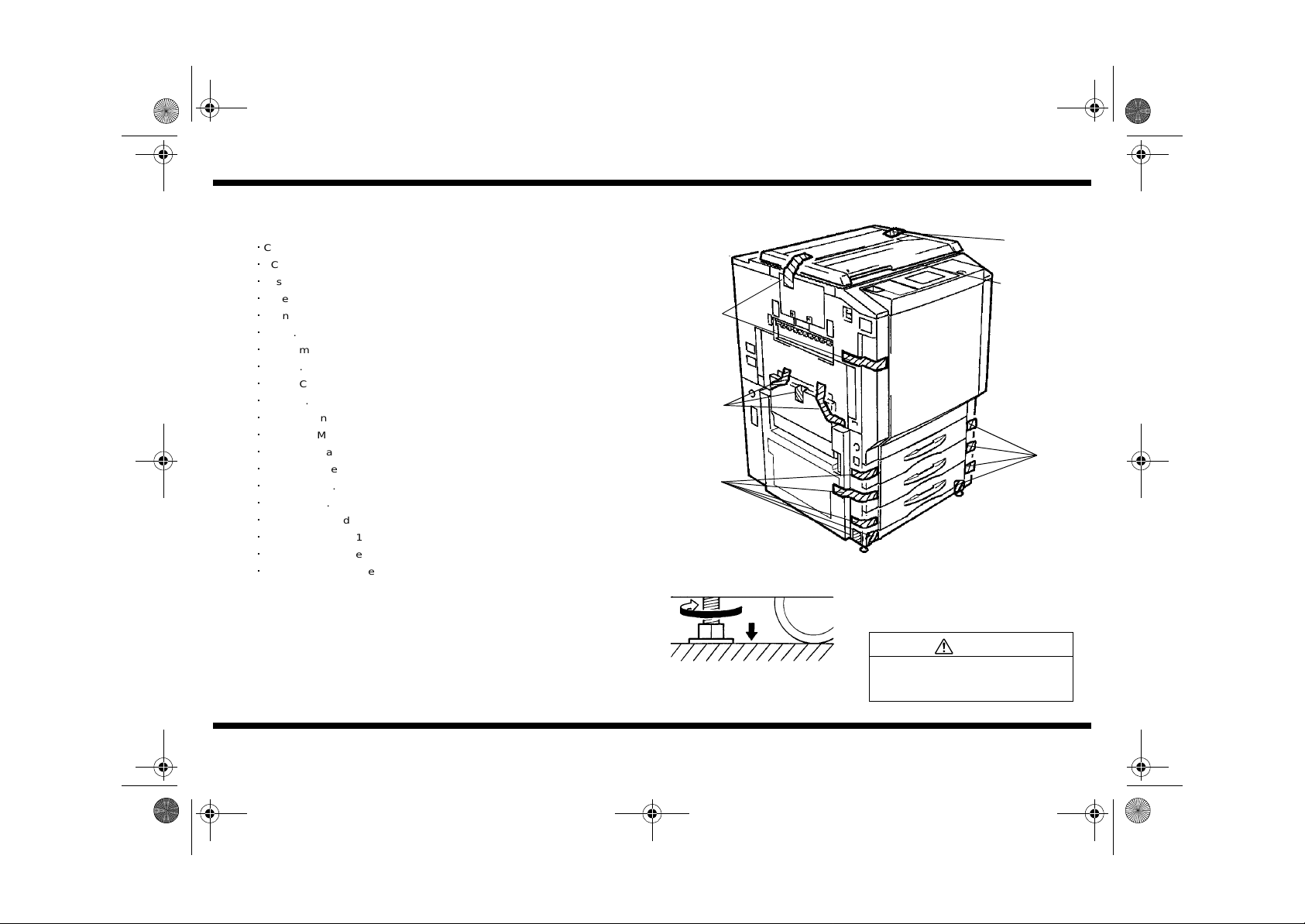

1. Turn the scanner locking pin about 90

°

counterclockwise and pull it out.

2. Attach the cover to the hole left by the

locking pin.

3. Remove the Right Upper Cover.

4. Remove two Original Glass Holders and

remove the Original Glass.

5. Remove three cushions and one Fixing

Plate.

1179U024AB

6. Install the Original Glass.

1179U023AA

7. Install the Right Upper Cover.

4447U054AA

8. Open the front door and secure the stopper

to the door with a screw.

Screw (4x8) x 1

1179U022AA

1179-7744-03

1144U011AA

– 2 –

Page 4

1179-7744-03.fm Page 3 Thursday, November 9, 2000 1:47 PM

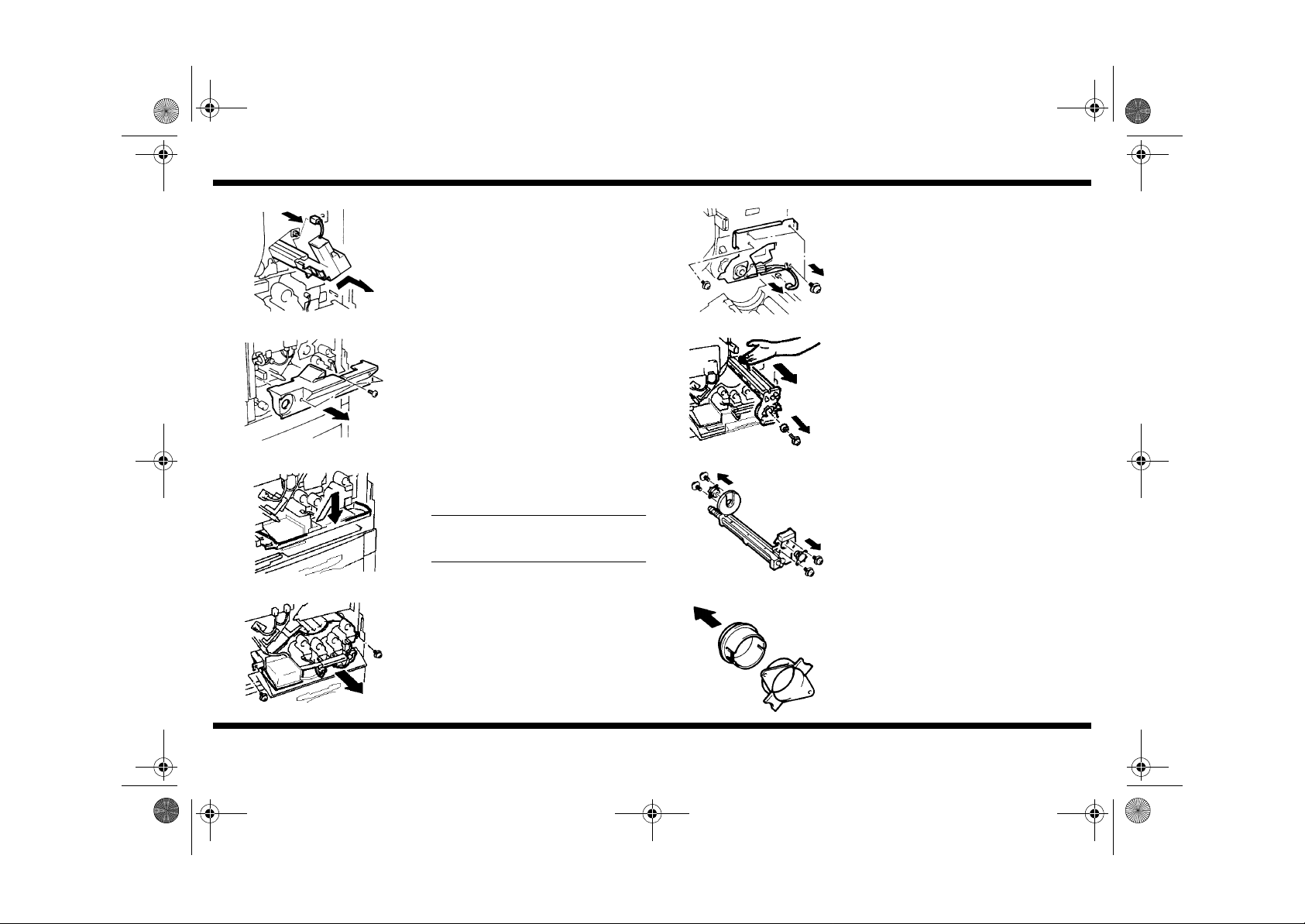

CF9001

1154U002AA

1179U002AA

1179U003AB

Holding

Plate

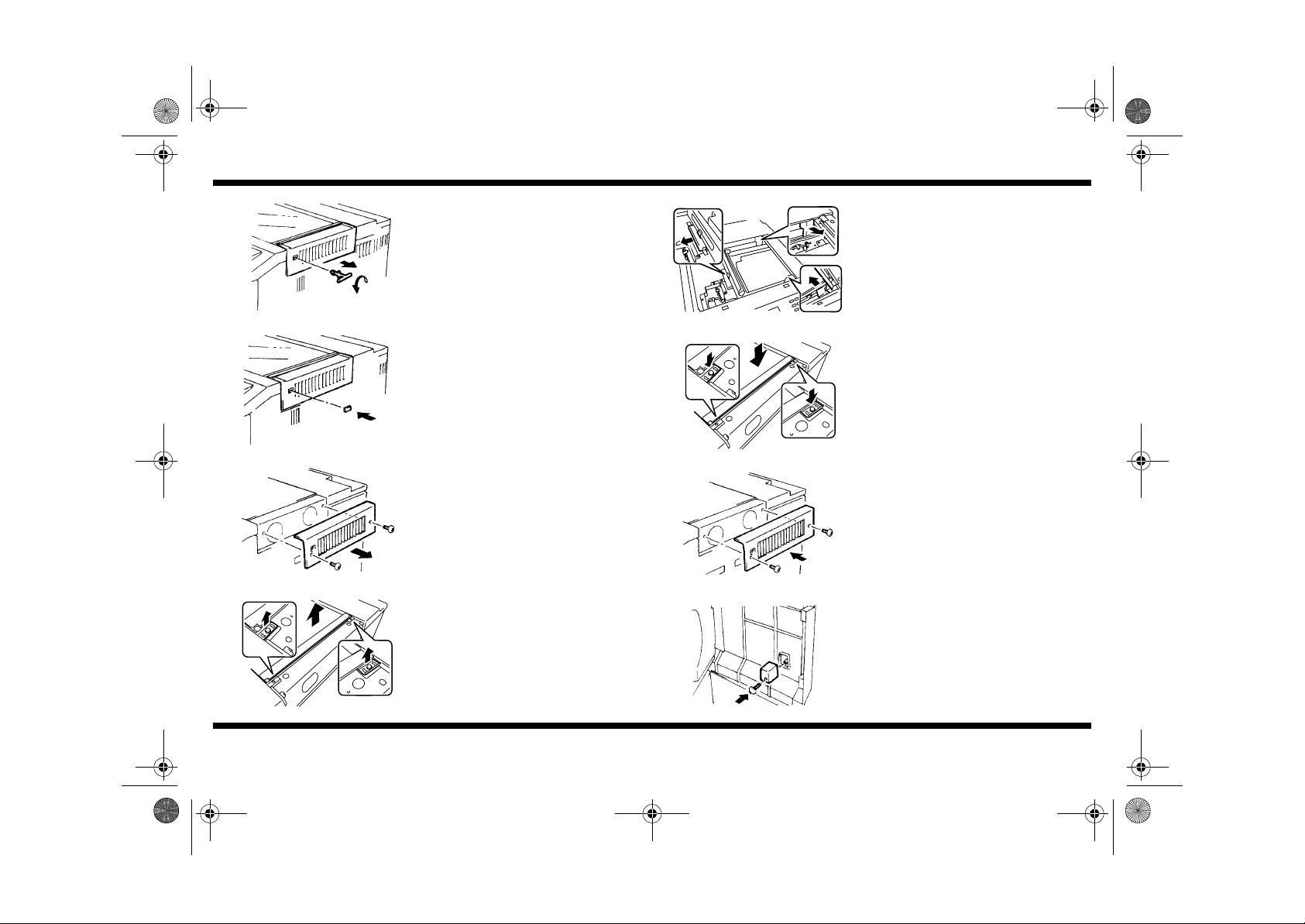

9. Remove the cushion packed above the

transfer drum lock release handle.

10.Pull off knob M9 and transfer unit lock lever

M4.

11.Remove 4 screws and the transfer unit cover.

12.Pull off the stops from the Transfer unit rails.

Remove the holding plate from the Transfer

unit corona assy.

1144U090KA

Tape

1144U082AB

Cushioning

Sheet

Holding Plate

protective

sheet

13.Remove the tape and the protective sheet

from the hopper unit.

14.Pull out the transfer drum unit and remove

the tape from the transfer drum.

15.Remove the cushioned holding plate

attached to the frame underneath the

Transfer Drum. Then pull out the cushioning

sheet.

Check to see if there are any hollows in the

Transfer Film while turning the drum

counterclockwise. If there are any hollows,

tightly wrap the Film around the drum again.

Refer to the Service Manual for the

procedure.

1179U004AA

1179-7744-03

179U021AB

– 3 –

Page 5

NOTES

1179-7744-03.fm Page 4 Thursday, November 9, 2000 1:47 PM

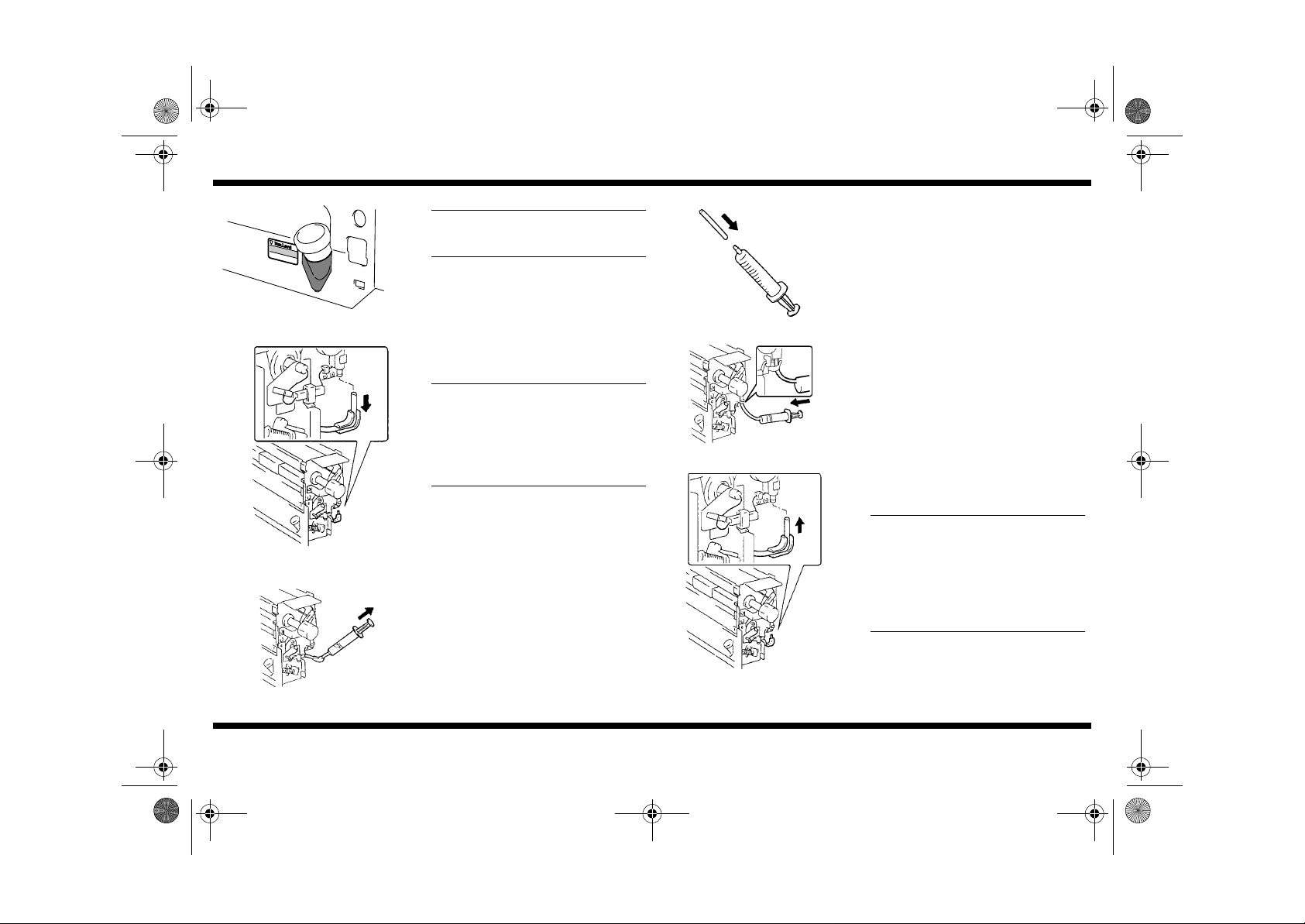

PREPARING THE FUSING UNIT

■

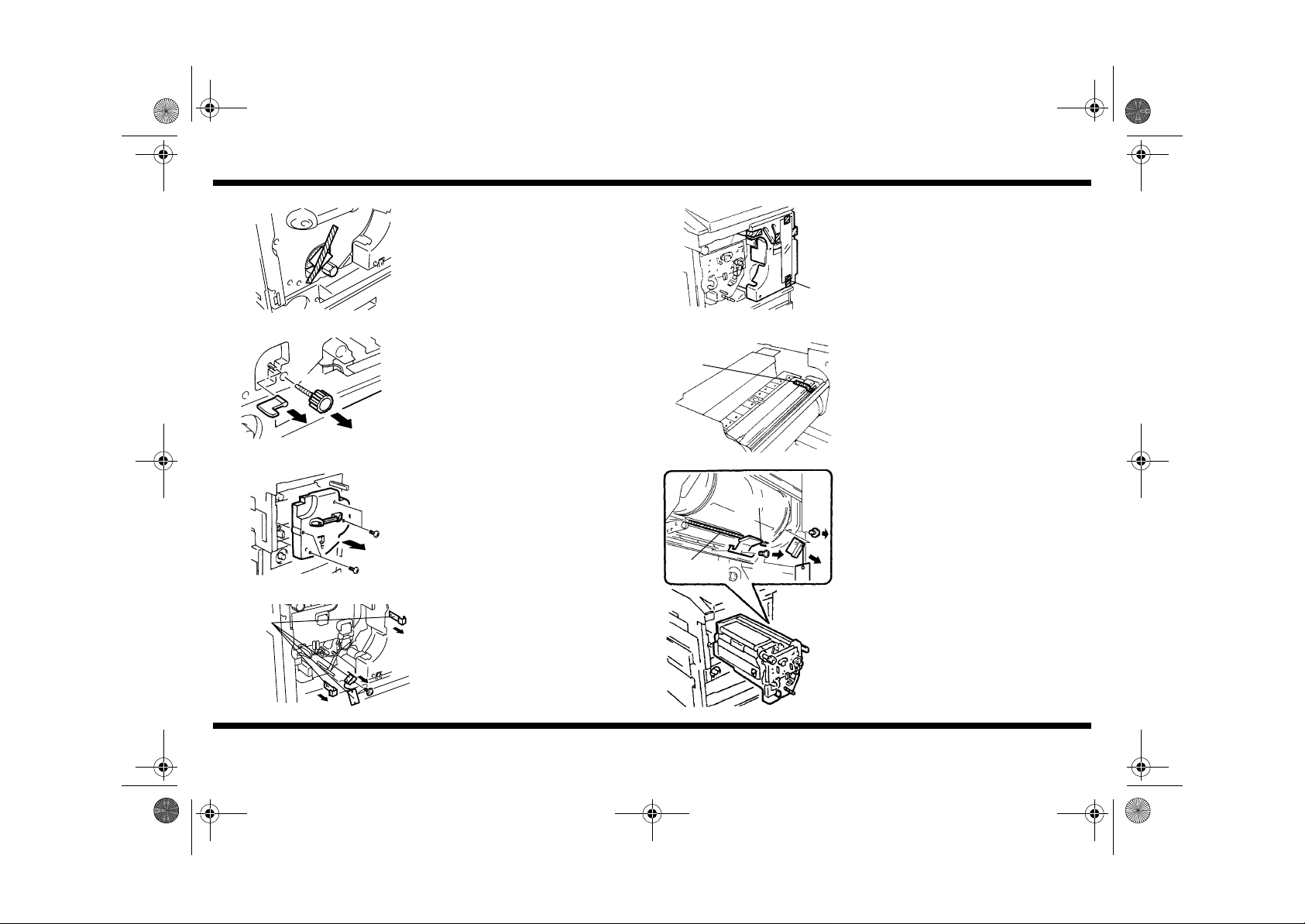

1. Unplug three connectors at the rear of the

Fusing Unit, remove 2 screws from

underneath the unit.

CF9001

Fusing Oil

Spout

Rubber

Tube

3. Gather th e can of oil (1 000ml ), sp out, sy ring e

and rubber tube from the accessories.

1144U102AA

1154U004AA

1144U103AA

1179-7744-03

Lift the unit out.

2. Remove the top cover of the fusing unit.

– 4 –

1154U066AA

1179U005AB

154U067AB

Syringe

4. Fill the syringe with 10ml of oil and inject it

into the fusing unit just inside the right side of

the unit between the cover and the blade

assy. Repeat with 10ml more. (Only use a

total of 20ml of oil.)

•

Only inject the oil into the space between

the cover and blade assy, not on the

blade, not over the upper roller, not over

the front and rear gear areas.

•

Be sure to inject the oil evenly.

•

Let nothing (dust, lint, hair, etc.) fall into

the Fusing Unit to contaminate it.

•

If setting up the copier at the workshop,

do not fill the fuser oil bottle until the

copier is moved to the user’s premises. In

order to make test copies at the

workshop, inject oil into the fuser as

described in step 4 above. 30ml of oil

makes about 20 copies. Inject more oil as

needed for testing purposes.

5. Remove the cap of the fuser oil bottle. Attach

the spout to the oil can and pour the oil into

the fuser oil bottle. Recap the fuser oil bottle.

Page 6

NOTE

1179-7744-03.fm Page 5 Thursday, November 9, 2000 1:47 PM

CF9001

1154U006AA

1144U104AA

NOTE

Pour the oil no higher than the Max. Level

Inicator on the Fusing Unit.

6. Leaving the valve in place, pull off the lower

tube from the Oil Pump Assy.

NOTES

•

Hold the valve when pulling the tube off or

the valve will come off with the tube.

•

Before pulling the tube and drawing the

oil, place a paper towel underneath the

pump section to catch any priming oil

leaking from the pump.

7. Insert the syringe into the tube and draw

about 5ml of oil from it.

8. Attach the rubber tube from the accessories

box to the syringe.

1144U106AA

9. Attach the tube to the lower end of the pump

and inject the 5ml of oil into it.

1179U006AB

10.Remove the tube and syringe, and plug back

in the lower tube of the Oil Pump Assy.

Do not turn any of the knobs, gears or

rollers of the Fusing Unit when the oil tank

is empty. The pump is primed with oil at

the factory. If anything is turned in the unit

when the tank is empty, the pump will lose

its priming oil and may not be able to pump

afterwards.

1144U105AA

1179-7744-03

1144U108AA

– 5 –

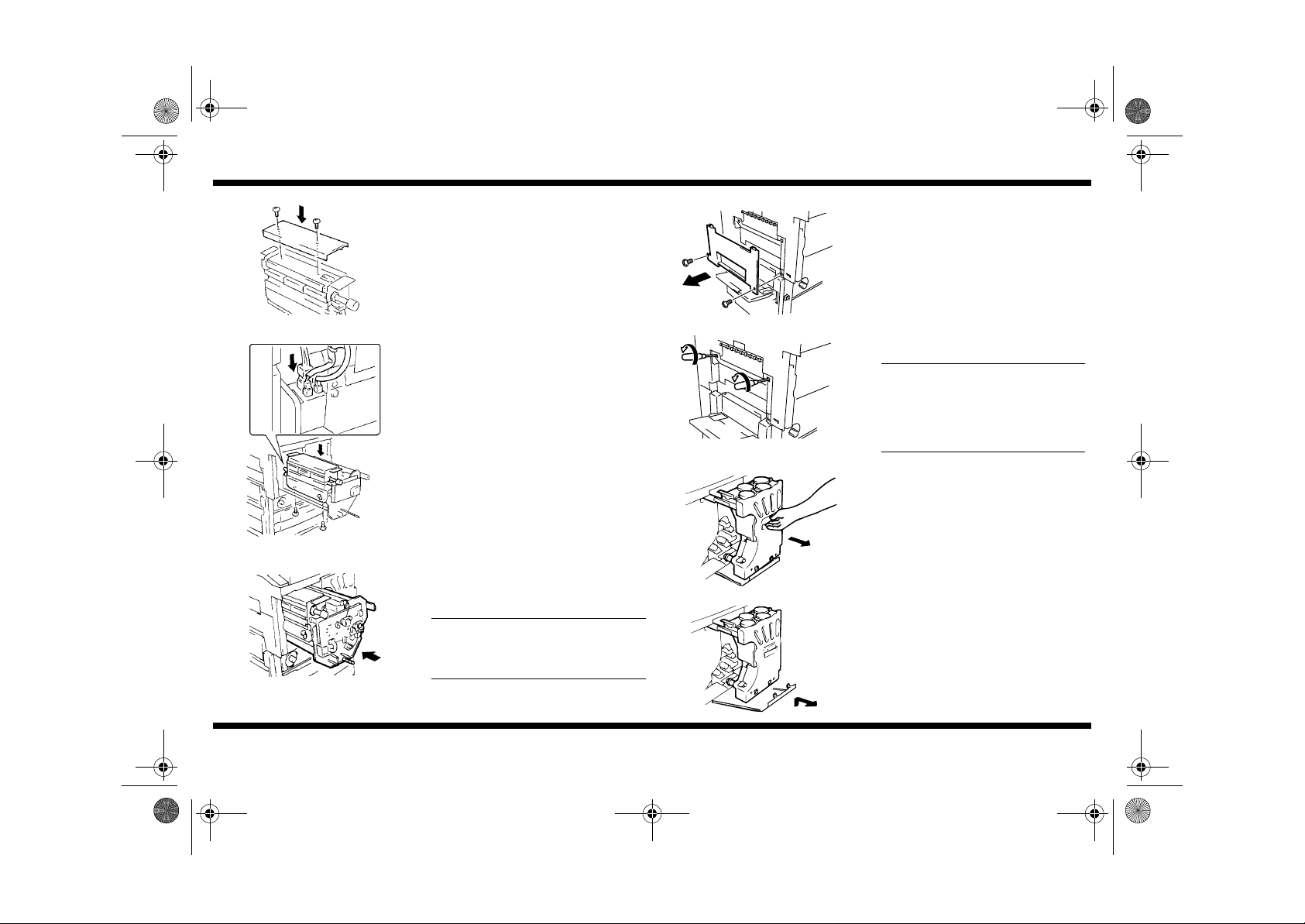

Page 7

NOTE

1179-7744-03.fm Page 6 Thursday, November 9, 2000 1:47 PM

CF9001

1144U109AA

1144U110AA

1144U086AA

11.Resecure the top cover.

12.Reinstall the unit with 2 screws and plug in

the 3 connectors.

13.Push the Transfer Drum Unit back into the

copier.

NOTE

Make sure the lock lever is in the unlocked

position when pushing the Transfer Drum

Unit into the copier.

1154U007AA

1154U008AA

TONER LOADING

■

1179N008AA

14.Open the manual feed table and remove the

Left Middle Cover from the copier.

15.Insert a screwdriver through the holes and

screw in the two Hexagonal Bolts (front and

rear) alternately until they are completely

tightened. Then loosen each Bolt four full

turns.

When backing off the bolts, do that in two

separate sequences by loosening each

bolt two turns each (at the front and rear)

alternately to achieve a uniform nip

width.

1. Pull out the Hopper Unit.

2. Remove the Toner Antispill Plate from the

bottom of the Hopper Unit.

1179-7744-03

1179N009AA

– 6 –

Page 8

1179-7744-03.fm Page 7 Thursday, November 9, 2000 1:47 PM

CF9001

1179U007AB

1144U115NA

1144L079AB

3. Loosen the 2 screws securing the Hopper

Unit and remove it.

NOTE

Be careful, the Hopper Unit is heavy.

4. Push the hopper rails back into the copier.

NOTE

Whenever the Toner Hopper is removed

from the copier, cover the exposed ports.

5. Sharply tap the toner bottle 5 times (from

about 10cm) on a hard surface.

Then turn it over and repeat.

6. Hold the bottle of toner as illustrated and

shake it vertically more than ten times. Then

remove the cap from the bottle.

7. Making sure not to pour the color toner into

the wrong hopper, set the upturned bottle

onto the hopper opening and turn clockwise

until it is secure.

1144U112AA

8. Tap the bottle to ensure complete emptying.

1144U113AA

9. Turn the bottle counterclockwise, remove it,

and close the lid of the hopper.

Repeat the same procedure for all 4 color

toners.

1144U114AA

1144L078AB

1179-7744-03

1179N011AA

– 7 –

Page 9

1179-7744-03.fm Page 8 Thursday, November 9, 2000 1:47 PM

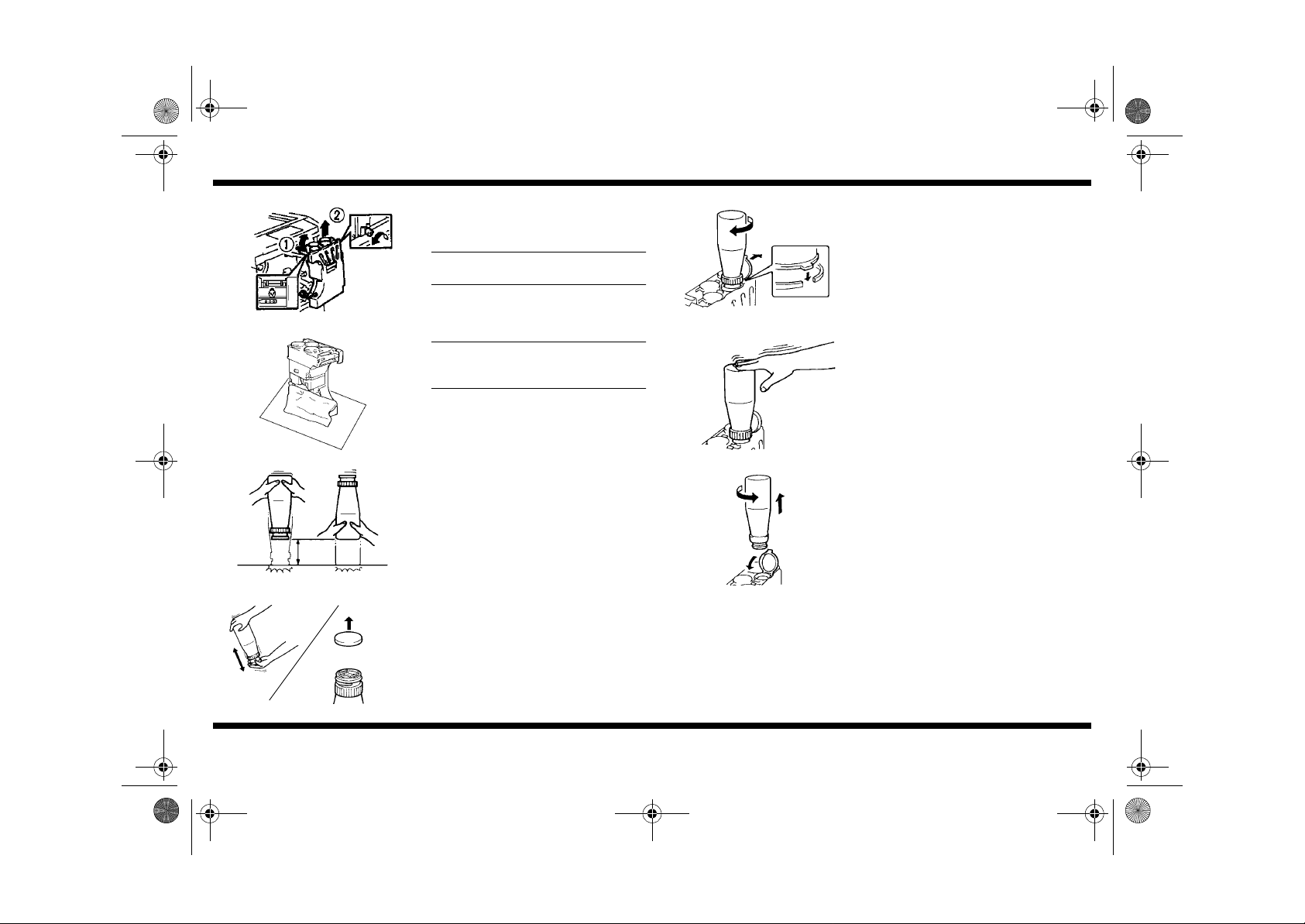

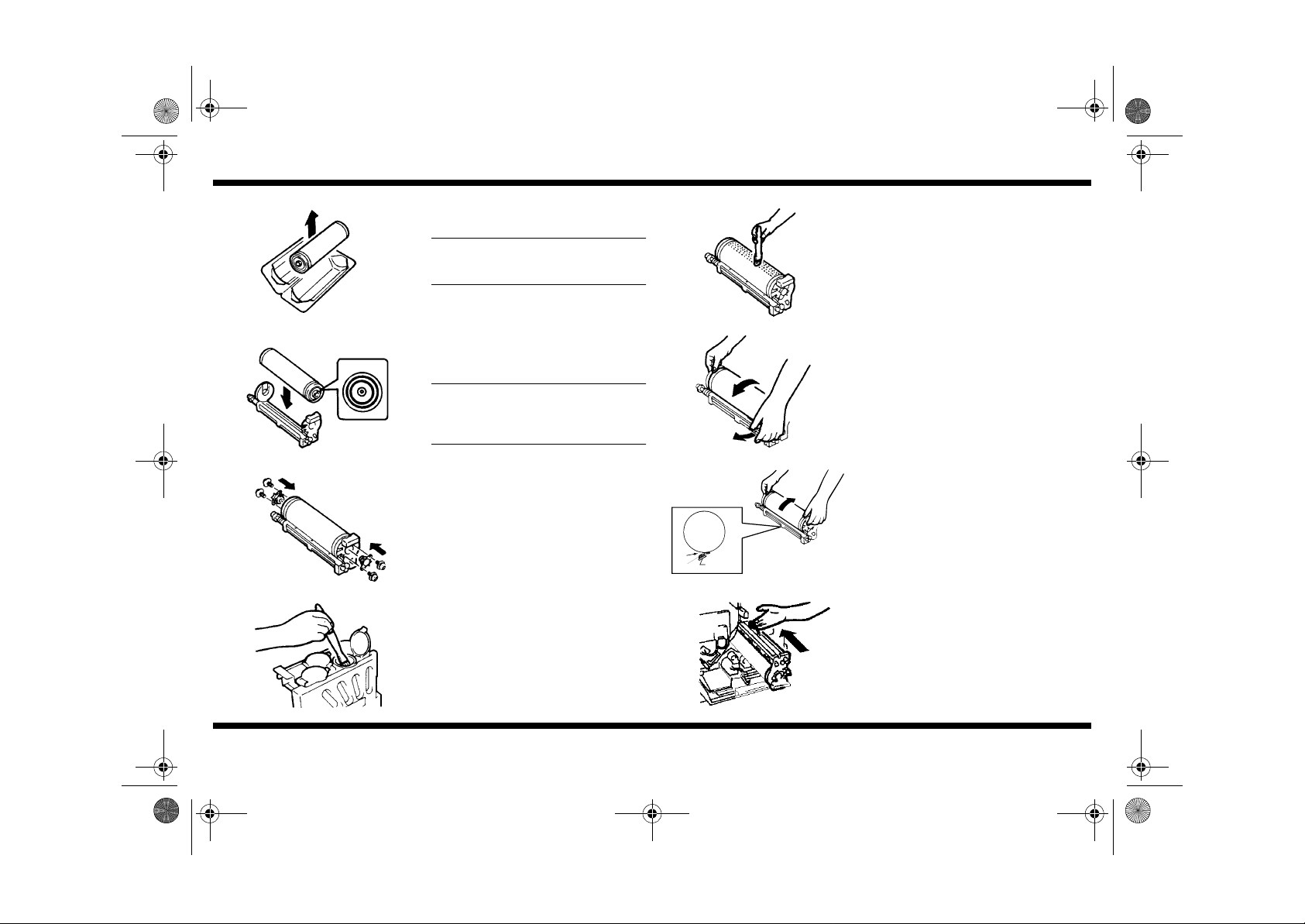

PC DRUM INSTALLATION

■

1. Unplug and pull out the Drum Charge

Corona Unit.

CF9001

5. Unplug the connector, remove 4 screws,

carefully remove the PC unit front flange.

1179U008AB

1144U026AA

1179U081AA

1179U086AA

1179-7744-03

2. Remove 3 screws and the Developer Unit

Cover.

3. Pull the Lock Release Lever handle up and

out, then push down.

NOTE

Make sure the upper drawer is closed

before operating the lock release lever.

4. Remove 2 screws and pull out the developer

unit a short distance.

1144U030KA

6. Remove the fixing screw and the Drum

Holder from the PC unit. Remove the PC

unit from the copier.

1179U083AA

7. Remove 2 screws and the packing holders

from the front and rear of the PC drum unit.

1144U033AA

8. Separate t he pa cki ng c olla rs ( blac k) fr om th e

holders.

1144U034AA

– 8 –

Page 10

a

Cleaning

Blade

Toner

PC Drum

1179-7744-03.fm Page 9 Thursday, November 9, 2000 1:47 PM

CF9001

1144U035AA

1144U036AA

1144U037AA

9. Unpack the PC drum.

NOTE

Do not touch the PC Drum surface with

your bare hands.

10.Install the PC Drum with the end having the

copper rings facing the front.

NOTE

Double-check that the PC Drum is installed

in the correct direction (copper rings to the

front).

11.Resecure the holders to the front and rear.

12.Dip a brush into one of the toner hoppers.

Any color toner will do.

1144U039AA

1144U040KA

1144U041NA

13.Apply a light coating of toner along the top of

the drum.

14.Unlocking the Cleaning Blade with the left

hand, grasp the edge of the drum with the

right hand and turn the drum

counterclockwise until the toner along the top

of the drum reaches the Cleaning Blade.

15.Lock the Cleaning Blade, grasp the drum by

the edges and turn the drum clockwise 3 full

turns. Afterwards, check area "a" to see if

any toner has fallen onto the Cleaning Blade.

If so, wipe the Blade.

Afterwards, check that the drum turns

smoothly.

16.Check to see the Transfer Drum and

Developing Unit are installed in the copier

and make sure their Lock Levers are in the

unlocked position. Carefully reinstall the PC

Drum Unit on the rail inside the copier.

1144U038AA

1179-7744-03

1179U084AA

– 9 –

Page 11

NOTE

1179-7744-03.fm Page 10 Thursday, November 9, 2000 1:47 PM

CF9001

1154U009AA

1179U085AA

OK

1154U010AA

X

Slide the PC Drum Unit along the rail.

Caution!

While sliding the unit into the copier, swing

the drum to the left to avoid scratching it on

a drum sensor and the Toner Scattering

Prevention Seal.

17.Check that the PC Drum Unit is correctly

installed.

1144U044AA

1179U009AA

Brass

1144U046KA

If the unit cannot be pushed all the way into

the copier, insert the PC drum key and turn

clockwise about 1/4 turn, then test the Unit

by pushing it in. Repeat this procedure until

the unit slides into place.

18.Attach the spring and Drum Holder with a

fixing screw.

Be careful to avoid the spring's recoil while

securing the Drum Holder.

19.Carefully refit the PC Unit front flange. First

reset the 3 black screws, then the brass

screw. Plug in the connector.

Black

20.Reinstall the Drum Charge Corona and plug

it in.

1179-7744-03

1154U011AA

1179U010AB

– 10 –

Page 12

NOTE

1179-7744-03.fm Page 11 Thursday, November 9, 2000 1:47 PM

STARTER LOADING

■

1. Pull out the Developing Unit.

2. Cover the exposed sleeve/magnet roller area

with the Mag Roller Shields.

NOTE

Do not permit any contamination of the

1179U088AA

sleeve/magnet rollers.

3. Plug in the single connector of the jumper

harness to the left of the unit, the two

connectors to the left at the rear of the unit.

1154U012AA

View from above.

CF9001

1144U053AA

1154U014AA

1179N003AA

1179N004AA

ON

4. Remove 1 screw and black toner feed chute.

The colors are in the order from left to right :

black, cyan, magenta, yellow.

5. Attach the starter chute.

6. With the front door open and no interlock

switch jig set, plug in the power cord and turn

ON the main switch.

The front door must be open before the

copier is turned ON.

1154U013AA

1179-7744-03

7. When the "The sectio n indicated by → is

open" warning appears on the display, press

the keys Stop → 0 → Stop → 2 to access the

Developer Change Mode.

1179P001CA

– 11 –

Page 13

NOTE

1179-7744-03.fm Page 12 Thursday, November 9, 2000 1:47 PM

CF9001

1144U063AA

1179P002CA

1179P003CA

8. With the Developer Change Mode Menu on

the display, insert the front door interlock

switch jig.

9. Touch "Developer Change."

10.Touch "Ex."

11.Touch “Black.”

Select the color of the starter to be loaded.

12.Press the Start key.

Developer activity will begin.

1179N005AA

13.Pour the starter i nto the replenishing port.

Make sure that the correct color of starter

is loaded in the correct developing unit.

1179U017AA

14.Empty the entire contents of the bottle and

press the Stop key.

Repeat step 5, 11-14 for each color starter.

15.When all 4 color starters have been loaded,

touch "Ex."

1179P004CA

1179-7744-03

1179P004CA

– 12 –

Page 14

NOTE

1179-7744-03.fm Page 13 Thursday, November 9, 2000 1:47 PM

STARTER AGITATION

■

16.Touch "On" for all four color starters and

press the start key to begin agitation.

When the activity is completed it will stop

automatically.

CF9001

20.Remove the starter chute.

1179P006CA

Pre-Image

Transfer

Charge

179U091AA

1179N007AA

1179U090AA

1179-7744-03

OFF

AIDC Sensor

17.After agitating all 4 color starters in the

Developer Mixing Chamber, clean the AIDC

sensor and the Pre-Image Trans fer Charge

section if they are dirty.

18.Turn OFF the main switch and unplug the

power cord.

Turn OFF the front door interlock switch.

19.Remove the mag. roller shields.

1154U015AA

21.Reinstall the toner feed chute.

When the toner chute is seated, press it

downward while securing it with a screw to

prevent toner dust leakage.

1144U057AA

22.Unplug the jumper harness.

Please keep the Jumper Harness for future

use.

1144U058AA

23.Push the developer unit back into the copier

and secure with the 2 screws.

1179U087AA

– 13 –

Page 15

1179-7744-03.fm Page 14 Thursday, November 9, 2000 1:47 PM

CF9001

1179U082AA

1154U016AB

ATDC/AIDC LEVEL ADJUSTMENT

■

1144U091AA

ON

1179N003AA

24.Firmly pull up on the developer lock release

lever and push the handle in.

25.Slide the lever as shown on the left.

1. Reattach the Transfer Unit lock lever and

lock the unit into position.

2. Plug in and turn ON the copier.

NOTE

At this time, make sure the front door

interlock switch is OFF

3. When the warning appears on the display,

press the keys Stop-0-S top-2 (in that order)

to enter the Developer Change mode.

1179P001CA

4. Turn ON the front door interlock switch.

1144U063AA

5. Touch "After Dev. (C/M/Y/BK) has been

changed."

1179P002CA

6. Touch "On" for all three colors.

1179-7744-03

1179N004AA

1179P007CA

– 14 –

Page 16

1179-7744-03.fm Page 15 Thursday, November 9, 2000 1:47 PM

CF9001

1179N005AA

1179P508CA

1179P009CA

7. Press the Start key to adjust the ATDC.

8. The activity will automatically stop when the

adjustment is completed.

Check that the adjustment result has been

OK. Then touch "ON" for Enter Ref. Value on

the ATDC Sensor Adjust (Auto) screen and

touch "Ex."

9. When the AIDC Sensor Adjust (Auto) screen

appears, press the start key.

When the activity is completed it will stop

automatically.

10.Check that the adjustment result has been

OK. Then, on the AIDC Sensor Adjust (Auto)

result screen, touch "Ex."

11.When the "AIDC offset" screen appears,

press the start key.

It will stop when the activity is completed.

1179P511CA

12.Touch "Ex."

1179P511CA

13.Press the start key when the "Black ATDC

Adjust" screen appears.

The "Black ATDC Adjust" runs for about

5 min. and will stop automatically. Touch

"Ex." and turn OFF the copier.

1179P012CA

14.Access the Tech. Rep. Mode screen. (Refer

to the Service Manual for the procedure.)

15.Touch “State Confirm.”

1179P010CA

1179-7744-03

4605P001CA

– 15 –

Page 17

1179-7744-03.fm Page 16 Thursday, November 9, 2000 1:47 PM

CF9001

1179P042CA

1179P045CA

1179P044CA

1179-7744-03

16.Touch “Bk Toner Sup. Status.”

17.Check that the values for “Dev. Constant” are

not “0.”

NOTE

If the Bk Developing Unit is defective, all

values for “Dev. Constant” are “0.”

If any of the “Dev. Constant” value is “0” :

Check the value for η of “PC Dev. Status.”

If the value for η is correct (η ≠ 99, η <

10000), carry out “Bk Toner Sup. Status”

again.

If the value for η is not correct, replace the

Bk Developing Unit, then make the check

again.

18.Touch “Ex.” and turn OFF the copier.

1179P044CA

19.Turn OFF the front door interlock switch.

1144U063KA

20.Install the Developer Unit Cover with 3

screws.

1144U026AA

21.Pull out the hopper rails and install the Toner

Hopper (secured by 2 thumb screw s).

Reattach the Toner Antispill Plate to the

bottom of the Hopper Unit and close the front

door.

1179N010AA

– 16 –

Page 18

1179-7744-03.fm Page 17 Thursday, November 9, 2000 1:47 PM

FUSER NIP LEVEL ADJUSTMENT

■

ON

1. Turn ON the copier.

At this time, make sure the front door is

closed.

CF9001

6. When the Start key changes from orange to

green, press the Start key.

1179N004AA

4605P001CA

4605P005CA

1179U012AA

1179-7744-03

2. Access the Tech. Rep. Mode screen. (Refer

to the Service Manual for the procedure.)

3. Touch "Machine Adjust 1."

4. Touch "Fuser Nip."

5. Place an A4(C) or Letter(C) size sheet of

paper crosswise into the drawer set for that

size.

– 17 –

1179N005AA

1179N020AA

1154U008AA

7. Measure the width of the stripe at points near

the front and rear edges. If should fall within

the following range.

Further, subtract the measurement taken at

the front from the measurement in the rear

(or vice versa) to check that the difference

between the two meets the specifications

given below.

<Specifications>

Fusing nip width (at the center): 8.5 ±0.3mm

Difference: Within 0.5mm

If the width measurements of the stripe on

the test print deviate from the given target

values, adjust the pressure bolts on the

fusing unit.

If > 6.3mm, loosen the pressure bolts.

If < 5.7mm, tighten the pressure bolts.

Make one more test print.

Page 19

1179-7744-03.fm Page 18 Thursday, November 9, 2000 1:47 PM

8. When the adjustment is completed, touch

"Ex."

1179P013CA

CF9001

1179-7744-03

– 18 –

Page 20

1179-7744-03.fm Page 19 Thursday, November 9, 2000 1:47 PM

FUSER SPEED LEVEL ADJUSTMENT 1

■

1. Load A3 or Ledger-size paper in the drawer

set for that size.

Open the Front Door and turn ON the

interlock switch.

CF9001

5. During the copy run, check the paper loop

between the Transfer Drum and Fusing

Roller.

1179U013AA

4605P005CA

1179P014CA

1179N005AA

1179-7744-03

2. Touch "Fuser Speed."

3. Touch "CF paper 120mm/s" and make an A3

or Ledger si ze copy.

4. Press the Start key. A half-tone test print will

be produced.

– 19 –

1154U023AA

1154U050AB

1154U051AB

1179P014CA

Paper Loop

Transfer

Drum

Paper Loop

Transfer

Drum

<The fuser speed is normal>

<If the fuser speed is too fast>

The paper is pulled by the Fusing Rollers,

preventing a paper loop from forming and

causing the paper to straighten.

Decrease the fuser speed by touching the

Down key until the loop is correctly formed.

Page 21

1179-7744-03.fm Page 20 Thursday, November 9, 2000 1:47 PM

1154UI052AB

Paper Loop

Transfer

Drum

Paper Loop

<If the fuser speed is too slow>

The paper is pushed by the Transfer Drum,

creating a large upward or downward loop.

CF9001

IF THE TEST PRINT CONTAINS ABRASIONS OR STRESS MARKS,

■

PERFORM THE FOLLOWING PROCEDURE.

1. If stress marks are at the front of the page,

loosen the front pressure bolt. If abrasions

are at the front of the page, tighten the front

pressure bolt.

Do not adjust the rear pressure bolt.

abrasion

1154U053AA

stress marks

2. If stress marks are at the rear of the page,

tighten the front pressure bolt. If abrasions

are at the rear of the page, loosen the front

pressure bolt.

1154U019AB

1179P014CA

abrasion

1154U053AA

1179-7744-03

Transfer

Drum

stress marks

Increase the fuser speed by touching the Up

key until the loop is correctly formed.

6. Check the test print for copy quality.

Do not adjust the rear pressure bolt.

1154U008AA

FUSER SPEED LEVEL ADJUSTMENT 2 (Fine Adjustment)

■

Since repeatedly adjusting the nip level an d

fuser speed may leave abrasions or stress

marks in the test print, tighten both the front

and rear pressure bolts of the Fusing Unit,

then start from the "FUSER NIP LEVEL

ADJUSTMENT" and perform the adjustment

again.

When the adjustment is completed, touch

"Ex." twice.

(a) Solid black adjustment

1. Load A3 or Ledger-size paper in the drawer

set for that size.

Open the Front Door and turn ON the

interlock switch.

1179U013AA

– 20 –

Page 22

1179-7744-03.fm Page 21 Thursday, November 9, 2000 1:47 PM

CF9001

4605P001CA

1179P036CA

1179P037CA

2. Touch "Test Print."

3. Touch "Halftone."

4. Touch "4 Color."

5. Press the Clear key and enter "200."

1179N005AA

1154U050AB

1154U052AB

Oil Tank

Oil Tank

Paper Loop

Transfer

Drum

Paper Loop

Transfer

Drum

6. Press the Start key.

*Following the same procedures as in FUSER

SPEED LEVEL ADJUSTMENT 1, check the

loop formed in the paper.

<The fuser speed is normal>

The loop in the paper does not touch the

bottom of the oil tank.

<If the fuser speed is too slow>

The loop in the paper bulges upward to tou ch

the bottom of the oil tank.

Increase the fuser speed by touching the Up

key so that the loop does not touch the

bottom of the oil tank.

Decrease the fuser speed by touching the

Down key until the loop is correctly formed.

1179P039CA

1179-7744-03

1179P014CA

– 21 –

Page 23

NOTE

1179-7744-03.fm Page 22 Thursday, November 9, 2000 1:47 PM

CF9001

(b) Blank sheet adjustment: Only when the speed has been changed in

(a) Solid black adjustment

"

1179U013AA

4605P001CA

1179P036CA

"

1. Load A3 or Ledger-size paper in the drawer

set for that size.

Open the Front Door and turn ON the

interlock switch.

2. Touch "Test Print."

3. Touch "Halftone."

4. Check that "Cyan" is selected.

1179P039CA

1179N005AA

1154U051AB

Oil Tank

Paper Loop

Transfer

Drum

5. Press the Clear key.

6. Press the Start key.

*Check the loop in the paper once again.

<The fuser speed is normal>

The loop in the paper does not touch the

bottom of the oil tank.

Decrease the fuser speed by touching the

Down key so that the loop does not touch the

bottom of the oil tank.

1179P037CA

1179-7744-03

– 22 –

1179P014CA

Using the same procedures, make only

FUSER SPEED LEVEL ADJUSTMENT

1 for "Thick Paper 1" and "OHP Film.

"

Page 24

1179-7744-03.fm Page 23 Thursday, November 9, 2000 1:47 PM

7. Reattach the Left Middle Cover to the copier.

1154U062AA

8. Reattach the Transfer Unit Cover, knob M9

and M4 lock lever.

1154U068AA

CF9001

1179-7744-03

– 23 –

Page 25

1179-7744-03.fm Page 24 Thursday, November 9, 2000 1:47 PM

GRADATION ADJUSTMENT

■

1. Turn OFF the front door interlock switch and

close the front door. Touch "Gradation

Adjust."

Touch "Gradation Adjust."

CF9001

4. Place the gamma test pattern onto the

original glass with the corner mark in the

corner indicated on the original glass.

(Follow the instruction on the display of the

Touch Panel.)

4605P001CA

1179P541CA

1179U013AA

1179N005AA

1179-7744-03

2. Place an A3 or Ledger size sheet of paper

into the drawer set for that size.

3. Press the Start key to produce a gamma test

pattern.

– 24 –

1144U074AA

1179N018AA

4605P001CA

1179N005AA

5. Cover the test pattern with 10 Sheets of

blank, white A3 or Ledger size paper and

close the Original Cover.

6. Press the Start key to read the gamma test

pattern. The test pattern doesn’t print out at

this time.

1179N005AA

7. When this step is completed, the Service

Mode Menu will reappear.

Touch "Gradation Adjust."

8. Press the Start key to produce another test

pattern. Repeat steps 4-8 two more times

using the latest produced test pattern each

time.

Page 26

1179-7744-03.fm Page 25 Thursday, November 9, 2000 1:47 PM

9. After “Gradation Adjust” has been

completed, check that the value for “Conv.

Value” falls within the reference value range.

Reference Value Range

High image density: 0±100

Low image density : 0±60

1179P541CA

If the value falls within the reference value

range, press the Panel Reset key and go to

“Image Quality Check” on the next page.

10.If the value falls outside the reference value

range, perform “Gradation Adjust” once

again and then check “Conv. Value.”

If the value falls within the reference value

range, press the Panel Reset key and go to

“Image Quality Check” on the next page.

1179P541CA

11.Press the Panel Reset key.

CF9001

1139U021BA

1179-7744-03

– 25 –

Page 27

1179-7744-03.fm Page 26 Thursday, November 9, 2000 1:47 PM

IMAGE QUALITY CHECK

■

1. Place the color chart on the original glass and make a copy.

2. Check for any streaks or voids in the halftone band.

Halftone Band

CF9001

3. If there are any streaks or voids, refer to the "Image Quality Problems" section in the Troubleshooting guide of the Service Manual.

1179-7744-03

– 26 –

Page 28

1179-7744-03.fm Page 27 Thursday, November 9, 2000 1:47 PM

MACHINE SETTING

■

1. Access the Tech. Rep. Mode screen. (Refer

to the Service Manual for the procedure.)

2. Touch "Setting 2."

CF9001

6. Set the paper size for each tray, then touch

"Ex."

4605P001CA

4605P002CA

1179P018CA

4605P002CA

1179-7744-03

3. Touch "Serial # Input."

4. Enter the serial number for the copier and

each installed option, then touch "Ex."

5. Touch "Paper Size."

– 27 –

1179P019CA

4605P002CA

1179N007AA

7. Select another mode according to your

needs.

When all settings are completed, touch "Ex."

8. Press the Panel Reset key and turn OFF the

copier.

OFF

Page 29

1179-7744-03.fm Page 28 Thursday, November 9, 2000 1:47 PM

CF9001

DRAWER SIZE CHANGE

■

1. Pull out the Drawer and remove the Side and

End Guide Plates.

1138U205A

2. Reposition the Side and End Guide Plates in

accordance with the size of paper being

used.

*Positions for the Side and End Guide Plates

are shown in the Table below.

1138U206A

Drawer Size Conversion Table

Paper Size

A5(T)/(L) 13 G 5-1/2 x8-1/2 (T)/(L) 14 H

B5(T)/(L) 11 K 8 x10-1/2 (T)/(L) 10 L

A4(T)/(L) 9 O 10-1/2 x8 (Y)/(C) 3 F

A4(Y)/(C) 1 G 8 x13 (T)/(L) 10 Q

B4(T)/(L) 4 S 8-1/2 x11 (T)/(L) 8 N

A3(T)/(L) 1 U 11 x8-1/2 (Y)/(C) 2 H

Guide Plate

Side End Side End

Paper Size

8-1/2 x13 (T)/(L) 8 Q

8-1/2 x14 (T)/(L) 8 R

11 x14 (T)/(L) 2 R

11 x17 (T)/(L) 2

Guide Plate

CHECKING THE 1-SIDED IMAGE REGISTRATION

■

1. Pull out the Drawer and load the paper into it.

Close the Drawer.

1179U014AA

2. Turn ON the copier.

Access the Tech. Rep. Mode screen. (Refer

to the Service Manual for the procedure.)

3. Touch " Machine Adjust. "

4605P001CA

4. Touch " PRT Area. "

4605P005CA

5. Touch "Left Margin."

1179-7744-03

4605P006CA

– 28 –

Page 30

1179-7744-03.fm Page 29 Thursday, November 9, 2000 1:47 PM

6. Touch the key for the Tray that was changed.

Press the Start Key and make a test print.

CF9001

PAPER LOADING FOR DRAWERS

■

Pull out the Drawer and load the paper into it.

Close the Drawer.

1179P020CA

Feeding direction

1179N014AA

1179P020CA

1179-7744-03

7. Measure the width of the white margin along

the edge of the test print.

Tolerance A : 3

8. If the width deviates from the tolerance

value, adjust with the Up / Down keys.

Then make another test print.

If the range of deviation is within the

Tolerance, touch "Ex."

Press the Panel Reset key and turn OFF/ON

the copier.

1.5 mm

±

1179U014AA

AFFIXING THE LABELS

■

1179U015AA

DEHUMIDIFYING SWITCH CHECK

■

1179U016AA

– 29 –

Stick the Labels into the positions shown in

the illustration.

Check that the Dehumidifying Switch is

turned ON. If the switch is turned OFF,

please turn it ON.

Page 31

123

456

789

0C

NOTE

1179-7744-03.fm Page 30 Thursday, November 9, 2000 1:47 PM

CF9001

LIST OUTPUT

■

4605P001CA

1179P021CA

1179N019AA

1179N005AA

1179-7744-03

1. Access the Tech. Rep. Mode screen. (Refer

to the Service Manual for the procedure.)

2. Touch "List Output."

3. Touch "Image Processing."

4. Place a stack of 15 sheets of A4 or Letter

size lengthwise paper on the manua l feed

table.

5. Press the Start key to output the Machine

Data.

Do steps 3-5 for each List (Setting/Adjust,

Counter).

Please keep the output Machine Data.

Press the Panel Reset key and turn OFF/ON

the copier.

Date/Time Input Check

■

4458N001AA

1179P022CA

1179P022CA

1179N001AA

– 30 –

1. Press the f oll o wi n g ke y s on t h e c o ntr ol pa ne l

in this order to show "Date/Time Input" on the

screen.

(1) Stop key

(2) "1," "1," "4," and "4" of 10-Key pad

(3) Clear key

2. On the Date/Time Input screen, check the

"Present Date/Time."

If the date/time data is correct, touch "Ex."

3. If the date/time data is wrong, enter the

current correct time of day and date from the

10-Key Pad.

4. Touch "OK."

5. Touch "Ex."

When the Copier location is changed, the

Support Feet must be readjusted bef ore

use.

Loading...

Loading...